Submitted:

07 April 2023

Posted:

11 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results

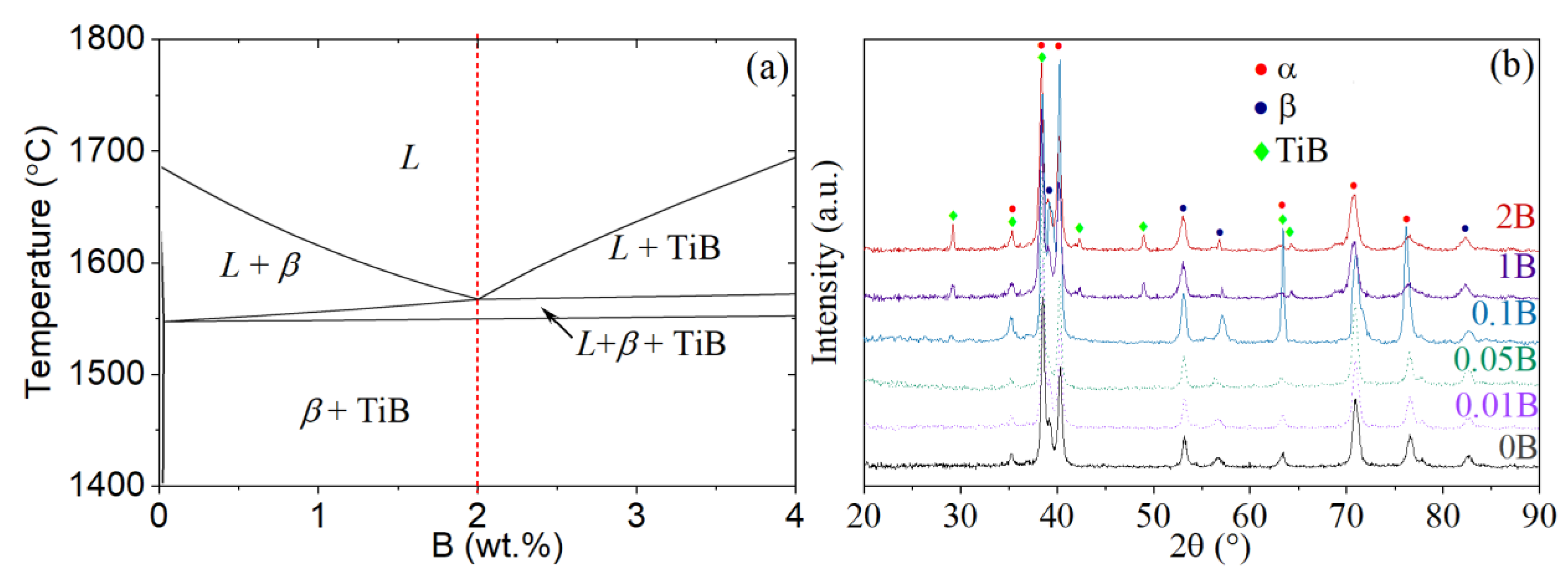

3.1. Phase Composition Analysis

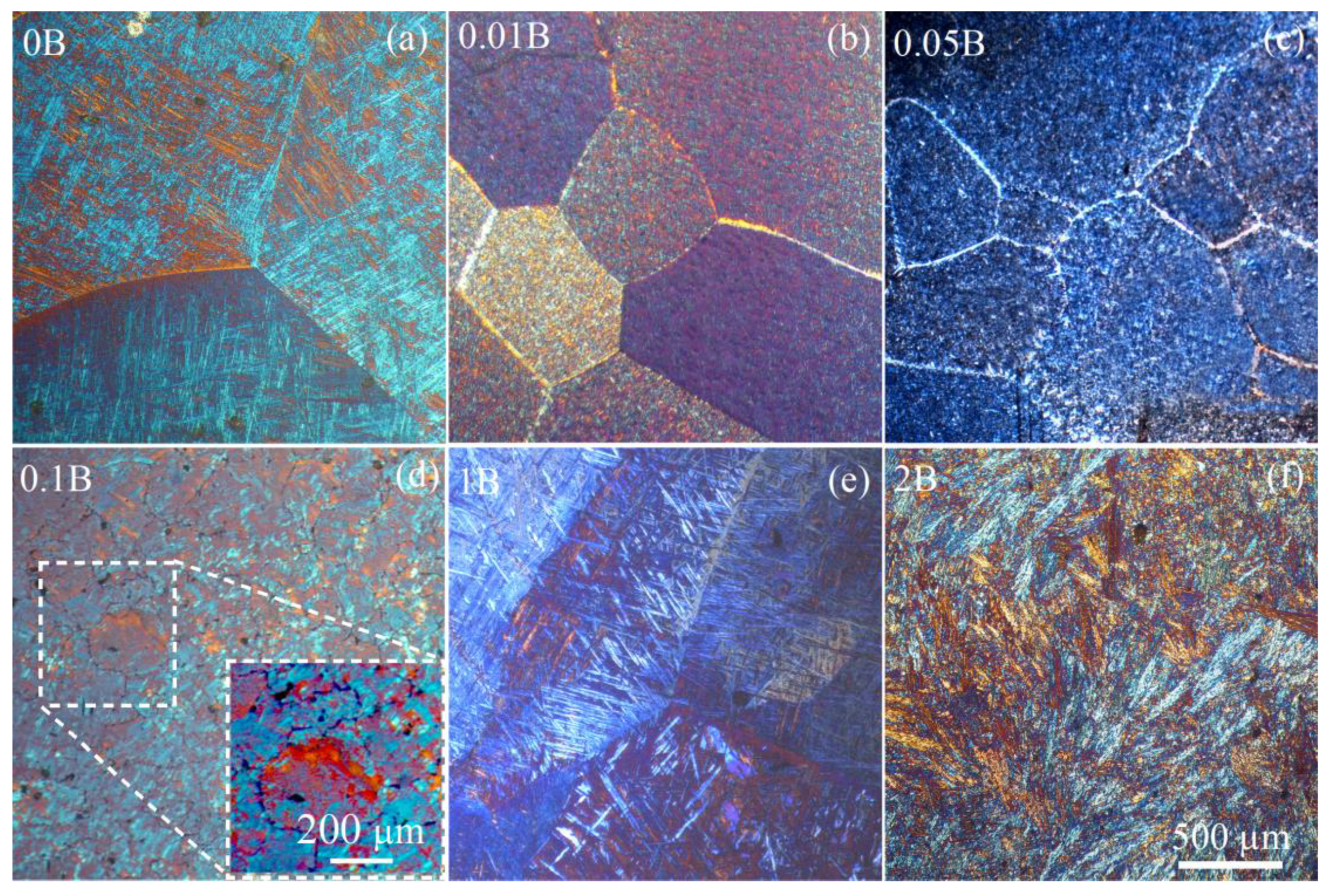

