Submitted:

04 February 2023

Posted:

06 February 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods

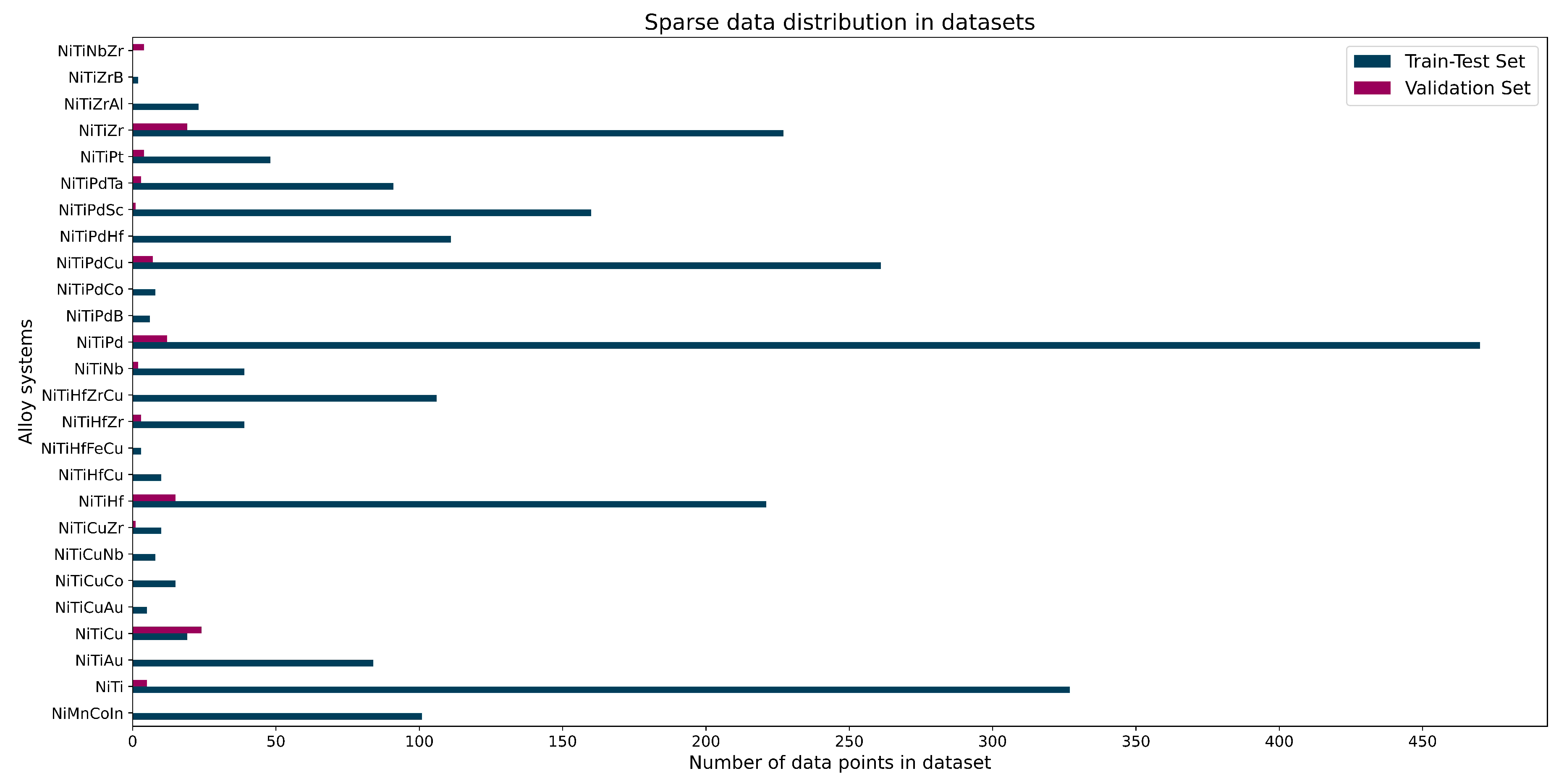

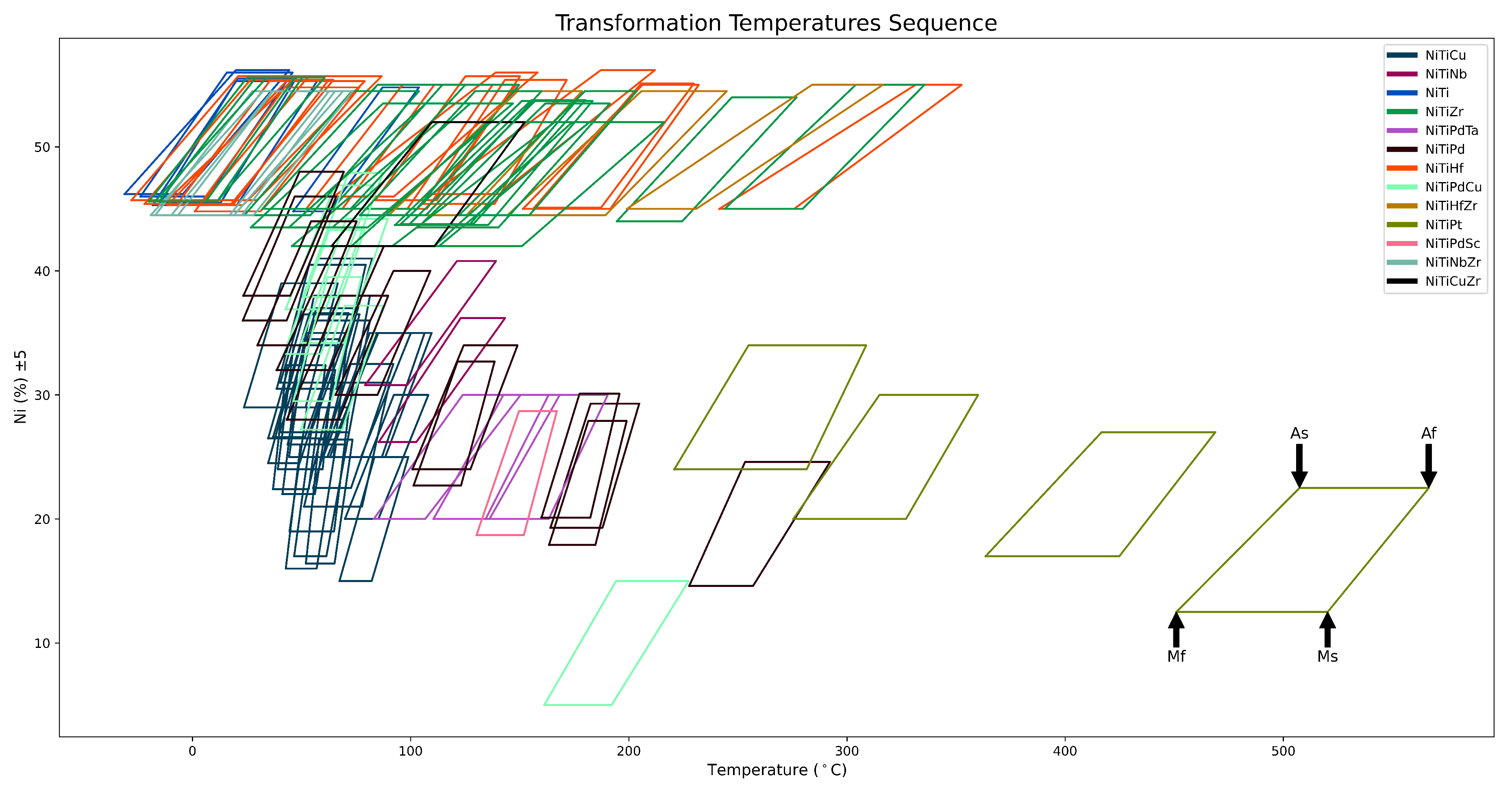

2.1. Data Preparation

2.2. CatBoost Surrogate Model

2.2.1. Background of the ML Algorithm

2.2.2. Loss Function and Evaluation

2.2.3. Hyperparameter Tuning

2.3. SHAP-Based Model Interpretation

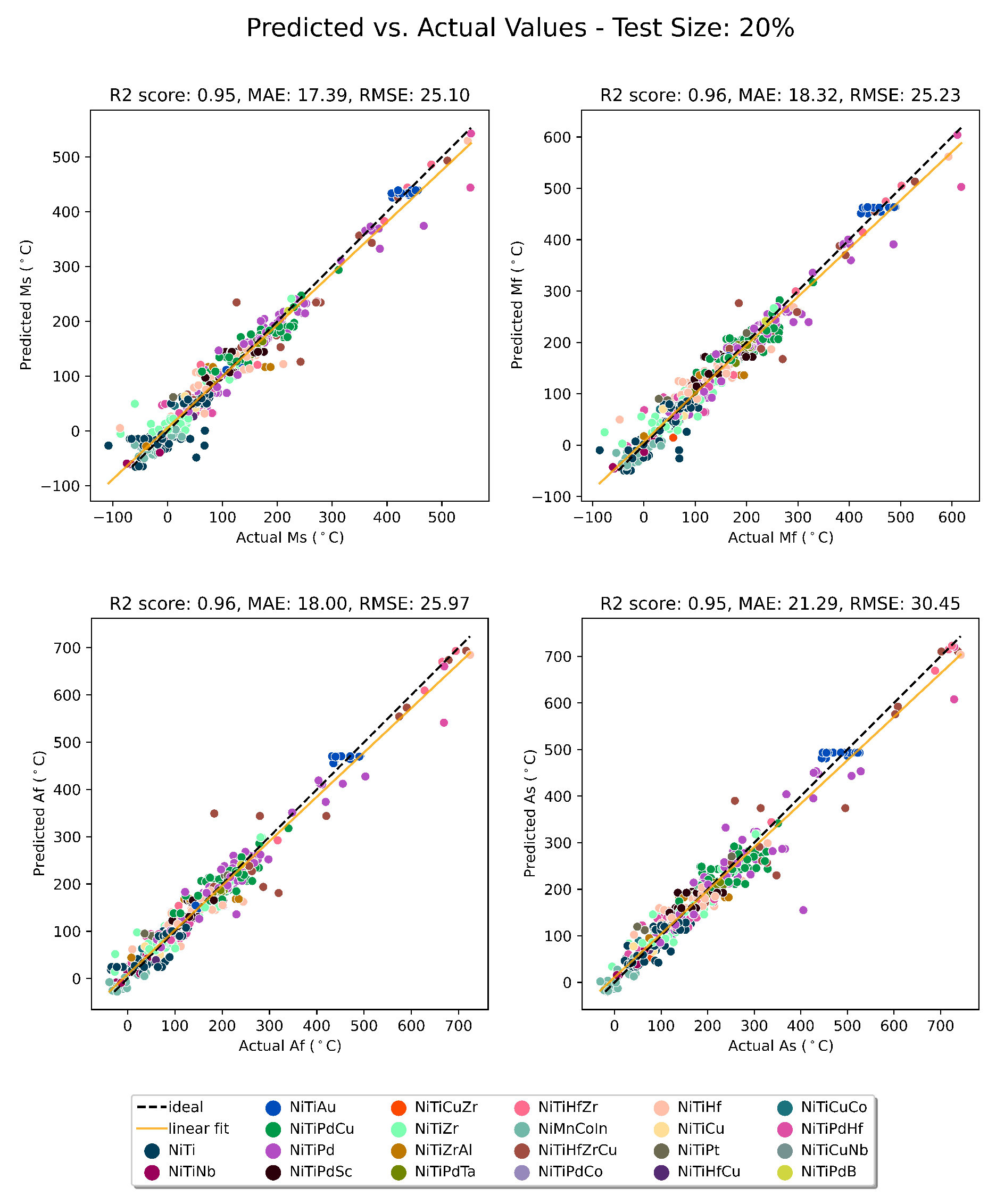

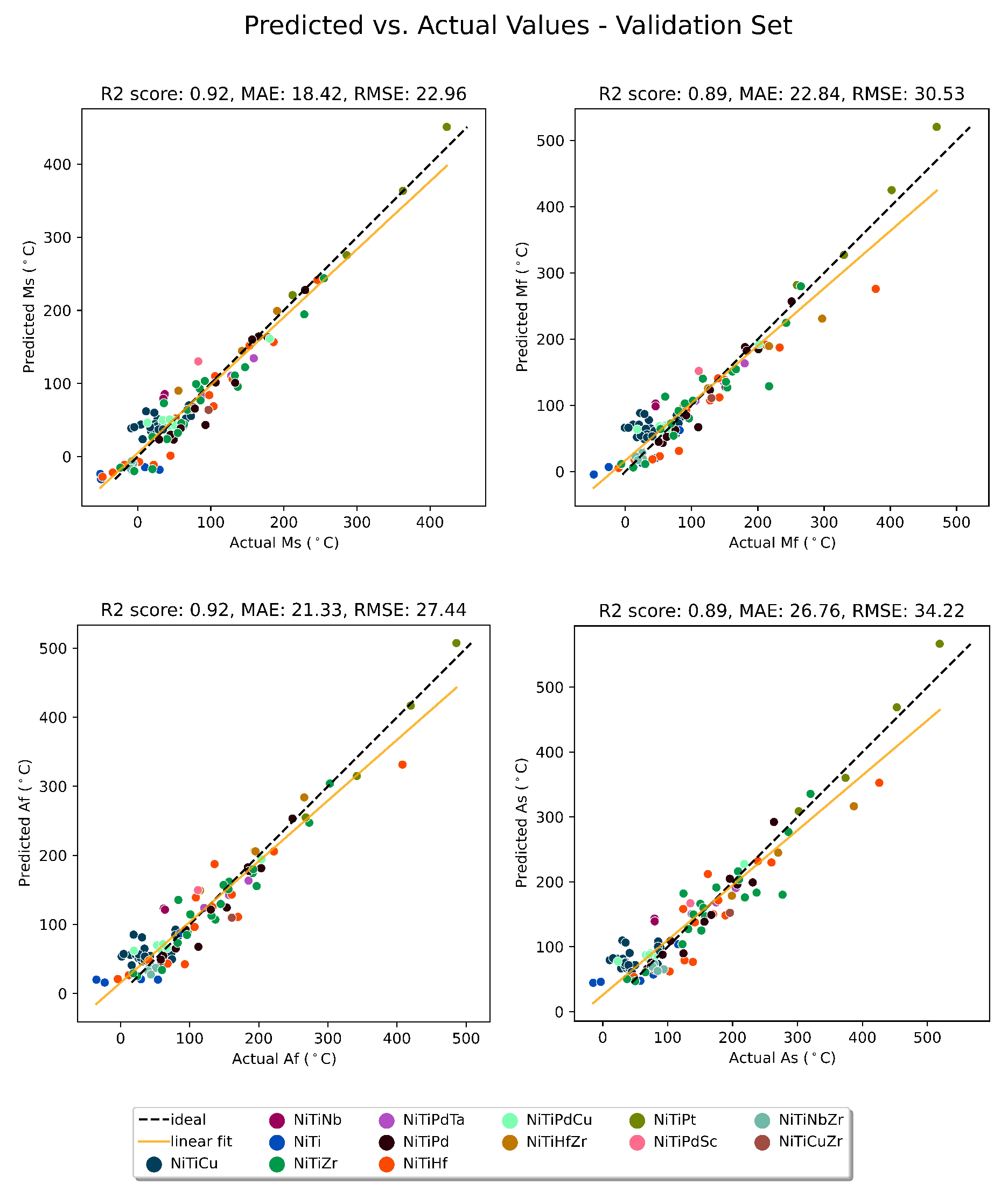

3. Results and Discussion

4. Conclusions

- Proper feature engineering with all processing parameters, composition-based features, and alloy system categorical features is the key to building a robust model that is able to predict transformation temperatures of a vast range of SMAs with a relatively low amount of data. In our study, the model could predict the transformation temperatures of 100 SMAs in the validation set after training by 2,394 data points for 137 alloys in the train/test set.

- The results shows that CatBoost is a promising ML surrogate model for the thermodynamic prediction of complex alloy systems. Considering its tree-based nature, it can adequately handle diverse data sets with a potentially high number of features, which is the case in most materials science studies. It also performs well with a relatively limited number of training data points. This tree-based boosting algorithm also provides a natural path to model interpretability.

