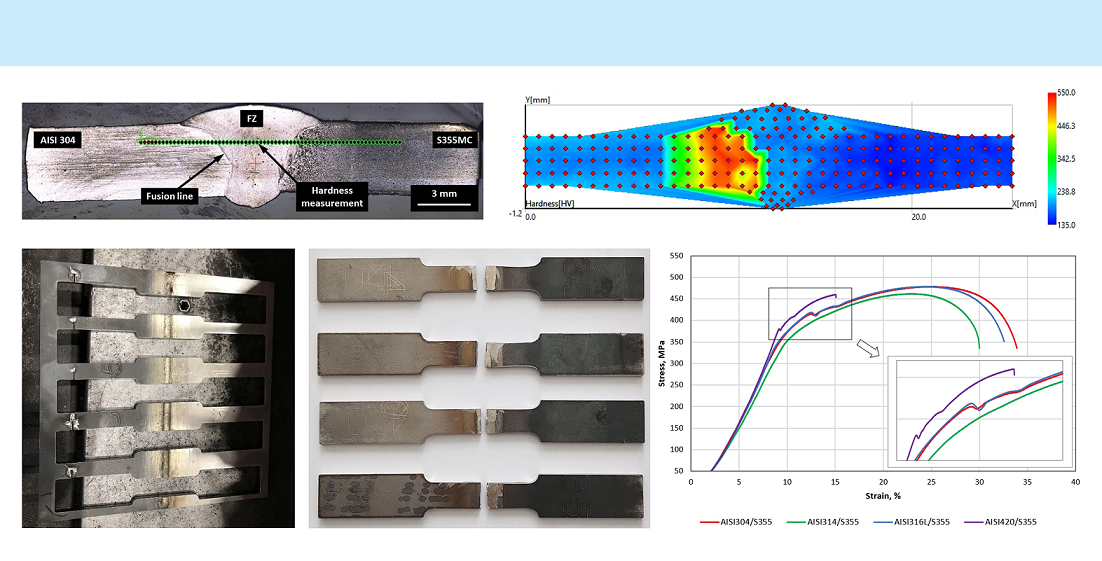

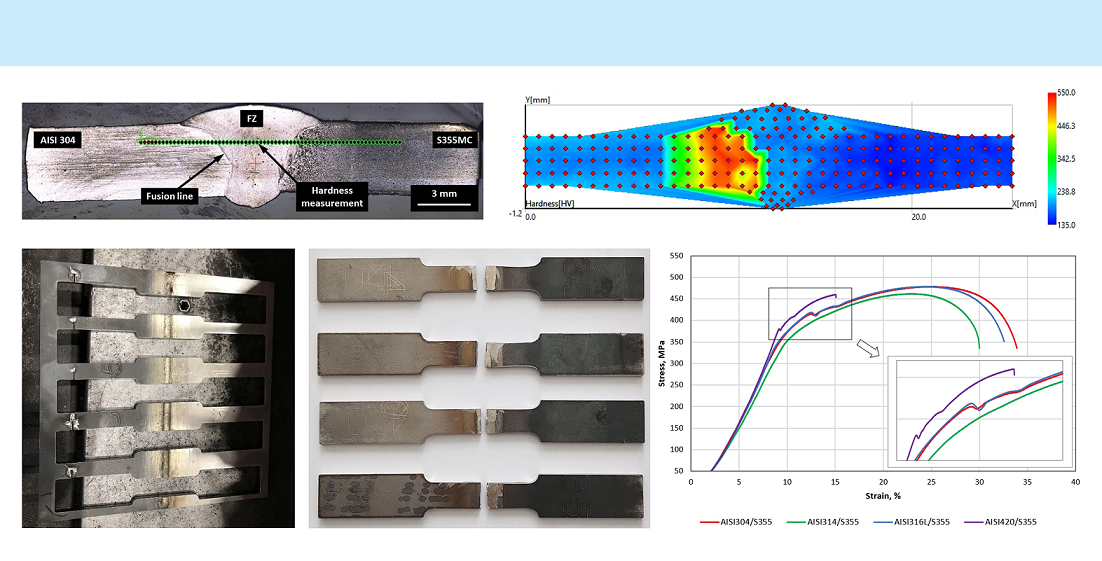

The present study utilizes a metal inert gas welding (MIG) to make a dissimilar weld joint of different stainless steel grades AISI 304, 314, 316L, 420 and a standard structural steel S355MC to estimate the correlation of a microstructure and the mechanical properties. The microstructure of the base metals (BM), the heat affected zone (HAZ), the fusion zone (FZ) and the weld seam were analyzed using optical microscopy. Optical microscopy did not reveal any presence of weld defects such as porosity or cracks. The analysis of microstructure showed that both the austenitic and martensitic stainless steel weld structures contain some retained delta ferrite and coarse Me23C6 carbides in the HAZ, while the FZ exhibits delta ferrite and some retained austenite. The hardness profiles revealed difference between austenitic and martensitic steel welds that the later showed extremely high values in the HAZ (~500 HV/0.1) which causes fracture in this zone. The welds of all austenitic steel grades withstood tensile test, showing the average tensile strength of 472 MPa with fracture observed in the base metal zone. It made clear that the use of a filler rod 308LSI is suitable only for the austenitic stainless and structural steel dissimilar welds, and not appropriate for martensitic-structural steel welds. The achieved results revealed that the higher hardness of the martensitic phase in the HAZ of AISI 420 is closely related with the formation of untempered coarse martensitic structure and higher carbon content.