Submitted:

28 April 2023

Posted:

28 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

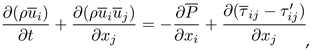

2. Materials and Methods

2.1. Preprocess

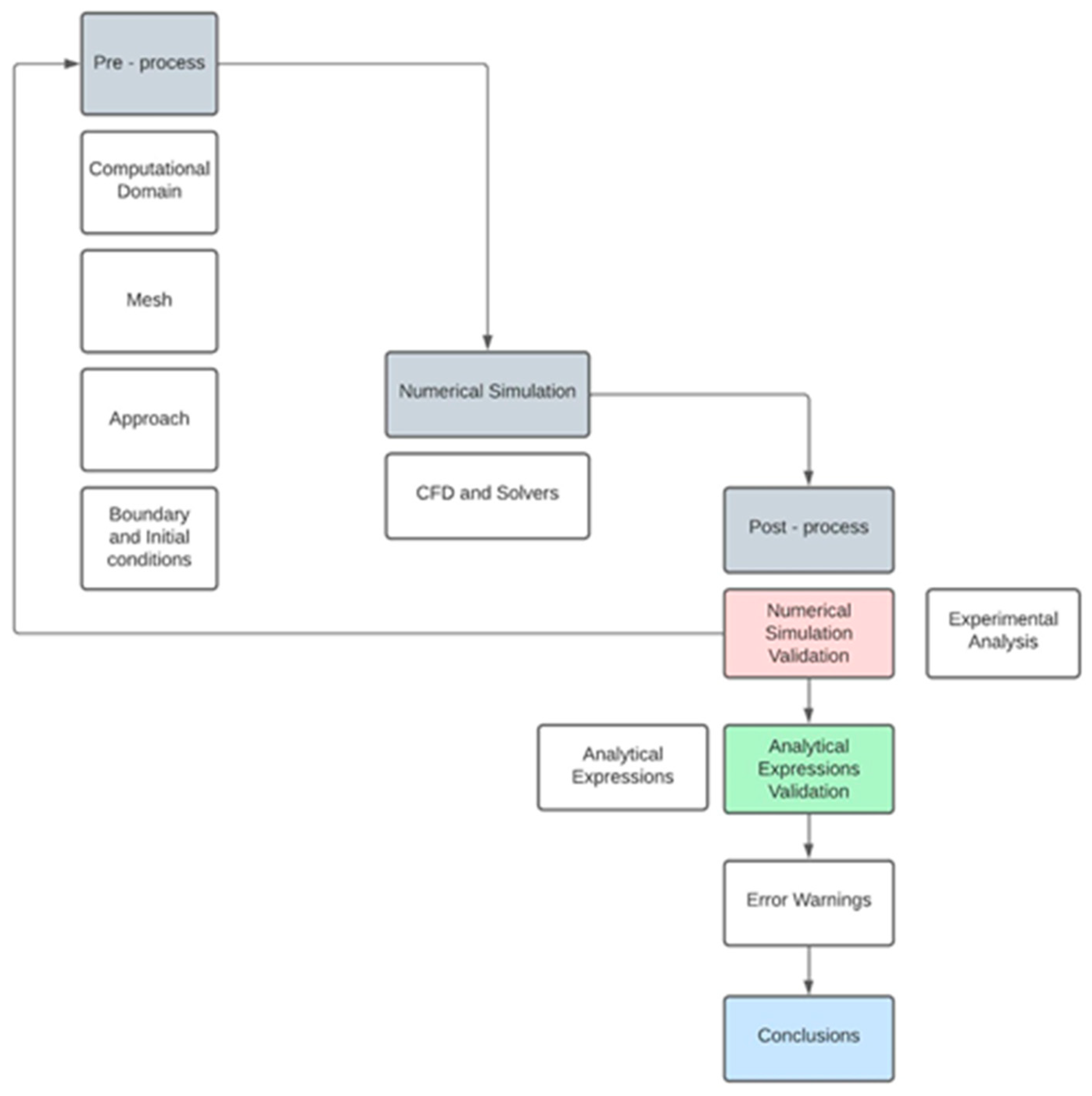

