1. Introduction

Everyone has a fundamental right to education, which must be guaranteed regardless of their abilities or physical conditions. Unfortunately, people with disabilities (PwDs) often face additional barriers and challenges, limiting their access to fundamental rights, such as education and health care. When PwDs, especially minors, are in the classroom, adaptations, or modifications, whether physical or methodological, are required to meet their needs, thus ensuring the inclusion of all students in classroom activities and benefitting from differentiated learning approaches [

1,

2].

In an effort to reduce this vulnerability, Assistive Technologies (ATs), defined as any tool, device, instrument or software, whether custom designed or standard, intended to facilitate the inclusion of PwDs in society, have been successfully used. According to the World Health Organization (WHO), approximately one billion people require ATs to enhance their functions, promoting their independence, freedom, and autonomy [

3,

4]. These ATs, as established by ISO 9999 [

5], play a crucial role in improving the autonomy of PwDs by replacing bodily functions and enabling their full participation in various aspects of life. In any case, the creation of these devices through Design Thinking (DT) is person-centered, and many disciplines converge in their creation, as demonstrated by the MIT D-Lab [

6] course that creates prostheses and ATs that serve to develop the education among students and improve the quality of life of people globally.

Significant progress has been reported in ATs in recent years; however, in some cases, this progress has resulted in an increase in the cost of ATs. This poses a considerable challenge as PwDs, already facing economic hardship and limited resources, have difficulty accessing these products. Despite their fundamental role in promoting inclusion and improving the quality of life of PwDs as well as in supporting their caregivers, ATs tends to be costly and difficult to access [

7,

8,

9].

In response to this challenge, the PAID project (Productos de Apoyo para la Inclusión de Personas con Discapacidad meaning Assistive Technology for the Inclusion of Persons with Disabilities) was launched in Antioquia, Colombia. This project develops strategies to promote social, labour and educational inclusion through the construction of ATs that can be easily replicated in diverse socioeconomic contexts. A community diagnosis in 10 municipalities provided an in-depth understanding of the needs of PwDs in the region. The findings were revealing: 41% of the PwDs used ATs, 30.2% faced obstacles in accessing them and 8.8% made ATs themselves. Moreover, 23.7% had not received formal education, including 25.9% who had not completed primary education and 24.5% of people aged 5–18 years did not attend school and an alarming 49.8% lacked basic reading and writing skills [

10].

The investigation utilized a hybrid methodological framework, merging a quantitative observational analysis with a qualitative ethnographic study. The quantitative segment employed a structured survey to capture numerical data, while the qualitative aspect leveraged ethnographic methods to gain insights into human behavior and cultural patterns.

The research apparatus, comprising two distinct surveys—one with 105 items for Persons with Disabilities (PwDs) and another with 70 open-ended questions for local stakeholders—was developed and subsequently validated by five specialists in the field of disability studies. These surveys aimed to gather data on various dimensions including municipal disability status, territorial characteristics, health, cultural and sports involvements, educational attainment, social engagement, and economic contributions.

Validation of the survey content was conducted using the Expert Judgment method and the Content Validity Coefficient (CVC) by Hernández-Nieto. This metric quantifies the consensus among evaluators regarding the survey items, requiring a minimum threshold of 0.80 for validity [

11]. The PwDs’ survey achieved a CVC of 0.94, and the stakeholders’ survey scored 0.87, averaging to a comprehensive CVC of 0.91, denoting high reliability.

The study included 710 participants from 10 municipalities in Antioquia, Colombia, with 464 PwDs completing the designated survey. The collected quantitative data primarily derived from these responses. Additionally, 246 stakeholders, identified for their influence and commitment to PwDs, provided qualitative insights through 120 interviews and participation in 23 focus groups. The research team, composed of seven health and social science experts, employed KoboToolbox for data collection and management [

12], ensuring comprehensive coverage without reported data omissions.

Data analysis embraced both quantitative and qualitative methods. The quantitative aspect utilized descriptive statistics to process the data, employing tools like Epidat, WinEpi, and Excel 2019 [

13,

14]. The qualitative data underwent a cyclical process of reduction, sorting, interpretation, and validation, facilitated by axial coding and information triangulation to structure the data effectively.

The sampling strategy balanced probabilistic and non-probabilistic methods, accommodating the diverse characteristics of the PwD population and ensuring equitable participation. Data collection was executed with personal visits to participants’ homes and workplaces, adhering to ethical standards and confidentiality protocols as mandated by national and international guidelines on human research.

