1. Introduction

The treatment of effluents generated by the petroleum industry poses a number of challenges for treatment, both generally [

1] and by membrane bioreactor (MBR) technology specifically [

2,

3]. Oil refinery effluents comprise an aggregation of a number of different wastewater streams generated by the refining of crude oil (or “crude”) by thermal fractionation to generate useful mineral oil-based products [

3]. These streams significantly differ in their composition, and are discharged at different times over the various refining sub-process cycles, leading to significant temporal variations in the aggregated effluent quality. Partly as a consequence of this, reported refinery effluent composition from different studies vary widely.

Studies of the application/implementation of MBR technology for refinery effluent treatment have tended to appraise biological treatment performance in terms of the removal of COD and oil factions at both bench-scale [

4,

5,

6,

7,

8,

9,

10] and pilot/full-scale [

11,

12,

13,

14]. Most of these studies also provide the membrane flux and/or permeability values, and these appear to vary widely. A recent review of full-scale MBR plants [

3] reported mean operating flux values of 9-15 L.m

-2.h

-1 (LMH) at mean influent COD levels between 150 and 990 mg.L

-1, with no evident correlation between the flux and COD load.

Two key specific and widely-recognized challenges to biological treatment of refinery effluents by MBR technology are:

- (a)

the fluctuation in salt concentration, due to intermittent discharges from the desalter, and

- (b)

the presence of suspended (or “free”) oil and grease (O&G)

Salinity shocks can perturb the microbial ecology in the biotreatment process, causing the release of extracellular polymeric substances (EPS), which are membrane foulants and can also promote foaming. High salinity can further inhibit the essential process biochemistry. O&G can accumulate on the screens and within the biological process tank and increases the hydrophobicity of the mixed liquor, resulting in a significant reduction in the membrane permeability [

6,

8]. Whereas the challenge of fluctuating salinity loads can be addressed by using flow equalisation, O&G must be substantially removed prior to the MBR step – normally through flotation (

Figure 1). Flotation usually comprises both gravity separation, using a simple API (American Petroleum Institute) separator followed by an air or gas-assisted separation process of induced gas or dissolved air flotation (IGF or DAF respectively).

Both published research at bench scale [

4,

5,

6,

7,

8] and performance measurements pertaining to pilot and full-scale plants [

3,

11,

14] have demonstrated reasonably effective removal of O&G by MBR technology. Removals of both O&G and COD have tended to exceed 90% according to bench-scale studies conducted under controlled conditions (

Table 1), but apparently decrease at high salinity levels [

7]. The data in

Table 1 indicates there to be some sensitivity of the fouling propensity to the combination of flux and O&G levels. Fouling appears to be largely mitigated by operation at unrealistically low flux levels, allowing extremely high feed O&G concentrations [

5,

7]. At more practical flux values evidence suggests that the O&G MBR feed concentration must be kept below 100 mg/L [

6,

12].

Notwithstanding correlations produced at bench-scale, influent O&G concentration limits are recommended by the MBR membrane technology suppliers based on operational knowledge and experience. These limits may apply to either the biological stage or the membrane separation stage. At the biological stage threshold concentrations of 50 mg/L and 150 mg/L have been recommended by the suppliers Toray and Microdyn Nadir respectively for fats oils and grease (or FOG), whereas at the subsequent membrane separation stage the suggested limit is considerably more conservative (10 mg/L, according to Microdyn Nadir). Against this, the removal efficiency appears to be fairly robust to changes in organic load, as represented by the COD or BOD concentration, according to bench-scale studies [

4] and data from full-scale refinery and petrochemical plants [

2,

14].

Whilst there have been a few studies establishing the efficacy of MBR technology for providing enhanced biological treatment of refinery effluents, the precise requirements and possible technoeconomic impacts of the pretreatment have been largely overlooked. Studies of gas or air-assisted flotation have tended to focus on the scientific aspects of the process [

15,

16], and those dedicated to refinery effluent treatment have been based predominantly in coagulation optimisation [

17,

18]. Few studies appear to have considered key engineering process facets - such as the cost benefit offered – within the context of refinery effluent treatment. The current study aims to examine such aspects with reference to a full-scale refinery effluent treatment plant (ETP), the specific objectives being to:

establish the treated effluent COD and O&G concentrations attained by the conventional physicochemical, flotation-based ETP,

quantify the energy requirements (as the specific energy consumption, SEC), chemical demand, and capital and operating expenditure (CAPEX and OPEX) associated with the above, and

compare these key parameter values with those projected for downstream treatment by an MBR.

