Highlights

Identified controllable process variables (CPV)

Subdivided CPV into tiers according to importance for specific molding process

Developed process window based on surface quality performance measures

Refined process window including mechanical properties

Utilized simulation to justify a less desirable region of process window

1. Introduction

Injection molding is a manufacturing process for plastic parts, that can be found in almost any industry, whether it be electronics, healthcare, consumer goods, or automotive. The global plastic injection molding market is expected to reach over 266 billion dollars by 2030 [

1]. The goal of Injection Molding, like any other manufacturing process, is to produce parts or products efficiently and effectively. Several factors involved in this process can significantly affect the resulting products. One such way to increase the performance of the injection molding process is to construct an operating envelope in which key controllable factors, or variables, have been delimited to produce acceptable values of the relevant performance measures of the specific injection molding process [

2,

3,

4,

5,

6]. This operating envelope is commonly called a process window. This paper focuses on developing a method based on experiments by which an injection molding process window can be constructed.

The following steps were followed to develop the process window.

Identify and establish key Controllable Process Variables (CPV) for the process, including material attributes, machine settings, and mold/part conditions.

Identify the relevant performance measures for the specific process such as part quality indicators and mechanical property values.

Develop a process window to delimit the controllable process variables such as packing time, injection speed, mold temperature, melt temperature, and packing pressure.

Supplement the experimental results, via simulation, to explain a condition that could arrive when a less desirable location in the process window has to be selected. The software utilized in this study was Moldex3D.

These steps are the basis of the methodology developed and each of them is discussed in detail in the following sections.

Each stage of the injection molding process critically influences the performance measures for the final product. It is desired to identify a region where the relevant controllable process variables within these stages, have a range or envelope of operation in which acceptable parts are produced. This is the so-called process window. This research focuses on developing an industrially relevant organized approach to define this acceptable range or process window. This window’s exact shape and size will depend not only on the part to be molded but also on the machine and the quality of the mold used.

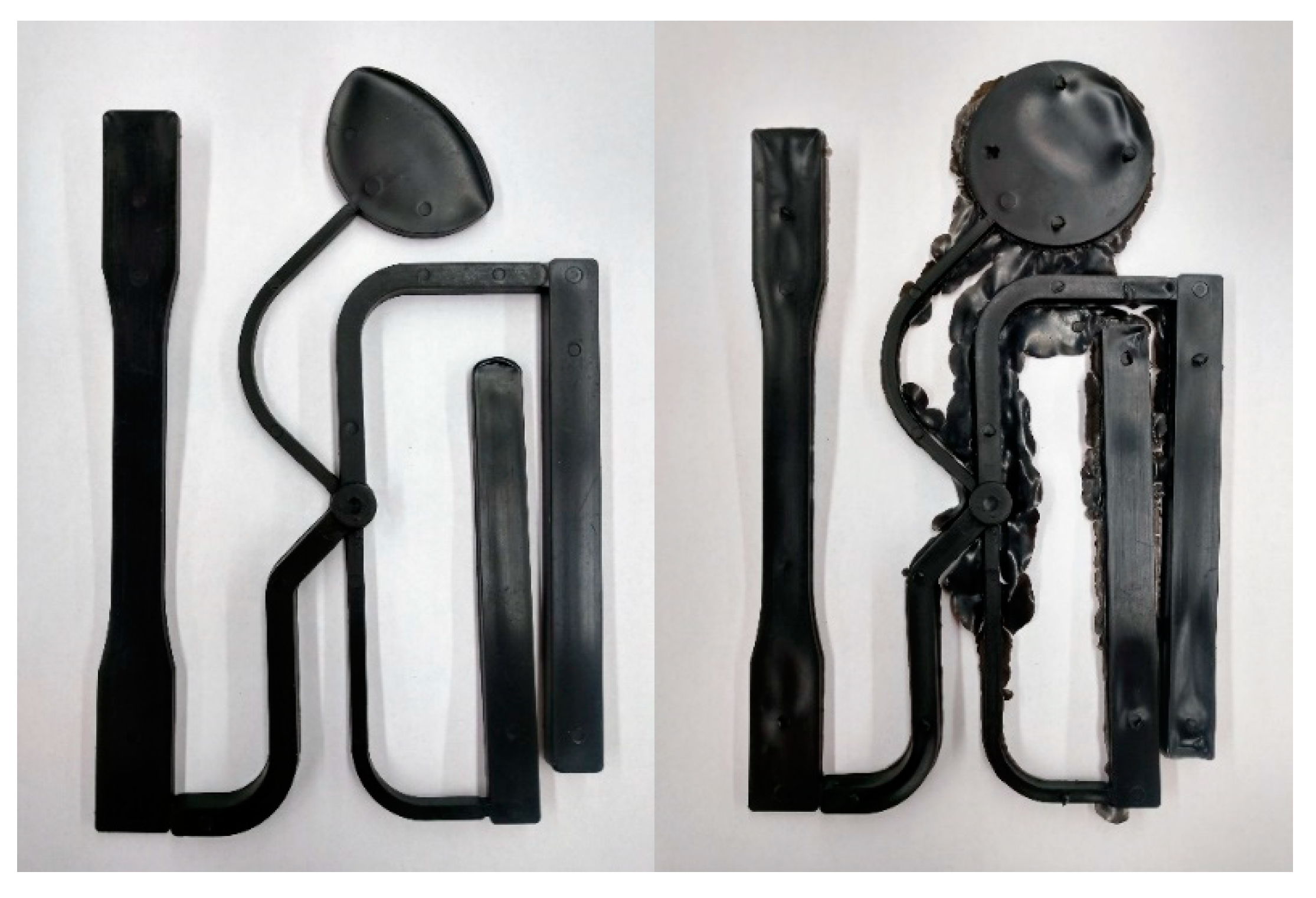

The machine used throughout this research was a Sumitomo 180-ton Injection molding Machine (SG180M-HP). The cavity of the mold used in this study produced the parts utilized for measuring mechanical properties as indicated by the American Society for Testing Materials (ASTM). The mold material was tool steel with several cooling lines running throughout both halves of the mold. When ejected from the mold, a sprue and cold runner system connects the 4 test samples utilized for mechanical testing, as shown in

Figure 1.

The 4 test samples produced include a tensile bar, two flexural bars with differing thicknesses of 3 mm and 6 mm, and a disk with a diameter of 50 mm. These samples can be used to conduct a variety of tests including tensile testing, 3-point bending, and impact testing such as the Izod or Dupont tests. The material used in this work was polypropylene, produced by Advanced Composites. The application of this material in industry was for automotive body panels.

When operating an injection molding machine, several settings must be selected to produce parts successfully. The definition of a “successful” part depends on the desired performance measures for the specific molding operation and will be outlined later, before the development of the final process windows. The settings that will be discussed here are those of most importance to the overall process and are used as the controllable variables of the process window to be developed. These key variables are melt temperature, mold temperature, injection screw speed, packing pressure, packing/cooling time, clamping force, and shot size. These variables are important in any injection molding operation. This research found it convenient and beneficial to separate these variables into tiers to help streamline and focus the development of the process window.

Table 1 below presents this concept.

The Primary Control Variables of mold temperature, melt temperature, and packing pressure were deemed most important for this molding operation as they would be the variables used to construct the boundaries of the process window.

The control variables of melt and mold temperature, and their effects on the resulting part and operation, closely interact with each other. The melt temperature must be high enough to allow the material to fill the mold completely, whereas the mold temperature can be adjusted to benefit cycle time, however, it will most likely affect the properties of the final part. Simply put, a balance must be achieved to produce parts effectively and efficiently. The last primary variable is packing pressure. This pressure ensures the mold cavity is fully filled and reduces thermal shrinkage as the material cools in the mold. It is important to note that the packing pressure values reported in this work are not the pressure on the polymer inside the mold cavity, but the pressure setting entered into the machine. When measured with sensors, the corresponding pressure inside the cavity is higher than the value displayed on the machine. For example, a machine packing pressure of 2.07 MPa corresponds to a cavity pressure of about 41.37 MPa [

7]. The approximate multiplier to calculate part pressure from machine pressure is twenty [

7].

Due to the effects of these 3 primary variables on the overall injection molding process and part quality, understanding their relationship is critical to delimiting a process window to produce acceptable, defect-free parts. Concerning the secondary control variables of injection screw speed and packing/cooling time, it will be seen in the experimental section that the values chosen for these variables can have serious implications on the resulting part and were analyzed before the primary control variables were studied. However, after these variables were delimited, specific settings or values were selected and kept constant throughout the process window development. Lastly, the tertiary control variables are those that can affect a particular molding operation but are easier to establish. The clamping force must be large enough to hold the two mold halves together but not too high to damage them. The shot size is determined by the volume of the molded part. These tertiary control variables required little analysis and were held at the same settings for the entirety of the process window development.

