1. Introduction

There is a lot of free thermal energy in the world. It comes from waste heat sources like engines, furnaces, boilers, and so on, as well as from the sun through natural heating. The thermoelectric (TE) effect is an efficient way to turn heat energy into electricity. The use of structural material for instance cement, for energy harvesting is attractive. People are paying more attention to TE technologies in the area of saving energy in buildings [

1,

2]. However, due to the inferiority of the conversion efficiency i.e. figure of merit, in-building energy harvesting is hard to realize in practice.

A high value of the figure of merit (ZT), which needs a high Seebeck coefficient, high electrical conductivity, and low thermal conductivity, is needed for a TE material to work well for energy conversion. Nanostructured materials are promising to achieve a high power factor and maintain low heat conductivity, which would improve ZT [

3]. Prior research [

4,

5,

6,

7,

8,

9,

10,

11,

12] used different methods to improve the ZT of thermoelectric cement composite, with a focus on either increasing the Seebeck coefficient or the electrical conductivity. The ways include making TE cement composites with expanded graphite [

4], carbon nanotubes [

5,

6], graphene nanoplatelets [

7], carbon fibers [

8], and metallic oxides (Fe

2O

3, ZnO, MnO

2) [

9,

10,

11,

12]. However, there were very few works to estimate the harvested electrical energy for the realization of their potential applications.

Thermoelectric (TE) energy harvesting refers to the generation of power, typically at a small scale, through the utilization of external sources of energy such as solar thermal energy, waste heat, ambient heat, heat emanating from the human body, and others. The primary objectives of small-scale TE energy harvesting devices are to enhance convenience and simplicity, reduce costs and increase longevity, ensure dependability, and promote ecological sustainability. Moreover, the utilization of ambient thermal energies presents a promising approach to mitigate the urban heat island (UHI) phenomenon. This means that they are good for the environment and can be used again and again. Small thermoelectric generators have the capability to extract energy from heat sources and can be implemented in various settings such as a wrist-watch [

13], a wood stove [

14], or a biomass cook stove [

15]. So, the investigation of thermoelectric energy harvesting devices is highly valuable as it facilitates the provision of power to compact, cordless, and portable electronic devices. Besides these energy harvesters are utilized in self-sustaining devices and wireless sensor networks [

16,

17] within intelligent structures, as they possess the ability to operate continuously and autonomously without the need for an external power supply.

This study involves the integration of Fe2O3, ZnO, and MnO2 nanostructured materials into graphene nanoplatelets-based cement composites. The findings indicate that the inclusion of 10 weight percent of both Zinc Oxide (ZnO) and Graphene nanoplatelets (GnP) can effectively enhance the peak power output of cement-based composites. A maximum electrical power output of approximately 1.5 Wm−2 can be obtained through the incorporation of a small quantity of metallic oxide (ZnO) and graphene into cement composites. The present study proposes an extension of the aforementioned works to enable the realization of a thermoelectric generator (TEG) comprising a p-type and n-type cement composite. The maximum power output of the TEG is estimated to be 0.55 mW when subjected to a temperature differential of 50 °C.

2. Materials and Methods

2.1. Sample preparation

The materials utilized in this study were employed in their as-received state without undergoing any additional purification procedures. The procurement of cement and bulk graphene nanoplatelets of H-grade (average particle size: 25 µm, specific density: 2.2 gcm−3, thickness: 15 nm, surface area: 50-80 m2g) was carried out from Toyo Matelan Co. Ltd., Japan, and XG Sciences, USA, correspondingly. Metallic oxides, such as Iron (III) oxide (Fe2O3) (molecular weight: 159.69 gmol−1, specific density: 5.15 gcm−3, purity: ≥ 99.9%), Zinc oxide (ZnO) (average particle size: ≤ 0.05 µm, molecular weight: 81.39 gmol−1, purity: > 97%) and Manganese (IV) oxide (MnO2) (average particle size: ≤ 10.0 µm, molecular weight: 86.94 gmol−1, specific density: 5.21 gcm−3, purity: ~ 85%), are acquired from Sigma-Aldrich Japan G.K.

Cement composite samples were prepared using metallic oxides (Fe

2O

3/ZnO/MnO

2) and GnP, with a mass ratio of 10 wt% each, as determined to yield optimal results according to [

7]. Three samples were prepared with the amount of 10.0 wt% by mass of cement with inclusions of GnP and Fe

