1. Introduction

The functions of lubricants include providing hydrodynamic lubrication at contact surfaces, maintaining and improving oil viscosity at alternating temperatures, inhibiting base oil oxidation, minimizing friction and wear, and protecting engine components from corrosion. Modern lubricants comprise several components, a significant part of which is the base oil, to which are added various antioxidants, viscosity modifiers, anti-wear additives, anti-foaming agents, pressure additives, detergent and dispersant additives. These additives are needed because the base oil alone cannot fulfill the requirements expected of it, and by adding different additives, they can give new properties to the base oil and improve existing properties. The composition of lubricants can vary widely due to the mixing of different ratios, and the properties of the lubricant also change with it. Several types of lubricants have already been developed to meet different needs [

1].

The molecules of the dispersant additive group surround solid and liquid impurities in the oil, envelop them and keep them suspended in the oil, thereby preventing their deposition in the engine or their accumulation, i.e., sludge formation [

2]. The dispersants can induce a charge on the insoluble particles, so the impurities are electrostatically stable. The various pollutants containing acidic groups and the dispersants containing basic amine sites attached to them interact to form salts. As a result, the charge of the impurity becomes negative and that of the dispersant positive, and thus, the other contaminants cannot create agglomerations with each other since there is a positively charged dispersant additive around each impurity. Therefore, they repel each other [

3]. Carbon particles can form in the lubricant of internal combustion engines, which is the result of thermal oxidation, the accumulation of which can lead to higher friction [

4] and more wear of the parts [

5].

Polyisobutylene succinimide (PIBSI) ashless dispersant additives are widely used in industry because they perform well at low temperatures. They are widespread due to their excellent dispersion of insoluble oxidation products. These dispersing additives have an amphiphilic structure and contain both polar and apolar groups of compounds. With the help of the polar head part, they can connect to insoluble particles and various metal surfaces, and the apolar tail part ensures hydrocarbon solubility. In addition, after binding to the surface and insoluble particles, the dispersant prevents the deposition of pollutants and the formation of larger agglomerations [

6]. Willermet presented the effect of various detergent and dispersant (including PIBSI) motor oil additives on each other. He found that the joint application of different additives is a complex task. From a tribological point of view, antagonistic and synergistic effects can be produced depending on the combination of additives. The investigation of additive interactions is a critical task in lubricant development. It makes an important distinction between how they interact with each other in the oil and how they interact in the tribological boundary layer [

7]. PIBSI is an additive type with general detergent/dispersant/anti-wear properties [

8] that can be widely used in modern, high-performance lubricating oils. However, PIBSIs can form combinations with unpredictable effects during their reactions with other additives. Therefore, it is essential to investigate the joint effect of additive pairs in engine oil development [

9]. Sági et al. demonstrated on PIBSIs containing molybdenum and molybdenum-sulfide reagents that the tribological properties depend to a large extent on the additives found in the lubricating oil in addition to the dispersant [

10,

11]. Bartha et al. investigated the strength of the interaction of different PIBSIs with zinc dialkyl dithiophosphates (ZDDP). They found that the anti-wear effect of ZDDP was reduced in the presence of PIBSI [

12].

Several of the most recent studies have already summarized that in the future, various nanoparticles [

13,

14,

15,

16,

17,

18], including oxide ceramics [

19,

20], can play the role of potential engine lubricant additives or even replace some of them. Studies have already proven the beneficial tribological effects of cupric oxide in commercial motor oil [

21], in base oil [

22] and in vegetable oil [

23] as well. The titania nanoadditive is excellent for the friction, wear and lubrication of closed mechanical equipment such as electric vehicle transmission [

24] or journal bearings [

25,

26]. In addition to using nanoparticles as a lubricant additive, another significant potential is their use in cutting fluids. According to the scientific literature, nanoparticles can achieve their favorable tribological effect because their small particle size allows them to fit between the contact surfaces and form a nanofilm there, which both helps the parts move on each other and protects them from high wear rates [

27]. There are several theories for the operation of nanoparticles in a tribological system: rolling bearing, mending effect, polishing effect, film formation, etc. However, these descriptions are simplified; the natural operating mechanism is different for each type of nanoparticle and is complicated to understand, so further studies are needed to understand the operation [

28].

Suppose there is insufficient dispersant around the nanoparticles through surface modification or a dispersant additive. In that case, they form an inhomogeneous mixture, agglomerate, settle and result in poor tribological performance. Research reports show that PIBSI is a suitable dispersant for homogenizing nanoparticles in lubricating oil. The joint effect of PIBSI and nanoparticles has been presented and proven in several combinations: the synergistic effect of nano-sized hBN [

29], polyaniline [

30], nano graphite, micro-PTFE particles against anti-wear and extreme pressure properties [

31], the friction and wear-reducing effect of WC and WS

2 [

32]. Zefu et al. tested 1 wt% LaF

3 nanoclusters in paraffin-based lubricating oil in the presence of PIBSI dispersant. During tribological tests with the lubricating oil produced in this way, significant reductions in friction and wear were experienced, which even exceeded the values of the base oil added with ZDDP. The LaF

3 additive produced La

2O

3 through a tribochemical reaction on the contact surface [

33]. According to Hongxing's report, the MoS

2 nanosheets dispersed with PIBSI showed an excellent anti-wear effect even when used in an ultra-low concentration (0.015 wt%). MoS

2 adhered to the surface, reducing friction by 51.6% and wear by 70% [

34]. Chen et al.'s experiment demonstrated the synergistic tribological effect between MoO

3 nanoparticles dispersed with PIBSI and ZDDP. They experienced reduced friction and wear on a diamond-like carbon coating during their study. During their surface analysis, they revealed some of the tribochemical reactions in the boundary layer, thereby demonstrating the fundamental operation of ZDDP and the transformation of MoO

3 [

35].

The main goal of this article is to experimentally investigate the combined action mechanism of ethyl oleate-surface modified CuO and TiO2 nanoparticles with 8 wt% Komad 323 base oil content in a specific tribosystem. The novelty of this article is that, since nanoparticles as potential engine lubricant additives are still in the research phase, there is little data and literature available on their effect on each other. The results' importance is that they provide information for understanding nanoparticle functioning. Knowing the impact of the dispersant and the nanoparticles on each other is crucial for advancing lubricating oil development.

2. Materials and Methods

The research used two transition metal oxide nanoceramics - cupric oxide (CuO) and titanium dioxide (TiO

2) -. Both came as an APS bulk powder, but the morphology of the individual nanoparticles is spherical. The particle size of cupric oxide nanopowder (supplied by Thermo Fisher GmbH, Kandel, Germany) is between 30-50 nm and its purity is higher than 99%. The titanium dioxide (titania) nanopowder has a purity higher than 99.9% and its particle size is under 32 nm. This material was shipped from Karlsruhe by Alfa Aesar GmbH, Germany.

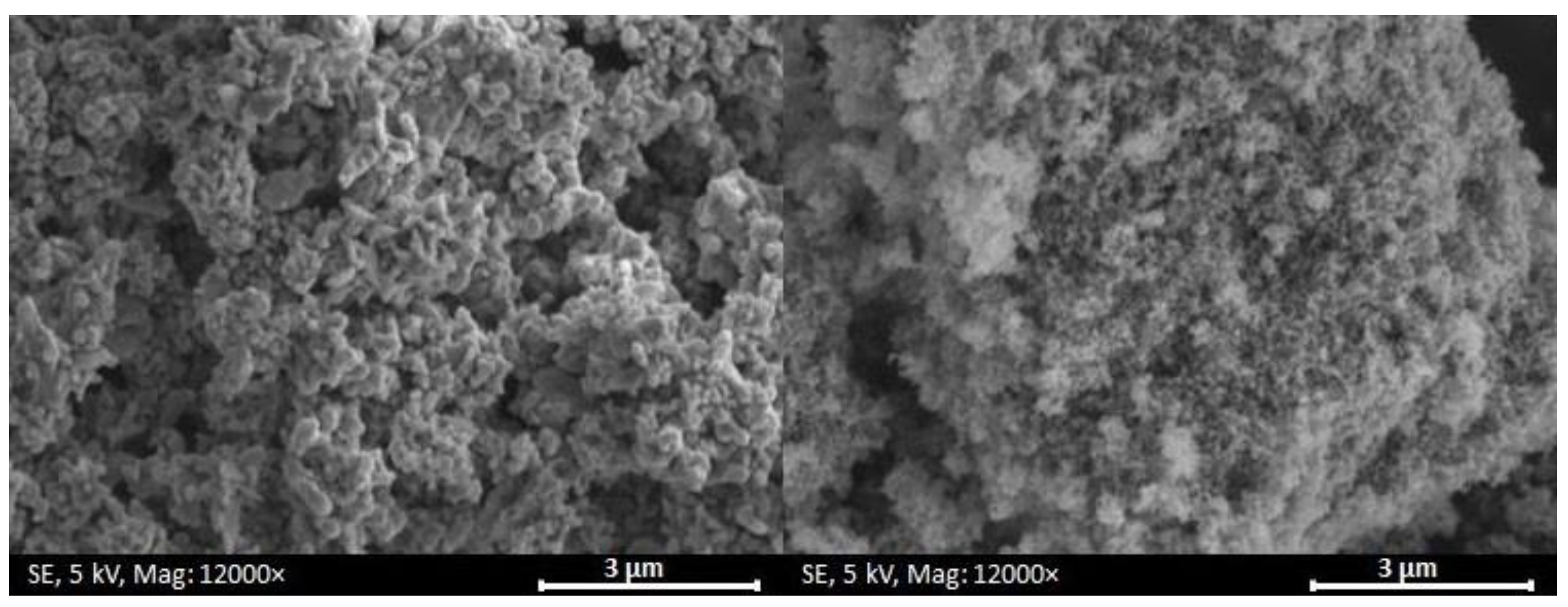

Figure 1 shows the scanning electron micrograph (SEM) of the used bulk nanopowders (CuO on the left and TiO

2 on the right) at a magnification 12000. The SEM examination of the nanopowders was carried out by the Institute for Nuclear Research (Debrecen, Hungary).

The basis of the lubricating oils used during the measurements provided by a Group III type base oil is a mixture of C20-C50 carbon chain alkanes produced by hydrocracking. Komad 323 is an ashless polyisobutylene polysuccinimide (PIBSI) dispersant additive developed for good solubility in lubricating oils as a common dispersant and a viscosity improver [

36]. Based on the most recent high-performance commercial lubricants, 8 wt% Komad 323 dispersant additive was added to this base oil. Group III oil added with Komad 323 dispersant was used as the basis of the measurements produced by the Hungarian MOL-LUB Kft. (Almásfüzitő, Hungary).

