Submitted:

19 February 2024

Posted:

20 February 2024

You are already at the latest version

Abstract

Keywords:

Introduction

| Material properties | value |

| Modulus of Elasticity (GPa) | 68.9 |

| Thermal conductivity (GPa) | 167 |

| Tensile strength (MPa) | 310 |

| Density(g/cm3)  | 2.70 |

| Chemical | Percentage |

| Si | 0.483 |

| Mn | 0.687 |

| Zn | 0.211 |

| Cr | 0.013 |

| Ni | 0.024 |

| Ti | 0.028 |

| Pb | 0.02 |

| Fe | 0.648 |

| Cu | 0.082 |

| Mg | 0.077 |

| B | 0.002 |

| V | 0.007 |

| Al | Balance |

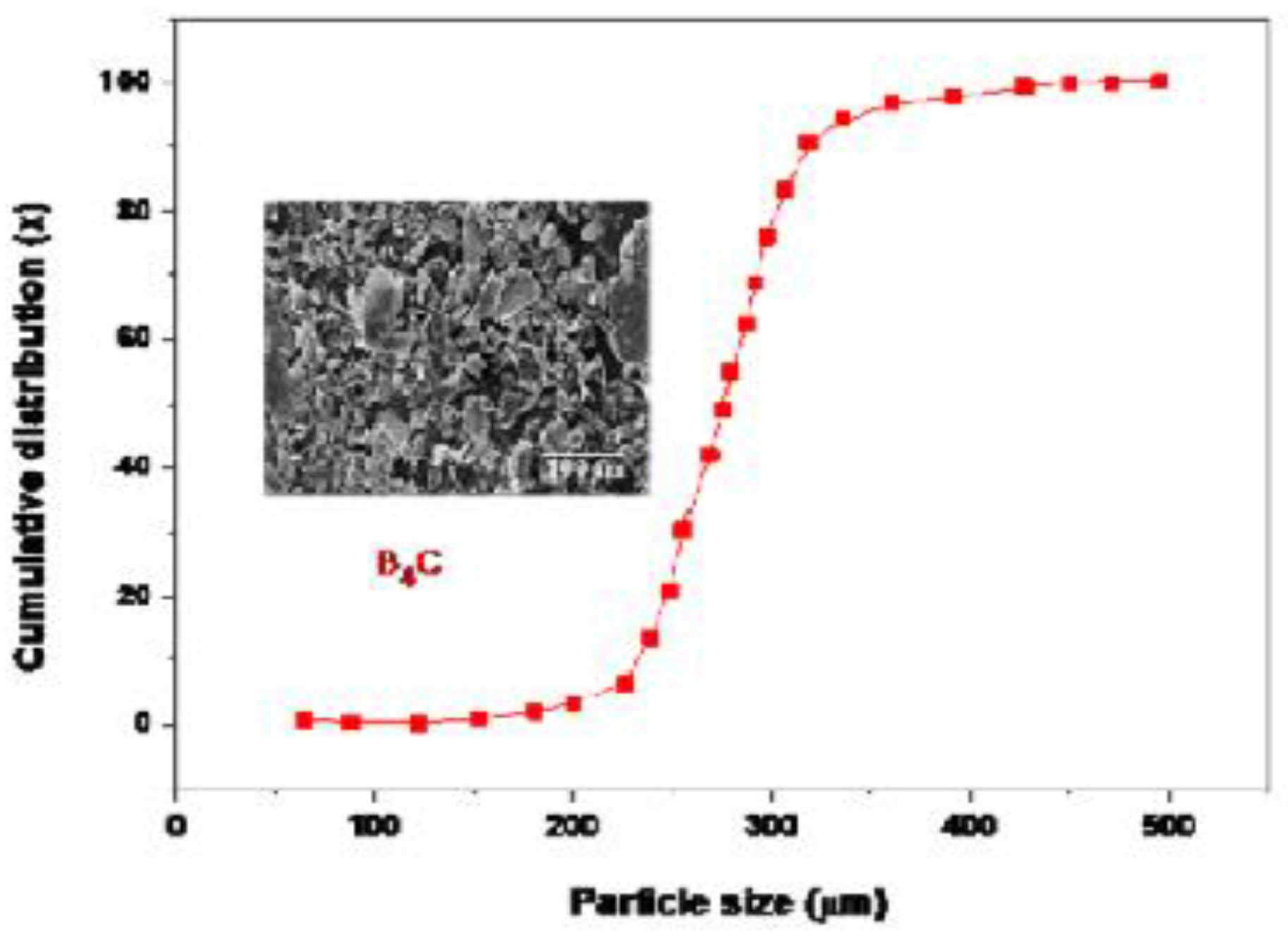

Reinforcement Materials

Boron Carbide (B4C)

| Chemical | Percentage |

| C | 19.7 |

| B | 79 |

| Fe | 1 |

| Si | 0.5 |

| Ca | 0.3 |

| F | 0.03 |

| Material | Compressive strength | Youngs modulus | Bending strength | Melting Point |

| B4C | 1960-3922MPa | 4500 kg/mm2 | 30-50 kg/mm2 | 24550 C |

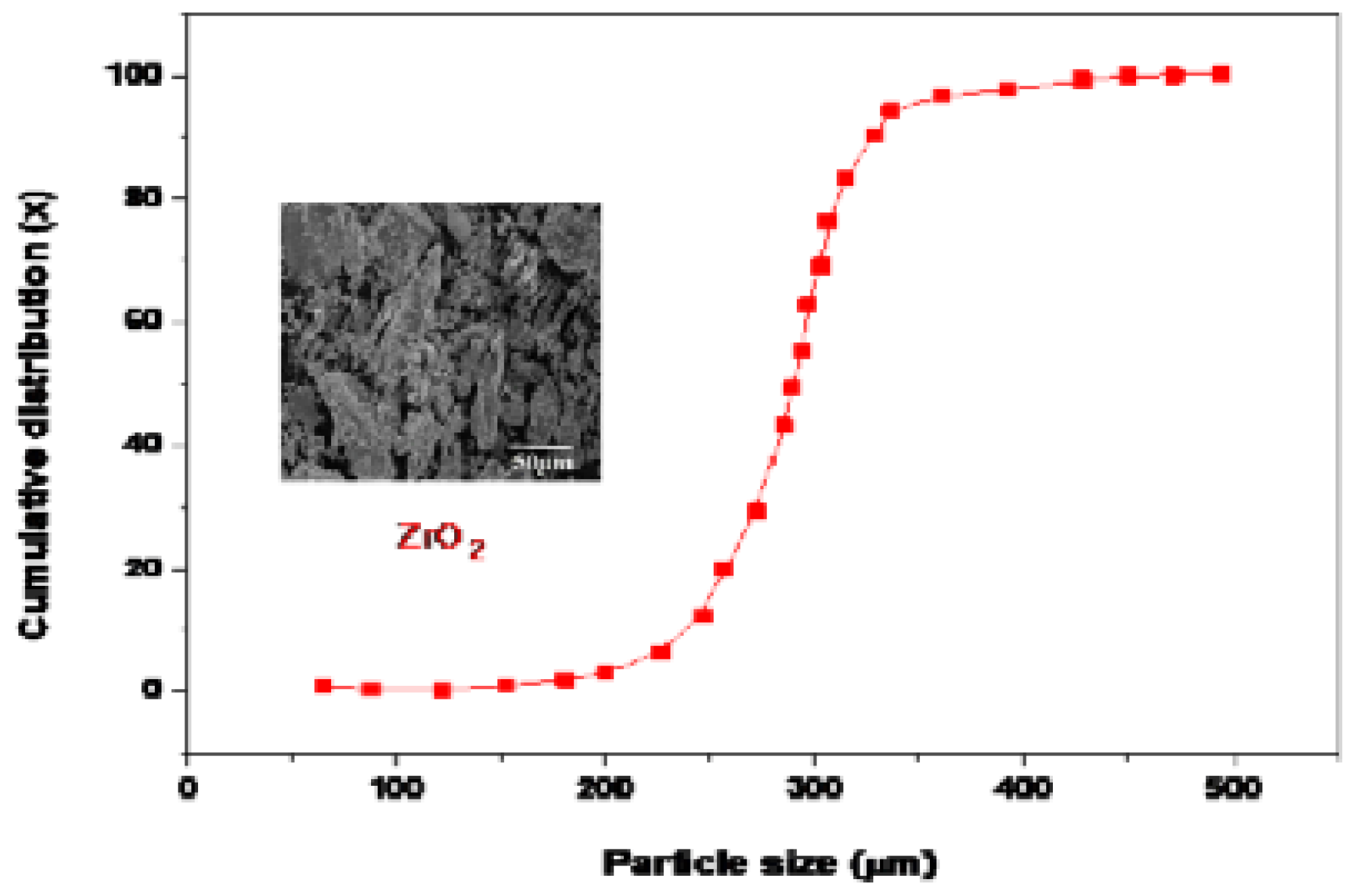

Zirconium Dioxide (ZrO2)