This research adheres to rigorous ethical standards, securing approval from relevant municipal and ethical bodies, and ensuring participant consent and data confidentiality throughout the study.

This paper details the development process of two ATs implemented in the PAID project, highlighting that 60 different designs were created. This study highlights the importance of these devices in improving accessibility and affordability to meet the needs and rights of PwDs. We emphasize the need for accessibility of these technologies to all, particularly in educational settings, aligned with existing literature on inclusion in biomedical engineering and education for PwDs.

2. Materials and Methods

The second objective of the project was to create 100 ATs, distributed in 10 ATs prioritized for each municipality. These products were designed based on specific criteria that ensured their uniqueness in the market, meeting people’s real needs, avoiding high manufacturing costs or being easily replicable. Therefore, according to the needs of PwDs, ATs were designed for all possible dimensions: cognitive, communicative, mobility, self-care, visual and auditory.

In pursuit of developing these ATs, the project adopted the Design Thinking (DT) methodology, supported by previous research [

15,

16,

17], which encompasses several key phases. The first phase, empathizing, involves identifying the specific needs of the target population, gaining a deep understanding of their experiences and living conditions. Following this, the defining phase occurs, where the problem to be addressed is identified, laying the foundation for subsequent solutions. Subsequently, in the ideation phase, brainstorming sessions are conducted to generate a myriad of ideas aimed at addressing the identified problems. During this phase, the solution that best addresses the problem is chosen for further refinement. Finally, the prototyping phase ensues, where the chosen solution is constructed and refined based on iterative feedback loops. Ultimately, the solution is evaluated with the target users to ensure its effectiveness and suitability, thus completing the DT process (see

Figure 1).

Subsequently, the ATs were designed with a focus on the ease of low-cost reproduction and the potential social impact that they could generate. To further support this approach, the creation of user and manufacturing manuals, freely available to everyone in the project webpage, was considered.

2.1. Information gathering (empathize)

To complete the needs assessment and information gathering, several activities were conducted with potential ATs recipients to understand the needs and experiences of these people, i.e., what is their perspective of the problem as stated in [

19]. It began with a community diagnosis in each of the municipalities, where interviews and observations were conducted to deeply understand the experiences and needs of PwDs. During the interviews, a custom template in Excel was used for data collection that contained, first, general information such as name, phone number, address, activity that is difficult for them and why, how they currently solve it, who would use the device and what limitations he or she has, how they believe they can solve it if they use the AT. Additionally, it included spatial measurements information, for example, stair tread and riser or an object where the AT was going to be supported. If necessary, the name of the object, its measurement, the unit of measurement, and a photo, were noted. Lastly, information about the user, where necessary anthropometric measurements were noted according to the AT, as well as the medical diagnosis and some relevant data.

To identify potential beneficiaries of ATs, focus groups were then held with the people in charge of managing the disability aspect in municipal institutions such as mayors’ offices, schools, child development centers, senior citizen well-being centers and some private institutions. Finally, meetings were convened with selected individuals and groups to conduct targeted surveys addressing the specific needs associated with the absence of ATs. Additionally, necessary anthropometric measurements were taken, tailored to the individual requirements, or spatial measurements were conducted for environmental assistive products.

2.2. Definition of the Assistive Technology to be designed (Define)

Based on the data collected, the challenges and specific requirements of the ATs were defined, enabling the prioritization of 10 ATs per municipality, totaling 100 ATs, encompassing 60 distinct types. These products, referred to as ‘concepts’ [

6], were selected based on one or more of the following criteria: 1) their absence in the market aligned with the needs of the population, 2) potential high costs associated with existing market options, or 3) their potential for easy replication. Adherence to these rigorous selection criteria underscores the strategic fusion of innovation, affordability, and scalability inherent in the chosen concepts. They stand poised to effectively address a myriad of pressing needs within the community, catalyzing meaningful societal transformation through their deployment.

2.3. Creation of assistive technology designs (Ideate)

The ideate process involved the creation of a design comprising the collective needs and solutions [

19]. This process may take several attempts to obtain the desired product. Creative ideas for AT solutions were generated through brainstorming sessions and workshops with stakeholders, relevant individuals in identifying needs, including PwDs. The product designs and models were created using Autodesk Fusion 360

® software, which designs, manufactures, projects, and simulates products in 3D. The relevant CAD models were made for each AT considering the selection of materials to be used since these are essential for a good simulation, if necessary.

