1. Introduction

Aged aluminum alloys have been widely used in aerospace, automotive, shipbuilding, and other fields because of their high strength and lightweight [

1,

2]. The research on their strengthening mechanism and properties has attracted much attention [

3,

4,

5,

6]. The high strength of the aged aluminum alloy is mainly due to the second-phase particles which precipitate in the supersaturated solid solution matrix and act as an obstacle to the dislocation motion [

7,

8,

9,

10,

11].

The Al-Mg-Si (6XXX-series) of aluminum alloys are a class of precipitation hardening materials containing high concentrations of magnesium and silicon solutes. The typical sequence of precipitation for Al-Mg-Si alloys is: SSSS (super-saturated solid solution) → Atomic clusters → GP zones → β″ → β′ → β. Previous studies have shown that the elongated needlelike coherent β″-precipitates and rod-shaped semi-coherent β′-precipitates in the

directions are considered to be the main sources of hardening [

12,

13,

14,

15]. Usually, these two precipitates are uniformly distributed on

. It is generally believed that

β″ has a more significant strengthening effect than

β′ [

16,

17,

18]. Previous work [

19] has quantitatively analyzed the strengthening effects of

β′ and

β″ by means of experimental characterization combined with the macro strength model of AA6XXX-series aging aluminum alloy. The samples of Al-0.66Mg-0.41Si (wt.%) alloy were cast, homogenized, rolled, solution heat treated, quenched to room temperature with water, and immediately aged at 180 ℃ for 3 hours and 6 hours, respectively, to obtain under-aged and peak-aged alloys.

In the past 20 years, based on the interaction mechanism between precipitate and dislocation, a lot of scholars have established many advanced yield strength models of aging strengthened aluminum alloys on the premise of simplifying the type and shape of precipitates. According to the dislocation theory, Myhr et al. [

20] evaluated the yield strength and hardness of Al–Mg–Si alloys from the hindrance of solute atoms and precipitates to dislocation movement. Esmaeili et al. [

21] further divided the yield strength model into a strong obstacle model and a weak obstacle model according to the characteristics of the interaction between precipitates and dislocations, and gave the applicability of the two models. Holmedal [

22] also considered the statistical particle-size and shape distributions of the precipitates to build a precipitation strengthening model, which solved the problem of low strength calculation due to the assumption that the morphology of the precipitates was spherical. These yield strength models can then be combined with crystal plasticity to simulate the tensile or shear response of the aluminum alloys.

The crystal plasticity method is a systematic meso-mechanical method, which connects the microstructure and properties of materials. The main purpose of the crystal plastic constitutive theory is to establish a plastic flow model, a work hardening model, and an evolution model of internal variables (such as slip system strength, dislocation density, etc.) conforming to the plastic deformation mechanism. The pioneering work of the crystal plasticity method was performed by Taylor [

23] for face cubic centered (FCC) polycrystals subject to large plastic strains, and its complete framework was established by Rice, Hill and Mandel et al. [

24,

25,

26]. Later, Peirce, Asaro and Kalidindi et al. [

27,

28,

29] further improved the crystal plasticity model and used the finite element method for numerical simulation, which marks the birth of the crystal plasticity finite element method (CPFEM).With the development of computer technology, Harren and Becker et al. [

30,

31] have simulated the mechanical properties of polycrystalline materials by means of crystal plasticity. At present, thanks to the proposal of many open-source programs [

32,

33,

34], crystal plasticity is widely used and has become a mature numerical simulation method.

However, so far the constitutive equations used in crystal plasticity simulations have only considered contributions from individual precipitates, but the types of precipitates have not been carefully distinguished. Therefore, the current work is mainly to build a single crystal strength model including the strengthening effects of two precipitates based on the experimental data, and to simulate the plastic deformation of the material by using the crystal plastic finite element method. Firstly, the uniaxial tensile experimental test results used to verify the simulation results of the subsequent analysis are presented. Then the strength model and the constitutive relation of crystal plasticity are constructed. Finally, the above model is numerically realized through finite element simulation, and the calculations with various orientation characteristics are set for comparative analysis to explore the error caused by the assumption of a single precipitate.

2. Material Characterization

Through a series of characterization of under-aged and peak-aged alloys with different aging time only, the composition, microstructure and nanostructure of the materials were examined [

19]. Under-aged alloy contains only

β″ precipitates, and peak-aged alloy contains

β″ and

β″ precipitates. The information obtained from the experiment will be used in the subsequent finite element simulation to determine part of the material parameters and for the construction of geometric models, mainly including the average diameter (

d) of crystal grains, matrix composition, the volume fraction (

f) of precipitates, and the average section radius (

) on

of precipitates, as shown in

Table 1.