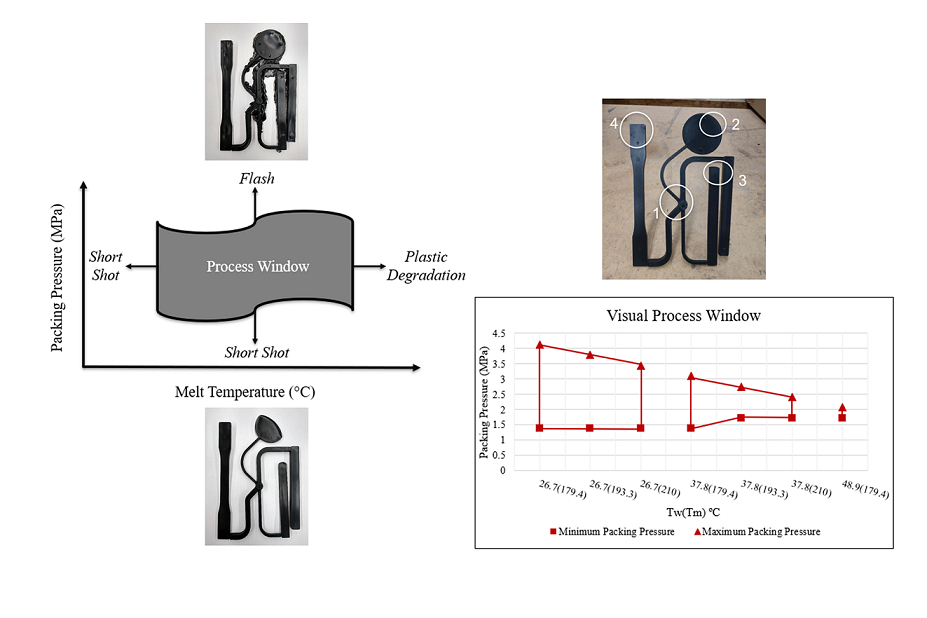

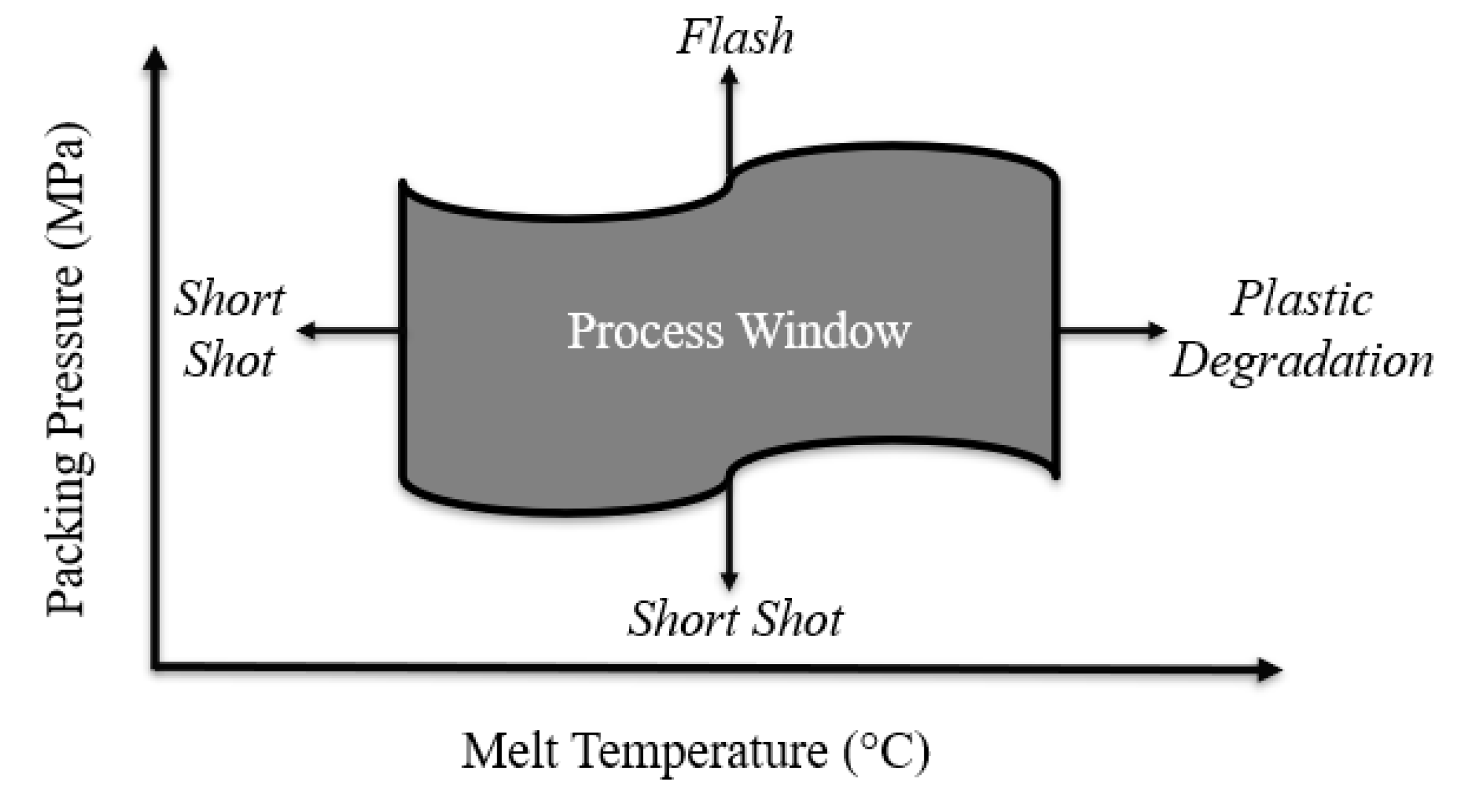

As the focus of this research was to develop a method to establish a process window to produce thermoplastic injection molded parts, it is necessary to understand the concept of such a window. A process window is a region that delimits the controllable process variables so that inside the boundaries of this region or window-like shape, acceptable parts, that is parts that comply with the desired performance measures, can be molded. Operating outside of the process window will produce molded parts that are unacceptable due to defects, such as flash, sink marks, and short shot. Examples of such defects are shown in the images below [

9].

Figure 3 below visually illustrates a process window that considers the controllable process variables of melt temperature and packing pressure.

When the selected values of the controllable process variables are near the center of the defined window, the part quality will be less influenced by undesired variations on the process variables due to unforeseen conditions likely caused by the molding environment. Therefore, the use of a process window in injection molding promotes a stable and more predictable manufacturing process [

8]. Although a particular process window will vary from one production setting to another, the method in which these windows can be found has the same steps and considerations. A method that can be used for constructing such a window will be presented throughout.

2. Experimental

The first step in developing an injection molding process window is to identify, define, and determine base values of the controllable process variables. Because the manufacturing of parts via injection molding is a complex problem, where each Controllable Process Variable (CPV) can have an impact on the resulting part, it is best to simplify and determine which variables will be changed and which will remain constant based on the goals of the process window being developed, which is the reason we divided them in primary, secondary and tertiary. It is best to only consider settings critical to the specific molding operation, as too many variables will greatly complicate the development method. We will discuss what CPVs were identified, how their values were found, and if they were kept as constants or varied as part of the process window.

Several values or ranges of the CPV can be defined based on known information about the specific molding material, mold, and injection molding machine as these factors will not change throughout the development process.

Table 2 provides the reference for each of these variables and lists their selected ranges or values.

Other variables can also be delimited but take more analysis to properly determine their values with respect to the specific operation. These variables are listed below and will be defined and discussed in more detail.

The CPV of mold closed time, injection screw speed, preliminary packing pressure, and packing/cooling time require further analysis to determine their respective values. These variables will likely have the most variation from one injection molding operation to another. Therefore, to determine the best settings for these variables, specific analysis must be conducted to isolate the influence of each variable and to determine its value regarding the unique molding operation. The values found by this analysis will be different from one operation to another, however, the method in which they are found will be similar. Although most of these values are later treated as constants in the development of the process window, to find their best values, they were each treated as independent variables during their specific analysis step. Discussion on how each of these variables is defined and the method used to determine their values is presented.

The table below presents the various settings that each of the CPV were set to during this analysis stage [

9].

To delimit the value needed for mold closed time, that is the time needed for the part to become solid enough so that it can be demolded without any blemishes. This value will later be subdivided between packing time and cooling time. Once the packing pressure does not affect the part quality the part is kept in the mold without a packing pressure that way the screw can start retracting for the next cycle and the mold stresses are minimized. The approach we recommend and is used in our group [

2,

9] is to start by calculating the conduction time (

), that is:

Where part thickness is the largest thickness of the part to be molded. This time is a naturally occurring time when making the heat conduction equation dimensionless and represents the time needed for the temperature in the center of the part to be such that its value minus the mold temperature becomes 10% of the maximum temperature difference (melt temperature minus mold temperature) if one assumes one directional heat transfer and constant mold wall temperature. We suggest and have used both in our lab and in our interactions with industry as an initial value, in general, a conservative number, that can be then decreased using experiments. For our case, we kept the calculated value as the mold closed time.