2. Method

2.1. Reference site

The reference site used for the study was the Kawrgosk Oil Refinery, situated 28 km from the city of Erbil in the Kurdistan region of Northern Iraq. The Kawrgosk Effluent Treatment Plant (KETP) process treatment train comprises the classical three-stage process for the physicochemical separation (

Figure 1), with supplementary steps of:

- a)

a preliminary separation step for bulk separation of the suspended oil, and

- b)

an additional neutralisation (pH adjustment) tank fitted between the API unit and the equalisation (EQ) tank.

Residence times have been calculated from the individual unit process dimensions for an assumed flow rate of 75 m

3.h

-1 (

Table 2). The performance of each individual unit process step was assessed through measurement of the COD, O&G and TSS (total suspended solids) concentrations along with the turbidity upstream and downstream of the API separator and DAF. The DAF received a dose of 25-40 mg/L polyaluminium chloride along with polyacrylamide flocculant. 16 sets of samples were taken between March and June 2022. Standard methods [

19] were used for all wastewater quality determinations.

2.2. Cost analysis

The total cost was determined as the net present value (NPV) expressed in terms of the CAPEX and OPEX [

20]:

D being the discount factor (assumed to be 5%) and

n the total plant life (or amortisation period), taken as 30 years.

The normalised CAPEX value (

LC = CAPEX per unit flow rate,

$ per m

3/d) of the MBR was determined using the method of Jalab et al [

21]. These authors captured published CAPEX data (

Table 3) either from specific existing installations [

22,

23] or commercial CAD software [

24], to generate cost curves (

LC as a function of flow capacity

QP). Further economic assessments have been conducted in which the cost of individual components has been collated and the total cost determined through aggregation [

25,

26]. The latter have tended to underestimate the actual cost, since the nominal cost of assembly along with the marginal costs (profit, contingency, etc) are not readily estimated. As with the previous study [

21] the CAPEX information was restricted to the cost of the installed capital equipment, excluding costs specific to the locality of the installation (i.e. civil engineering costs).

The normalised OPEX values (

LO in

$.m

-3) were calculated from energy and consumables consumption. For all pretreatment processes other than the DAF and API the energy costs were assumed to be negligible. Baseline values for chemical consumption and waste generation were provided by the Kawrgosk Oil Refinery owners. Previously published OPEX values for the MBR [

21] were updated for changes in commodity prices, and specifically energy, chemicals and membranes (

Table 4) according to the Chemical Engineering Plant Cost Index (CEPCI), and used to determine the total normalised OPEX in

$/m

3 according to the method of Jalab et al [

21] (

Table 5). Waste disposal costs were excluded, since the cost of arguably the most sustainable option of monoincineration varies considerably [

28]. CAPEX data for the flotation processes were taken from textbook sources [

29].

The total energy consumption for the MBR is the sum of the process biology aeration demand EA,bio, and the energy associated with membrane permeation Em. The latter is the sum of the air scour energy, the energy for sludge recirculation between the membrane and process tank, and the membrane permeation energy. The cost associated with this energy consumption is added to the other non-energy related cost components (membrane replacement, chemicals consumption and waste disposal) to give the total OPEX.

Annualising all scheduled OPEX at a discount factor of 5% over a 30y amortisation period simplifies Equation 1 to:

The above equation was used to compare the total cost incurred by the individual key process steps of the envisaged treatment train, namely the API, DAF and MBR. The operating cost LO for the MBR includes membrane replacement every 8 years.

