1. Introduction

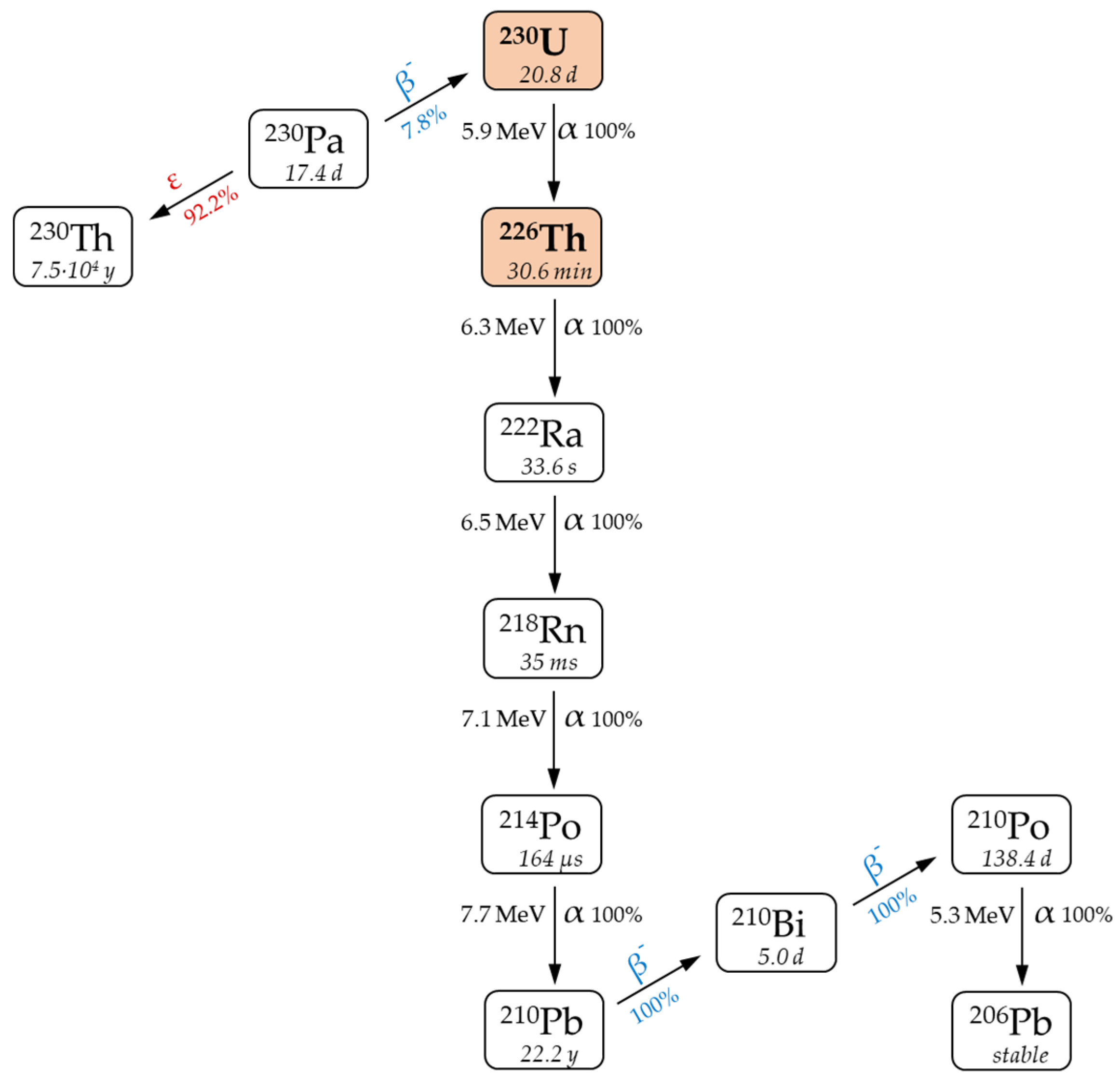

Targetry alpha therapy (TAT) is effective for the treatment of various oncological diseases due to the property of α-particles to release a large amount of energy in a limited area of living tissue (~ 10 cell diameters). One of the promising radionuclides for TAT is

230U (T

1/2 = 20.2 d) [

1]. The decay of

230U generates a chain of short-lived products and it is leads to the emission of five α-particles with a total energy of 33.5 MeV (

Figure 1), resulting in effective cell damage [

2]. The short-lived daughter alpha emitter

226Th (T

1/2 = 30.6 min) is also attractive radionuclide for using in TAT [

3]. In terms of nuclear properties, the

230U/

226Th pair is similar to the well-researched

225Ac/

213Bi generator pair [

4].

The expected therapeutic efficacy of

230U/

226Th has not been demonstrated yet, nevertheless, research is underway to find optimal chelating agents that can stably bind

in vivo 230U [

5] and

226Th [

6].

The effective way of

230U and

226Th production is required in order to successfully implement these radionuclides in TAT.

230U can be produced directly via nuclear reactions

231Pa(p,2n)

230U [

7] and

231Pa(d,3n)

230U [

8]. The initial

231Pa (T

1/2 = 3.3·10

4 y) is a decay product of

235U, it must be isolated from aged uranium samples. The raw material is hardly accessible, which makes limitations on this method. Another approach uses reactions of thorium nuclei with accelerated protons and deuterons, leading to the formation of

230Pa precursor decaying into

230U with a branching ratio of 7.8%:

232Th(p,3n)

230Pa→

230U and

232Th(d,4n)

230Pa→

230U.

Scientific organizations worldwide are actively developing the production of

230U through irradiation of

232Th with protons [10–13]. This method has proven to be the most effective in terms of product yield compared with the reactions with deuterons [14,15]. Moreover, the maximum of the

232Th(p,3n)

230Pa reaction excitation function is around 20 MeV [

9,15], which enable up-scaled production of

230U on accessible commercial cyclotrons. At higher energy of protons (> 70 MeV)

230U can be obtained as a byproduct in

225Ac production [16,17] along with

223Ra [18].

230U from proton-irradiated thorium contains a chemically inseparable impurity of long-lived uranium isotopes. This impurity was evaluated in our previous paper [15] as up to 0.02% 232U (T1/2 = 68.9 y) and 0.001% 233U (T1/2 = 1.6·105 y). Long-lived admixture makes the medical use of 230U as a source in a radionuclide generator of 226Th more prospective than a direct application.

226Th is considered to be an alternative to another promising generator-produced short-lived radionuclide 213Bi (T1/2 = 45.6 min) [19]. 226Th provides a greater impact on cancer cells compared with 213Bi. A rapid cascade of four α-particles initiated by 226Th decay deposits totally 27.7 MeV, while 213Bi emits only one α-particle with an energy of 8.4 MeV. 226Th-radiopharmaceuticals can be effective for therapy of epithelial or easily accessible tumors [20]. Radioimmunoconjugates Nimotuzumab-p-SCN-Bn-DTPA(DOTA) were synthesized in our previous paper and their specificity towards EGFR overexpressing epidermoid carcinoma A431 cells has been demonstrated [21]. A major advantage of 226Th-TAT compared with 230U-TAT is that there is no problem of uncontrolled redistribution of recoiled daughter nuclide (for 230U such nuclide is 226Th itself), which might cause considerable toxic effects to heathy tissues.

Due to the relatively short half-life of 226Th, time economy becomes a major requirement throughout the entire process from obtaining 226Th to radiopharmaceutical administration. For this reason, the generator system must ensure the rapid and efficient separation of the accumulated thorium radionuclide. Various methods of liquid-liquid extraction [22,23], extraction chromatography [24–26] and ion exchange chromatography [27–29] have been developed for the separation of thorium and uranium. For instance, for the selective isolation and determination of U, Th and a number of other radionuclides in water (sample volume up to 1 L), methods based on their sorption with TEVA Resin and UTEVA/TRU Resin sorbents have been recommended [30,31]. The chromatographic methods are more appropriate for a 230U/226Th generator because they usually provide 226Th in a small volume of eluate containing reduced amount of long-lived impurities.

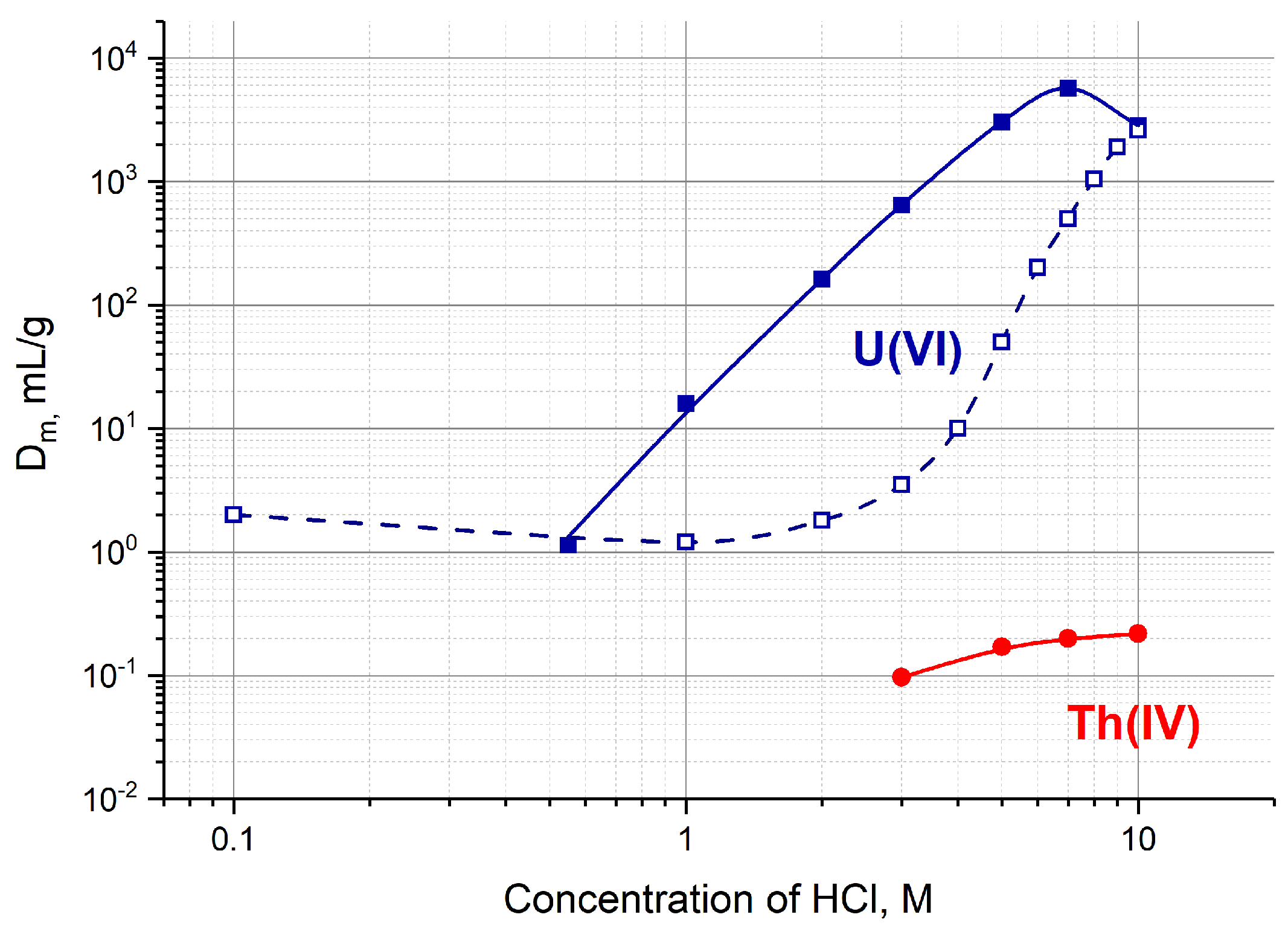

Effective separation of U(VI) and Th(IV) can be achieved on sorbents displaying anion-exchange properties in strong hydrochloric acid solutions. As it can be seen in

Figure 2, U(VI) exhibits high affinity to a strong base anion-exchange resin Dowex 1 (or AG 1) and to an extraction chromatographic resin TEVA at c(HCl) > 6 M, whereas Th(IV) is not retained. The both resins were tested as sorbents for

230U/

226Th «direct» generator [21]. TEVA Resin proved to be more preferable, it provided high

226Th yield in less volume of eluate (1-2 mL). Furthermore, the maximal mass distribution ratio D

m of U(VI) adsorbed on TEVA Resin is located around 7 M HCl, whereas the largest adsorption of U(VI) on AG 1 corresponds to HCl concentration greater than 9 M (

Figure 2). High acidity of final

226Th eluate is found to be the main disadvantage assuming the extra-time needed to convert the eluate into neutral solution prior to labeling.