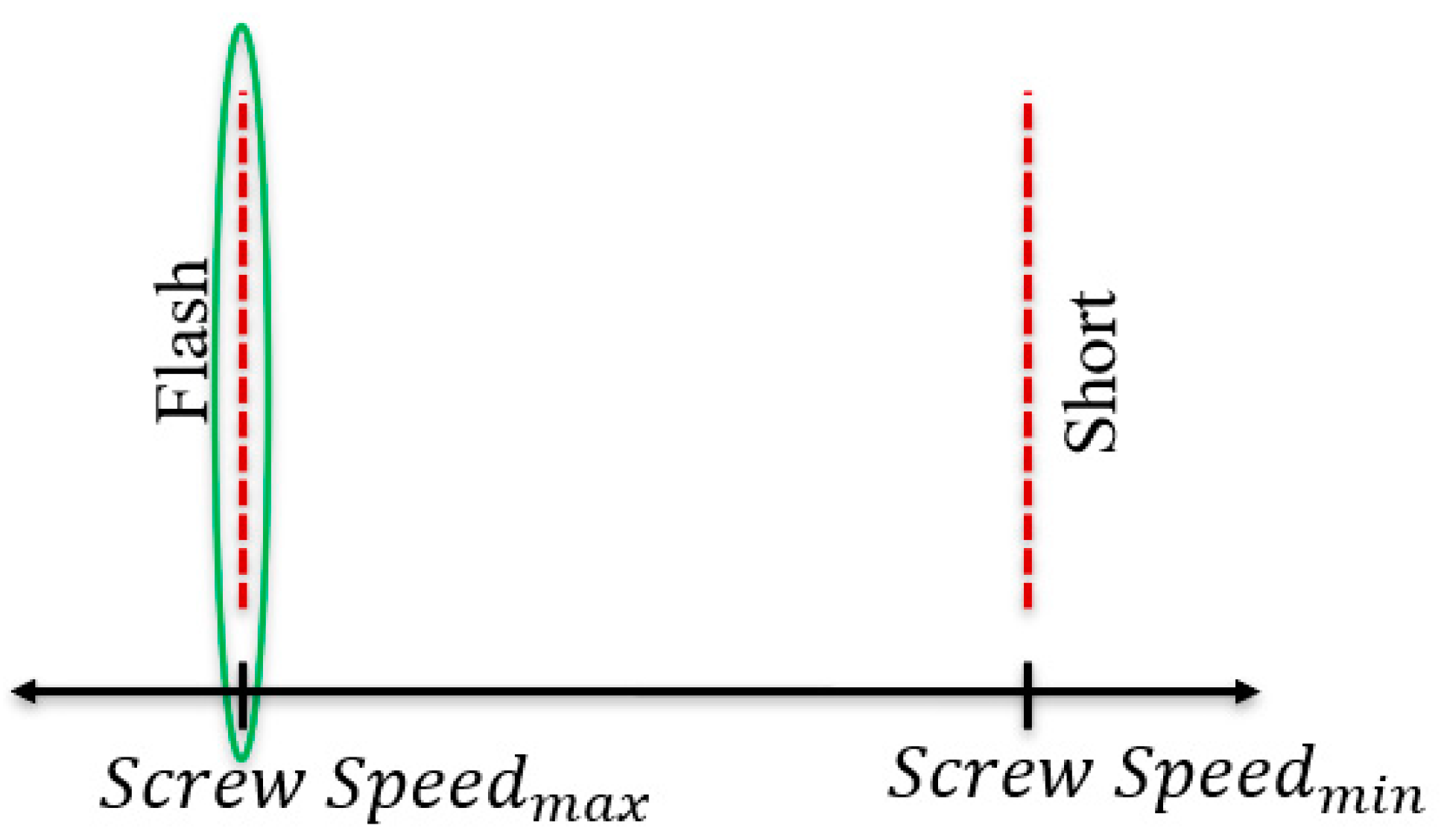

The injection screw speed of an injection molding machine is the speed at which the screw or plunger moves during the injection stage. Correctly determining the value of this setting is important as injecting too fast will cause flash but injecting too slow will cause the melt front to solidify before the part is completely filled, also known as short shot. The goal of this analysis was to find a maximum injection speed before flashing occurs to reduce the total cycle time but also produce an acceptable part. This concept is represented and discussed below.

Again, the goal of these experiments was to find the injection screw speed just on the boundary before flashing occurs. With regards to this research, it was unnecessary to explore the righthand side of the spectrum as injecting the material slowly into the mold has no real benefit and would slow cycle times. However, slower injection time may in some cases, produce better results such as surface finish, and therefore should be explored if applicable [

10].

Several iterations were conducted to establish the proper setting for injection screw speed. To focus on the injection of the material and the screw speed, values associated with packing were minimized by selecting a very low packing pressure of 10 psi (0.07 MPa) and allocating zero seconds of the calculated conduction time to packing (entire 52 seconds was set to cooling). Our group has found that using a cushion position that is ten percent of the total shot size (0.210 inches (53.34mm)) is good practice. Using the settings above, molded parts were produced and visually analyzed. Screw speeds ranging from 0.2 in/s to 10 in/s (5.1 – 254 mm/s) were tested as shown in

Table 4 above.

After the completion of these trials, a visual inspection [

9] of the parts was conducted to determine the best value for this setting. It was found that at a speed less than or equal to 2.0 in/s (50.8 mm/s) the mold would be filled without flash. The setting of injection screw speed was thus established at this constant value during the process window development trials and considered as a secondary control variable.

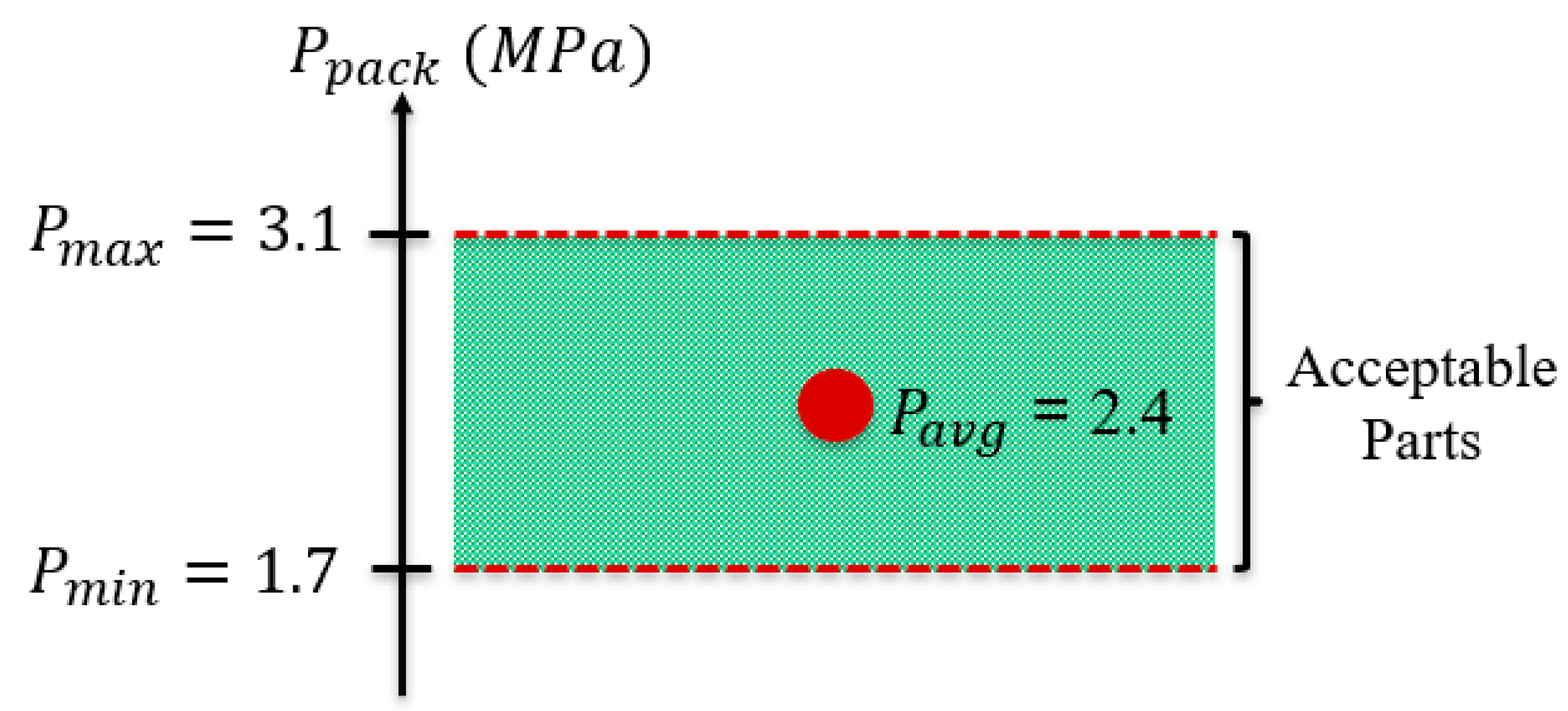

Although packing pressure will be used as a primary CPV during the development of the process window itself, it is necessary to find a “preliminary” setting for this CPV to select values for the other settings. The procedure to delimit this initial packing pressure was to run injection molding trials and vary the packing pressure. By doing so, a preliminary process window related to packing pressure is found in which an acceptable maximum (

) and acceptable minimum (

) packing pressure are found. Pressures outside this window would either cause the part to flash or produce a short shot [

9]. From this process window, an average of

and

was calculated. This

will be the value used as the preliminary packing pressure in the remaining analysis trials. The experiments and analysis conducted to preliminarily delimit the packing pressure are as follows.