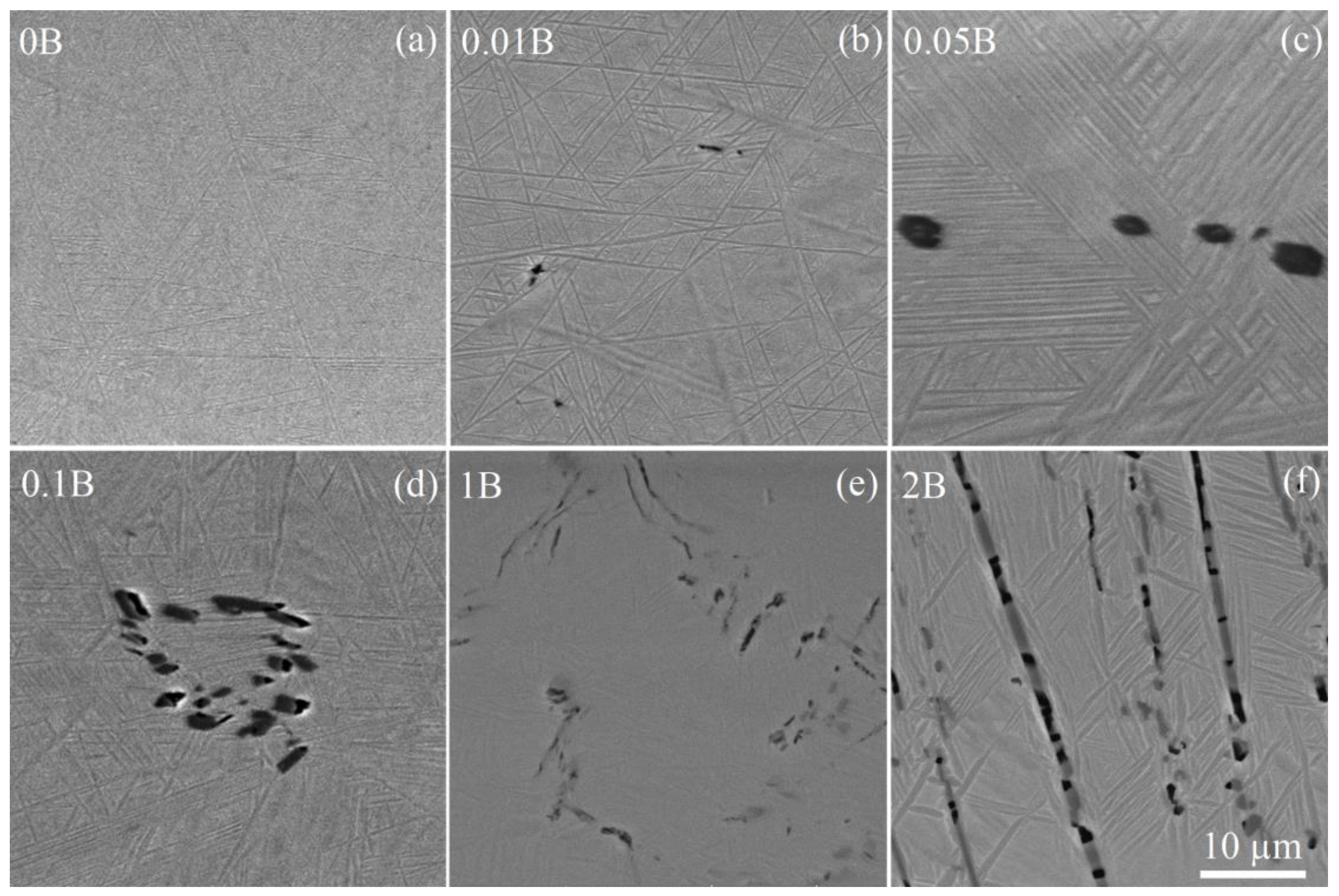

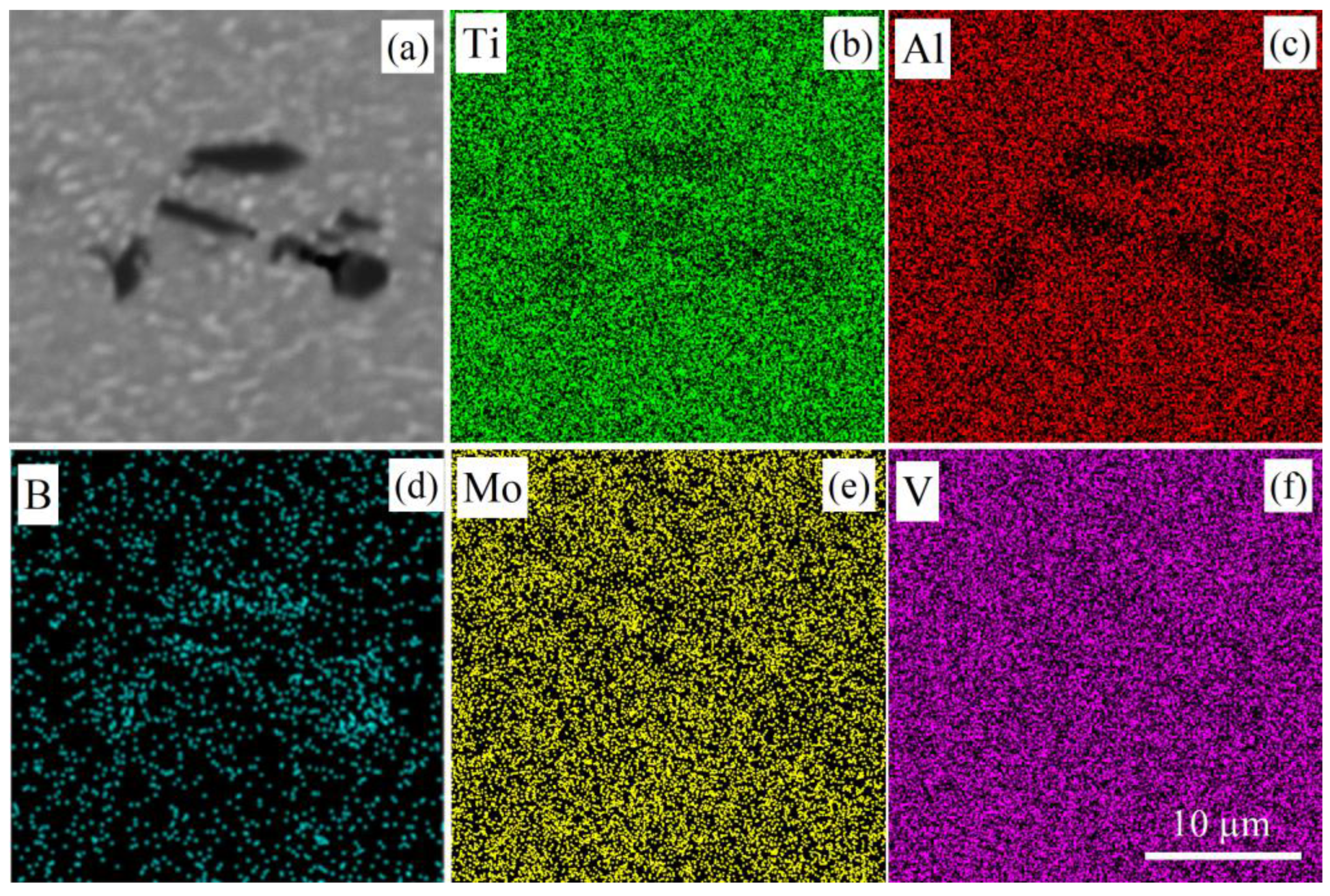

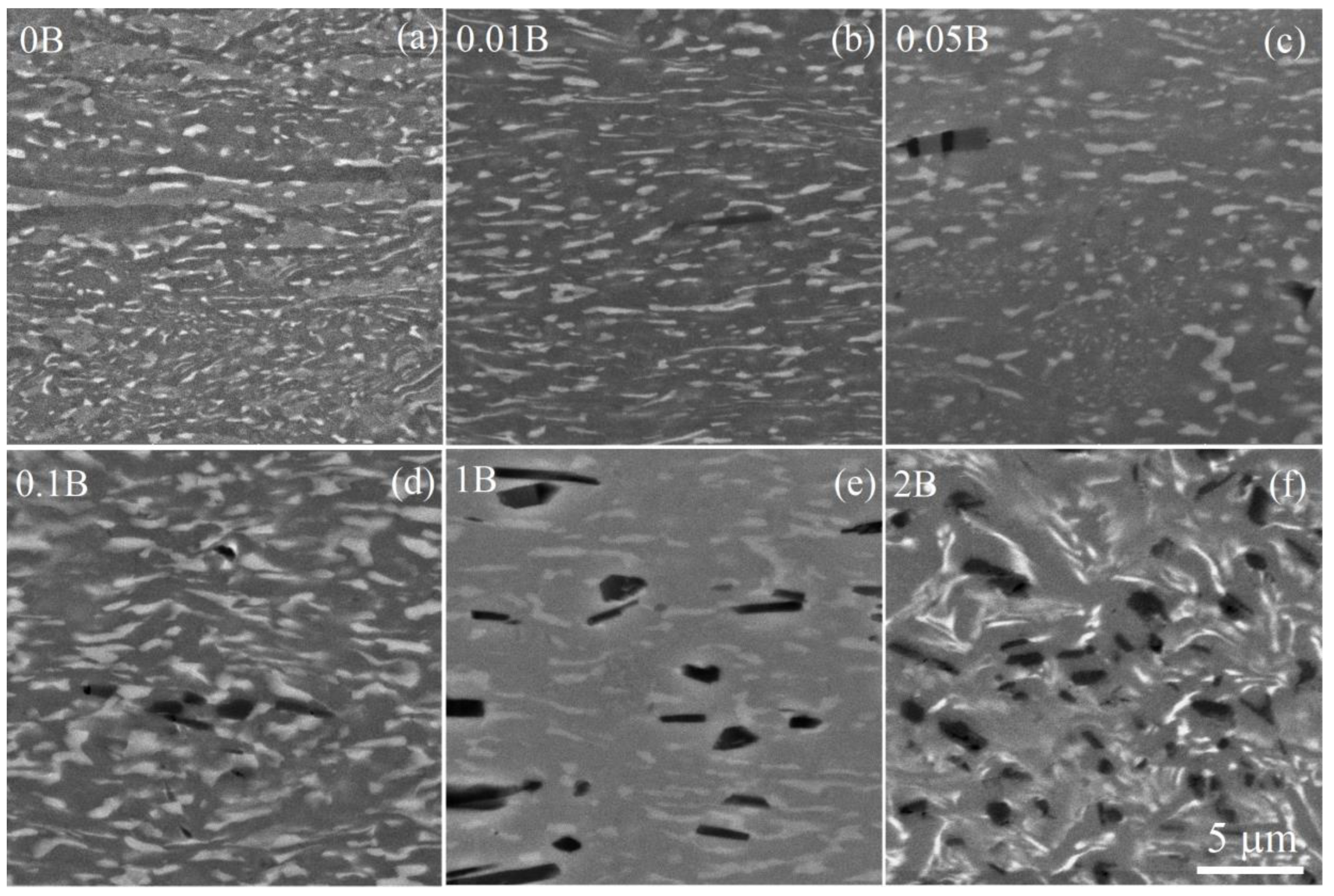

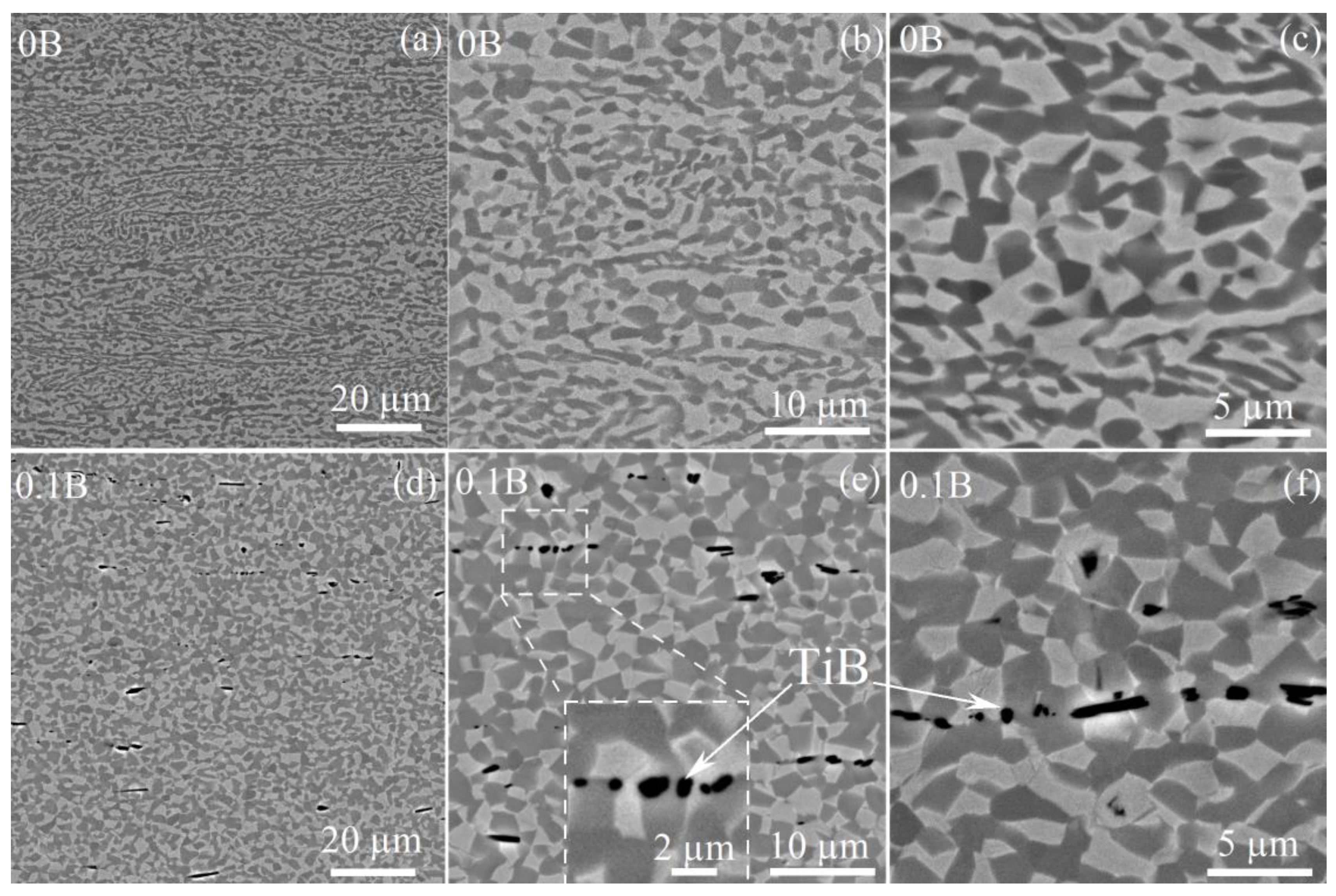

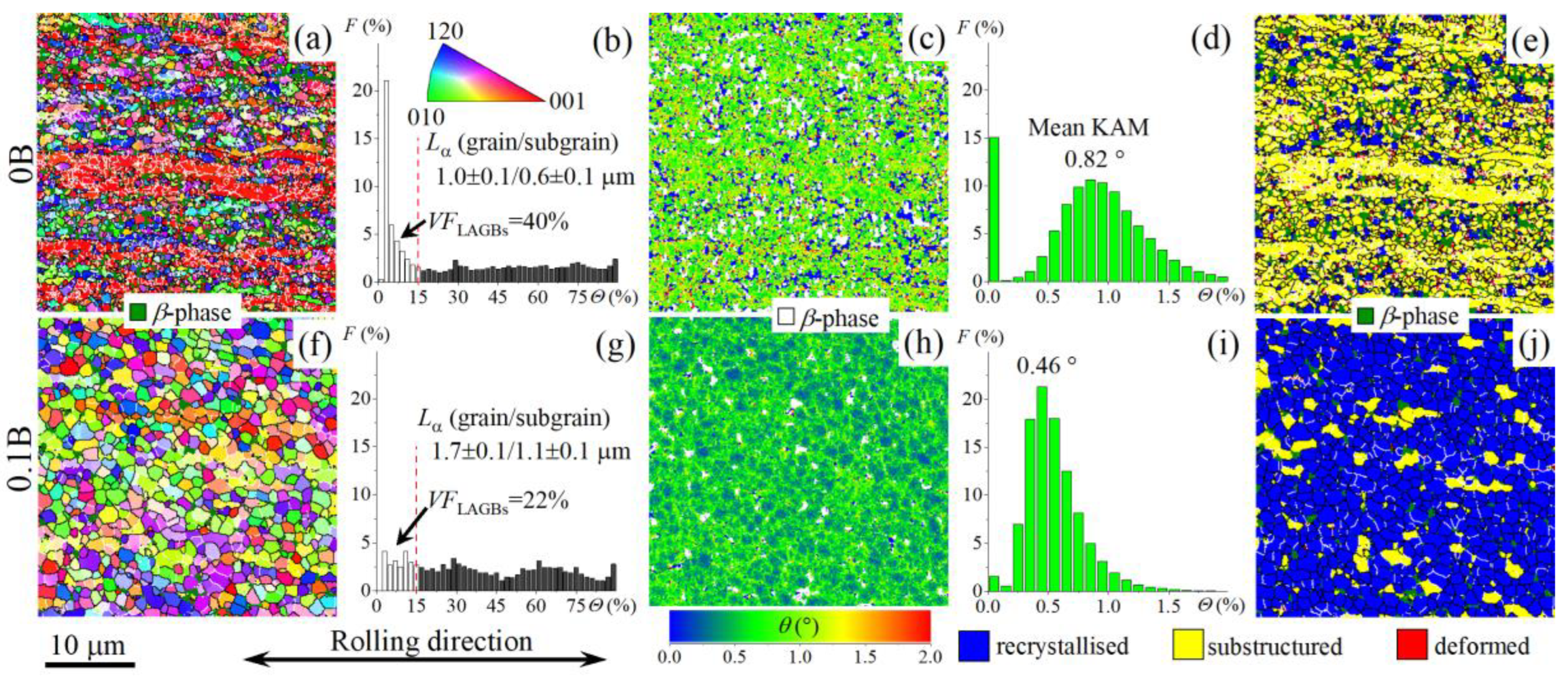