2O

3 (10% GnP, 10% Fe

2O

3), GnP and ZnO (10% GnP, 10% ZnO), and GnP and MnO

2 (10% GnP, 10% MnO

2), respectively. The dimension of the samples is 2×2×10 mm

3. The methodology for preparing the samples has been explicated in the preceding study [

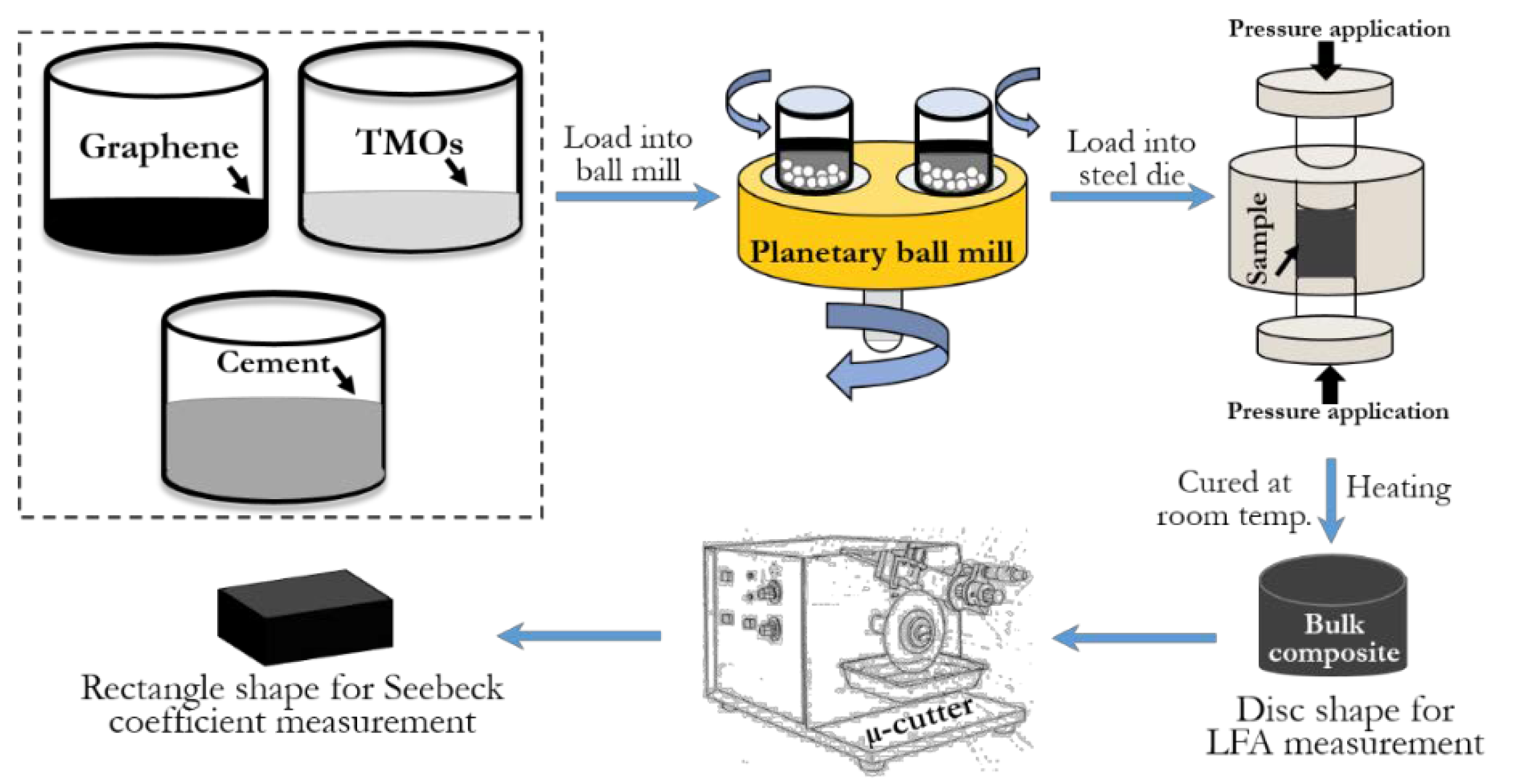

7] and is visually depicted in

Figure 1. To summarize, the raw materials are homogenized using a planetary ball mill, subsequently compacted to achieve bulk form, subjected to ambient temperature curing, and finally heated to eliminate any residual moisture. The cylindrical specimen has been retained for thermal evaluation, whereas the rectangular bar has been extracted from the identical cylindrical specimen to be employed in the four-probe setup. The measurement of the Seebeck coefficient and electrical conductivity is conducted concurrently through the utilization of a four-probe system (RZ2001i) manufactured by Ozawa Science, Japan. The temperature range for the measurement is set between 25 °C and 75 °C. The study of thermal conductivity was conducted through the utilization of the laser flash technique. This involved the measurement of specific heat capacity and thermal diffusivity using a differential scanning calorimeter (DSC-60A, Shimadzu Corporation, Japan) and a laser flash apparatus (Netzsch LFA 457 MicroFlash, Germany), respectively.