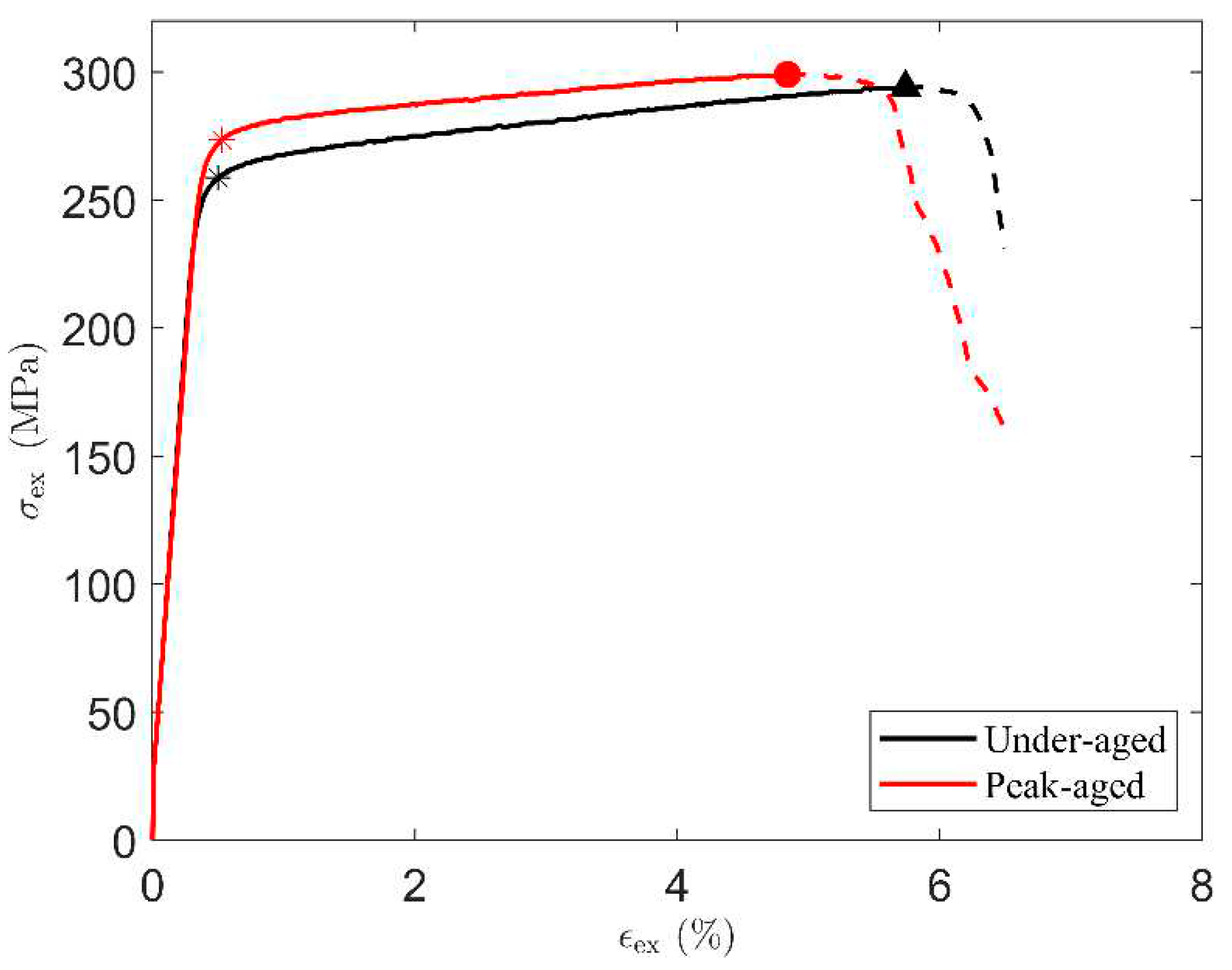

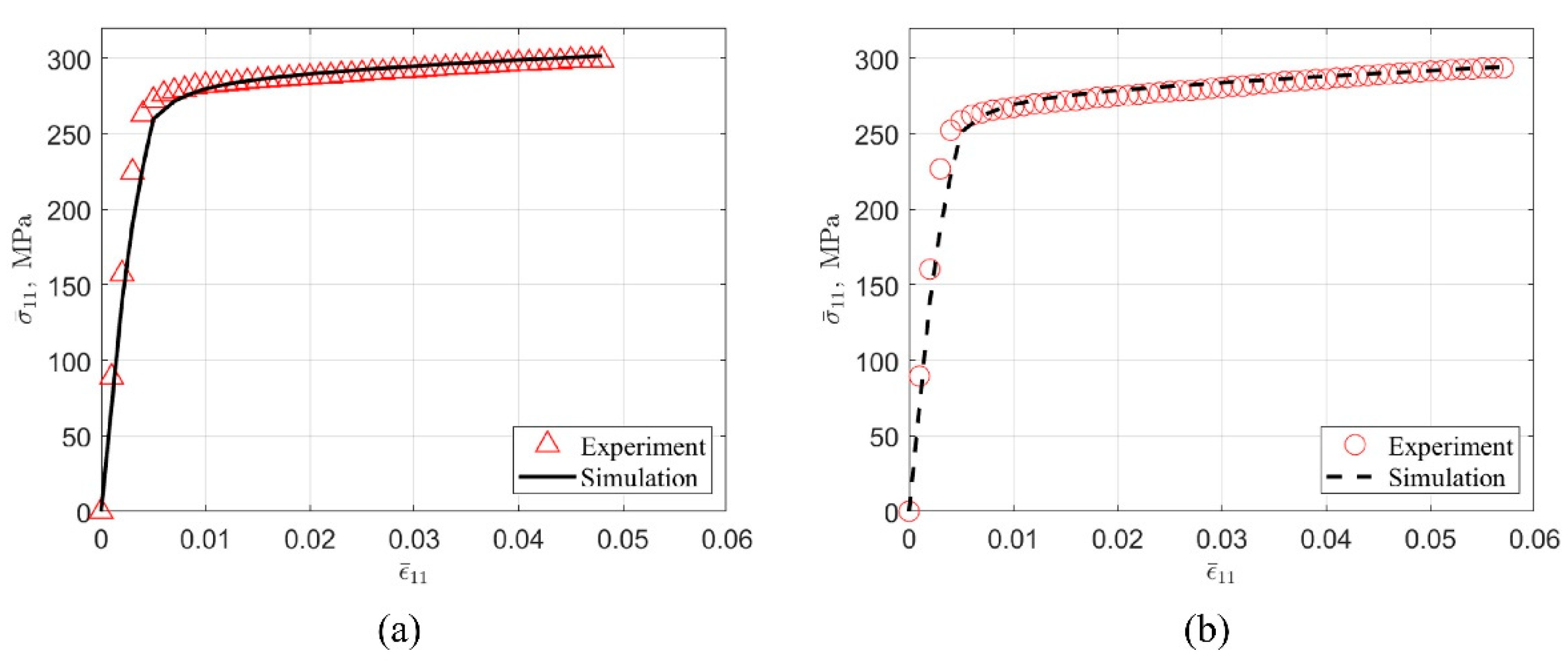

Uniaxial tensile test is the most common method to evaluate the mechanical properties of aging-strengthened aluminum alloys in the laboratory. The complete stress-strain curve (true stress–strain curve) of the under-aged alloy and the peak-aged alloy obtained by the test is shown in

Figure 1.

The effective area of the true stress-strain curve prior to material failure is shown as a solid line in the figure. The Young’s modulus

, 0.2% offset yield strength

σy, yield strain

єy, and tensile strength

σmax with corresponding strain

єmax can be obtained from the stress-strain curve, which are recorded in

Table 2. In addition, work hardening occurs after yielding and continues until the stress reaches

σmax. The maximum work hardening

σw,max is the difference between

σmax and

σy. The alloy used in this work is similar to AA 6063-T832 [

35] in terms of magnesium and silicon content, heat treatment process, and yield stress and tensile strength in the peak-aged state.

In addition, considering that the material has not undergone excessive deformation processing from the casting of the alloy until the preparation of the uniaxially stretched sample, and the experimental data is the average of the simulation results of several different samples, it can be assumed that the material orientation is random.

3. Modeling

The numerical method used in this paper is the CPFEM to simulate the uniaxial tensile deformation of the polycrystalline aggregate. The finite element (FE) simulation is mainly completed by the commercial finite element software ABAQUS. The theoretical part mainly includes strength model and crystal plasticity constitutive model. The strength model is mainly based on the work of Esmaeili et al. [

21], a model considering the strengthening effect of two kinds of precipitates is constructed. Subsequently, the strategy of Khadyko et al. [

36] was used to convert the macroscopic yield stress into the initial flow stress of the single crystal. The crystal plastic model is mainly used to describe the strain hardening behavior of materials, to capture the possible locations of crack initiation, and to explore the effects of microstructure parameters on mechanical properties.

3.1. Strength Model

The yield strength of the Al-Mg-Si Alloys

is assumed to be obtained by the linear superposition of several mechanisms [

20,

21,

37]:

where

is the initial yield strength of polycrystalline pure aluminum,

is contribution from alloying elements in solid solution, and

is the strengthening contribution from precipitation hardening.

Generally Speaking,

is negatively related to the grain size, which satisfies the Hall–Petch relationship:

where

is the intrinsic strength of Al,

is the Hall-Petch constant, and

the diameter of the grain.

The solid solution strengthening is provided by the solid solution elements in the matrix, and the total strengthening effect is superimposed by the contribution of each element.

can be expressed as [

20]:

where

is the concentration of a specific alloying element in the solid solution and

is the corresponding scaling factor. Here, the solid solution strengthening contribution of those trace elements is not considered. It is worth noting that the yield strength calculated from formula (1) or by uniaxial tensile test is based on the assumption that the material is macroscopically isotropic.