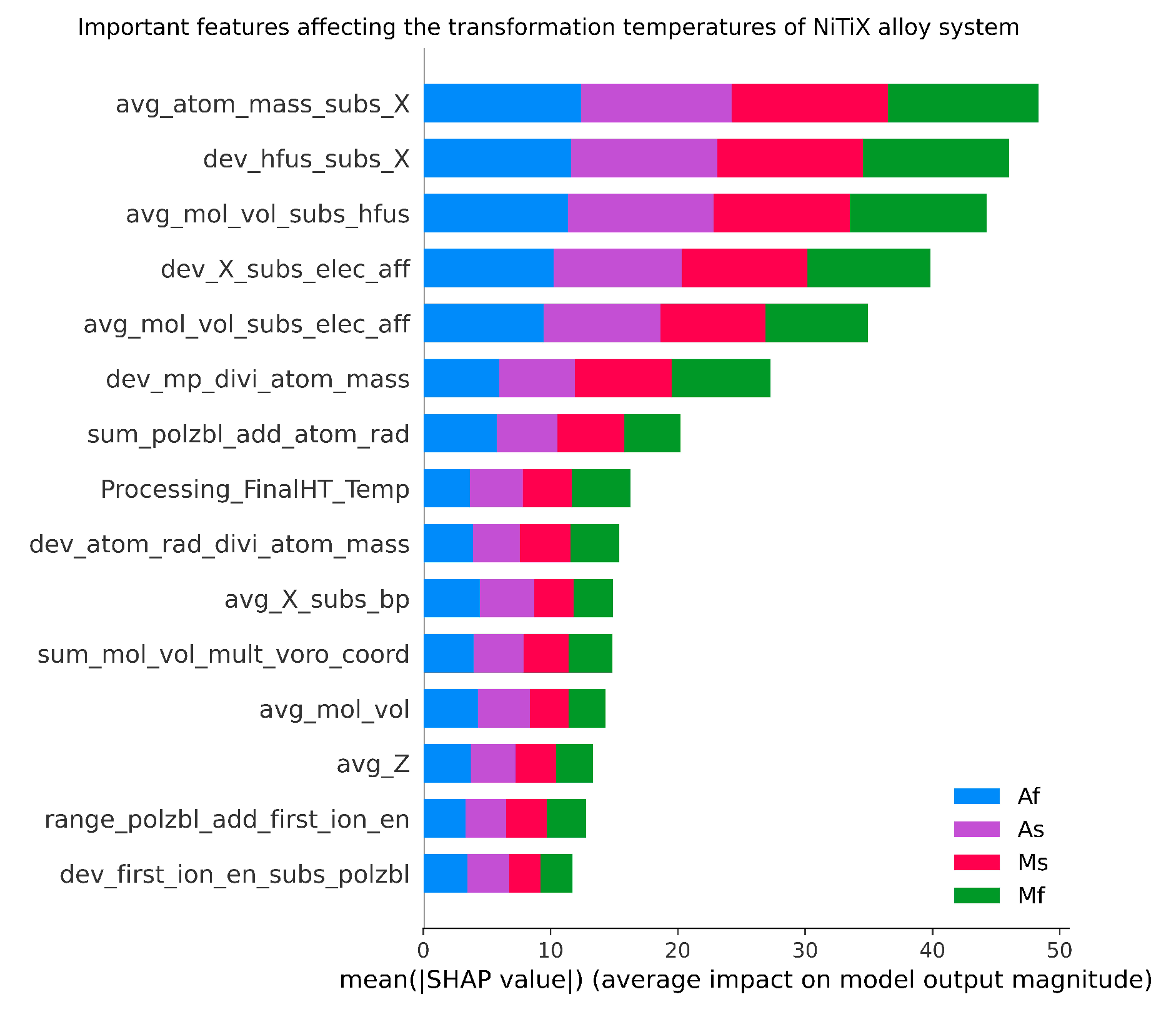

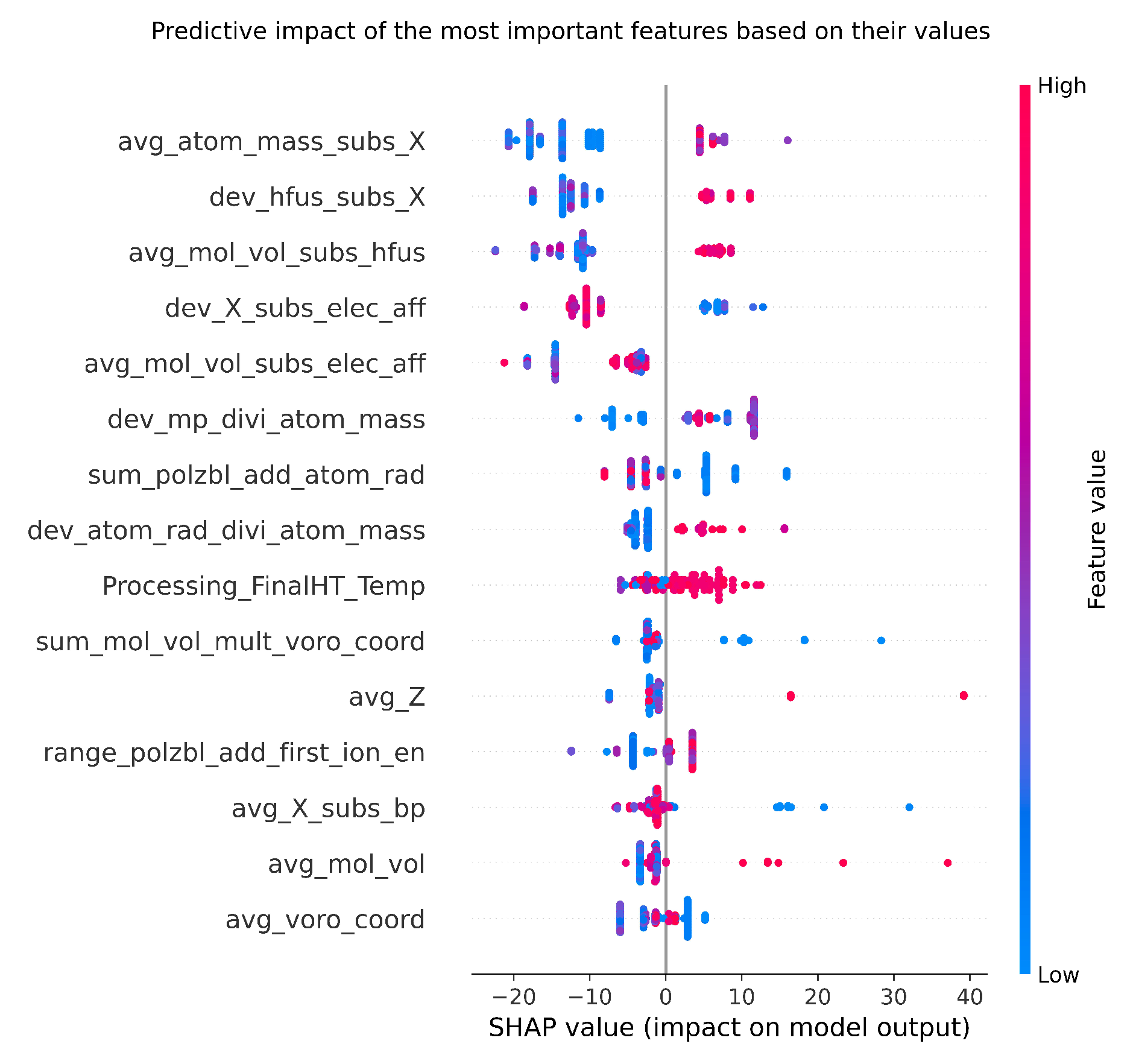

- The dependency of transformation temperatures on processing parameters, chemical, and electronic properties was shown and discussed.

Data Availability Statement

Acknowledgments

References

- J. Ma, I. Karaman, and R. D. Noebe, “High temperature shape memory alloys,” International Materials Reviews, vol. 55, no. 5, pp. 257–315, 9 2010.

- J. Perkins, Ed., Shape Memory Effects in Alloys. Boston, MA: Springer US, 1975.

- K. Otsuka and K. Shimizu, “Pseudoelasticity and shape memory effects in alloys,” International Metals Reviews, vol. 31, no. 1, pp. 93–114, 1 1986.

- R. Snodgrass and D. Erickson, “A multistage elastocaloric refrigerator and heat pump with 28 K temperature span,” Scientific Reports, vol. 9, no. 1, p. 18532, 12 2019.

- L. Mañosa, D. González-Alonso, A. Planes, E. Bonnot, M. Barrio, J.-L. Tamarit, S. Aksoy, and M. Acet, “Giant solid-state barocaloric effect in the Ni–Mn–In magnetic shape-memory alloy,” Nature Materials, vol. 9, no. 6, pp. 478–481, 6 2010.

- C. Bechtold, C. Chluba, R. Lima de Miranda, and E. Quandt, “High cyclic stability of the elastocaloric effect in sputtered TiNiCu shape memory films,” Applied Physics Letters, vol. 101, no. 9, p. 091903, 8 2012. [CrossRef]

- J. Tušek, K. Engelbrecht, L. P. Mikkelsen, and N. Pryds, “Elastocaloric effect of Ni-Ti wire for application in a cooling device,” Journal of Applied Physics, vol. 117, no. 12, p. 124901, 3 2015. [CrossRef]

- J. Tušek, K. Engelbrecht, L. Mañosa, E. Vives, and N. Pryds, “Understanding the Thermodynamic Properties of the Elastocaloric Effect Through Experimentation and Modelling,” Shape Memory and Superelasticity, vol. 2, no. 4, pp. 317–329, 12 2016. [CrossRef]

- S.-M. Kirsch, F. Welsch, N. Michaelis, M. Schmidt, A. Wieczorek, J. Frenzel, G. Eggeler, A. Schütze, and S. Seelecke, “NiTi-Based Elastocaloric Cooling on the Macroscale: From Basic Concepts to Realization,” Energy Technology, vol. 6, no. 8, pp. 1567–1587, 8 2018. [CrossRef]

- H. Sehitoglu, Y. Wu, and E. Ertekin, “Elastocaloric effects in the extreme,” Scripta Materialia, vol. 148, pp. 122–126, 4 2018. [CrossRef]