All those assistive technology products (AT) who are susceptible to undergo damage, due load applied during its lifecycle, were assessed, and optimized by means of Finite Elements Method (FEM). The first step consists of building a CAD model of the AT by means of Autodesk FUSION 360 software. Then, all the loads including the self-weight are applied on the surfaces of the AT. The mechanical properties such as Young Modulus, yield stress and Poisson ratio are assigned to any one of the components of the model. A Mesh Sensitivity Analysis is performed to diminish the error due to size mesh who divides the model; no more than 10% relative error (RE) is accepted to approve the mesh size. Finally, the model is solved to know the critical stresses, displacements, and Safety factor. All loads were increased by a factor of 1.1 for greater safety.

Additionally, a validation process was completed by a local company experienced in accessibility. In this phase, the AT designs were thoroughly reviewed, and the necessary redesigns and adjustments were made on an individual basis to improve their accessibility.

2.4. Construction of initial prototypes (Prototype)

The prototyping stage involves the creation of initial product constructions aimed at testing their durability, functionality, and usability in accordance with the requirements or expressed needs of the recipients. As emphasized by the Interaction Design Foundation (IxDF) [

18], this phase is experimental and may entail multiple iterations to achieve the final product. To facilitate this process, low-cost prototypes of the designed assistive technologies (ATs) were developed utilizing affordable materials and straightforward fabrication techniques. Mainly, materials such as medium-density fiberboard (MDF), plywood, PLA for 3D printing, and square steel tubing were utilized, ensuring that all materials could be sourced locally and at an economical price. This approach not only allowed for cost-effective prototyping but also ensured accessibility to materials for future production, thereby promoting sustainability and scalability of the project. Additionally, the utilization of locally available materials contributed to the empowerment of local economies and fostered community engagement throughout the prototyping process.

2.5. Testing with built prototypes (Testing)

Following the construction of the initial prototypes, a rigorous physical testing and validation process was initiated. Once the prototypes were safely constructed without final finishes such as paint and sealant, the project team conducted a series of physical tests in the laboratory. Collaborating closely with the end users who would ultimately receive the assistive technologies (ATs), these tests aimed to assess the prototypes’ durability, functionality, and safety. The comprehensive testing process allowed for the detection of any potential manufacturing issues and provided the opportunity to refine the solutions as needed. Additionally, a local company experienced in accessibility conducted an additional validation to ensure that the prototypes met basic accessibility criteria.

Furthermore, to ensure the practical functionality and usability of the prototypes in real-world settings, field visits were organized to the municipalities with the prototypes. During these visits, the end users were actively involved in testing the prototypes. This user-centered approach not only provided valuable feedback for further refinement but also fostered meaningful engagement with the local communities. These collaborative efforts were instrumental in tailoring the final products to meet the specific needs and preferences of the end users, thereby enhancing their overall effectiveness and impact.

2.6. Delivery of Assistive Technology

Once the tests of the initial prototypes were approved, progress was made towards their final construction, and finally, they were delivered to end users, individuals, groups, schools, and disability guides, in the municipalities. During the deliveries [

20], training was provided to instruct the users regarding the use of the ATs and a continuous follow-up to ensure the effective and sustained usage of these ATs, thereby maximizing their impact and efficacy within the targeted user base.

By adhering to this comprehensive approach of deployment, training, and follow-up, the endeavor ensured not only the widespread dissemination of essential AT solutions but also the empowerment of end users through proficient utilization, ultimately fostering greater independence and inclusivity within the community.

3. Results

The PAID project delivered 112 APs with 60 various designs adapted to the needs identified in each municipality. The following are the process and results for two ATs that can be integrated into educational processes: adapted handles and a desk adapted for wheelchair users.

3.1. Information gathering

Several visits were made to each of the participating municipalities to gather the information needed in designing the ATs. This information was collected in a custom Excel file for each municipality, containing the following information: name of the person or group, contact information, difficult activities, how they solve them now, how they think they could solve them if they had an AT, photos, measurements, and additional observations.

For the collection of information regarding adapted handles, specific needs were identified across multiple municipalities, including a lack of fine motor skills and difficulties in tasks such as writing, eating, or holding objects. To address these needs effectively, it was decided to develop an adjustable product that could cater to multiple individuals. Consequently, the decision was made to utilize an elastic Velcro strap for adjustability. On the other hand, for the adapted desk, precise measurements of the end user were taken to ensure complete adaptation to their needs. However, for reproducibility purposes, the table’s height can be easily modified, as the width is suitable to accommodate any wheelchair.