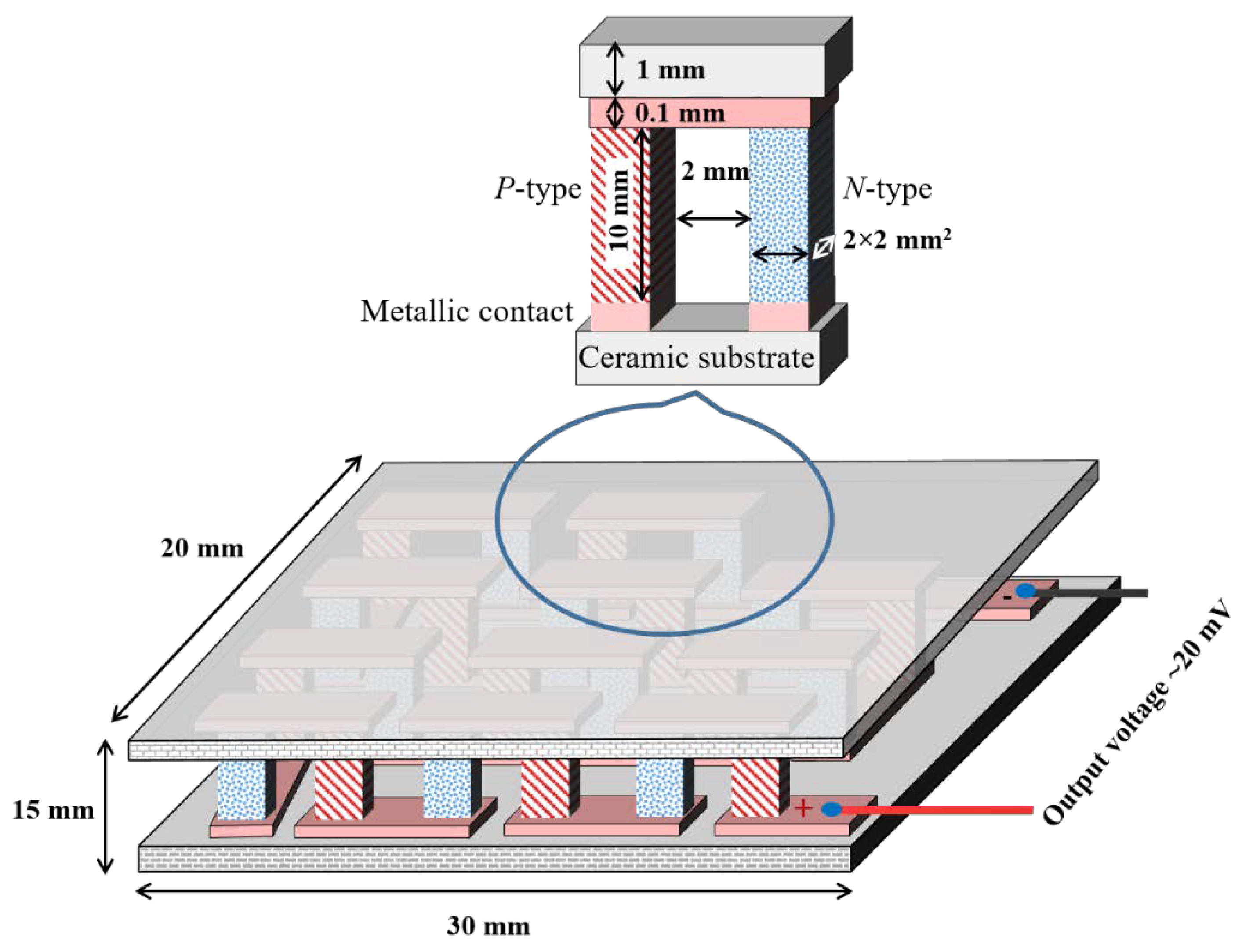

2.2. Thermodynamics of a thermoelectric generator

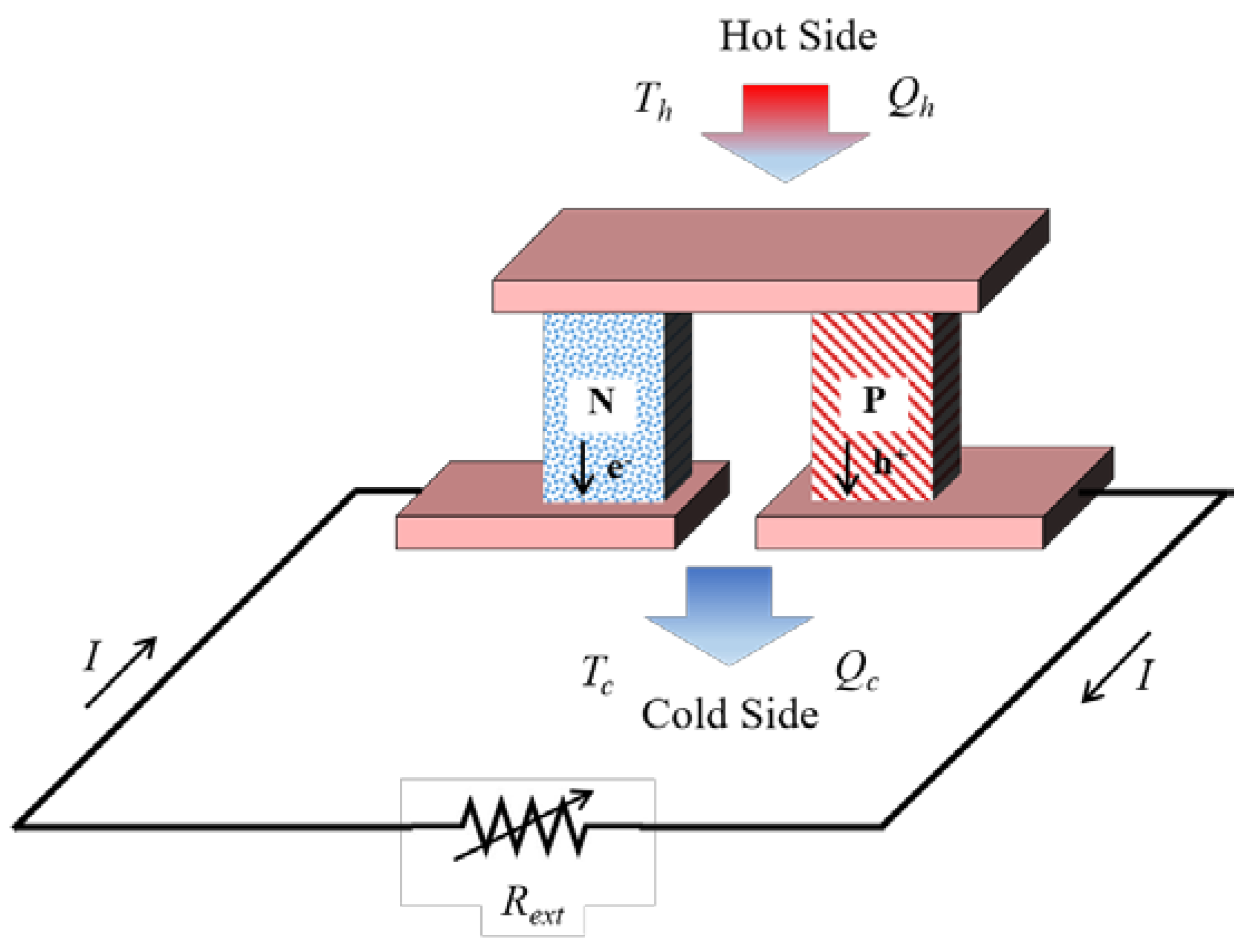

The schematic diagram of a thermoelectric generator is depicted in

Figure 2, wherein the symbols R, S, and K denote the net resistance, Seebeck coefficient, and thermal conductance of the device, respectively. For the sake of simplicity, it is assumed that all parameters of the generator are independent of temperature.

The absorbed heat Q

h on the hot side can be mathematically expressed as follows:

The second term in the equation represents the Joule heating occurring within the sample, with the assumption that an equal amount of heat is distributed to both sides. The third term accounts for the thermal current's backflow. Likewise, the dissipated heat Q

c on the lower temperature side can be represented as such.

The total power output of the thermoelectric module can be expressed in terms of its internal properties, as per the First Law of Thermodynamics.

The total power output depicted in

Figure 2 may be characterized by an external load resistance.

The total voltage can be obtained by equating equations (3) and (4).

The electrical current for the module can be derived from Equation (5).

The magnitude of the electric current (I) remains constant regardless of the quantity of thermocouples present in the system. Upon substitution of the variable "I" into Equation (5), the resulting expression yields the voltage that exists across the module.

The output power, denoted as P, is equivalent to

The maximum electrical power that can be transferred occurs when the external resistance (R

ext) is equal to the internal resistance (R), resulting in the maximum electrical power output.

The variables L, A, and σ represent the length, area, and electrical conductivity of the sample, respectively. The thermoelectric conversion efficiency can be expressed as the quotient of the power output and the heat absorbed at the hot side.

To achieve the highest possible thermoelectric conversion efficiency, one can derive the conversion efficiency equation in Eq. (10) with respect to R

ext/R and equate it to zero. Subsequently, the highest attainable conversion efficiency, denoted as η

max, is determined.

Therefore, the thermoelectric device relies on two fundamental parameters, namely Pmax and ηmax.

3. Results and Discussion

3.1. Thermoelectric properties

The Seebeck coefficient was not measurable in cement due to its restricted electrical conduction, resulting in both values being regarded as zero. The electrical conductivity (σ) of the samples containing ZnO demonstrates superior values in comparison to the other composites containing Fe2O3 and MnO2, correspondingly. The ZnO composite exhibits a maximum electrical conductivity of approximately 14.0 Scm−1, which displays a positive correlation with temperature. This observation suggests the characteristic behavior of semiconductors. The composites containing Fe2O3 and MnO2 exhibit a comparable pattern to that of ZnO, with the highest conductivity values being approximately 8.5 Scm-1 and 5.5 Scm-1, respectively.

The measured Seebeck coefficient (S) values for each of the samples demonstrate a positive (+ve) indication, indicating that the composites that were synthesized possess characteristics of p-type semiconductors. The composites containing Fe

2O

3, ZnO, and MnO

2 exhibit a maximum Seebeck coefficient of 105 µVK

−1 at 70 °C, approximately 140 µVK

−1 at 70 °C, and 100 µVK

−1 at 65 °C, respectively. The determination of thermal conductivity (κ) is achieved through the correlation between thermal diffusivity and specific heat capacity. It is revealed that the thermal conductivity average values of the composite containing Fe

2O

3, ZnO, and MnO

2 are around 0.65, 0.95, and 0.90 Wm

−1K

−1, respectively. The non-dimensional figure of merit (ZT) is derived using the formula:

. The cement composite containing Fe

2O

3, ZnO, and MnO

2 exhibits a maximum ZT value of 0.5×10

−2, 1.00×10

−2, and 0.2×10

−2, respectively.

Table 1 presents a comprehensive list of the thermoelectric parameters that were obtained.