Agglomerations can form between the oxide ceramic nanoparticles and as a result, the nanoparticles begin to agglomerate and settle in the lubricant. Agglomerations harm the tested oil samples in several ways. The larger agglomerations cannot dissolve completely in the oil, so they cause inhomogeneity and rapid sedimentation. Sedimentation can affect the measurement results because of the changed concentration of nanoparticles remaining in the lubricant. To avoid agglomerations, the surface of the nanoparticles must be modified, which creates a coating on the surface of the nanoparticles and prevents the formation of aggregations. The nanoparticles got an ethyl oleate surface modification during the present research, which required 90% oleic acid, 99.6% ethyl alcohol and bulk nanopowders. These three substances were added to each other considering the appropriate proportions, then heated to a temperature of 75±5°C with continuous stirring for 2 hours. 75°C is the proper temperature at which oleic acid and ethyl alcohol react and form ethyl oleate, which coats the surface of the nanoparticles. After 2 hours, it is necessary to evaporate the excess alcohol, which can be solved by placing it in a drying cabinet heated to 80°C. After complete drying, the surface-modified nanopowder is ready to prepare lubricants. The authors presented the surface modification method in their previous article [

37].

The variable parameter of the oil samples used for the measurements was the concentration of nanoparticles. Based on the literature and previous results, the tests were conducted with nanoadditive concentrations of 0.1, 0.2...0.5 wt%. The oil samples used for the measurements were prepared in several steps. Toluene was added to the dry nanopowder for proper dispersion of the nanoparticles. The Group III base oil containing 8 wt% Komad 323 and the mixture must be left under constant stirring for 20 hours due to the evaporation of the toluene. The last step in preparing the oil sample to achieve an utterly homogeneous state is placing the mixture in an ultrasonic cleaner for 15 minutes at 50°C, which helps break down any remaining agglomerations. After that, the oil mixture is homogeneous, stable and suitable for performing tribology measurements. The fresh oil sample was used immediately; the oil mixture was stored on a magnetic stirrer until the tribotest started. The reference measurements were carried out with a Group III oil with 8 wt% Komad 323 content that was made with the same preparation process but did not contain nano-particles.

The practical testing of the lubricating oils was performed on a linear oscillating tribometer (Tribological Laboratory of Széchenyi István University in Győr, Hungary). The equipment used is an Optimol SRV®5 tribometer with a ball-disc test specimen pairing, which can adequately represent tribological systems in the automotive industry. The test specimens used for the measurements comply with the ISO 19291:2016 standard. The ball is a test specimen made of 10 mm diameter 100Cr6 bearing steel, with a hardness of 61 HRC and a surface roughness of Ra 0.035 µm. The disc test specimen is a cylinder with a diameter of 24 mm and a height of 7.9 mm, which is also made of 100Cr6 bearing steel. The disc was treated with the vacuum arc remelting method, resulting in a hardness of 62 HRC. The roughness of the coated disc surface is Ra 0.035 µm. Before the tests, the specimens were cleaned in an ultrasonic cleaner immersed in brake cleaner for 15 minutes at a moderate temperature of 50°C so their surface was contamination-free.

The test specimens were then installed in the tribometer. The oil doped with nanoparticles in a closed oil circuit with continuous circulation provided the lubricant supply for the test specimens. The measurements were based on the modified ISO 19291:2016 standard [

38]. To simulate the operating temperature of internal combustion engines, the measurements were performed at a temperature of 100°C. After installation, the equipment heats the system to a temperature of 100°C with continuous oil circulation (225 ml/h), but with test specimens not yet performing relative movement, and keeps it there for 5 minutes. During the warm-up and maintenance phase, a normal force of 50 N is already applied to the ball. The oscillation test consists of two parts: after the warm-up, the ball begins to move along a 1 mm stroke length at a frequency of 50 Hz while the normal force is still 50 N. This 30-second interval with a low load (50 N) is intended to allow the lubricating oil to spread in the lubrication area and get between the contact surfaces and the surfaces to penetrate. After that, the load increases to 100 N and the measurement runs continuously for 2 hours. During the entire measurement process (2 hours and 30 seconds), friction is recorded at high speed with a frequency of 25 kHz. The high-frequency data collection aims to calculate the friction absolute integral value (FAI) from the data recorded during the ball's movement. The FAI value represents well the total friction during the ball's direction, which has a static and a kinetic section. The integral equation for calculating the FAI value is the following, where “s” is the stroke length and “µ” is the measured friction value:

During the tribotest, the magnitude of the static friction was investigated. During the oscillating movement of the ball, it stops and restarts at the dead ends. As it starts moving, the peak value of the friction can be measured as static friction (SF). The determination of the FAI and SF value for measurement is the average of the values measured in the last 1000 seconds of the tribotest.

Test specimens worn during tribometer tests are placed in an ultrasonic cleaner after the measurement. The test bodies were immersed in brake cleaner for 15 minutes and cleaned at a temperature of 50°C. The Surface Analytic Laboratory and the Material Testing Laboratory of Széchenyi István University in Győr, Hungary, performed wear tests on the cleaned specimens. The results of the microscopic evaluation of the surface analysis help to understand the operation of the tribosystem. The ball's mean wear scar diameter (MWSD) on the specimen is characterized using a Keyence VHX-1000-type digital microscope (Keyence International, Mechlin, Belgium) according to the ISO 19291:2016 standard. The mean wear scar diameter is determined by the average wear widths parallel to and perpendicular to the direction of movement formed on the ball. The wear on the disc was examined with a Leica DCM 3D digital confocal microscope (Leica Camera AG, Wetzlar, Germany), which numerically calculates the size of the worn volume after scanning the surface. The high-magnification images were taken with a Hitachi S-3400N (Hitachi Ltd., Chiyoda, Tokyo, Japan) scanning electron microscope (SEM), which can be used to visualize the surface of the tribofilm, showing the different wear types formed on the surface. The parts of the used nanopowders remaining on the surface were localized. Their quantities can be deduced using the additional energy dispersive X-ray spectroscopy (EDX) equipment (Bruker, Billerica, MA, USA) belonging to the SEM. The SEM and EDX images of the disc were taken at two points along the centerline of the wear track in the direction of movement: in the center, where the ball's speed is at maximum, and at the dead center, where the ball stops. From a tribological point of view, the two areas are entirely different. Due to the high relative speed in the middle, hydrodynamic lubrication occurs more efficiently, while in the dead spots, the characteristics of static friction shape the surface structure. The SEM and EDX images were taken in secondary electron mode at a magnification 1000 with 15 kV accelerating voltage and 11.5 mm working distance.

Each different lubricating oil sample was tested with 4 measurements each. The results were calculated from their average and standard deviation. The results were processed in Excel with the 'average' and 'stdev.p' functions.

