1. Introduction: high intensity TW/cm2 crystal processing

Matter at extreme conditions of pressures above 1 megabar (

Pa) and high temperatures as in the interior of planets - the warm dense matter (WDM) - is one of the active fields of research [

1]. High-pressure and high-temperature phases of materials can be created by ultra-fast thermal quenching of a small modified volume inside transparent material, e.g., sapphire [

2,

3]. Internally confined micro-explosions create WDM conditions similar to the centre of the Earth. For point-like energy deposition, it is informative to present Sedov’s solution, where the radius,

R, of the shock wave is increasing in time

t as [

4,

5]:

where

is the instantaneous (in space and time) release of energy,

is the constant dependent on the adiabatic coefficient

(

for air),

is the mass density in an unperturbed medium, and

i is the dimensionality coefficient

for spherical and

for cylindrical explosion; here

is the heat capacities at constant pressure and volume, respectively. Such a shock wave launched from the focal volume creates highly dynamic conditions of high pressures and temperatures, which lead to formation of new materials [

2,

3]. Also, metastable amorphous phases can be produced as shown for sapphire [

6] due to ultra-fast thermal quenching of small volume modified by fs-laser pulse triggered explosion.

The micro-explosion hydrodynamics was shown to follow the established and tested macroscopic versions of strong explosions [

7]. The Evolution of micro-explosion is characterized by the independent parameters: energy

E (or pressure

P), density

, and radius

r, while the two other parameters required for the full description of the hydrodynamic processes the velocity and time can be expressed as

and

, respectively. It is shown that micro-explosions triggered by tightly focused fs-laser pulses are self-similar with macro-explosions made by a

large energy deposition when the time

t and space

r are

times larger [

7]. All hydro-dynamic phenomena with the same initial pressure and density but differing in space and time scales are described by the same hydrodynamic equations.

Strong structural modifications induced by high-intensity ultra-short laser pulses could be modified by a post-processing steps of high temperature annealing (HTA) in different gaseous environment, which is a promising direction of research explored in this study.

Here, we show results of laser ablation of sapphire and its high temperature annealing (HTA) for surface roughness reduction and reconstruction of surfaces with ablated ripples. The conditions to recover a crystalline smooth surface up to the rim of the ablated pits were found, which can be useful for applications to 2D materials.

2. Results and Discussion: Laser Ablation of Crystals and High Temperature Annealing

Femtosecond laser ablation is the process by which laser pulses with fs pulse duration are focused through an objective lens of different numerical apertures to the surface of materials in order to create high intensity which break down the material and cause its ablation. This is a 2D/3D sculpturing method that can reach sub-micron precision. For the discussed experiment sapphire, Al2O3, was the material of choice. Sapphire is a hard and inert material that requires TW/cm2 intensities for ablation. Among its virtues is high transparency in UV-to-IR spectral range (200 - 4000 nm) and high heat conductivity. This makes sapphire optics a promising target for industrial and space applications.

Using PHAROS (Light Conversion Ltd.) laser system with

nm wavelength,

fs pulse duration, focusing with objectives lenses with numerical apertures of

and

resulted in focal spots calculated by Airy disk formula (

) of

m and

m. The Rayleigh length is

m and

m, which is half of the depth of focus (in air). For example, for the pulse energy of

J (on the sample), fluence was

J/cm

2 and average intensity

TW/cm

2. Laser repetition rate was

kHz and linear density of pulses was varied for larger or smaller overlap (typically

pulse/mm), which affected the material removal rate.