3. Results and Discussion

3.1. Pretreatment unit process performance

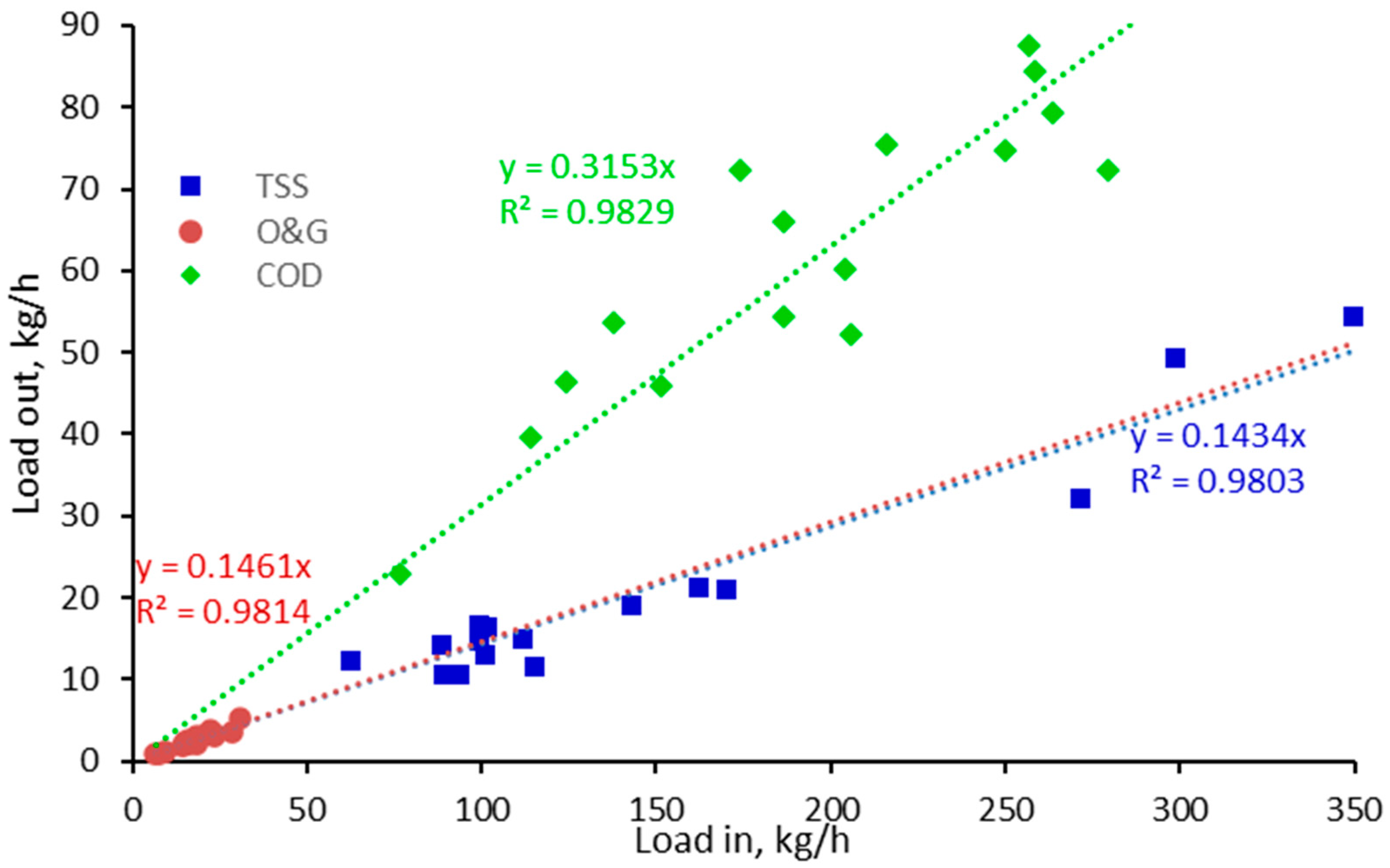

The pollutant load in kg/h to the individual process steps varied as a function of both pollutant concentration and flow rate (55-75 m