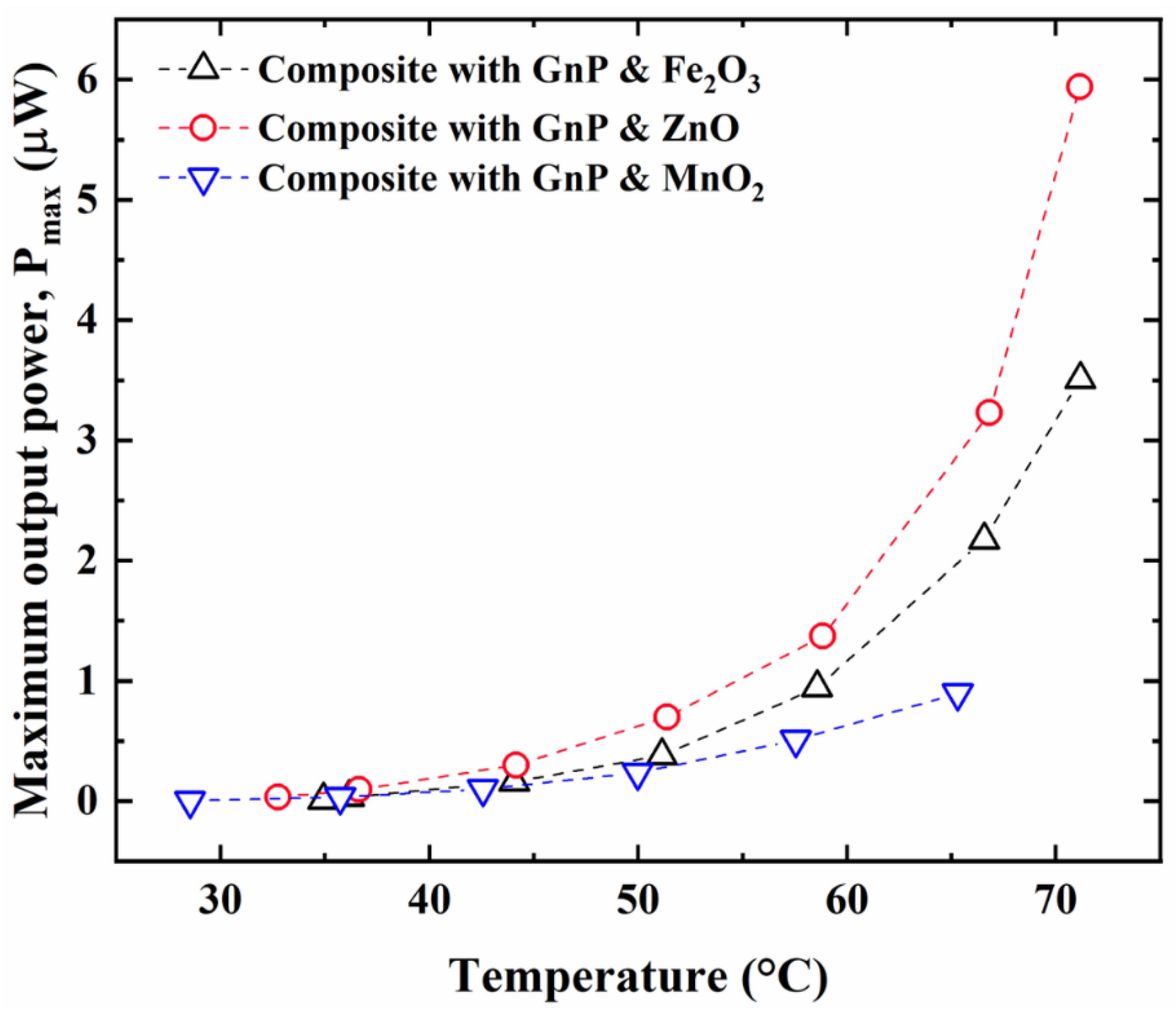

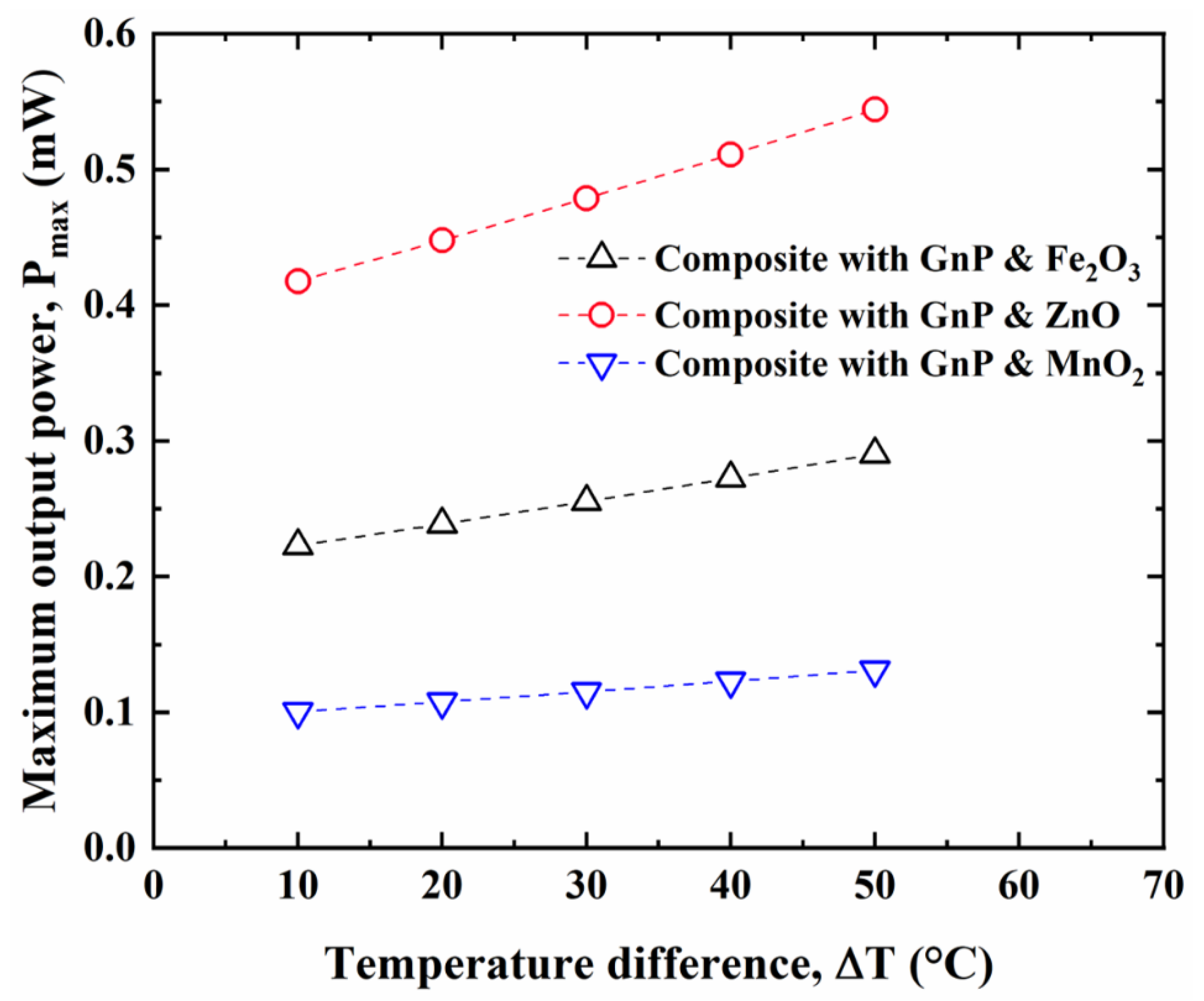

3.2. Analysis of maximum electrical power output

The Seebeck coefficients (S), electrical conductivity (σ), and dimensions such as length (L) and area (A) of composites containing graphene nanoplatelets (GnP) and metallic oxide (Fe

2O

3/ZnO/MnO

2) were utilized in the calculation of power. The maximum electrical power output, denoted as P

max, for the GnP-based cement composites with oxides inclusions is evaluated based on the obtained thermoelectric parameters via equation (9). As illustrated in

Figure 3, the maximum power output (P

max) is observed to be 3.5 µW at approximately 70 °C when utilizing GnP-Fe

2O

3 integrations. Conversely, the employment of GnP-MnO

2 inclusions yields a P

max of approximately 1 µW at 65 °C. Composites containing GnP-ZnO demonstrated a respective increase of 42% and 83% compared to composites containing GnP-Fe

2O

3 and GnP-MnO

2.