To delimit and isolate the packing pressure, several of the other molding variables were set to specific values. For example, the melt temperature was set to the middle value of the range provided by the material supplier. With regard to time, the overall mold closing time was kept equal to the calculated conduction time of 52 seconds. At this stage, this entire length of time was allocated to packing time (

), and the cooling time (

) was set to zero, again shown in

Table 4 above. During this analysis, samples were produced with packing pressures ranging from 100 psi to 750 psi (0.69 – 5.17 MPa). Each part produced was then analyzed to find defects and determine the

and

of the preliminary packing pressure window. To find this range a combination of visual inspection and measurements was utilized.

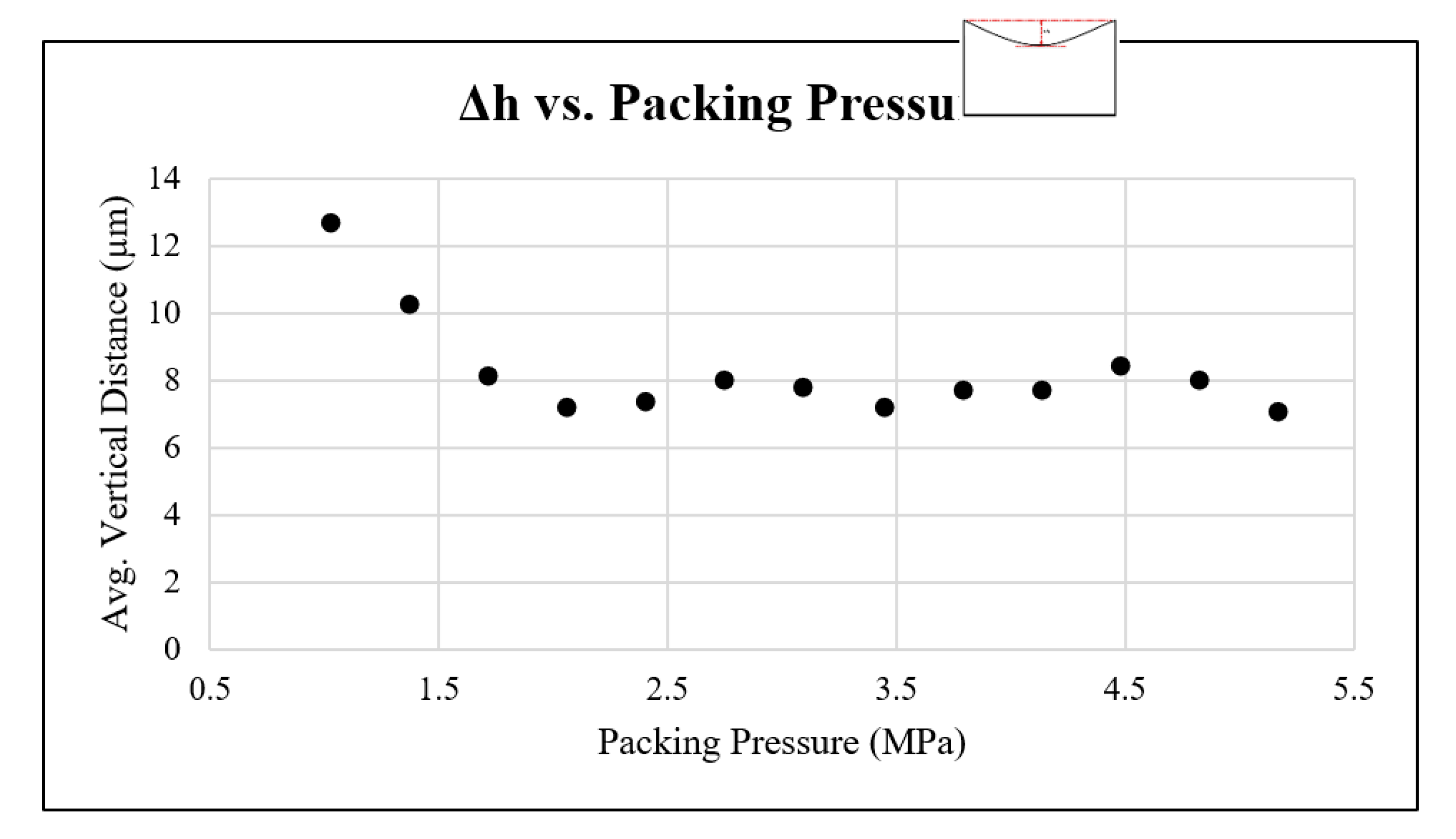

To determine the minimum boundary both visual inspection for defects and the measurement of the surfacing profile of the molded parts using a profilometer were utilized. The results of these measurements are shown in the figure below.

Figure 5.

Average vertical distance versus packing pressure measured by profilometer.

Figure 5.

Average vertical distance versus packing pressure measured by profilometer.

As can be seen from the above figure, as packing pressure is increased the vertical distance from the highest outside edge of the measured piece to the lowest middle point becomes stable. From these measurements it can be seen that 1.7 MPa is the initial packing pressure value where the surface profile begins to level out, indicating the part is completely filled. Additionally, visually inspecting the molded parts found that all corners and end pieces were completely filled, and no sink marks were seen, beginning at this value. Therefore, a minimum packing pressure of 1.7 MPa was determined.

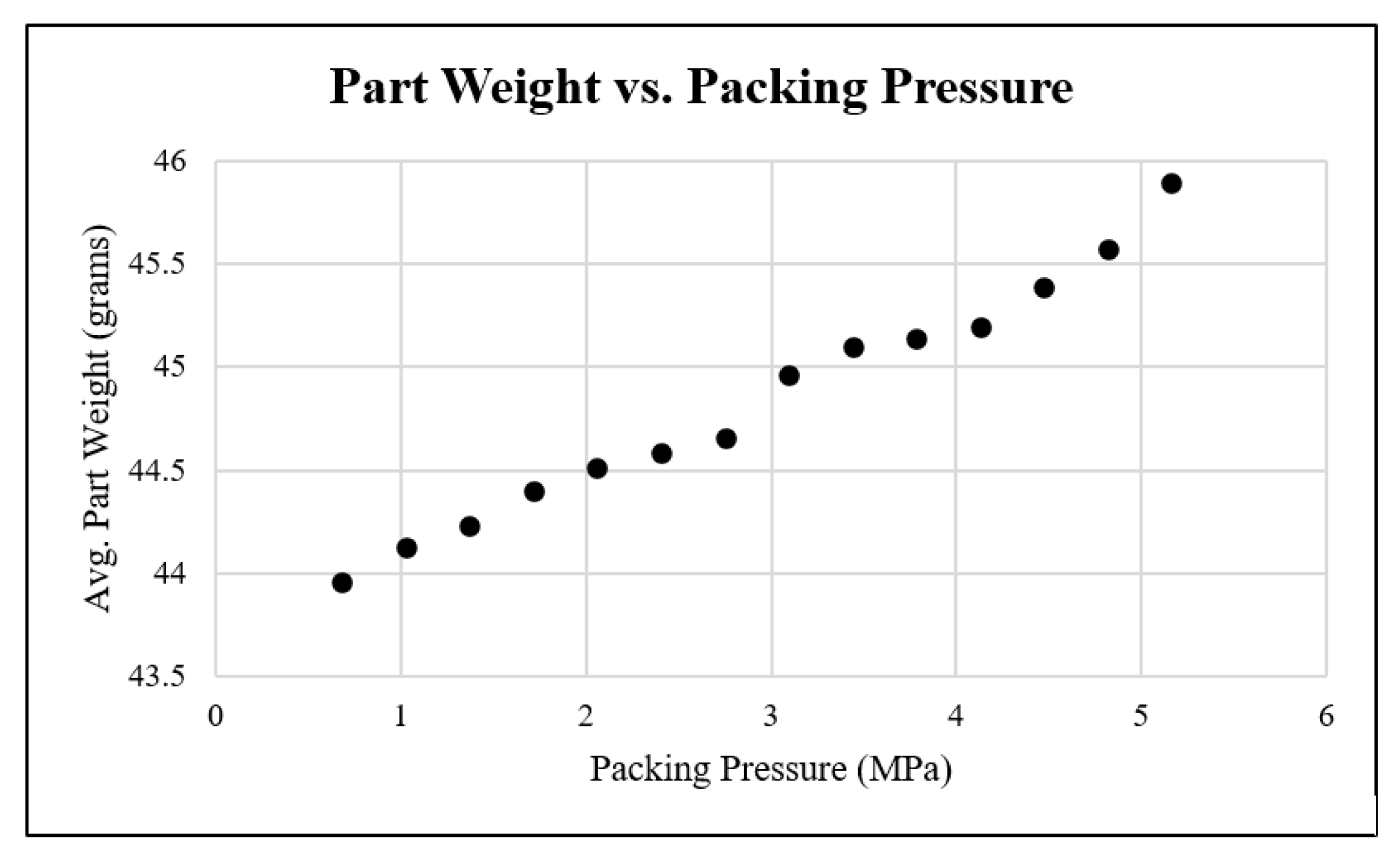

To determine the maximum limit for the preliminary packing pressure, several other measurements were utilized. One such measurement was the total part weights. These results are shown in the figure below.