3.2. Analysis of the Microstructure after Solidification, Thermomechanical Treatment, and Post-Deformation Annealing

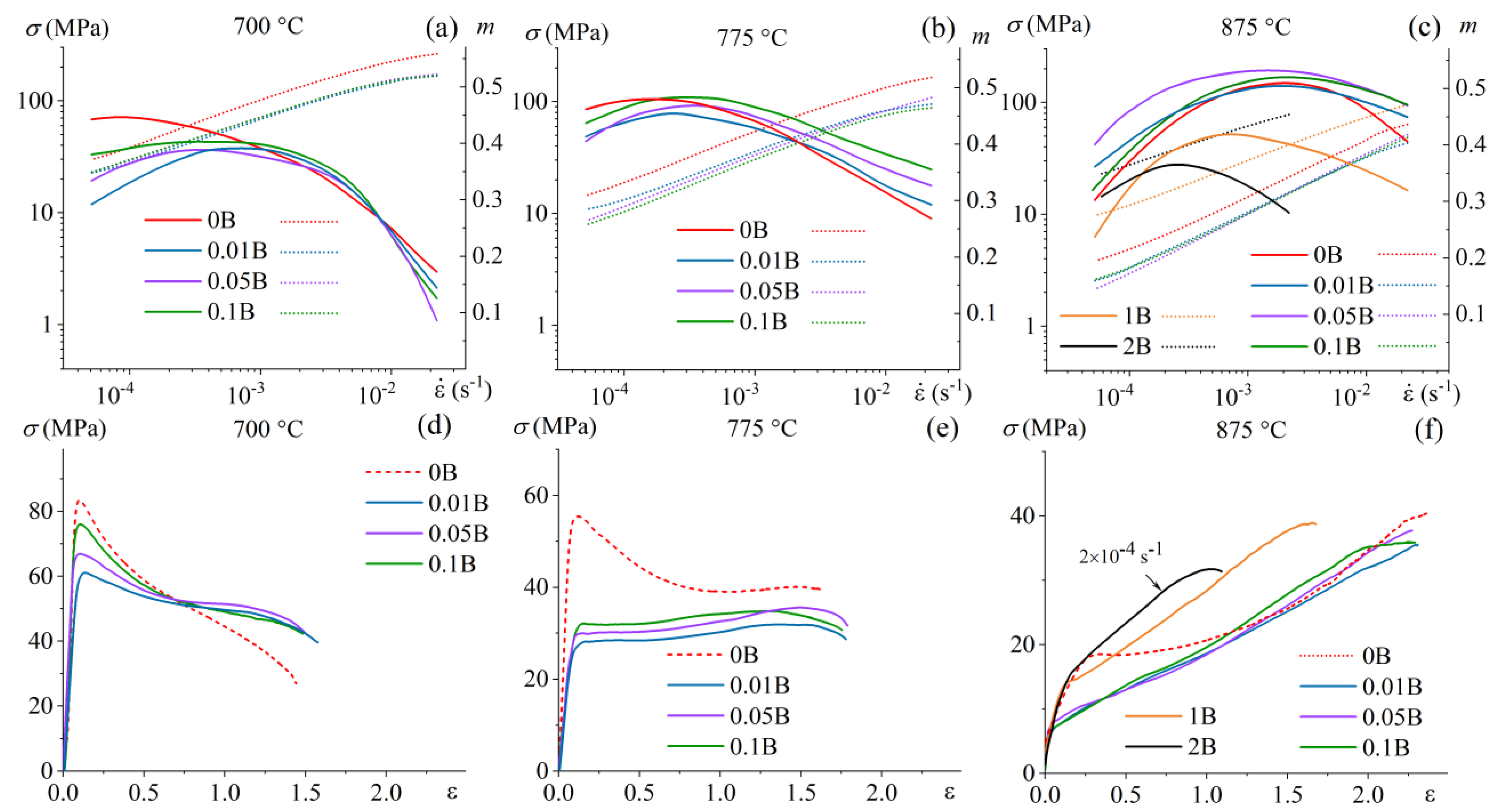

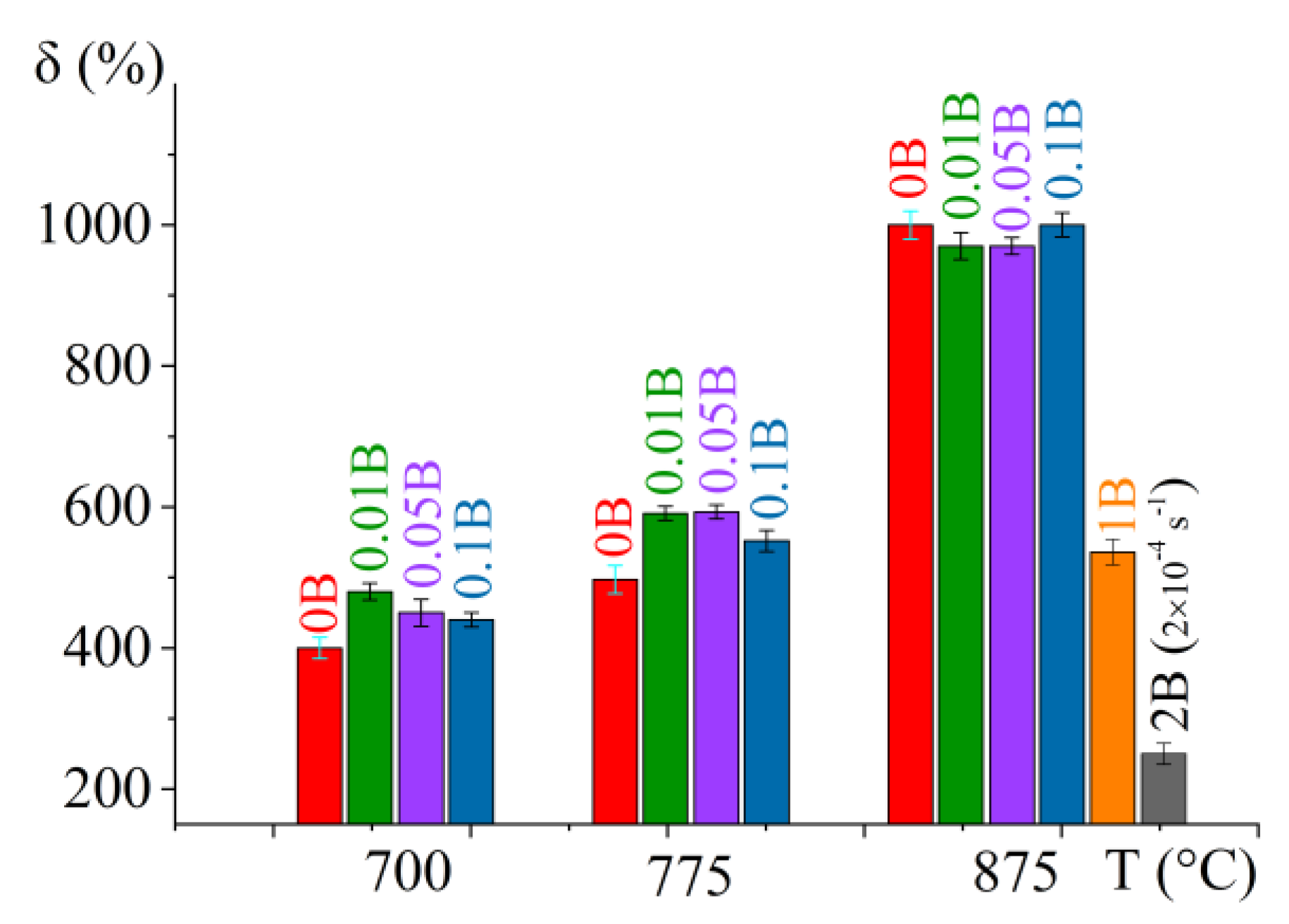

3.4. Superplastic Deformation

3.5. Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moiseyev, V.N. Titanium Alloys: Russian Aircraft and Aerospace Applications; CRC Press: Boca Raton, FL, USA, 2005; ISBN 9780849332739. [Google Scholar]

- Ridley, N. Metals for Superplastic Forming. Superplast. Form. Adv. Met. Mater. Methods Appl. 2011, 3–33. [Google Scholar] [CrossRef]

- Novikov, I.I.; Portnoj, V.K. Superplastizität von Legierungen; VEB Deutscher Verlag fur Grundstoffindustrie. Leipzig, Ed.; 1985.