3. Results

3.1. Cupric Oxide

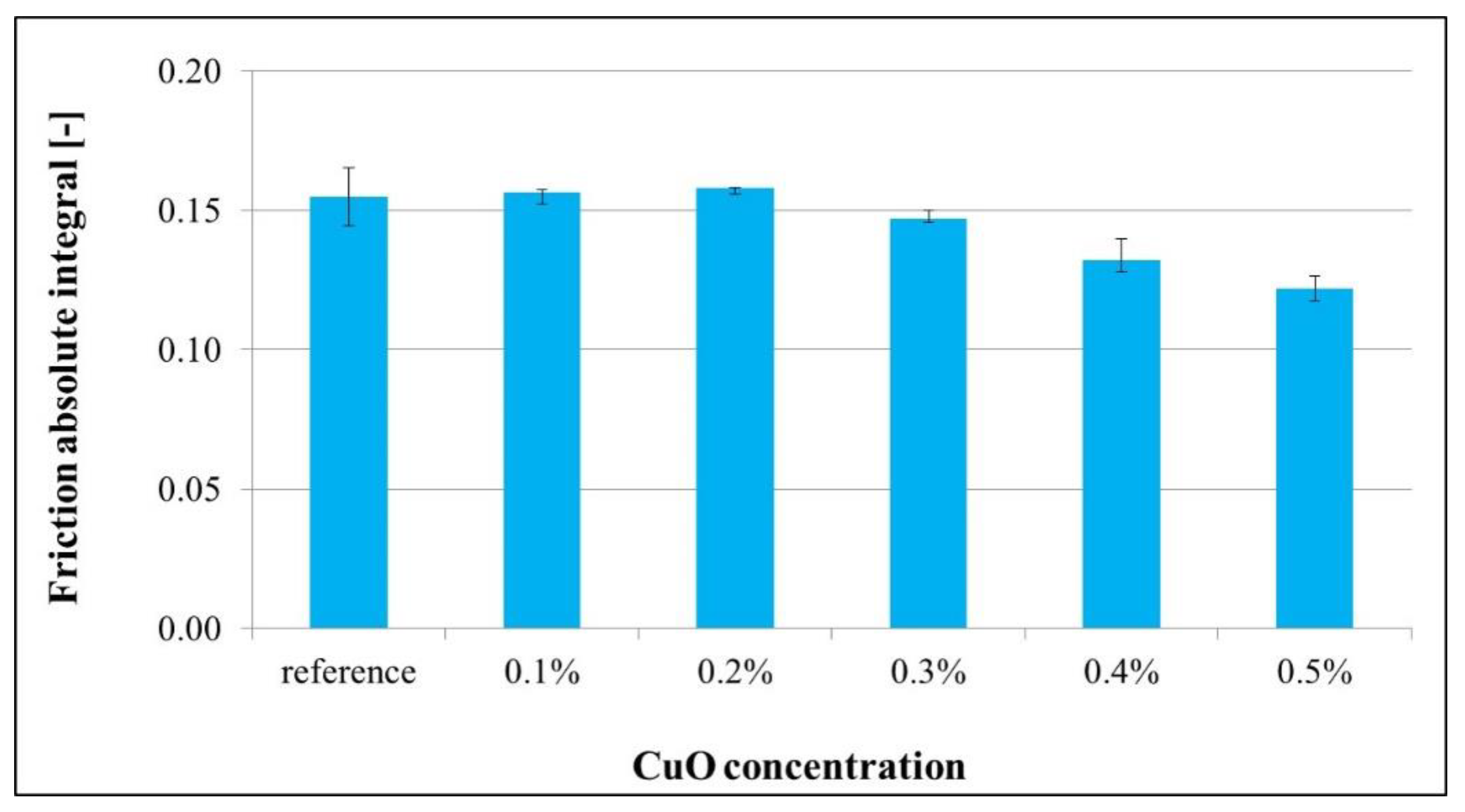

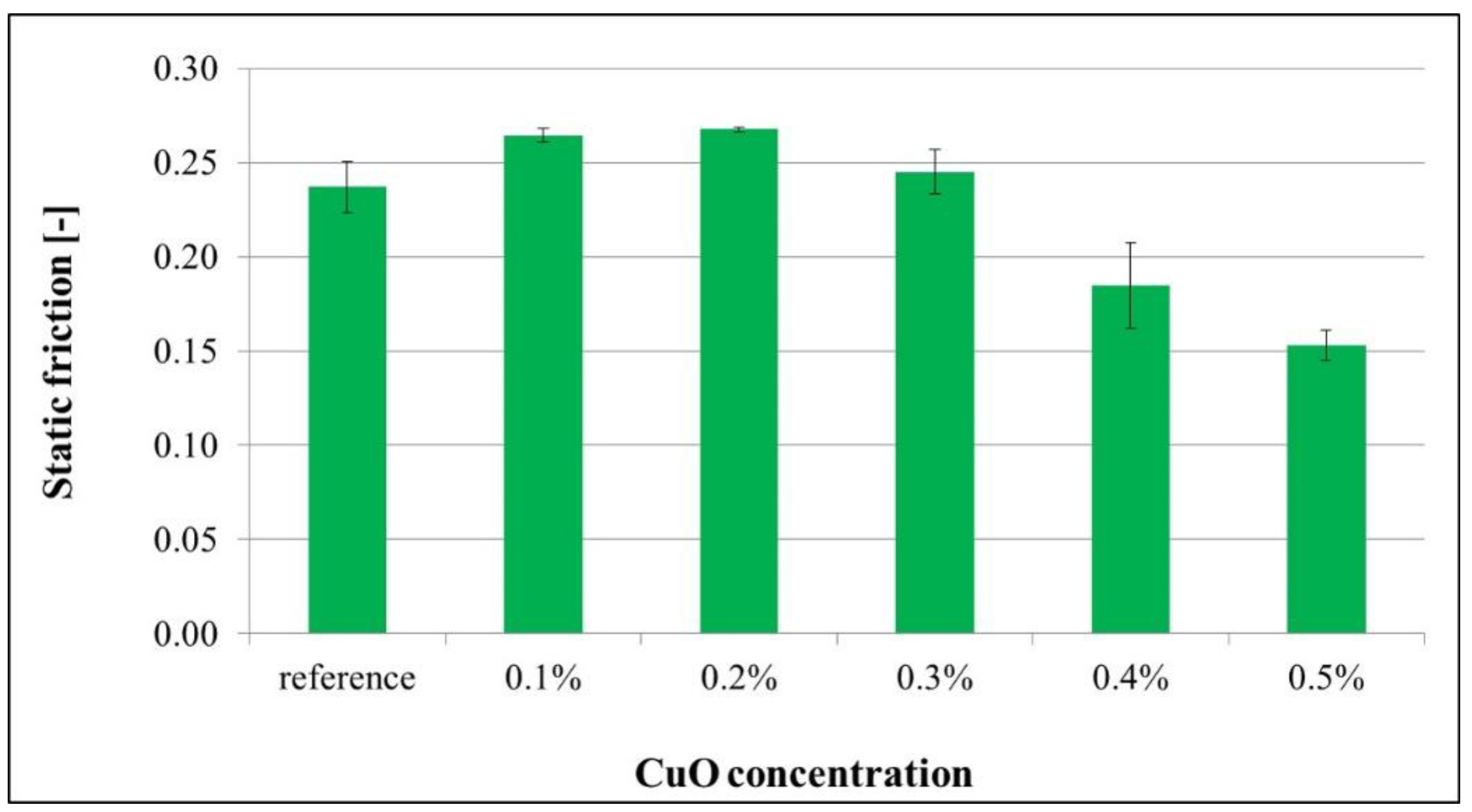

The friction values measured during the tribotests of the CuO nanoadditive-containing lubricant show a similar tendency when examining the friction absolute integral (FAI) values (

Figure 2) and the static friction (SF) values (

Figure 3). The trend shows that for both types of friction, the magnitude of friction increases slightly at low CuO concentrations (0.1 and 0.2 wt%). When using the oil containing 0.2 wt% CuO nanoparticles with the highest friction, the FAI value increased by 2%, while the SF increased by 13%. However, both types of friction show a decreasing trend when using medium and high CuO concentrations. The results show that the higher the applied CuO concentration, the better the friction-reducing effect of the nano-additive. For a CuO content of 0.5 wt%, the FAI value decreases by 21%, while the SF value decreases by 35%. By comparing the results of the two types of friction, it can be seen that CuO nanoparticles have a more significant effect on static friction than on kinematic friction while used in the environment of Komad 323 dispersant additive.

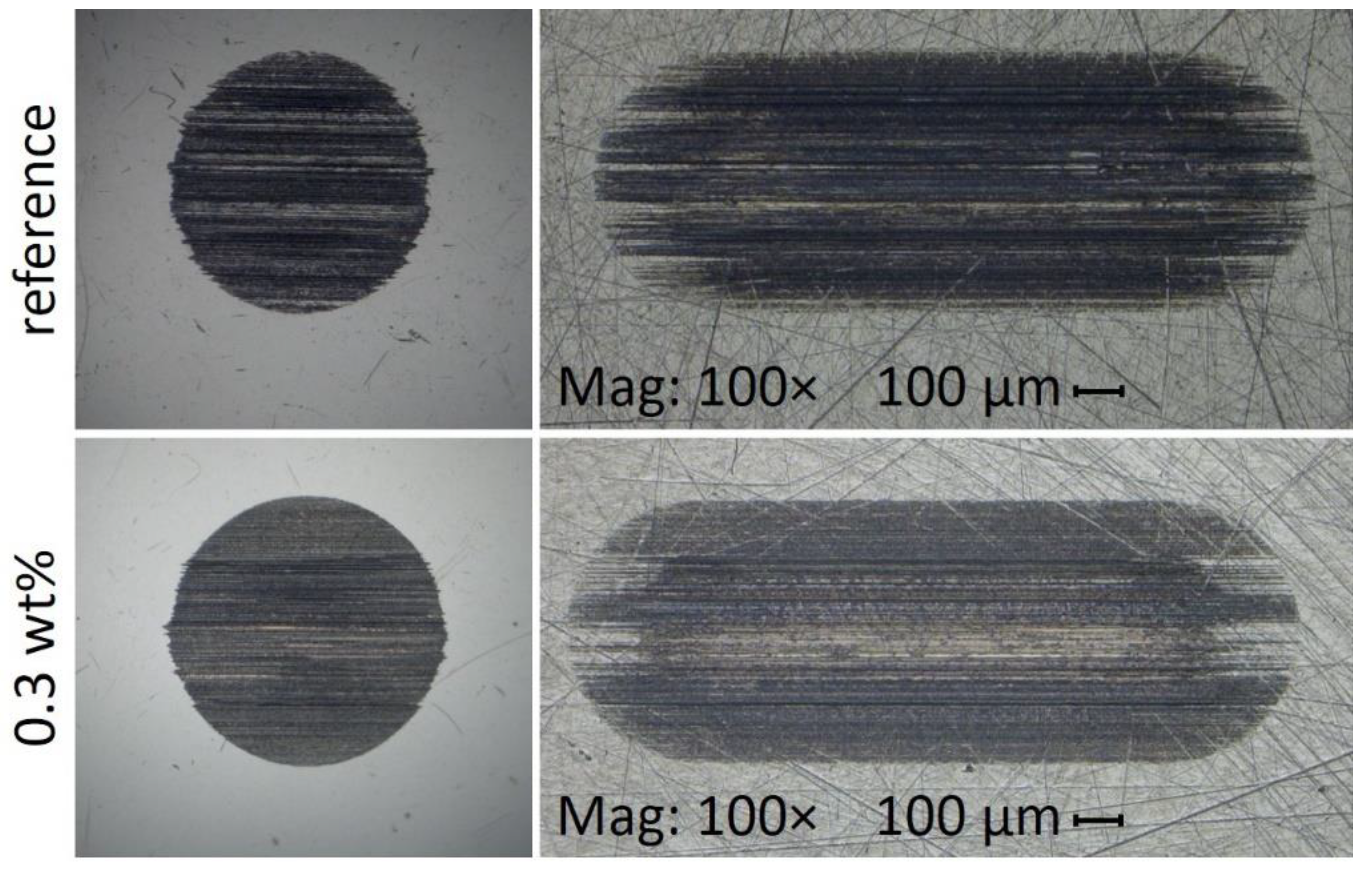

Figure 4 shows the digital micrographs of the wear marks of the disc made with reference and 0.3 wt% CuO lubricating oil. When comparing the wear marks created with two different oils, it can be concluded that they are similar. The dimensions of the wear marks generated with reference and CuO nanodoped lubricant are identical. Both are characterized by deep, longitudinal abrasion grooves indicating the main wear. When comparing the wear marks of the balls, it can be concluded that the effect of the CuO nanoparticles resulted in a more even and regular wear mark, with less of the profound rough abrasion effect. When comparing the wear marks of the discs, it can be established that the wear in the outer area of the wear marks is so thin that the remains of the grooves of the original surface treatment can still be observed. However, in the case of CuO nanoadditive, the surface wear is less deep. For both types of oil, the wear is deeper in the middle areas. While the central location of the reference wear mark shows a picture indicating rough wear, when measuring the oil sample doped with nano-sized CuO, a wide longitudinal stripe with a yellowish color change can be observed in the middle of the wear mark. Thin yellowish lines can also be kept in the same parts of the ball test specimen measured with CuO nanoadditive.

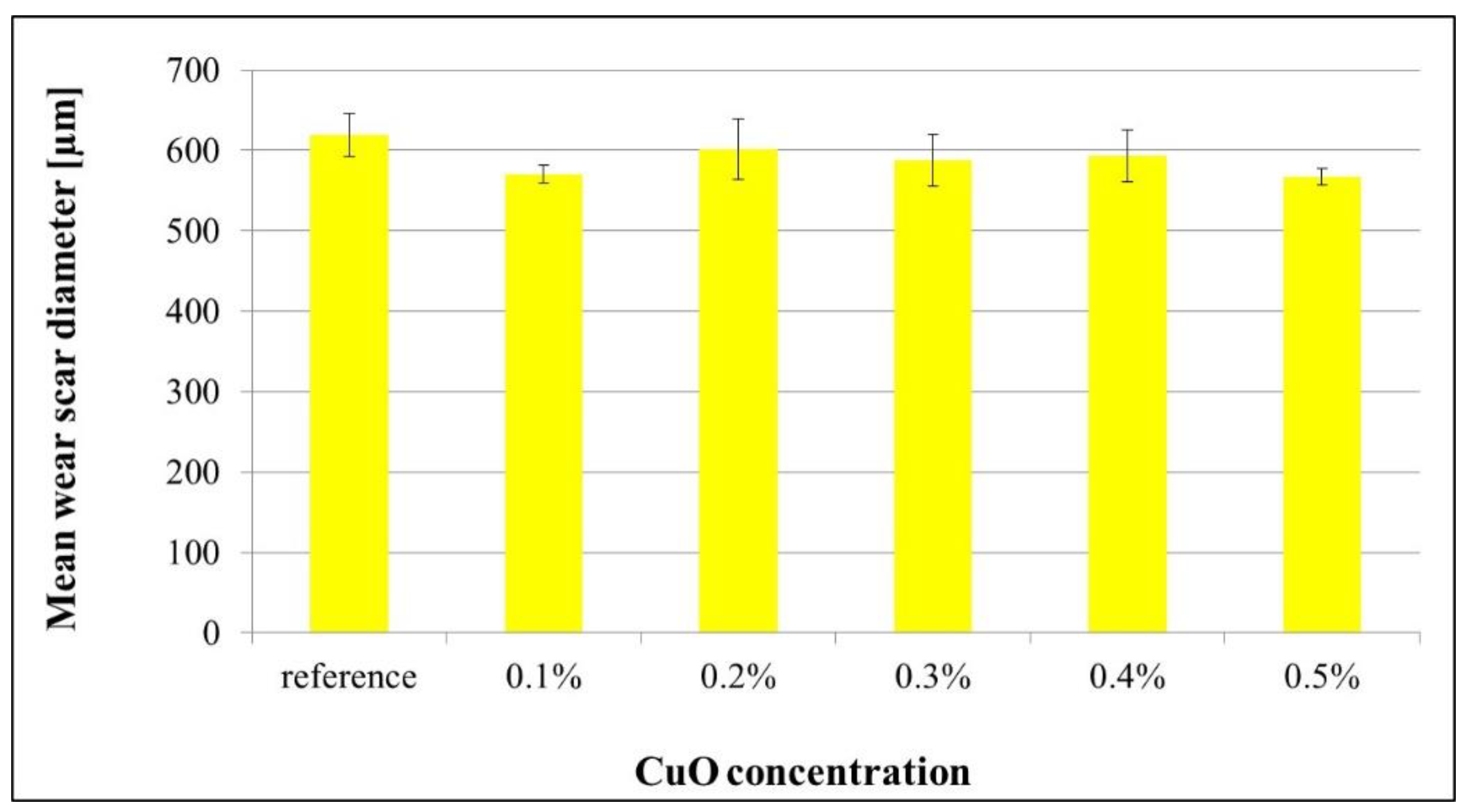

Figure 5 illustrates the averages of the mean wear scar diameter (MWSD) values measured on the ball when different CuO concentrations are used. The results show no characteristic correlation when using different concentrations of nano-sized CuO particles. Regardless of the nanoparticle concentration, the CuO nanoparticles reduced the MWSD value roughly uniformly by 3-8%.