| Properties | Value |

| Density (g/cm3) | 5.68 |

| Melting point (0C) | 2715 |

| Appearance | Powder form white |

| Molar mass | 123.218 g/mol |

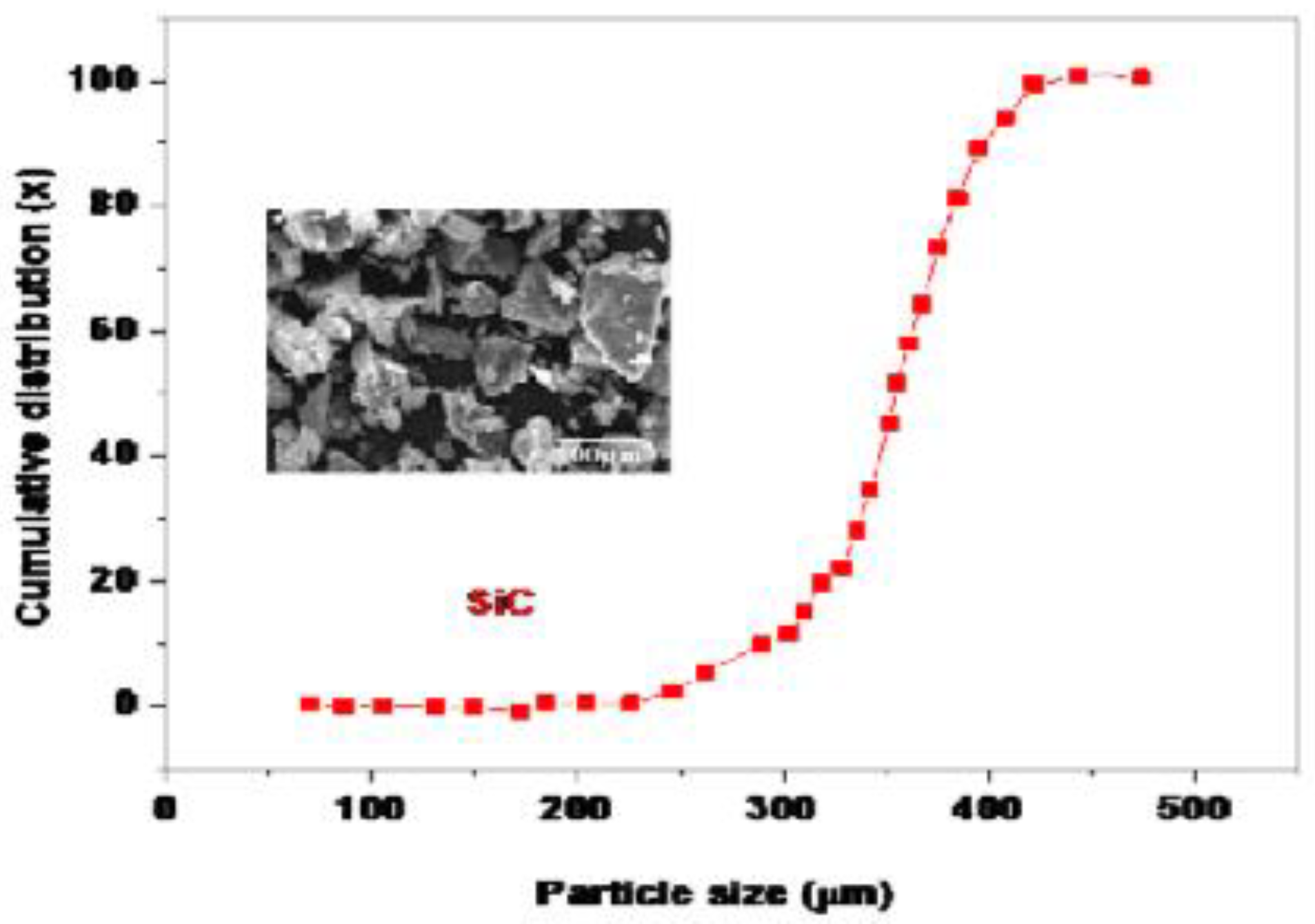

Silicon Carbide (SiC)

| Chemical | Wt. % Percentage |

| c | 0.3 |

| Al | 0.1 |

| Fe | 0.08 |

| SiO2 | 0.5 |

| Si | 0.3 |

| SiC | 98.5 |

| Properties | Value |

| Melting Point | 2730°C |

| Density | 3.22 g/cm3 |

| Poisson’s Ratio | 0.35 |

| Tensile strength | 0.1379 GPa |

| Yield strength | 21 GPa |

| Elongation | 6% |

| Thermal Conductivity | 120 W/m-K |

| Modulus of Elasticity | 90 GPa |

Research Methodology:

Stir Casting Method

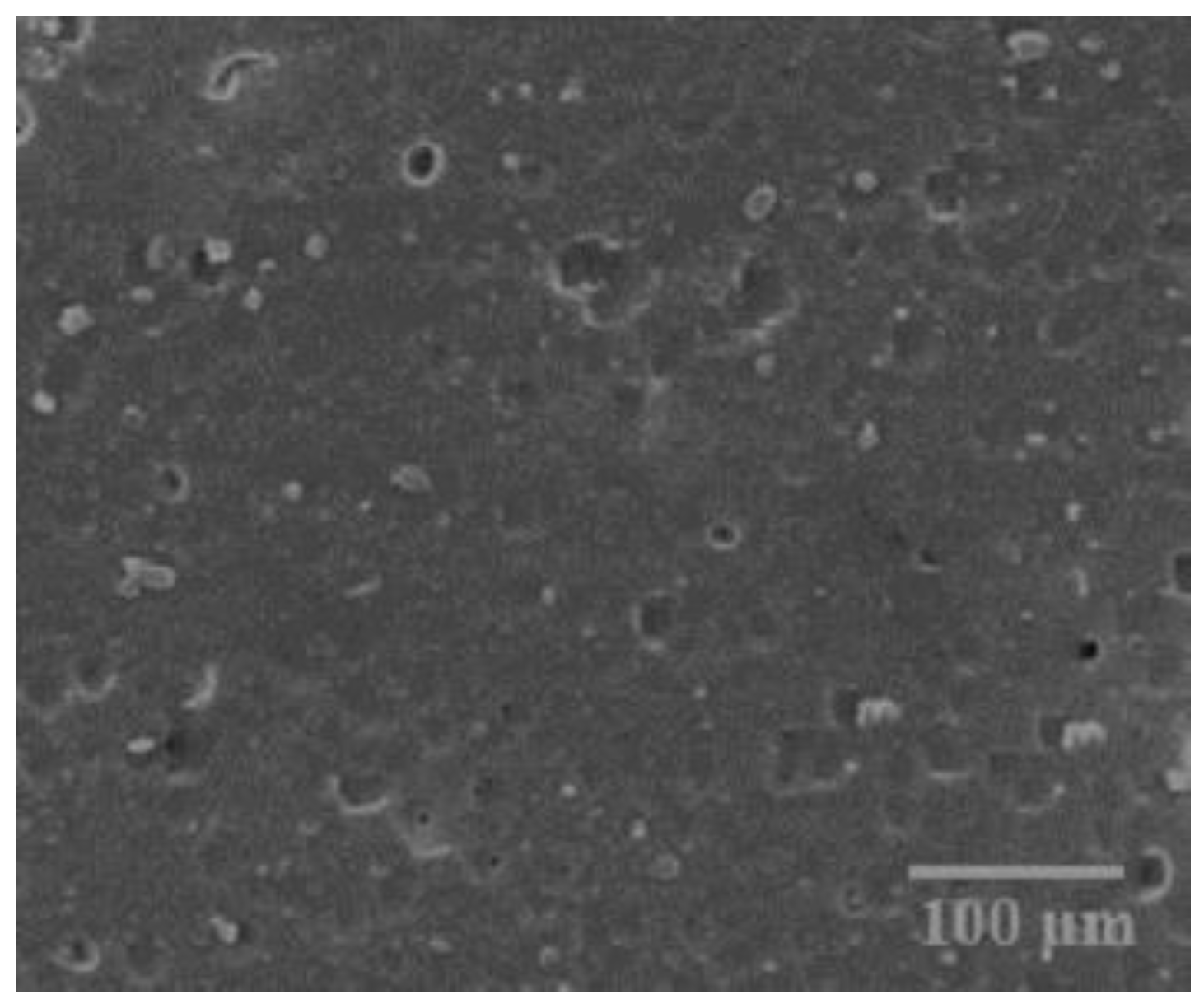

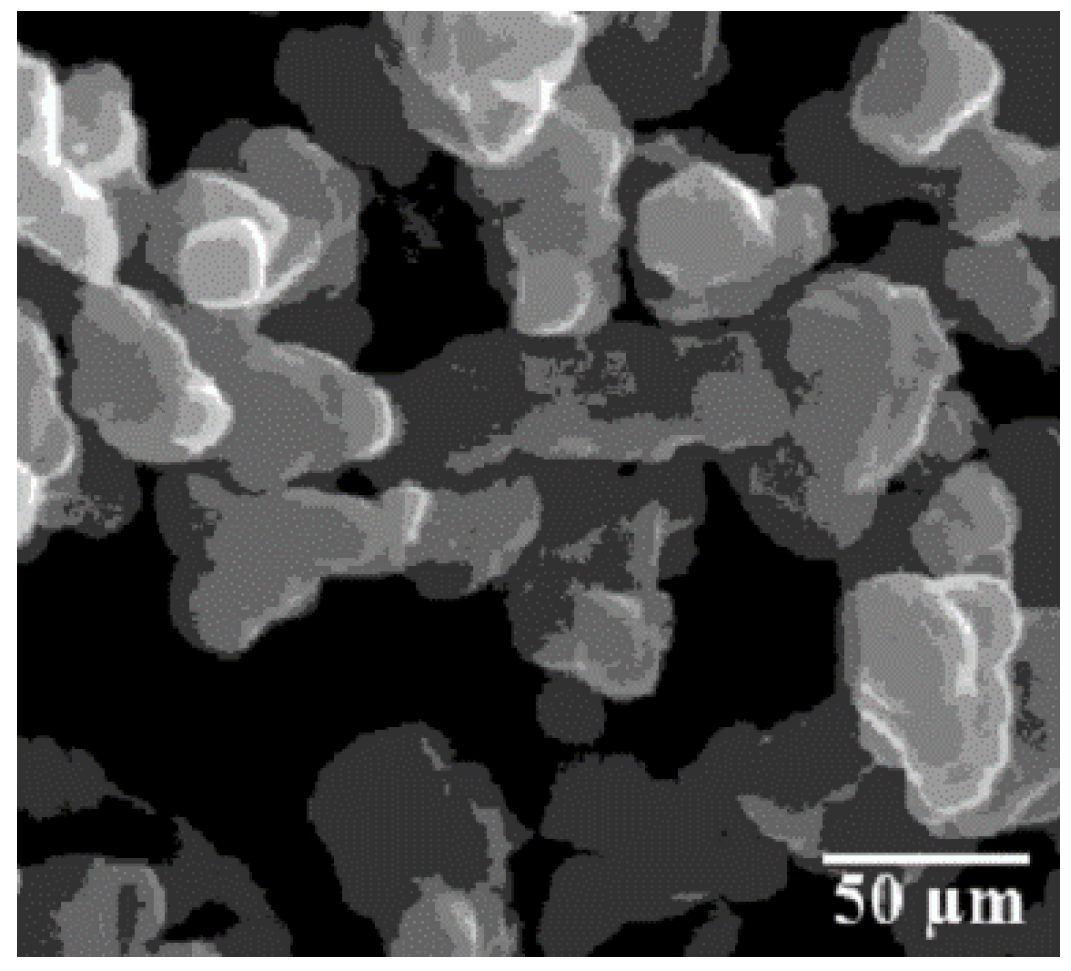

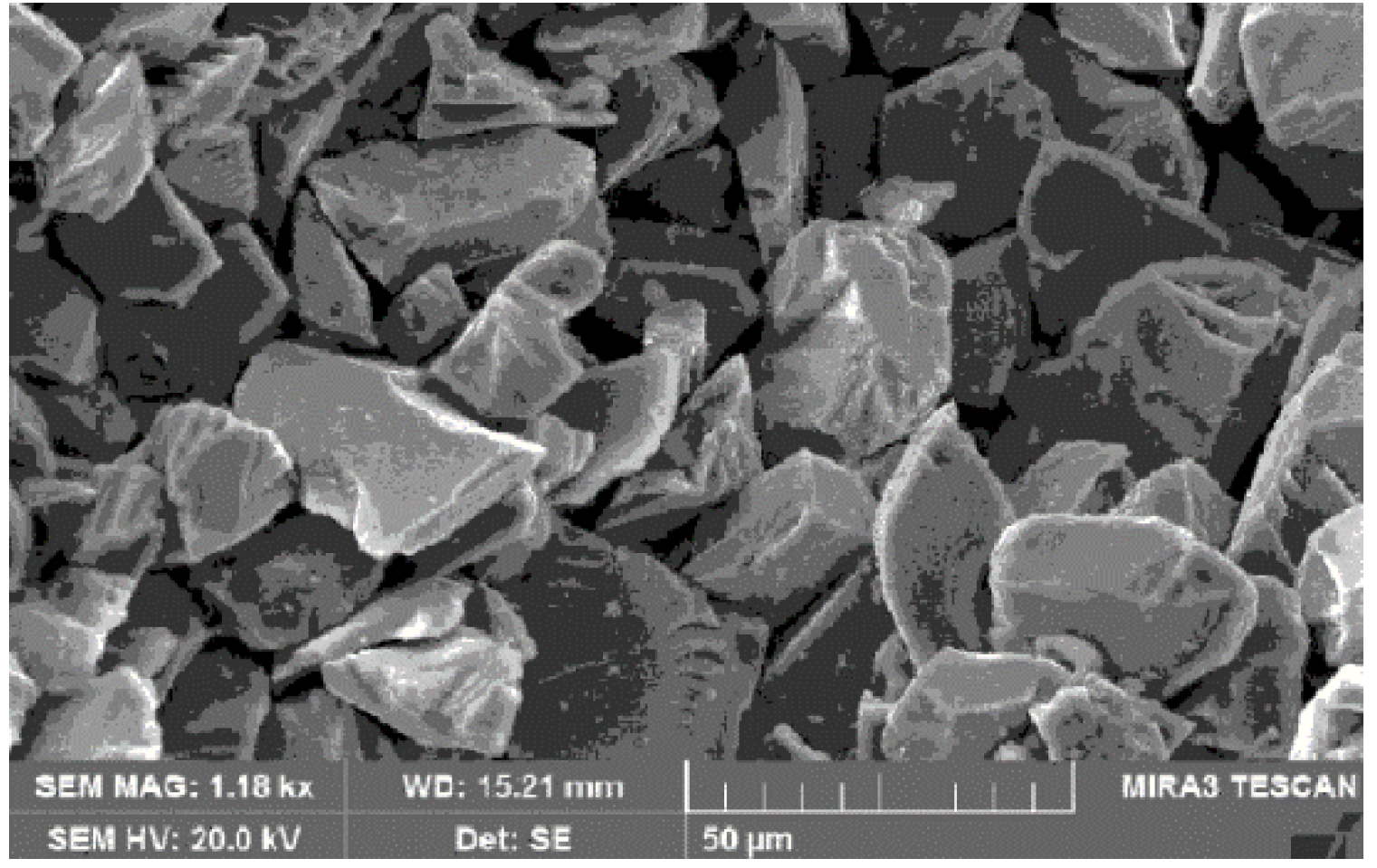

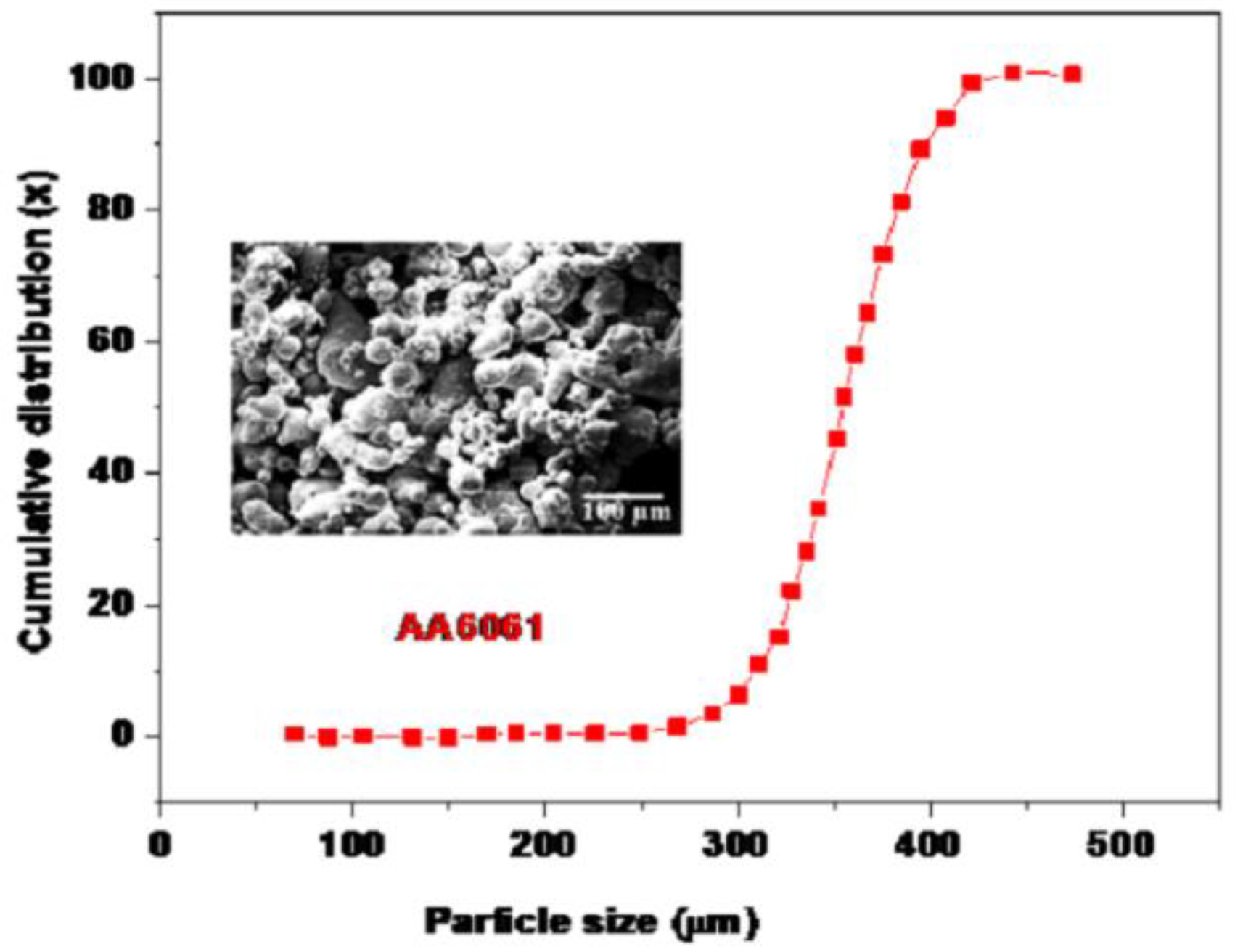