- Meier, M.L.; Lesuer, D.R.; Mukherjee, A.K. A Grain Size and Fl Volume Fraction Aspects of the Superplasticity of Ti-6A1-4V; 1991; Vol. 136.

- Sieniawski, J.; Motyka, M. Superplasticity in Titanium Alloys. J. Achiev. Mater. Manuf. Eng. 2007. [Google Scholar]

- Sinha, V.; Srinivasan, R.; Tamirisakandala, S.; Miracle, D.B. Superplastic Behavior of Ti-6Al-4V-0. 1B Alloy. Mater. Sci. Eng. A 2012, 539, 7–12. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. Deformation Mechanisms during Superplastic Testing of Ti-6Al-4V-0. 1B Alloy. Mater. Sci. Eng. A 2013, 574, 205–217. [Google Scholar] [CrossRef]

- Imayev, V.M.; Gaisin, R.A.; Imayev, R.M. Effect of Boron Addition on Formation of a Fine-Grained Microstructure in Commercially Pure Titanium Processed by Hot Compression. Mater. Sci. Eng. A 2015, 639, 691–698. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S.; Tamirisakandala, S.; Miracle, D.B.; Srinivasan, R. Development of Solidification Microstructure in Boron-Modified Alloy Ti-6Al-4V-0. 1B. Acta Mater. 2011. [Google Scholar] [CrossRef]

- Singh, G.; Ramamurty, U. Boron Modified Titanium Alloys. Prog. Mater. Sci. 2020, 111, 100653. [Google Scholar] [CrossRef]

- Palty, A.E.; Margolin, H.; Nielsen, J.P. TITANIUM NITROGEN AND TITANIUM BORON SYSTEMS. Trans. Am. Soc. Met. 1954, 46, 312–328. [Google Scholar]

- Yang, Y.F.; Yan, M.; Luo, S.D.; Schaffer, G.B.; Qian, M. Modification of the α-Ti Laths to near Equiaxed α-Ti Grains in as-Sintered Titanium and Titanium Alloys by a Small Addition of Boron. J. Alloys Compd. 2013, 579, 553–557. [Google Scholar] [CrossRef]

- Nandwana, P.; Nag, S.; Hill, D.; Tiley, J.; Fraser, H.L.; Banerjee, R. On the Correlation between the Morphology of α and Its Crystallographic Orientation Relationship with TiB and β in Boron-Containing Ti-5Al-5Mo-5V-3Cr-0. 5Fe Alloy. Scr. Mater. 2012, 66, 598–601. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Fu, B.; Torres, K.; Thompson, G.B.; Srinivasan, R.; Cherukuri, B.; Tiley, J. Nucleation and Growth of α-Ti on TiB Precipitates in Ti-15Mo-2.6Nb-3Al-0.2Si-0.12B. Philos. Mag. 2011, 91, 850–864. [CrossRef]

- SEN, I.; TAMIRISAKANDALA, S.; MIRACLE, D.; RAMAMURTY, U. Microstructural Effects on the Mechanical Behavior of B-Modified Ti–6Al–4V Alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Chong, Y.; Gholizadeh, R.; Yamamoto, K.; Tsuji, N. New Insights into the Colony Refinement Mechanism by Solute Boron Atoms in Ti-6Al-4V Alloy. Scr. Mater. 2023, 230, 115397. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. The Influence of Temperature and Strain Rate on the Deformation Response and Microstructural Evolution during Hot Compression of a Titanium Alloy Ti–6Al–4V–0. 1B. J. Alloys Compd. 2013, 548, 110–125. [Google Scholar] [CrossRef]

- Gaisin, R.A.; Imayev, V.M.; Imayev, R.M.; Gaisina, E.R. Effect of Boron Addition on Recrystallization Behavior of Commercially Pure Titanium Subjected to Hot Compression. Lett. Mater. 2015, 5, 124–128. [Google Scholar] [CrossRef]

- Srinivasan, R.; Miracle, D.; Tamirisakandala, S. Direct Rolling of As-Cast Ti-6Al-4V Modified with Trace Additions of Boron. Mater. Sci. Eng. A 2008, 487, 541–551. [Google Scholar] [CrossRef]

- Roy, S.; Sarkar, A.; Suwas, S. On Characterization of Deformation Microstructure in Boron Modified Ti-6Al-4V Alloy. Mater. Sci. Eng. A 2010, 528, 449–458. [Google Scholar] [CrossRef]

- Gaisin, R.A.; Imayev, V.M.; Imayev, R.M.; Gaisina, E.R. Microstructure and Hot Deformation Behavior of Two-Phase Boron-Modified Titanium Alloy VT8. Phys. Met. Metallogr. 2013, 114, 339–347. [Google Scholar] [CrossRef]

- Stefanescu, D.M.; Ruxanda, R. Solidification Structures of Titanium Alloys. In Metallography and Microstructures; ASM International, 2004; pp. 116–126.

- Cheng, T. . The Mechanism of Grain Refinement in TiAl Alloys by Boron Addition — an Alternative Hypothesis. Intermetallics 2000, 8, 29–37. [CrossRef]

- Tamirisakandala, S.; Bhat, R.B.; Tiley, J.S.; Miracle, D.B. Grain Refinement of Cast Titanium Alloys via Trace Boron Addition. Scr. Mater. 2005, 53, 1421–1426. [Google Scholar] [CrossRef]

- CHERUKURI, B.; SRINIVASAN, R.; TAMIRISAKANDALA, S.; MIRACLE, D. The Influence of Trace Boron Addition on Grain Growth Kinetics of the Beta Phase in the Beta Titanium Alloy Ti–15Mo–2.6Nb–3Al–0.2Si. Scr. Mater. 2009, 60, 496–499. [Google Scholar] [CrossRef]

- Bilous, O.O.; Artyukh, L.V.; Bondar, A.A.; Velikanova, T.Y.; Burka, M.P.; Brodnikovskyi, M.P.; Fomichov, O.S.; Tsyganenko, N.I.; Firstov, S.O. Effect of Boron on the Structure and Mechanical Properties of Ti–6Al and Ti–6Al–4V. Mater. Sci. Eng. A 2005, 402, 76–83. [Google Scholar] [CrossRef]

- Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Improved Ductility and Oxidation Resistance of Cast Ti–6Al–4V Alloys by Microalloying. J. Alloys Compd. 2014, 602, 235–240. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. Enhanced Superplasticity for (A+β)-Hot Rolled Ti-6Al-4V-0. 1B Alloy by Means of Dynamic Globularization. Mater. Des. 2014. [Google Scholar] [CrossRef]