Looking at

Figure 6, which displays the total weights of the mold part in grams, it can be seen that from about 2.76 to 3.79 MPa there is an increasing trend in the weights of the molded parts. This was taken as an indication that the flash being seen was becoming more significant and therefore unacceptable. It was also observed that as the packing pressure was increased the final cushion position of the injection screw significantly changed. At around 2.76 MPa a large drop-off from the machine setting of 0.210 inches (5.33 mm) was seen. This indicates that the screw was going well past its desired final position and pushing extra material into the mold causing significant flash when higher packing pressures were introduced. Combining these results along with visual inspection a maximum value of 3.1 MPa was determined.

From the above analysis, the resulting process window shown in

Figure 7 was developed.

From these findings, an average packing pressure of 2.4 MPa was calculated. This was used in the additional trials to determine the values of the remaining non-primary controllable variables. Once these values have been established, packing pressure will be treated as a primary controllable process variable during the development of the final process window.

The calculated conduction time of 52 seconds is subdivided into packing time and cooling time. Determining the ratio between these two periods is important, since after the point when the packing pressure has no effect, is desirable to switch from packing to just cooling so the screw can start retracting, as well as to avoid unnecessary stresses on the mold. The process undertaken to delimit this ratio, its justification, and the resulting times are as discussed below.

First, a range of ratios between

and

was selected with respect to the total conduction time. At each of these ratios and the settings shown in

Table 4, injection molded samples were collected, inspected, and measured.

Utilizing both the measurement of part weight and surface profile via profilometer [

9] it was found that the packing-to-cooling time ratio must be greater than 20 to 80, or 10.4 seconds and 41.6 seconds, respectively. To support the results from part weight and shrinkage measurements [

9], tensile testing of the parts was conducted. For each of the six-time ratios, tensile testing was completed. These results are presented in

Table 5 below.

With a combination of part weights, surface profile, and tensile test, the ratio can be delimited. As stated, the results of the weights and profilometer indicated that the use of ratios less than 20:80 is not desirable [

9], and this is supported by the tensile test results. The ratio of one hundred percent packing time and zero percent cooling is also not acceptable as it does not allow the screw to start retracting early enough to prepare material for the next cycle. Thus, slowing production. Additionally, by completing a conduction time analysis on the part’s cylindrical sprue it was found that packing for more than approximately 45 seconds will not be beneficial as a large percent of the sprue cross-section, or entry into the mold will have solidified.

Combining all the experimental evidence, it was determined that the best packing time to cooling time ratio is 40 to 60 percent respectively as shown in

Table 6. This conclusion was reached based on several factors. Firstly, the samples produced under this ratio visually appeared the best. The weight and profilometer measurements also supported this ratio as the samples were shown to be completely filled. Additionally, this ratio produced the best mechanical properties, with the highest tensile stress at yield and break, along with increased ductility (tensile strain at break).

These secondary settings would remain constant throughout the development of the process window discussed in the remaining sections.

3. Results and Discussion

With the secondary and tertiary process variables established, we can proceed to develop the process window. As previously stated, mold temperature, melt temperature, and packing pressure are the primary CPV that will define the boundaries of the process window. The table below summarizes all the controllable variables and their values as found previously.

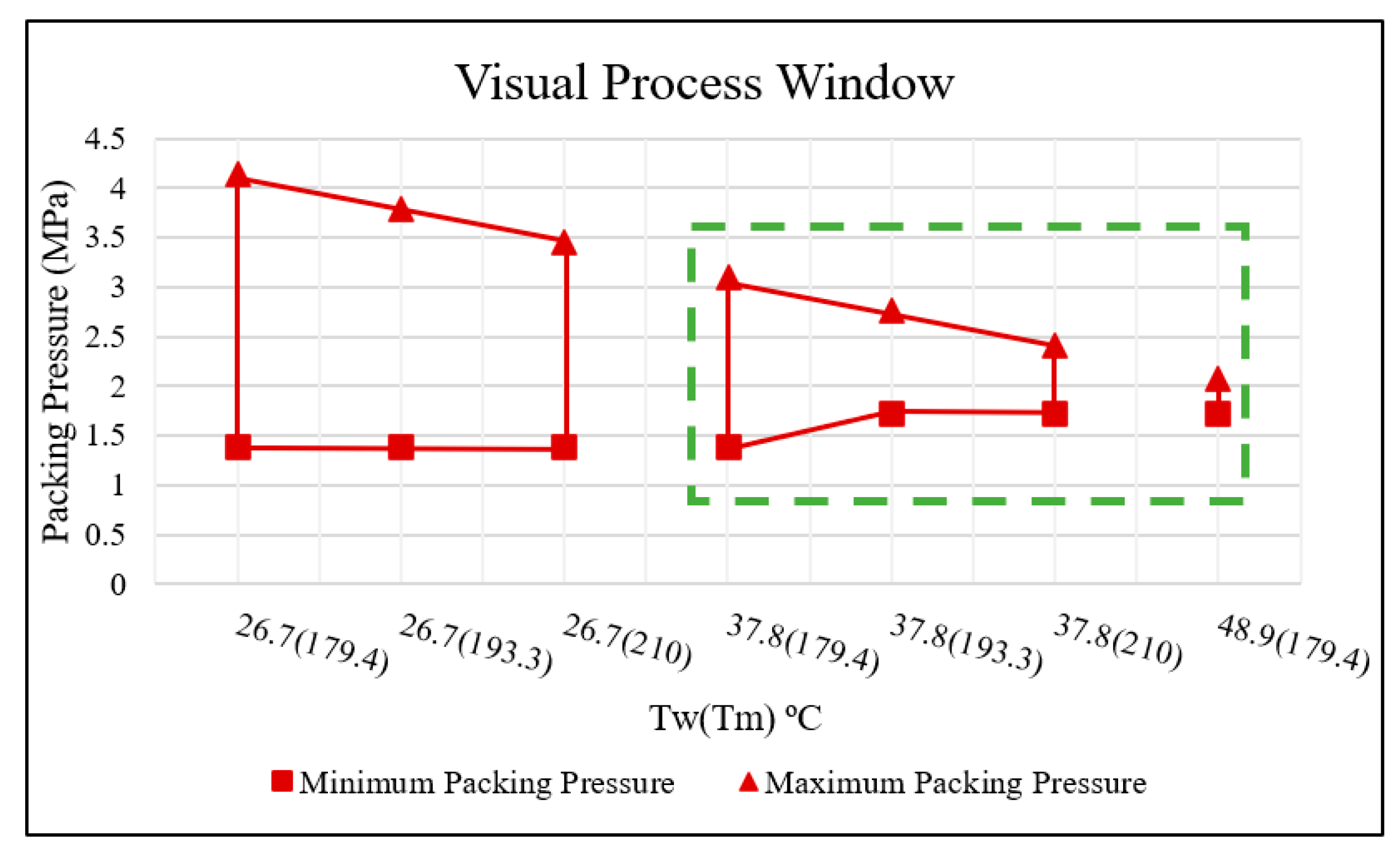

As the primary CPV will define the boundaries of the process window, their effect on the performance measures is evaluated next. A full factorial for both temperatures at three levels was conducted. Ten samples at each setting were collected. The values of the melt temperature used are 179.4, 193.3, and 210 °C. The values for the mold temperatures are 26.7, 37.8, and 48.9 °C. Packing pressure was varied at each temperature combination until a minimum and maximum value was found for each. Nine unique temperature combinations were tested all with various levels of packing pressure. To thoroughly construct the process window, a total of more than 750 parts were modeled and analyzed. The first window that was developed was a window based on visual inspection.

Quality standards [

9] are established in order to define what constitutes an acceptable part. These standards will likely vary on a case-by-case basis, but they must be defined to keep the process repeatable and measurable. In the case of this research, visual quality standards were developed to focus on key areas or zones of the part being produced.