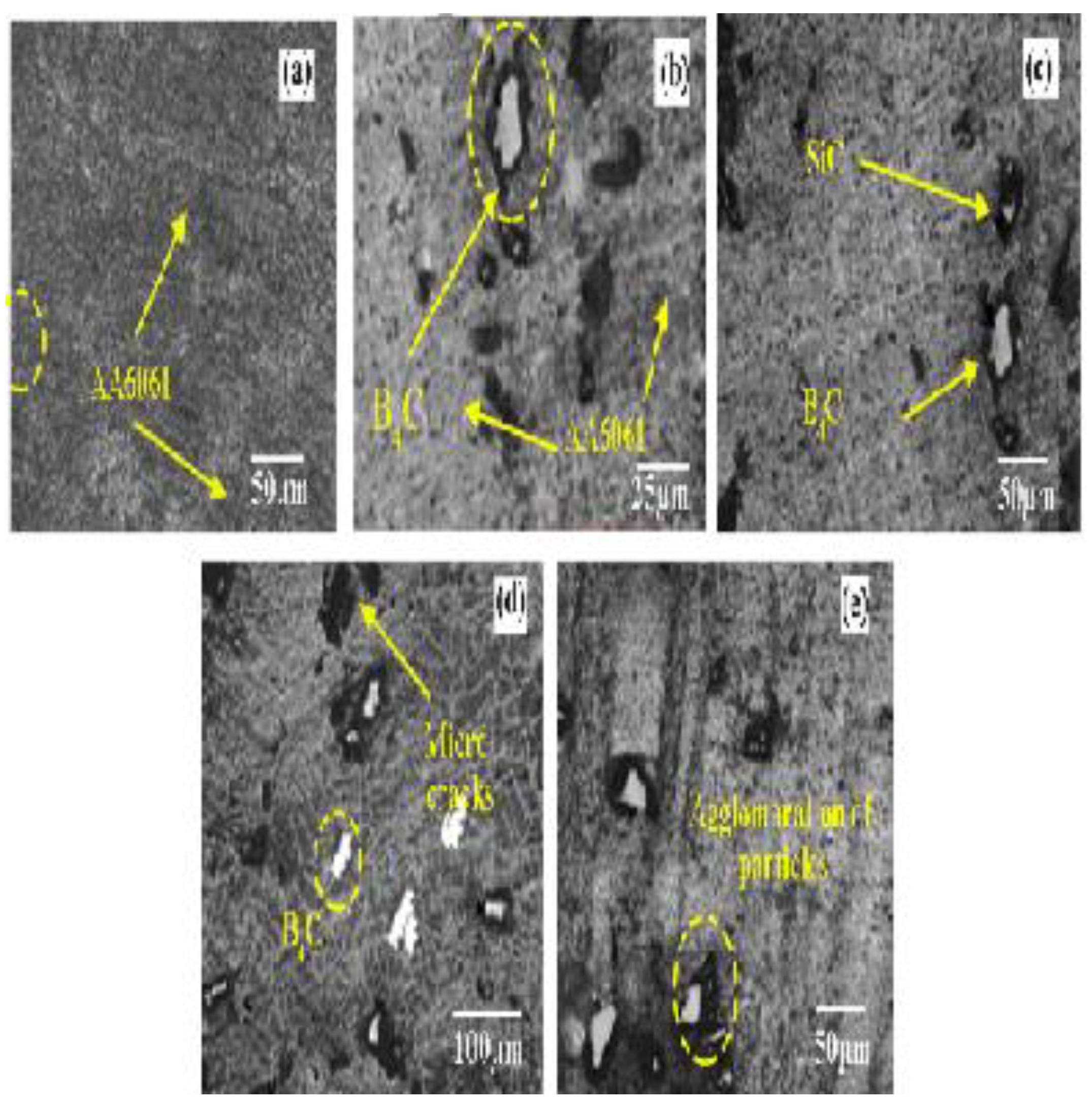

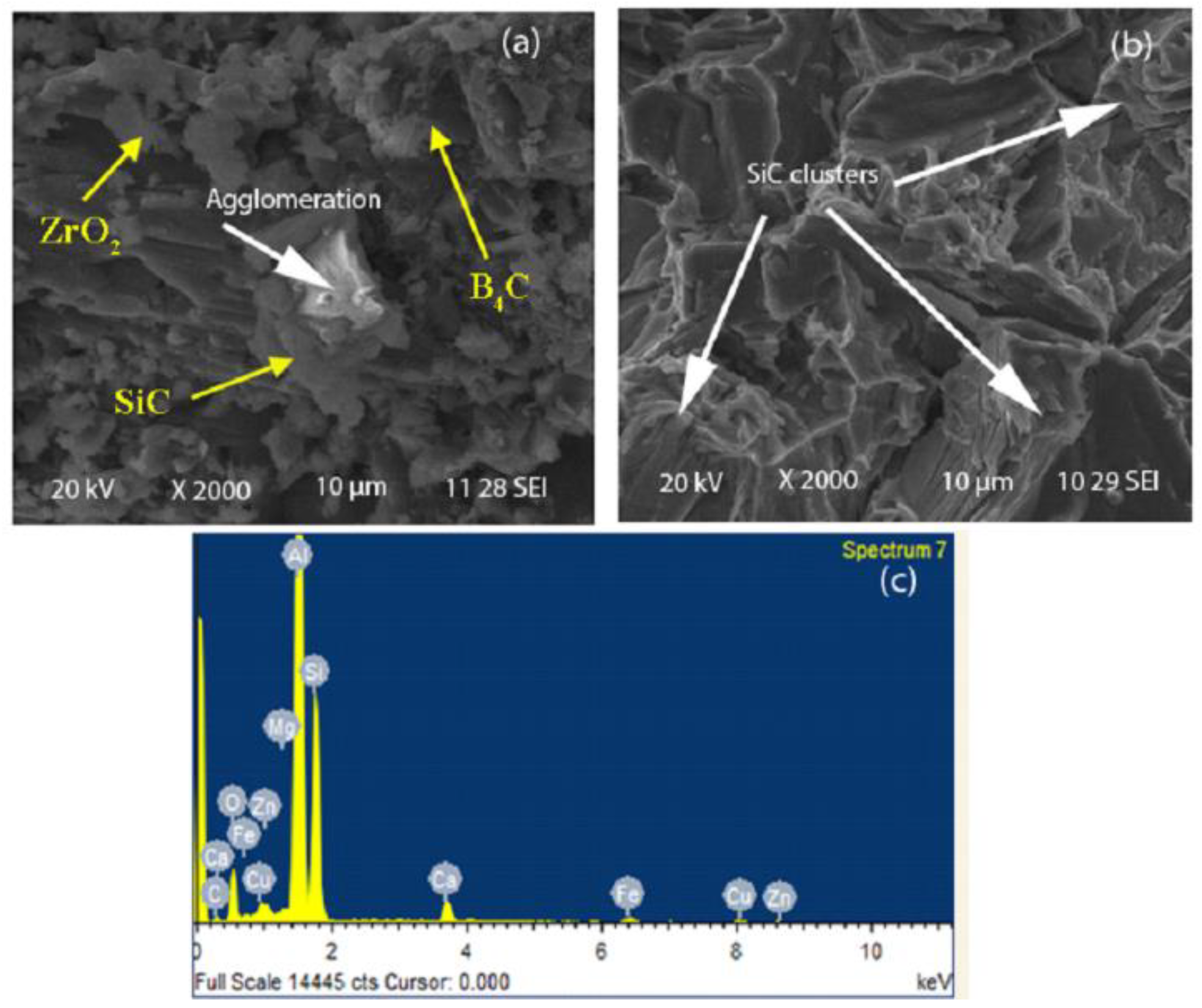

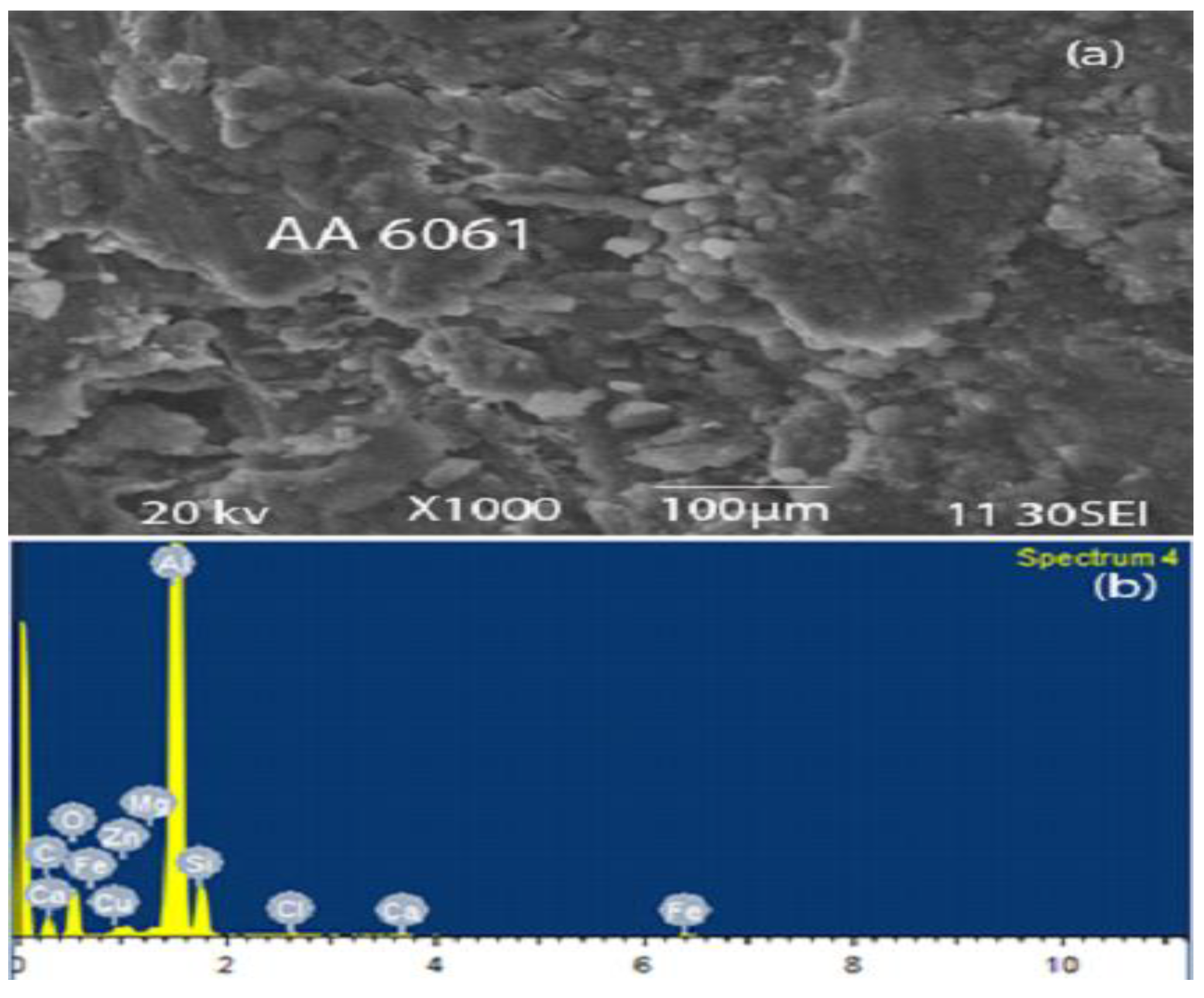

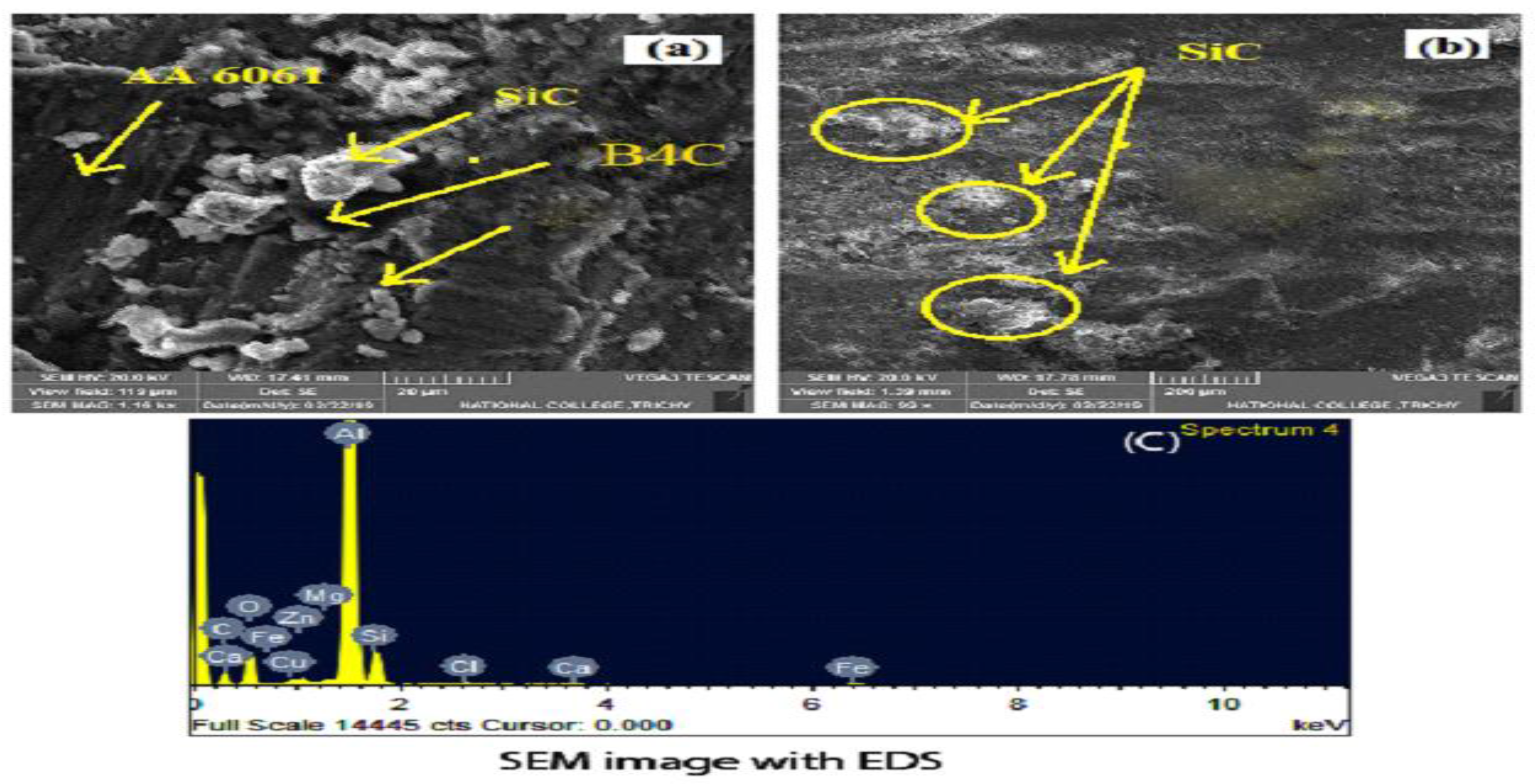

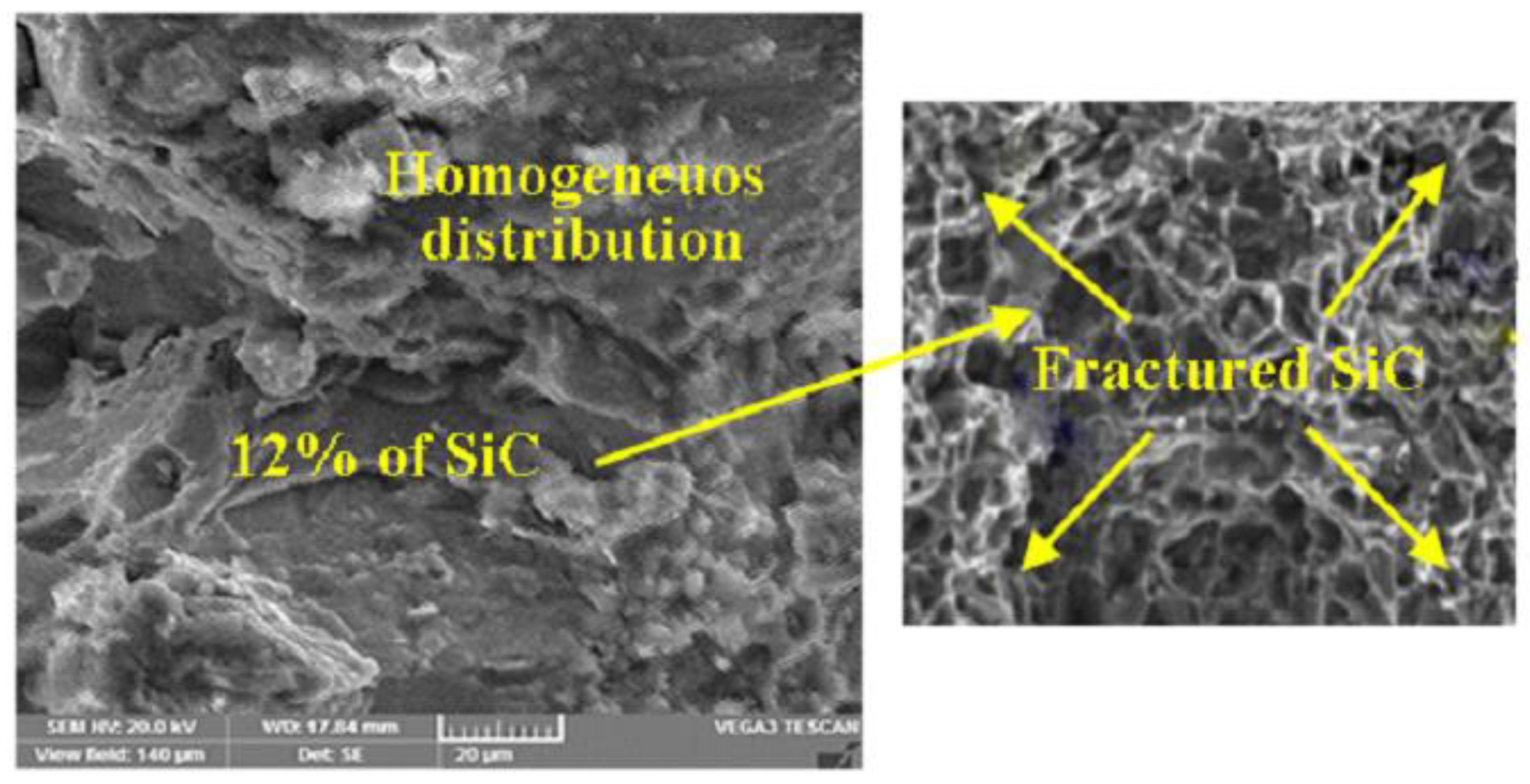