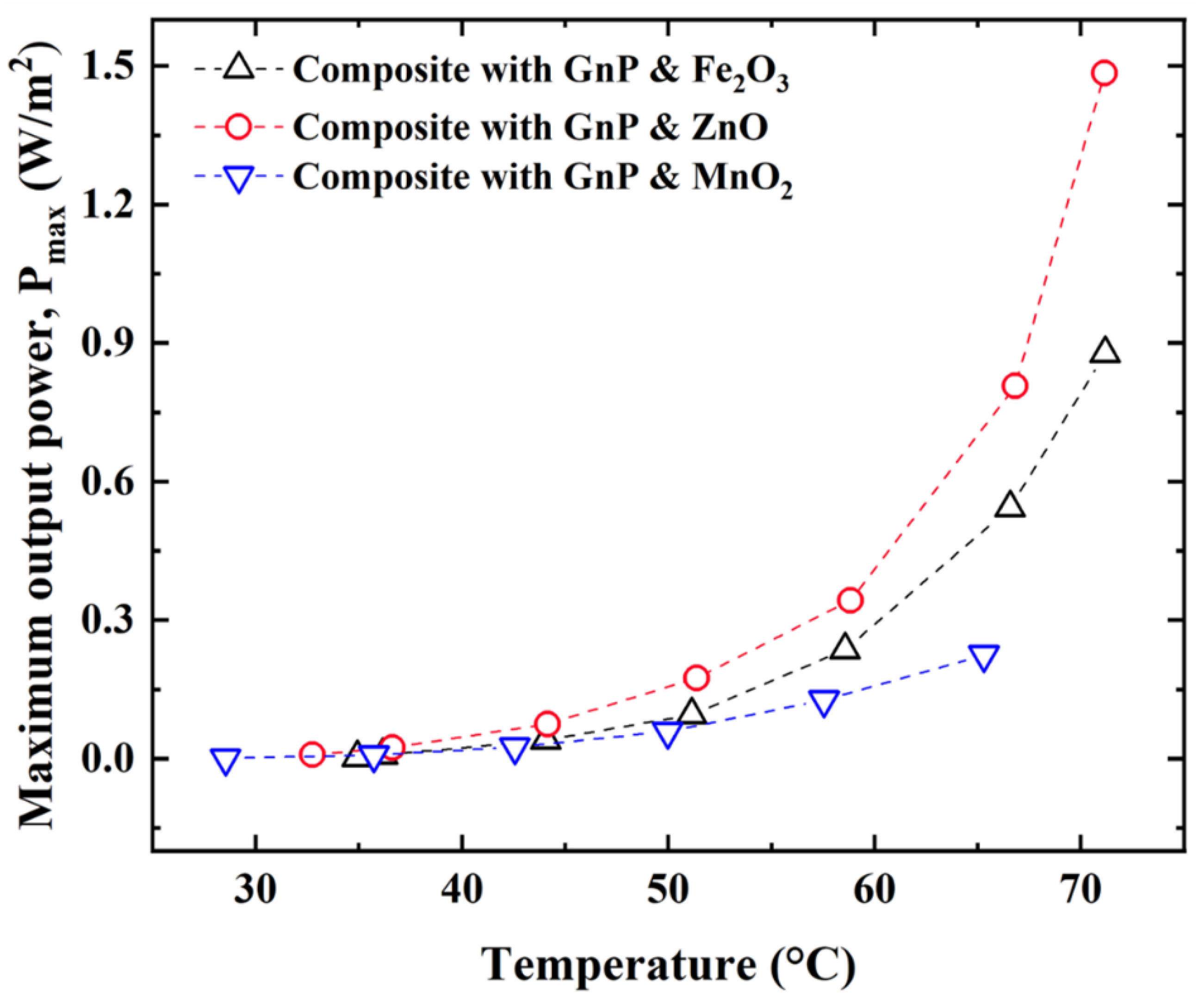

In order to assess the power output produced by the actual area and conduct a comparative analysis with other energy harvesting mechanisms, the value of P

max is recalculated for the cement composites, taking into account the surface area of one square meter of the sample, as depicted in

Figure 4. The data presented in this figure suggests that the incorporation of composites in pavements, roofs, or building surfaces can result in a power output of approximately 1.5 W per square meter, given a temperature differential of approximately 50 °C. This can be achieved through the use of solely p-type GnP-ZnO added cement composites with a thickness of 10 mm. The estimated value surpasses the reported value of a thermoelectric generator (TEG) when utilizing a human body source, as evidenced by a recorded value of 0.285 Wm

−2 [

18]. According to a study [

19], the Seebeck coefficient at the intersection of a PN-junction created by p- and n-type cement composite was found to be higher than that of the individual components. So, the integration of GnP-ZnO composite and n-type cement composites may result in a significant enhancement of the Seebeck coefficient, thereby enabling a potential increase in the total output power.

To derive an estimate of the output power generated by a thermoelectric generator (TEG) based on cement composites, it is necessary to utilize a combination of p-type and n-type composites. These composites must be arranged in a manner such that their junctions are electrically connected in series and thermally connected in parallel. This current study exclusively yielded a thermoelectric cement composite of p-type. Therefore, it is imperative to take into account the n-type. Wei et al. [

20] have reported on a cement composite with n-type characteristics that exhibit a maximum Seebeck coefficient of approximately −52 µVK

−1 at a temperature of around 70 °C, utilizing expanded graphite. This work is comparable in terms of loading concentration into the cement. The maximum electrical power for a structural thermoelectric generator has been calculated based on the Seebeck coefficient of the reported n-type composite and our p-type composite (GnP and Fe

2O

3/ZnO/MnO

2), as per reference [

21]. According to

Figure 5, the fabrication of a cement composite device utilizing an expanded graphite TE element (n-type) and a graphene-ZnO TE element (p-type) can result in a maximum power output of 0.55 mW when subjected to a temperature difference of 50 °C.

3.3. Analysis of open-circuit voltage

The aforementioned maximum power output has been computed utilizing the maximum power transfer theorem, which involves assuming that the external load resistance is equivalent to the internal resistance of the generator. Nevertheless, in pragmatic scenarios, a potential discrepancy may arise between internal and external resistance. So, the analysis of the open-circuit voltage of a thermoelectric device is of utmost importance. The highest Seebeck coefficient among the three metallic oxides (Fe

2O

3, ZnO, MnO

2) was observed in a p-type cement composite containing graphene and ZnO, with a value of +141 µVK

−1. On the other hand, an n-type cement composite containing expanded graphite exhibited a Seebeck coefficient of −52 µVK

−1 [

20]. The maximum anticipated absolute output voltage at the open circuit can be determined by evaluating the Seebeck coefficient values of the p-type and n-type cement composites. Specifically, a temperature gradient of 10 K would result in an output voltage of |1.9 mV| ([|+141| + |−52|] × 10 = 1.9 mV) [

21]. However, to achieve a cement composite-based thermoelectric generator (TEG) with the capability to power functional devices, a minimum of 20 mV must be produced. The aforementioned value is derived from the requirement of voltage amplification through a voltage step-up converter in common use cases such as LED powering and energy storage in a capacitor. The LTC3108, a DC-to-DC converter that operates without additional power requirement, is a commercially available ultralow voltage step-up converter as reported in reference [

22]. The converter has the capability to increase the output voltage from 2.2 V to 5 V, given an input of 20 mV. A Japanese research group [

23] utilized a commercial converter to power an LED through a polymer-based TEG. The TEG comprises 300 thermoelements arranged in 10 parallel and 30 series and generates an output voltage of 40 mV. Based on the preceding information, it can be inferred that to achieve a voltage step-up conversion of at least 20 mV, approximately 22 thermoelements are necessary for our TEG when subjected to a temperature gradient of 10 K.

Figure 6 depicts a potential configuration of thermoelements that alternate between p-type and n-type.