Figure 8 below highlights these areas.

Within each of the respective locations of the part, a visual inspection for defects was conducted looking for such things as flash and sink marks. As depicted in the image above zones 2, 3, and 4 were inspected for complete fill and lack of shrinkage in corners and edges. Additionally, zones 1 and 3 were inspected for significant flashing. With these quality standards defined, they were used to analyze parts produced at various packing pressures and temperatures. If the quality standards defined were not met by particular molded samples, then the associated molding condition was deemed unacceptable. From this analysis, the boundaries or minimum and maximum acceptable packing pressure for each of the 9 temperature combinations was found, therefore, producing a visual process window.

The resulting visual process window was developed by utilizing the defined quality standards and inspecting the molded parts produced [

9]. Based on the standards, a minimum and maximum packing pressure value for each temperature combination, mold temperature and melt temperature, were found. The visual process window is produced by overlaying these ranges onto a single plot.

Figure 9 below represents the visual process window of this particular molding process.

Several features of this resulting process window must be discussed, along with a justification of the resulting window based on fundamental principles. Firstly, it may be noted that only 7 temperature combinations are included within the developed window when 9 such combinations were molded. This occurred because no parts produced above the mold and melt temperature settings of 48.9 °F and 179.4 °C were found to be acceptable based on the quality standards. Because these molded parts were found to be visually defective, they were also filtered out or eliminated from the later mechanical property analysis.

In terms of fundamentals, the resulting visual process window is justified. The steady decrease in acceptable maximum packing pressure (the upper bounds of the window) is supported by the fact that as the temperature is increased the thermoplastic material will be less viscous and therefore increase potential leakage causing the defect of flashing. This was observed on molded parts above the maximum boundary. The acceptable minimum packing pressure is affected by increasing temperature as well. Increased temperature also causes increased shrinkage as the part cools in the mold. This explains the increase in the minimum packing pressure values once mold temperatures are at or above 37.8 °C. Parts below the designated minimum were observed to have sink marks or were short in filling.

From the trend seen in the process window, it can be noted that mold temperature appears to have a greater effect on the developed window and part acceptability. The packing pressure range for each temperature combination greatly reduces as mold temperature is increased. This relationship is most likely material and part dependent.

The left side, the side with lower mold temperature, is more robust, that is, would allow for more uncontrollable variations in your molding environment and still enable the production of acceptable parts. Additionally, because the mold temperature is low, the molded part cools faster and can be ejected sooner, promoting shorter cycle time. For this particular molding operation, the right side of the visual process window is less desirable and may only be used as a boundary of limitation. However, depending on the complexity of the part, the right side or higher mold and melt temperatures may be necessary, as illustrated with an example in a later section.

The process window based on visual inspection, is a great tool to delimit the relevant CPV, and select the most robust region of the CPV domain. However, it was believed that the visual inspection used to construct the injection molding process window is only part of the whole development process and more analysis is needed to promote and produce a more robust solution. This is particularly true for semicrystalline material and less important for an amorphous material [

11].

Since our material is semicrystalline, to develop a more robust process window, analysis of the mechanical properties of the parts produced within the visual process window is necessary. Although the visual process window developed indicates to a molder how to operate their machine in order to produce visually acceptable parts, it does not include the effect on mechanical properties of the part. The general approach in industry is to define acceptable parts based on visual inspection, mechanical properties are rarely considered for specific parts after they are molded [

12]. This could lead to unacceptable parts in particular for semicrystalline materials [

11]. This research aimed to further the analysis beyond just the visual process window and develop a more refined process window that takes mechanical properties into consideration. Mechanical properties, in particular, ductility may be affected by process conditions for semicrystalline materials [

11].

The desired mechanical properties of a particular injection molded part will vary from one product to another. In the case of this analysis, experiments were conducted to determine the tensile properties of the samples produced. With the visual process window already defined the molding conditions and the number of samples for the tensile test were decreased, as parts deemed visually unacceptable were not tested mechanically. The two properties that will be discussed to generate a more refined process window are tensile strain at yield and tensile strain at break, or ductility. The results of these two properties are presented and discussed below.

Looking at the tensile strain at yield results the effects the CPV have on this property become clear, as higher values indicate that the part can be deformed to a greater degree before yielding, or the start of plastic/permanent deformation begins. In terms of packing pressure, the samples produced with increasing pressure result in higher tensile strain in all combinations of mold and melt temperatures. Additionally, with regards to temperature, lower melt temperatures produce samples of increased tensile strain. In all three cases of different mold temperatures, the lower range of the melt temperature (179.4 °C) produces the highest strain values. Lastly, it can be observed that overall, the mold temperature of 26.7 °C produces higher tensile strain results. In conclusion, these results indicate that the mechanical property of tensile strain at yield is benefited from higher packing pressure and lower mold and melt temperatures, as it takes longer or more deformation to cause parts molded at these conditions to yield.

Table 8.

Tensile Strain (Displacement) at Yield (%).

Table 8.

Tensile Strain (Displacement) at Yield (%).

| |

|

|

26.7 |

|

|

37.8 |

|

48.9 |

| |

|

179.4 |

193.3 |

210 |

179.4 |

193.3 |

210 |

179.4 |

193.3 |

210 |

| Packing Pressure (MPa) |

1.38 |

12.691 |

11.897 |

11.897 |

12.000 |

11.420 |

10.722 |

12.125 |

11.679 |

|

| 1.72 |

13.323 |

11.917 |

11.917 |

12.444 |

11.934 |

11.234 |

12.680 |

11.726 |

|

| 2.07 |

13.365 |

12.183 |

12.183 |

13.012 |

12.719 |

11.578 |

13.122 |

|

|

| 2.41 |

14.201 |

12.425 |

12.425 |

13.838 |

12.971 |

11.716 |

|

|

|

| 2.76 |

14.944 |

12.848 |

12.848 |

14.223 |

12.948 |

12.225 |

|

|

|

| 3.10 |

15.466 |

13.234 |

13.234 |

14.758 |

13.388 |

|

|

|

|

| 3.45 |

15.018 |

13.324 |

13.324 |

15.005 |

|

|

|

|

|

| 3.79 |

15.849 |

13.005 |

13.005 |

|

|

|

|

|

|

| 4.14 |

16.617 |

13.284 |

|

|

|

|

|

|

|

Table 9.

Tensile strain (Displacement) at Break (%).

Table 9.

Tensile strain (Displacement) at Break (%).

| |

|

|

26.7 |

|

|

37.8 |

|

48.9 |

| |

|

179.4 |

193.3 |

210 |

179.4 |

193.3 |

210 |

179.4 |

193.3 |

210 |

| Packing Pressure (MPa) |

1.38 |

118.557 |

180.703 |

165.851 |

150.313 |

148.742 |

188.623 |

146.582 |

175.032 |

|

|

| 1.72 |

134.699 |

182.579 |

141.534 |

177.650 |

155.772 |

151.928 |

160.629 |

158.783 |

|

|

| 2.07 |

136.120 |

181.355 |

151.462 |

140.261 |

155.257 |

149.869 |

135.287 |

|

|

|

| 2.41 |

125.384 |

247.614 |

262.226 |

145.024 |

187.168 |

145.354 |

|

|

|

|

| 2.76 |

299.574 |

371.187 |

271.889 |

158.577 |

234.021 |

210.268 |

|

|

|

|

| 3.10 |

320.251 |

340.745 |

370.961 |

198.609 |

316.248 |

|

|

|

|

|

| 3.45 |

344.143 |

373.189 |

371.243 |

237.441 |

|

|

|

|

|

|

| 3.79 |

371.349 |

336.061 |

400.026 |

|

|

|

|

|

|

|

| 4.14 |

325.522 |

377.526 |

|

|

|

|

|

|

|

|

The table above presents the results of the tensile strain at break or the ductility of the various samples that were tested mechanically. These results provide similar conclusions to the results found for the tensile strain at yield. Higher ductility is achieved by samples that are both molded at higher packing pressures and lower mold and melt temperature combinations. With high ductility, parts molded under these conditions will deform but not break or fail easily.

The analysis of tensile strain at yield and at break indicates that the percent crystallinity of the samples at lower temperatures is most likely lower and thus they are more ductile. This has been corroborated Differential Scanning Calorimetry (DSC) [

11,

13,

14]. Through these results, justification to the claim that further analysis of the mechanical proprieties would be beneficial in generating a more refined injection molding process window and more acceptable parts is achieved. The findings discussed indicate that improvements can be made to the visual process window originally found to produce a window that promotes parts of both visual and mechanical success. This may not be the case for amorphous materials [

11,

13].