Another approach is based on reverse scheme of 230U/226Th generator, i.e. the parent 230U is not fixed on the column filled with sorbent while the daughter 226Th remains adsorbed. An extraction chromatographic DGA Resin containing diglycolamide derivative is reported to be appropriate for obtaining 226Th in citric buffer solution that is amenable to direct labeling with minimal losses of time [12]. However, the 226Th eluate recovered from the reported reverse 230U/226Th generator contains at least 0.2% of 230U [12], which is unacceptable for clinical trials so far.

In the presented article, we investigate different schemes of two-column 230U/226Th generator pursuing two goals: i) obtaining 226Th of high purity in a solution amenable to further labeling; ii) reducing the time of 226Th production. The first column serves for fixing the parent 230U and elution of 226Th. The second column is intended to adsorb 226Th from a strongly acidic solution and then to desorb it with diluted or neutral solution. This concept was early proposed and tested for 225Ac/213Bi generator [33–35]. In the first column, 225Ac formed an extremely strong complex with bis-(2-ethylhexyl)methanediphosphonic acid (H2DEH[MDP]) immobilized on a silica support (Ac Resin). Products of 225Ac decay, 221Fr, and 213Bi were eluted with 1 M HCl and concentrated on the second column filled with ion exchanger AG-MP 50 from 0.2 M HCl. Then, 213Bi was eluted from the second column with 0.1 M HI. The high efficiency of this approach makes it suitable for implementation for 230U/226Th pair as well.

2. Materials and Methods

All chemicals were of p.a. (pro analysis) quality or higher, obtained from Merck (Darmstadt, Germany), and used without additional purifications. All experiments were carried out using de-ionized “Milli-Q” water (18 MΩ·cm-1). DGA Resin (N,N,N`,N`tetroctyldiglicolamide as an extracting agent), TEVA Resin (quaternary ammonium salt Aliquate 336 as an extracting agent), TRU Resin (octyl(phenyl)-N,N-di-isobutylcarbomoylmethylphosphine oxide dissolved in tributylphosphate), and UTEVA Resin (dipentil pentylphosphonate as an extracting agent) with 50–150 μm particle size were obtained from Triskem, France.

Citric buffer solutions (10-4 – 10-1 M, pH 5.0±0.1) were prepared by dissolving the corresponding solid acid sample and adding small portions of 1 M NaOH to obtain a solution with the required pH value.

Measurements of operational pH values were performed with an Orion 2 Star Benchtop pH meter using an Orion 8103SC combination pH electrode. Commercial pH Titrisol buffer concentrates (Merck p.a.) were used to calibrate the setup at room temperature.

Acid-base titration with indicators methyl orange and phenolphthalein was used to determine the acid content in commercial solutions of concentrated HCl and HNO3, as well as in 226Th containing eluate.

The experiments were carried out at the temperature of 21±2 ˚C.

2.1. Gamma-ray spectroscopy

The measurement of radionuclide activities was performed by γ-ray spectrometry using a high resolution HP Ge detector (ORTEC GEM15P4-70). Samples were counted at different detector-source distances respecting the level of dead-time less than 10%. The detector efficiency at the used distances were determined with standard calibration sources. Net peak areas in detected photopeaks were evaluated by means of GammaVision32 software.

The characteristic γ-ray emission of

226Th (111.1 keV, 3.29%) and

222Ra (324.3 keV, 2.77%) [

2] were used for activity quantification of various generator testing samples.

2.2. Target preparation and irradiation, and 230U isolation

Metallic thorium supplied by Institute for Physics and Power Engineering (IPPE, Russia) was used as target material. Thorium plates of (2.2 × 2.5) cm2 approximate dimensions with thickness of 1.5-2.0 mm were fabricated and packed in copper and aluminum foil envelopes served for beam monitoring as well. Each package was encapsulated in a graphite shell sealed with high-temperature silicone adhesive. Several targets were irradiated at linear proton accelerator of the Institute for Nuclear Research of the Russian Academy of Sciences (INR RAS, Russia) [36] with initial energy of 120-130 MeV. The beam current and total beam charge were 3-5 µA and 12-18 µA·h, respectively.

The dissolution of irradiated thorium was performed as described previously [17,37] four to five days after the end of bombardment (EOB). The protactinium fraction including 230Pa was recovered from the solution according to the procedure reported [15] and kept in 7 М HCl / 0.1 M HF solution for 230U accumulation during 27-28 days. Traces of Nb (mainly 95Nb) and Ru (103,106Ru) radioisotopes were the impurities of 230Pa/230U.

A chromatographic technique close to the one developed by A.W. Knight [38] was implemented for separation of 230U from 230Pa. The solution with radionuclides was loaded onto a column filled with 2 mL of TEVA Resin. Due to the presence of fluoride ions, Pa(V) together with Ru(IV) were eluted while U(VI) and Nb(V) were retained on the resin. The column was washed with 7 М HCl / 0.1 M HF solution to remove the rest of Pa(V). The washing was added to the Pa(V) eluate and the combined solution was kept for the next 230U accumulation. Then, having the column been washed with 7 М HCl solution, U(VI) and a part of Nb(V) were desorbed with 0.1 М HCl solution. The desorbate was adjusted to 3 M HCl by adding concentrated hydrochloric acid; and, following the known procedure [12,39], this solution was passed through a column filled with 1 mL of DGA Resin. The uranium fraction was adsorbed while the 95Nb was washed out of the column. Finally, 230U was eluted with a small amount of 0.1 М HCl solution.

2.3. Generator schemes for producing 226Th

2.3.1. Preparation of a parent 230U column

A plastic column of ~ 5 mm in diameter was filled with 1 mL of TEVA Resin equilibrated with 7 М HCl. The resin was fixed inside by two frits at the bottom and at the top of column. The 230U solution was evaporated and reconstituted in 7 М HCl. The resulting solution was passed through the column followed by washing a solution of 7 M HCl. The uranium was adsorbed under these conditions, the loaded activity of 230U was 300-350 kBq. Approximately a month after the 230U isolation and loading, a second part of 230U was accumulated, separated from 230Pa as described above and added to the column.

The prepared column served as a parent one, it could work as a one-column generator providing

226Th elution in 7 M HCl. A typical differential curve of

226Th elution is shown in

Figure A1. Furthermore, the parent column was a part of two-column generator schemes.

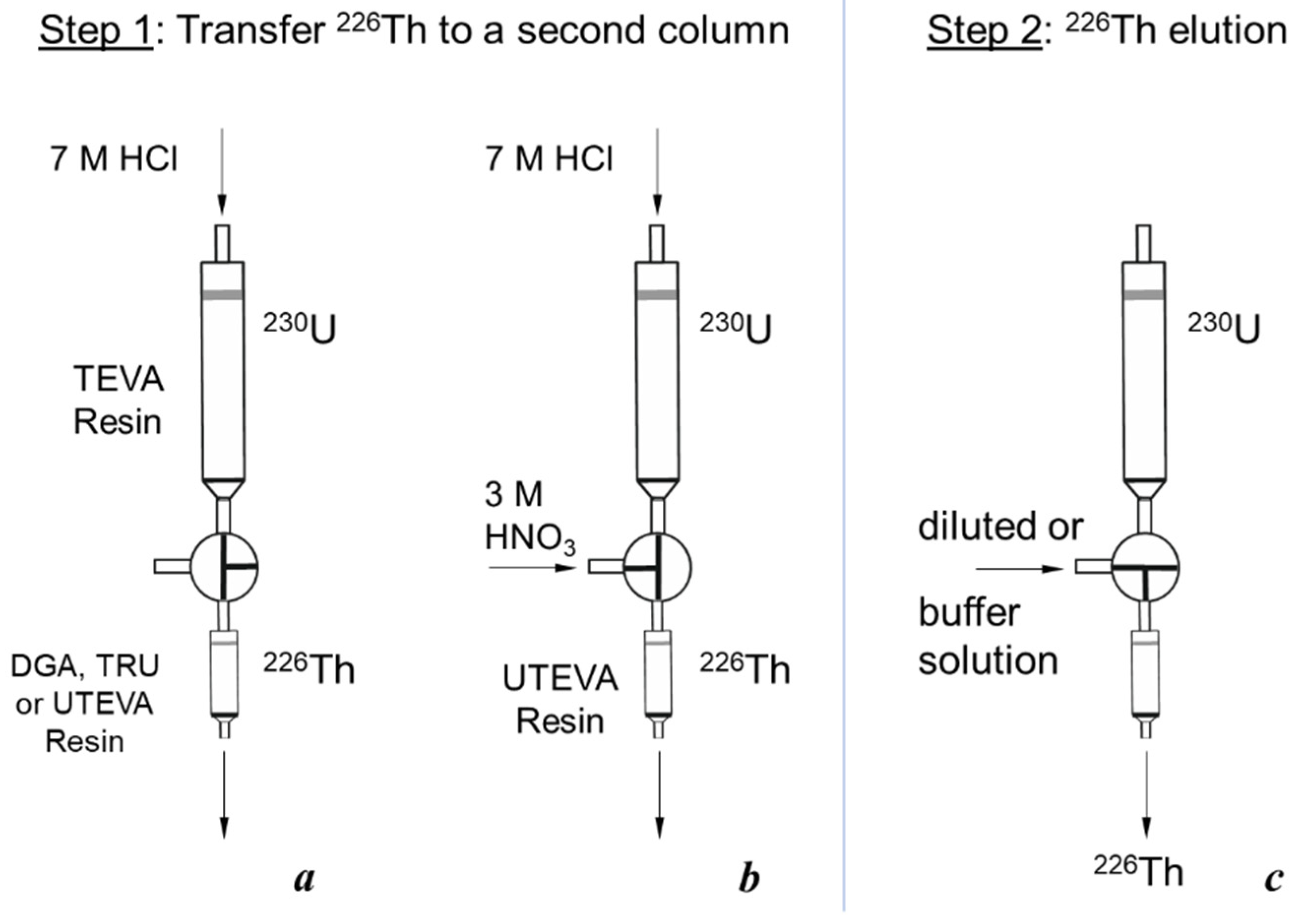

2.3.2. Two-column 230U/226Th generator scheme and 226Th elution cycle

A general scheme of

230U/

226Th generator comprised two columns connected in series via a three-valve cock as shown in

Figure 3. The parent TEVA column containing

230U was the first column and a column filled with TRU, UTEVA or DGA Resin served as a second one that could be changeable when necessary. A milking procedure included two common steps: 1) transfer

226Th with 7 M HCl solution from the parent column to the second one (

Figure 3a); 2)

226Th elution with diluted HCl or citric buffer solution (

Figure 3c). Eluates were collected for measurement of

226Th and

230U activity and eluate acidity. Flow rates of solutions passing through the columns were kept and controlled with a peristaltic pump. The values of flow rate were 1 and 0.6 ml/min for Step 1 and 2, respectively.

