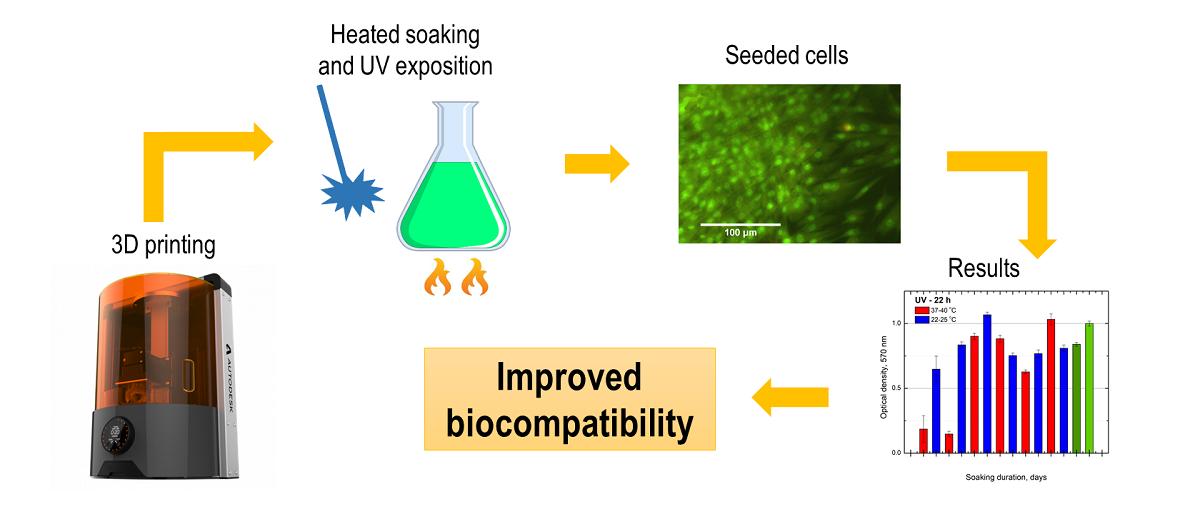

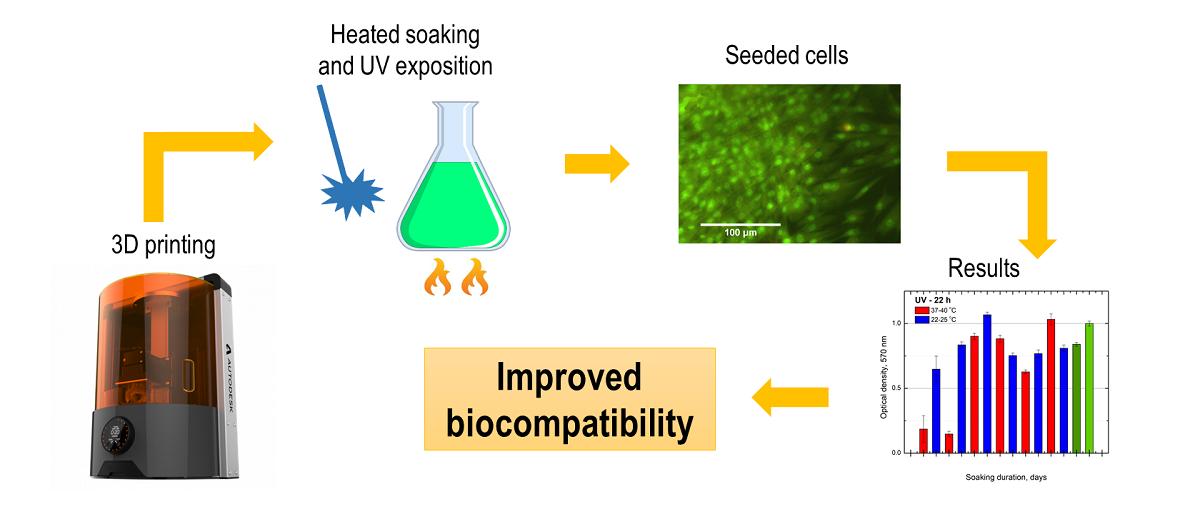

In this experimental report the biocompatibility of elastomeric scaffold structures made via stereolithography employing table-top 3D printer (Ember, Autodesk) and commercial resin FormLabs Flexible (FormLabs) was studied. The samples were manufactured using standard printing and development protocol, which is known to inherit cytotoxicity due to remaining non-polymerized remaining monomers, despite the polymerized material being fully biocompatible. Additional steps were taken to remedy this problem: the fabricated structures were soaked in isopropanol and methanol for different conditions (temperature, duration) in order to leach out the non-polymerized monomers. Also printed structures were UV exposed to assure maximum polymerization degree of the material. Post-processed structures were seeded with myogenic stem cells and the number of live cells was evaluated as an indicator for the material biocompatibility. The straightforward post-processing protocol enhances the biocompatibility by 7 times after 7 days soaking in isopropanol and methanol and is comparable to control (glass and polystyrene) samples. This proposes the approach as a novel and simple method to be widely applicable for dramatic cytotoxicity reduction of optically 3D printed micro-/nano-scaffolds for biomedical applications.