The utilization of cement composite thermoelectric generators (TEGs) that have a voltage output range of 20 to 50 mV, either with or without a step-up converter to drive the DC voltage produced in a capacitor, has the potential to provide power to low-consumption electronic devices that are integrated with buildings. These devices may include ultra-low-power microcontrollers and wireless sensor networks [

24]. According to a study [

25], the utilization of advanced devices such as smart home technologies and Internet of Things (IoT) applications can be facilitated if the voltage generated by the TE generator (TEG) exceeds 100 mV.

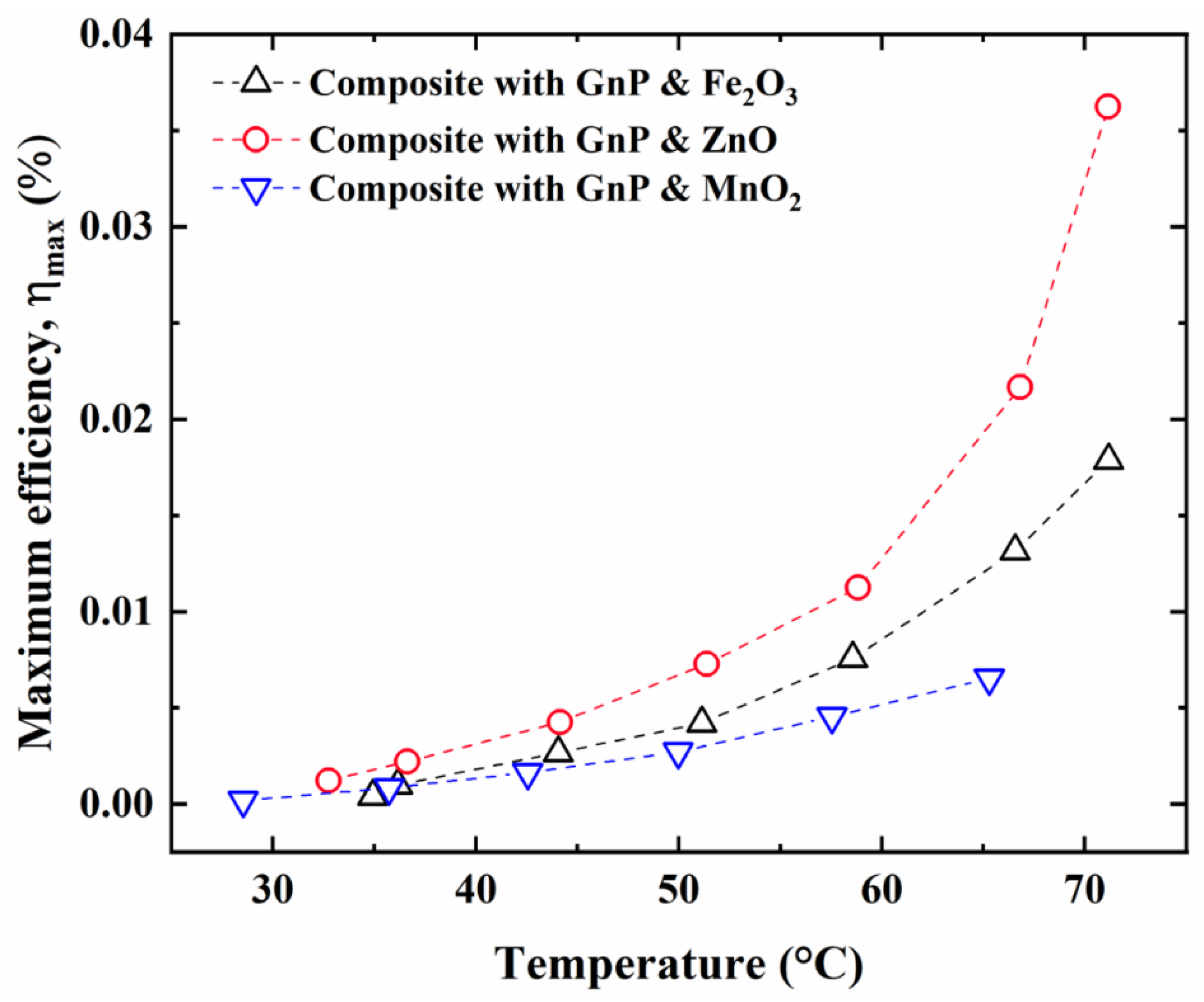

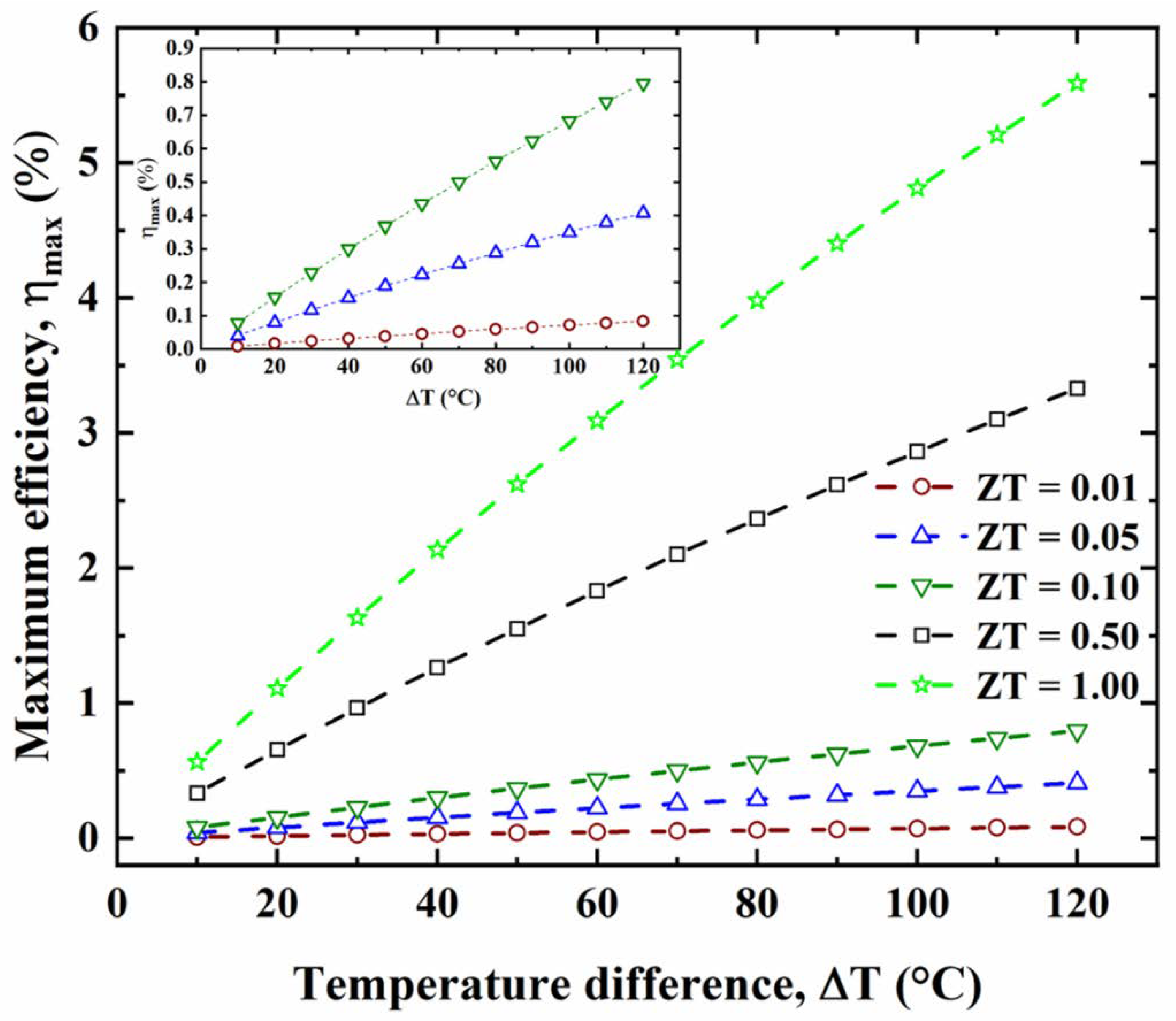

3.4. Analysis of energy conversion efficiency

The thermoelectric efficiency of cement composites containing graphene nanoplatelets (GnP) and metallic oxides (Fe

2O3/ZnO/MnO

2) has been determined by applying Eq. (11).

