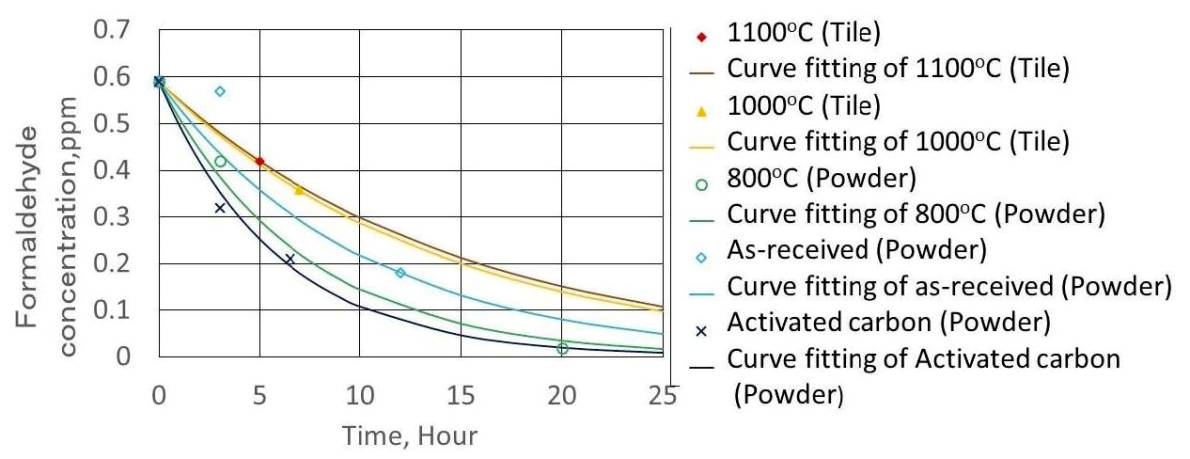

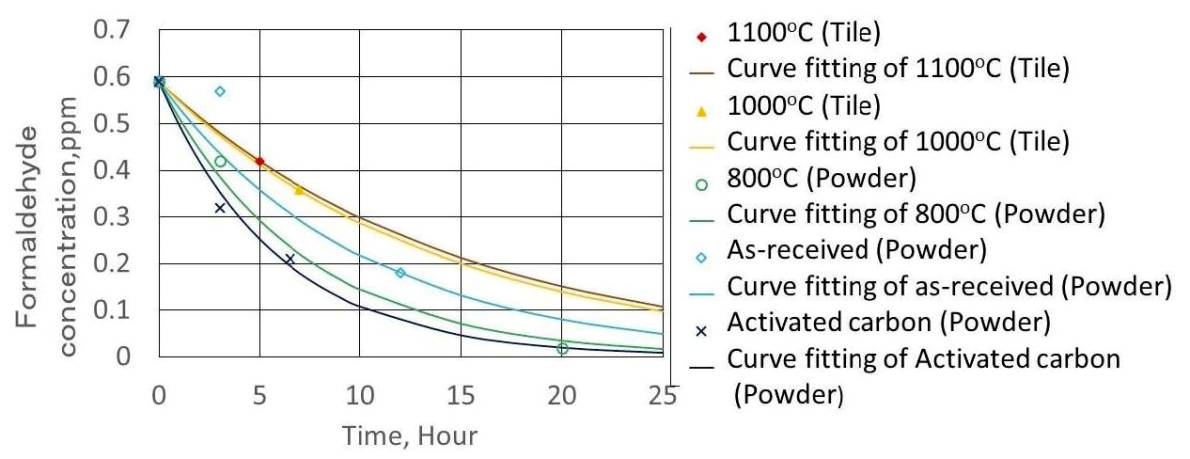

Wasted Green tuff powder produced by cutting Towada stone is recycled as environmental cleaning material. The optimum temperature for green tuff powder calcination to reduce the hydroxyl radical produced in hydrogen peroxide decomposition with ultraviolet light (UV) and no light. The green tuff calcined at 800 °C shows the large decomposition rate of hydrogen peroxide with no UV light when measured by using ESR. With UV light, the optimum temperature for calcinating the green tuff powder in order to reduce hydroxyl radical is also 800 °C. Next, the powder calcined at 800 °C is used to produce the tile by compression and heating, and then the formaldehyde adsorption rate was measured. The green tuff powder calcined at 800 °C showed a high adsorption rate, similar to that of the activated carbon. The tiles formed at 40 MPa and heated st 1100 °C were the strongest and also adsorbed formaldehyde. The adsorbed formaldehyde on the green tuff tile and powder might have a possibility to decompose by photocatalytic.