3/h). Correlations of the outlet and inlet TSS, O&G and COD loads for the DAF (

Figure 2) revealed a near linear relationship (R

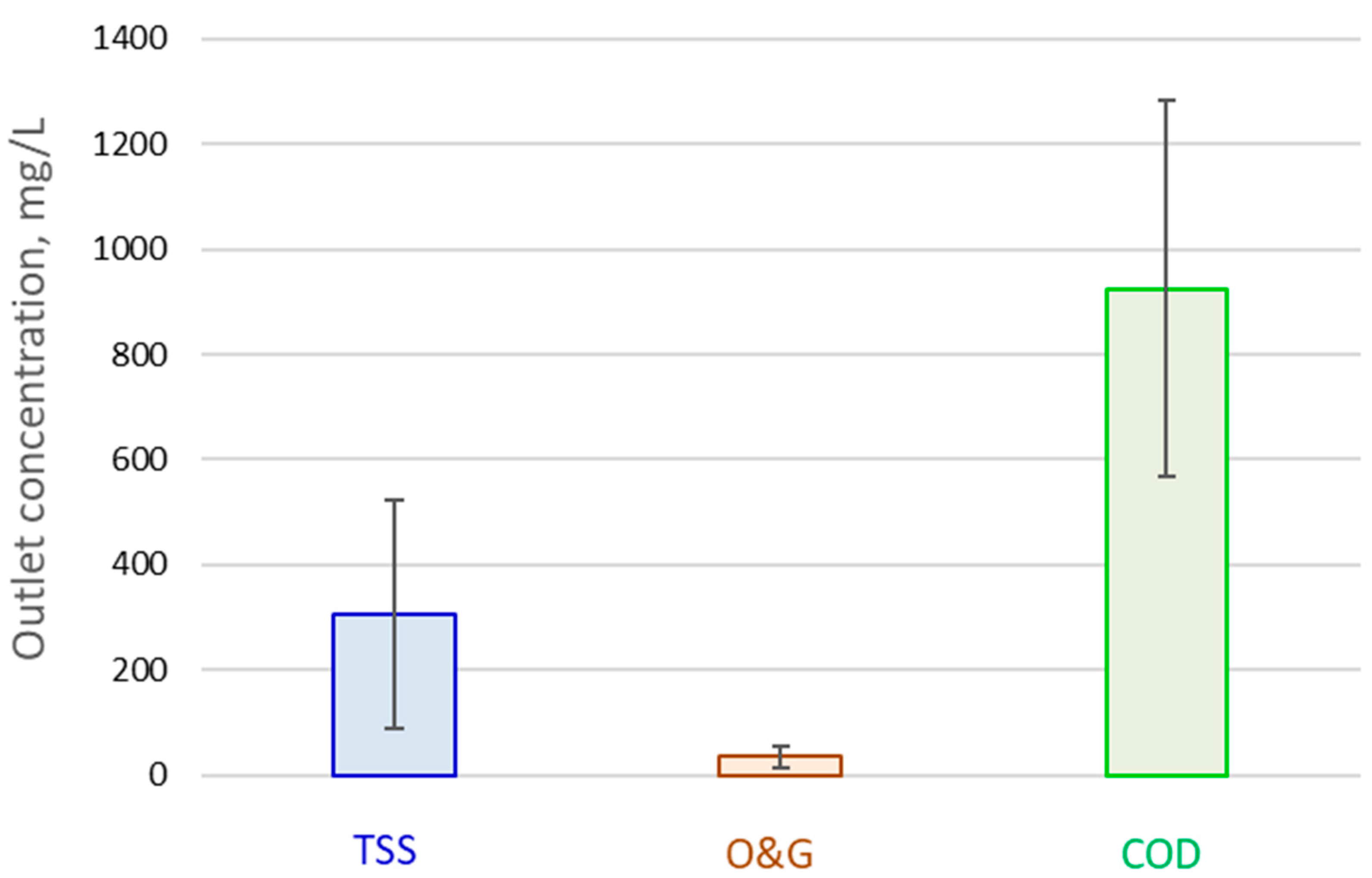

2 = 0.980-0983) for all three parameters, with a lower mean percentage removal for the COD (69%) than for the TSS and O&G (85-86% for both) due presumably to the substantial soluble fraction. The outlet concentrations for these three water quality determinants was thus proportional to the inlet load, and thus subject to a degree of data scatter as indicated by the standard deviation values (

Figure 3).