- J. Liu, T. Gottschall, K. P. Skokov, J. D. Moore, and O. Gutfleisch, “Giant magnetocaloric effect driven by structural transitions,” Nature Materials, vol. 11, no. 7, pp. 620–626, 7 2012.

- D. Gehring and I. Karaman, “Evolution of anisotropic and negative thermal expansion in rolled equiatomic nickel-titanium martensite,” Scripta Materialia, vol. 186, pp. 142–146, 9 2020.

- J. Monroe, D. Gehring, I. Karaman, R. Arroyave, D. Brown, and B. Clausen, “Tailored thermal expansion alloys,” Acta Materialia, vol. 102, pp. 333–341, 1 2016. [CrossRef]

- J. Ma and I. Karaman, “Self-adaptive, ultra-low elastic modulus shape memory alloys,” Washington, DC, 2017.

- J. Ma, I. Karaman, and E. Flickinger, “Variably flexible metal article and methods of making the same,” Washington, DC, 2020.

- J. Sharma, K. G. Suresh, M. M. Raja, and P. Walke, “Martensitic Transition, Magnetic, Microstructural and Exchange Bias Properties of Melt Spun Ribbons of Mn-Ni-Sn Shape Memory Heusler Alloy,” Frontiers in Materials, vol. 11, p. 520630, 2020. [CrossRef]

- K. Binder and A. P. Young, “Spin glasses: Experimental facts, theoretical concepts, and open questions,” Reviews of Modern Physics, vol. 58, no. 4, pp. 801–976, 10 1986.

- S. Morito, T. Kakeshita, K. Hirata, and K. Otsuka, “Magnetic and martensitic transformations in Ni50AlxMn50-x alloys,” Acta Materialia, vol. 46, no. 15, pp. 5377–5384, 9 1998. [CrossRef]

- S. Chatterjee, S. Giri, S. K. De, and S. Majumdar, “Reentrant-spin-glass state in Ni 2 Mn 1.36 Sn 0.64 shape-memory alloy,” Physical Review B, vol. 79, no. 9, p. 092410, 3 2009. [CrossRef]

- W. J. Buehler, J. V. Gilfrich, and R. C. Wiley, “Effect of Low-Temperature Phase Changes on the Mechanical Properties of Alloys near Composition TiNi,” Journal of Applied Physics, vol. 34, no. 5, pp. 1475–1477, 5 1963. [CrossRef]

- F. E. Wang, W. J. Buehler, and S. J. Pickart, “Crystal Structure and a Unique “Martensitic” Transition of TiNi,” Journal of Applied Physics, vol. 36, no. 10, pp. 3232–3239, 10 1965. [CrossRef]

- C. M. Wayman, “Some Applications of Shape-Memory Alloys,” JOM, vol. 32, no. 6, pp. 129–137, 6 1980.