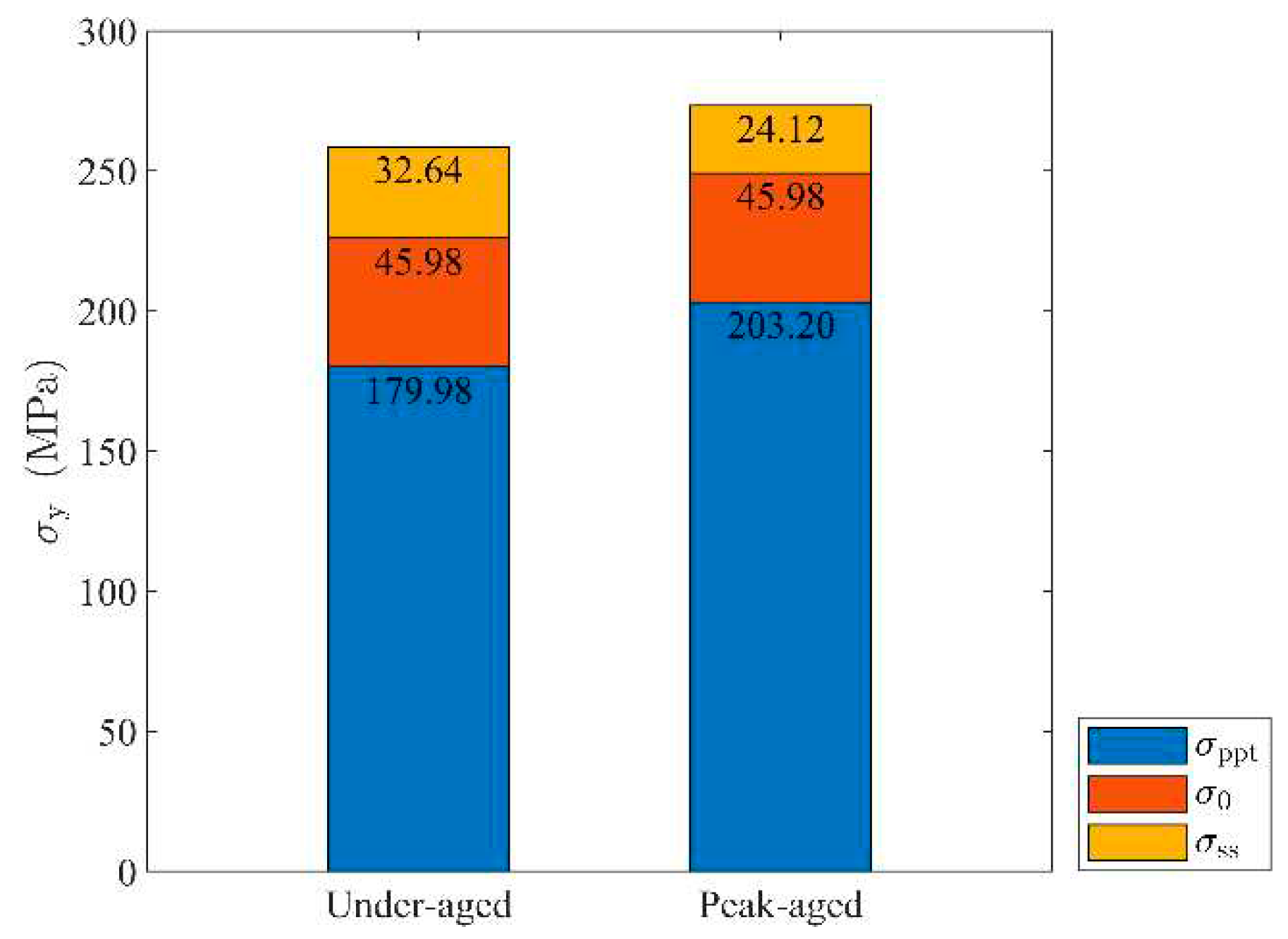

Table 3 lists all the parameter values used in this section. The experimental data in

Table 1 and

Table 2 are used in Formula (1)~(3) to obtain

,

and

, and the results are shown in

Figure 2. Later,

will be used to obtain the hindrance of precipitates to lattice slip on the single crystal level.

It can be seen from

Figure 2 that the age strengthening contribution of the two alloys has reached about 70%, and the solid solution strengthening effect decreases as Mg and Si enter the precipitates and the other second phase such as AlFeSi [

19]. In addition, the contribution of the solid solution strengthening effect is only about 10%, and it can be considered that the solid solution basically does not strengthen the alloy in this work.

In reality, the main mechanism of plastic deformation of aluminum alloy is that the resolved shear stress on the slip system exceeds the initial slip resistance

required for activation of the slip system.

is the most critical physical quantity that reflects the strength of a material in the theory of crystal plasticity. The expression of

is similar to

:

where the contribution to the critical resolved shear stress from the intrinsic strength of aluminum, the solid solution and the particles are denoted

,

and

, respectively.

is a constant derived from the literature.

can be expressed as [

38]:

where,

and

have basically the same meaning, but corresponding to different material scales. It is assumed that there is a linear relationship between

and

,

.

is the coefficient to be calibrated, which depends on the distribution position of solid solution elements and the microstructure characteristics of the material.

The work of Khadyko et al. [

36] showed that

and

were connected through Taylor factor

M:

Therefore, formula (4) is finally expressed as:

It is worth noting that

M is a value highly related to the statistical characteristics of the crystallographic orientation. Khadyko et al. [

36] gives the possible range of values in aluminum alloys. This parameter value will be calibrated in the finite element realization of the crystal plastic constitutive process below. It is reasonable to assume that underaged and peak-aged alloys have the same

M because the grain does not undergo rotation and large deformation during aging. A general value range of

M (2.4~3.1) was given by Bahrami et al. [

15].

Table 3.

Parameters of strength model.

Table 3.

Parameters of strength model.

| Parameter |

Value |

Ref. |

|

10.0 |

[39] |

|

17.0 |

[40] |

|

0.326 |

[41] |

|

29.0, 66.3 |

[20] |

3.2. Crystal Plasticity Constitutive Model

The crystal structure of Al phase in Al-Mg-Si alloy is FCC, which contains only one set of slip system

, including 12 slip systems involved in plastic deformation. The list of all the available slip systems for FCC can be referred to Bassani [

42]. When the stress on the slip system reaches the critical value required for slip, plastic deformation occurs.

The theory of crystal plasticity has two main aspects. One is to describe the plastic deformation behavior of a single crystal grain, and the other is to obtain the macroscopic plastic response in the category of polycrystals by coordinating the deformation between individual crystal grains.

3.2.1. Single Crystal Constitutive Equations

The model used in this work was originally developed by Asaro [

43]. Under the action of external load, the crystal grains of polycrystalline materials will deform and rotate. The deformation gradient

of each individual crystal can be decomposed into a lattice deformation gradient

and a plastic deformation gradient

:

where

reflects the elastic deformation and rotation of the crystal lattice, and

denotes the plastic deformation of the crystal lattice along the slip direction.

The velocity gradient

is defined as:

where

and

are the elastic velocity gradient and plastic velocity gradient defined in the current configuration, respectively, and

is the plastic velocity gradient defined in the intermediate configuration.

For the plastic deformation due to slip, the relationship between the plastic velocity gradient and the plastic slip rate

on each slip system

satisfies the following relationship:

where, the unit vectors

and

are the slip directions in the reference configuration and the deformation configuration respectively, and the unit vectors

and

represent the normal of the slip surface in these two configurations.

and

can be easily obtained by

and

:

was approximated by a power law, assuming that plastic flow occurs under all non-zero stresses without any yield condition or loading/unloading condition:

where

is the reference shear strain rate,

is the critical resolved shear stress, and

the slip rate sensitivity parameter. It is assumed that the

of all slip systems has the same initial value

. According to Schmid’s law, the resolved shear stress

on the

αth slip system can be defined as:

where

is the Kirchhoff stress tensor. By introducing

,

and

,

can be expressed as:

where

is the fourth-order elastic modulus tensor, and for FCC materials, it only contains three independent constants

,

and

.

The strain hardening equation is:

where

are the slip hardening moduli, and the sum ranges over all activated slip systems. For FCC materials,

formally a 12*12 matrix, the components on the main diagonal indicate self-hardening moduli, and the components on the non-main diagonal indicate latent hardening moduli. A simple form of

is:

where

is set as the level of latent hardening relative to self-hardening, usually between 1 and 1.4. The expression of

is in a simple form proposed by Peirce, Asaro and Needleman [

44]:

where

is the initial hardening modulus,

the saturated flow stress, and

the Taylor cumulative shear strain on all slip systems:

By analogy to the relationship between

and

, the

can be calculated approximately with the following formula based on the data in

Table 1:

The uneven height of the local stress and strain of the material is often a sign of failure and destruction, and the accumulated plastic deformation

and local plastic dissipation energy

are two common physical quantities that predict the location of microcracks in materials [

45,

46,

47]. The expressions of

and

are as follows:

In order to determine the plastic behavior of polycrystals, it is necessary to convert the output of the micro model to the macro, and the macro-scale deformation can be regarded as uniform. The main homogenization models are Sachs model [

48], Taylor model [

12], and self-consistent model [

49], all of which assume that the stress and strain inside the crystal are uniform.

3.2.2. Polycrystal morphology and homogenization method

Miyamoto’s [

50] work shows that coupling the crystal plasticity model to the finite element calculation is a good way to study the confinement effect of adjacent grains. This method takes into account the interaction between grains, satisfing both the stress equilibrium and strain compatibility.