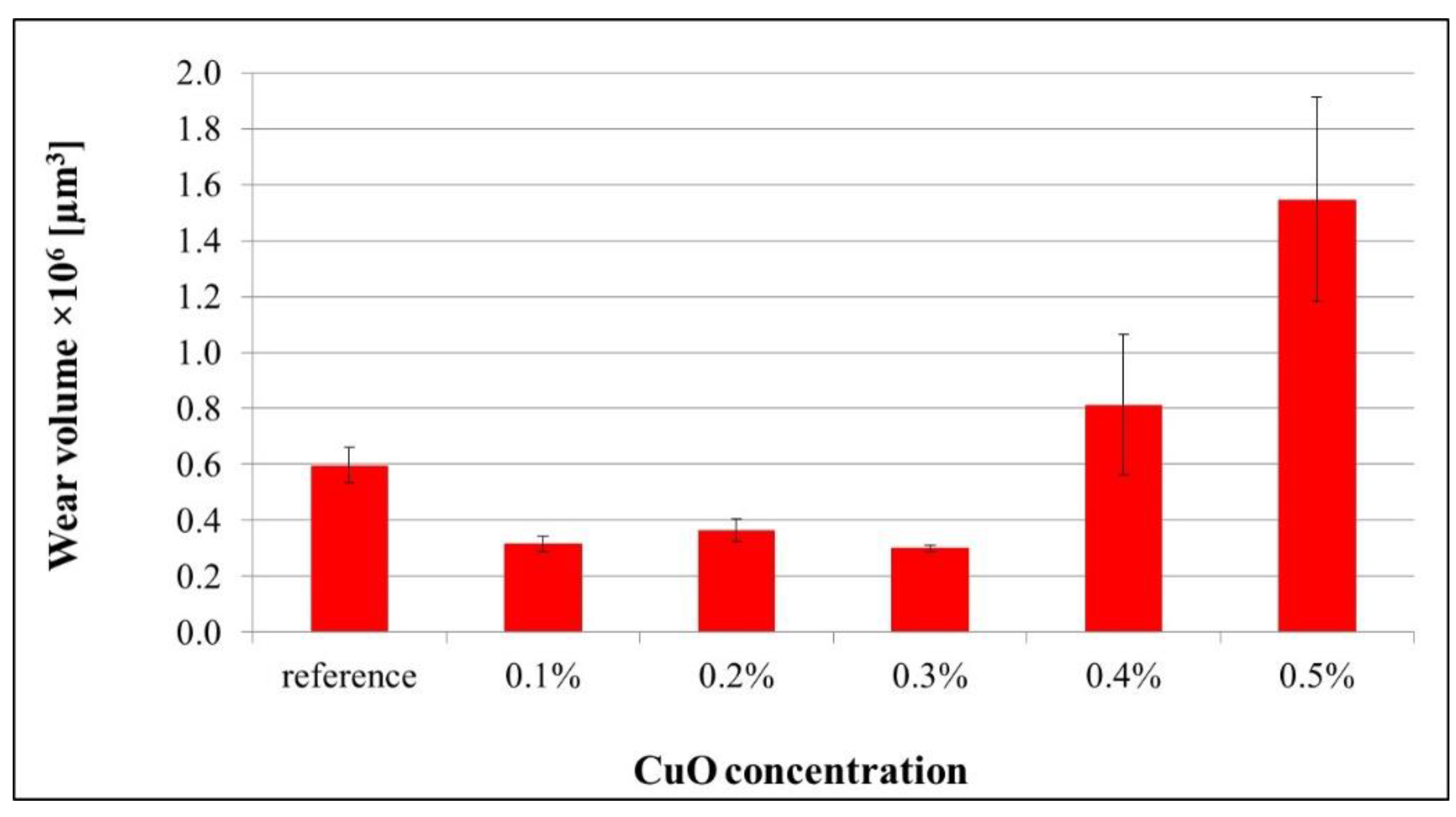

The results of the disc wear volume (WV) tests show a contrary trend to the results of the friction coefficient measurements (

Figure 6). The wear volume is significantly reduced by 39-50% when medium and low (≤0.3 wt%) CuO nanoparticle concentrations are used. The CuO 0.3 wt% oil sample had the most excellent reducing effect (-50%). The component's wear increases drastically at high CuO concentrations, creating a deep wear trench on the disc's surface. Along with the increasing wear volume, the standard deviation of the measured values also increases.

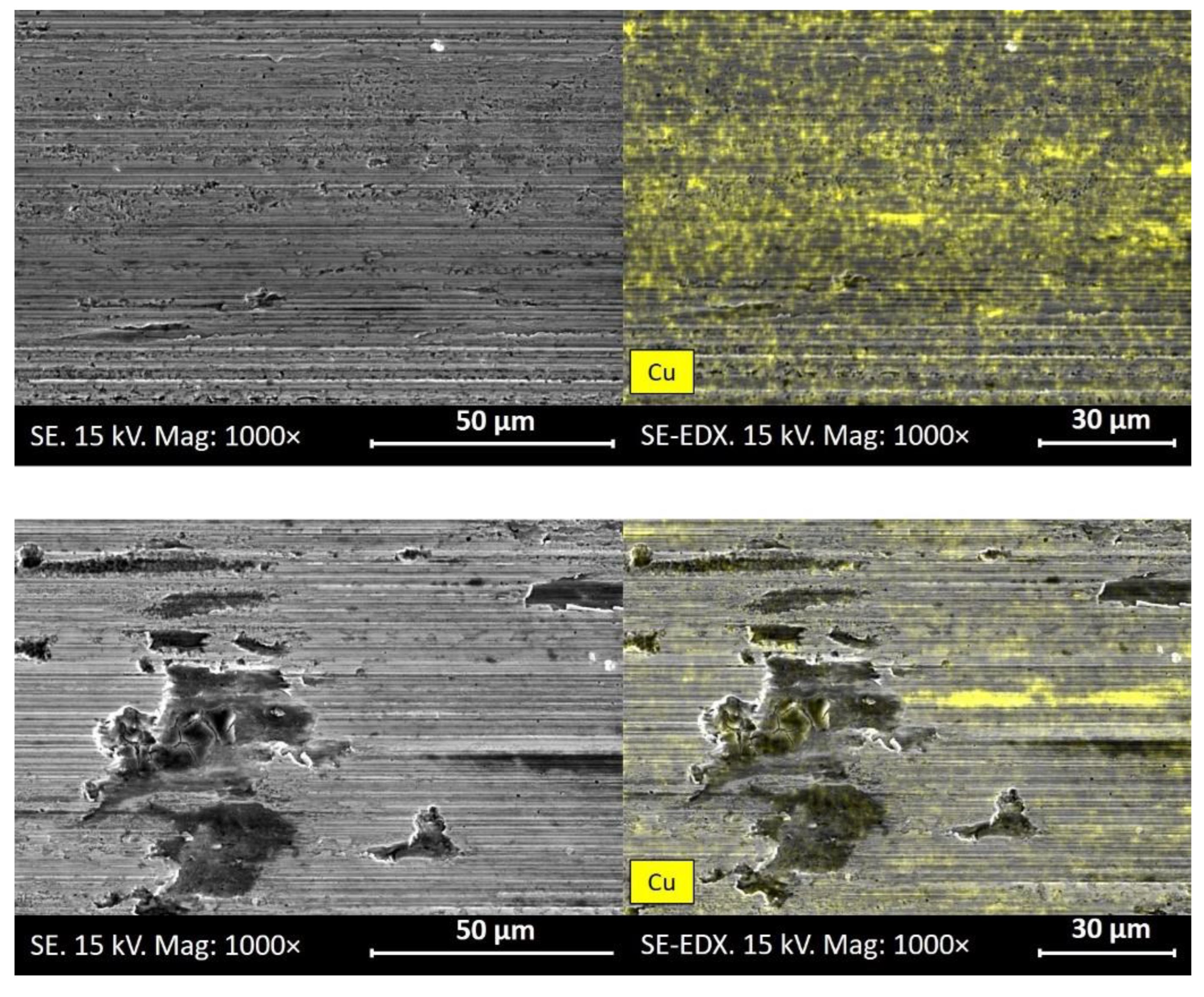

The images taken from the scanning electron microscopic examination of the wear track made with 0.3 wt% CuO nano additive oil are shown in

Figure 7. The pictures in the top row were taken at the center of the wear track, and the images in the bottom row were taken at the dead center. The ball's relative speed is highest in the center of the wear track. From the SEM image taken in the middle of the wear track (top left), it can be established that two main types of wear dominate the wear track: longitudinal abrasion trenches and microcracks/spallings formed from minor or significant fatigue wear. In addition, some plastic deformation and larger pieces of debris performing three-body abrasion are also visible. The SEM image taken at the dead center (bottom left) of the wear track shows an extreme degree of fatigue wear and already formed deep craters. Cracks indicating fatigue wear can be observed in many places. The characteristic longitudinal abrasion grooves can still be observed on most surfaces. In this way, the oil-carrying capacity of the surface with fatigue craters increases, thereby reducing friction.

In the right column of

Figure 7, the EDX images indicate where the copper element appeared in the wear track in yellow. Since neither the samples nor the oil contains copper-containing components, it can be concluded that all copper signals entering the EDX can be derived from the CuO nanoadditive. In the top right image, it can be seen that a lot of copper can be found on most of the worn surfaces. Since EDX is also suitable for quantitative determination, the normalized amount of elemental copper on the surface can be determined in mass percent (see quantitative table in

Table 1). It was found that in the middle of the wear mark, the pre-curling of the copper element (and with it the occurrence of the CuO nano-additive) is lower (Cu = 1.43 norm.wt%) than in the dead center of the wear (Cu = 3.17 norm.wt%). The EDX image taken at the dead center of the wear (bottom right) shows a sizeable island-like area rich in copper. It can be found in a similar smaller extent in the central regions of the wear mark. These areas are the elemental copper islands deposited on the tribofilm, formed from the CuO nanoadditive via triboreduction and smeared on the surface as elemental copper. Areas covered with such pure copper have a beneficial effect on reducing friction [

22]. The large amount of copper in the dead center is less evenly distributed than in the center of the wear track. However, a large amount found positively affects keeping the static friction value low.