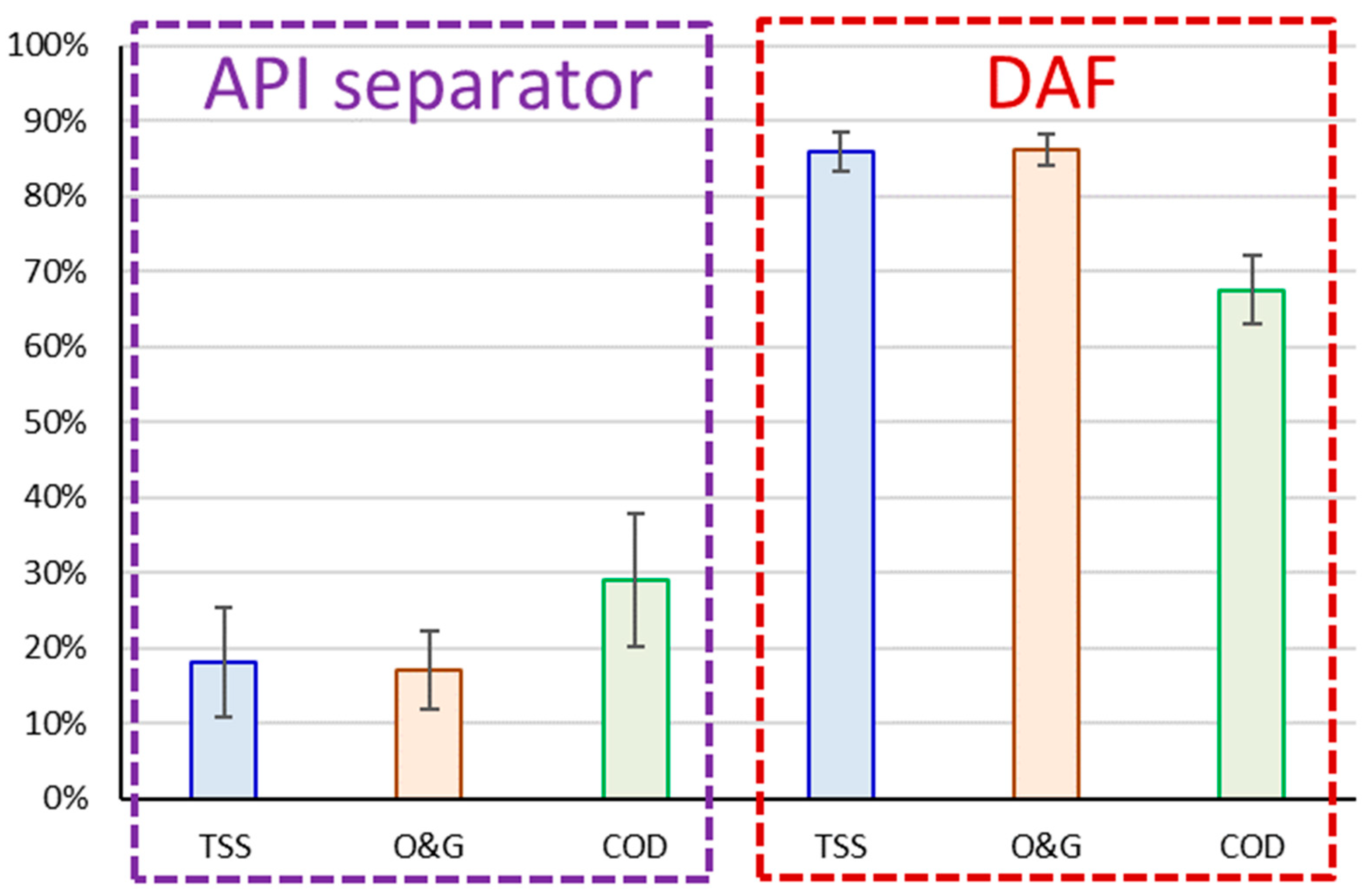

A comparison of the removals attained by the API and DAF stages (

Figure 4) indicate the expected significantly greater % removal of all the pollutants by the DAF than by the API. However, contrary to the DAF trend, the API achieved higher COD than O&G and TSS removal (29% cf. 17-18%), suggesting that the COD removed at that stage was largely associated with the TSS and O&G.

Removals of COD by the DAF were significantly lower than those which have been reported previously for pilot-plant trials on oil refinery effluent. O&G, COD and TSS removals of 92-98% have been reported for a DAF using a 100 mg.L

-1 dose of alum applied under optimal conditions of air saturator pressure and air–water ratio [

17]. However, there is clearly an economic incentive for minimising the required coagulant dose. Much lower COD removals of around 68% - comparable with those values employed in the current study – were obtained at a lower coagulant dose of around 25 mg.L

-1 based on a previous bench-scale test [

18]. The maximum coagulant dose applied in the current study was 40 mg/L.

3.2. Pretreatment unit costs

A consistent basis for comparing the CAPEX of the two physical separation stages is through using textbook information for CAPEX generated on the same basis [

29]. Accordingly, a reference value for the CAPEX is provided for a specific flow rate and a correction exponent used to adjust this CAPEX value for different flows or, in the case of the DAF, surface area,

viz:

where

X refers to flow capacity or surface area. The CAPEX values can then be corrected for 2023 USD using the CEPCI index. The resulting

LC data (

Table 6) indicate that, as expected, the DAF incurs a significantly higher capital cost than the API.

The pretreatment OPEX is largely associated with the energy and chemicals consumption. The low-energy and chemical-free nature of the API separator means that this unit operation contributes little to the OPEX. It is therefore reasonable to limit the pretreatment OPEX evaluation to the DAF.

Based on the upper threshold dose of 40 mg/L alum and a bulk cost of

$350 per ton, the cost of coagulant dosing equates to

$0.014.m-3. The cost of polymer dosing can be conservatively estimated as being similar to this value, giving a total of

$0.028 m

-3 for DAF chemical dosing. The SEC for DAF is widely accepted as being in the range 0.05-0.075 kWh.m

-3 [

30], though lower values in the range 0.035-0.047 kWh.m

-3 have been recently reported [

31] and a mean value of 0.05 kWh.m

-3 determined at a full-scale dairy effluent treatment plant [

32]. For the current study the total installed power of the recirculation pump, compressor, skimmer and mixers was 12.7 kW (

Table 2), equating to an SEC of 0.127 kWh.m

-3 at the maximum flow of 100 m

3.h

-1 specified for the DAF. The absorbed power would therefore always be lower than this threshold value.