- Kotov, A.D.; Postnikova, M.N.; Mosleh, A.O.; Mikhaylovskaya, A.V. Influence of Fe on the Microstructure, Superplasticity and Room-Temperature Mechanical Properties of Ti–4Al–3Mo–1V-0. 1B Alloy. Mater. Sci. Eng. A 2022, 845, 143245. [Google Scholar] [CrossRef]

- Tamirisakandaia, S.; Miracle, D.B.; Srinivasan, R.; Gunasekera, J.S. Titanium Alloyed with Boron. Adv. Mater. Process. 2006, 164, 41–43. [Google Scholar]

- Hill, D.; Banerjee, R.; Huber, D.; Tiley, J.; Fraser, H.L. Formation of Equiaxed Alpha in TiB Reinforced Ti Alloy Composites. Scr. Mater. 2005, 52, 387–392. [Google Scholar] [CrossRef]

- Ivasishin, O.M.; Teliovych, R.V.; Ivanchenko, V.G.; Tamirisakandala, S.; Miracle, D.B. Processing, Microstructure, Texture, and Tensile Properties of the Ti-6Al-4V-1. 55B Eutectic Alloy. Metall. Mater. Trans. A 2008, 39, 402–416. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. Deformation Mechanisms during Superplastic Testing of Ti-6Al-4V-0. 1B Alloy. Mater. Sci. Eng. A 2013. [Google Scholar] [CrossRef]

- Zadorozhnyy, V.Y.; Shchetinin, I.V.; Chirikov, N.V.; Louzguine-Luzgin, D.V. Tensile Properties of a Dual-Axial Forged Ti–Fe–Cu Alloy Containing Boron. Mater. Sci. Eng. A 2014, 614, 238–242. [Google Scholar] [CrossRef]

- Chandravanshi, V.K.; Sarkar, R.; Kamat, S.V.; Nandy, T.K. Effect of Boron on Microstructure and Mechanical Properties of Thermomechanically Processed near Alpha Titanium Alloy Ti-1100. J. Alloys Compd. 2011, 509, 5506–5514. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhailovskaya, A.V.; Mosleh, A.O.; Pourcelot, T.P.; Prosviryakov, A.S.; Portnoi, V.K. Superplasticity of an Ultrafine-Grained Ti–4% Al–1% V–3% Mo Alloy. Phys. Met. Metallogr. 2019, 120, 60–68. [Google Scholar] [CrossRef]

- Mosleh, A.O.; Mikhaylovskaya, A. V.; Kotov, A.D.; Sitkina, M.; Mestre-Rinn, P.; Kwame, J.S. Superplastic Deformation Behavior of Ultra-Fine-Grained Ti-1V-4Al-3Mo Alloy: Constitutive Modeling and Processing Map. Mater. Res. Express 2019. [Google Scholar] [CrossRef]

- Mosleh, A.O.; Kotov, A.D.; Vidal, V.; Mochugovskiy, A.G.; Velay, V.; Mikhaylovskaya, A.V. Initial Microstructure Influence on Ti–Al–Mo–V Alloy’s Superplastic Deformation Behavior and Deformation Mechanisms. Mater. Sci. Eng. A 2021, 802, 140626. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Mosleh, A.O.; Mestre-Rinn, P.; Kotov, A.D.; Sitkina, M.N.; Bazlov, A.I.; Louzguine-Luzgin, D.V. High-Strength Titanium-Based Alloy for Low-Temperature Superplastic Forming. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2021, 52, 293–302. [Google Scholar] [CrossRef]

- Kotov, A.D.; Postnikova, M.N.; Mosleh, A.O.; Mikhaylovskaya, A.V. Influence of Fe on the Microstructure, Superplasticity and Room-Temperature Mechanical Properties of Ti–4Al–3Mo–1V-0. 1B Alloy. Mater. Sci. Eng. A 2022, 845, 143245. [Google Scholar] [CrossRef]

- Imayev, V.M.; Gaisin, R.A.; Imayev, R.M. Effect of Boron Addition on Formation of a Fine-Grained Microstructure in Commercially Pure Titanium Processed by Hot Compression. Mater. Sci. Eng. A 2015, 639, 691–698. [Google Scholar] [CrossRef]

- Tamirisakandala, S.; Bhat, R.B.; Tiley, J.S.; Miracle, D.B. Grain Refinement of Cast Titanium Alloys via Trace Boron Addition. Scr. Mater. 2005, 53, 1421–1426. [Google Scholar] [CrossRef]

- Suzuki, Y.; Xu, Y.; Morito, S.; Otsuka, K.; Mitose, K. Effects of Boron Addition on Microstructure and Mechanical Properties of Ti–Td–Ni High-Temperature Shape Memory Alloys. Mater. Lett. 1998, 36, 85–94. [Google Scholar] [CrossRef]

- YEN, F.-C.; HWANG, K.-C. Microstructures, Mechanical Properties, and Shape Memory Characteristics of Powder Metallurgy Ti51Ni49 Modified with Boron. Metall. Mater. Trans. A 2012, 43, 687–696. [Google Scholar] [CrossRef]

- Liu, C.T.; Schneibel, J.H.; Maziasz, P.J.; Wright, J.L.; Easton, D.S. Tensile Properties and Fracture Toughness of TiAl Alloys with Controlled Microstructures. Intermetallics 1996, 4, 429–440. [Google Scholar] [CrossRef]

- Christodoulou, J.A.; Flower, H.M. The Role of Borides in Near-γ Titanium Aluminides. Adv. Eng. Mater. 2000, 2, 631–638. [Google Scholar] [CrossRef]

- Hu, D. A Quarter Century Journey of Boron as a Grain Refiner in TiAl Alloys. TMS Annu. Meet. 2014, 21–30. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; Nogita, K. ; St. John, D.H.; Dargusch, M.S. Effects of Boron on Microstructure in Cast Titanium Alloys. Scr. Mater. 2008, 59, 538–541. [Google Scholar] [CrossRef]

- Tamirisakandala, S.; Bhat, R.B.; Miracle, D.B.; Boddapati, S.; Bordia, R.; Vanover, R.; Vasudevan, V.K. Effect of Boron on the Beta Transus of Ti-6Al-4V Alloy. Scr. Mater. 2005, 53, 217–222. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Mikhaylovskaya, A.V.; Levchenko, V.S.; Portnoy, V.K. Formation of Microstructure and the Superplasticity of Al–Mg-Based Alloys. Phys. Met. Metallogr. 2017, 118, 96–103. [Google Scholar] [CrossRef]

- Tarshis, L.A.; Walker, J.L.; Rutter, J.W. Experiments on the Solidification Structure of Alloy Castings. Metall. Trans. 1971, 2, 2589–2597. [Google Scholar] [CrossRef]

- Gan, G.; Yang, B.; Zhang, B.; Jiang, X.; Shi, Y.; Wu, Y. Refining Mechanism of 7075 Al Alloy by In-Situ TiB2 Particles. Materials (Basel). 2017, 10, 1–11. [Google Scholar] [CrossRef]

- Sun, M.; Yang, D.; Zhang, Y.; Mao, L.; Li, X.; Pang, S. Recent Advances in the Grain Refinement Effects of Zr on Mg Alloys: A Review. Metals (Basel). 2022, 12. [Google Scholar] [CrossRef]

- Okamoto, H.; Massalski, T.B. Section I: Basic and Applied Research Binary Alloy Phase Diagrams. 1994, 15, 500–521.