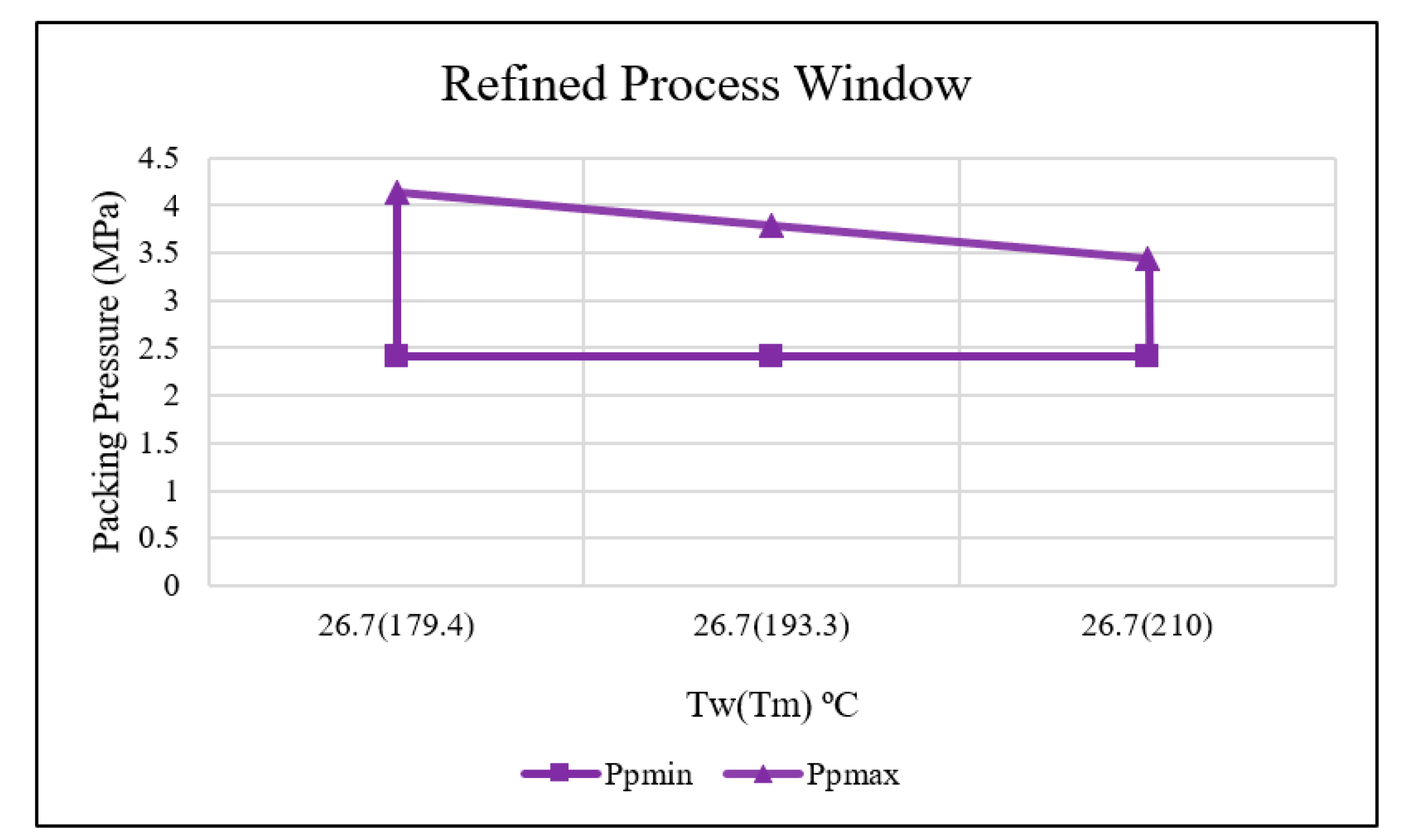

When considering both visual inspection and mechanical properties, a new, refined process window can be created. Recall that it was found that using lower mold and melt temperatures produced better tensile strain properties. Combining both the finding of the visual process window and the tensile strain testing, a final refined process window can be produced.

This process window shown above suggests operating at a mold temperature of 26.7 °C and a melt temperature from 179.4 °C to 210 °C. Additionally, packing pressure should be set between 2.41 and 4.14 MPa, depending on temperature. This process window will promote a more stable and predictable injection molding operation by reducing the impact of undesirable variation from the molding environment and also improve the resulting parts' visual and mechanical property quality.

For complicated parts, in particular parts with thin sections, it may be necessary to mold at higher temperatures in order to completely fill the part or to use the least desirable region of the process window. We will illustrate this with a simple example, where we analyze the filling of a flat plate with increasing length using a fan gate, as shown schematically in

Figure 11. The results are summarized in

Table 10. The CAE software used in this case is Moldex3D.

The specifics of this example were to construct a flat plate of a certain length. Then run filling stage analysis using Moldex3D to determine if the temperature allow the flat plate to successfully fill. If the plaque was successfully filled, a new plaque of longer length was then analyzed. If the temperatures used did not allow the mold to fill completely then the temperature values were increased. This process was repeated for a variety of flat plate lengths and used the mold and melt temperature ranges recommended by the material supplier and used in the original visual process window.

With the case study defined, several simulations were completed. The results of these runs are shown below.

As can be seen from the table, plates of shorter lengths fill successfully at lower mold and melt temperatures. However, as the plate length increases higher temperatures, specifically melt temperature, are required to fill the mold completely.

The results indicate that temperature ranges found to be the best in promoting visual and mechanical success during the experimental development of the process windows do not allow for complete filling in certain cases of the thin plate molds. Although it was found earlier that visual inspection and mechanical properties benefited from lower melt and mold temperatures, the simulations show that such temperatures may need to be increased in order to fill the mold when considering large thin-walled parts. The right side, or the side representing higher temperatures of the visual process window shown in

Figure 12 is better justified by this case study. We selected a flat plate for simplicity and easier discussion; however, we could have also done the same analysis with the ASTM mold. Whereas before the right side of the process window was only used as a boundary of limitation, the simulations conducted indicate that although this area of the process window is not as robust, it may be necessary in order to produce fully filled parts. Again, it must be stated that the shape and size of a particular process window and the values of the key CPV will vary from one operation to another.

Molding thermoplastic parts that are both visually appealing and mechanically sound is desired. However, the specific material and part dimensions of a particular operation may limit these quality factors. The simulations conducted as a part of this case study indicate that in order to successfully fill a thin plate, areas of the developed process window with higher mold and melt temperatures may have to be utilized as indicated in

Figure 12.

4. Conclusion

This research presented a method for the experimental development of an injection molding process window. By following each stage of the injection molding process, key controllable process variables were able to be isolated and analyzed. Using this method, and defined quality standards, a visual process window was first found. This window focused on obtaining parts with acceptable appearance. In addition, this work proposed that this visual process window was only part of the solution, in particular for semicrystalline materials, and there was a need to include mechanical testing as part of developing the process window. Conducting tensile testing, a more refined process window was developed. This refined window allowed for parts with both good acceptable appearance and adequate mechanical properties to be produced. This is especially true for semi-crystalline materials [

11].

A special case study utilizing simulation was also presented which helped to justify the use of specific regions of the experimental process windows, even if less robust from the visual and mechanical properties point of view.

In summary, the proposed approach can be summarized as follows. First identify and establish key controllable process variables, including material attributes, machine settings, and mold/part conditions. Once this initial information is collected determine the key performance measures and develop quality/measurement standards for the particular operation. Next, using part and material characteristics calculate your conduction time (). Then by following the order of each of the stages in the injection molding process, isolate and analyze each CPV to determine its range or value. To produce a large sample of molded parts, vary relevant controllable process variables such as mold temperature, melt temperature, and packing pressure. Using the produced molded parts and the defined performance measures develop a visual process window. Lastly, refine the process via mechanical property analysis.

The seven steps above represent the general method used to experimentally construct the process windows presented and discussed in this work. It is suggested that the use of these steps will allow for the development of process windows in other injection molding operations. Again, it is important to note that the specific values presented during this work correspond to the particular molding process investigated (mold/part, machine, and material). Such values will likely differ from one molding process to another. This work is intended to present and provide a more standardized and thorough procedure for experimentally developing injection molding process windows. The steps highlighted above summarize the detailed research completed and the results presented throughout showcase the success of the method developed.

5. Future Work

Firstly, it is suggested that the experimental method for developing injection molding process windows be tested further. Research using other materials or molding operations will help to test the robustness of the method presented. This research would also help to improve process window development strategies.

Due to the time commitment of conducting experimental research, it is also recommended that further analysis of simulation be pursued. In the case of this research, simulation is used as a supplementary tool, to help better understand the experimental results. However, simulation software has promising potential to help develop injection molding process windows in a more direct way. In the future, with the help of the experimental results presented, strides in conducting more detailed simulation analysis involving injection molding process window development will be possible. Work is currently being done in this area.

References

- Plastic injection molding market (by raw material type: Polypropylene, acrylonitrile butadiene styrene, polystyrene, high density polyethylene, and others; and by application: Automobile, consumer goods, electronics, packaging, Building & Construction, and healthcare) - global industry analysis, size, share, growth, trends, regional outlook, and forecast 2021 – 2030. Precedence Research. https://www.precedenceresearch.com/plastic-injection-molding-market. Accessed , 2023. 17 January.