- A. D. Korotaev, Y. I. Chumlyakov, V. F. Esipenko, and L. S. Bushnev, “Superelasticity effects in single crystals of Cu-15% Al-2% Co with non-coherent particles due to twinning,” Physica Status Solidi (a), vol. 82, no. 2, pp. 405–412, 4 1984. [CrossRef]

- T. Yoneyama, H. Doi, H. Hamanaka, T. Noda, Y. Okamoto, M. Karibe, M. Mogi, and F. Miura, “Evaluation of super-elasticity characteristics of orthodontic Ni-Ti alloy wire.” THE JOURNAL OF THE STOMATOLOGICAL SOCIETY, JAPAN, vol. 56, no. 1, pp. 93–101, 3 1989. [CrossRef]

- M. Wuttig, L. Liu, K. Tsuchiya, and R. D. James, “Occurrence of ferromagnetic shape memory alloys (invited),” Journal of Applied Physics, vol. 87, no. 9, pp. 4707–4711, 5 2000. [CrossRef]

- T. Inamura, Y. Fukui, H. Hosoda, K. Wakashima, and S. Miyazaki, “Mechanical properties of Ti–Nb biomedical shape memory alloys containing Ge or Ga,” Materials Science and Engineering: C, vol. 25, no. 3, pp. 426–432, 5 2005. [CrossRef]

- K. Masumoto, Y. Horiuchi, T. Inamura, H. Hosoda, K. Wakashima, H. Kim, and S. Miyazaki, “Effects of Si addition on superelastic properties of Ti–Nb–Al biomedical shape memory alloys,” Materials Science and Engineering: A, vol. 438-440, no. SPEC. ISS., pp. 835–838, 11 2006. [CrossRef]

- D. PING, C. CUI, F. YIN, and Y. YAMABEMITARAI, “TEM investigations on martensite in a Ti–Nb-based shape memory alloy,” Scripta Materialia, vol. 54, no. 7, pp. 1305–1310, 4 2006. [CrossRef]

- D. Canadinc, W. Trehern, J. Ma, I. Karaman, F. Sun, and Z. Chaudhry, “Ultra-high temperature multi-component shape memory alloys,” Scripta Materialia, vol. 158, pp. 83–87, 1 2019. [CrossRef]

- Y. Wang and Y. Zheng, “The microstructure and shape memory effect of Ti–16 at.%Nb alloy,” Materials Letters, vol. 62, no. 2, pp. 269–272, 1 2008.

- B. L. Wang, L. Li, and Y. F. Zheng, “In vitro cytotoxicity and hemocompatibility studies of Ti-Nb, Ti-Nb-Zr and Ti-Nb-Hf biomedical shape memory alloys,” Biomedical Materials, vol. 5, no. 4, p. 044102, 8 2010. [CrossRef]

- J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, “Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes,” Advanced Engineering Materials, vol. 6, no. 5, pp. 299–303, 5 2004. [CrossRef]

- M.-H. Tsai and J.-W. Yeh, “High-Entropy Alloys: A Critical Review,” Materials Research Letters, vol. 2, no. 3, pp. 107–123, 7 2014.

- Y. Zhang, T. T. Zuo, Z. Tang, M. C. Gao, K. A. Dahmen, P. K. Liaw, and Z. P. Lu, “Microstructures and properties of high-entropy alloys,” Progress in Materials Science, vol. 61, pp. 1–93, 4 2014. [CrossRef]

- D. Miracle and O. Senkov, “A critical review of high entropy alloys and related concepts,” Acta Materialia, vol. 122, pp. 448–511, 1 2017.

- S. H. Zadeh, H. Jafarian, N. Park, and A. Eivani, “Regulating of tensile properties through microstructure engineering in Fe-Ni-C TRIP steel processed by different strain routes of severe deformation,” Journal of Materials Research and Technology, vol. 9, no. 3, pp. 2903–2913, 5 2020. [CrossRef]

- G. Firstov, T. Kosorukova, Y. Koval, and V. Odnosum, “High Entropy Shape Memory Alloys,” Materials Today: Proceedings, vol. 2, pp. S499–S503, 2015. [CrossRef]

- L. Wang, C. Fu, Y. Wu, R. Li, X. Hui, and Y. Wang, “Superelastic effect in Ti-rich high entropy alloys via stress-induced martensitic transformation,” Scripta Materialia, vol. 162, pp. 112–117, 3 2019. [CrossRef]

- T. Umale, D. Salas, B. Tomes, R. Arroyave, and I. Karaman, “The effects of wide range of compositional changes on the martensitic transformation characteristics of NiTiHf shape memory alloys,” Scripta Materialia, vol. 161, pp. 78–83, 3 2019. [CrossRef]

- Y. Yamabe-Mitarai, “TiPd- and TiPt-Based High-Temperature Shape Memory Alloys: A Review on Recent Advances,” Metals, vol. 10, no. 11, p. 1531, 11 2020.