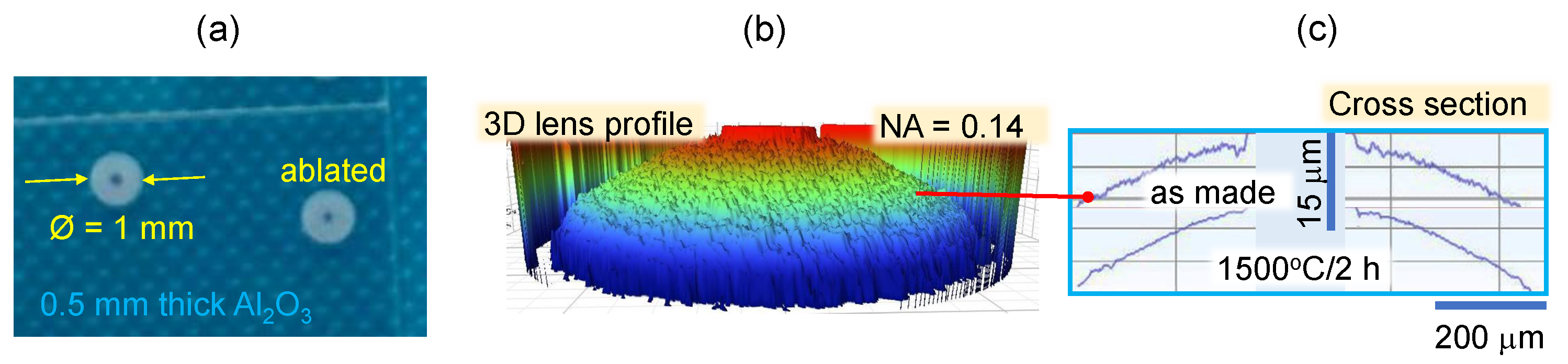

Figure 1(a) shows laser ablated 1-mm-diameter lenses imprinted into the surface of sapphire.

HTA was carried out using a horizontal Nabertherm tube furnace. The recipe starts by ramping up to 1500∘C at 150∘C an hour, holding at 1500∘C for 2 hours, ramping down to 1400∘C at 200∘C per hour and finally, allowing it to cool to 30∘C at 100∘C and hour. The extra step down to 1400∘C was to test how quickly it was possible to ramp down and has been further tested up to 450∘C per hour rates.

2.1. Roughness Reduction of Ablated Sapphire Surfaces

Front-side ablation was used with laser pulses traveling from air-into-Al

2O

3; back-side ablation occurs when the focus is placed onto the exit plane (Al

2O

3-to-air). This is usually possible with samples thinner than 0.5 mm and at less tight focusing with

. It took

min to ablate the profile of a 1-mm-diameter lens with a height of

m. Surface roughness of as-ablated surface was

nm and was reduced to

nm after 2 hr annealing (

Figure 1(c)). However, light scattering was still strong and the surface remained visibly white. Initial roughness was also dependent on the focusing conditions and pulse overlap during ablation. Other smoothing strategies need to be tested, e.g., ablation with more focused pulses. When ablation takes place at the very top of lens profile (surface of sapphire) there was a strong change in ablation conditions, which resulted in non-ablated plateau, which is ≈

m in diameter (

Figure 1). This is a known issue and can be circumvented by placing a micro-layer of a matching refractive index material, e.g., asilica film, that allows to ablate sapphire [

8]; the added layer is later washed out in solvent/acid.

The effect of HTA was examined through the ablation of crystalline flat c-plane Al

2O

3 which lead to better understanding of surface changes. Since the maximum temperature used was

C, which is much lower than the melting point of Al

2O

3C, surface restructuring by surface tension driven flow of the molten phase was absent and other contributions from surface diffusion at atomic level, coarsening of debris nanoparticles, as well as sublimation took place. Sapphire has a melting point of 2053

∘C and boiling temperature of 2980

∘C. It has recently been shown that lower temperatures with larger times can also yield surface re-flow, which can be understood from length of diffusion scaling

, where

[cm

2/s] is the surface diffusion coefficient and

t is time. Temperatures of 1100

∘C and 1200

∘C at 3, 6, 9, 18, and 30 hours (in air ambience) have been tested and showed smoothing of c-plane sapphire terraces in step configurations [

9]. Laser modified regions under high intensity irradiated in air also might have surface formation of ceramic ALON phase (AlN)

x (Al

2O

3)

with

. Generation of defects, vacancies, and interstitials under high intensity fs-pulses is taking place, e.g., F

+ color center of the oxygen vacancy with a trapped electron created by fs-laser machining of sapphire is fully annealed at 1100

∘ [

10]. Frenkel pair defects - interstitial-vacancy - observed earlier by MeV-electron irradiated high-pressure cubic-BN was induced by fs-laser pulses [

11] at similar conditions used in this study. Chemical bond breaking by high intensity laser pulses can create metal enriched regions on the surface of oxides and nitrides due to formation of volatile O

2 and N

2. Such laser ablated surfaces of oxides rich with defects, debris, and depleted of oxygen are expected to be restructured by HTA. We chose O

2 flow in order to facilitate surface migration of Al-atoms to form terraces of Al

2O

3 under oxygen supply. This is one probable contribution to formation of smooth crystalline surface.

