Submitted:

27 July 2023

Posted:

31 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Literary Review

4. Results

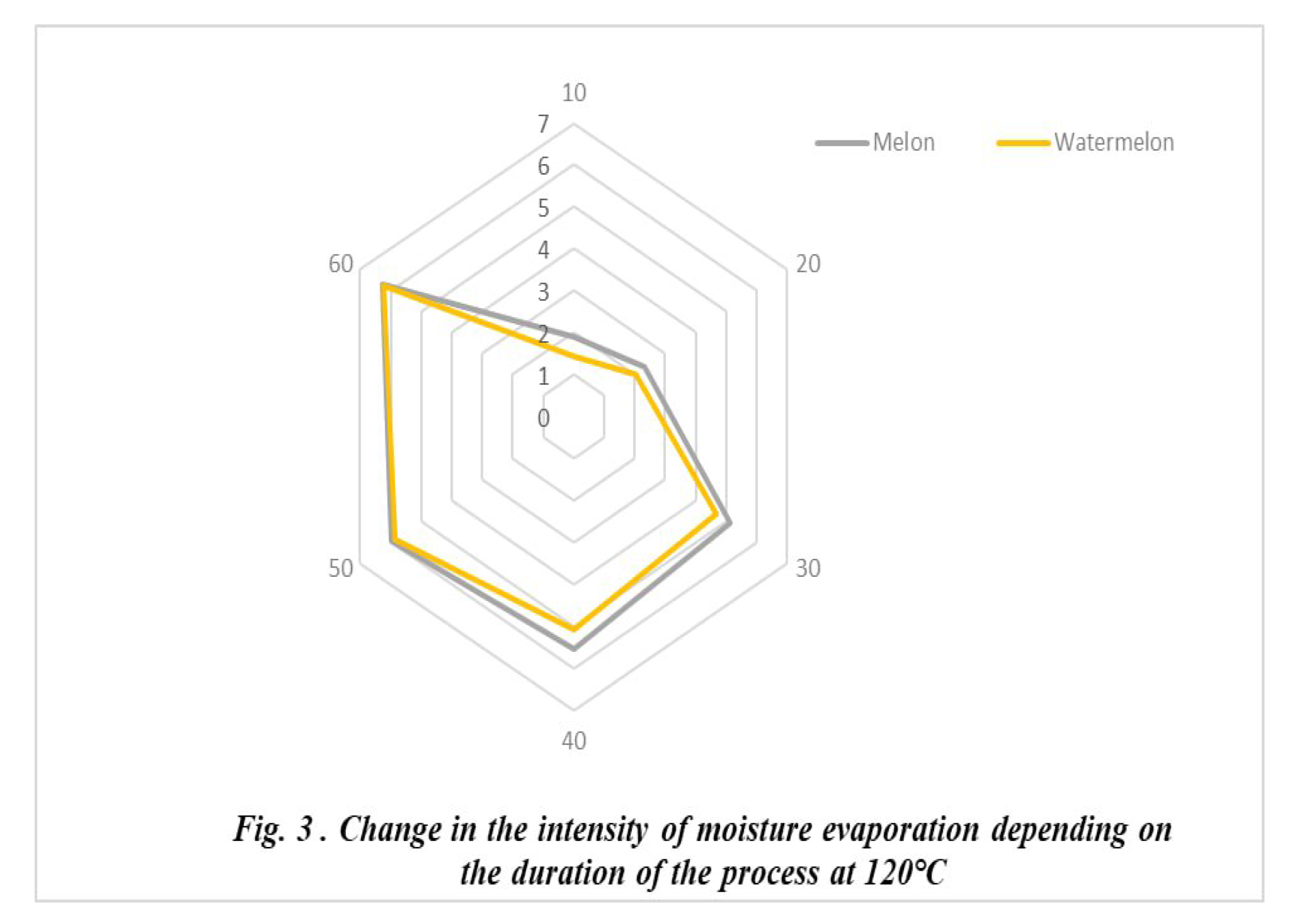

| Heat treatment temperature, °C | Processing time, min | |||||

|---|---|---|---|---|---|---|

| 10 | 30 | 50 | 60 | |||

| Evaporation of moisture and volatile substances, % | ||||||

| from melon seeds | ||||||

| 100 | 1,47 | 1,78 | 2,21 | 2,78 | 3,22 | 3,65 |

| 110 | 1,66 | 2,11 | 3,17 | 3,44 | 3,99 | 4,24 |

| 120 | 1,90 | 2,34 | 5,11 | 5,54 | 5,97 | 6,29 |

| 130 | 2,60 | 3,03 | 5,24 | 6,02 | 6,34 | 6,99 |

| from watermelon seeds | ||||||

| 100 | 1,12 | 1,54 | 2,05 | 2,57 | 3,29 | 4,18 |

| 110 | 1,31 | 1,78 | 3,11 | 3,38 | 4,03 | 4,78 |

| 120 | 1,45 | 2,02 | 4,67 | 5,07 | 5,87 | 6,25 |

| 130 | 1,57 | 2,23 | 4,97 | 5,41 | 6,12 | 6,78 |

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Terlova E.A., Kozhevnikov V.Yu. Activation of the extraction process of vegetable oils in a microwave electromagnetic field //Bulletin of SSTU. 2012, № 2 (66). Issue 2., 171-177. https://scholar.google.com/.

- [ O’zdst 1199:2009(2009)] O’zdst 1199:2009, Vegetable oils. The method of determining the chromaticity. Tashkent. Gosstandart. -2009. - 11 pages.

- [O’zDSt 1203:2009.(2009)] O’zDSt 1203:2009. Vegetable oils. Method for determining the acid number. Tashkent. Gosstandart. -2009. - 10 pages.

- [O’zDSt 1193:2009.(2009)] O’zDSt 1193:2009. Vegetable oils. Methods for determining moisture and volatile substances. Tashkent. Gosstandart. -2009. - 11 pages.

- N.S. Arutyunyan, E.A. Arisheva, L.I. Yanova, M.A. Kamyshan / Laboratory workshop on fat processing technology – M.: Light and food industry. -1983 – 152 p . www.studmed.ru/arutyunyan-n-s-arisheva-e-a-yanova-l-i-kamyshan-m-a-laboratornyy-praktikum-po-tehnologii-pererabotki-zhirovb0ec5370cf6.html.

- O’zDSt 1200:2009. Vegetable oils. Methods for determining the peroxide number. Tashkent. Gosstandart. -2009. - 9 pages.

- Under the total. ed. prof. Rzhekhina V.P. et al. Guidelines on research methods, technological control and accounting of production in the fat and oil industry. -L.: VNIIZH. -1967. -vol.2 -661 p. https://search.rsl.ru/ru/record/01008296031. 0100.