Before starting a tribotest, a viscosimetry measurement was performed on the lubricating oils. The density and viscosity measurements were carried out at a temperature of 100°C. The measured values are shown in

Table 2, from which it can be concluded that the 0.3 wt% CuO content of the lubricating oil sample changes the viscosity and density of the liquid to a negligible extent. The viscosity of the lubricating oil can be considered insignificant for the value of the measured friction.

In summary, it can be concluded that the 8 wt% Komad 323 dispersant content of the base oil does not cooperate properly with the CuO nanoparticles homogenized in the oil sample. Up to the maximum CuO concentration of 0.3 wt%, the wear rate is low, but due to the antagonistic effect of the additives, CuO nanoparticles can not reduce the system's friction properly. As a summary of the electron microscopic results of the wear track of the disc tested with an oil sample containing 0.3 wt% CuO nanoadditive, it can be concluded that, in addition to the application of the CuO nanoadditive, the surface suffered a large amount of fatigue wear in addition to natural abrasive wear. The oil-carrying ability of extreme crater wear on the dead spots and the elemental copper spots formed on the surface through triboreduction helped to reduce friction. CuO nanoparticle concentrations higher than this (≥0.4 wt%) cause an extreme increase in wear volume. Based on the tribological results, the oil sample containing 0.3 wt% CuO nanoparticles performed the best overall: although the SF value was 3% higher than the value of the reference oil, the FAI value calculated over the entire stroke length was 5% lower than that. At the end of the measurement, the MWSD measured on the ball was, on average, 5% lower, while the WV was 50% lower compared to the reference. In the presence of Komad 323 dispersant, CuO nano additive could not create a tribofilm that would be sufficiently resistant to the applied load in the long term. The degree of fatigue wear would likely increase during more extended measurements, which suggests the use of lower CuO concentrations. The use of the oil sample containing 0.1 wt% CuO may be considered in the future for real applications since its tribological performance is similarly favorable compared to the oil sample containing 0.3 CuO. However, the lower particle concentration means a more cost-effective solution.

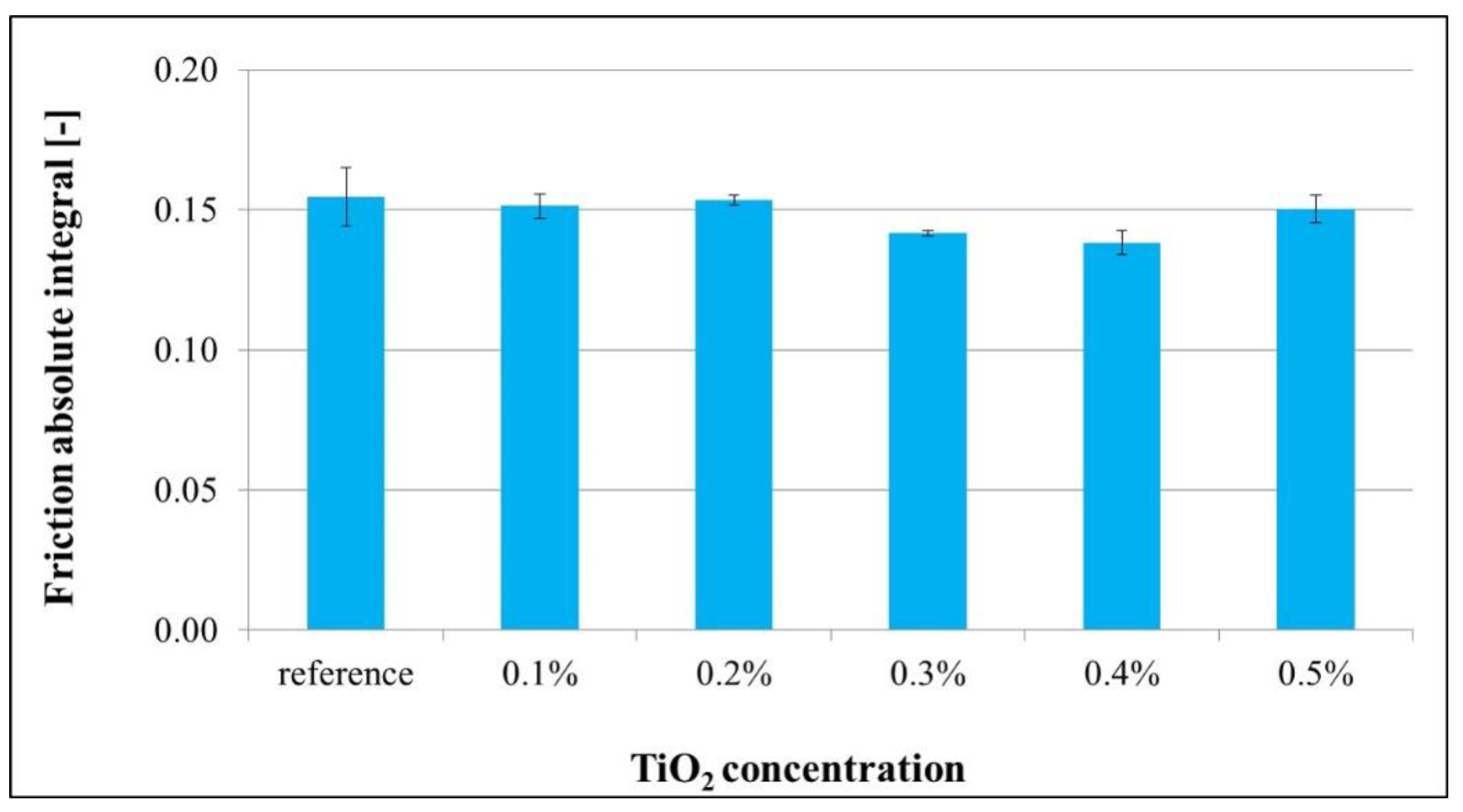

3.2. Titanium Dioxide

Based on the results of the tribometer friction measurement, it can be concluded that all applied titania concentrations could reduce the FAI (

Figure 8) and the SF (

Figure 9) values to a small extent. From the comparison of the two figures, it can be concluded that the titania nanoparticles reduce the SF value slightly more. Examining both types of friction can suppose that medium and high titania concentrations performed better in friction reduction. In the case of FAI values, the reduction rate is 3-11%, while in the case of SF values, a decrease of 11-14% can be observed. It can be observed that the standard deviation of the measured values decreases when examining the FAI values, while the same phenomenon is not observed in the case of the SF results.

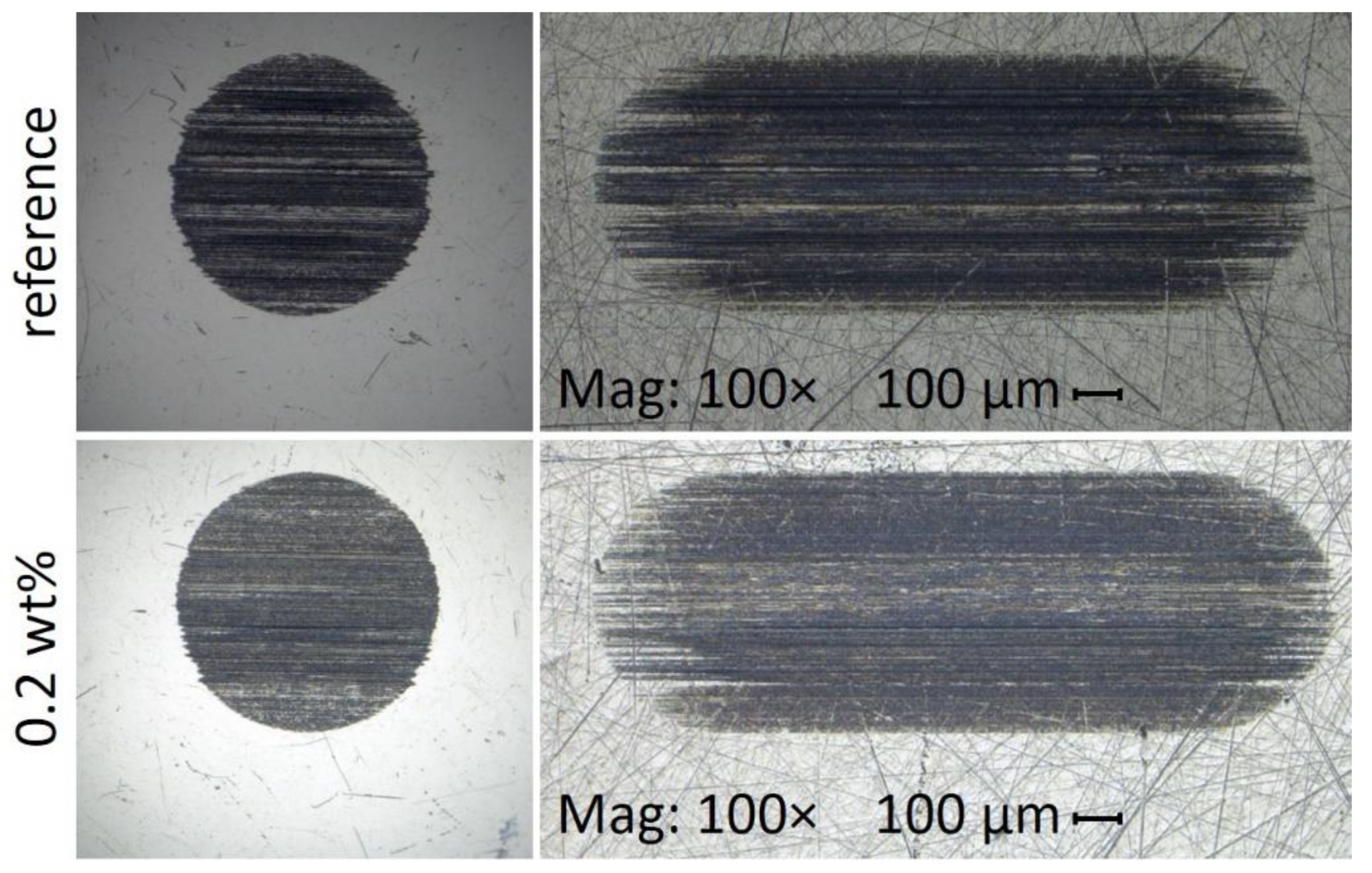

Figure 10 shows the digital micrographs of two pairs of test specimens made with a reference (top) and a lubricating oil containing 0.2 wt% titania nanoadditive (bottom). When comparing the wear images, it can be established that their dimensions are similar and that the longitudinal traces of abrasion wear are the determining factor for both. When examining the wear of the balls, it can be concluded that the titania nanoparticles protect the surface from deep abrasion wear, thus resulting in a more regular spitting mark. In the case of both oil samples, the longitudinal wear marks on the disc are deepest in the middle, and the furrows of the original surface roughness can still be observed in the outer areas. The wear mark created with oil containing 0.2 titania nano additives is less deep.

