Submitted:

08 May 2023

Posted:

09 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

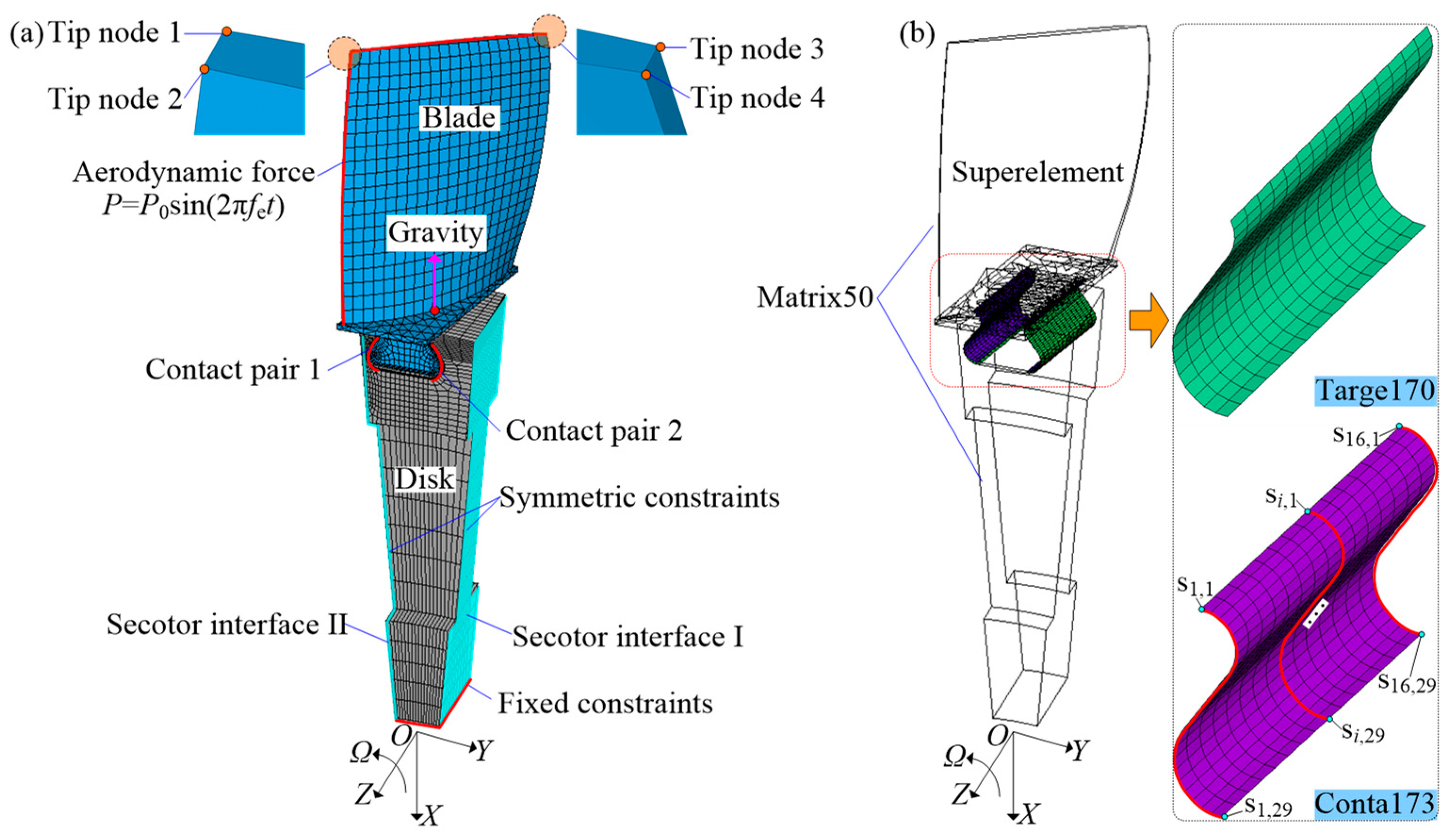

2. Finite element model

3. Dynamic characteristic analysis

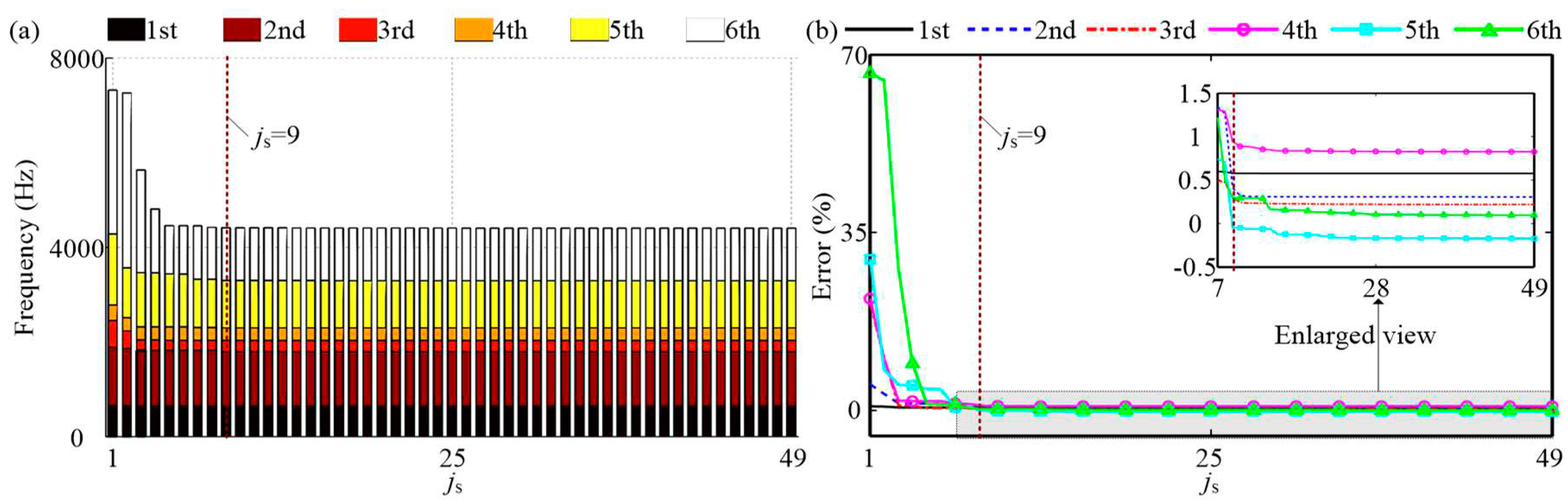

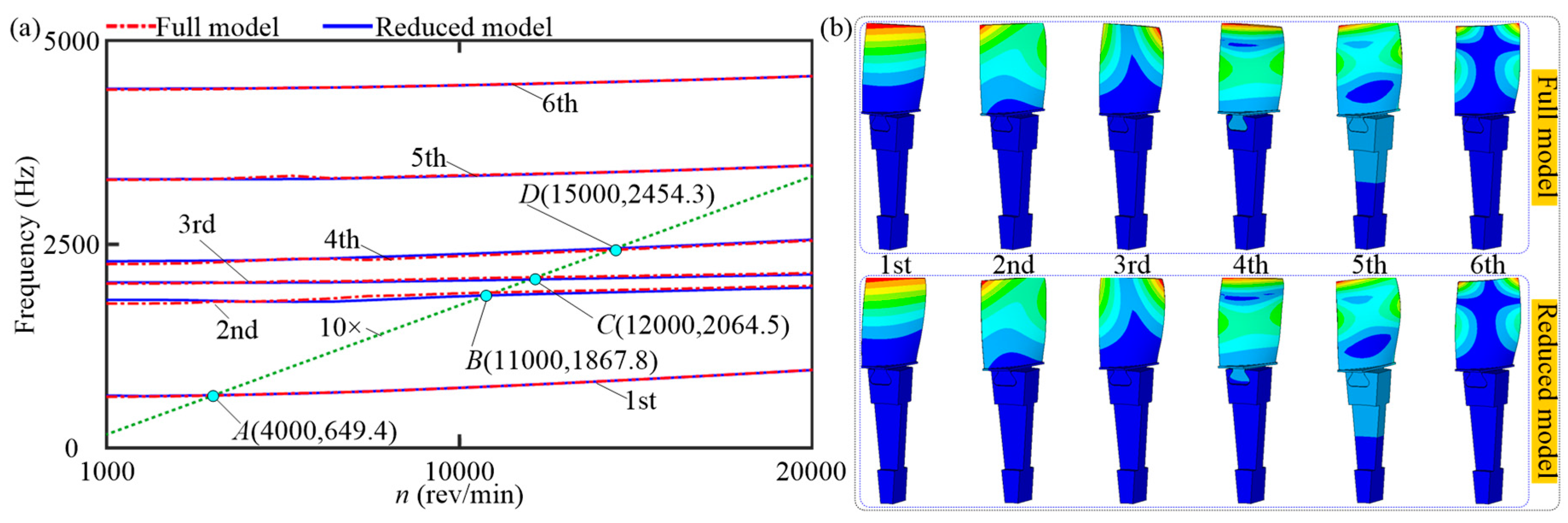

3.1. Modal characteristics