In this work, we construct a representative volume element (RVE) and use a homogenization strategy to simulate the macroscopic mechanical behavior of the material, in which the macroscopic quantities are equal to the volume-weighed sum of those over microstructural domains [

51]. The macro-scale true stress

and strain

are the volume-averaged values computed from the local true stress and strain of the whole domain

as follows:

3.3. Establishment of FE Model

In this work, the commercial finite element software ABAQUS was used to simulate the uniaxial tension of the peak-aged Al-Mg-Si alloy containing

β″ and

β′ precipitates. The constitutive theory of crystal plasticity in section 2.2 can be realized by using the time integration strategy in the user subroutine UMAT provided by ABAQUS. The UMAT used in this work is mainly based on Huang [

52].

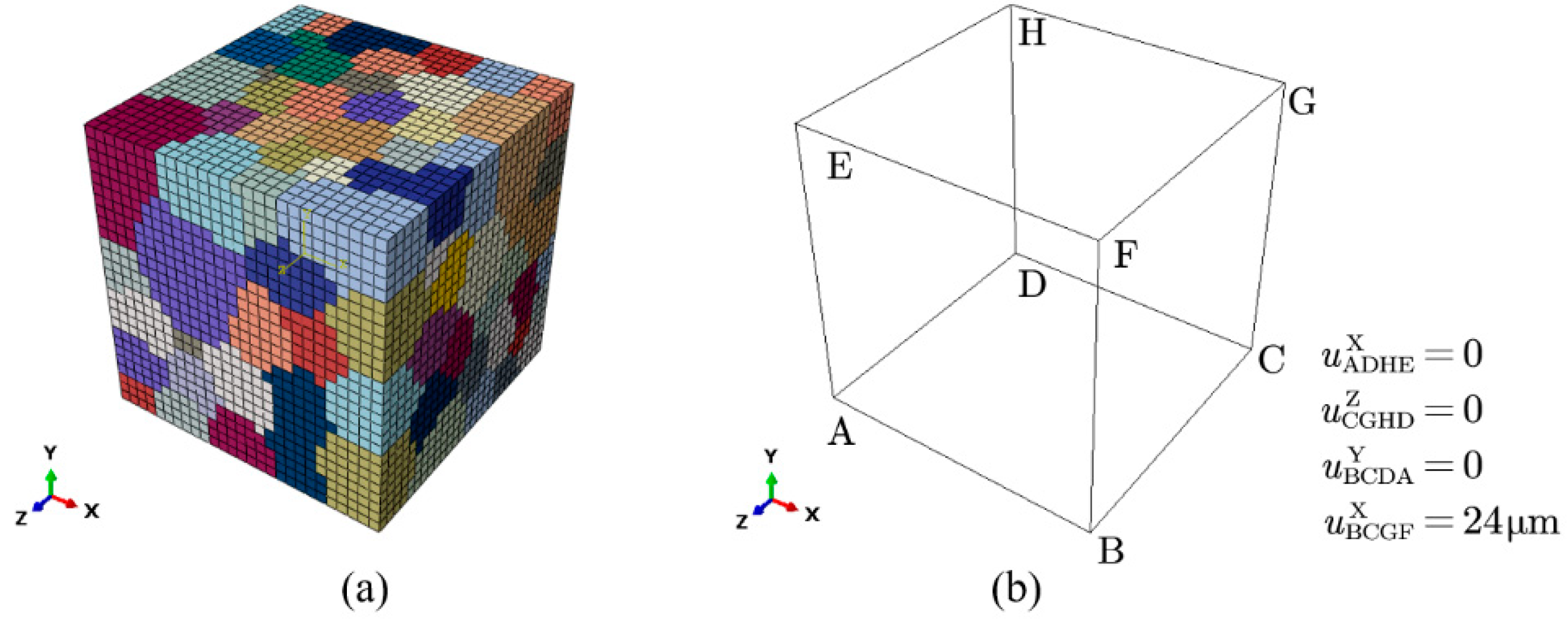

Table 1 shows that the under-aged alloy and the peak-aged alloy have the same grain size, because the grains will not grow up when aged at 180 ℃. Based on the average grain size obtained from experiments, a square RVE, with a side length of 400 μm is constructed in Neper [

32], which contains a total of 19,683 elements (C3D8 in ABAQUS) and 27 elements in each direction, as shown in

Figure 3(a). The orientation of the grains is random, and two sets of different material parameters are set to represent under-aged alloy and peak-aged alloy. This modeling method is mainly established by Diard et al. [

53], which not only takes into account the calculation accuracy, but also ensures that each grain has enough mesh description to reflect the non-uniformity of the internal deformation of the crystal. 6% engineering strain (24 μm) is applied to RVE to simulate uniaxial tensile deformation.

Figure 3(b) shows the boundary conditions of tensile test. At first, displacements of three adjacent surfaces of the polycrystalline aggregate are fixed. Then, displacement loading is applied on the front surface along X axis during calculation.

3.4. Parameter Calibration

When using the user subroutine UMAT to numerically realize the constitutive relationship established in

Section 3.2, there are a total of 9 parameters (

,

,

,

,

,

,

,

and

) that need to be determined, as shown in

Table 4. Six of them (

,

,

,

,

and

) were from literature [

40,

54], and three of them (

,

and

) can be assessed according to the experimental stress-strain curve [

55,

56]. In addition, the values of

and

in this work are 2.8 and 2, respectively.