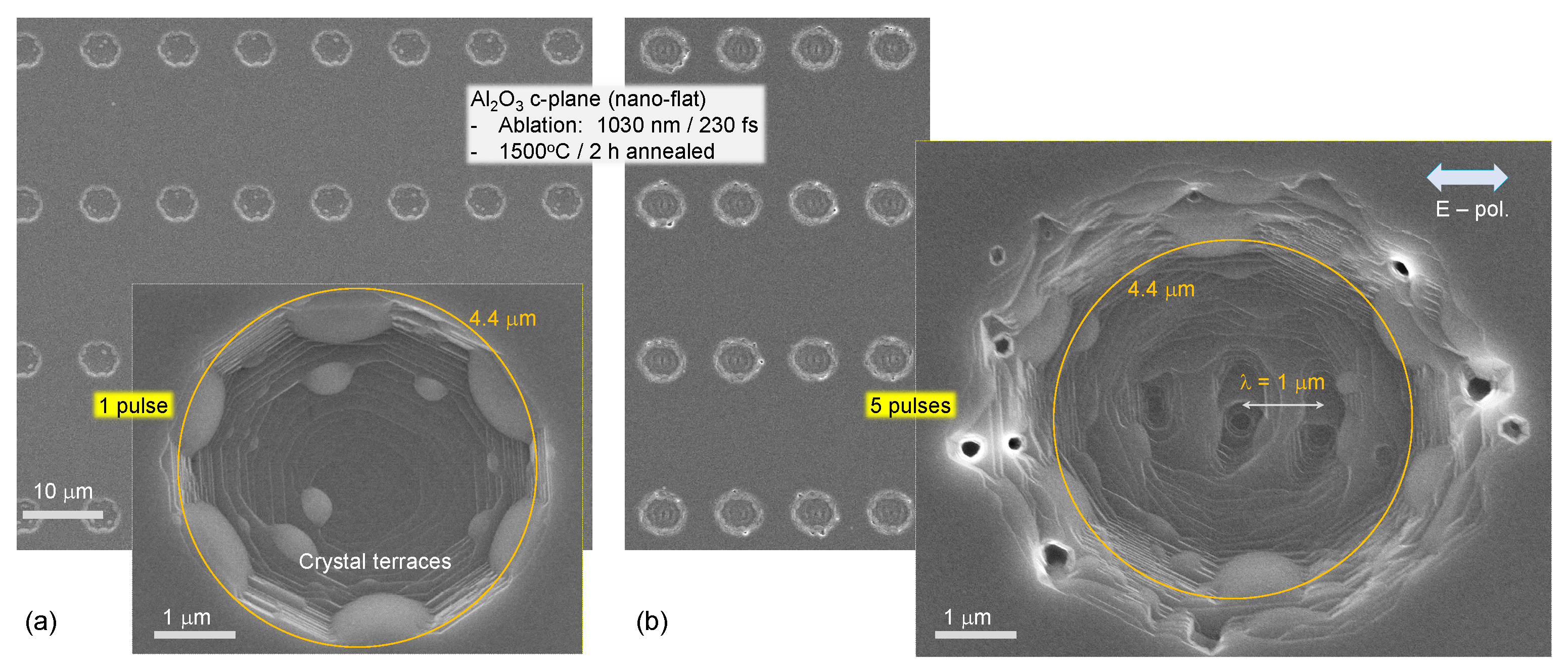

2.2. Recovery of crystalline smooth surface on ablated sapphire

Figure 2 shows scanning electron microscopy (SEM) images of single and five-pulse ablated sites after HTA in O

2 flow. A single pulse of

J which corresponds to a fluence of

J/cm

2 and an average intensity of

TW/cm

2 ablated a hole of 300 nm depth and a re-healed 4.4

m diameter, which almost perfectly matching the focal diameter of 4.8

m. After annealing, a perfectly smooth surface was observed near the rim of the ablated pit . When the number of pulses was two or more, formation of ripples [

12] was observed (see structure of period

m at the bottom (

Figure 2(b))). Recovering smooth surface during HTA in O

2 flow is a promising outcome for opto-electronic applications of 2D materials.