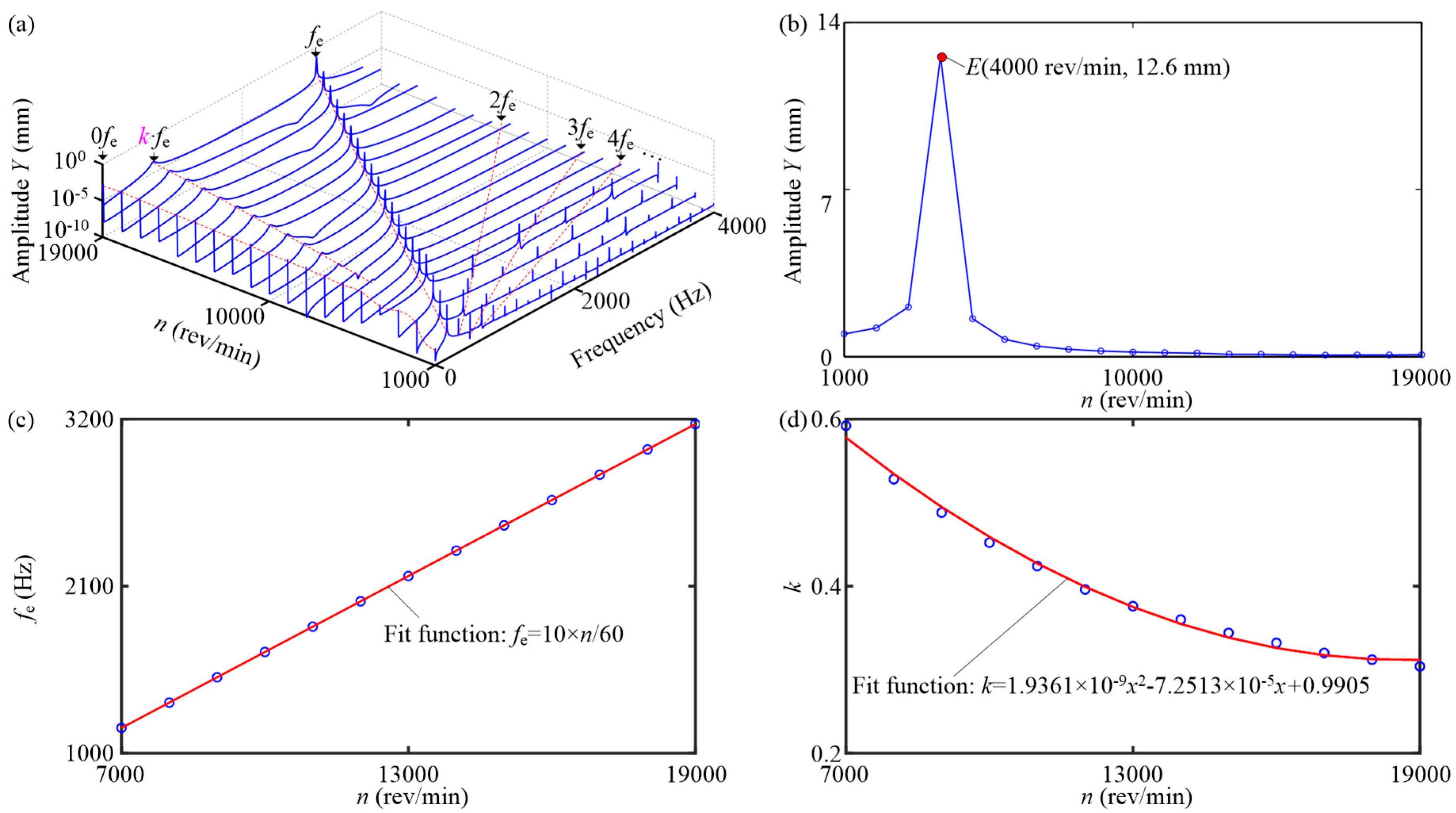

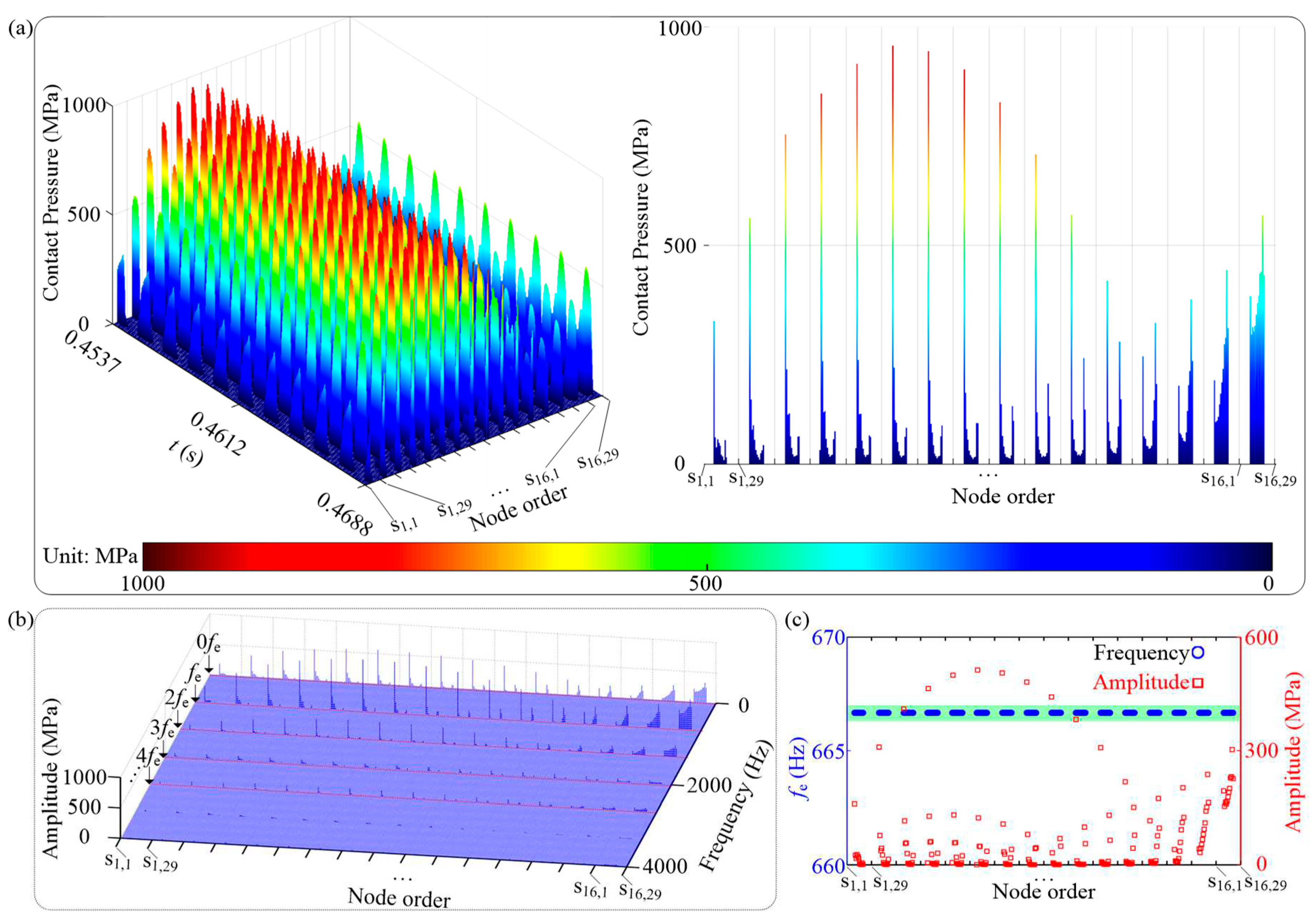

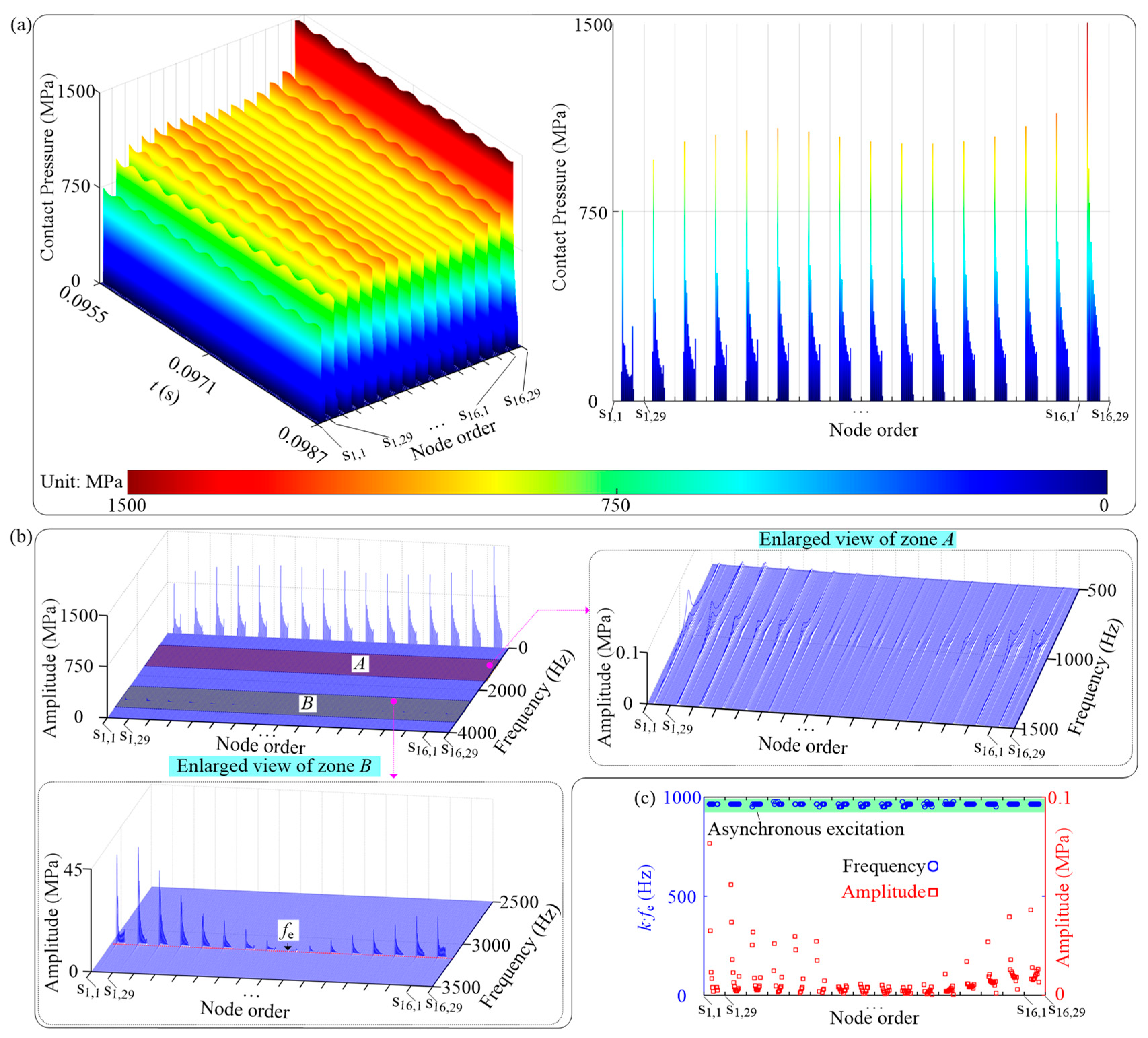

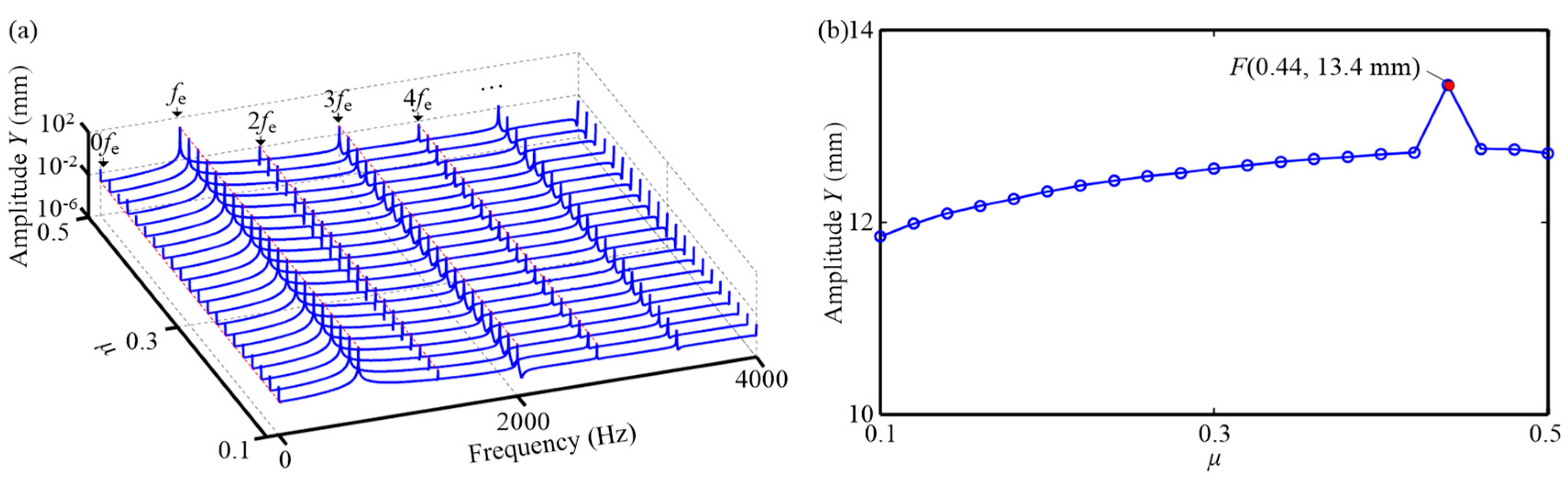

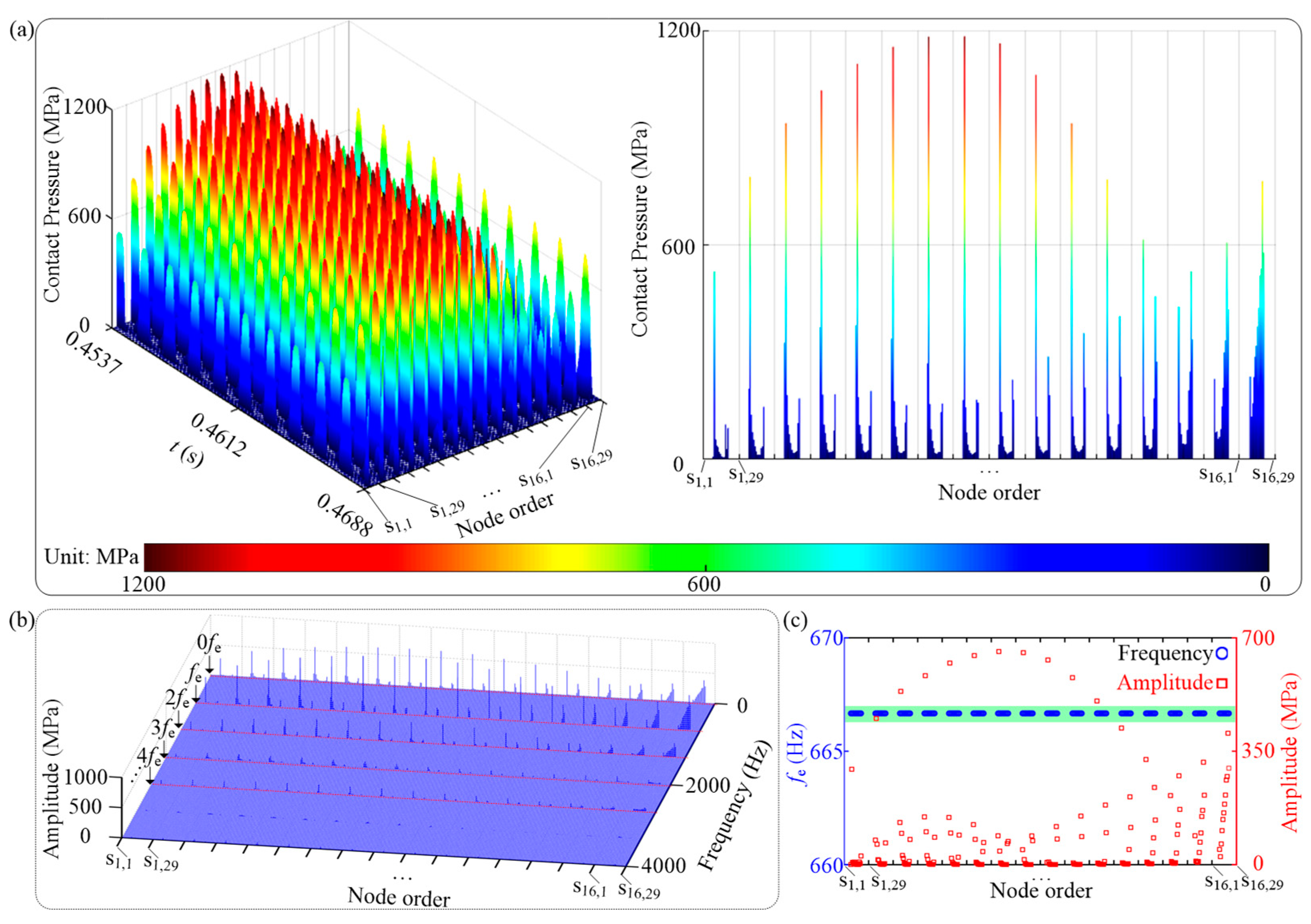

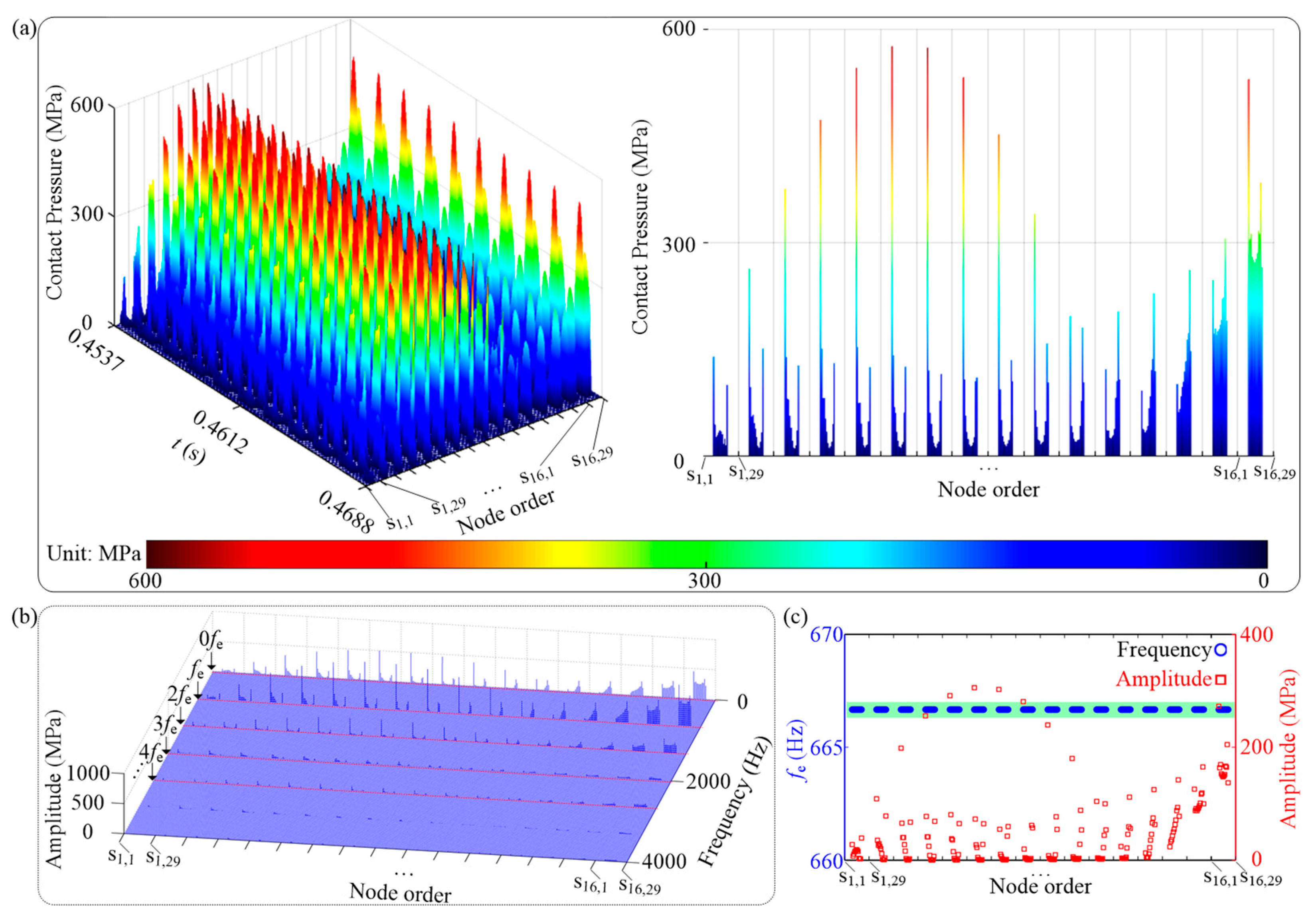

3.2. Nonlinear vibration characteristics

4. Conclusions

Acknowledgments