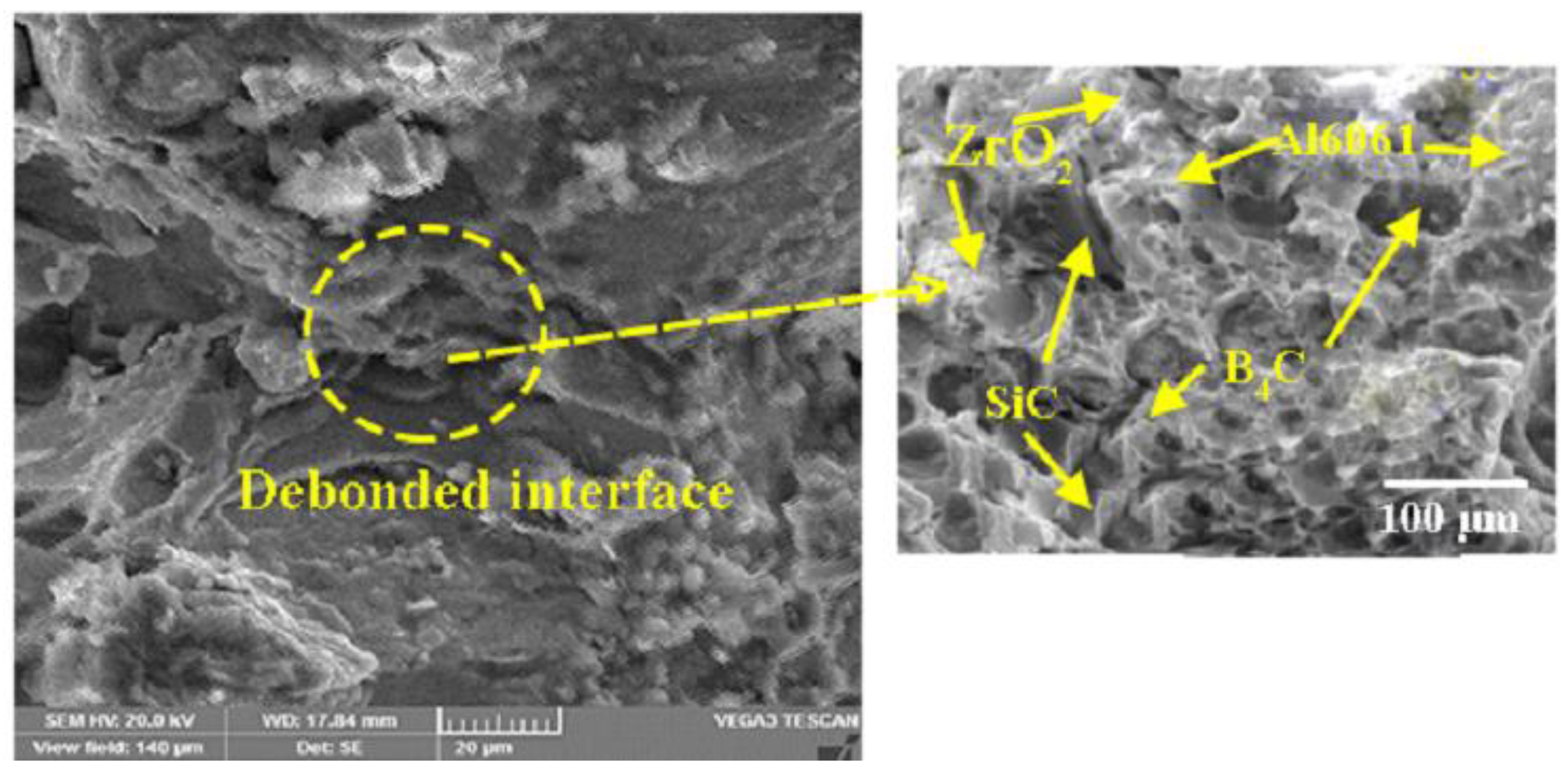

Microstructure Analysis

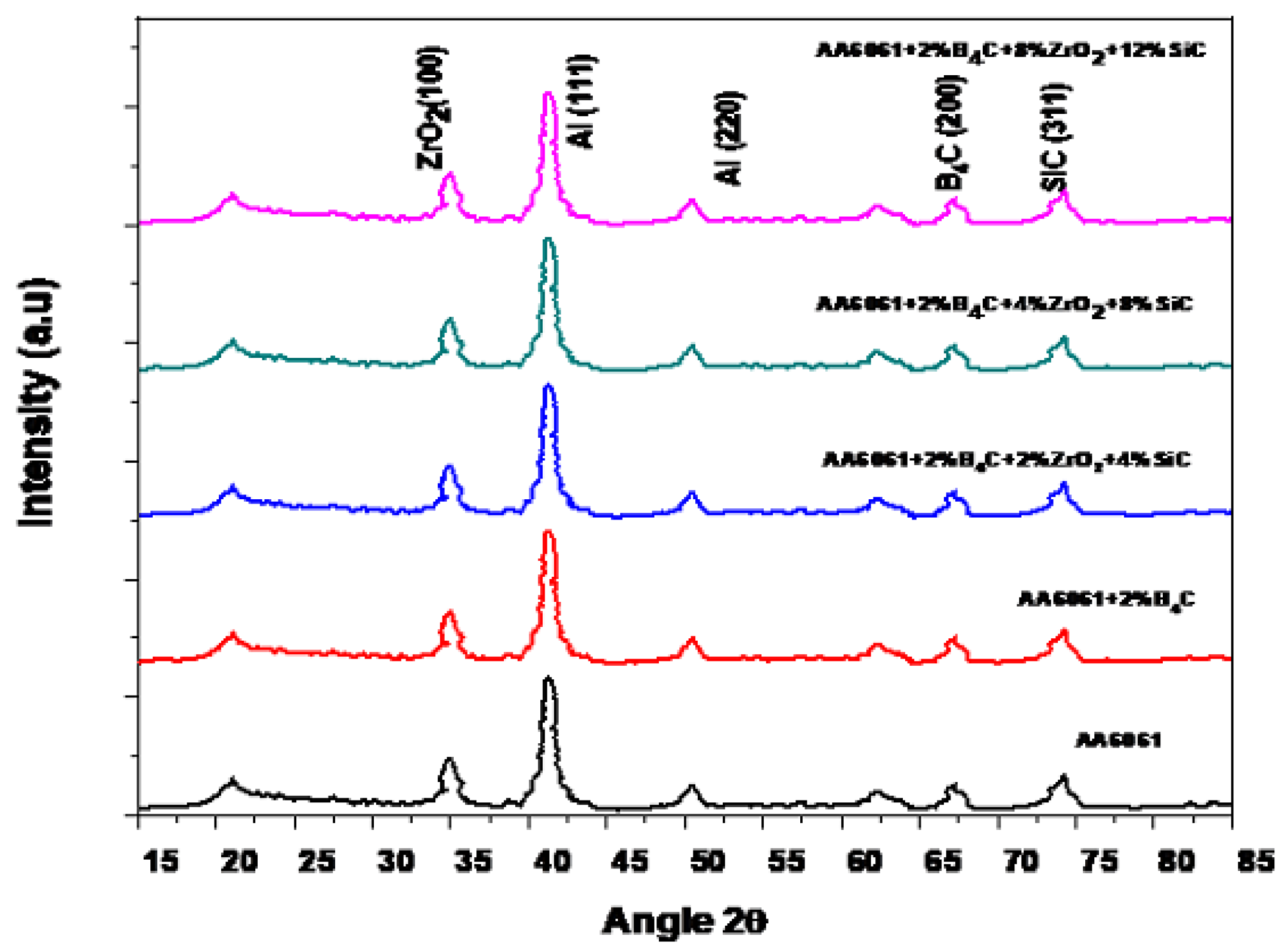

XRD Analysis

EDS Analysis

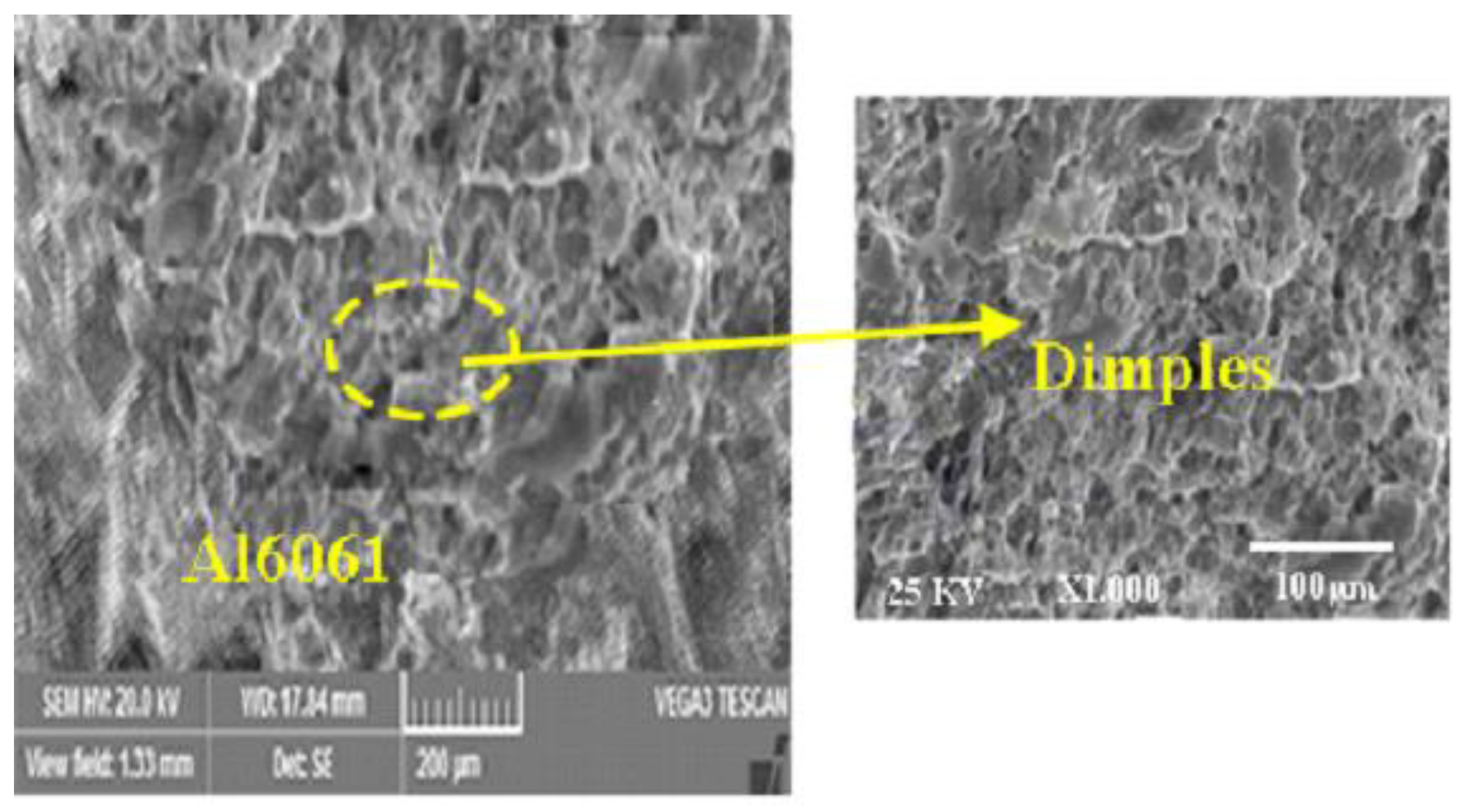

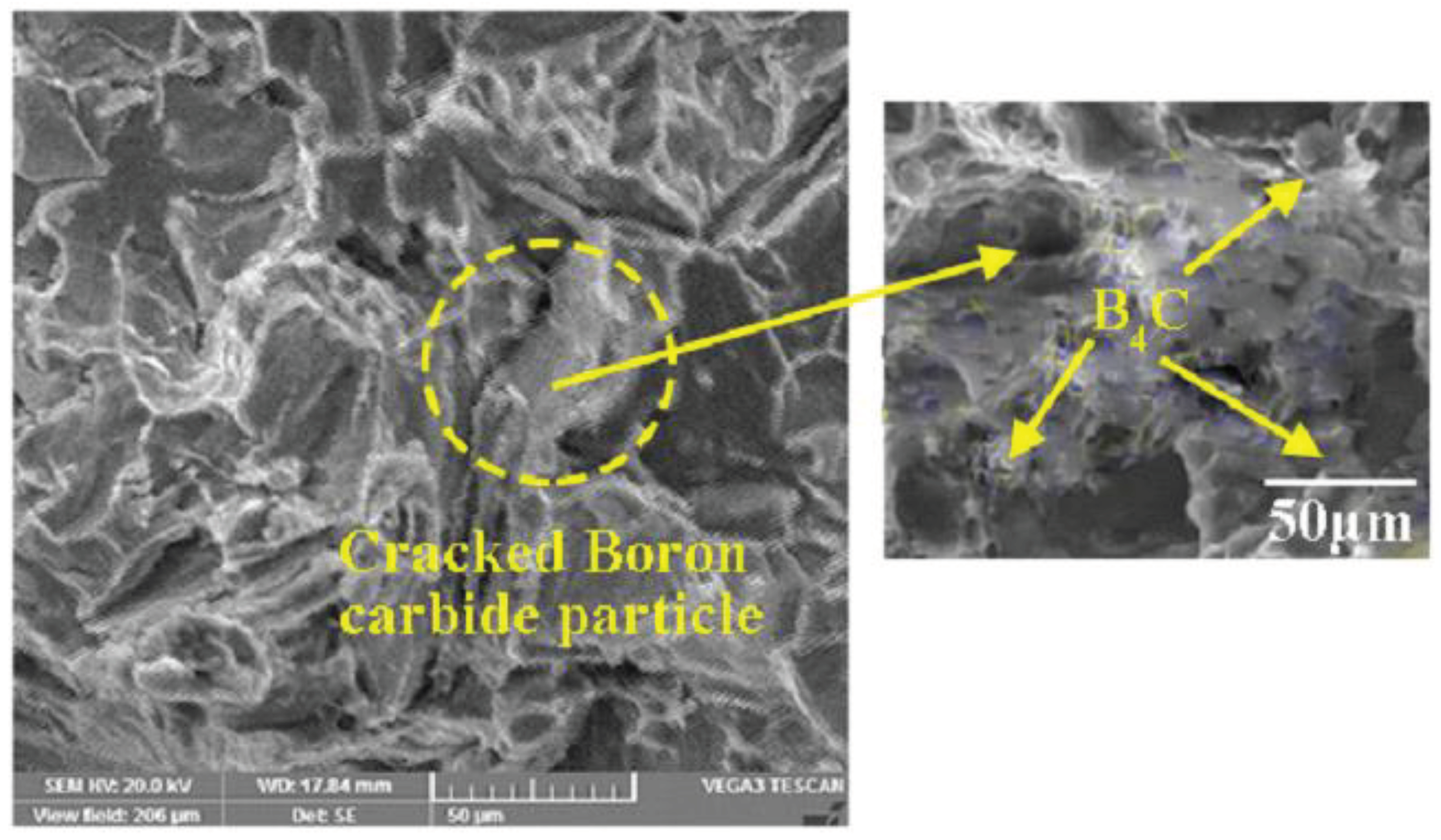

Fractography Analysis

Conclusion

- Using a stir casting approach to examine the Al6061 microstructure and found that there were no pores in the hybrid composites (AA6061+B4C/ZrO2/SiC). The study discovered that the microstructures of the B4C/SiC-reinforced composites typically showed a homogeneous dispersion of ZrO2/SiC particles inside the matrix of 6%ZrO2+12%SiC composites.