3.2. Assistive Technology design

For each identified need, a design was created in Autodesk Fusion 360

® Software, or an application design document was prepared, if required. In some cases, the same AT could solve several needs identified in the same municipality or in a different one. The designs of the adapted handles and the adapted desk (

Figure 2) for wheelchair users were created based on the educational and personal autonomy environment.

3.3. Finite element testing

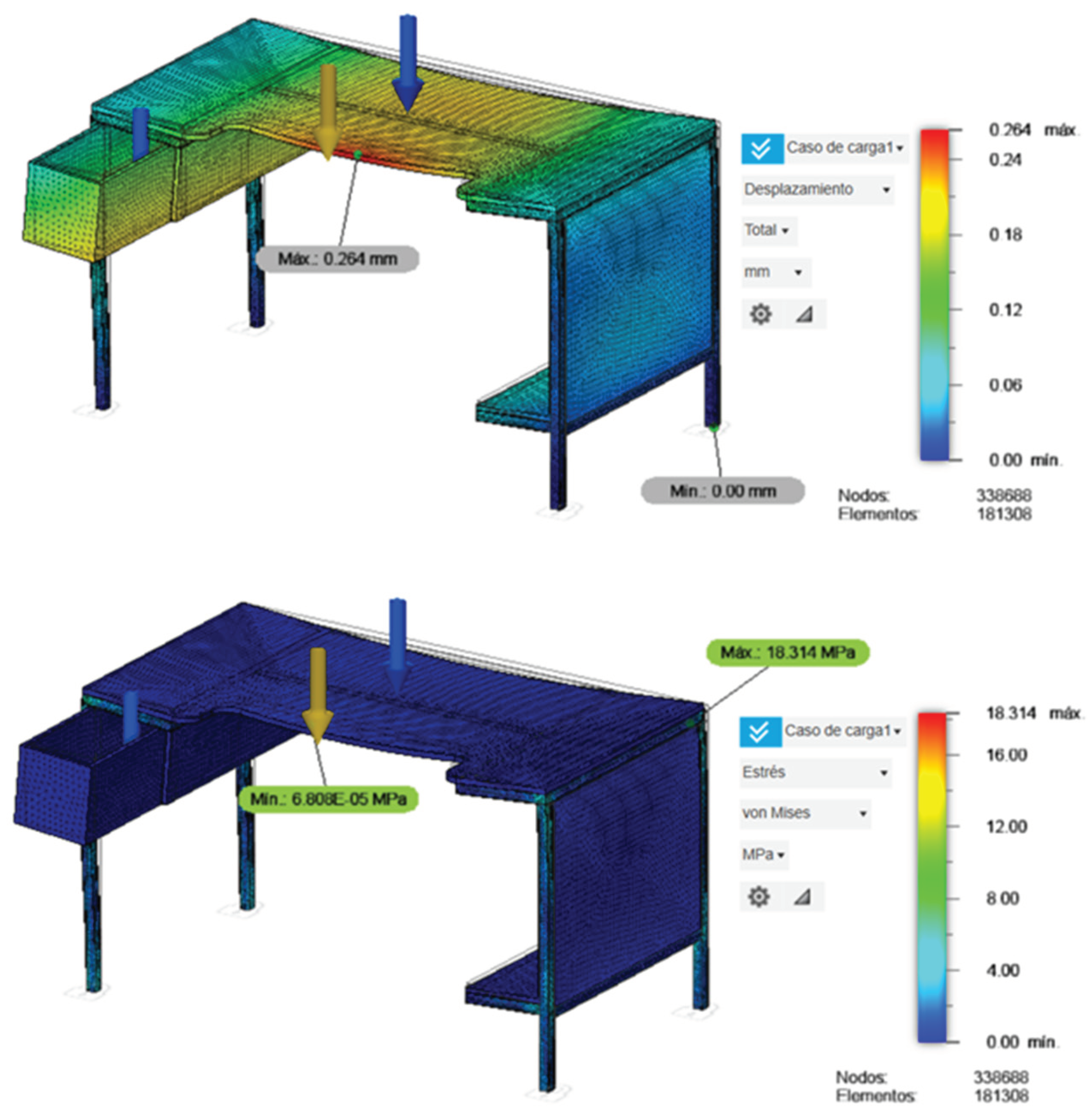

3.3.1. Adaptive desk

Figure 3 shows the CAD design of the adaptive desk. Loads of 80 N were applied on the board, 20 N on the drawer, 80 N on the CPU shelf, in addition to the self-weight. The support elements were simulated in AISI 1020 steel and the wooden elements using MDF panels.