The MWSD results measured on the ball are shown in

Figure 11. The results do not correlate titania concentration and MWSD results. Each applied titania concentration reduced the MWSD value measured on the ball by 4-12%.

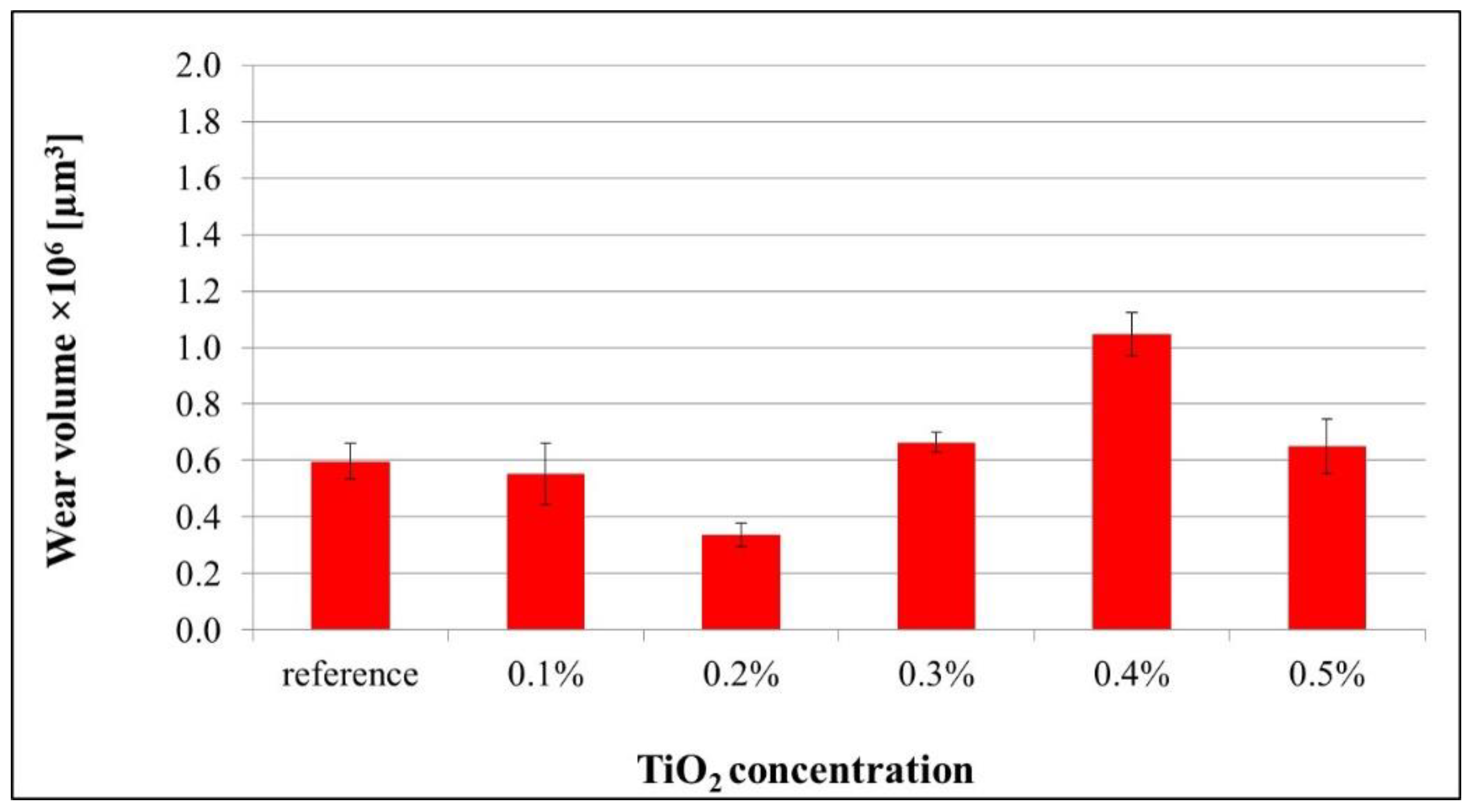

The analysis of the wear volume results shows in

Figure 12 that the WV decreases compared to the reference in the case of low titania concentrations (≤0.2 wt%), while 0.3 wt% and above increases it. The best wear reduction was the lubricating oil containing 0.2 wt% nano-titania, with a decrease of 44% compared to the reference.

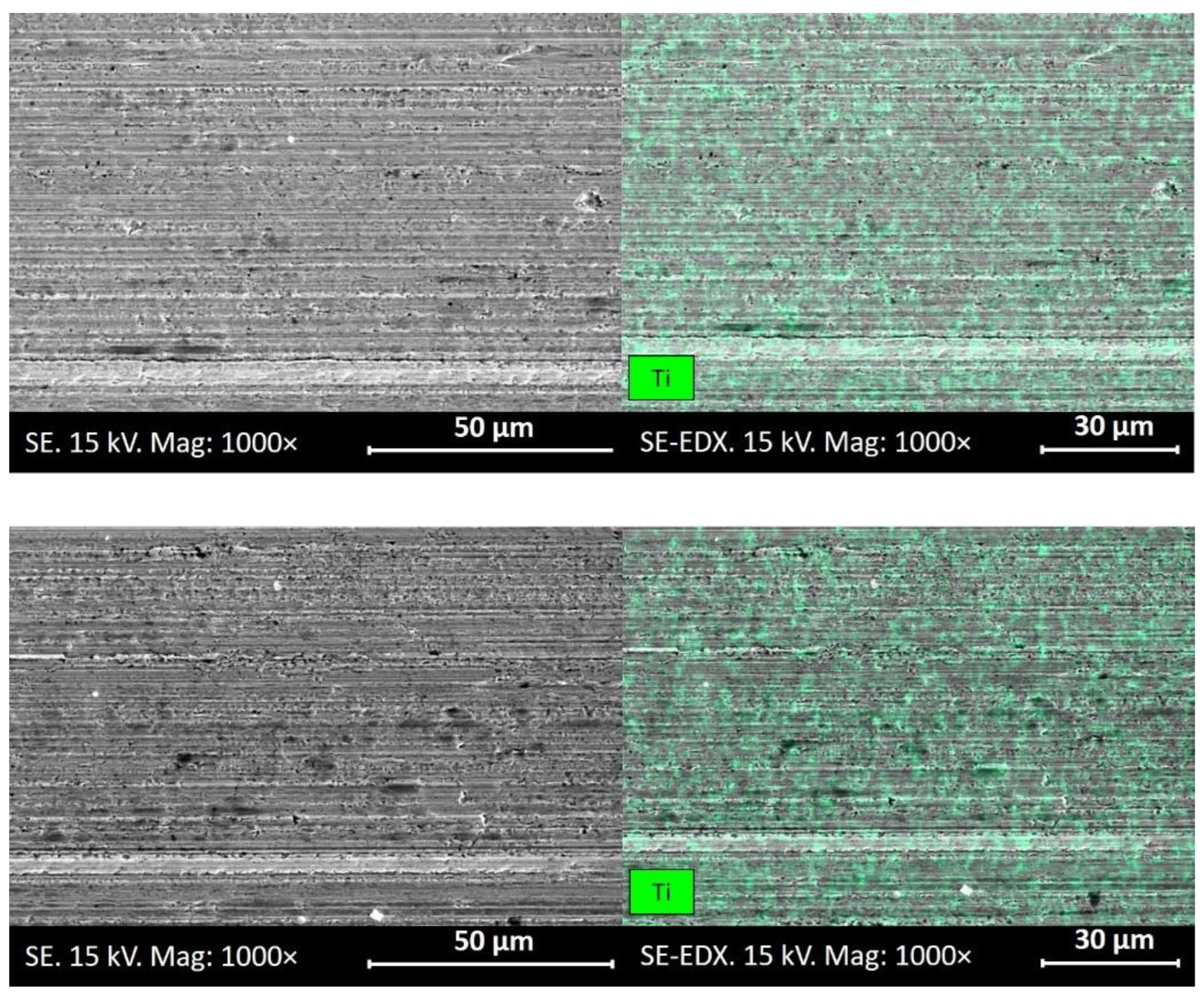

Figure 13 shows the SEM examination of the wear track of the disc tested with lubricating oil containing 0.2 wt% nano-sized titania. The top left image shows an SEM image taken in the middle area of the wear track, which shows that the primary type of wear is uniform but not a large amount of fatigue wear, with small spallings. In addition, the characteristic abrasion grooves in the direction of movement, traces of plastic deformations and spots with a dark oxide layer can also be found in the wear marks. The SEM image taken at the dead center shows a very similar surface, with the slight difference that there is more wear debris in the wear mark.

The quantitative evaluation of the EDX analysis (see

Table 3) showed that in the middle of the wear mark (Ti = 0.33 norm.wt%) and in the dead center (Ti = 0.39 norm.wt%), there is almost the same amount of titanium, the sole source of which is the applied titania nano additive. In the right-hand column of

Figure 13, the places of occurrence of titanium can be seen marked in green; the titania nanoadditive is evenly located in the boundary layer. The quantitative analysis of the element composition of the surface showed that the texture is rich in oxygen; its occurrence is around 3.32-4.56 norm.wt%. The presumable high hardness of the oxygen-rich boundary layer formed on the surface helped the anti-wear properties. Based on the SEM and EDX results, it can be concluded that the entire surface of the wear track is uniform in terms of wear and composition.

Table 4 shows the viscosity measurement results of the oil sample containing 0.2 wt% titania compared to the reference sample. Based on the measured values, it can be concluded that the 0.2 wt% titania content of the lubricating oil changed the density and viscosity of the used sample to a negligible extent (<1%). It can be concluded that the 0.2 wt% titania content does not have such an effect on the viscosity increase of the oil that it significantly increases the amount of friction measured on the tribometer.

As a summary of the tribological results, it can be concluded that the titania nanoparticles cooperated adequately with the 8 wt% Komad 323 dispersant content of the lubricating oil. From a tribological point of view, it is uncertain to determine the optimal concentration of titania nanoadditive. Lubricating oils containing 0.1, 0.3 and 0.5 wt% titania showed similar results. The lubricant sample containing 0.4 wt% titania showed the best friction-reducing results (-11-13%), but its effect on the WV was significantly worse (+75%) than the reference. Lubricating oil with 0.2 wt% titania provides the most consistent performance overall, where the significant wear reduction effect (-10% MWSD and -44% WV) should be emphasized, while it does not or only slightly reduces friction (-1-2%). Based on the SEM+EDX analysis, the conclusion that can be drawn is that the wear of the surface includes uniform spalling due to mild fatigue. The composition of the surface is consistent. The TiO2 nanoparticles and the Komad 323 additive benefit each other, producing a boundary layer rich in oxygen and containing ~0.33-0.39 norm.wt% titanium can be formed on the surface. This boundary layer ensures favorable tribological properties.