References

- Ma H, Wang D, Tai X Y, Wen B C. Vibration response analysis of blade-disk dovetail structure under blade tip rubbing condition[J]. Journal of Vibration and Control. 2017, 23(2): 252-271. [CrossRef]

- Quaegebeur S, Chouvion B, Thouverez F. Nonlinear dynamic analysis of three-dimensional bladed-disks with frictional contact interfaces based on cyclic reduction strategies[J]. International Journal of Solids and Structures. 2022, 236-237: 111277. [CrossRef]

- Li C F, Shen Z C, Zhong B F, Wen B C. Study on the nonlinear characteristics of a rotating flexible blade with dovetail interface feature[J]. Shock and Vibration. 2018, Volume 2018, Article ID 4923898, 13 pages. [CrossRef]

- Li C F, Liu X W, Tang Q S, Chen Z L. Modeling and nonlinear dynamics analysis of a rotating beam with dry friction support boundary conditions[J]. Journal of Sound and Vibration. 2021, 498: 115978. [CrossRef]

- She H X, Li C F, Tang Q S, Wen B C. Veering and merging analysis of nonlinear resonance frequencies of an assembly bladed disk system[J]. Journal of Sound and Vibration. 2021, 493: 115818. [CrossRef]

- Shangguan B, Xu Z. Experimental study of friction damping of blade with loosely assembled dovetail attachment[J]. Proceedings of the Institution of Mechanical Engineers Part A-Journal of Power and Energy. 2012, 226(6):738-750. [CrossRef]

- Shangguan B, Yu F L, Duan J Y, Gao S, Xiao J F. A fractal contact friction model and nonlinear vibration response studies of loosely assembled blade with dovetail root[C]. Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, 2016.