The TRU or DGA Resin was loaded into a plastic column of ~ 3 mm in diameter, the height of resin bed was 11-12 mm (resin volume ~ 0.1 mL). A diameter of column for UTEVA Resin was ~ 5 mm, the height of UTEVA bed was 55-58 mm (~ 1 mL). Each column was equipped with a bottom and top frits.

For some experiments with the UTEVA column, we modified Step 1 as it is shown in

Figure 3b. A flow of 7 M HCl solution (0.5 mL/min) after passing the parent

230U column was mixed with a flow of 3 M HNO

3 solution (0.5 mL/min) resulting in the 1 ml/min flow of 3.5 M HCl / 1.5 M HNO

3 solution at the entrance of UTEVA Resin column.

2.4. 230U measurements

The content of 230U in eluates was usually measured overnight for complete 226Th decay. 230U was assayed by γ-ray spectroscopy via the daughter radionuclides 226Th and 226Ra.

Distribution of 230U along the TEVA Resin column was monitored by scanning through a 4 mm wide slit between the lead blocks. The measurements were performed after 230U loading onto the TEVA Resin column and regularly after milking.

3. Results and Discussion

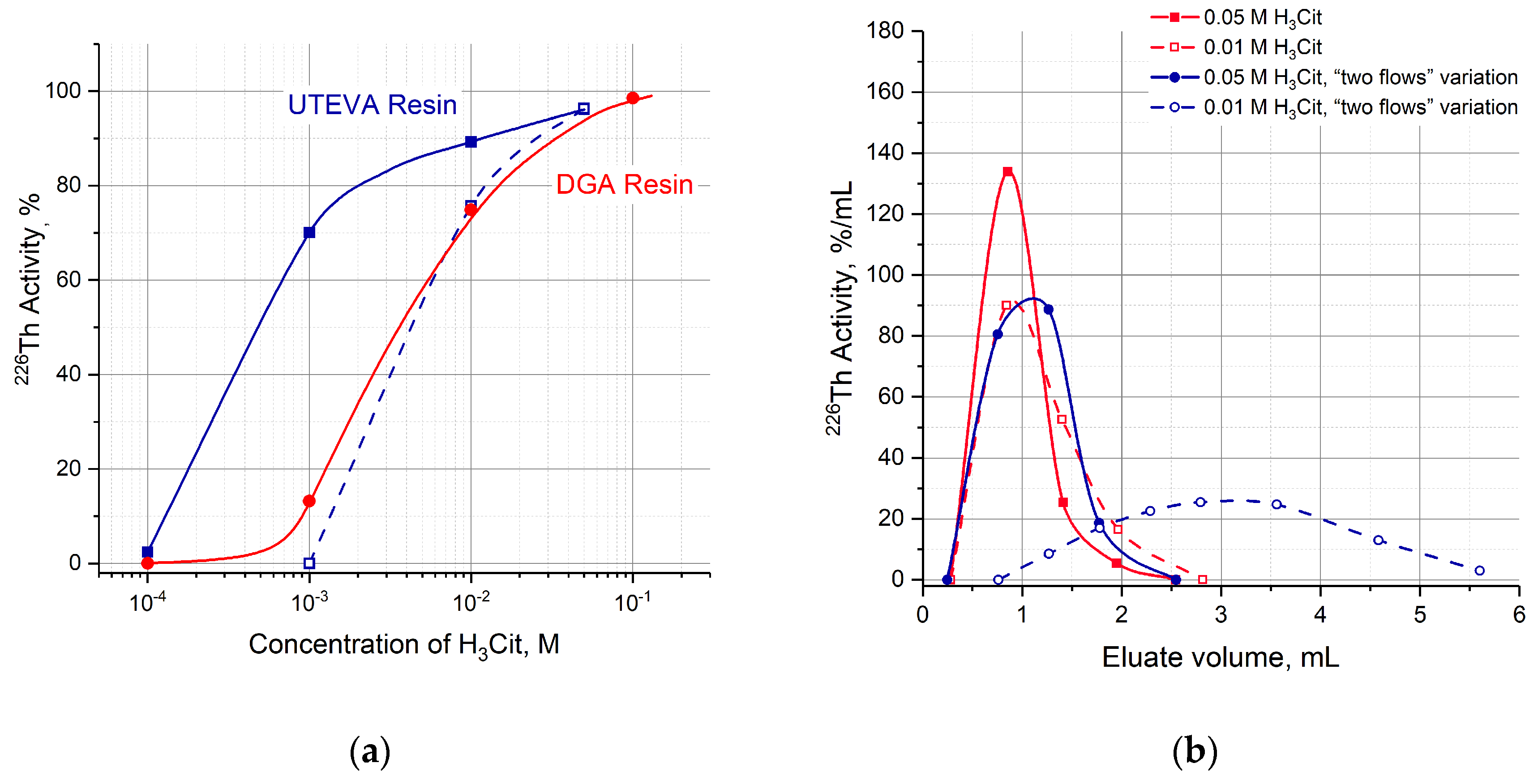

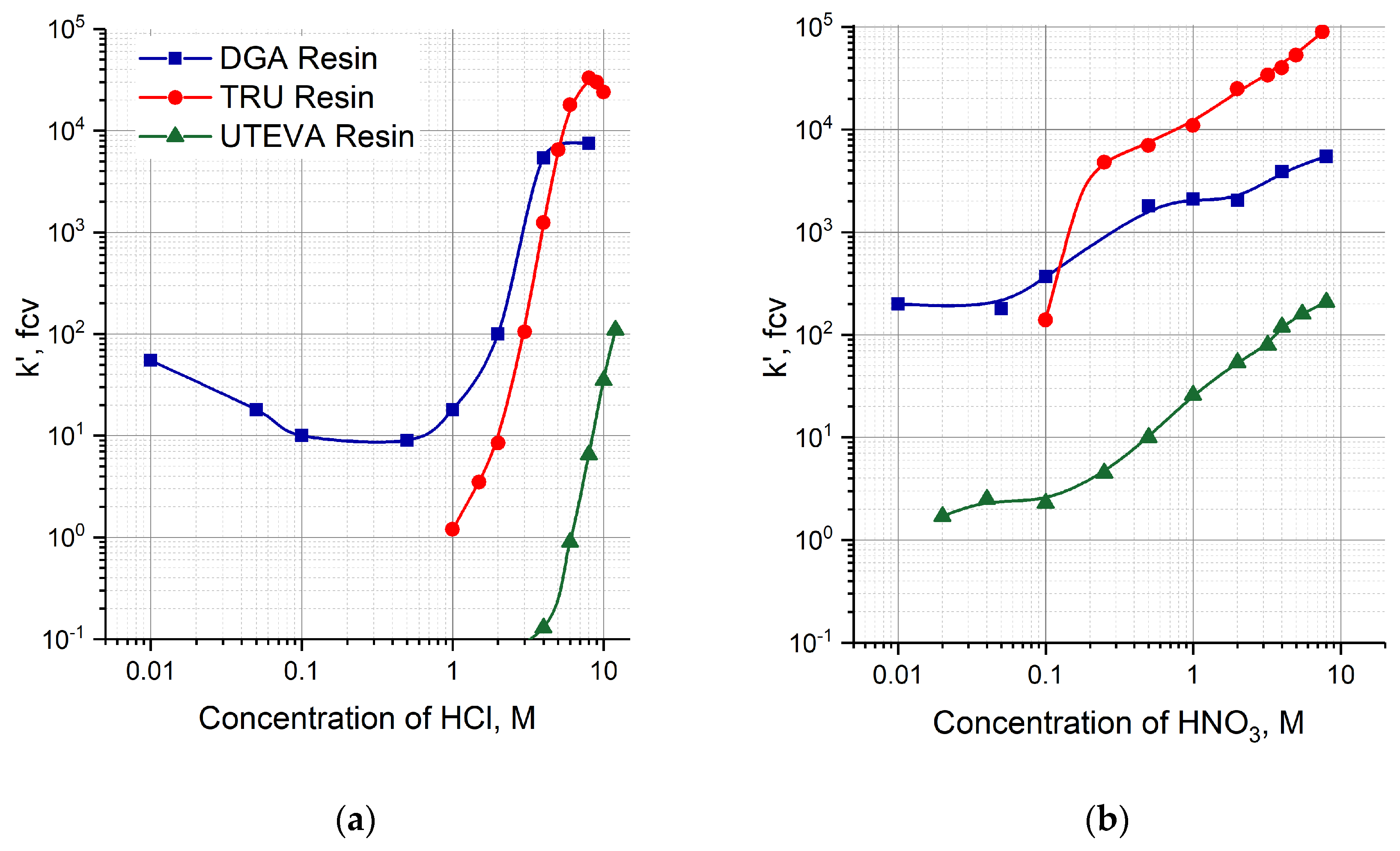

A two-column

230U/

226Th generator was proposed and investigated for fast

226Th production in diluted or neutral citric solution. The parent

230U was adsorbed onto the first column filled with TEVA Resin (Triskem Int.). On reaching the transient equilibrium, the daughter

226Th was separated and eluted with strong HCl solution. The role of second column was to reduce quickly the acidity of