An SEC of 0.075 kWh.m-3 infers an absorbed power of around 60% of the installed power and equates to an energy cost of $0.015 m-3 for an assumed tariff of $0.2 kWh-1 - the approximate domestic tariff in the US in 2023. The LO value for the DAF stage is accordingly $0.043 m-3. For an SEC based on the installed power the DAF LO value is $0.053 m-3.

From Equation (2), the NPV for the API and DAF stages is:

where

LO ranges between

$0.043 and

$0.053 m-3. The NPV is thus in the range of

$2.4-2.5m, ignoring labour and waste disposal costs. The mean flow of the waste stream generated is 4.2 m

3/d, constituting ~0.5% of the feed flow at the flow rate of 1800 m

3.d

-1.

3.2. Projected MBR costs

A specific CAPEX curve for a municipal MBR,

LC,MBR in k

$ per m

3.d

-1 has been presented [

21], based on published data sets for municipal wastewater treatment [

22,

23,

24] (

Table 3). According to this analysis,

LC,MBR follows a power law relationship with

QP:

where the coefficient

m = 167 and the exponent

n = -0.462. This yields an

LC,

MBR of

$5.23k per m

3.d

-1 flow rate at the flow capacity

QP of 1800 m

3.d

-1, giving a total CAPEX of

$9.4m in 2019. Allowing for inflation based on the annual CEPCI values, the projected CAPEX for 2023 for a US-located installation would be

$12.3m, hence

LC,

MBR =

$6870 per m3/d, to which the membrane cost contributes ~4.5% based on a specific area cost

LM of

$85 m

-2 and a flux

J of 12 LMH.

The values of the individual specific energy consumption (SEC) and OPEX components were calculated from the governing equations (

Table 5) to give the total energy consumptions associated with the membrane operation and process biology (

Table 7).

The total SEC for the MBR is thus 0.857 kWh.m-3. Based on the assumed energy cost of $0.2 kWh-1, the energy costs for the MBR come to $0.171 m-3. Added to an estimated chemicals cost of $0.02 m-3 the total MBR OPEX is $0.191 m-3.

The NPV of the MBR process, according to Equation 2, is then:

It is germane to consider the performance in terms of the SEC and cost normalised against the COD load removed (

Table 8). This provides a true indication of the value provided by the individual process steps.

Based on these figures, it is evident that:

the DAF removes more than double the COD load of the downstream MBR;

the energy consumption of the pretreatment stages is an order of magnitude less for than for the MBR;

the overall cost, as represented by the NPV, of the pretreatment is around one sixth of that of the MBR step;

the NPV normalised against the COD removed is around 20 times less for the pretreatment than for the MBR.

The higher COD load removed by the DAF compared with the MBR is a consequence of the higher influent concentration of suspended COD for the DAF. This permits efficient removal at a relatively low retention time of ~50 minutes (

Table 2), compared with a projected retention time of around 12 hours for the MBR.

The observations regarding energy consumption and relative COD removed corroborates the conclusions from a recent study of dairy effluent treatment based on a comparable treatment scheme [

32]. The observation regarding the total cost, as represented by the net present value, reflects both the relatively low cost of the API and DAF units compared with the MBR and the high energy consumption and capital cost associated with biochemical degradation of the COD. Given that the latter is roughly proportional to the COD load, optimising the DAF to achieve higher COD removal will almost certainly provide a cost benefit.

However, the DAF incurs a significant chemical demand and generates a waste stream containing the undegraded organic matter and with a relatively high inorganic content compared with the waste stream from the MBR. The cost of managing this waste stream, and the associated end disposal of the waste solids, thus presents a significant component of the overall cost. Arguably the most sustainable widely implemented method for this duty has been mono-incineration, the cost of which varies widely according to different governing factors [

28]. Disposal at the KETP site is currently through landfilling or containerised storage on site – neither of which can be considered sustainable in the long term.

4. Conclusions

Practical measurement of the performance of a representative full-scale pre-treatment scheme for MBR purification of refinery effluent treatment has demonstrated the API-DAF sequence to be extremely cost effective. Around 90 % removal of TSS and O&G is achieved by this sequence, with the O&G reliably removed to levels below 50 mg/L in the treated effluent thereby affording a downstream MBR reasonable protection against membrane fouling. In terms of the COD, the removal is significantly lower (around 75% overall) compared with a projected >90% removal by the MBR. However, the API-DAF specific energy consumption in kWh per m3 effluent treated is almost an order of magnitude lower than for the MBR (0.091 vs 0.86 kWh.m-3), and the total cost (in terms of the net present value, NPV) around one sixth that of the MBR. Moreover, when normalised against the COD removed the pretreatment is fifteen times more energy efficient than the MBR (0.066 vs. 1.03 kWh.kgCOD-1).