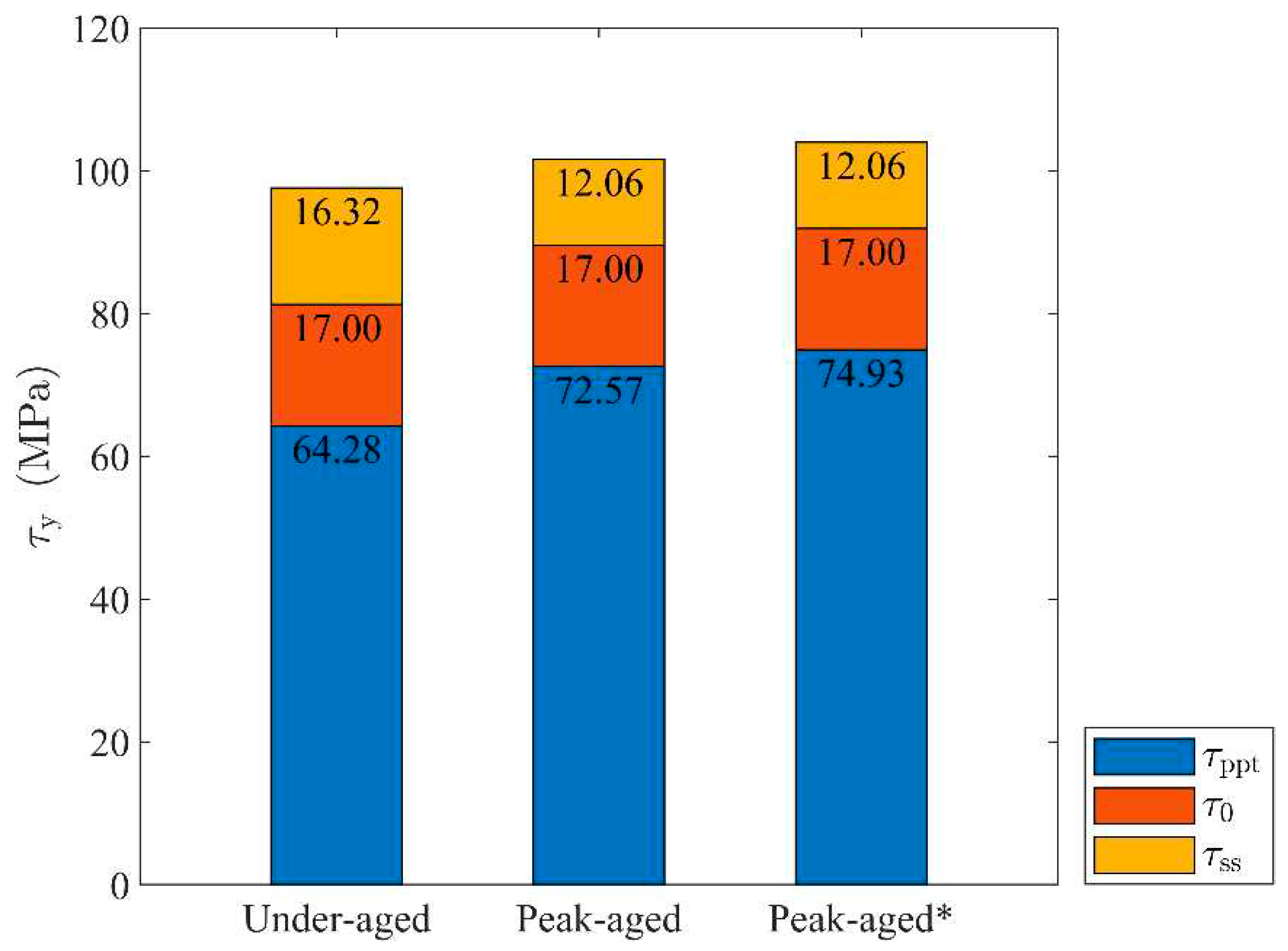

Considering that the targeted alloy 6063-T832 alloy in this work is of the highest strength among the 6063 alloys, it can be approximately assumed that the precipitates is Orowan particles. The precipitation strengthening effect calculation formula proposed by Esmaeili et al. [

21] is used to express the contribution of the precipitates as a function of volume fraction, and the superposition of the two precipitation strengthening effects follows the composite criterion proposed by Myhr et al. [

38]. The expression for

reads:

where

and

are the strengthening coefficients of

β′ and

β″ precipitates, respectively, and their values can be obtained as 623.05 MPa and 670.15 MPa based on the volume fraction in

Table 1. In the past, whether it was refined quantitative characterization based on experimental observations, or simulation and performance prediction of peak-aged precipitates, it was basically used to assume that the peak-aged precipitates had a single composition, only

β″ phase. Based on the above parameter calibration results, we consider

β′ with a volume fraction of 0.57% in the peak-aged alloy as

β″ to design the calculation example peak-aged*, in order to explore the possible prediction bias caused by the assumption of a single precipitate. Since there is no

β′ phase, it can be approximately considered that the two items of

and

are consistent with under-aged, and the key difference is

. All parameters are recorded in

Figure 4 and

Table 4.