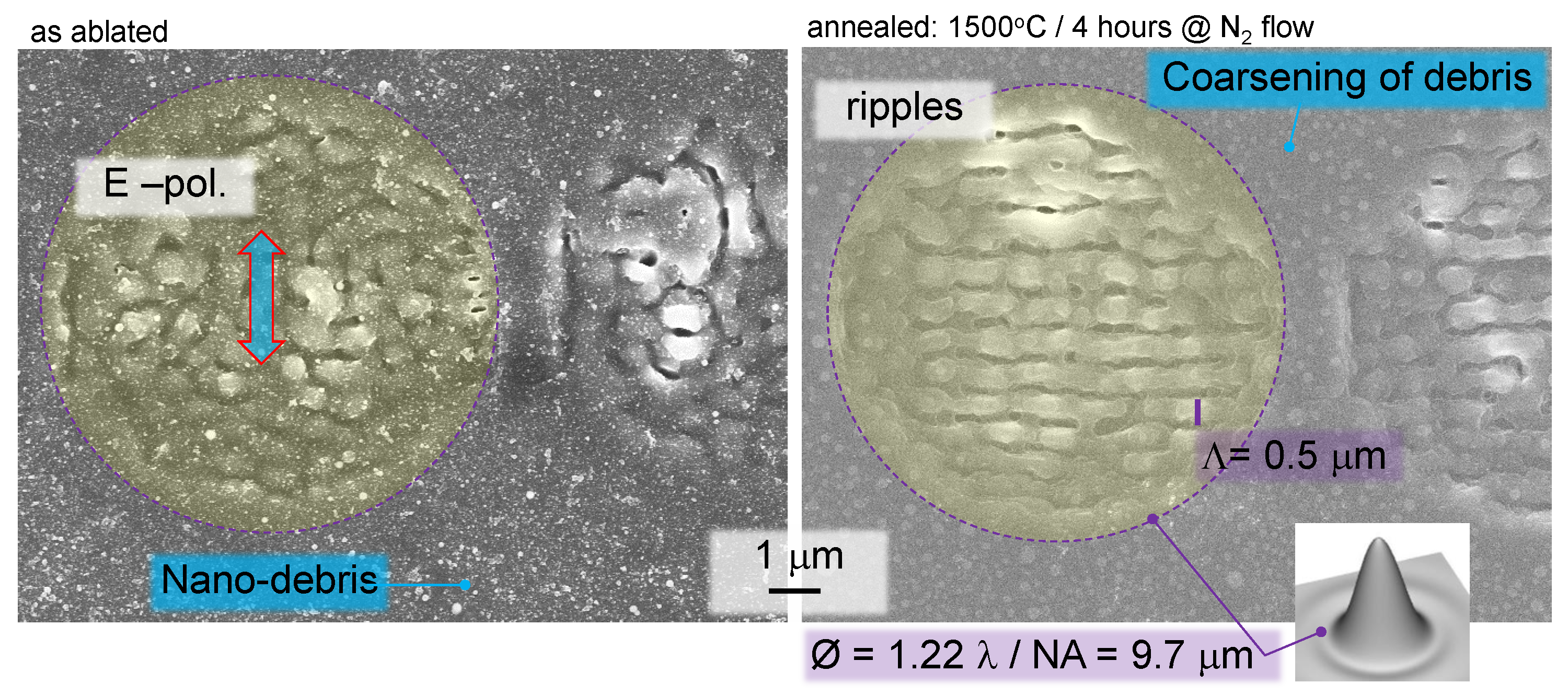

When focusing using less tight objective lens

, where the focal spot is twice that shown in

Figure 2 and single pulse ablation with HTA in N

2 flow, the results are different in terms of more debris left after annealing (

Figure 3). Nitrogen rich atmosphere was not favorable to recovery of crystalline surface as compared with oxygen flow (see discussion above). Also, a pattern of single pulse ablation showed non-periodic structure with close-to-wavelength feature length. Also, there was no typical ablation crater, rather a nano-textured surface resembling thermally quenched molten phase. The pulse fluence used was