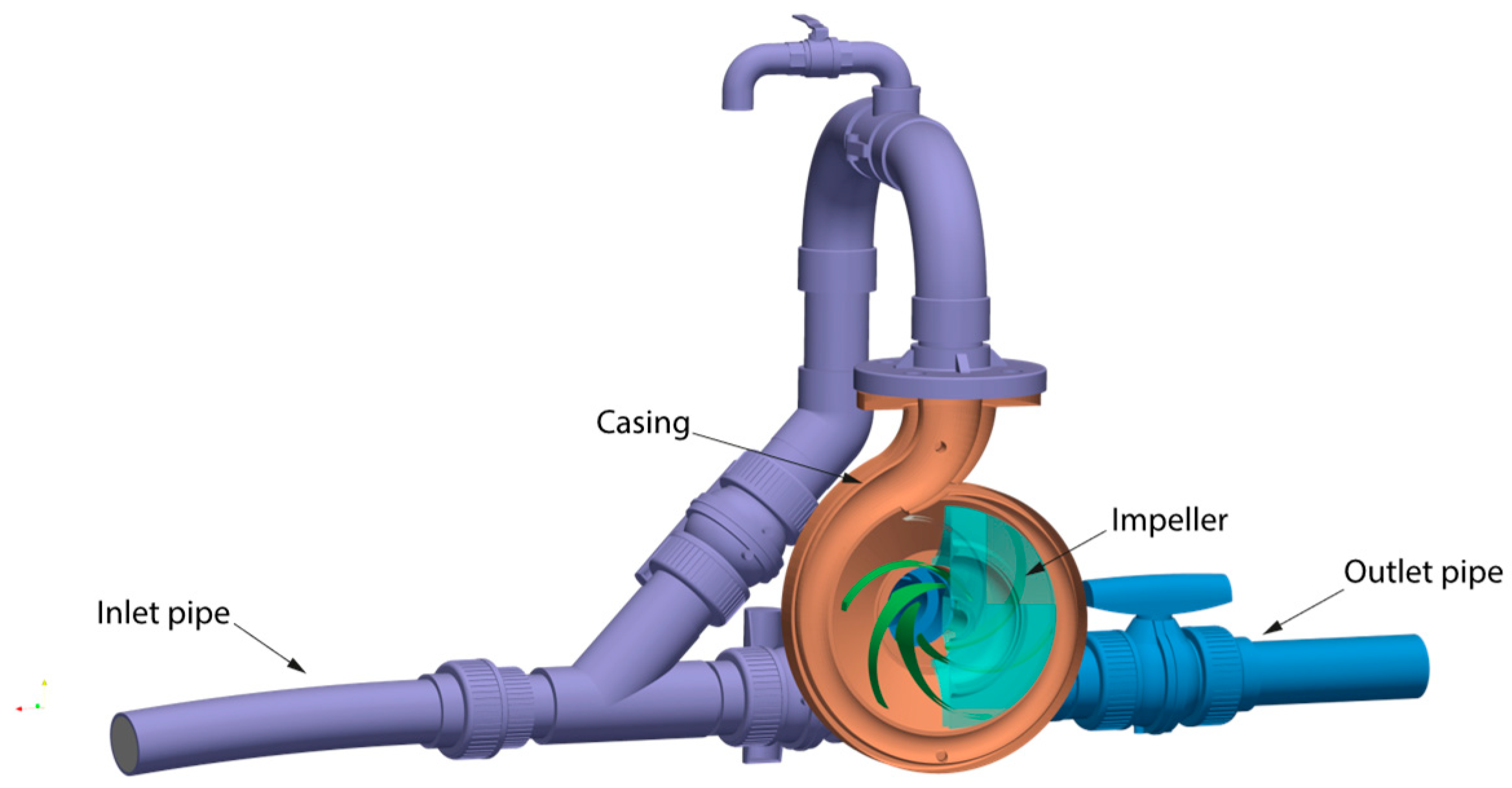

2.1.1. Computational Domain

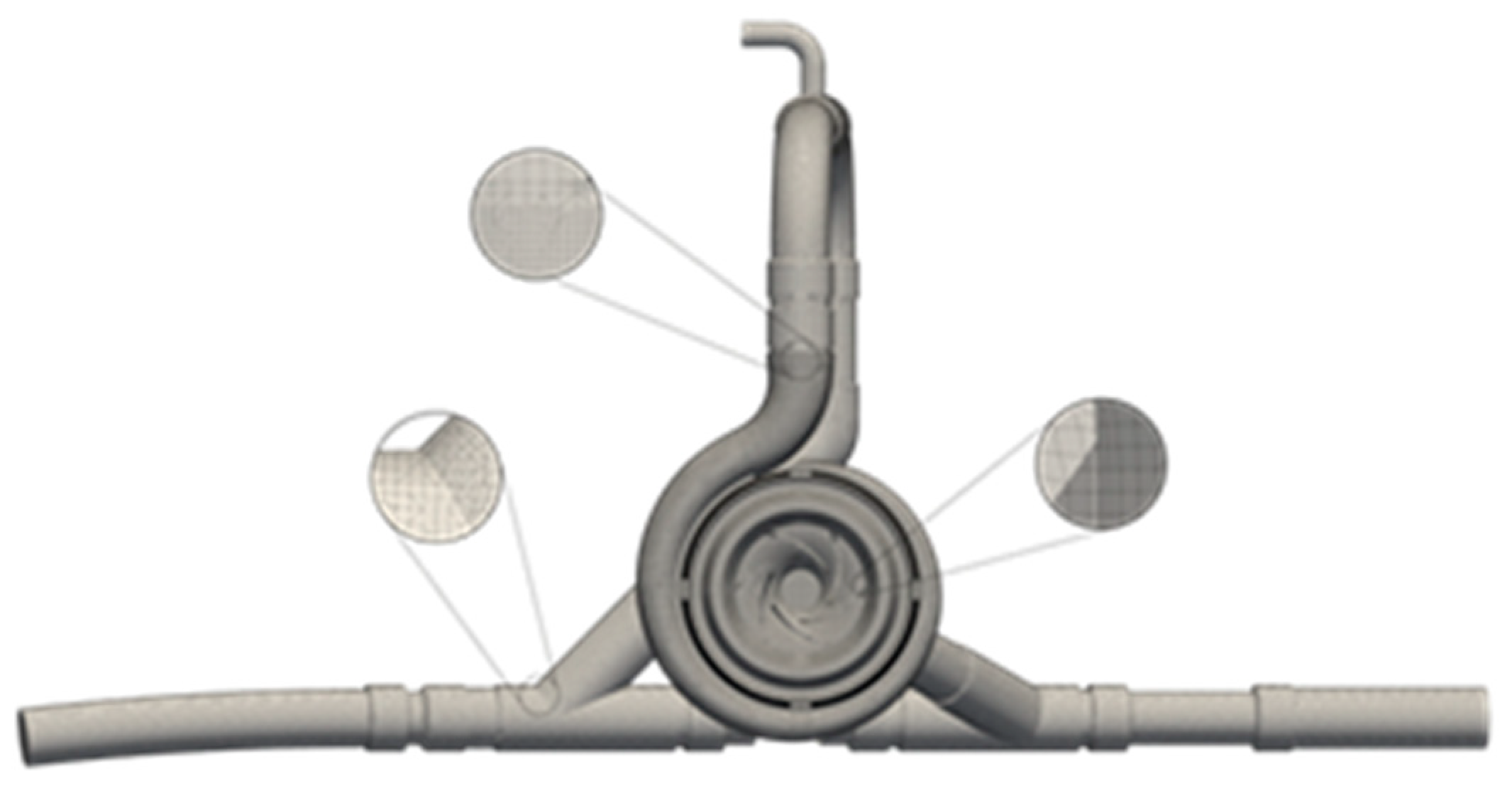

2.1.2. Mesh

2.1.3. Approach

2.1.4. Boundary and Initial Conditions

2.2. Numerical Simulation

2.2.1. CFD

(1)

(1)

(2)

(2)