4. Discussion and Conclusions

Each nanoparticle has an individual effect on tribological performance when used together with dispersants of the polyisobutylene succinimide type. The combined effect of the nanoadditive and the dispersant is unpredictable but can be tested experimentally; therefore, compatibility studies are essential. Knowledge of the synergistic and antagonistic effects is valuable for developing nanoparticle-containing lubricants. This research carried out successful tribological experiments to examine these effects. The conclusions that could be derived from the results of this study are:

In the applied tribological system, CuO nanoadditive and Komad 323 dispersant had opposite effects on the friction-wear volume ratio at low and high concentrations, depending on the nanoparticle concentration. When a low CuO concentration (≤0.2 wt%) was used, the friction increased, but the wear decreased. In the case of a high CuO concentration (≥0.4 wt%), the friction decreased significantly, but the wear increased drastically. The wear width was 3-8% lower than the reference value for all CuO concentrations. Based on the tribological results, the oil sample containing 0.3 wt% CuO nanoadditive, considered optimal, reduced the friction by 5% for the entire stroke, increased the adhesion friction by 3%, reduced the wear diameter of the ball by 5%, and the wear volume of the disc reduced by 50%.

The SEM analysis of the disc worn with lubricating oil containing nano-sized CuO showed that the surface suffers from extreme fatigue wear, the starting point of which is the dead center. The EDX analysis of the specimen showed areas covered with elemental copper produced during triboreduction [

22]. The elemental composition test established a 1.43-3.17 norm.wt% copper on the surface.

The synergistic effect of TiO2 and Komad 323 can be observed and the friction and ball wear diameter decreased slightly in all concentrations. The friction-wear volume is inversely proportional for TiO2 concentrations ≥0.3 wt%. The wear volume improved compared to the reference only for low TiO2 concentrations. Based on the results of the tested tribological system, the lubricating oil sample containing 0.2 wt% TiO2 nanoadditive can be considered optimal: 1% reduction in friction over the entire stroke length, 2% reduction in adhesion friction, 10% reduction in mean wear scar diameter and 44% reduction in wear volume.

SEM+EDX analysis of the wear of the disc tested with 0.2 wt% TiO2 additive showed that the surface has minimal fatigue wear. A boundary layer rich in oxygen with a titanium content of 0.33-0.39 norm.wt% is formed on the surface.

Viscosity measurement of oil samples with an optimal concentration of nanoadditives established that the nanoadditives modify the density and viscosity of the lubricant to a minimal extent (difference <1%).

It isn't easy to compare the obtained results with the available scientific literature. The tribological effect of nanoparticles could only be compared with literature where dispersant-nanoparticle pairs were examined in an oily medium. Although the action of polyisobutylene succinimide-type dispersants has been investigated in many traditional and experimental engine oil additive pairings, there has been very little nanoparticle pairing research. Tribological systems without dispersants or using other dispersants will produce a different effect; their results for a discussion can only be used to a limited extent. As Bartha stated, it is necessary to examine specific dispersant-nanoparticle pairs because the combined effects can only be revealed in this way [

9]. To establish the synergistic-antagonistic impact and to understand precisely how it works, it is necessary to examine the dispersion form of Komad 323 with the CuO and TiO

2 nanoparticles [

7]. It would be essential to investigate the effect of the ethyl oleate coating of the originally surface-modified nanoparticles on the nanoparticle-dispersant interaction. According to Anthony's report, although nano-additives create a favorable boundary layer with good anti-wear properties, long load tests are challenging. The results obtained with CuO nanoparticles fully support this report. Tribological studies with TiO

2 nanoadditive confirmed that nanoparticles increase the oil's viscosity. Despite this, nanoparticles with high thermal stability can reduce the coefficient of friction [

28]. As Chen [

35] did, to understand the entire operation, it is necessary to look in detail at the reactions in the boundary layer.

The results are valuable and usable for lubricant oil development research. In the future, the focus needs to be on the reactions. The relationship between the nanoparticle and the dispersant and how they interact with each other must be investigated. The targeted direction of future research is the thin film analysis of the tribological boundary layer. Conclusions regarding the tribochemical reactions must be drawn from the reaction products connected to the surface to understand the additives' actual operation.

Author Contributions

Conceptualization, Á.I.S.; methodology, Á.I.S.; formal analysis, Á.I.S. and M.M.; investigation, M.M.; resources, H.H.; data curation, Á.I.S.; writing—original draft preparation, Á.I.S. and M.M.; writing—review and editing, Á.I.S.; visualization, Á.I.S. and M.M.; supervision, H.H.; project administration, Á.I.S.; funding acquisition, Á.I.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

This article is published in the framework of the project "Synthetic fuels production and validation in cooperation between industry and university", project number "ÉZFF/956/2022-ITM_SZERZ". The authors would like to thank Álmos Dávid Tóth, Achillesz Morvai, Attila Csík and Jan Rohde-Brandenburger for their general support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Travis, P.H. Adsorption of Polyisobutylene-Based Dispersants onto Carbon Black. Dissertation, University of Southern Mississippi, Hattiesburg, MS 39406, USA, 2019.

- E.S., Forbes; E.L., Neustadter. The mechanism of action of polyisobutenyl succinimide lubricating oil additives. Tribology 1972, 5, pp. 72-77. [CrossRef]

- E.J., Seddon; C.L., Friend; J.P. Roski. Detergents and Dispersants. In Chemistry and Technology of Lubricants, 3rd ed.; R.M., Mortier; M.F., Fox; S.T., Orszulik, Eds.; Springer: Dordrecht, Netherlands, 2009; pp. 213-236. [CrossRef]

- Enzhu, H.; Xianguo, H.; Tianxia, L.; Ling, F.; Karl, D.D.; Hongming, X. The role of soot particles in the tribological behavior of engine lubricating oils. Wear 2013, 304, pp. 152-161. [CrossRef]

- A., Tomlinson; B., Scherer; E., Karakosta; M., Oakey; T.N., Danks; D.M., Heyes; S.E., Taylor. Adsorption properties of succinimide dispersants on carbonaceous substrates. Carbon 2000, 38, pp. 13-28. [CrossRef]

- Shengpei, W.; Shasha, Y.; Jianxiang, F.; Shenggao, L. Multifunctional lubricant additive derived from polyisobutylene succinimide dispersant. Journal of Dispersion Science and Technology 2021, 42, pp. 396-406. [CrossRef]

- P.A., Willermet. Some engine oil additives and their effects on antiwear film formation. Tribology Letters 1998, 5, pp. 41-47. [CrossRef]

- Amal, M.N.; Nehal, S.A.; Khalid, I.A.E-A.; Abdel-Azim, A.A.A. Synthesis and Evaluation of Detergent/Dispersant Additives from Polyisobutylene Succinimides. International Journal of Polymeric Materials 2006, 55, pp. 703-713. [CrossRef]

- Bartha, L.; Deák, Gy.; Hancsók, J.; Baladincz, J.; Auer, J.; Kocsis, Z. Polyfunctional PIB succinimide type engine oil additives. Lubrication Science 2001, 13, pp. 313-328. [CrossRef]

- Sági, R.; Bartha, L.; Beck, Á.; Balandincz, J. Investigation of PIB-succinimides in engine oils. International Journal of Applied Mechanics and Engineering 2006, 11, pp. 507-513.

- Sági, R.; Bartha, L.; Balandincz, J. Investigation of Modified PIB-Succinimides in Low SAPS Engine Oils. Hungarian Journal of Industrial Chemistry 2009, 37, pp. 27-30.

- Bartha, L.; Deák, Gy.; Kovács, M.; Kocsis, Z.; Vuk, T. Interaction of PIB-succinimides and other Engine Oil Additives. Lubrication Science 1997, 9, pp. 173-180. [CrossRef]

- Huabing, Y.; Xuecheng, Z.; Zhiwei, G.; Yicong, X.; Xiang, R.; Chengqing, Y. Synergetic effects of surface textures with modified copper nanoparticles lubricant additives on the tribological properties of cylinder liner-piston ring. Tribology International 2023, 178, 108085. [CrossRef]

- Hua, J.; Xianjun, H.; Yucong, Q.; Haijun, L.; Mohamed, K.A.A.; Karl, D.D. A tribological behavior assessment of steel contacting interface lubricated by engine oil introducing layered structural nanomaterials functionalized by oleic acid. Wear 2023, 524-525, 204675, . [CrossRef]

- Alper, U.; İlker, A. Investigation of 1-octanethiol capped ZnS nanoparticles as lubricant additives and tribological behavior of oil-based nanolubricant. Wear 2023, 530-531, 205029. [CrossRef]

- Wang, X.B.; Liu, W.M. Nanoparticle-Based Lubricant Additives. In Encyclopedia of Tribology, Wang, Q.J.; Chung, Y.W., Eds.; Springer: Boston, MA, 2013. [CrossRef]

- María, J.G.G.; Amor, M.A.; María, J.P.C.; Carmen, A-L.; Ben, T.; Josefa, F.; Mark, H. Comparison between thermophysical and tribological properties of two engine lubricant additives: electrochemically exfoliated graphene and molybdenum disulfide nanoplatelets. Nanotechnology 2020, 32, 025701. [CrossRef]

- Mohamed, K.A.A.; Xianjun, H.; Mohamed, A.A.A. Anti-wear properties evaluation of frictional sliding interfaces in automobile engines lubricated by copper/graphene nanolubricants. Friction 2020, 8, 905-916. [CrossRef]

- Yashvir, S.; Erween, A.R.; Nishant, K.S.; Abhishek, S.; Amneesh, S.; Arkom P. Friction and wear characteristics of chemically modified mahua (madhuca indica) oil based lubricant with SiO2 nanoparticles as additives. Wear 2022, 508-509, 204463. [CrossRef]

- Sara, Z.; Mohammad, S.; Alireza, B.; Amin, A.; Esmaeil, E. A review on Nanoparticle Application as an Additive in Lubricants. Advanced Journal of Chemistry-Section B 2022, 4, pp. 209-221. [CrossRef]

- Asrul, M.; Zulkifli, N.W.M.; Masjuki, H.H.; Kalam M.A. Tribological Properties and Lubricant Mechanism of Nanoparticle in Engine Oil. Procedia Engineering 2013, 68, pp. 320-325. [CrossRef]

- Tóth, Á.D.; Szabó. Á.I.; Kuti, R.; Rohde-Brandenburger, Jan. Tribological investigation of applicability of nano-sized cupric oxide (CuO) ceramic material in automotive vehicles. FME Transactions 2021, 49, pp. 335-343. [CrossRef]

- Kumar, D.S.; Garg, H.C.; Kumar, G. Tribological analysis of blended vegetable oils containing CuO nanoparticles as an additive. Materials Today: Proceedings 2022, 51, pp. 1259-1265. [CrossRef]

- Liñeira del Río, J.M.; Mariño, F.; López, E.R.; Gonçalves, D.E.P.; Seabra, J.H.O.; Fernández, J. Tribological enhancement of potential electric vehicle lubricants using coated TiO2 nanoparticles as additives. Journal of Molecular Liquids 2023, 371, 121097. [CrossRef]

- Suryawanshi, S.; Pattiwar, J. Experimental Study on an Influence of Bearing Geometry and TiO2 Nanoparticle Additives on the Performance Characteristics of Fluid Film Lubricated Journal Bearing. Tribology in Industry 2019, 41, pp. 220-236. [CrossRef]