Figure 7 displays the efficiency plot of GnP-Fe

2O

3, GnP-ZnO, and GnP-MnO

2 cement composites while maintaining a constant cold side temperature of 25°C and varying the hot side temperature. The data presented in this figure suggests that there is a positive correlation between the hot side temperature and the maximum efficiency, as the latter tends to increase as the former increases. The GnP-ZnO composite exhibits the highest efficiency (0.04%) as expected, owing to its superior figure of merit in comparison to GnP-Fe

2O

3 and GnP-MnO

2. Nevertheless, the projected efficacy exhibits a notable disparity when juxtaposed with alternative energy harvesting mechanisms. The primary cause of the reduced efficiency is attributed to the limited temperature differential existing between the warmer and cooler regions. One potential solution for enhancing the energy conversion of cement composite TEG is to ensure an abundant heat supply. The figure presented as

Figure 8 demonstrates that the maximum power conversion efficiency achievable at a temperature difference of 100 K is approximately 0.1%, with a corresponding ZT value of 0.01. The aforementioned level of efficacy is attained through the utilization of a polymer thermoelectric apparatus, which serves the purpose of energizing Light Emitting Diodes [

23]. It is worth noting that the maximum thermoelectric efficiency (η

max) exhibits greater magnitude in the presence of high values of the thermoelectric figure of merit (ZT) and temperature difference (ΔT). Achieving an improvement of at least one order of magnitude in the figure of merit for cement composite, as compared to the presently highest reported values [

11], would lead to the attainment of an efficiency level of 1.0%. Thus, significant enhancement in ZT is required for the practical implementation of thermoelectric devices based on cement composites.

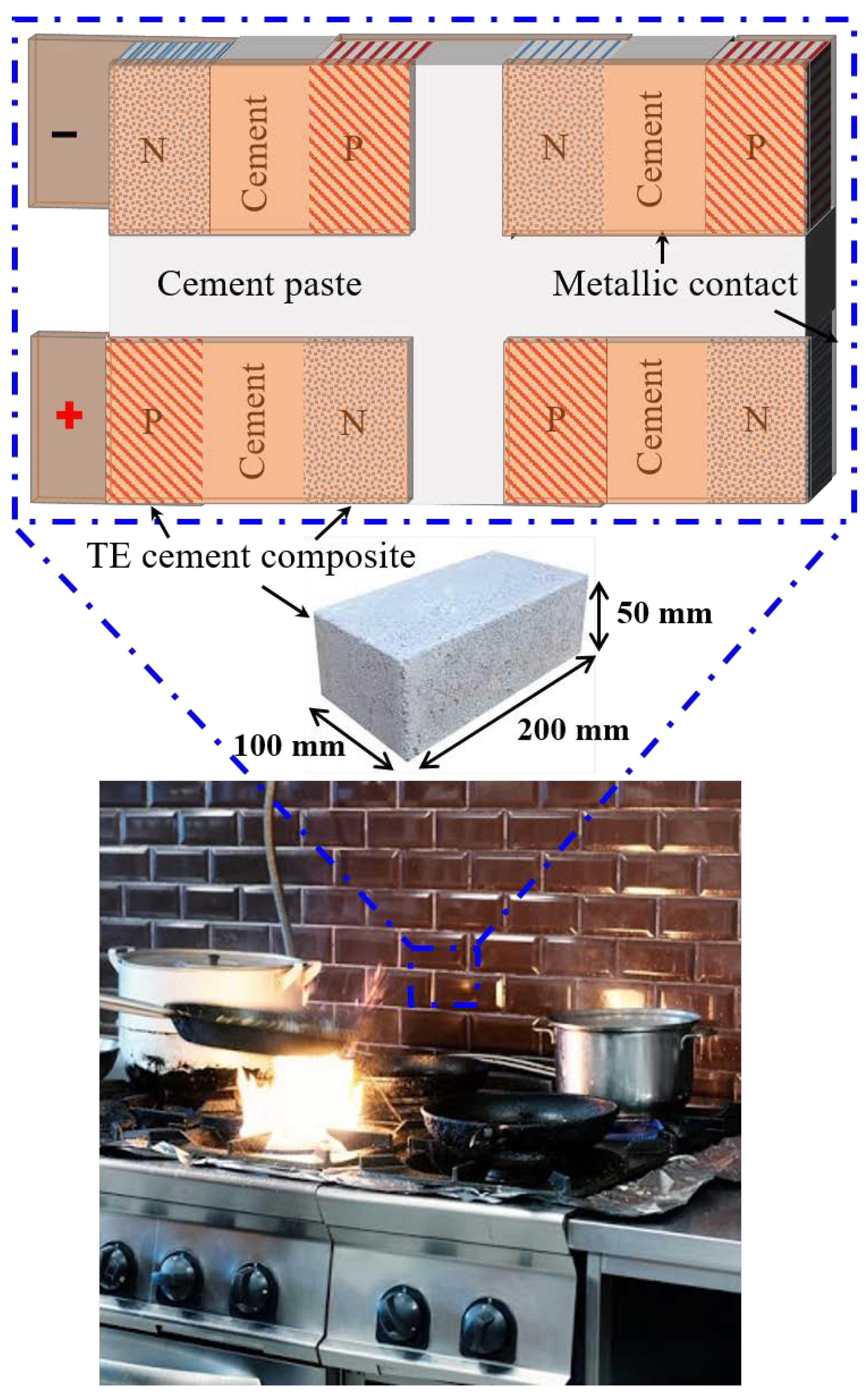

3.5. Potential application of thermoelectric cement composite

The utilization of thermoelectric cooling technologies in buildings has garnered increased attention within the realm of energy conservation. In the realm of thermoelectric cooling technologies, conventional thermoelectric materials, such as Bi

2Te

3, were utilized to construct thermoelectric devices that were subsequently affixed to the wall and window of a study [

26]. However, if the concrete wall exhibits thermoelectric properties, utilizing its thermoelectric effect for energy generation and cooling would be a more efficient and practical approach. Thermoelectric cement composite devices exhibit promising potential for employment in the field of ambient energy harvesting. This technology has the capability to capture residual heat energy present in diverse locations such as building envelopes, urban areas, roads, kitchen environments, and others. For example, the surface temperature of a concrete wall adjacent to a kitchen stove, particularly in a restaurant setting, has the potential to reach temperatures ranging from 60 to 70 degrees Celsius, despite the ambient air temperature remaining at room temperature. The thermal gradient presents a viable prospect for harnessing thermoelectric advancements to convert dissipated thermal energy into electrical power.

Figure 9 illustrates a potential configuration of a wall composed of thermoelectric cement composite material for energy harvesting. For this purpose, the employment of thermoelectric cement composites in the form of thick rectangular slabs measuring 200×100×50 mm

3 is considered.