- O’zDSt 596:1993. Cotton seeds are technical. Method of determination of moisture and volatile substances. Tashkent. Gosstandart. -1993. - 18 p.

- Ed. Nechaeva A.I. Food chemistry. Laboratory workshop. –S.Pb.: Giord. -2006. -302 p. https://www.studmed.ru/nechaev-ap-i-dr-pischevaya-himiya_dfd0f24503d.html.

- Dragan I.V. Scientific support of the process of forpressing oilseeds and the development of compositions of vegetable oils for functional purposes: dissertation of the Candidate of Technical Sciences. – Voronezh, -2015. – pp.88-96. https://scholar.google.com/.

- A.N. Ostrikov, L.I. Vasilenko, M.V. Kopylov. The current state and main directions of improvement of oil presses. Information review /GOUVPO Voronezh, state technol. Acad. -2011. -pp. 40-51. https://scholar.google.com/.

- Beloborodov V.V. Basic processes of vegetable oil production. - M.: - 1966. -pp.85-89. https://scholar.google.com/.

- Goldovsky A.M. Theoretical foundations of vegetable oil production. -Pishchepromizdat. -M.: -1958. -pp. 64-71. https://scholar.google.com/.

- Lobanov V.I., Buzoverov S.Yu., Zheltunov M.G. Influence of humidity and size of sunflower seeds on the process of collapse. //Bulletin of the Altai State Agrarian University No. 12 (158), 2017. - pp. 152-156 https://scholar.google.com/.

- Frolova L. N., V. Vasilenko. II century, Dragan I. V., Mikhailova A. N. Study of the regularities of the preliminary extrusion preparation of oilseeds for the pressing process. //Vestn. VSUIT, - 2015. - L" 2. - pp. 27-29.https://cyberleninka.ru/.

- Yamshchikova A. E. Influence of heat treatment and consumption of antioxidants on the oxidation of a mixture of sunflower and rapeseed oils. Materials of the 14th International Scientific and Practical Student Conference "Chemistry and Life". -Novosibirsk, -2015. -pp.92-95.

- Pat. 2567745 Russia, Method of obtaining vegetable oil and cake from melon seeds: IPC C11B 1/04 (2006.01) In /Derevenko. V., Mirzoev G. H., and Tagakov. V.; KubSTU. - N 2014135991/13; Publ. https://scholar.google.com/.