226Th solution, i.e. a sorbent for second column was expected to retain

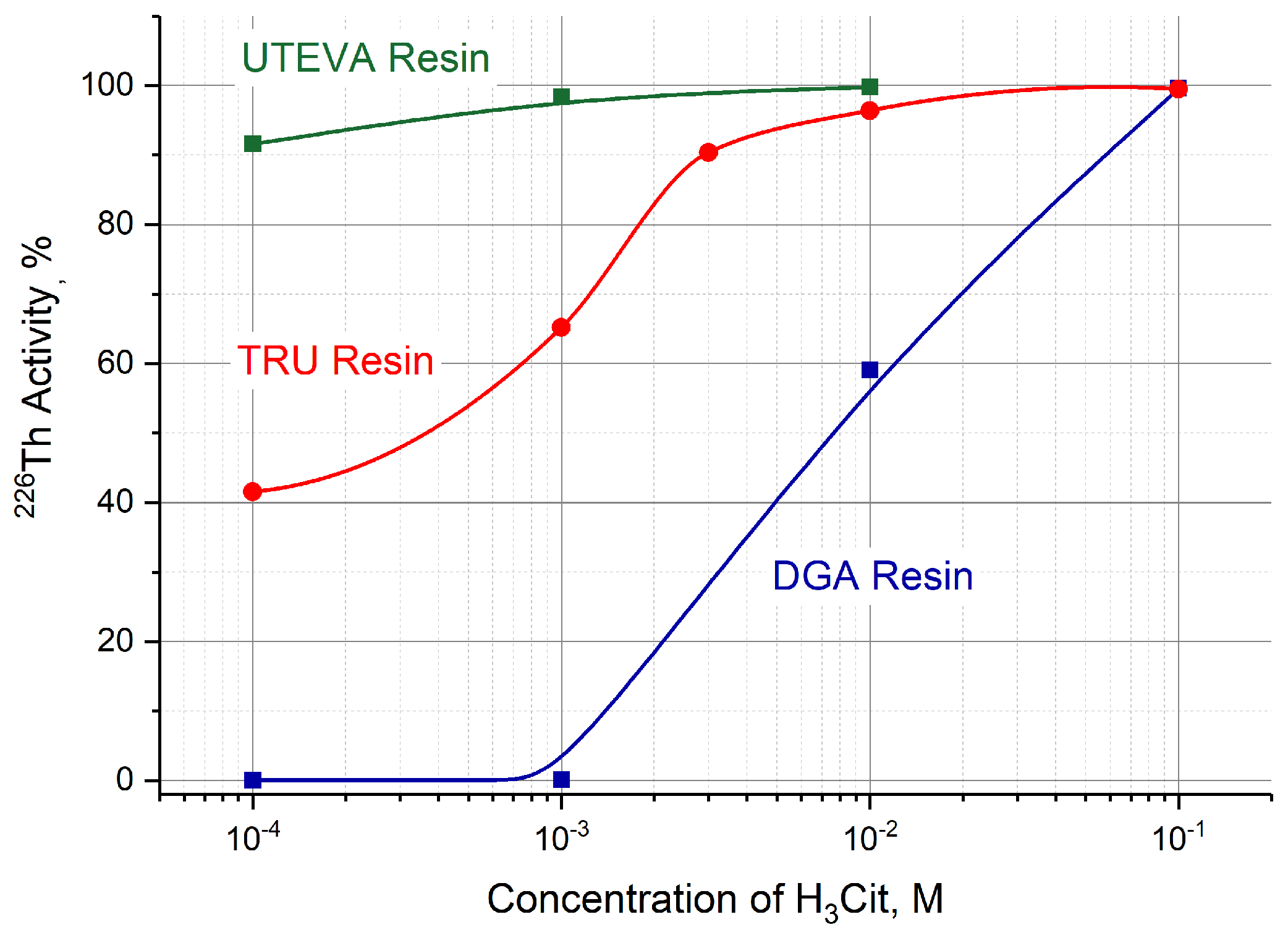

226Th from the strong HCl solution and to desorb it into a diluted solution. Three extraction chromatographic resins eligible for this purpose were considered: TRU Resin, UTEVA Resin and DGA Resin (all Triskem Int.). According to the reported data [40–42] obtained in static conditions and shown in

Figure 4a, the resins can be arranged in a row with respect to Th(IV) retention from < 5 M HCl solution:

In order to evaluate the feasibility of two-column 230U/226Th generator, the column experiments on 226Th sorption from 7 M HCl and its desorption with diluted HCl solutions were carried out.

3.1. Elution of 226Th from the second column with HCl solutions

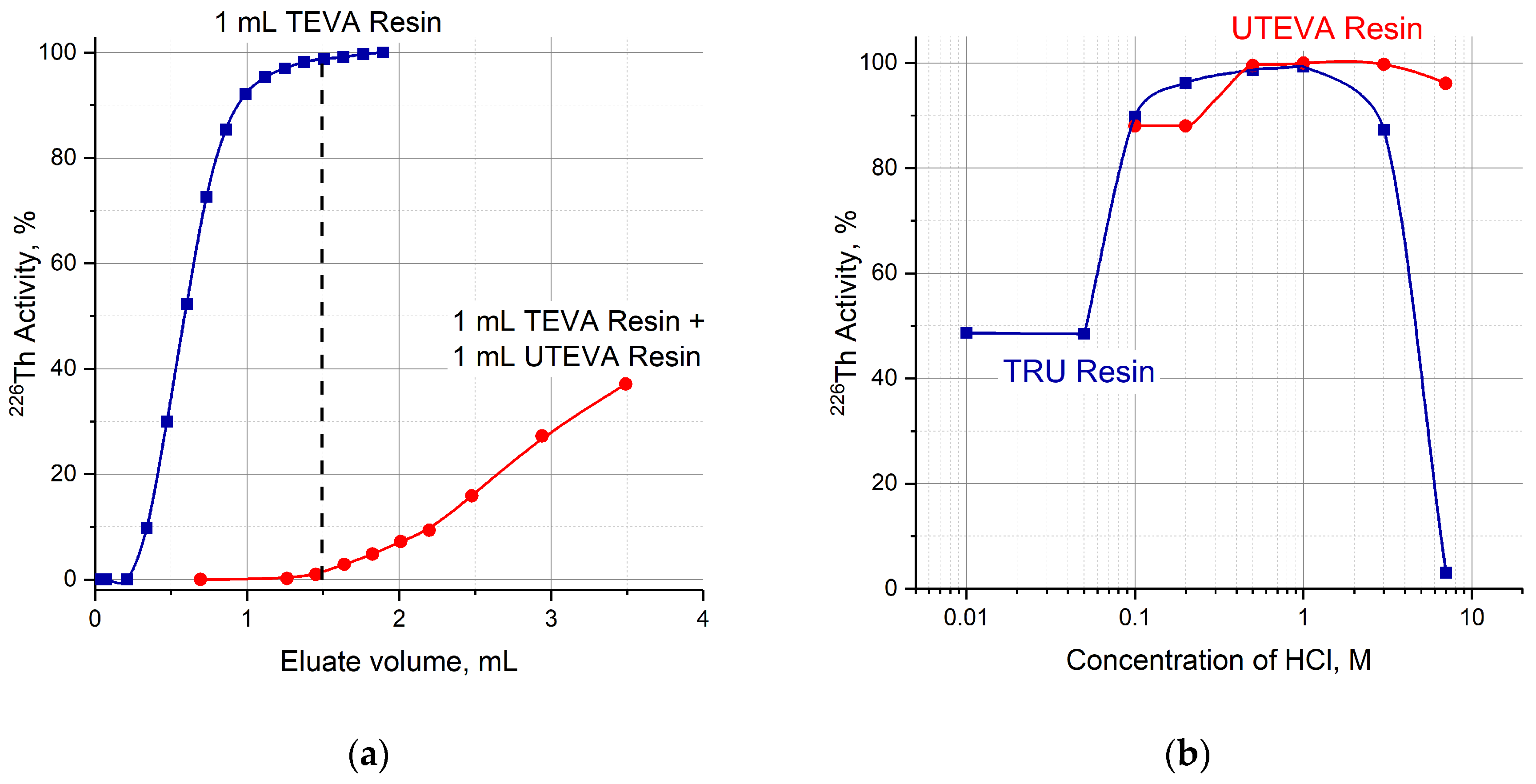

First, the transfer

226Th to a second column was investigated (

Figure 3a, Step 1).

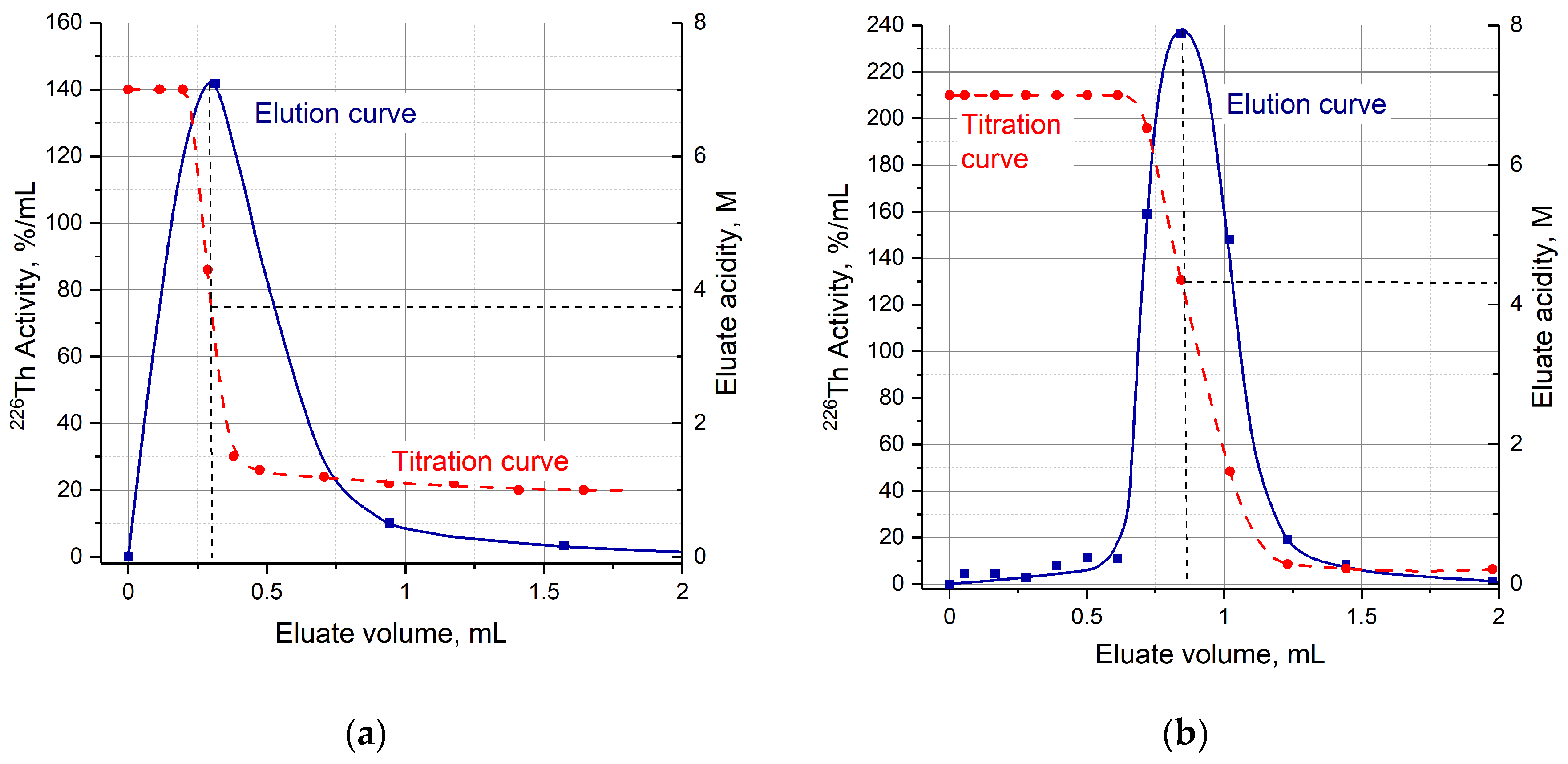

226Th was easily stripped off the parent column with 7 M HCl solution, the concentration corresponding to the maximum of U(VI) sorption on TEVA Resin (

Figure 2). The integral

226Th elution curve (blue line in

Figure 5a) indicates that the solution volume of 1.5 mL was sufficient to wash out ≥ 99% of

226Th. DGA Resin and TRU Resin displays high adsorption of

226Th from 7 M HCl solution (

Figure 4a), the values of

k’ Th(IV) attain 10

4. When the second column was filled with 0.1 mL of these resins and connected directly to the exit of parent column,

226Th was completely adsorbed onto the second column. In contrast, the values of

k’ Th(IV) on UTEVA Resin are below 10 under the same conditions. Therefore, the quantity of UTEVA Resin in the second column was increased up to 1 mL to ensure a tolerable breakthrough of

226Th less than 3% (red line in

Figure 5a).