4. Conclusions

The utilization of a structural cement composite as the basis for a thermoelectric generator presents promising prospects for the harvesting of ambient energy. This technology can capture and convert untapped thermal energy in various settings such as buildings, pavements, and industrial environments into usable electrical energy. A temperature differential of approximately 50°C can result in the attainment of a power output of 1.5 W by a composite material consisting of graphene and ZnO added to cement, occupying an area of one square meter and having a height of 10 mm. It is possible to store the calculated energy within a capacitor and subsequently apply it within a wired or wireless communication network for various buildings. The incorporation of energy-saving and harvesting technology in buildings has the potential to facilitate the development of energy-efficient buildings and environmentally sustainable construction practices, leading to the creation of multifunctional smart buildings and civil structures.

Author Contributions

Conceptualization, S.G.; methodology, S.G.; software, B.B.S.; formal analysis, S.G., investigation, S.G.; resources, B.B.S.; writing—original draft preparation, S.G.; writing—review and editing, B.B.S.; visualization, S.G.; supervision, B.B.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are thankful to Professor Michitaka Ohtaki, Interdisciplinary Graduate School of Engineering Sciences, Kyushu University, Japan and Dr. Sivasankaran Harish, Department of Mechanical Engineering, The University of Tokyo, Japan for their valuable contributions.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Z. Liu, L. Zhang, G. Gong, H. Li, G. Tang. Review of solar thermoelectric cooling technologies for use in zero energy buildings. Energy Build. 2015, 102, 207–216. [CrossRef]

- Y.W. Kim, J. Ramousse, G. Fraisse, P. Dalicieux, P. Baranek. Optimal sizing of a thermoelectric heat pump (THP) for heating energy-efficient buildings. Energy Build. 2014, 70, 106–116. [CrossRef]

- S. Sakane, T. Ishibe, T. Taniguchi, N. Naruse, Y. Mera, T. Fujita, M.M. Alam, K. Sawano, N. Mori, Y. Nakamura. Thermoelectric power factor enhancement based on carrier transport physics in ultimately phonon-controlled Si nanostructures. Mater. Today Energy. 2019, 13, 56–63. [CrossRef]

- J. Wei, L. Zhao, Q. Zhang, Z. Nie, L. Hao. Enhanced thermoelectric properties of cement-based composites with expanded graphite for climate adaptation and large-scale energy harvesting. Energy Build. 2018, 159, 66–74. [CrossRef]

- J. Wei, Y. Fan, L. Zhao, F. Xue, L. Hao, Q. Zhang. Thermoelectric properties of carbon nanotube reinforced cement-based composites fabricated by compression shear. Ceram. Int. 2018, 44, 5829–5833. [CrossRef]

- L. Tzounis, M. Liebscher, R. Fuge, A. Leonhardt, V. Mechtcherine. P- and n-type thermoelectric cement composites with CVD grown p- and n-doped carbon nanotubes: Demonstration of a structural thermoelectric generator. Energy Build. 2019, 191, 151–163. [CrossRef]

- S. Ghosh, S. Harish, K.A. Rocky, M. Ohtaki, B.B. Saha. Graphene enhanced thermoelectric properties of cement based composites for building energy harvesting. Energy Build. 2019, 202, 1–7.

- J. Wei, Q. Zhang, L. Zhao, L. Hao, C. Yang. Enhanced thermoelectric properties of carbon fiber reinforced cement composites. Ceram. Int. 2016, 42, 11568–11573. [CrossRef]

- T. Ji, X. Zhang, X. Zhang, Y. Zhang, W. Li. Effect of Manganese Dioxide Nanorods on the Thermoelectric Properties of Cement Composites. J. Mater. Civ. Eng. 2018, 30, 04018224–1. [CrossRef]

- T. Ji, X. Zhang, W. Li. Enhanced thermoelectric effect of cement composite by addition of metallic oxide nanopowders for energy harvesting in buildings. Constr. Build. Mater. 2016, 115, 576–581. [CrossRef]

- S. Ghosh, S. Harish, M. Ohtaki, B.B. Saha. Enhanced Figure of Merit of Cement Composites with Graphene and ZnO Nanoinclusions for Efficient Energy Harvesting in Buildings. Energy. 2020, 198, 117396. [CrossRef]

- S. Ghosh, S. Harish, M. Ohtaki, B.B. Saha. Enhanced Thermoelectric Figure of Merit in Cement Composites with Graphene and Metallic Oxide Hybrid Nanostructures. Materials Today Energy. 2020, 18, 100492. [CrossRef]

- Snyder, GJ. Small thermoelectric generators. Electrochem Soc Interface. 2008, 17, 54–56. [Google Scholar] [CrossRef]

- Champier D, Bédécarrats JP, Kousksou T, Rivaletto M, Strub F, Pignolet P. Study of a TE (thermoelectric) generator incorporated in a multifunction wood stove. Energy. 2011, 36, 1518–1526. [CrossRef]

- Champier D, Bedecarrats JP, Rivaletto M, Strub F. Thermoelectric power generation from biomass cook stoves. Energy. 2010, 35, 935–942. [Google Scholar] [CrossRef]

- Karl H, Andreas W, Adam W. Wireless sensor networks. In: Goos G, Hartmanis J, Leeuwen J van, editors. 1st Eur. Work. EWSN, Springer; 2004.

- Knight C, Davidson J, Behrens S. Energy options for wireless sensor nodes. Sensors. 2008, 8, 8037–8066. [Google Scholar] [CrossRef]

- Settaluri KT, Lo H, Ram RJ. Thin thermoelectric generator system for body energy harvesting. J Electron Mater. 2012, 41, 984–988. [Google Scholar] [CrossRef]

- Wen S, Chung DDL. Cement-based thermocouples. Cem Concr Res. 2001, 31, 507–510. [Google Scholar] [CrossRef]

- Wei J, Zhao L, Zhang Q, Nie Z, Hao L. Enhanced thermoelectric properties of cement-based composites with expanded graphite for climate adaptation and large-scale energy harvesting. Energy Build. 2018, 159, 66–74. [Google Scholar] [CrossRef]

- Tzounis L, Liebscher M, Fuge R, Leonhardt A, Mechtcherine V. P- and N-type thermoelectric cement composites with CVD grown p- and n-doped carbon nanotubes: Demonstration of a structural thermoelectric generator. Energy Build. 2019, 191, 151–163. [Google Scholar] [CrossRef]

- Converter VS-U. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/LTC3108.pdf (accessed on 8 May 2020).

- Wei Q, Mukaida M, Kirihara K, Naitoh Y, Ishida T. Polymer thermoelectric modules screen-printed on paper. RSC Adv. 2014, 4, 28802–28806. [Google Scholar] [CrossRef]

- Shi Y, Wang Y, Deng Y, Gao H, Lin Z, Zhu W, et al. A novel self-powered wireless temperature sensor based on thermoelectric generators. Energy Convers Manag. 2014, 80, 110–116. [Google Scholar] [CrossRef]

- Lu X, Yang SH. Thermal energy harvesting for WSNs. Conf Proc - IEEE Int Conf Syst Man Cybern. 2010, 3045–3052.

- Liu ZB, Zhang L, Gong GC, Luo YQ, Meng FF. Experimental study and performance analysis of a solar thermoelectric air conditioner with hot water supply. Energy Build. 2015, 86, 619–625. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).