Table 1 shows the mechanical properties of the materials. The results show that the maximum stress occurs in one of the steel bars with 18.3 M Pa, much lower than the yield stress of the material; The maximum displacement is 0.264 mm in the center of the board. The safety factor is 11.3 as shown in

Table 2, which in turn presents the convergence results of the mesh sensitivity analysis.

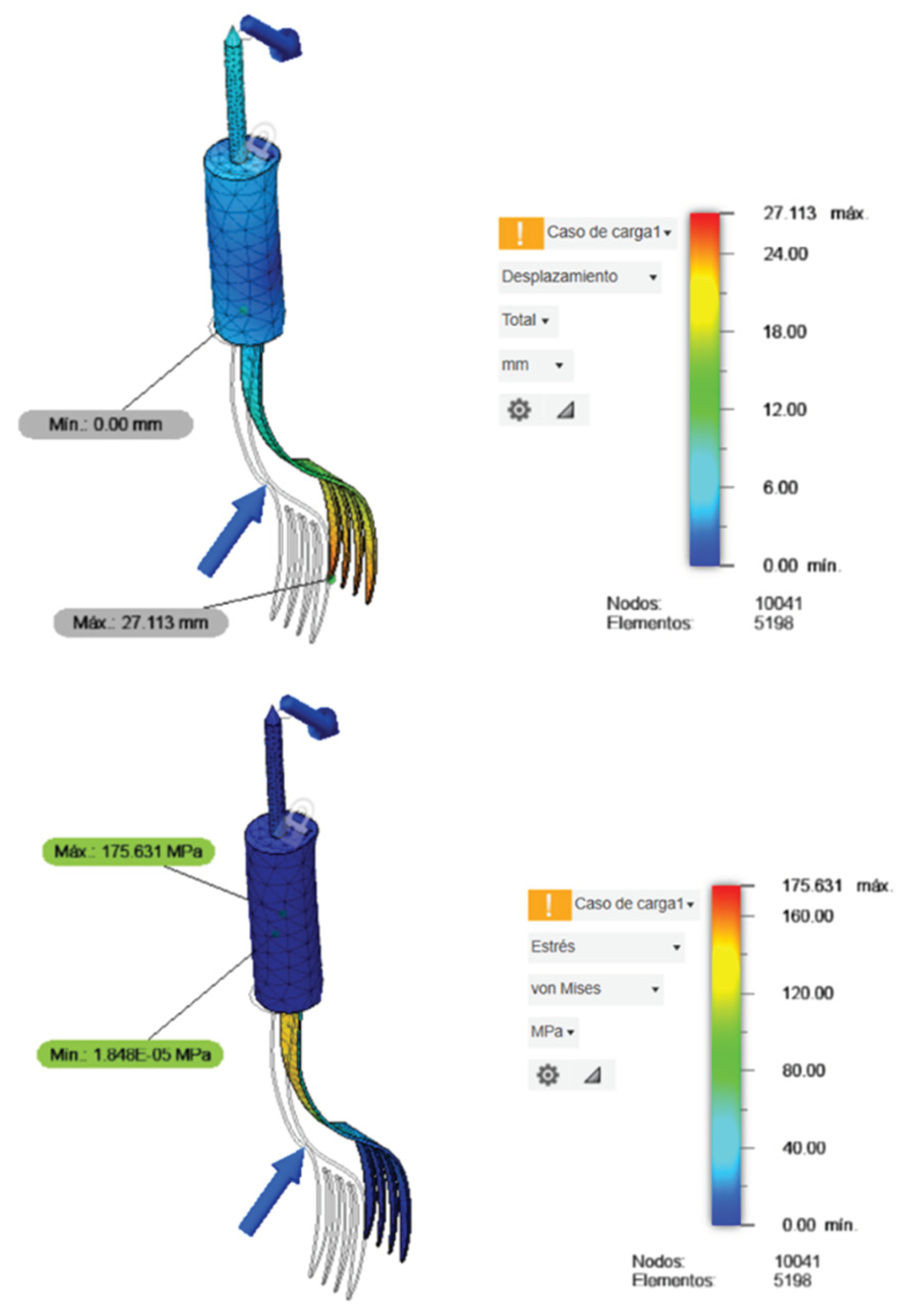

3.3.2. Hand Grip

Figure 4 shows the CAD design of the Hand Grip. Loads of 10 N were applied on the tip of the fork and 2 N on the tip of the pencil. The Hand Grip was simulated in Ecoflex 30

® Rubber whose mechanical properties are shown in

Table 1. The results show that the maximum stress occurs in steel fork with 175,6 M Pa; inside the hand Grip, but its maximum is no greater than 1 M Pa; The maximum displacement is 27 mm, produced by the fork. The safety factor is 1,18 as shown in

Table 2, and its convergence results of the mesh sensitivity analysis, as well.