2.2.2. CFD and Solvers

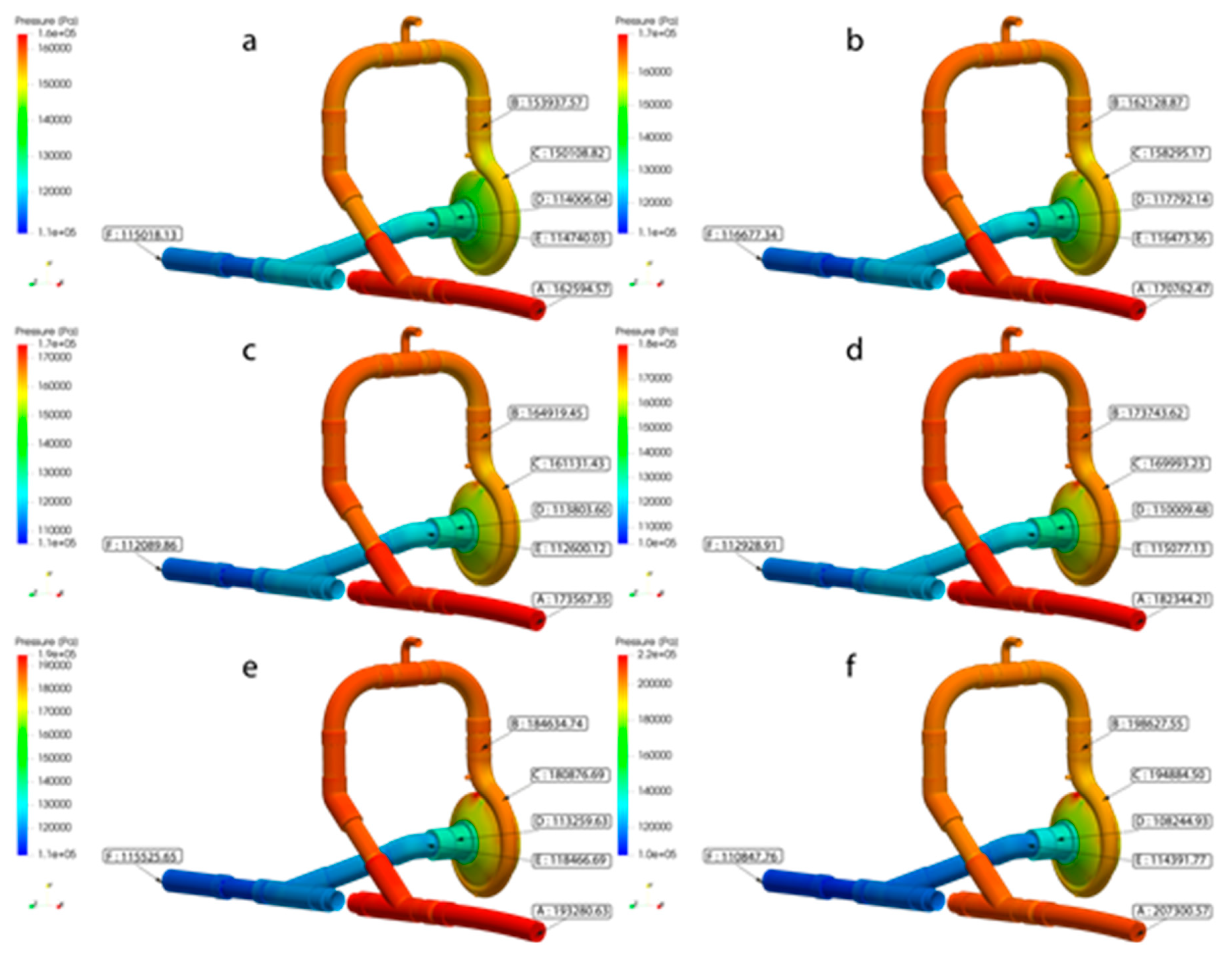

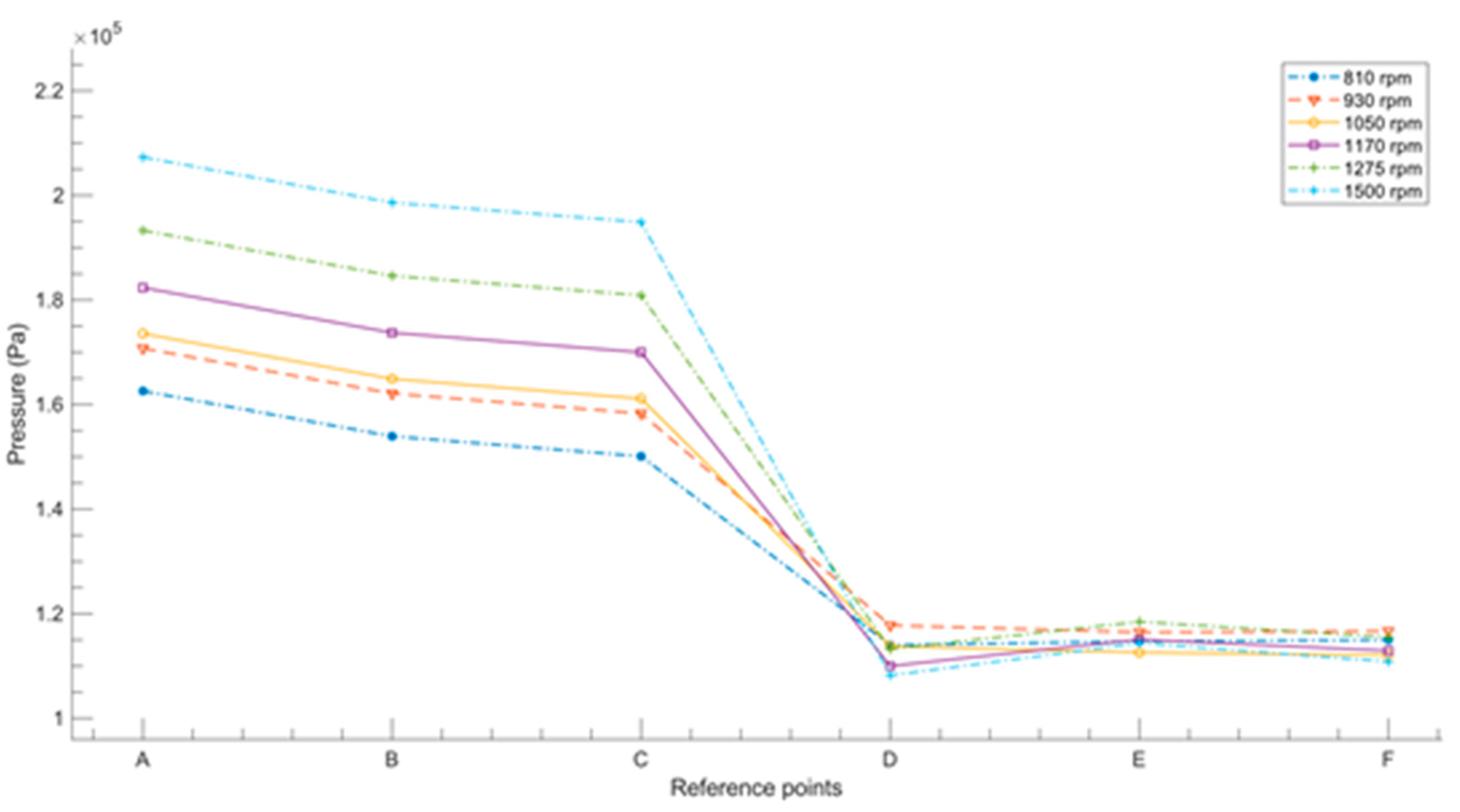

3. Results

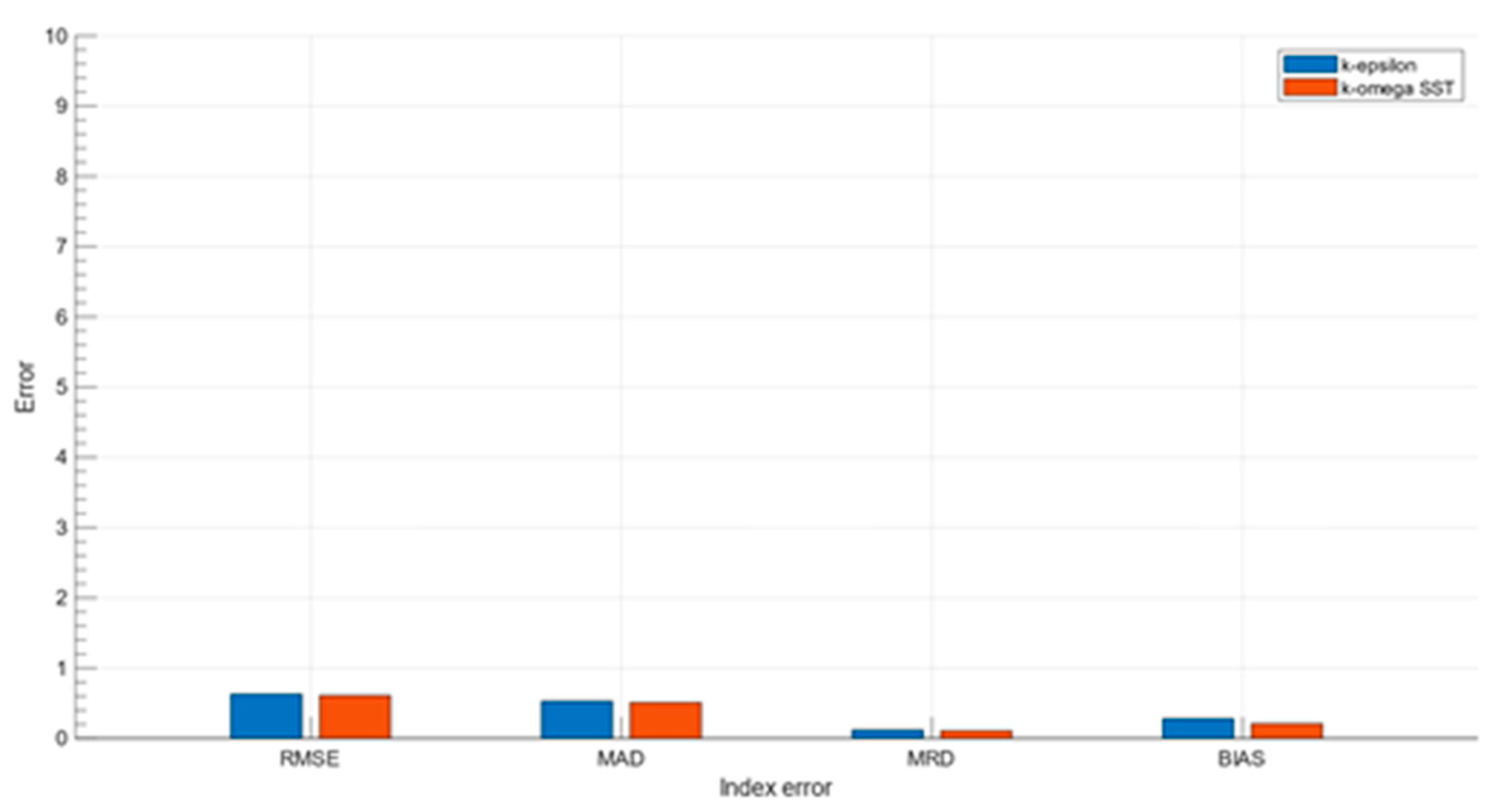

3.1. Numerical simulation validation

3.1.1. Mesh quality

3.1.2. Calibration

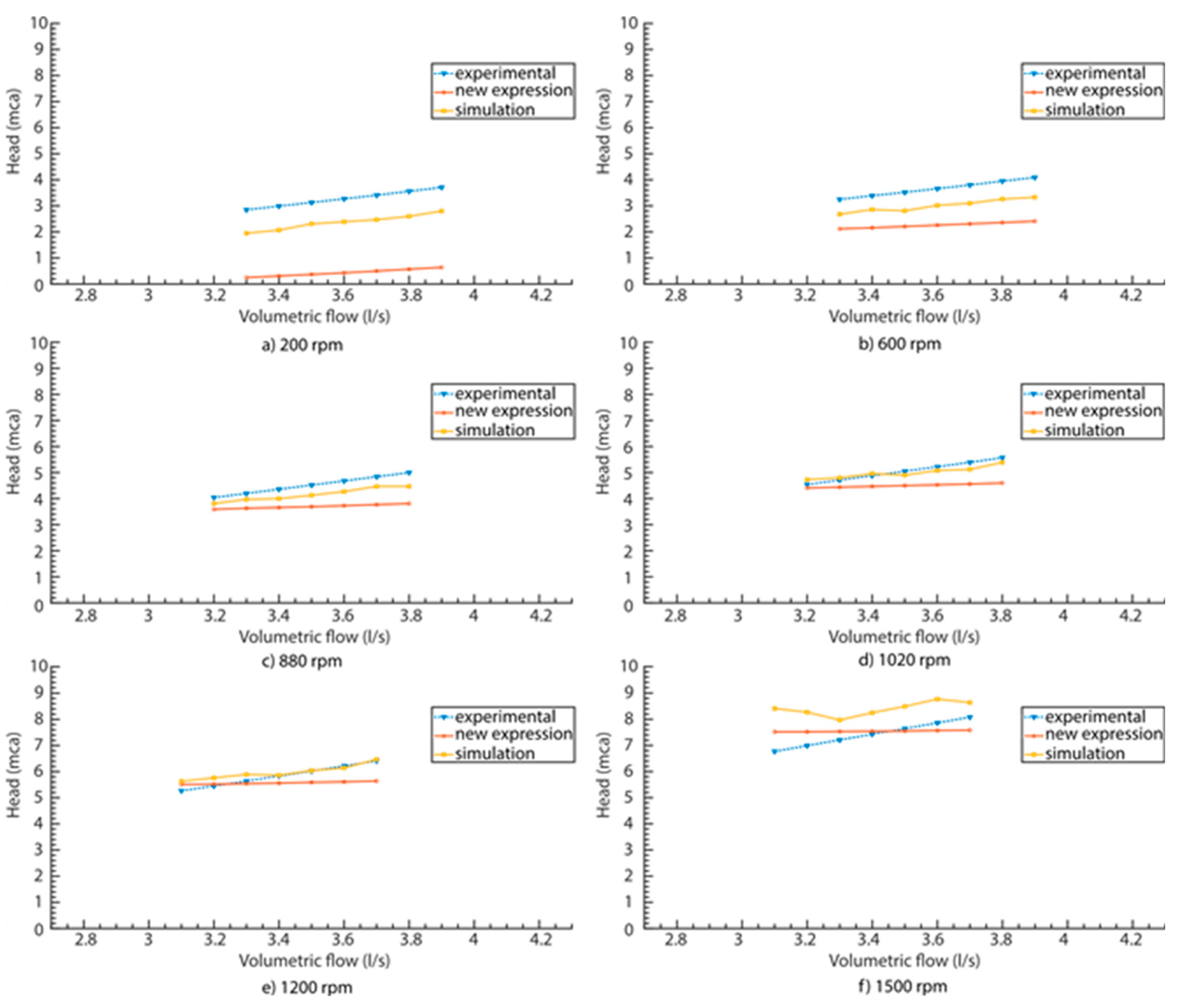

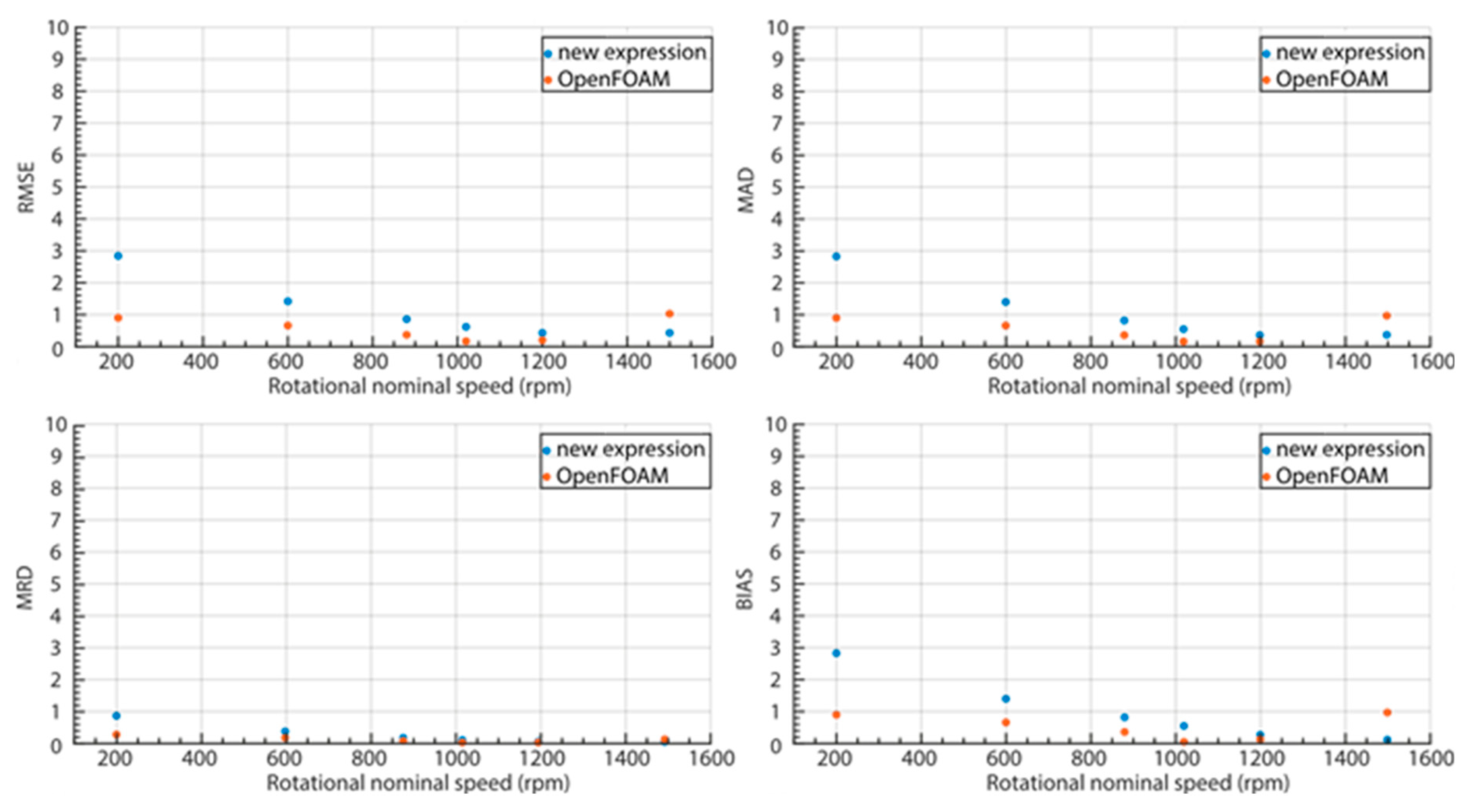

3.2. Analytical Expressions Validation

3.2.1. Analytical Expressions-New expressions to predict PATs behaviour

3.2.2. Analytical Expressions Validation

3.2.3. Error Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- A Plua, F.; Sánchez-Romero, F.-J.; Hidalgo, V.; López-Jiménez, P.A.; Pérez-Sánchez, M. New Expressions to Apply the Variation Operation Strategy in Engineering Tools Using Pumps Working as Turbines. Mathematics 2021, 9, 860. [Google Scholar] [CrossRef]

- M. Farley, “Leakage Management and Control,” Who, pp. 1–98, 2001, [Online]. Available: http://whqlibdoc.who.int/hq/2001/WHO_SDE_WSH_01.1_pp1-98.pdf.