J/cm

2 or average intensity of

TW/cm

2, which is smaller by more than an order of magnitude than the the self-clamping intensity of fs-pulse

W/cm

2, when multi-filaments are formed in air [

13] and could cause a random pattern of dot-like modifications similar to those in SEM image (

Figure 3(a)). Formation and quenching of a molten phase is more probable. Under such high intensity 43 TW/cm

2/pulse exceeding the ablation threshold of sapphire by

times, formation of a highly excited plasma skin layer of tens of manometers was expected during the laser pulse [

14]. Light-matter interaction takes place as if there is a nano-film of different optical permittivity

placed on dielectric sapphire;

is the complex refractive index. Such transient material state described by changing permittivity

is called Die-Met (from dielectric and metal-like plasma) [

14]. It has strong absorption due to reduced

n and increased

due to electron generation and is also referred to as epsilon-near-zero (ENZ) state

[

15].

The ablation of thin films, which proceeds after the end of laser pulse, follows an imprint of a fs-laser pulse intensity. Such modulation has

period and, under multi-pulse exposure, reveals itself as ripples [

12]. After HTA, a more orderly ripple pattern emerged with period smaller than

. The period of ripple-like pattern which evolved after HTA (

Figure 3(b)) resembles ripples ablated under multi-pulse exposure. We put forward here a conjecture (for future validation) that light intensity modulation

occurred due to presence of highly excited plasma nano-layer. Such modification of sub-surface region at the sapphire-plasma interface is hidden from SEM observation in

Figure 3(a), which shows surface of a quenched molten phase. HTA was responsible to restructure surface and the imprinted modification was revealed.