3.4. Construction of the prototypes

The construction process of the prototypes for the adapted handles was intricate and involved multiple steps. A dual-purpose design was employed, featuring a rounded shape achieved using a 5 mm diameter steel rod, and a flat shape accommodated by a 3D printed object designed for utensils (

Figure 5). This design variation aimed to cater to a diverse range of needs and preferences among users. The construction process involved pouring silicone rubber into a PVC tube containing an elastic Velcro strap and a 3D printed mold, strategically placed to facilitate the positioning of flat elements such as cutlery. The silicone rubber used in the prototypes was readily available from local chemical stores at an affordable price, enhancing accessibility for replication. Additionally, the materials utilized for the mold included PVC tubing, wood, steel tubing, elastic Velcro, and the 3D printed object, which can be downloaded from the project’s website for printing. This approach ensured the accessibility and affordability of materials required for prototype construction, facilitating the scalability and replicability of the adapted handle design.

To manufacture the adaptive desk, a meticulous process was followed, beginning with the precise cutting of wood and metal tubes to match the measurements specified in the 3D design. Specifically, 15 mm thick plywood, known for its robustness, was chosen for its durability and resilience. The plywood underwent a series of treatments to enhance both its appearance and longevity, including polishing, staining, varnishing, and sealing. These steps not only imbued the wood with an aesthetically pleasing finish but also augmented its resistance to wear and tear over time. Additionally, square steel tubing measuring 1 inch in diameter and 1.1 mm in thickness was selected for its structural integrity and stability.

Furthermore, the metal tubes underwent meticulous welding to ensure seamless integration and structural integrity, followed by painting to enhance both aesthetics and corrosion resistance. Subsequently, in accordance with the design specifications, the metal tubes were assembled atop the wooden surface of the desk using screws (

Figure 6). This assembly process was conducted with precision to ensure stability and longevity, essential considerations for a desk intended for wheelchair users.

3.5. Mechanical and usability testing

The prototypes underwent rigorous testing procedures to ensure their robustness and functionality in real-world scenarios. Finite Element Method (FEM) simulations confirmed compliance with established standards, complemented by physical tests conducted in the University EIA laboratory to validate performance against design specifications. Modifications were made to address identified shortcomings, such as adding additional tubing to support the weight of computer components on the adapted desk, specifically the CPU, and trimming Velcro straps for improved fit on adapted handles, ensuring optimal usability and user satisfaction. These iterative testing and refinement processes exemplify the project’s commitment to delivering high-quality, user-centric solutions for individuals with disabilities, enhancing their accessibility and quality of life.

3.6. Construction of the final version of the Assistive Technology

Following the creation of prototypes and thorough field testing, refinements were made to perfect the construction of the ATs intended for deployment in the designated municipalities. For the adapted handles, multiple trials were conducted using a single prototype, ensuring comprehensive evaluation of usability and comfort. Subsequently, after adjustments were made to the Velcro straps to optimize fit, the remaining handles were produced in their final version. Similarly, in the case of the adapted desk, mechanical testing was performed to validate structural integrity, particularly in supporting the weight of the CPU. Once final adaptations were made to reinforce this aspect, the delivery process commenced.

3.7. Delivery and training

During the delivery phase of the manufactured products, AT training sessions were conducted to equip individuals with the necessary knowledge and skills for safe and proper usage. In addition to ensuring end-users’ proficiency, training extended to disability advocates and support personnel, particularly relevant when ATs were destined for general aid repositories. For instance, during the delivery of adapted handles, both end-users and disability advocates received training on their usage and maintenance. Similarly, for the adapted desk, end-users were instructed on utilizing the keyboard tray equipped with locking rails for enhanced usability. This training initiative was systematically implemented across all 112 ATs distributed across the 10 municipalities, underscoring the project’s commitment to fostering inclusive and accessible practices.

Figure 7 provides a visual representation of the delivery process for the adapted desk.