- Niu, W.-J.; Feng, Z.-K. Evaluating the performances of several artificial intelligence methods in forecasting daily streamflow time series for sustainable water resources management. Sustain. Cities Soc. 2020, 64, 102562. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Riasi, A.; Kandi, A. Selection optimization of variable speed pump as turbine (PAT) for energy recovery and pressure management. Energy Convers. Manag. 2020, 227, 113586. [Google Scholar] [CrossRef]

- Orouji, H.; Haddad, O.B.; Fallah-Mehdipour, E.; Mariño, M.A. Modeling of Water Quality Parameters Using Data-Driven Models. J. Environ. Eng. 2013, 139, 947–957. [Google Scholar] [CrossRef]

- Vakilifard, N.; Anda, M.; Bahri, P.A.; Ho, G. The role of water-energy nexus in optimising water supply systems – Review of techniques and approaches. Renew. Sustain. Energy Rev. 2018, 82, 1424–1432. [Google Scholar] [CrossRef]

- Ferrarese, G.; Malavasi, S. Perspectives of Water Distribution Networks with the GreenValve System. Water 2020, 12, 1579. [Google Scholar] [CrossRef]

- Islam, M.S.; Babel, M.S. Economic Analysis of Leakage in the Bangkok Water Distribution System. J. Water Resour. Plan. Manag. 2013, 139, 209–216. [Google Scholar] [CrossRef]

- Bibri, S.E.; Krogstie, J. Smart sustainable cities of the future: An extensive interdisciplinary literature review. Sustain. Cities Soc. 2017, 31, 183–212. [Google Scholar] [CrossRef]

- Bach, P.M.; Rauch, W.; Mikkelsen, P.S.; McCarthy, D.T.; Deletic, A. A critical review of integrated urban water modelling – Urban drainage and beyond. Environ. Model. Softw. 2014, 54, 88–107. [Google Scholar] [CrossRef]

- Raboaca, M.S.; Bizon, N.; Trufin, C.; Enescu, F.M. Efficient and Secure Strategy for Energy Systems of Interconnected Farmers′ Associations to Meet Variable Energy Demand. Mathematics 2020, 8, 2182. [Google Scholar] [CrossRef]

- Morani, M.C. , Carravetta, A., D’Ambrosio, C. and Fecarotta, O. A new preliminary model to optimize PATs location in a water distribution network. Environmental Sciences Proceedings 2020, 2, 57. [Google Scholar]

- Gupta, A.; Bokde, N.; Marathe, D.; Kulat, K. Leakage Reduction in Water Distribution Systems with Efficient Placement and Control of Pressure Reducing Valves Using Soft Computing Techniques. Eng. Technol. Appl. Sci. Res. 2017, 7, 1528–1534. [Google Scholar] [CrossRef]

- Ávila, C.A.M.; Sánchez-Romero, F.-J.; López-Jiménez, P.A.; Pérez-Sánchez, M. Optimization tool to improve the management of the leakages and recovered energy in irrigation water systems. Agric. Water Manag. 2021, 258, 107223. [Google Scholar] [CrossRef]

- Ramos, H.; Borga, A. Pumps as turbines: an unconventional solution to energy production. Urban Water 1999, 1, 261–263. [Google Scholar] [CrossRef]

- Gallagher, J.; Harris, I.M.; Packwood, A.J.; McNabola, A.; Williams, A.P. A strategic assessment of micro-hydropower in the UK and Irish water industry: Identifying technical and economic constraints. Renew. Energy 2015, 81, 808–815. [Google Scholar] [CrossRef]

- Ávila, C.A.M.; Sánchez-Romero, F.-J.; López-Jiménez, P.A.; Pérez-Sánchez, M. Leakage Management and Pipe System Efficiency. Its Influence in the Improvement of the Efficiency Indexes. Water 2021, 13, 1909. [Google Scholar] [CrossRef]

- Ávila, C.A.M.; Sánchez-Romero, F.-J.; López-Jiménez, P.A.; Pérez-Sánchez, M. Definition of the Operational Curves by Modification of the Affinity Laws to Improve the Simulation of PATs. Water 2021, 13, 1880. [Google Scholar] [CrossRef]

- Ávila, C.A.M.; Sánchez-Romero, F.-J.; López-Jiménez, P.A.; Pérez-Sánchez, M. Optimization tool to improve the management of the leakages and recovered energy in irrigation water systems. Agric. Water Manag. 2021, 258, 107223. [Google Scholar] [CrossRef]

- García, I.F.; Novara, D.; Mc Nabola, A. A Model for Selecting the Most Cost-Effective Pressure Control Device for More Sustainable Water Supply Networks. Water 2019, 11, 1297. [Google Scholar] [CrossRef]

- Pérez-Sánchez, M.; Sánchez-Romero, F.J.; Ramos, H.M.; López-Jiménez, P.A. Improved Planning of Energy Recovery in Water Systems Using a New Analytic Approach to PAT Performance Curves. Water 2020, 12, 468. [Google Scholar] [CrossRef]

- Lee, S.; Pomeroy, C.; Burian, S. Setting Future Water Rates for Sustainability of a Water Distribution System. J. Water Resour. Plan. Manag. 2021, 147, 04020108. [Google Scholar] [CrossRef]

- Ahmadi, S.; Saboohi, Y.; Vakili, A. Frameworks, quantitative indicators, characters, and modeling approaches to analysis of energy system resilience: A review. Renew. Sustain. Energy Rev. 2021, 144, 110988. [Google Scholar] [CrossRef]

- Stefanizzi, M.; Capurso, T.; Balacco, G.; Binetti, M.; Camporeale, S.M.; Torresi, M. Selection, control and techno-economic feasibility of Pumps as Turbines in Water Distribution Networks. Renew. Energy 2020, 162, 1292–1306. [Google Scholar] [CrossRef]

- Renzi, M.; Rudolf, P.; Štefan, D.; Nigro, A.; Rossi, M. Installation of an axial Pump-as-Turbine (PaT) in a wastewater sewer of an oil refinery: A case study. 10th International Conference on Applied Energy (ICAE). LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE; pp. 665–676.