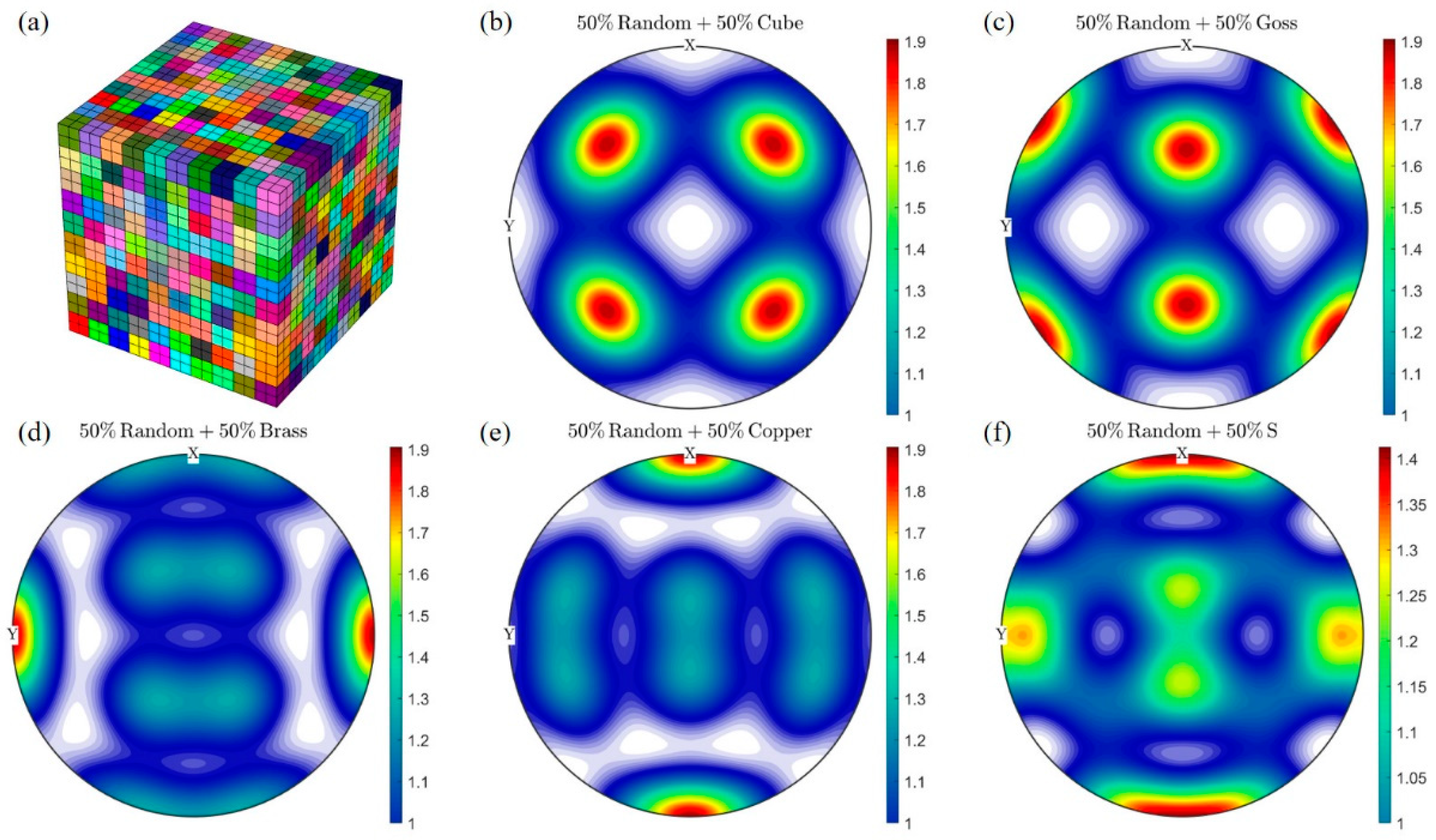

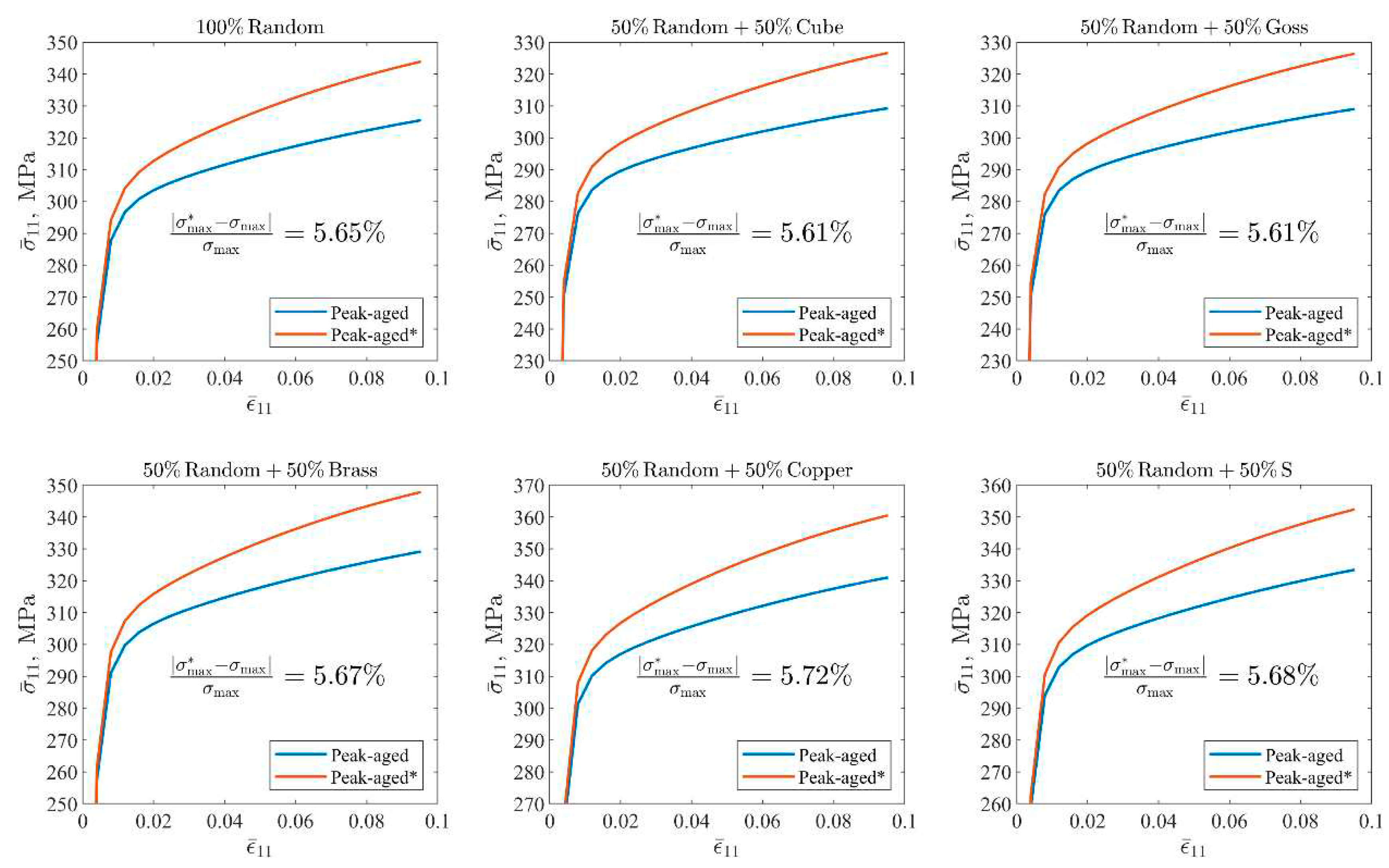

By comparing the calculation results of peak-aged and peak-aged* with the experimental results, it is possible to explore the prediction bias caused by the assumption of a single precipitation phase. The overall stress-strain response of RVE is closely related to the orientation characteristics, but is basically unrelated to the morphology of grains and the geometric characteristics of grain boundaries. In order to make the simulation results as inclusive as possible of various realistic orientation characteristics, an RVE containing 1000 grains of the same shape and size was constructed, each represented by eight C3D8 cube elements, as shown in

Figure 5. The length of the model will no longer reflect the geometry of the grains. The purpose of this model is to discretize the assumed overall orientation features by using as many grains as possible without too much computational burden, and the geometry of the individual grains is completely consistent to minimize the influence of non-oriented features. The work of Manchiraju et al. [

57] has demonstrated the effectiveness of this modeling strategy.

A total of six sets of orientation information are designed. One set is completely random, and five sets of composites of specific orientation and random orientation are designed. This design refers to the work of Choi et al. [

58,

59] and Mishra et al. [

11], in order to take possible anisotropy into consideration as much as possible. The five specific orientations are Cube-

, Goss-

, Brass-

, Copper-

and S-

.

Figure 5 shows the distribution of five sets of composite orientations on the

plane. Considering that the maximum stretching amount of the reference alloy 6063-T832 alloy is about 12%, and the crystal plastic finite element method lacks effective mechanism support for the prediction of material failure, we apply boundary conditions with reference to

Figure 2, and set the stretching amount as the 10% of the side length of the cube, taking the statistical average value of the stress component of RVE in the stretching direction after stretching as the estimated value of the maximum tensile strength, and comparing the results of the two examples of peak-aged and peak-aged*.

4. Results and Discussions

Figure 6 shows the true stress-strain curve obtained from the experimental test and the simulation. The difference between the experiment and the simulation is that the grain orientation and morphology of the RVE are different from the actual material, and the state variables used in the crystal plasticity model cannot fully reflect all the material deformation mechanisms. It can be seen intuitively from the figure that the slope of the curve gradually decreases, indicating that the work hardening ability of the material decreases with the increase of deformation. This simulation result is an intuitive response of formula (17).

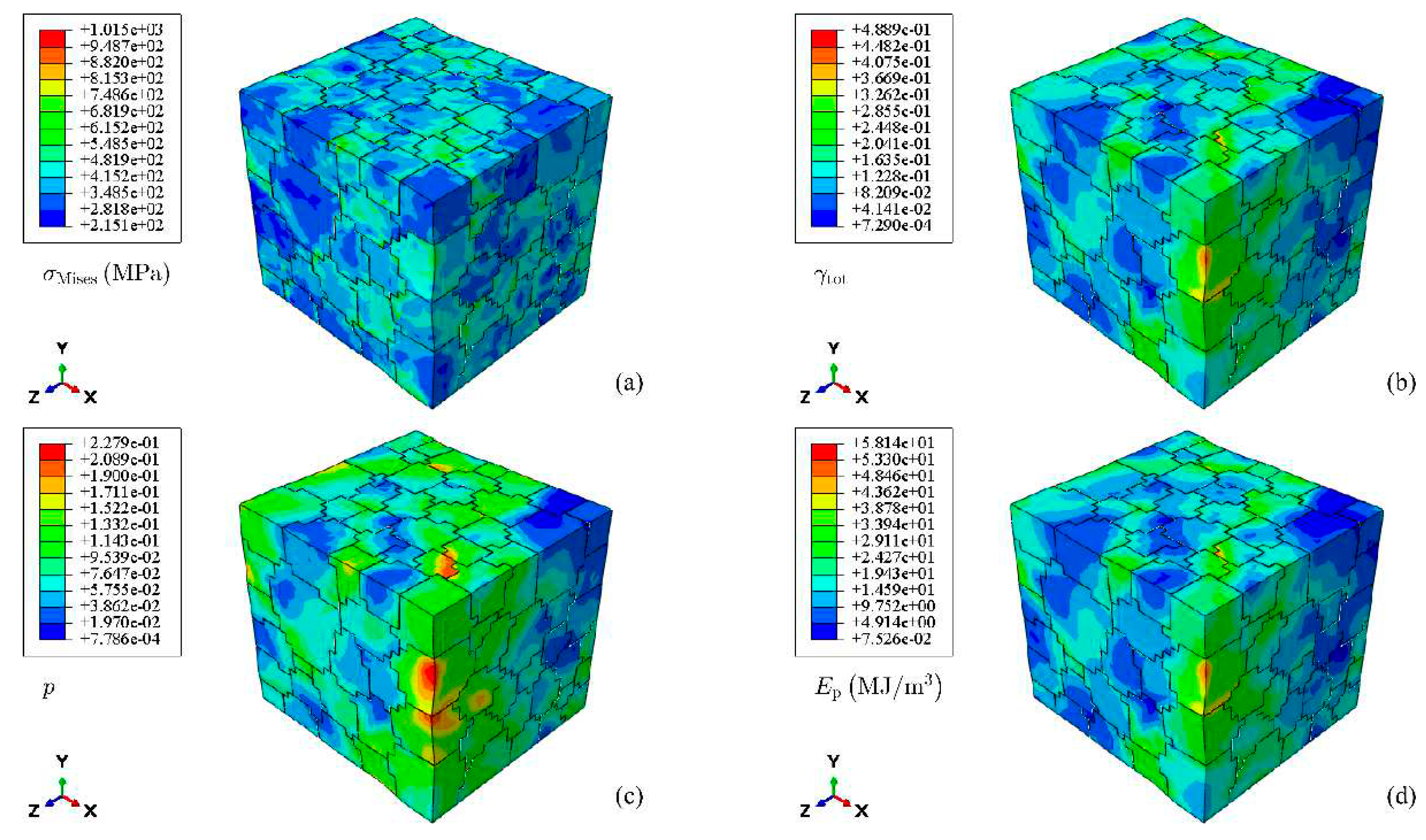

Figure 7 shows the distribution of the Mises stress component

, Taylor cumulative shear strain

, cumulative plastic strain

and plastic dissipation energy

of RVE in turn.