3.8. User and manufacturing manuals

To ensure the reproducibility of the ATs, the project proposed the creation of an open access website where all the information collected during the project could be found. The AT part includes user and manufacturing manuals written in a simple, easy-to-read manner, designed to be read with a screen reader, with descriptions of materials, photos and, in some cases, alternative methods that can be used to make them, as well as alternative text for the images. It also has a contact channel to reach out to the researchers in case of doubts.

3.9. Assistive Technology development workshops

As part of the strategies implemented to address the social appropriation of knowledge from the project, workshops were held in the municipalities to develop AT, where low-cost materials such as cardboard, wood, silicone or sheets of paper, and their respective provisional manufacturing manuals were brought, for example, in San Vicente Ferrer (

Figure 8). This was offered to provide initial training in the creation of ATs, with the intention that people, especially teachers who could most frequently use this type of experience in their daily work, would be able to manufacture ATs that they would find useful within those designed for all municipalities at the end of the project.

4. Discussion

The impact of Component 2 of this project, which is responsible for the design and manufacturing of assistive technologies (ATs), extends far beyond the mere creation of accessible and affordable solutions. It encompasses a holistic approach that emphasizes inclusivity, accessibility, and empowerment. One key aspect of this impact lies in the utilization of low-cost materials for the majority of ATs, ensuring affordability and accessibility for individuals across diverse socioeconomic backgrounds. Additionally, the development of user and manufacturing manuals with free access underscores the project’s commitment to accessibility criteria, including easy reading formats and alternative text for screen readers, facilitating widespread adoption and usage.

Furthermore, the project’s impact transcends individual users to encompass entire communities within the department of Antioquia. Through workshops and seminars on AT manufacturing conducted in collaboration with various municipalities, the project has empowered community members to harness the transformative potential of technology. These initiatives highlight how anyone, armed with the right materials and knowledge, can create products that enhance daily living and contribute to community development. The resulting impacts are multifaceted, ranging from personal and familial empowerment, as individuals gain autonomy in previously challenging tasks, to broader social benefits, as enhanced participation in educational and work environments fosters community progress and inclusivity. By fostering a culture of innovation and accessibility, Component 2 of the project has catalyzed positive change at both individual and societal levels, laying the groundwork for a more inclusive and equitable future.

5. Conclusions

Affordable ATs play a significant role in improving the quality of life of PwDs, especially in rural areas and municipalities. Considering that many of these people have limited financial resources, it is easy for them to make these products using materials that are readily available in their own communities. Moreover, the advantage of these products lies in their flexibility, as they are not subject to institutional regulations and can be redesigned according to the specific needs of each user.

The handles and the adapted desk manufactured serve their purpose: to help PwDs participate in the classroom and to eliminate potential barriers observed during visits to the municipalities.

The DT proved to be a fundamental tool in the creation of innovative products that ensure the participation of the population in their community, increase their capabilities when performing activities in educational environments and when correctly applied, can even help a person to work. Additionally, this methodology proves to be beneficial when applied to an interdisciplinary work group to maximize the effectiveness of achieving the planned objective.

Supplementary Materials

The project website is

https://www.proyectopaid.com/. The Excel spreadsheet template used to gather information about people with disabilities (PwDs) in the municipalities.

Funding

the authors received funding for the preparation and publication of this article from the Ministry of Science, Technology, and Innovation (Minciencias) Colombia, grant number SGR12021001 (Project: Development of social innovation strategies through the construction of Assistive Technology contributing to inclusive education to support the labour and productive inclusion of people with disabilities in the department of Antioquia; grant number BPIN2020000100191). EIA University participated as the main executor of the project, with the participation and collaboration of the social corporation El Comité de Rehabilitación de Antioquia and the local private company Whee.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Institutional Review Board (or Ethics Committee) of EIA University (code P201909-18, 4 March 2020).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study. All technical documentation of the PAID project was reviewed and approved by the ethics committee of EIA University.

Data Availability Statement

The original contributions presented in the study are included in the article and supplementary material, further inquiries can be directed to the corresponding author/s. The supplementary material spreadsheet will be made available by the authors on request.

Acknowledgments

In this section, you can acknowledge any support given which is not covered by the author contribution or funding sections. This may include administrative and technical support, or donations in kind (e.g., materials used for experiments).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- [W. Zilz and Y. Pang, “Application of assistive technology in inclusive classrooms,” Disability and Rehabilitation: Assistive Technology, vol. 16, no. 7. Taylor and Francis Ltd., pp. 684–686, 2021. [CrossRef]

- UNICEF, “Diseño Universal para el Aprendizaje y libros de texto digitales accesibles,” UNICEF.