The data indicate that investment in the pretreatment steps to optimize COD removal is likely to provide a cost benefit since the energy demanded by aerobic COD removal by the biological process, such as the MBR, is directly proportional to the COD concentration. However, a key variable is the cost of the management and end disposal of the waste solids. There is a clear need to encompass this element in future cost analyses.

Author Contributions

Conceptualization, S.J.J., A.M.R, and K.K.H.D.; funding acquisition, K.K.H.D.; writing—original draft, K.K.H.D.; writing—reviewing and editing, S.J.J., A.M.R and K.K.H.D.; project administration, K.K.H.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the support and advice provided by Mr. Alan Azad Rauof of the KAR Group.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Narayan Thorat, B.; Kumar Sonwani, R. Current technologies and future perspectives for the treatment of complex petroleum refinery wastewater: A review. Biores. Technol. 2022, 355, 127263. [CrossRef]

- Asante-Sackey, D.; Rathilal, S.; Tetteh, E. K.; Armah, E. K. Membrane bioreactors for produced water treatment: A mini-review. Membranes 2022, 12(3), 12030275. [CrossRef]

- Dizayee, K.H.D; Judd, S.J. A brief review of the status of low-pressure membrane technology implementation for petroleum industry effluent treatment. Membranes 2022, 12, 391. [CrossRef]

- Sambusiti, C.; Saadouni, M.; Gauchou, V.; Segues, B.; Ange Leca M.; Baldoni-Andrey, P.; Jacob, M. Influence of HRT reduction on pilot scale flat sheet submerged membrane bioreactor (sMBR) performances for Oil&Gas wastewater treatment. J. Membrane Sci. 2020, 594, 117459. [CrossRef]

- Fulazzaky, M., Setiadi, T., & Fulazzaky, M. A. An evaluation of the oilfield-produced water treatment by the membrane bioreactor. J. Env. Chem. Eng. 2020, 8(5), 104417. [CrossRef]

- Abass, O.K.; Fang, F.; Zhuo, M.; Zhang, K. Integrated interrogation of causes of membrane fouling in a pilot-scale anoxic-oxic membrane bioreactor treating oil refinery wastewater. Sci. Total Environ. 2018, 642, 77-89. [CrossRef]

- Sharghi, E. A.; Bonakdarpour, B.; Roustazade, P.; Amoozegar, M.A.; Rabbani, A.R. The biological treatment of high salinity synthetic oilfield produced water in a submerged membrane bioreactor using a halophilic bacterial consortium. J. Chem. Technol. Biotech. 2013, 88(11), 2016-2026. [CrossRef]

- Brooks, A. Immersed membrane bioreactor for oily water treatment, PhD Thesis, March 2006, Cranfield University.

- Ahmadi, M.; Benis, K.Z.; Faraji, M.; Shakerkhatibi, M.; Aliashrafi, A. Process performance and multi-kinetic modeling of a membrane bioreactor treating actual oil refinery wastewater. J. Water Process Eng. 2019, 28, 115–122. [CrossRef]

- Alsalhy Q. F.; Almukhtar, R. S.; & Alani, H. A. Oil refinery wastewater treatment by using membrane bioreactor (MBR). Arab. J. for Sci. Eng. 2016, 41(7), 2439-2452. [CrossRef]

- Cerqueira, A.C.; Lopes, T.; Santiago, V.; Vallero, M.; Trovati, J.; Arntsen, B.; Syed, W. Design and Performance of the First Full Scale Membrane Bioreactor Plant Treating Oil Refinery Effluent in Brazil. Proc. Water Environ. Fed. WEFTEC 2013, 3573–3584. [CrossRef]

- Bigham, J.; Kosic, A.; Arntsen, B.; Penny, J.; Katz, S. Upgrading refinery wastewater treatment with MBR to new discharge standards at marathon petroleum’s Detroit refinery. Paper presented at the Water Environment Federation Technical Exhibition and Conference 2017, WEFTEC 2017, 8, 5543-5554.