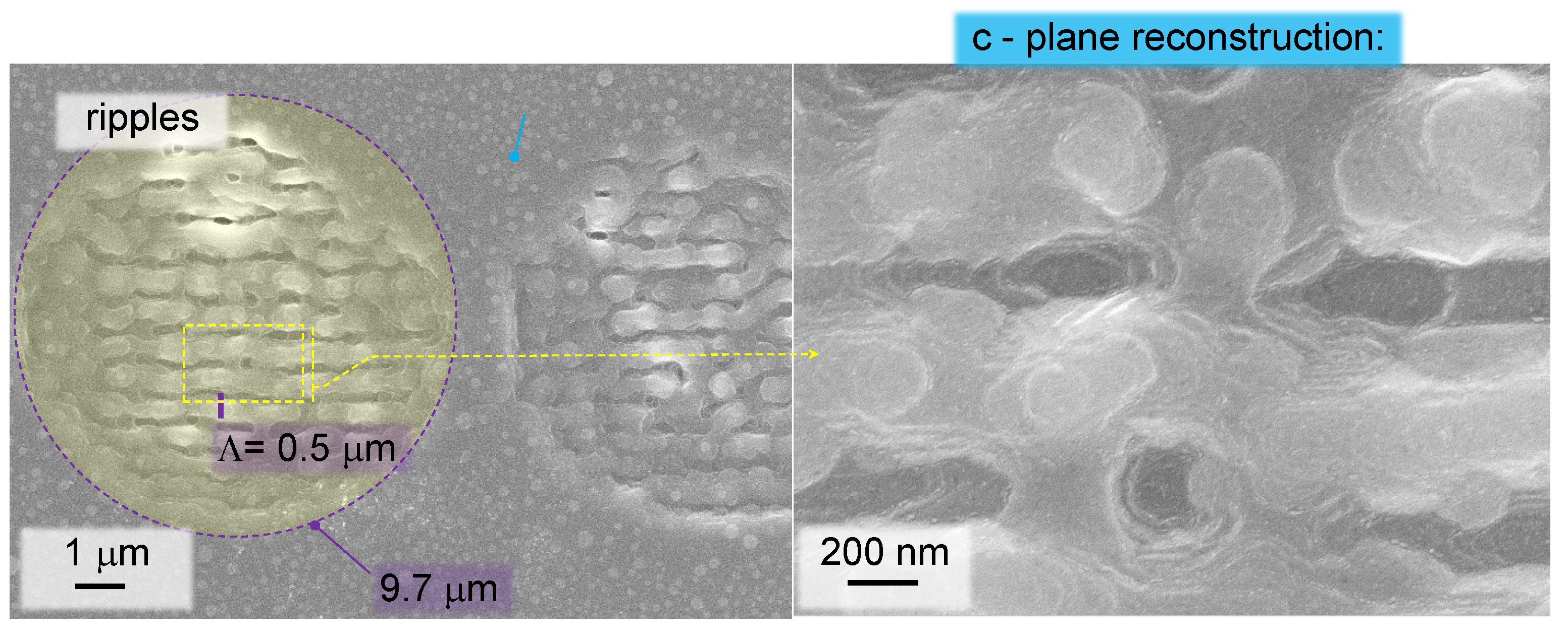

Figure 4 shows closeup SEM views of the ripples with evident re-crystallisation following c-plane of Al

2O

3 (hexagonal pits). Even HTA temperature protocol was the same, the surface quality of HTA treated ablated surface had more debris as compared with that made under O

2 flow (

Figure 2).

3. Conclusions and Outlook

Sapphire ablation with different numerical apertures ( and 0.14) and similar pulse energies (J and J) are compared. SEM images showed the formation of ripples with period close to the wavelength of the laser irradiation for the and, interestingly, it was half of the wavelength of the laser for . After the samples had undergone high temperature annealing at 1500∘C for 2 to 4 hours in either an O2 or N2 environment these ripples underwent restructuring and a crystalline step-like structures become apparent. It was also shown that annealing in an O2 environment reduced the amount of debris and the surface become smooth. In the case of HTA in N2, however, debris were still present and their coarsening took place. Detailed X-ray Photoelectron Spectroscopy (XPS) experiments are planned for detailed understanding of material modification on the surface during HTA in O2 and N2 flow. Apparently, the O2 flow was important factor for restoration of a smooth c-plane surface by HTA.

We show that the restructuring of laser ablated crystalline surfaces can be applied to the fabrication of micro-optical elements in reducing the surface roughness and allowing for tighter control over the surface profile while maintaining the precision of a shape definition. Differently from glasses [

16], where HTA cause a surface tension driven reflow and formation of spherical surfaces which might be different from the required shape for a defined optical function. However, the true extent of the control over surface roughness is yet to be fully explored using this technique. The optimal time of annealing and the optimal temperature to achieve the most restructuring without sacrificing the surface profile will be determined in future studies. Sublimation via solid-to-gas occurring along with solid-fusion-vaporisation stages during HTA need better understanding and can be different in other crystals.

Author Contributions

Conceptualisation, S.J., S.H.N.; investigation, D.S., A.T. D.M., T.K.; writing—original draft preparation, S.J., D.S.; review and editing, all authors. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Australian Research Council, grant number LP190100505. S.J. is grateful for startup funding from the Nanotechnology Facility at Swinburne and to the Workshop-on-Photonics for the technology transfer project, which installed the first industrial-grade microfabrication setup in Australia. Part of this study was made during a Grand Challenge undergraduate project of A.T. Mechanisms of light-matter interactions were discussed with Prof. Eugene G. Gamaly.