- T. Chakraborty, J. Rogal, and R. Drautz, “Unraveling the composition dependence of the martensitic transformation temperature: A first-principles study of Ti-Ta alloys,” Physical Review B, vol. 94, no. 22, p. 224104, 12 2016. [CrossRef]

- K. Wang, S.-L. Shang, Y. Wang, Z.-K. Liu, and F. Liu, “Martensitic transition in Fe via Bain path at finite temperatures: A comprehensive first-principles study,” Acta Materialia, vol. 147, pp. 261–276, 4 2018. [CrossRef]

- J. Platl, H. Leitner, C. Turk, and R. Schnitzer, “Determination of Martensite Start Temperature of High-Speed Steels Based on Thermodynamic Calculations,” steel research international, vol. 91, no. 8, p. 2000063, 8 2020. [CrossRef]

- Q. Dai, X. Cheng, Y. Zhao, X. Luo, and Z. Yuan, “Design of martensite transformation temperature by calculation for austenitic steels,” Materials Characterization, vol. 52, no. 4-5, pp. 349–354, 7 2004. [CrossRef]

- P. L. Narayana, S.-W. Kim, J.-K. Hong, N. S. Reddy, and J.-T. Yeom, “Estimation of Transformation Temperatures in Ti–Ni–Pd Shape Memory Alloys,” Metals and Materials International, vol. 24, no. 5, pp. 919–925, 9 2018. [CrossRef]

- M. Mehrpouya, A. Gisario, M. Nematollahi, A. Rahimzadeh, K. S. Baghbaderani, and M. Elahinia, “The prediction model for additively manufacturing of NiTiHf high-temperature shape memory alloy,” Materials Today Communications, vol. 26, p. 102022, 3 2021. [CrossRef]

- D. Xue, D. Xue, R. Yuan, Y. Zhou, P. V. Balachandran, X. Ding, J. Sun, and T. Lookman, “An informatics approach to transformation temperatures of NiTi-based shape memory alloys,” Acta Materialia, vol. 125, pp. 532–541, 2 2017. [CrossRef]

- Y. Zhang and X. Xu, “Transformation Temperature Predictions Through Computational Intelligence for NiTi-Based Shape Memory Alloys,” Shape Memory and Superelasticity, vol. 6, no. 4, pp. 374–386, 12 2020.

- H. Chen, W. Xu, Q. Luo, Q. Li, Y. Zhang, J. Wang, and K.-C. Chou, “Thermodynamic prediction of martensitic transformation temperature in Fe-C-X (X=Ni, Mn, Si, Cr) systems with dilatational coefficient model,” Journal of Materials Science & Technology, vol. 112, pp. 291–300, 6 2022. [CrossRef]

- X. Huang, H. Wang, W. Xue, A. Ullah, S. Xiang, H. Huang, L. Meng, G. Ma, and G. Zhang, “A combined machine learning model for the prediction of time-temperature-transformation diagrams of high-alloy steels,” Journal of Alloys and Compounds, vol. 823, p. 153694, 5 2020. [CrossRef]

- X. Tian, D. Shi, K. Zhang, H. Li, L. Zhou, T. Ma, C. Wang, Q. Wen, and C. Tan, “Machine-learning model for prediction of martensitic transformation temperature in NiMnSn-based ferromagnetic shape memory alloys,” Computational Materials Science, vol. 215, p. 111811, 12 2022. [CrossRef]

- H. Lukas, S. G. Fries, and B. Sundman, Computational Thermodynamics. Cambridge University Press, 7 2007.

- W. Mu, M. Rahaman, F. L. Rios, J. Odqvist, and P. Hedström, “Predicting strain-induced martensite in austenitic steels by combining physical modelling and machine learning,” Materials & Design, vol. 197, p. 109199, 1 2021. [CrossRef]

- J. Peng, Y. Yamamoto, J. A. Hawk, E. Lara-Curzio, and D. Shin, “Coupling physics in machine learning to predict properties of high-temperatures alloys,” npj Computational Materials, vol. 6, no. 1, p. 141, 12 2020.

- S. Liu, B. B. Kappes, B. Amin-ahmadi, O. Benafan, X. Zhang, and A. P. Stebner, “Physics-informed machine learning for composition – process – property design: Shape memory alloy demonstration,” Applied Materials Today, vol. 22, p. 100898, 3 2021. [CrossRef]

- A. Y.-T. Wang, S. K. Kauwe, R. J. Murdock, and T. D. Sparks, “Compositionally restricted attention-based network for materials property predictions,” npj Computational Materials, vol. 7, no. 1, p. 77, 12 2021.

- J. D. Hunter, “Matplotlib: A 2D graphics environment,” Computing in Science and Engineering, vol. 9, no. 3, pp. 90–95, 2007.

- S. M. Lundberg and S.-I. Lee, “A Unified Approach to Interpreting Model Predictions,” in Advances in Neural Information Processing Systems, I. Guyon, U. V. Luxburg, S. Bengio, H. Wallach, R. Fergus, S. Vishwanathan, and R. Garnett, Eds., vol. 30. Curran Associates, Inc., 2017.

- W. Trehern, R. Ortiz-Ayala, K. Atli, R. Arroyave, and I. Karaman, “Data-driven shape memory alloy discovery using Artificial Intelligence Materials Selection (AIMS) framework,” Acta Materialia, vol. 228, p. 117751, 4 2022. [CrossRef]

- K. Choudhary, K. F. Garrity, A. C. E. Reid, B. DeCost, A. J. Biacchi, A. R. H. Walker, Z. Trautt, J. Hattrick-Simpers, A. G. Kusne, A. Centrone, A. Davydov, J. Jiang, R. Pachter, G. Cheon, E. Reed, A. Agrawal, X. Qian, V. Sharma, H. Zhuang, S. V. Kalinin, B. G. Sumpter, G. Pilania, P. Acar, S. Mandal, K. Haule, D. Vanderbilt, K. Rabe, and F. Tavazza, “The Joint Automated Repository for Various Integrated Simulations (JARVIS) for data-driven materials design,” npj Computational Materials, vol. 6, no. 1, 7 2020.