- Cunningham, W.; Felch, C.; Smith, D.; & Vollstedt, T. Ecoright™ MBR pilot study investigating treatability of a saudi aramco refinery wastewater. Paper presented at the 86th Annual Water Environment Federation Technical Exhibition and Conference 2013, WEFTEC 2013, 6, 3537-3557. [CrossRef]

- Judd, S.J. Industrial MBRs: Membrane Bioreactors for Industrial Wastewater Treatment 2014. IWA Publishing: Lon, UK.

- Edzwald, J. K. Dissolved air flotation and me. Water Res. 2010, 44(7), 2077-2106. [CrossRef]

- Rajapakse, N.; Zargar, M.; Sen, T., Khiadani, M. Effects of influent physicochemical characteristics on air dissolution, bubble size and rise velocity in dissolved air flotation: A review. Sep. Purif. Technol. 2022, 289, 120772. [CrossRef]

- Tetteh, E. K.; Rathilal, S. Evaluating pre- and post-coagulation configuration of dissolved air flotation using response surface methodology. Processes 2020, 8(4), 383. [CrossRef]

- Vasseghian, Y. Modeling and optimization of oil refinery wastewater chemical oxygen demand removal in dissolved air flotation system by response surface methodology. Adv. Environ. Technol. 2015, 1(3), 129-135. [CrossRef]

- APHA (2017). Standard Methods for the Examination of Water and Wastewater (23rd ed.). Washington DC: American Public Health Association.

- Verrecht, B.; Maere, T.; Nopens, I.; Brepols, C.; Judd, S. The cost of a large-scale hollow fibre MBR. Water Res. 2010, 44, 5274–5283. [CrossRef]

- Jalab, R.; Awad, A.; Nasser, M.; Miner-Matar, J.; Adham, S.; Judd, S. An empirical determination of the whole-life cost of FO-based open-loop wastewater reclamation technologies. Water Res. 2019, 163, 114879. [CrossRef]

- Itokawa, H.; Tsuji, K.; Yamashita, K.; Hashimoto, T. Design and operating experiences of full-scale municipal membrane bioreactors in Japan. Water Sci. Technol. 2014, 69, 1088–1093. http://dx.doi.org/10.2166/wst.2014.020.

- Iglesias, R.; Simón, P.; Moragas, L.; Arce, A.; Rodriguez-Roda, I. Cost comparison of full-scale water reclamation technologies with an emphasis on membrane bioreactors. Water Sci. Technol. 2017, 75, 2562–2570. http://dx.doi.org/10.2166/wst.2017.132.

- Cashman, S.; Mosely, J. Life Cycle Assessment and Cost Analysis of Water and Wastewater Treatment Options for Sustainability: Influence of Scale on Membrane Bioreactor Systems. USEPA report, 2016, EPA/600/R-16/243, December 2016.

- Fletcher, H.; Mackley, T.; Judd, S. The cost of a package plant membrane bioreactor. Water Res. 2007, 41(12), 2627-2635. [CrossRef]

- Lo, C. H.; McAdam, E.; Judd, S. The cost of a small membrane bioreactor. Water Sci. Technol. 2015, 72(10), 1739-1746. [CrossRef]

- Gao, T.; Xiao, K.; Zhang, J.; Xue, W.; Wei, C.; Zhang, X.; Liang, S.; Wang, X.; Huang, X. Techno-economic characteristics of wastewater treatment plants retrofitted from the conventional activated sludge process to the membrane bioreactor process. F. Environ. Sci. Engng. 2022, 16(4), 49. https://journal.hep.com.cn/fese/EN/10.1007/s11783-021-1483-6.

- Capodaglio, A. G., Olsson, G. Energy issues in sustainable urban wastewater management: Use, demand reduction and recovery in the urban water cycle. Sustainability 2020, 12(1), 12010266. [CrossRef]

- Woods, D. R. Rules of thumb in engineering practice 2007. App. B: Capital Costs Guidelines, 376-436, Wiley. https://onlinelibrary.wiley.com/doi/book/10.1002/9783527611119.

- Brandt, M. J.; Johnson, K. M.; Elphinston, A. J.; Ratnayaka, D. D. Twort’s water supply: 7th edition. 2017, Butterworth-Heinemann: Oxford, UK.

- Cha, G.; Choi, S.; Lee, H.; Kim, K.; Ahn, S.; Hong, S.K. Improving energy efficiency of pretreatment for seawater desalination during algal blooms using a novel meshed tube filtration process. Desalination 2020, 486, 114477. [CrossRef]

- Żyłka, R.; Karolinczak, B.; Dąbrowski, W. Structure and indicators of electric energy consumption in dairy wastewater treatment plant. Sci. Total Environ. 2021, 782, 146599. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).