- M. Pérez- Sánchez, F. J. M. Pérez- Sánchez, F. J. Sánchez-Romero, H. Ramos M, and P. A. López-Jiménez, Bombas operando como turbinas (PAT) : principios de funcionamiento y selección. Universidad Politécnica de Valencia, 2020.

- Binama, M.; Su, W.-T.; Li, X.-B.; Li, F.-C.; Wei, X.-Z.; An, S. Investigation on pump as turbine (PAT) technical aspects for micro hydropower schemes: A state-of-the-art review. Renew. Sustain. Energy Rev. 2017, 79, 148–179. [Google Scholar] [CrossRef]

- Novara, D.; Carravetta, A.; McNabola, A.; Ramos, H.M. Cost Model for Pumps as Turbines in Run-of-River and In-Pipe Microhydropower Applications. J. Water Resour. Plan. Manag. 2019, 145, 04019012. [Google Scholar] [CrossRef]

- C. P. Thoma, D. C. P. Thoma, D., & Kittredge, “Centrifugal pumps operated under abnormal conditions,” J. Power Sources, vol. 73, no. 1, pp. 881–884, 1931.

- P. D. A.J. Stepanoff, Centrifugal and Axial Flow Pumps: Theory, Design, And Application. 1957.

- S. Childs, “Convert pumps to turbines and recover HP.,” Hydro Carbon Proces- sing Pet. Refine, vol. 41, pp. 173–174.

- Jain, S.V.; Patel, R.N. Investigations on pump running in turbine mode: A review of the state-of-the-art. Renew. Sustain. Energy Rev. 2014, 30, 841–868. [Google Scholar] [CrossRef]

- Fecarotta, O.; McNabola, A. Optimal Location of Pump as Turbines (PATs) in Water Distribution Networks to Recover Energy and Reduce Leakage. Water Resour. Manag. 2017, 31, 5043–5059. [Google Scholar] [CrossRef]

- Moazeni Faegheh; Khazaei Javad, “Optimal energy management of water-energy networks via optimal placement of pumps-as-turbines and demand response through water storage tanks.,” Appl. Energy, vol. 283, p. 116335, 2021.

- Rossi, M.; Renzi, M. A general methodology for performance prediction of pumps-as-turbines using Artificial Neural Networks. Renew. Energy 2018, 128, 265–274. [Google Scholar] [CrossRef]

- S. G. Prasad, V. S. G. Prasad, V., Shukla, S. N., & Joshi, “Performance characteristics of pump as turbine. Indian PumpsTitle,” Indian Pumps, vol. 38, no. 4, pp. 5–9, 2006.

- Williams, A. Pumps as turbines for low cost micro hydro power. Renew. Energy 1996, 9, 1227–1234. [Google Scholar] [CrossRef]

- J. C. Páscoa, F. J. J. C. Páscoa, F. J. Silva, J. S. Pinheiro, and D. J. Martins, “A new approach for predicting PAT-pumps operating point from direct pumping mode characteristics,” 2012.

- Rossi, M.; Righetti, M.; Renzi, M. Pump-as-turbine for Energy Recovery Applications: The Case Study of An Aqueduct. Energy Procedia 2016, 101, 1207–1214. [Google Scholar] [CrossRef]

- Plua, F.; Hidalgo, V.; Cando, E.; Pérez-Sánchez, M.; López-Jiménez, P. Pumps as Turbines (PATs) by Analysis with CFD Models. Int. J. Adv. Sci. Eng. Inf. Technol. 2022, 12, 1098–1104. [Google Scholar] [CrossRef]

- S. Rawal, “Numerical Simulation on a Pump Operating in a turbine mode,” Proc. 23rd Int. users Symp., 2007.

- Nautiyal, H.; Kumar, V.; Thakur, A. CFD Analysis on Pumps Working as Turbines. Hydro Nepal: J. Water, Energy Environ. 1970, 6, 35–37. [Google Scholar] [CrossRef]

- Páscoa, J.C.; Silva, F.J.; Pinheiro, J.S.; Martins, D.J. Accuracy details in realistic CFD modeling of an industrial centrifugal pump in direct and reverse modes. J. Therm. Sci. 2010, 19, 491–499. [Google Scholar] [CrossRef]

- H. Carravetta, A. H. Carravetta, A., Fecarotta, O., & Ramos, “Numerical simulation on Pump As Turbine: mesh reliability and performance concerns.,” in 2011 International Conference on Clean Electrical Power (ICCEP), 2011, pp. 169–174.

- Carravetta, A.; Fecarotta, O.; Del Giudice, G.; Ramos, H. Energy Recovery in Water Systems by PATs: A Comparisons among the Different Installation Schemes. Procedia Eng. 2014, 70, 275–284. [Google Scholar] [CrossRef]

- F. Pugliese, F. F. Pugliese, F. De Paola, N. Fontana, M. Giugni, G. Marini, and J. F. Francos, “Experimental and numerical investigation of centrifugal Pumps As Turbines,” in Proceedings of the 10th International Conference on Energy Efficiency in Motor Driven System, 2017, pp. 6–7.