The transferred

226Th was eluted with different HCl solutions as it is shown in

Figure 3c (Step 2). The DGA Resin exhibits the greatest retention of

226Th among the studied resins from diluted hydrochloric solutions (

Figure 4a). Our results of column experiments were in a good agreement with the

k’ data. The elution of

226Th with 0.3 M HCl solution, which is the most favorable for

226Th desorption, resulted in 40% of

226Th yield in 6 mL of eluate. For other HCl concentrations, the

226Th yield was even lower.

The efficiency of

226Th desorption from the second columns filled with TRU and UTEVA Resins versus the concentration of hydrochloric solution is presented in

Figure 5b. The optimal range of

226Th desorption was 0.4-1 M HCl for TRU Resin and 0.5-2 M HCl for UTEVA Resin. Typical

226Th elution curves (

Figure 6) display that

226Th was completely eluted in ~ 1 mL of eluate. It is interesting to note that the width of

226Th chromatographic peaks from the TRU Resin and UTEVA Resin columns is almost the same, although the bed volume of UTEVA Resin is 10 times larger than that of TRU Resin.

Despite the fact that the HCl concentration of the solution entering the second column was relatively low, the eluate acidity from both TRU Resin and UTEVA Resin columns was 3-4 M [H

+]. The detailed titration curves of eluate collected by portions (

Figure 6) demonstrate that

226Th is eluted on the HCl concentration drastic gradient when one solution is replaced by another. Maximum of

226Th chromatographic peak corresponds to H

+ concentration around 4 M. Thus, use of dilute HCl solutions allowed us to decrease eluate acidity by only two times.

3.2. Elution of 226Th from the second column with citric buffer solutions

After transferring from the parent column to a second one containing TRU, UTEVA or DGA Resin,

226Th can be desorbed with a neutral citric buffer solution. The efficiency of

226Th desorption was studied as a function of H

3Cit (pH 5.0) concentration in the range of 10

-4 M – 10

-1 M. The dependencies plotted on the graph (

Figure 7) are arranged in the order reflecting the above-mentioned sequence of resins’ affinity for thorium (IV). For all the resins, 0.1 M citric buffer solution wholly recovered

226Th.

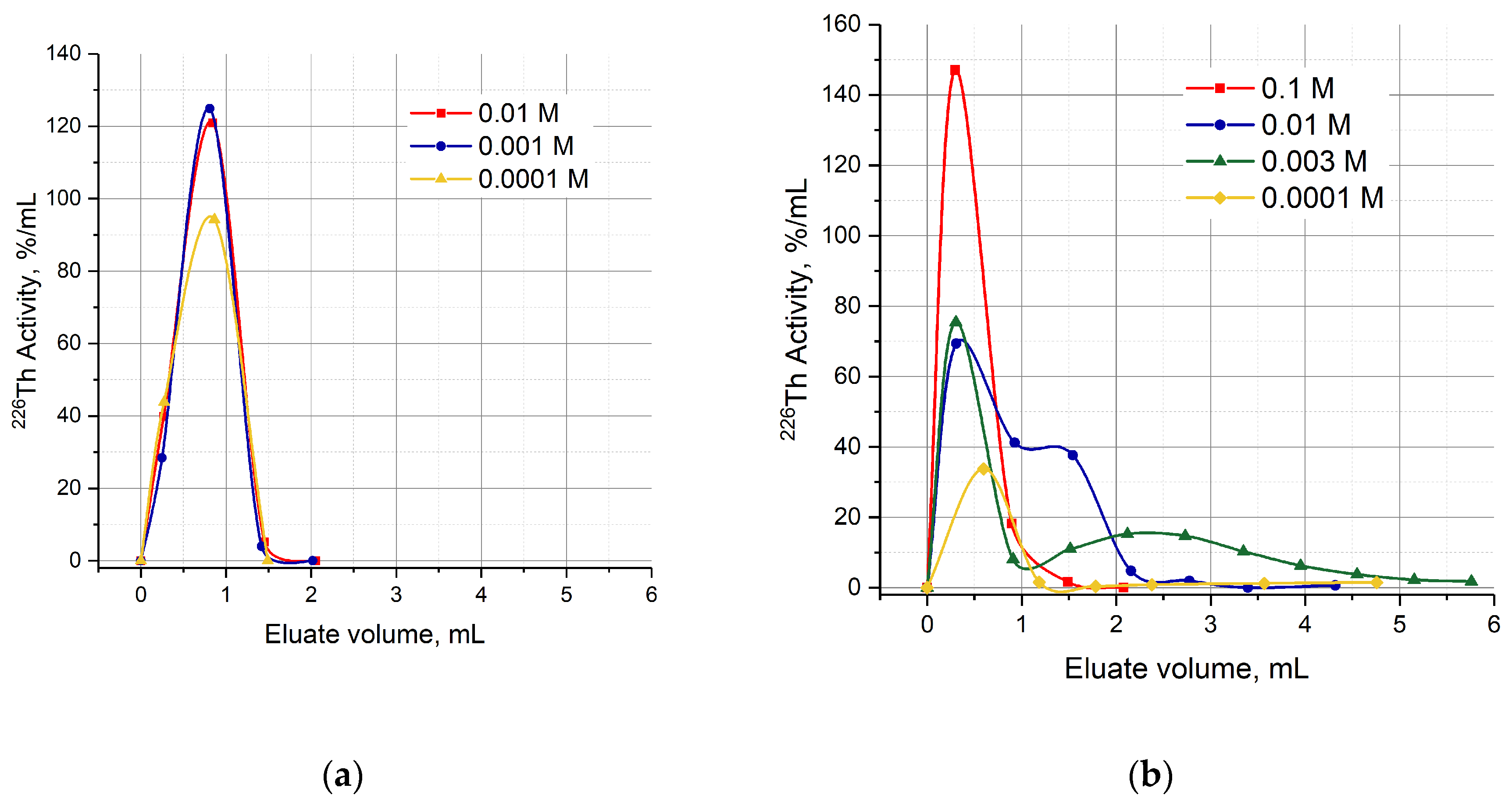

Typical curves of

226Th elution from the UTEVA Resin and DGA Resin columns consisted of the only chromatographic peak within the given range of citric acid concentration (

Figure 8a). Similar to the

226Th elution with dilute hydrochloric solutions, the peak maximum followed the acidity gradient. Otherwise, two chromatographic peaks were observed when

226Th was eluted from the TRU column with citric buffer solutions (

Figure 8b). The first peak was in the same way related to HCl concentration gradient. The position of maximum

Vmax of second peak, as well as the capacity factor

k’ defined as

[40] (

Vc is free volume of sorbent in a column), depended on the citric acid concentration.

According to the literature data, various complexes of Th(IV) are coexisting in citric acid media depending on pH values and salinity [43,44]. At pH 5-6 the predominant species are ThCit

35- and ThCit

2(OH)

24- [43] with cumulative formation constants (logβ) of 28 and 15, respectively. In more acidic solution (pH<1) the speciation shifts towards cation forms of Th(IV), e.g. Th

4+ and ThCit

+ (logβ = 14). It is evident that all these species may exhibit different affinities to the resins and the detailed analysis is complicated. However, in the case of TRU Resin the dependence of

k’ Th(IV) on citric acid concentration may be expressed by a simple correlation helpful for practice use:

where

and

are empiric constants.

Satisfactory values of

226Th yield (> 90%) in small amount of eluate (1-1.5 mL) were obtained for all the studied resins, the eluate characteristics are listed in

Table 1.

It was found that eluate acidity remained relatively excessive for immediate synthesis of labeled compounds. In order to keep 226Th on the second column during the substitution of acidic medium with neutral one, the influence of nitrate ions was studied.

3.3. Stabilization of 226Th on the second column before elution

The ability of Th(IV) to form stable anionic complexes with nitrate ions is widely used to separate it from other elements. Comparison of

k’ values for DGA, TRU and UTEVA resin reveals higher sorption of Th(IV) from nitric solutions (

Figure 4b) than from hydrochloric ones (

Figure 4a), especially for the acidity below 1 M. Taking this fact into account, we modified the procedure of

226Th production from the two-column

230U/

226Th generator.

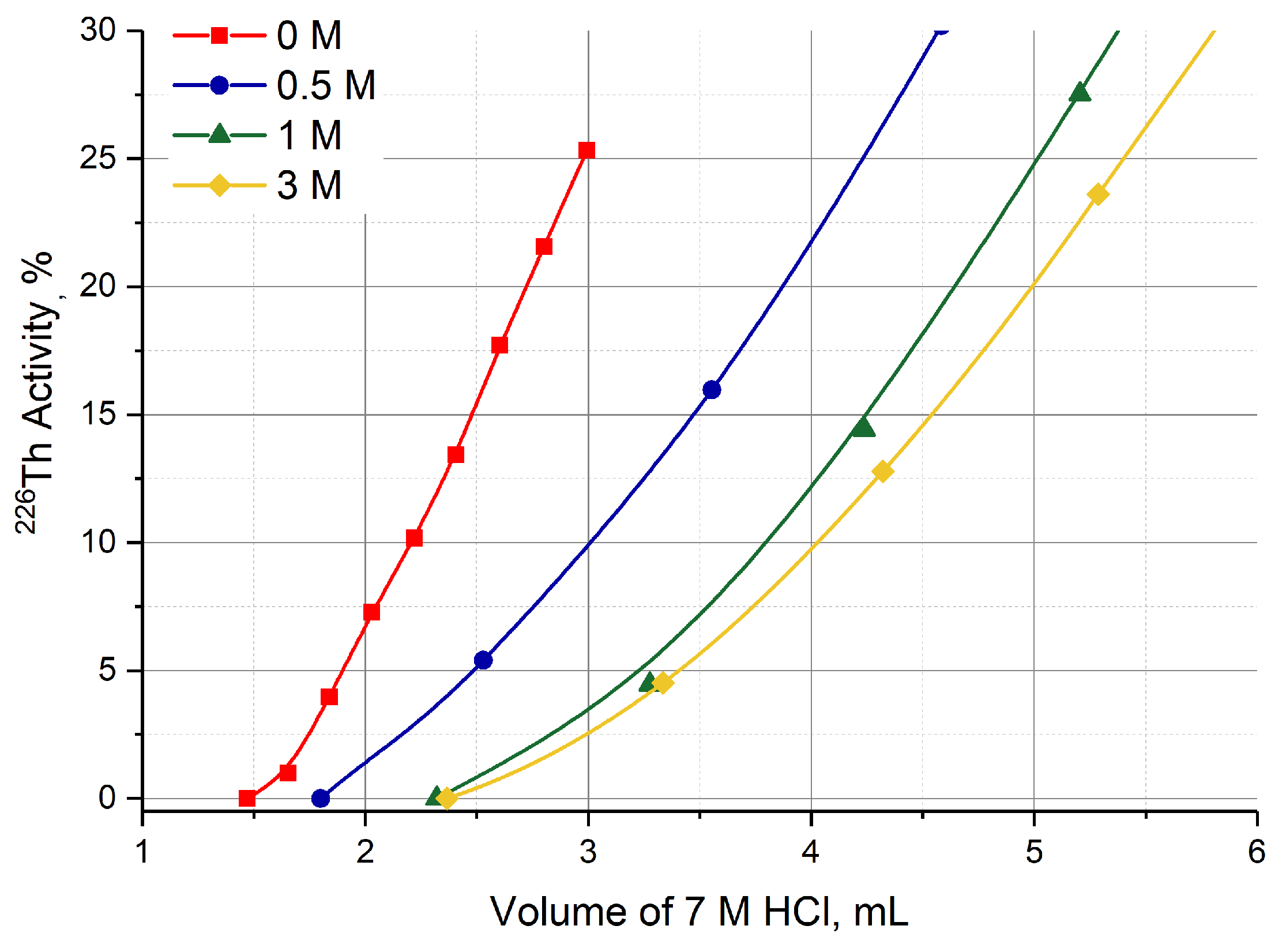

The initial part of modification consisted in the pre-treatment of second column. Before transferring

226Th from the parent column (Step 1), 10 mL of HNO

3 solution of a certain concentration was passed through the second column with the flowrate of 1 mL/min. For the DGA and TRU Resins, HNO

3 concentration was 0.1 M, which corresponds to moderate values of capacity factor 150 <

k’ Th(IV) < 350 (

Figure 4b). In the case of UTEVA Resin, the values of k’ Th(IV) for dilute nitric acid solutions are small; they grow with increasing acid concentration and reach values around 100 in the region of 3-4 M HNO

3.