- Agglomeration increased simultaneously with increase in B4C in 2%B4C and pure AA6061 compositions. Less porosity was observed in the 12%SiC hybrids, although they exhibited a higher degree of aggregation than the micro-structure when compared to the other composites.

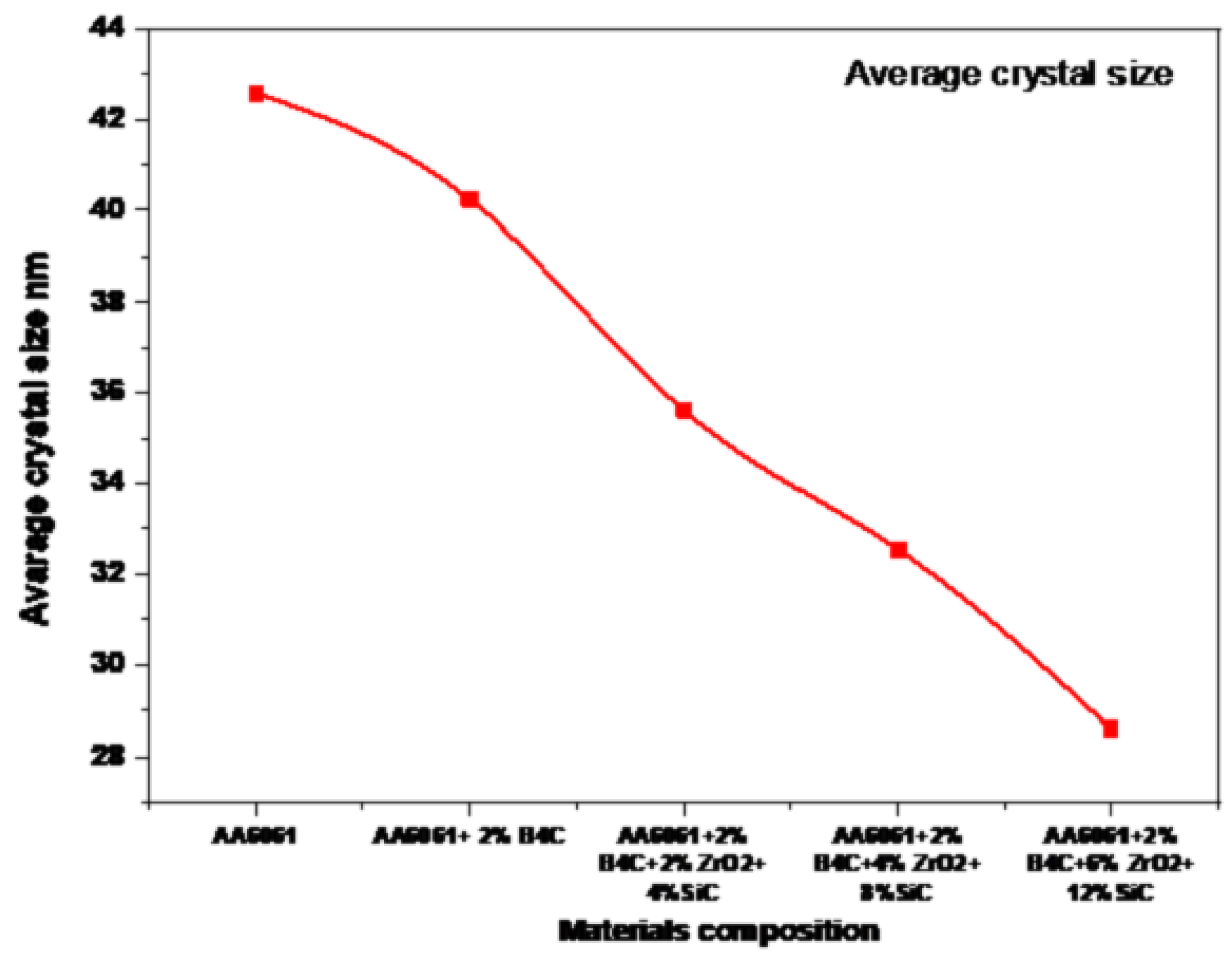

- The Scherrer equation was used to determine the crystal size. As a result, AA6061 had a larger crystal size of 42.58 nm as opposed to the hybrid composites of AA6061/2%B4C/8%ZrO2/12%SiC, which had a crystal size of 28.6 nm.

References

- S. Muzeer, S. Sivaganesan (2022), “Tribological behaviour of aluminium based hybrid metal matrix composites (Al6061/B4C/ZrO2/SiC)”, Materials Today Proceedings”, Volume 56, Part 1, 2022, Pages 507-513.

- Hanumanth GS, Irons GA. Particle incorporation by melt stirring for the production of metal-matrix composites. J Mater Sci 1993; 28:2459–65. [CrossRef]

- Surappa MK. Aluminium matrix composites: challenges and opportunities. Sadhana 2003;28(1–2):319–34. [CrossRef]

- Macke A, Schultz BF, Rohatgi P. Metal matrix composites offer the automotive industry an opportunity to reduce vehicle weight, improve performance. Adv Mater Processes 2012;170(3):19–23.

- Christy TV, Murugan N, Kumar S. A comparative study on the microstructures and mechanical properties of Al 6061 alloy and the MMC Al 6061/TiB2/12p. J Miner Mater Charact Eng 2010;9:57–65.

- Miracle DB. Metal matrix composites-from science to technological significance. Compos Sci Technol 2005; 65:526–40.

- Prabu SB, Karanamoorty L, Kathiresan S, Mohan B. Influence of stirring speed and stirring time on distribution of particulates in cast metal matrix composite. J Mater Process Technol 2006; 171:268–73.

- Miracle DB. Metal matrix composites-from science to technological significance. Compos Sci Technol 2005; 65:526–40. [CrossRef]

- 9Kumar S, Vasumathi M. Applying visualization techniques to study the fluid flow pattern and the particle distribution in the casting of metal matrix composites. J Manufact Proc 2020; 58:668-76.

- Velavan K, Palanikumar K, Natarajan E, Lim WH. Implications on the influence of mica on the mechanical properties of cast hybrid (Alþ 10% B4Cþ Mica) metal matrix composite. J Mater Res Technol 2021; 10:99-109.

- S. Muzeer, S. Sivaganesan (2022), “Wear Optimization of Aluminium and Hybrid Reinforcement Metal Matrix Composites Using Response Surface Methodology”, Materials Science Forum (Volume 1073), 37-48. [CrossRef]

- Yuvaraj N, Aravindan S, Vipin. Fabrication of Al5083/B 4 C surface composite by friction stir processing and its tribological characterization. J Mater Res Technol 2015; 4:398–410,.

- Sambathkumar M, Navaneetha Krishnan P, Ponappa KSKS. Mechanical and Corrosion Behavior of Al7075 (Hybrid) Metal Matrix Composites by Two Step Stir Casting Process. Lat Am J Solids Struct 2016; 7075:243–55. [CrossRef]

- Maniammal K, Madhu G, Biju V. X-ray diffraction line profile analysis of nanostructured nickel oxide: Shape factor and convolution of crystallite size and microstrain contributions. [CrossRef]

- Zheng R, Hao X, Yuan Y, Wang Z, Ameyama K, Ma C. Effect of high-volume fraction of B4C particles on the microstructure and mechanical properties of aluminum alloy-based composites. J Alloys Compd 2013. [CrossRef]

- Dhas, DSEJ, Velmurugan, C, Wins, KLD2018, ‘Investigations on the effect of tungsten carbide and graphite reinforcements during spark erosion machining of aluminium alloy (AA5052) hybrid composite’. Silicon’, vol 10, no.6, pp. 2769-2781, ISSN: 1876-9918. [CrossRef]

- Amirkhan Lou S & Niroumand B. 2011, Development of Al356/SiCp cast composites by injection of SiCp containing composite powders Mater Des’, vol. 32, no.4 pp. 1895-1902, ISSN: 0264-1275.

| S.No | Composition | AA6061 | B4C | ZrO2 | SiC |

| g | g | g | g | ||

| 1 | Al6061 | 1500 | 0 | 0 | 0 |

| 2 | Al6061+2%B4C | 1470 | 30 | 0 | 0 |

| 3 | Al6061+2% B4C +2%ZrO2+ 4%SiC | 1380 | 30 | 30 | 60 |

| 4 | Al6061+2% B4C +4%ZrO2+ 8%SiC | 1290 | 30 | 60 | 120 |

| 5 | Al6061+2% B4C +6%ZrO2+ 12%SiC | 1200 | 30 | 90 | 180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).