- H. Cochrane and B. Malas, “International education standards for prosthetics and orthotics occupations,” in Global perspectives on assistive technology, Geneva: World Health Organization (WHO), Aug. 2019, pp. 155–168.

- L. Clarke, L. Puli, E. Ridgewell, M. P. Dillon, and S. Anderson, “Regulation of assistive technology practitioners to drive workforce training and retention,” in Global perspectives on assistive technology, Geneva: World Health Organization (WHO), Aug. 2019, pp. 169–190.

- Normalización Española (UNE), “UNE-EN ISO 9999:2022 Productos de apoyo. Clasificación y terminología.,” AENOR. Normalización Española (UNE), Feb. 22, 2023.

- B. J. Ranger and A. Mantzavinou, “Design thinking in development engineering education: A case study on creating prosthetic and assistive technologies for the developing world,” Dev Eng, vol. 3, pp. 166–174, Jan. 2018. [CrossRef]

- J. A. Stramondo, “The right to assistive technology,” Theor Med Bioeth, vol. 41, no. 5–6, pp. 247–271, Dec. 2020. [CrossRef]

- R. Matter, M. Harniss, T. Oderud, J. Borg, and A. H. Eide, “Assistive technology in resource-limited environments: a scoping review,” Disability and Rehabilitation: Assistive Technology, vol. 12, no. 2. Taylor and Francis Ltd., pp. 105–114, Feb. 17, 2017. [CrossRef]

- W. Ben Mortenson, L. Demers, M. J. Fuhrer, J. W. Jutai, J. Lenker, and F. DeRuyter, “How assistive technology use by individuals with disabilities impacts their caregivers,” American Journal of Physical Medicine and Rehabilitation, vol. 91, no. 11. pp. 984–998, Nov. 2012. [CrossRef]

- D. A. Ossa Pulgarín, T. González Gómez, M. C. Mejía Jaramillo, and S. Munera, “Social participation among people with disabilities: a visible need with a lack of intervention,” Social Sciences & Humanities Open. Aug. 07, 2023. [CrossRef]

- A Hernández-Nieto R. Data collection instruments in the social sciences and biomedical sciences [Internet]. Merida, Venezuela: CreateSpace Independent Publishing Platform; m2011 [cited 2022 Feb 24]. 370 p. Available online: https://www.academia.edu/37886946/Instrumentos_de_recoleccion_de_datos_en_ciencias_sociales_y_ciencias_biomedicas_Rafael_Hernandez_Nieto_pdf.

- KoboToolbox. About Us | Caja de herramientas de Kobo. 2022. [Online]. Available online: https://www.kobotoolbox.org/about-us/.

- Epidat. EPIDAT - Consellería de Sanidade - Servizo Galego de Saúde. 2016. [Online]. Available online: https://www.sergas.es/Saude-publica/EPIDAT?idioma=es.

- WinEpi. WinEpi: Working in epidemiology. 2021. [Online]. Available online: http://www.winepi.net/menu1.php.

- R. F. Dam and Y. S. Teo, “The History of Design Thinking,” Interaction Design Foundation - IxDF. Accessed: Dec. 17, 2023. [Online]. Available online: https://www.interaction-design.org/literature/article/design-thinking-get-a-quick-overview-of-the-history.

- Y. Cai, J. Lin, and R. Zhang, “When and how to implement design thinking in the innovation process: A longitudinal case study,” Technovation, vol. 126, Aug. 2023. [CrossRef]

- A. Liu and S. Lu, “Functional design framework for innovative design thinking in product development,” CIRP J Manuf Sci Technol, vol. 30, pp. 105–117, Aug. 2020. [CrossRef]

- Interaction Design Foundation - IxDF, “What is Design Thinking?,” Interaction Design Foundation - IxDF. Accessed: Dec. 18, 2023. [Online]. Available online: https://www.interaction‐design.org/literature/topics/designthinking.

- V. Malele and M. E. Ramaboka, “The Design Thinking Approach to students STEAM projects,” in Procedia CIRP, Elsevier B.V., 2020, pp. 230–236. [CrossRef]

- Organización Mundial de la Salud (OMS), Pautas para el suministro de sillas de ruedas manuales en entornos de menores recursos. Organización Mundial de la Salud, 2008.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).