- Bayer V., Heilman R. I. Method of processing oilseed flakes before oil extraction. //Oils and fats. -2016. -7-8. - p.22-23. http://www.oilbranch.com/magazine/archive/viewdoc/2016/7/1415.html.

- Yulchiev A.B. Optimization of the process of obtaining high-grade cottonseed oil using microwave processing of mint. //Fat and oil industry. - 2015. - No. 5. - pp.20-22. https://scholar.google.com/.

- Dufort S., Rigal L. and Mulungui Z. Twin-screw extruder for oil extraction: I. Direct pressing of oleic sunflower seeds. Journal of the American Society of Petrochemicals, 76(9). doi: 10.1007/s11746-999-0206-0. (1999) https://scholar.google.com/.

- Olson R. Modern processing of rapeseed. Journal of the American Society of Petrochemicals, 69(3). doi: 10.1007/BF02635885. (1992). p. 195-198. https://scholar.google.com/.

- Vadke V. S., Sosulsky F. V. Mechanics of oil extraction from canola. Journal of the American Society of Petrochemicals, 65(7), doi: 10.1007/BF02660576. (1988). p. 1169-1176. https://scholar.google.com/.

- Azadmard-Damirchi S., Habibi-Nodeh F., Hesari J., Nemati M., Achachluei B. F. The effect of pretreatment with microwaves on oxidative stability and nutraceutical content in rapeseed oil. Food Chemistry, 121(4), doi: 10.1016/J.foodchem.2010.02.006. (2010). P. 1211-1215. https://scholar.google.com/.

- Irfan I., Pavelzik E. The effect of rapeseed treatment with microwave and radiofrequency radiation on oil extraction and its quality. Part II: Impact on oil quality. Fett/Lipid, 101(5), doi: 10.1002/(SICI)1521-4133(199905)101:53.0.CO ;2-M. (1999). pp. 168-171. https://scholar.google.com/.

- Kato H., Kobayashi Y., Kanai G., Iijima U., Takekura K., Tokashi T. Investigation of microwave pretreatment at oil extraction plants: the effect of microwave pretreatment on oil extraction and oil storage in rapeseed. Journal of the Society of Agricultural Structures (Japan), 39(3), doi: 10.11449/sasj1971.39.207. (2008). pp. 207-214.

- . List G. R., Mounts A. S., Lancer A. S., Holloway R. K. Influence of humidity, microwave heating and hot steam treatment on phospholipase D activity in soybeans and soy flakes. Journal of the American Society of Petrochemicals, 67(11), doi: 10.1007/BF02540508. (1990). p. 867-871. https://scholar.google.com/.

- Oberndorfer, C., Lücke, W. The effect of rapeseed treatment by microwave and radiofrequency application on oil extraction and oil quality. Part I: influence on mechanical oil extraction. Fett/Lipid, 101(5), doi: 10.1002/(SICI)1521-4133(199905)101:53.0.CO;2-1. (1999). P. 164-167. https://scholar.google.com/.

- Mizutani, T., Hashimoto, H. Effect of grinding temperature on hydroperoxide and offflavor contents during soymilk manufacturing process. Journal of Food Science, 69(3), doi: 10.1111/j.1365-2621.2004.tb13379.x. (2004). pp. 112-116. https://scholar.google.com/.

- Tripathi, M. K., Mangaraj, S., Kumar, M., Sinha, L. K., Giri, S. K., Ali, N. Effect of processing condition on the quality and beany flavor of soymilk. Current Science, 109(6), doi: 10.18520/v109/i6/1164-1171. (2015). pp. 1164– 1171. https://scholar.google.com/.

- Willkens, W. F., Mattick, L. R., & Hand, D. B. Effect of processing method on oxidative off-flavors of soy milk. Food Technology, 21(12), (1967). P. 86-89. https://scholar.google.com/.

- Linich E.P. Functional nutrition. Textbook. Ed.: Lan. -2017. -p.180. ISBN: 978-5-8114-2553-2. www.litres.ru.

- D. M. C. Champathi Gunathilake, Wijitha Senadeera. Mild Hydrothermal Treatment for Improving Outturn of Basmati Rice. AgriEngineering 2023, 5, p.992–1004. https://doi.org/10.3390/ agriengineering5020062 https://scholar.google.com/.

- Tikhomirova N.A. Technology of functional nutrition products. - M.:Frantera. -2002. -214 p. https://search.rsl.ru/.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).