- Gundarneeya, T.P.; Vakharia, D.P. Performance analysis of journal bearing operating on nanolubricants with TiO2, CuO and Al2O3 nanoparticles as lubricant additives. Materials Today: Proceedings 2021, 45, pp. 5624-5630. [CrossRef]

- Zaman, A.A.A.A.; Ayad, M.T.; Muhannad, A-W. A review of use of nanoparticle additives in lubricants to improve its tribological properties. Materials Today: Proceedings 2022, 52, pp. 1442-1450. [CrossRef]

- Anthony, C.O.; Mohd, K.A.H.; Samion, S.; Charles, A.N.J.; Abu, B.R.; Mohammed, B.A. Nano-Particles Additives as a Promising Trend in Tribology: A Review on their Fundamentals and Mechanisms on Friction and Wear Reduction. Evergreen 2021, 8, pp. 777-798. [CrossRef]

- Prashant, G.; Manoj, K.G.; Jayashree, B. Synergism between particles of PTFE and hBN to enhance the performance of oils. Wear 2017, 384-385, pp. 169-177. [CrossRef]

- Vinay, S.; Jayashree, B. Polyaniline Nanoparticles: A Novel Additive for Augmenting Thermal Conductivity and Tribo-Properties of Mineral Oil and Commercial Engine Oil. Lubricants 2022, 10, 300. [CrossRef]

- Manoj, K.G.; Meghashree, P.; Jayashree, B. Combination of nano-particles of graphite and PTFE in the right amount for synergism as anti-wear and extreme pressure additive in oil. Surface Topography: Metrology and Properties 2021, 9, 035049. [CrossRef]

- Yosef, J. Effect of nanoparticle additives on the tribological behavior of oil under boundary lubrication. Dissertation, Iowa State University, Ames, IA 50011, USA, 2018.

- Zefu, Z.; Laigui, Y.; Weimin, L.; Qunji, X. The effect of LaF3 nanocluster modified with succinimide on the lubricating performance of liquid paraffin for steel-on-steel system. Tribology International 2001, 34, pp. 83-88. [CrossRef]

- Hongxing, W.; Blake, J.; Liping, W.; Guangneng, D.; Shuncheng, Y.; Junfeng, Z. High-efficiency preparation of oil-dispersible MoS2 nanosheets with superior anti-wear property in ultralow concentration. Journal of Nanoparticle Research 2017, 19, 339. [CrossRef]

- Chen, S.; Song, N.; Zhang, S.; Zhang, Y.; Yu, L.; Zhang, P. Synergistic tribological effect between polyisobutylenes succinimide-modified molybdenum oxide nanoparticle and zinc dialkyldithiophosphate for reducing friction and wear of diamond-like carbon coating under boundary lubrication. Friction 2023, 11, pp. 2021-2035. [CrossRef]

- Nehal, S.A.; Amal, M.N.; Hamdy, S.A-H.; Ahmed, F.E-K. Preparation, characterization, and evaluation of some ashless detergent/dispersant additives for lubricating engine oil. Applied Petrochemical Research 2016, 6, pp. 49-58. [CrossRef]

- Tóth, Á.D.; Mike-Kaszás, N.; Bartus, G.; Hargitai, H.; Szabó, Á.I. Surface Modification of Silica Nanoparticles with Ethyl Oleate for the Purpose of Stabilizing Nanolubricants Used for Tribological Tests. Ceramics 2023, 6, 980-993. [CrossRef]

-

ISO 19291:2016(E); Lubricants—Determination of Tribological Quantities for Oils and Greases—Tribological Test in the Translator Oscillation Apparatus. International Organization for Standardization: Geneva, Switzerland, 2016.

Figure 1.

SEM images of the bulk powder of the applied oxide nanoparticles under a magnification of 12000: CuO nanopowder on the left, TiO2 nanopowder on the right.

Figure 1.

SEM images of the bulk powder of the applied oxide nanoparticles under a magnification of 12000: CuO nanopowder on the left, TiO2 nanopowder on the right.

Figure 2.

Measured friction absolute integral values resulted from the nanolubricants with different cupric oxide concentrations.

Figure 2.

Measured friction absolute integral values resulted from the nanolubricants with different cupric oxide concentrations.

Figure 3.

Measured static friction coefficient values resulted from the nanolubricants with different cupric oxide concentrations.

Figure 3.

Measured static friction coefficient values resulted from the nanolubricants with different cupric oxide concentrations.

Figure 4.

Recording of wear images with a digital microscope. Pictures of the wear on the balls are on the left side, while on the right side, the wear on the discs can be seen. The top row shows the wear marks of a specimen pair tested with a reference oil sample, and the bottom row shows the wear marks of a specimen pair tested with an oil sample doped with 0.3 wt% CuO nanoparticles.

Figure 4.

Recording of wear images with a digital microscope. Pictures of the wear on the balls are on the left side, while on the right side, the wear on the discs can be seen. The top row shows the wear marks of a specimen pair tested with a reference oil sample, and the bottom row shows the wear marks of a specimen pair tested with an oil sample doped with 0.3 wt% CuO nanoparticles.

Figure 5.

Measured mean wear scar diameter values caused by the nanolubricants with different cupric oxide concentrations.

Figure 5.

Measured mean wear scar diameter values caused by the nanolubricants with different cupric oxide concentrations.

Figure 6.

Measured wear volume values caused by the nanolubricants with different cupric oxide concentrations.

Figure 6.

Measured wear volume values caused by the nanolubricants with different cupric oxide concentrations.

Figure 7.

SEM and EDX images of the wear track of the disc with 0.3 wt% nano-sized CuO additive doped lubricant. The top row shows the pictures taken at the center of the wear track, and the bottom row shows the images taken at the center of the wear track (both in the center line of the movement).

Figure 7.

SEM and EDX images of the wear track of the disc with 0.3 wt% nano-sized CuO additive doped lubricant. The top row shows the pictures taken at the center of the wear track, and the bottom row shows the images taken at the center of the wear track (both in the center line of the movement).

Figure 8.

Measured friction absolute integral values resulted from the nanolubricants with different titanium dioxide concentrations.

Figure 8.

Measured friction absolute integral values resulted from the nanolubricants with different titanium dioxide concentrations.

Figure 9.

Measured static friction coefficient values resulted from the nanolubricants with different titanium dioxide concentrations.

Figure 9.

Measured static friction coefficient values resulted from the nanolubricants with different titanium dioxide concentrations.

Figure 10.

Recording of wear images with a digital microscope. Pictures of the wear on the balls are on the left side, while on the right side, the wear on the discs can be seen. The top row shows the wear marks of a specimen pair tested with a reference oil sample, and the bottom row shows the wear marks of a specimen pair tested with an oil sample doped with 0.2 wt% TiO2 nanoparticles.

Figure 10.

Recording of wear images with a digital microscope. Pictures of the wear on the balls are on the left side, while on the right side, the wear on the discs can be seen. The top row shows the wear marks of a specimen pair tested with a reference oil sample, and the bottom row shows the wear marks of a specimen pair tested with an oil sample doped with 0.2 wt% TiO2 nanoparticles.

Figure 11.

Measured mean wear scar diameter values caused by the nanolubricants with different titanium dioxide concentrations.

Figure 11.

Measured mean wear scar diameter values caused by the nanolubricants with different titanium dioxide concentrations.

Figure 12.

Measured wear volume values caused by the nanolubricants with different titanium dioxide concentrations.

Figure 12.

Measured wear volume values caused by the nanolubricants with different titanium dioxide concentrations.

Figure 13.

SEM and EDX images of the wear track of the disc with 0.2 wt% nano-sized TiO2 additive doped lubricant. The top row shows the images taken at the center of the wear track, and the bottom row shows the pictures taken at the center of the wear track (both in the center line of the movement).

Figure 13.

SEM and EDX images of the wear track of the disc with 0.2 wt% nano-sized TiO2 additive doped lubricant. The top row shows the images taken at the center of the wear track, and the bottom row shows the pictures taken at the center of the wear track (both in the center line of the movement).

Table 1.

The quantitative results of the EDX analysis in the middle point and dead center of the wear track of the disc were tested by lubricating oil containing 0.3 wt% CuO nanoparticles. The values are given in normalized mass percentage.

Table 1.

The quantitative results of the EDX analysis in the middle point and dead center of the wear track of the disc were tested by lubricating oil containing 0.3 wt% CuO nanoparticles. The values are given in normalized mass percentage.

| Element |

Stroke-middle section |

Dead center |

| Fe |

91.56 |

88.85 |

| Cr |

1.68 |

1.64 |

| Si |

0.46 |

0.45 |

| O |

0.55 |

0.82 |

| C |

4.32 |

5.07 |

| Cu |

1.43 |

3.17 |

Table 2.

Comparison of the viscosity measurement results of an oil sample containing 0.3 wt% cupric oxide at 100 °C with Group III + 8 wt% Komad 323 reference lubricating oil.

Table 2.

Comparison of the viscosity measurement results of an oil sample containing 0.3 wt% cupric oxide at 100 °C with Group III + 8 wt% Komad 323 reference lubricating oil.

| Parameter on 100°C |

Group III + 8 wt% Komad 323 |

Group III + 8 wt% Komad 323 + 0.3% CuO |

Change [%] |

| Dynamic viscosity [mPa·s] |

4.6269 |

4.6320 |

+0.11% |

| Kinematic viscosity [mm2/s] |

5.9109 |

5.8975 |

-0.23% |

| Density [g/cm3] |

0.78277 |

0.78542 |

+0.34% |

Table 3.

The quantitative results of the EDX analysis in the middle point and dead center of the wear track of the disc were tested by lubricating oil containing 0.2 wt% TiO2 nanoparticles. The values are given in normalized mass percentage.

Table 3.

The quantitative results of the EDX analysis in the middle point and dead center of the wear track of the disc were tested by lubricating oil containing 0.2 wt% TiO2 nanoparticles. The values are given in normalized mass percentage.

| Element |

Stroke-middle section |

Dead center |

| Fe |

90.87 |

89.48 |

| Cr |

1.74 |

1.72 |

| Si |

0.80 |

0.77 |

| O |

3.32 |

4.56 |

| C |

2.95 |

3.08 |

| Ti |

0.33 |

0.39 |

Table 4.

Comparison of the viscosity measurement results of an oil sample containing 0.3 wt% titanium dioxide at 100 °C with Group III + 8 wt% Komad323 reference lubricating oil.

Table 4.

Comparison of the viscosity measurement results of an oil sample containing 0.3 wt% titanium dioxide at 100 °C with Group III + 8 wt% Komad323 reference lubricating oil.

| Parameter on 100°C |

Group III + 8 wt% Komad 323 |

Group III + 8 wt% Komad323 + 0.2% TiO2

|

Change [%] |

| Dynamic viscosity [mPa·s] |

4.6269 |

4.6719 |

+0.97% |

| Kinematic viscosity [mm2/s] |

5.9109 |

5.9577 |

+0.79% |

| Density [g/cm3] |

0.78277 |

0.78418 |

+0.18% |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).