- Plua, F.; Hidalgo, V.; López-Jiménez, P.A.; Pérez-Sánchez, M. Analysis of Applicability of CFD Numerical Studies Applied to Problem When Pump Working as Turbine. Water 2021, 13, 2134. [Google Scholar] [CrossRef]

- Nautiyal, H.; Kumar, V.; Thakur, A. CFD Analysis on Pumps Working as Turbines. Hydro Nepal: J. Water, Energy Environ. 1970, 6, 35–37. [Google Scholar] [CrossRef]

- Hidalgo, V.; Velasco, M.; Cando, E.; Valencia, E.; Simbaña, S.; Puga, D.; Mora, C.; Escaler, X. Rotatory 3D structured mesh study using openFOAM to simulate the flow in francis turbine. Mater. Today: Proc. 2022, 49, 142–148. [Google Scholar] [CrossRef]

- Hidalgo, V.; Escaler, X.; Valencia, E.; Peng, X.; Erazo, J.; Puga, D.; Luo, X. Scale-Adaptive Simulation of Unsteady Cavitation Around a Naca66 Hydrofoil. Appl. Sci. 2019, 9. [Google Scholar] [CrossRef]

- Pérez-Sánchez, M.; Simão, M.; López-Jiménez, P.A.; Ramos, H.M. CFD Analyses and Experiments in a PAT Modeling: Pressure Variation and System Efficiency. Fluids 2017, 2, 51. [Google Scholar] [CrossRef]

- Hidalgo, V.; Díaz, C.; Erazo, J.; Simbaña, S.; Márquez, D.; Puga, D.; Velasco, R.; Mafla, C.; Barragán, G.; Parra, C.; et al. Simplified simulation of a small Pelton turbine using OpenFOAM. 2021, 774, 012075. [CrossRef]

- File structure of OpenFOAM cases.” https://www.openfoam.com/documentation/user-guide/2-openfoam-cases/2.1-file-structure-of-openfoam-cases (accessed Jan. 11, 2022).

- Huang, S.; Wei, Y.; Guo, C.; Kang, W. Numerical Simulation and Performance Prediction of Centrifugal Pump’s Full Flow Field Based on OpenFOAM. Processes 2019, 7, 605. [Google Scholar] [CrossRef]

- Fecarotta, O.; Aricò, C.; Carravetta, A.; Martino, R.; Ramos, H.M. Hydropower Potential in Water Distribution Networks: Pressure Control by PATs. Water Resour. Manag. 2014, 29, 699–714. [Google Scholar] [CrossRef]

- Novara, D.; McNabola, A. A model for the extrapolation of the characteristic curves of Pumps as Turbines from a datum Best Efficiency Point. Energy Convers. Manag. 2018, 174, 1–7. [Google Scholar] [CrossRef]

- Shah, S.R.; Jain, S.V.; Patel, R.N.; Lakhera, V.J. CFD for centrifugal pumps: A review of the state-of-the-art. Procedia Eng. 2013, 51, 715–720. [Google Scholar] [CrossRef]

| Location | The Capacity of the Plant (kW) | Year of Installation |

|---|---|---|

| Sainyabulli Province, Laos | 2 | 2008 |

| Thima Kenya | 2.2 | 2001 |

| Mae Wei Village, Thailand | 3 | 2008 |

| West Java, Indonesia | 4.5 | 1992 |

| Kinko village, Tanzania | 10 | 2006 |

| Fazenda Boa Esperanca, Brazil | 45 | 2007 |

| Ambotia Micro-hydro project, India | 50 | 2004 |

| British Columbia, Canada | 200 | - |

| Vysni Lhoty, Czech Republic | 332 | 2008 |

| Parameter | Value/Characteristic |

|---|---|

| Element type | Hexahedra, Polyhedra, Prism |

| Number of Elements | 827578 |

| Hexaedral | 639704 |

| Prism | 28238 |

| Polyhedra | 159612 |

| Number of Nodes | 1203219 |

| Number of Patches | 8 |

| Max.Aspect Ratio | 14.68619 |

| Min.Surface Area | 6.19213 e-09 |

| Min.Volume | 1.39587e-11 |

| Max Skewness | 12.918596 |

| Initial Conditions | Value |

|---|---|

| Turbulent Kinetic Energy ( ) | 0.032856(m2/s2) |

| Turbulent Dissipation Rate ( ) | 0.320573(m2/s3) |

| Specific turbulent Dissipation Rate ( ) | 108.4104(s-1) |

| Turbulent kinematic viscosity (nut) | 3.03 x 10-4(m2/s) |

| Runner1 | Runner | RunnerIn | Volute | Pipe-Inlet | Pipe-Outlet | Inlet | Outlet | |

|---|---|---|---|---|---|---|---|---|

| Velocity (u-m/s) | movingWallVelocity uniform (0 0 0) |

movingWallVelocity uniform (0 0 0) |

movingWallVelocity uniform (0 0 0) |

fixedValue uniform (0 0 0) |

fixedValue uniform (0 0 0) |

fixedValue uniform (0 0 0)v |

flowRateInletVelocity volumetricFlowRate constant 0.0045 |

inletOutlet valueuniform (0 0 0) |

| Static Pressure (p-m2/s2) |

zeroGradient | zeroGradient | zeroGradient | zeroGradient | zeroGradient | zeroGradient | zeroGradient | uniform 115.198(810) 116.694(930) 112.472(1050) 112.909(1170) 115.756(1275) 110.971(1500) |

| %Error | ||||||

|---|---|---|---|---|---|---|

| Referenced sections | 810 | 930 | 1050 | 1170 | 1275 | 1500 |

| A | 8,724% | 14,297% | 8,218% | 0,035% | 12,881% | 14,042% |

| B | 4,455% | 10,425% | 4,286% | 5,324% | 9,068% | 13,066% |

| C | 5,979% | 12,040% | 5,643% | 3,999% | 10,389% | 11,936% |

| F | 0,156% | 0,014% | 0,340% | 0,018% | 0,199% | 0,111% |

| Experimental | Simulation | ||||

|---|---|---|---|---|---|

| k-e | k-w-SST | ||||

| n(rpm) | H (mca) | H (mca) | % Error | H (mca) | % Error |

| 200 | 3,27 | 2,28 | 30,23 | 2,39 | 27,00 |

| 600 | 3,66 | 2,90 | 20,74 | 3,02 | 17,58 |

| 880 | 4,68 | 4,21 | 10,10 | 4,27 | 8,73 |

| 1020 | 5,22 | 5,03 | 3,67 | 5,08 | 2,70 |

| 1200 | 6,22 | 6,21 | 0,12 | 6,14 | 1,30 |

| 1500 | 7,86 | 8,60 | 9,35 | 8,77 | 11,52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).