- Villarreal-Marroquín MG, Chen P-H, Mulyana R, Santner TJ, Dean AM, Castro JM. Multiobjective optimization of injection molding using a calibrated predictor based on physical and simulated data. Polymer Engineering & Science. 2016, 57, 248–257. [Google Scholar] [CrossRef]

- Marroquín MG, Castro JM, Mondragón ÓL, Ríos MC. Optimisation via simulation: A metamodelling-based method and a case study. European J of Industrial Engineering. 2013, 7, 275–294. [Google Scholar] [CrossRef]

- Rodríguez AB, Niño E, Castro JM, Suarez M, Cabrera M. Injection molding process windows considering two conflicting criteria: Simulation results. ASME International Mechanical Engineering Congress and Exposition. 2012, 3, 1447–1453. [Google Scholar] [CrossRef]

- Villarreal-Marroquin MG, Cabrera-Rios M, Castro JM. A multicriteria simulation optimization method for injection molding. A multicriteria simulation optimization method for injection molding. Proceedings of the 2011 Winter Simulation Conference (WSC). 2011, 2390–2402. [Google Scholar] [CrossRef]

- Villarreal-Marroquín MG, Mulyana R, Castro JM, Cabrera-Ríos M. Selecting process parameter in injection molding via simulation optimization. Journal of Polymer Engineering. 2011, 31, 387–395. [Google Scholar] [CrossRef]

- Mulyana, R. Design of Experiments and Data Envelopment Analysis Based Optimization in Injection Molding. 2006.

- Yu S, Zhang Y, Yang D, Zhou H, Li J. Offline Prediction of Process Windows for Robust Injection Molding. Journal of Applied Polymer Science. 2014, 131. [Google Scholar] [CrossRef]

- Myers, M. Experimental Development of an Injection Molding Process Window. 2023.

- Ebnesajjad, S. 10 - Injection molding. Fluoroplastics. 2015, 236–281. [Google Scholar] [CrossRef]

- Cai, K. Effect of Processing Parameters on Mechanical Properties During Injection Molding. 2018.

- Zhang D, Bartlett L, Cai K, et al. Difference in Mechanical Properties Between Plastic and Metal Molds for Injection Molding a Talc Reinforced Rubber Modified Polypropylene. Polymer Engineering & Science. 2022, 62, 3470–3475. [Google Scholar] [CrossRef]

- Bartlett, LP. A preliminary study of using plastic molds in injection molding. 2017.

- Bartlett L, Grunden E, Mulyana R, Castro JM. A preliminary study on the performance of additive manufacturing tooling for injection molding. SPE ANTEC.:100-104.

Figure 1.

Picture of molded ASTM part.

Figure 1.

Picture of molded ASTM part.

Figure 2.

Examples of defects short shot, flash, and sink marks.

Figure 2.

Examples of defects short shot, flash, and sink marks.

Figure 3.

Example of a process window considering melt temperature and packing pressure.

Figure 3.

Example of a process window considering melt temperature and packing pressure.

Figure 4.

Injection screw speed spectrum with defect boundaries.

Figure 4.

Injection screw speed spectrum with defect boundaries.

Figure 6.

Average molded part weight versus packing pressure.

Figure 6.

Average molded part weight versus packing pressure.

Figure 7.

Determined preliminary packing pressure process window.

Figure 7.

Determined preliminary packing pressure process window.

Figure 8.

Visual quality standard zones on molded part.

Figure 8.

Visual quality standard zones on molded part.

Figure 9.

Visual process window.

Figure 9.

Visual process window.

Figure 10.

Final refined process window.

Figure 10.

Final refined process window.

Figure 11.

Thin plate model (0.375 m x 0.1m x 0.002m) with software Moldex3D.

Figure 11.

Thin plate model (0.375 m x 0.1m x 0.002m) with software Moldex3D.

Figure 12.

Visual process window highlighted with simulation results.

Figure 12.

Visual process window highlighted with simulation results.

Table 1.

Control Variable Tiers.

Table 1.

Control Variable Tiers.

| Primary Control Variable |

Mold Temperature () |

| Melt Temperature () |

| Packing Pressure () |

| Secondary Control Variable |

Injection Screw Speed |

| Packing Time () |

| Cooling Time () |

| Tertiary Control Variable |

Shot Size |

| Clamping Force |

Table 2.

Known Variables and Their Origin.

Table 2.

Known Variables and Their Origin.

| Variable |

Origin |

Value/Setting |

| Mold Temperature () |

Material Supplier |

80 – 120 °F (26.7 – 48.9 °C) |

| Melt Temperature () |

Material Supplier/Molder Experience |

355 – 410 °F (179.4 – 210 °C) |

| Shot Size |

Part Volume |

2.10 in (53.34 mm) |

| Clamping Force |

Molder Experience |

120 Ton (1067.6 kN) |

Table 3.

Variables Needing Further Analysis.

Table 3.

Variables Needing Further Analysis.

| Variable |

|---|

| Mold Closed Time |

| Injection Screw Speed |

| Preliminary Packing Pressure () |

| Packing () and Cooling () Time |

Table 4.

CPV Settings for Injection Screw Speed Trials.

Table 4.

CPV Settings for Injection Screw Speed Trials.

| CPV |

Value |

| Mold Temperature () |

80 °F (26.7 °C) |

| Melt Temperature () |

380 °F (193.3 °C) |

| Packing Pressure () |

10 – 750 psi (0.07 – 5.2 MPa) |

| Injection Screw Speed |

0.2 – 10 in/s (5.1 – 254 mm/s) |

| Packing Time () |

0 – 52 s |

| Cooling Time () |

0 – 52 s |

| Shot Size |

2.10 in (53.34 mm) |

| Clamping Force |

120 Ton (1067.6 kN) |

Table 5.

Tensile Test Mechanical Property Results (Average of 5 Samples Each).

Table 5.

Tensile Test Mechanical Property Results (Average of 5 Samples Each).

|

(%) |

Tensile stress at Maximum Load [MPa] |

Tensile strain (Displacement) at Yield (Zero Slope) [%] |

Tensile stress at Yield (Offset 0.2 %) [MPa] |

Tensile stress at Break (Standard) [MPa] |

Tensile strain (Displacement) at Break (Standard) [%] |

Modulus Young [MPa] |

| 100/0 |

19.279 |

12.122 |

8.843 |

14.271 |

145.491 |

909.661 |

| 80/20 |

19.353 |

11.950 |

8.510 |

14.864 |

254.9 |

992.231 |

| 60/40 |

19.367 |

11.447 |

8.443 |

13.596 |

118.440 |

1013.861 |

| 40/60 |

19.311 |

12.040 |

8.891 |

15.230 |

299.206 |

914.458 |

| 20/80 |

19.515 |

10.776 |

8.397 |

13.621 |

128.562 |

1019.808 |

| 0/100 |

18.169 |

7.246 |

8.831 |

15.54 |

38.87 |

941.908 |

Table 6.

Established Packing and Cooling Time Ratio.

Table 6.

Established Packing and Cooling Time Ratio.

|

(%) |

(%) |

(s) |

(s) |

| 40 |

60 |

20.8 |

31.2 |

Table 7.

Key Molding Variables and Determined Values.

Table 7.

Key Molding Variables and Determined Values.

| Control Variable Tiers |

Variable |

Setting |

| Primary Control Variable |

Mold Temperature |

Controllable Process Variable (CPV) |

| Melt Temperature |

CPV |

| Packing Pressure |

CPV |

| Secondary Control Variable |

Injection Screw Speed |

2.0 in/s (50.8 mm/s) |

| Conduction Time |

52 s |

| Packing Time |

20.8 s |

| Cooling Time |

31.2 s |

| Tertiary Control Variable |

Shot Size |

2.10 in (53.34 mm) |

| Clamp Force |

120 Ton (1067.6 kN) |

Table 10.

Simulated Variables and Run Results.

Table 10.

Simulated Variables and Run Results.

| Plate Length (m) |

(°C) |

(°C) |

(s) Calculated |

(s) Simulated |

Filled? |

| 0.2 |

26.7 |

179.4 |

1.4 |

1.422 |

Y |

| 0.3 |

26.7 |

179.4 |

2.1 |

2.148 |

Y |

| 0.35 |

26.7 |

179.4 |

2.45 |

3.205 |

N |

| 26.7 |

193.3 |

2.45 |

2.606 |

Y |

| 0.375 |

26.7 |

193.3 |

2.625 |

3.479 |

N |

| 26.7 |

210 |

2.625 |

2.764 |

Y |

| 37.8 |

179.4 |

2.625 |

3.462 |

N |

| 37.8 |

193.3 |

2.625 |

2.963 |

Y |

| 0.4 |

37.8 |

193.3 |

2.8 |

3.881 |

N |

| 37.8 |

210 |

2.8 |

3.132 |

Y |

| 48.9 |

179.4 |

2.8 |

3.735 |

N |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).