Starting from these data obtained in static conditions, the UTEVA column was pre-treated with a HNO

3 solution of various concentrations and

226Th losses during Step 1 were studied. The results presented in

Figure 9 display that the

226Th losses when transferring from the TEVA column to UTEVA one with 7 M HCl solution noticeably diminished along with increasing the concentration of HNO

3 used for UTEVA pre-treatment. For 3 M HNO

3 solution, the breakthrough of

226Th began after passing not less than 2.5 mL of 7 M HCl.

In addition, a variation of Step 1 was tested (

Figure 3b) that provided the flow of 7 M HCl solution carrying

226Th to be equally mixed with the flow of 3 M HNO

3 solution at the entrance of the UTEVA column (“two flows” variation). As a result,

226Th breakthrough was not observed even after 20 mL of 7 M HCl (> 20 bed volumes).

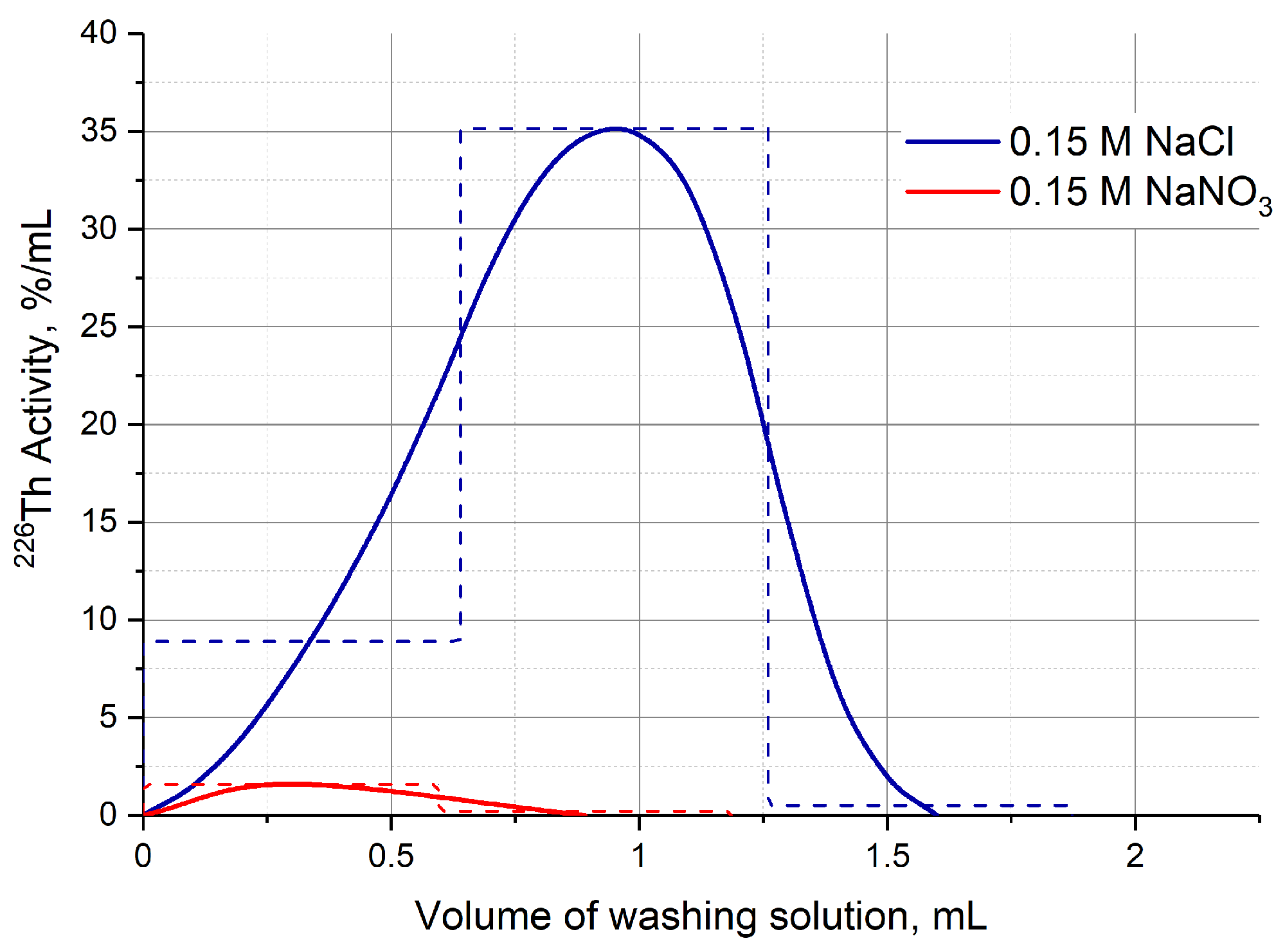

The other part of the second column modification was carried out after Step 1 and involved substituting the 7 M HCl medium with dilute or neutral one. Solutions of 0.1 M HNO

3, 0.15 M NaCl and 0.15 M NaNO

3 were studied. Full change of medium in the DGA column took place after passing 1.0-1.2 mL of each solution, and

226Th losses did not exceed 3%. In the case of TRU column,

226Th was partially washed out on the HCl concentration gradient (similar to

Figure 6b) regardless of the substituting solution, its losses ranged from 10% to 40% and were poorly reproducible. The UTEVA Resin retained well

226Th when the solutions of 0.1 M HNO

3 and 0.15 M NaNO

3 were passed through the second column, whereas the 0.15 M NaCl solution washed out up to 28% of

226Th (

Figure 10).

Having replaced the strongly acidic medium in the second column,

226Th was washed out with a citric buffer solution (pH 5.0) of various concentrations (

Figure 11a). The results obtained for the UTEVA column:

i) without the pre-treatment and medium substitution (green line in

Figure 7);

ii) with the pre-treatment and substitution of 7 M HCl with 0.15 M NaNO

3 solution (blue solid line in

Figure 11a);

iii) with the pre-treatment, “two flows” variation and the substitution (blue dashed line in

Figure 11a)

allow us to suggest that increasing contact time of the UTEVA Resin and nitric solution led to more and more difficult

226Th recovery. The relative positions of

226Th elution curves (

Figure 11b) are also in line with the suggestion.

Figure 11.

(a) Different modes of 226Th recovery with citric buffer solutions: from UTEVA Resin column pre-treated with 3 M HNO3 (blue solid curve), 226Th elution with “two flows” variation (blue dashed curve), and from DGA Resin columns pretreated with 3 M HNO3 (red solid curve); (b) Curves of 226Th elution depending on the variations of 226Th recovery from UTEVA columns.

Figure 11.

(a) Different modes of 226Th recovery with citric buffer solutions: from UTEVA Resin column pre-treated with 3 M HNO3 (blue solid curve), 226Th elution with “two flows” variation (blue dashed curve), and from DGA Resin columns pretreated with 3 M HNO3 (red solid curve); (b) Curves of 226Th elution depending on the variations of 226Th recovery from UTEVA columns.

Moreover, the influence of the contact time was evaluated in parallel experiments that included the 3 M HNO

3 pre-treatment of UTEVA column, the HCl substitution with 0.15 M NaNO

3 solution and the

226Th elution with a 10

-3 M citric buffer solution. As the pre-treatment duration increased from 10 minutes to 10 hours, the efficiency of

226Th production decreased from 70% (see in

Figure 11a) to zero. The behavior of UTEVA resin may be explained by the fact that the

k’ Th(IV) dependence in nitric solutions is higher than that in hydrochloric solutions over the entire concentration range (

Figure 4).

Two most effective procedures for obtaining

226Th from the two-column

230U/

226Th generator are presented in

Table 2.

The overall time of 226Th eluate production was within 5-7 minutes. The time expenditure was slightly shorter when the DGA column was used, because its size was 10 times smaller than that of the UTEVA column. Meanwhile, the use of UTEVA Resin for the second column resulted in the high yield of 226Th in а less concentrated solution (0.01-0.05 M H3Cit, pH 4.5-5.0).

