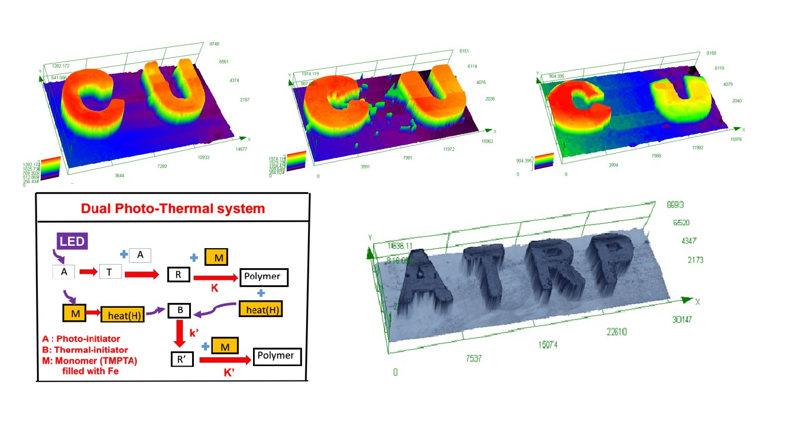

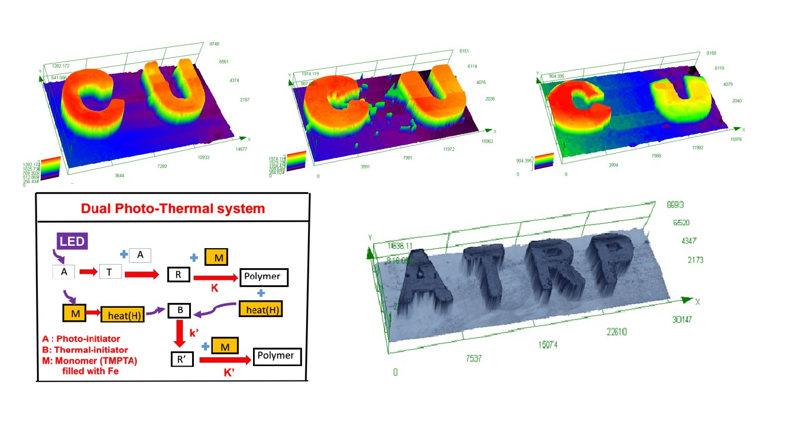

This article presents, for the first time, the efficacy and curing depth analysis of photo-thermal dual polymerization in metal (Fe) polymer composites for 3D printing of a 3-component (A/B/M) system based on the proposed mechanism of our group, in which the co initiators A and B are Irgacure-369, and charge-transfer complexes (CTC), respectively; and the monomer M is TMPTA filled by Fe. Our formulas show the depth of curing (Zc) is an increasing function of the light intensity, but a decreasing function of the Fe and photoinitiator concentrations. Zc is enhanced by the additive [B] which produces extra thermal radical for polymerization under high temperature. The heat (or temperature) increase in the system has two components : (i) due to the light absorption of Fe filler, and (ii) heat released from the exothermic photopolymerization of the monomer. The heat is transported to the additive (or co-initiator) [B] to produce extra radical R' and enhance the monomer conversion function (CF). The CF has two opposite trends in their time profiles: (i) for small Fe concentration (F), it is a time decaying function; and (ii) for large Fe, it is a time increasing profile. This switching feature predicted by our formula is also justified by our measured data. The Fe filler leads to temperature increase, but also limits the light penetration leading to lower CF and Zc, which could be overcome by the additive initiator [B] in thick polymers. the new finding of optimal Fe for maximal CF and Zc are explored theoretically.