Figure 7(a) and 7(b) show that the strain deformation and stress response between grains are obviously different, and the stress and strain distribution inside the grains is not uniform. The main reason lies in the elastoplastic anisotropy caused by the difference in grain orientation, so stress and strain concentrations occur when the grain boundary reaches the stress balance and strain coordination at the same time. Combined with the distribution diagram of shear strain, the crystal plastic deformation at the stress concentration can be more intuitively understood.

Figure 7(c) and 7(d) show the distribution of

and

, both of which record the history of deformation. In comparison with

,

more accurately reflects the unevenness of the internal deformation of the grain. Comparing

Figure 7(b) and 7(d), it can be seen that the distribution characteristics of

and

are consistent with each other.

Figure 8 shows the uniaxial tensile simulation results of peak-aged and peak-aged*. As the deformation increases, the calculated difference between the two materials becomes more and more obvious. The calculation deviation of the maximum tensile strength is around 5.65%, and there is no obvious orientation difference. Even though some of the assumptions made in this work are not absolutely rigorous, the error of the single precipitated phase assumption in the simulation results of crystal plasticity cannot be ignored. The strain hardening behaviors corresponding to different initial textures are also different. Cube and Goss textures are easier to deform than random textures, and Brass textures present an overall mechanical response consistent with random textures. Copper and S textures reflect stronger deformation resistance than random textures.

5. Conclusions

In this work, based on the previous experimental results, a single crystal strength model considering the grain size, solid solution strengthening effect, and aging strengthening effect is constructed, and the uniaxial stretching process of polycrystalline RVEs is simulated. Two samples with the same composition, the same front-end production process, and only different aging times were selected for comparison to quantitatively distinguish the relative mechanical properties of the two precipitations that play a major strengthening role in peak-aged Al alloys.

The simulated stress-strain curves are in good agreement with the experimental data, confirming that the used constitutive parameters of a single crystal strength model with two kinds of precipitates are based on real physical implications and thus allow a quantitative description of the deformation behavior at the peak of aging. It is further found that with the increase of aging time, the strength is improved but the deformability is weakened.

By constructing two calculation examples of different precipitated phase compositions and using them to simulate the maximum tensile strength of several materials with typical textures, it is concluded that the two kinds of precipitation should be considered separately when simulating the mechanical response of 6XXX in the future. Compared with past simulation studies that only predict yield strength, the introduction of the crystal plasticity finite element method at the present work can capture richer stress-strain response details and take into account key microstructural information such as real grain geometry and material orientation.

In addition, the findings of this study are not limited to 6XXX aluminum alloys and can help evaluate the production and application of other age-strengthened alloys. The current study presents a preliminary result that has not yet considered material porosity versus microcracks, and will detail different microstructural details in the near future.

Author Contributions

Data curation, Writing—original draft, X.Z.; Investigation, Q.H. and K.L.; Conceptualization, Writing—review & editing, Supervision, H.M. and Y.D.; Conceptualization, Writing— review & editing, Supervision, Funding acquisition, Project administration, Y.K. and Y.L.; Conceptualization, Results review, Writing—review, N.X. and X.L.. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Natural Science Foundation of China (Grant Numbers: 52331002, 52101029, 52201010), and the Funds for International Cooperation and Exchange of the National Natural Science Foundation of China (Grant No. 51820105001).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Numerical computations were partly performed on Hefei advanced computing center.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hirsch, J.; uuml; rgen. Aluminium in Innovative Light-Weight Car Design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Engler, O.; Hirsch, J. Texture control by thermomechanical processing of AA6xxx Al–Mg–Si sheet alloys for automotive applications—A review. Mater. Sci. Eng. A 2002, 336, 249–262. [Google Scholar] [CrossRef]

- Wang, X.; Embury, J.D.; Poole, W.J.; Esmaeili, S.; Lloyd, D.J. Precipitation strengthening of the aluminum alloy AA6111. Metall. Mater. Trans. A 2003, 34, 2913–2924. [Google Scholar] [CrossRef]

- Kohar, C.P.; Zhumagulov, A.; Brahme, A.; Worswick, M.J.; Mishra, R.K.; Inal, K. Development of high crush efficient, extrudable aluminium front rails for vehicle lightweighting. Int. J. Impact Eng. 2016, 95, 17–34. [Google Scholar] [CrossRef]

- Muhammad, W.; Brahme, A.P.; Kang, J.; Mishra, R.K.; Inal, K. Experimental and numerical investigation of texture evolution and the effects of intragranular backstresses in aluminum alloys subjected to large strain cyclic deformation. Int. J. Plast. 2017, 93, 137–163. [Google Scholar] [CrossRef]

- Song, M. Modeling the hardness and yield strength evolutions of aluminum alloy with rod/needle-shaped precipitates. Mater. Sci. Eng. A 2007, 443, 172–177. [Google Scholar] [CrossRef]

- Ardell, A.J. Precipitation hardening. Metall. Trans. A 1985, 16, 2131–2165. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 2013, 15, 30–36. [Google Scholar] [CrossRef]

- Guo, Z.; Sha, W. Quantification of Precipitation Hardening and Evolution of Precipitates. Mater. Trans. 2002, 43, 1273–1282. [Google Scholar] [CrossRef]

- Mishra, S.; Yadava, M.; Kulkarni, K.N.; Gurao, N.P. A theoretical investigation of the effect of precipitate habit plane on plastic anisotropy in age hardenable aluminium alloys. Model. Simul. Mater. Sci. Eng. 2018, 26. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C.; Polmear, I.J. The Effect of Precipitate Shape and Orientation on Dispersion Strengthening in High Strength Aluminium Alloys. Mater. Sci. Forum 1996, 217–222, 1257–1262. [Google Scholar] [CrossRef]

- Russell, K.G.; Ashby, M.F. Slip in aluminum crystals containing strong, plate-like particles. Acta Metall. 1970, 18, 891–901. [Google Scholar] [CrossRef]

- Miao, W.F.; Laughlin, D.E. Precipitation hardening in aluminum alloy 6022. Scr. Mater. 1999, 40, 873–878. [Google Scholar] [CrossRef]

- Bahrami, A.; Miroux, A.; Sietsma, J. An Age-Hardening Model for Al-Mg-Si Alloys Considering Needle-Shaped Precipitates. Metall. Mater. Trans. A 2012, 43, 4445–4453. [Google Scholar] [CrossRef]

- Zandbergen, H.W.; Andersen, S.J.; Jansen, J. Structure Determination of Mg5Si6 Particles in Al by Dynamic Electron Diffraction Studies. Science 1997, 277, 1221–1225. [Google Scholar] [CrossRef]

- Wenner, S.; Holmestad, R. Accurately measured precipitate–matrix misfit in an Al–Mg–Si alloy by electron microscopy. Scr. Mater. 2016, 118, 5–8. [Google Scholar] [CrossRef]

- Ding, L.; Jia, Z.; Nie, J.-F.; Weng, Y.; Cao, L.; Chen, H.; Wu, X.; Liu, Q. The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy. Acta Mater. 2018, 145, 437–450. [Google Scholar] [CrossRef]

- Yang, M.; Chen, H.; Orekhov, A.; Lu, Q.; Lan, X.; Li, K.; Zhang, S.; Song, M.; Kong, Y.; Schryvers, D.; et al. Quantified contribution of β″ and β′ precipitates to the strengthening of an aged Al–Mg–Si alloy. Mater. Sci. Eng. A 2020, 774. [Google Scholar] [CrossRef]

- Myhr, O. Modelling of the age hardening behaviour of Al–Mg–Si alloys. Acta Mater. 2001, 49, 65–75. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J.; Poole, W.J. A yield strength model for the Al-Mg-Si-Cu alloy AA6111. Acta Mater. 2003, 51, 2243–2257. [Google Scholar] [CrossRef]