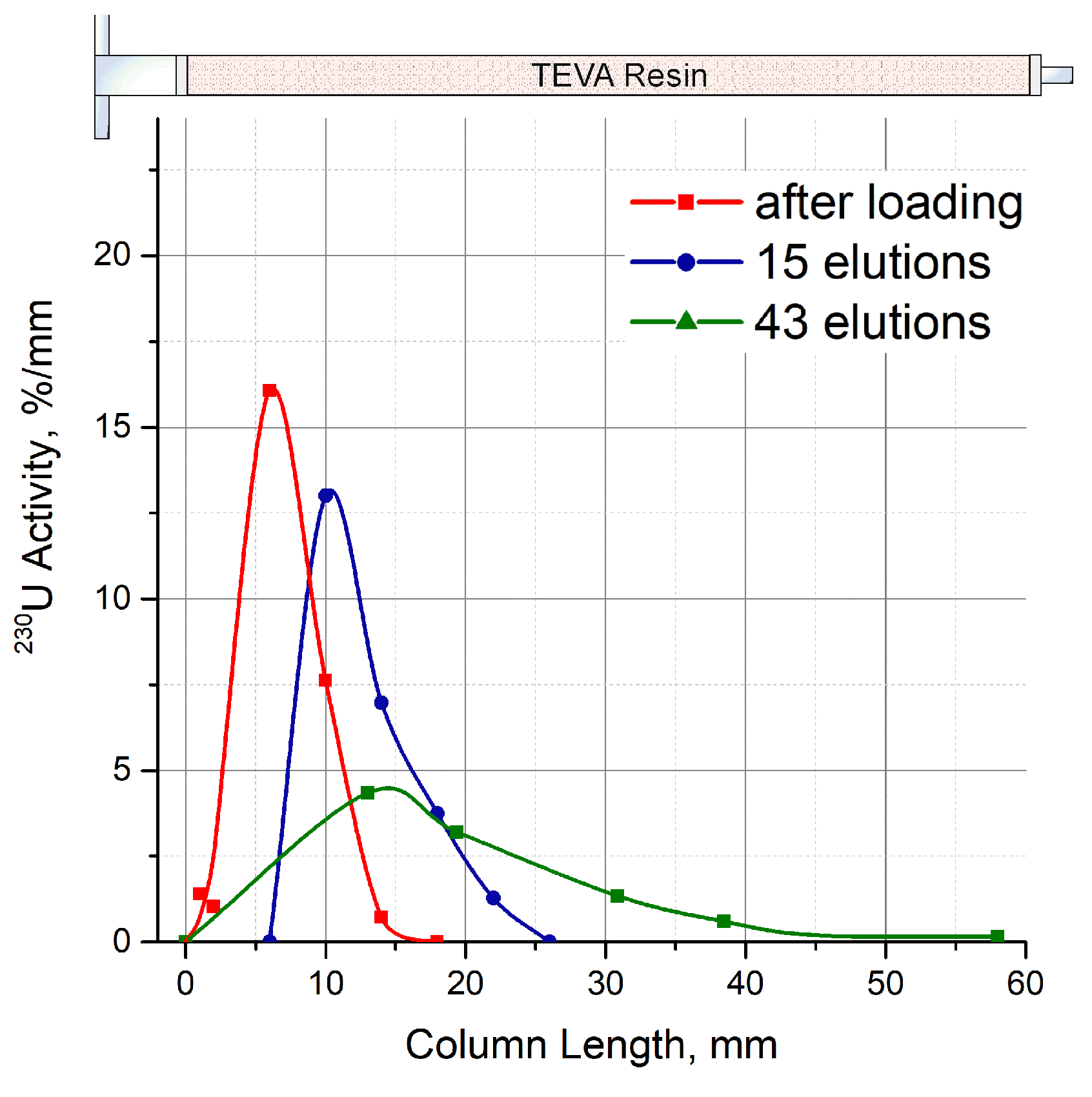

3.4. Long-term performance of two-column 230U/226Th generator

Following the developed procedure, the solution of 7 M HCl was only passed through the parent column containing

230U adsorbed on TEVA Resin. The distribution of

230U along with the length of parent column was monitored throughout the generator lifetime (

Figure A2). Usually, two cycles of

226Th production per weekday were performed over two months. The total volume of 7 M HCl solution passed through the parent column was about 200 mL including accessory operations and a loading of second portion of

230U. According to the calculation illustrated by

Figure A3, one third of the initial amount of

230U was additionally accumulated from

230Pa in 27-28 days after the first separation and then loaded onto the parent column.

Due to the two-column scheme of 226Th production, the proposed generator provided deep purification 226Th from 230U. It was found that the 230U impurity in the 226Th eluates did not exceed 0.01%, which was at least one order of magnitude better in comparison with the literature data reported [12].

4. Conclusions

We have proposed and tested the proof-of-concept of a two-column 230U/226Th generator for rapid producing 226Th amenable to further labeling. The first 230U column with TEVA Resin furnished 226Th in 7 M HCl solution. The second column retained 226Th from the strongly acidic solution and then released it with a diluted hydrochloric or neutral citric buffer solution. Analysis based on the dependence of capacity factor k’ Th(IV) on the concentration of hydrochloric and nitric acid allowed us to consider DGA, TRU and UTEVA Resins as promising sorbents for the second column.

High yields (> 97%) of 226Th elution from TRU and UTEVA Resins with a small volume (~ 1 mL) of diluted HCl solutions were obtained. However, the resulting acidity of eluate was 3-4 M [H+] regardless of the solution concentration entering the second column. The titration analysis displayed that 226Th was eluted on the HCl concentration gradient when one solution was replaced by another.

Elution of 226Th transferred to the second column containing DGA, TRU or UTEVA Resin was studied with citric buffer solutions (pH 5.0) in two modes. Direct 226Th desorption was also influenced by the acidity gradient. While 226Th was stripped off the UTEVA and DGA columns in one chromatographic peak, a typical curve of 226Th elution from the TRU column consisted of two chromatographic peaks within the studied range of citric acid concentration. The first peak followed the HCl concentration gradient, and the second one may be attributed to 226Th complexation with citrate ions in the course of TRU column elution. The satisfactory yields were achieved by 226Th elution from the second column filled with any of the studied resins. For TRU and DGA Resins, 1-1.5 mL of 0.1 M H3Cit (pH 5.0) solution extracted more than 90% of 226Th, while the UTEVA Resin column demonstrated similar effectiveness with less concentrated citric buffer solutions (down to 10-3 M H3Cit). The acidity of citric eluates was about two times lower than the diluted HCl solution’s eluates but still relatively high for immediate labeling.

The neutral citric-buffered 226Th eluates were obtained when nitrate ions were introduced. The second column was initially put in contact with a nitric acid solution. Then, after 226Th transfer from the parent column, the acidic medium of second column was substituted with neutral one keeping 226Th immobile. The solution of 0.15 M NaCl and of 0.15 M NaNO3 were used for the DGA and UTEVA column, respectively. Finally, 226Th was extracted with citric buffer solution: 0.1 M H3Cit from the DGA column and 0.01-0.05 M H3Cit from the UTEVA one. Thus, one cycle of generator milking took 5-7 minutes and produced > 90% of 226Th in 1.5 ml of eluate, pH 4.5-5.0.

The proposed two-column 230U/226Th generator was tested over two months including a second loading of 230U additionally accumulated from 230Pa. The 230U impurity in 226Th eluate was less than 0.01% allowing to use it directly in synthesis of radiopharmaceutical compounds.

Author Contributions

Conceptualization: S. Ermolaev; methodology: S. Ermolaev and A. Skasyrskaya; validation: S. Ermolaev, A. Skasyrskaya and A. Vasiliev; formal analysis: S. Ermolaev and A. Skasyrskaya; investigation: S. Ermolaev, A. Skasyrskaya and A. Vasiliev; writing—original draft preparation: S. Ermolaev and A. Vasiliev; writing—review and editing: S. Ermolaev and A. Vasiliev; visualization: S. Ermolaev and A. Vasiliev; supervision: S. Ermolaev; funding acquisition: S. Ermolaev. All authors have read and agreed to the published version of the manuscript.

Funding

The reported study was funded by RFBR, project number 20-53-15007.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

Curve of 226Th elution from TEVA Resin column.

Figure A1.

Curve of 226Th elution from TEVA Resin column.

Figure A2.

Distribution of activity along with the length of TEVA Resin column (0.4 mL) in the 230U/226Th generator depending on the number of elutions.

Figure A2.

Distribution of activity along with the length of TEVA Resin column (0.4 mL) in the 230U/226Th generator depending on the number of elutions.

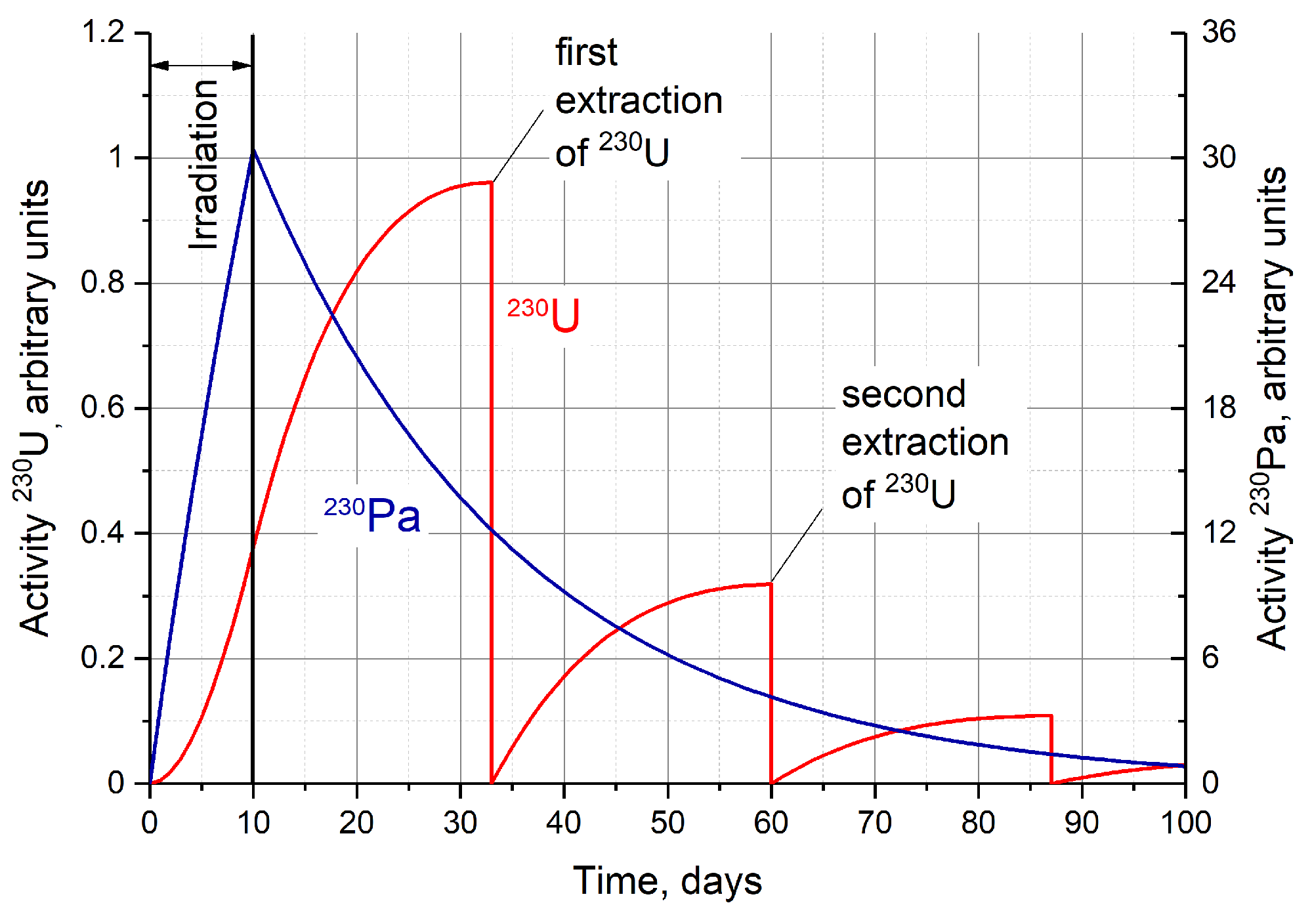

Figure A3.

Activity of 230Pa produced by a typical irradiation of thorium target [15] following by its isolation and periodic extraction of 230U. .

Figure A3.

Activity of 230Pa produced by a typical irradiation of thorium target [15] following by its isolation and periodic extraction of 230U. .

References

- Alfassi, Z. B., Bonardi, M., Groppi, F., & Menapace, E. (2006). A new alpha-emitter for nuclear medicine: 230U, Journal of Radioanalytical and Nuclear Chemistry, 270(2), 483-487. [CrossRef]

- National Nuclear Data Center, Brookhaven National Laboratory, USA, http://www.nndc.bnl.gov/nudat3/.

- Makvandi M, Dupis E, Engle JW, et al. Alpha-emitters and targeted alpha therapy in oncology: from basic science to clinical investigations. Targeted oncology. 2018;13(2):189-203. [CrossRef]

- Le Du, A. (2011). Study of in vivo generators Pb-212/Bi--212 and U-230/Th-226 for alpha radioimmunotherapy (No. FRNC-TH--8349). Nantes Univ.(France).