- Lassalle M, Firrone C M. A parametric study of limit cycle oscillation of a bladed disk caused by flutter and friction at the blade root joints[J]. Journal of Fluids and Structures. 2018, 76: 349-366. [CrossRef]

- Zucca S, Firrone C M, Gola M M. Numerical assessment of friction damping at turbine blade root joints by simultaneous calculation of the static and dynamic contact loads[J]. Nonlinear Dynamics. 2012, 67(3): 1934-1955. [CrossRef]

- Appaji Gowda B M, Yeshovanth H R, Siddaraju C. Investigation and efficient modeling of an dovetail attachment in aero-engine[J]. Procedia Materials Science. 2014, 5: 1873-1879. [CrossRef]

- Chen J J, Zang C P, Zhou B, Petrov E P. A study of friction microslip modeling for dynamic analysis of bladed discs with root joints[J]. Journal of Mechanical Engineering Science. 2018, 233(8): 2599-2641. [CrossRef]

- Chen J J, Zang C P, Zhou B, Petrov EP. High-fidelity calculation of modal damping caused by friction at blade roots for single blades and tuned bladed disc assemblies[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science. 2021, 235(15): 2810-2831. [CrossRef]

- Joannin C, Chouvion B, Thouverze F, Mbaye M, Ousty J P. Nonlinear modal analysis of mistuned periodic structures subjected to dry friction[J]. Journal of Engineering for Gas Turbines and Power. 2016, 138(7): 072504. [CrossRef]

- Schwarz S, Kohlmann L, Hartung A, Gross J, Scheel M, Krack M. Validation of a turbine blade component test with frictional contacts by phase-locked-loop and force-controlled measurements[J]. Journal of Engineering for Gas Turbines and Power. 2020, 142(5): 051006. [CrossRef]

- Liu T Y, Zhang D, Xie Y H. A nonlinear vibration analysis of forced response for a bladed-disk with dry friction dampers[J]. Journal of Low Frequency Noise, Vibration and Active Control. 2019, 38(3-4): 1522-1539. [CrossRef]

- Canale G, Kinawy M, Maligno A, Sathujoda P, Citarella R. Study of mixed-mode cracking of dovetail root of an aero-engine blade like structure[J]. Applied Sciences. 2019, 9(18): 3825. [CrossRef]

- Yuan J, Schwingshackl C, Salles L, Wong C, Patsias S. Reduced order method based on an adaptive formulation and its application to fan blade system with dovetail joints[C]. Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, 2020.

- Anandavel K, Prakash R V, Davis A. Effect of preloading on the contact stress distribution of a dovetail interface[J]. World Academy of Science, Engineering and Technology. 2010, 4(10):1107-1112. [CrossRef]

- Fernandes R, El-Borgi S, Ahmed K, Friswell M I, Jamia N. Static fracture and modal analysis simulation of a gas turbine compressor blade and bladed disk system[J]. Advanced Modeling and Simulation in Engineering Sciences. 2016, 3, Article number 30, 23 pages. [CrossRef]

- Wei D S, Ma M D, Zhang H, Hu C, Wang Y R. Study of the variation of contact state near the contact boundary in a dovetail attachment under different loads[J]. Engineering Failure Analysis. 2019, 105: 518-526. [CrossRef]

| Cases | Analysis type | Gravity | Constant parameters | Varying parameters |

| 1 | Prestressed modal | No | n=4000 rev/min, μ=0.3, P0=0 MPa | js∈[1, 49], Δjs=1 |

| 2 | js=10, μ=0.3, P0=0 MPa | n∈[1000, 20000] rev/min, Δn=1000 rev/min | ||

| 3 | Transient | Yes | js=10, P0=0.1 MPa, μ=0.3 | fe=10⋅n/60, n∈[1000, 20000] rev/min, Δn=1000 rev/min |

| 4 | js=10, P0=0.1 MPa, fe=10⋅n/60,n=4000 rev/min | μ∈[0.1, 0.5], Δμ=0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).