- S. K. Kauwe, J. Graser, A. Vazquez, and T. D. Sparks, “Machine Learning Prediction of Heat Capacity for Solid Inorganics,” Integrating Materials and Manufacturing Innovation, vol. 7, no. 2, pp. 43–51, 6 2018. [CrossRef]

- S. K. Kauwe, J. Graser, R. Murdock, and T. D. Sparks, “Can machine learning find extraordinary materials?” Computational Materials Science, vol. 174, p. 109498, 3 2020. [CrossRef]

- A. Y. T. Wang, R. J. Murdock, S. K. Kauwe, A. O. Oliynyk, A. Gurlo, J. Brgoch, K. A. Persson, and T. D. Sparks, “Machine Learning for Materials Scientists: An Introductory Guide toward Best Practices,” Chemistry of Materials, vol. 32, no. 12, pp. 4954–4965, 6 2020. [CrossRef]

- C. L. Clement, S. K. Kauwe, and T. D. Sparks, “Benchmark AFLOW Data Sets for Machine Learning,” Integrating Materials and Manufacturing Innovation 2020 9:2, vol. 9, no. 2, pp. 153–156, 5 2020. [CrossRef]

- R. J. Murdock, S. K. Kauwe, A. Y. T. Wang, and T. D. Sparks, “Is Domain Knowledge Necessary for Machine Learning Materials Properties?” Integrating Materials and Manufacturing Innovation 2020 9:3, vol. 9, no. 3, pp. 221–227, 8 2020. [CrossRef]

- G. Van Rossum and F. L. Drake, Python 3 Reference Manual. Scotts Valley, CA: CreateSpace, 2009.

- “JARVIS-Tools — JARVIS-Tools documentation.” [Online]. Available: https://jarvis-tools.readthedocs.io/en/master/index.html.

- “kaaiian/CBFV: Tool to quickly create a composition-based feature vector.” [Online]. Available: https://github.com/kaaiian/CBFV.

- L. Breiman, “Random Forests,” Machine Learning, vol. 45, no. 1, pp. 5–32, 2001. [CrossRef]

- T. Chen and C. Guestrin, “XGBoost: A Scalable Tree Boosting System,” Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, 2016.

- G. Ke, Q. Meng, T. Finley, T. Wang, W. Chen, W. Ma, Q. Ye, and T.-Y. Liu, “LightGBM: A Highly Efficient Gradient Boosting Decision Tree,” in Advances in Neural Information Processing Systems, I. Guyon, U. V. Luxburg, S. Bengio, H. Wallach, R. Fergus, S. Vishwanathan, and R. Garnett, Eds., vol. 30. Curran Associates, Inc., 2017.

- L. Prokhorenkova, G. Gusev, A. Vorobev, A. V. Dorogush, and A. Gulin, “CatBoost: unbiased boosting with categorical features,” Advances in neural information processing systems, vol. 31, 2018.

- Y. Freund, R. Schapire, and N. Abe, “A short introduction to boosting,” Journal-Japanese Society For Artificial Intelligence, vol. 14, no. 771-780, p. 1612, 1999.

- Y.-Y. Song and Y. Lu, “Decision tree methods: applications for classification and prediction.” Shanghai archives of psychiatry, vol. 27, no. 2, pp. 130–5, 4 2015.

- C. Bentéjac, A. Csörgő, and G. Martínez-Muñoz, “A comparative analysis of gradient boosting algorithms,” Artificial Intelligence Review, vol. 54, no. 3, pp. 1937–1967, 3 2021. [CrossRef]

- D. B. Rubin, “The bayesian bootstrap,” The annals of statistics, pp. 130–134, 1981.

- T. O. Kvålseth, “Cautionary Note about R 2,” The American Statistician, vol. 39, no. 4, pp. 279–285, 11 1985. [CrossRef]

- T. Chai and R. R. Draxler, “Root mean square error (RMSE) or mean absolute error (MAE)? – Arguments against avoiding RMSE in the literature,” Geoscientific Model Development, vol. 7, no. 3, pp. 1247–1250, 6 2014. [CrossRef]

- P. I. Frazier, “A Tutorial on Bayesian Optimization,” arXiv, 7 2018.

- F. Nogueira, “Bayesian Optimization: Open source constrained global optimization tool for Python,” 2014. [Online]. Available: https://github.com/fmfn/BayesianOptimization.

- M. Waskom, “seaborn: statistical data visualization,” Journal of Open Source Software, vol. 6, no. 60, p. 3021, 4 2021. [CrossRef]

- “iWantHue.” [Online]. Available: http://medialab.github.io/iwanthue/.

- F. Pedregosa, G. Varoquaux, A. Gramfort, V. Michel, B. Thirion, O. Grisel, M. Blondel, P. Prettenhofer, R. Weiss, V. Dubourg, J. Vanderplas, A. Passos, D. Cournapeau, M. Brucher, M. Perrot, and E. Duchesnay, “Scikit-learn: Machine Learning in Python,” Journal of Machine Learning Research, vol. 12, no. 85, pp. 2825–2830, 2011.

- C. P. Frick, A. M. Ortega, J. Tyber, A. Maksound, H. J. Maier, Y. Liu, and K. Gall, “Thermal processing of polycrystalline NiTi shape memory alloys,” Materials Science and Engineering: A, vol. 405, no. 1-2, pp. 34–49, 9 2005. [CrossRef]

| CBFV Python library | ||

| Parameters | Values | Comment |

| elem_prop | jarvis | The other good option is ’oliynyk’. It generates fewer features; hence it is computationally cheaper. However, we got slightly better results using ‘jarvis’. |

| extend_features | True | - |

| sum_feat | True | It generates 438 more features when used with jarvis. |

| CatBoost Python library | ||

| Parameters | Values | Comment |

| boosting_type | Plain | The classic gradient boosting scheme. |

| learning_rate | 0.2092 | Boosting learning rate. |

| depth | 6 | Depth of the tree. |

| l2_leaf_reg | 0.05992 | Coefficient at the L2 regularization term of the cost function. |

| bagging_temperature | 0.5562 | Assigning random weights to objects by using the Bayesian bootstrap. |

| loss_function | MultiRMSE | The metric to use in training. |

| eval_metric | MultiRMSE | The metric used for overfitting detection. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).