- Holmedal, B. Strength contributions from precipitates. Philos. Mag. Lett. 2015, 95, 594–601. [Google Scholar] [CrossRef]

- Taylor, G.I. Plastic strain in metals. J. Inst. Met. 1938, 62, 307–324. [Google Scholar]

- Rice, J.R. Inelastic constitutive relations for solids: An internal-variable theory and its application to metal plasticity. J. Mech. Phys. Solids 1971, 19, 433–455. [Google Scholar] [CrossRef]

- Hill, R.; Rice, J.R. Constitutive analysis of elastic-plastic crystals at arbitrary strain. J. Mech. Phys. Solids 1972, 20, 401–413. [Google Scholar] [CrossRef]

- Mandel, J. Equations constitutives et directeurs dans les milieux plastiques et viscoplastiques. Int. J. Solids Struct. 1973, 9, 725–740. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Asaro, R.J. Micromechanics of crystals and polycrystals. Adv. Appl. Mech. 1983, 23, 1–115. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Bronkhorst, C.A.; Anand, L. Crystallographic texture evolution in bulk deformation processing of FCC metals. J. Mech. Phys. Solids 1992, 40, 537–569. [Google Scholar] [CrossRef]

- Harren, S.V.; Dève, H.E.; Asaro, R.J. Shear band formation in plane strain compression. Acta Metall. 1988, 36, 2435–2480. [Google Scholar] [CrossRef]

- Becker, R. Analysis of texture evolution in channel die compression—I. Effects of grain interaction. Acta Metall. Et Mater. 1991, 39, 1211–1230. [Google Scholar] [CrossRef]

- Quey, R.; Kasemer, M. The Neper/FEPX Project: Free / Open-source Polycrystal Generation, Deformation Simulation, and Post-processing. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1249. [Google Scholar] [CrossRef]

- Yaghoobi, M.; Ganesan, S.; Sundar, S.; Lakshmanan, A.; Rudraraju, S.; Allison, J.E.; Sundararaghavan, V. PRISMS-Plasticity: An open-source crystal plasticity finite element software. Comput. Mater. Sci. 2019, 169, 109078. [Google Scholar] [CrossRef]

- Roters, F.; Diehl, M.; Shanthraj, P.; Eisenlohr, P.; Reuber, C.; Wong, S.L.; Maiti, T.; Ebrahimi, A.; Hochrainer, T.; Fabritius, H.O.; et al. DAMASK – The Düsseldorf Advanced Material Simulation Kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput. Mater. Sci. 2019, 158, 420–478. [Google Scholar] [CrossRef]

- Davis, J.R. Properties and selection: Nonferrous alloys and special-purpose materials. 1990.

- Khadyko, M.; Myhr, O.R.; Dumoulin, S.; Hopperstad, O.S. A microstructure-based yield stress and work-hardening model for textured 6xxx aluminium alloys. Philos. Mag. 2016, 96, 1047–1072. [Google Scholar] [CrossRef]

- Esmaeili, S.; Lloyd, D.J.; Poole, W.J. Modeling of precipitation hardening for the naturally aged Al-Mg-Si-Cu alloy AA6111. Acta Mater. 2003, 51, 3467–3481. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø.; Schäfer, C. An Extended Age-Hardening Model for Al-Mg-Si Alloys Incorporating the Room-Temperature Storage and Cold Deformation Process Stages. Metall. Mater. Trans. A 2015, 46, 6018–6039. [Google Scholar] [CrossRef]

- Deschamps, A.; Brechet, Y. Influence of predeformation and ageing of an Al–Zn–Mg alloy—II. Modeling of precipitation kinetics and yield stress. Acta Mater. 1998, 47, 293–305. [Google Scholar] [CrossRef]

- Li, Y.L.; Kohar, C.P.; Mishra, R.K.; Inal, K. A new crystal plasticity constitutive model for simulating precipitation-hardenable aluminum alloys. Int. J. Plast. 2020, 132, 102759. [Google Scholar] [CrossRef]

- Loucif, A.; Figueiredo, R.B.; Baudin, T.; Brisset, F.; Chemam, R.; Langdon, T.G. Ultrafine grains and the Hall–Petch relationship in an Al–Mg–Si alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2012, 532, 139–145. [Google Scholar] [CrossRef]

- Bassani, J.L.; Wu, T.-Y. Latent hardening in single crystals. II. Analytical characterization and predictions. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1997, 435, 21–41. [Google Scholar] [CrossRef]

- Asaro, R.J. Crystal Plasticity. J. Appl. Mech. 1983, 50, 921–934. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. Material rate dependence and localized deformation in crystalline solids. Acta Metall. 1983, 31, 1951–1976. [Google Scholar] [CrossRef]

- Skelton, R.P. Cyclic hardening, softening, and crack growth during high temperature fatigue. Mater. Sci. Technol. 1993, 9, 1001–1008. [Google Scholar] [CrossRef]

- Manonukul, A.; Dunne, F.P.E. High– and low–cycle fatigue crack initiation using polycrystal plasticity. Proc. R. Soc. London. Ser. A: Math. Phys. Eng. Sci. 2004, 460, 1881–1903. [Google Scholar] [CrossRef]

- Cheong, K.; Smillie, M.; Knowles, D. Predicting fatigue crack initiation through image-based micromechanical modeling. Acta Mater. 2007, 55, 1757–1768. [Google Scholar] [CrossRef]

- Sachs, G. Plasticity problems in metals. Trans. Faraday Soc. 1928, 24, 84. [Google Scholar] [CrossRef]

- Kröner, E. Zur plastischen verformung des vielkristalls. Acta Metall. 1961, 9, 155–161. [Google Scholar] [CrossRef]

- Miyamoto, H.; Sumikawa, M.; Miyoshi, T. Interpretation of mechanical behavior of pure aluminum in terms of microstructures. The 1971 Conference on Mechanical Behavior of Materials.

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Huang, Y. A User-Material Subroutine Incorporating Single Crystal Plasticity in the ABAQUS Finite Element Program. 1991.

- Diard, O.; Leclercq, S.; Rousselier, G.; Cailletaud, G. Evaluation of finite element based analysis of 3D multicrystalline aggregates plasticity. Int. J. Plast. 2005, 21, 691–722. [Google Scholar] [CrossRef]

- Khadyko, M.; Dumoulin, S.; Børvik, T.; Hopperstad, O.S. Simulation of large-strain behaviour of aluminium alloy under tensile loading using anisotropic plasticity models. Comput. Struct. 2015, 157, 60–75. [Google Scholar] [CrossRef]

- Zhang, K.-S.; Ju, J.W.; Li, Z.; Bai, Y.-L.; Brocks, W. Micromechanics based fatigue life prediction of a polycrystalline metal applying crystal plasticity. Mech. Mater. 2015, 85, 16–37. [Google Scholar] [CrossRef]

- Zheng, X.; Kong, Y.; Chang, T.; Liao, X.; Ma, Y.; Du, Y. High-Throughput Computing Assisted by Knowledge Graph to Study the Correlation between Microstructure and Mechanical Properties of 6XXX Aluminum Alloy. Mater. (Basel) 2022, 15. [Google Scholar] [CrossRef]

- Manchiraju, S.; Anderson, P.M. Coupling between martensitic phase transformations and plasticity: A microstructure-based finite element model. Int. J. Plast. 2010, 26, 1508–1526. [Google Scholar] [CrossRef]

- Choi, S.H.; Barlat, F.; Liu, J. Effect of precipitates on plastic anisotropy for polycrystalline aluminum alloys. Metall. Mater. Trans. A 2001, 32, 2239–2247. [Google Scholar] [CrossRef]

- Choi, S.H.; Cho, J.H.; Oh, K.H.; Barlat, F.; Chung, K.; Kwon, J.W. Prediction of yield surfaces of textured sheet metals. Metall. Mater. Trans. A 1999, 30, 377–386. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).