- Anil Kumar, V.; Murty, S.V.S.N.; Gupta, R.K.; Rao, A.G.; Prasad, M.J.N.V. Effect of Boron on Microstructure Evolution and Hot Tensile Deformation Behavior of Ti-5Al-5V-5Mo-1Cr-1Fe Alloy. J. Alloys Compd. 2020, 831, 154672. [Google Scholar] [CrossRef]

- Hill, D.; Banerjee, R.; Huber, D.; Tiley, J.; Fraser, H.L. Formation of Equiaxed Alpha in TiB Reinforced Ti Alloy Composites. Scr. Mater. 2005, 52, 387–392. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in Metals and Ceramics; Cambridge University Press, 1997; ISBN 9780521561051.

- Yutao Zhai, P.S.; Bolzoni, L.; Qu, Y. Fabrication and Characterization of In Situ Ti-6Al-4V / TiB. Metals (Basel). 2022. [Google Scholar] [CrossRef]

- Zhu, J.; Kamiya, A.; Yamada, T.; Shi, W.; Naganuma, K. Influence of Boron Addition on Microstructure and Mechanical Properties of Dental Cast Titanium Alloys. Mater. Sci. Eng. A 2003, 339, 53–62. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Klimova, M.; Stepanov, N.; Vershinina, T.; Ivanisenko, Y.; Salishchev, G. Effect of High-Pressure Torsion on Structure and Properties of Ti-15Mo/TiB Metal-Matrix Composite. Materials (Basel). 2018, 11, 2426. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Janiszewski, J.; Stasyuk, O.O.; Bondarchuk, V.I.; Savvakin, D.G.; Cieplak, K.; Goran, D.; Soni, P.; Prikhodko, S.V. Mechanical Behavior of Titanium Based Metal Matrix Composites Reinforced with TiC or TiB Particles under Quasi-Static and High Strain-Rate Compression. Materials (Basel). 2021, 14, 6837. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, G.; Ma, X.L.; Lu, K. Strain-Induced Refinement in a Steel with Spheroidal Cementite Subjected to Surface Mechanical Attrition Treatment. Acta Mater. 2008, 56, 78–87. [Google Scholar] [CrossRef]

- Wu, T.; Wang, M.; Gao, Y.; Li, X.; Zhao, Y.; Zou, Q. Effects of Plastic Warm Deformation on Cementite Spheroidization of a Eutectoid Steel. J. Iron Steel Res. Int. 2012, 19, 60–66. [Google Scholar] [CrossRef]

- Portnoy, V.K.; Rylov, D.S.; Levchenko, V.S.; Mikhaylovskaya, A.V. The Influence of Chromium on the Structure and Superplasticity of Al–Mg–Mn Alloys. J. Alloys Compd. 2013, 581, 313–317. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Kotov, A.D.; Mikhaylovskaya, A.V. The Microstructure and High-Strain-Rate Superplasticity of the Al–Mg–Ni–Fe–Mn–Cr–Zr Alloy. Phys. Met. Metallogr. 2019, 120, 1006–1013. [Google Scholar] [CrossRef]

| Alloy | Al | Mo | V | B | Ti |

|---|---|---|---|---|---|

| 0B | 4.2 | 3.0 | 1.1 | - | Bal. |

| 0.01B | 4.1 | 3.2 | 1.0 | 0.01 | Bal. |

| 0.05B | 4.1 | 2.9 | 0.9 | 0.05 | Bal. |

| 0.1B | 3.9 | 3.1 | 1.1 | 0.1 | Bal. |

| 1B | 4.2 | 3.0 | 1.0 | 1 | Bal. |

| 2B | 4.3 | 3.1 | 1.1 | 2 | Bal. |

| Alloy | TiB size (µm) | TiB volume fraction (%) | Grain size (µm) |

|---|---|---|---|

| 0B | - | 700±70 | |

| 0.01B | 0.7±0.2 | 0.1 | 490±40 |

| 0.05B | 1.4±0.3 | 0.2 | 410±30 |

| 0.1B | 2.5±0.4 | 1.1 | 210±20 |

| 1B | 2.5±0.5 | 5.0 | 670±50 |

| 2B | 2.9±0.5 | 10.8 | 750±80 |

| Alloy | TiB size (µm) | L⊥/L∥ | Grain size (µm) | Volume fraction (%) | ||||

|---|---|---|---|---|---|---|---|---|

| L∥ | L⊥ | α | β | α | β | TiB | ||

| 0B* | - | - | - | 1.0±0.2 | 0.5±0.1 | 80 | 20 | - |

| 0.01B* | 2.1±0.3 | 0.6±0.1 | 0.3 | 1.0±0.1 | 0.7±0.1 | 82 | 18 | 0.2 |

| 0.05B* | 2.2±0.4 | 0.7±0.1 | 0.3 | 1.0±0.1 | 0.7±0.1 | 80 | 20 | 0.3 |

| 0.1B* | 2.8±0.2 | 0.7±0.3 | 0.2 | 0.9±0.1 | 0.6±0.1 | 78 | 18 | 1.1 |

| 1B** | 3.1±0.9 | 0.7±0.2 | 0.2 | 1.2±0.1 | 0.8±0.1 | 76 | 19 | 5.2 |

| 2B** | 1.0±0.2 | 1.0±0.1 | 1.0 | 1.0±0.1 | 0.6±0.1 | 70 | 20 | 10.5 |

| Alloy | YS (MPa) | UTS (MPa) | δ (%) |

|---|---|---|---|

| 100 pct strain at 875 °C / 1×10-3 s-1 and air cooling | |||

| 0B | 770 ± 10 | 860 ± 10 | 7 ± 1 |

| 0.01B | 733 ± 7 | 840 ± 10 | 6 ± 1 |

| 0.05B | 678 ± 8 | 840 ± 10 | 7 ± 1 |

| 0.1B | 680 ± 7 | 870 ± 5 | 7 ± 1 |

| 1B | 830 ± 8 | 1020 ± 6 | 1.1 ± 0.4 |

| 2B | - | 778 ± 5 | - |

| 100 pct strain at 875 °C / 1×10-3 s-1, water cooling and ageing at 480 °C for 16 h | |||

| 0.01В | 865 ± 7 | 982± 8 | 7 ± 1 |

| 0.1В | 780 ± 7 | 960 ± 5 | 5 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).