Institutional Review Board Statement

Not applicable

Informed Consent Statement

Not applicable

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Batani, K.; Batani, D.; He, X.; Shigemori, K. Recent progress in matter in extreme states created by laser. Matter and Radiation at Extremes 2022, 7, 013001. [Google Scholar] [CrossRef]

- Juodkazis, S.; Nishimura, K.; Tanaka, S.; Misawa, H.; Gamaly, E.E.; Luther-Davies, B.; Hallo, L.; Nicolai, P.; Tikhonchuk, V. Laser-Induced Microexplosion Confined in the Bulk of a Sapphire Crystal: Evidence of Multimegabar Pressures. Phys. Rev. Lett. 2006, 96, 166101. [Google Scholar] [CrossRef] [PubMed]

- Vailionis, A.; Gamaly, E.G.; Mizeikis, V.; Yang, W.; Rode, A.; Juodkazis, S. Evidence of super-dense Aluminum synthesized by ultra-fast micro-explosion. Nature Communications 2011, 2, 445. [Google Scholar] [CrossRef] [PubMed]

- Zel’dovich, Y.B.; Raizer, Y.P. Physics of Shock Waves and High-Temperature Hydrodynamic Phenomena; Dover, Dover Books on Physics, New York, 2002.

- Campanella, B.; Legnaioli, S.; Pagnotta, S.; Poggialini, F.; Palleschi, V. Shock waves in laser-induced plasmas. Atoms 2019, 7. [Google Scholar] [CrossRef]

- Juodkazis, S.; Nishimura, K.; Misawa, H.; Ebisui, T.; Waki, R.; Matsuo, S.; Okada, T. Control over the State of Crystallinity: Sapphire. Adv. Mat. 2006, 18, 1361–1364. [Google Scholar] [CrossRef]

- Juodkazis, S.; Misawa, H.; Gamaly, E.G.; Luther-Davis, B.; Hallo, L.; Nicolai, P.; Tikhonchuk, V. Is the nano-explosion really microscopic? J. Non-Crystall. Solids 2009, 355, 1160–1162. [Google Scholar] [CrossRef]

- Liu, X.Q.; Zhang, Y.L.; Li, Q.K.; Zheng, J.X.; Lu, Y.M.; Juodkazis, S.; Chen, Q.D.; Sun, H.B. Biomimetic sapphire windows enabled by inside-out femtosecond laser deep-scribing. PhotoniX 2022, 3, 2662–1991. [Google Scholar] [CrossRef]

- Yadav, M.J.; Aravindan, S.; Rao, P.V.; Maithani, Y.; Singh, J.P. Surface morphology evolution of C-plane sapphire during multi-step thermal annealing. Surface Topography: Metrology and Properties 2022, 10, 045015. [Google Scholar] [CrossRef]

- Kudrius, T.; Šlekys, G.; Juodkazis, S. Surface-texturing of sapphire by femtosecond laser pulses for photonic applications. J. Phys. D: Appl. Phys. 2010, 43, 145501. [Google Scholar] [CrossRef]

- Buividas, R.; Aharonovich, I.; Seniutinas, G.; Wang, X.W.; Rapp, L.; Rode, A.V.; Juodkazis, S. Photoluminescence from voids created by femtosecond-laser pulses inside cubic-BN. Opt. Lett. 2015, 40, 5711–5713. [Google Scholar] [CrossRef]

- Buividas, R.; Mikutis, M.; Juodkazis, S. Surface and bulk structuring of materials by ripples with long and short laser pulses: Recent advances. Progress Quantum Electronics 2019, 38, 119–156. [Google Scholar] [CrossRef]

- Hsu, W.H.; Masim, F.; Balcytis, A.; Juodkazis, S.; Hatanaka, K. Dynamic position shifts of X-ray emission from a water film induced by a pair of time-delayed femtosecond laser pulses. Optics Express 2017, 25, 24109–24118. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V. Ultrafast re-structuring of the electronic landscape of transparent dielectrics: new material states (Die-Met). Appl. Phys. A 2018, 124, 1–11. [Google Scholar] [CrossRef]

- Ng, S.; Juodkazis, S., Nanoscale plasmonic printing (in Ultrafast Laser Nanostructuring: the Pursuit of Extreme Scales; Eds. R Stoian and J Bonse); Springer Series in Optical Science, 2023; Vol. 239, p. Chapter 25.

- H., B.; D., K. Technical Glasses - Physical and Technical Properties. Technical report, SCHOTT AG, Hattenbergstrasse 10 55122 Mainz Germany, 2020.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).