- Joshua J. Woods, Ryan Unnerstall, Abbie Hasson, Diane S. Abou, Valery Radchenko, Daniel L. J. Thorek, and Justin J. Wilson Stable Chelation of the Uranyl Ion by Acyclic Hexadentate Ligands: Potential Applications for 230U Targeted α-Therapy Inorganic Chemistry 2022 61 (7), 3337-3350. [CrossRef]

- Ferrier MG, Li Y, Chyanand MK, et. al. Thorium chelators for targeted alpha therapy: Rapid chelation of thorium-226. J Label Compd Radiopharm. 2020;63:502–516. [CrossRef]

- Morgenstern, A.; Lebeda, O.; Stursa, J.; Bruchertseifer, F.; Capote, R.; McGinley, J.; Rasmussen, G.; Sin, M.; Zielinska, B., and Apostolidis, C. Production of 230U/226Th for Targeted Alpha Therapy via Proton Irradiation of 231Pa. Anal. Chem. 2008, 80(22), 8763–8770. [CrossRef]

- Morgenstern, A.; Lebeda, O.; Stursa, J.; Capote, R.; Sin, M.; Bruchertseifer, F.; Zielinska, B.; Apostolidis, C. Cross-Sections of the Reaction Pa231(d, 3n)U230 for the Production of U230/Th226 for Targeted α Therapy. Phys. Rev. C. 2009, 80(5), 054612.

- Morgenstern, A.; Apostolidis, C.; Bruchertseifer, F.; Capote, R.; Gouder, T.; Simonelli, F.; Sin, M.; Abbas, K. Cross-Sections of the Reaction 232Th(p,3n)230Pa for Production of 230U for Targeted Alpha Therapy. Appl. Radiat. Isot. 2008, 66(10), 1275–1280. [CrossRef]

- Radchenko, V.; Engle, J. W.; Wilson, J. J.; Maassen, J. R.; Nortier, M. F.; Birnbaum, E. R.; John, K. D.; Fassbender, M. E. Formation Cross-Sections and Chromatographic Separation of Protactinium Isotopes Formed in Proton-Irradiated Thorium Metal. Radiochim. Acta. 2016, 104(5), 291–304. [CrossRef]

- Friend, M.; Mastren, T.; Parker, T.; Vermeulen, C.; Brugh, M.; Birnbaum, E.; Nortier, F.; Fassbender, M. Production of 230Pa by Proton Irradiation of 232Th at the LANL Isotope Production Facility: Precursor of 230U for Targeted Alpha Therapy. Appl. Radiat. Isot. 2019, 156(22), 108973. [CrossRef]

- Mastren, T.; Stein, B. W.; Parker, T. G.; Radchenko, V.; Copping, R.; Owens, A.; Wyant, L.; Brugh, M.; Kozimor, S.; Nortier, F., et al. Separation of Protactinium Employing Sulfur-Based Extraction Chromatographic Resins. Anal. Chem.2018, 90(11), 7012–7017. [CrossRef]

- Steyn, G. F., Motetshwane, M. A., Szelecsényi, F., & Brümmer, J. W. (2021). Pairing of thorium with selected primary target materials in tandem configurations: Co-production of 225Ac/213Bi and 230U/226Th generators with a 70 MeV H− cyclotron. Applied Radiation and Isotopes, 168, 109514. [CrossRef]

- Duchemin, C.; Guertin, A.; Haddad, F.; Michel, N.; Metivier, V. 232Th(d, 4n)230pa Cross-Section Measurements at ARRONAX Facility for Production of 230U. Nucl. Med. Biol. 2014, 41(Suppl), e19–e22. [CrossRef]

- N. Vasiliev, S.V. Ermolaev, E. V. Lapshina, M. G. Bravo & A. K. Skasyrskaya (2022) Production of 230Pa as a Source for Medical Radionuclides 230U and 226Th Including Isolation by Liquid–liquid Extraction, Solvent Extraction and Ion Exchange, 40:7, 735-755. [CrossRef]

- Ermolaev, S. V., Zhuikov, B. L., Kokhanyuk, V. M., Matushko, V. L., Kalmykov, S. N., Aliev, R. A., ... & Myasoedov, B. F. (2012). Production of actinium, thorium and radium isotopes from natural thorium irradiated with protons up to 141 MeV. Radiochimica Acta, 100(4), 223-229. [CrossRef]

- Aliev, R. A.; Ermolaev, S. V.; Vasiliev, A. N.; Ostapenko, V. S.; Lapshina, E. V.; Zhuikov, B. L.; Zakharov, N. V.; Pozdeev, V. V.; Kokhanyuk, V. M.; Myasoedov, B. F., et al. Isolation of Medicine-Applicable Actinium-225 from Thorium Targets Irradiated by Medium-Energy Protons. Solvent. Extr. Ion Exch.2014, 32(5), 468. [CrossRef]

- Vasiliev, A. N.; Ostapenko, V. S.; Lapshina, E. V.; Ermolaev, S. V.; Danilov, S. S.; Zhuikov, B. L.; Kalmykov, S. N. Recovery of Ra-223 from Natural Thorium Irradiated by Protons. Radiochim. Acta, 2016, 104(8), 539–547. [CrossRef]

- Ermolaev, S., Skasyrskaya, A., & Vasiliev, A. (2021). A Radionuclide Generator of High-purity Bi-213 for Instant Labeling. Pharmaceutics, 13(6), 914. [CrossRef]

- Ahenkorah, S., Cassells, I., Deroose, C. M., Cardinaels, T., Burgoyne, A. R., Bormans, G., ... & Cleeren, F. (2021). Bismuth-213 for targeted radionuclide therapy: From atom to bedside. Pharmaceutics, 13(5), 599. [CrossRef]

- Bravo M. G., Egorova B. V., Vasiliev A.N., Lapshina E. V., Ermolaev S.V., Durymanov M.O. DTPA(DOTA)-Nimotuzumab Radiolabeling with Generator-Produced Thorium for Radioimmunotherapy of EGFR-Overexpressing Carcinomas. Current Radiopharmaceuticals, accepted for publication. [CrossRef]

- Sharma JN, Ruhela R, Harindaran KN, Mishra SL, Tangri SK, Suri AK (2008) Separation studies of uranium and thorium using tetra(2-ethylhexyl) diglycolamide (TEHDGA) as an extractant. J RadioanalNucl Ch 278:173-177. [CrossRef]

- Pathak PN, Veeraraghavan R, Prabhu DR, Mahajan GR, Manchanda VK (1999) Separation studies of uranium and thorium using di-2-ethylhexyl isobutyramide (D2EHIBA). Separ Sci Technol 34:2601-2614. [CrossRef]

- Raju CSK, Subramanian MS (2007) Sequential separation of lanthanides, thorium and uranium using novel solid phase extraction method from high acidic nuclear wastes. J Hazard Mater 145:315-322. [CrossRef]

- Carter HE, Warwick P, Cobb J, Longworth G (1999) Determination of uranium and thorium in geological materials using extraction chromatography. Analyst 124:271-274. [CrossRef]

- Yokoyama T, Makishima A, Nakamura E (1999) Separation of thorium and uranium from silicate rock samples using two commercial extraction chromatographic resins. Anal Chem 71:135-141. [CrossRef]

- Korkisch J, Tera F (1962) Anion Exchange Separation of Uranium, Thorium and Bismuth. Fresen Z Anal Chem 186:290-295. [CrossRef]

- Alhassanieh O, Abdul-Hadi A, Ghafar M, Aba A (1999) Separation of Th, U, Pa, Ra and Ac from natural uranium and thorium series. Appl Radiat Isotopes 51:493-498. [CrossRef]

- Carswell DJ (1957) Separation of Thorium and Uranium Nitrates by Anion Exchange. J Inorg Nucl Chem 3:384-387. [CrossRef]

- Horwitz, E.P., et al. “Separation and Preconcentration of Actinides by Extraction Chromatography using a supported liquid anion exchanger: Application of the characterization of high-level nuclear waste solutions”Analytica Chimica Acta, 310, 63-78 (1995). [CrossRef]

- Maxwell, S.L., “Rapid Analysis of Emergency Urine and Water Samples,” Journal of Radioanalytical and Nuclear Chemistry, 275(3), 497-502 (2008). [CrossRef]

- Kraus, K. A., Moore, G. E., & Nelson, F. (1956). Anion-exchange Studies. XXI. Th(IV) and U(IV) in Hydrochloric Acid. Separation of Thorium, Protactinium and Uranium1,2. Journal of the American Chemical Society, 78(12), 2692–2695. [CrossRef]

- Wu, C.; Brechbiel, M. W.; Gansow, O. A. An Improved Generator for the Production of 213Bi from 225Ac. Radiochim. Acta. 1997, 79, 141–144. [CrossRef]

- Dietz, M. L.; Horwitz, E. P. Applications of Extraction Chromatography in the Development of Radionuclide Generator Systems for Nuclear Medicine. Ind. Eng. Chem. Res. 2000, 39(9), 3181–3188. [CrossRef]

- Vasiliev, A. N.; Zobnin, V. A.; Pavlov, Y.; Chudakov, S.; M, V. Radiation Stability of Sorbents in Medical 225Ac/213Bi Generators. Solvent. Extr. Ion Exch. 2021, 39, 353–372. [CrossRef]

- Zhuikov, B. L., Kokhanyuk, V. M., Konyakhin, N. A., Vincent J.: Target irradiation facility and targetry development at 160 MeV proton beam of Moscow linac. Nucl. Instrum. Methods Phys. Res., Sect. A 438, 173 (1999). [CrossRef]

- Ermolaev, S.V.; Vasilev, A. N.; Lapshina, E. V., Zhuikov, B. L. Method of Producing Actinium-225. Russian Patent № 2 725 414, 12.12.2019.

- Knight, A. W., Eitrheim, E. S., Nelson, A. W., Nelson, S., & Schultz, M. K. A simple-rapid method to separate uranium, thorium, and protactinium for U-series age-dating of materials. Journal of environmental radioactivity, 2014, 134, 66-74. [CrossRef]

- Pourmand, A., Dauphas, N. Distribution coefficients of 60 elements on TODGA resin: application to Ca, Lu, Hf, U and Th isotope geochemistry. Talanta, 2010, 81(3), 741-753. [CrossRef]

- Horwitz, E. P., McAlister, D. R., Bond, A. H., & Barrans Jr, R. E. (2005). Novel extraction of chromatographic resins based on tetraalkyldiglycolamides: characterization and potential applications. Solvent extraction and ion exchange, 23(3), 319-344. [CrossRef]

- Horwitz P., Dietz M., Chiarizia R., Diamond H., Analytica Chimica Acta, 266, pp. 25-37 (1992). [CrossRef]

- Horwitz P., Chiarizia R. Dietz M., Diamond H., Nelson, D.; Analytica Chimica Acta, 281, pp. 361-372 (1993). [CrossRef]

- Raymond, D. P., Duffield, J. R., & Williams, D. R. (1987). Complexation of plutonium and thorium in aqueous environments. Inorganica Chimica Acta, 140, 309-313. [CrossRef]

- Choppin, G. R., Erten, H. N., & Xia, Y. X. (1996). Variation of stability constants of thorium citrate complexes with ionic strength. Radiochimica Acta, 74(s1), 123-128. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).