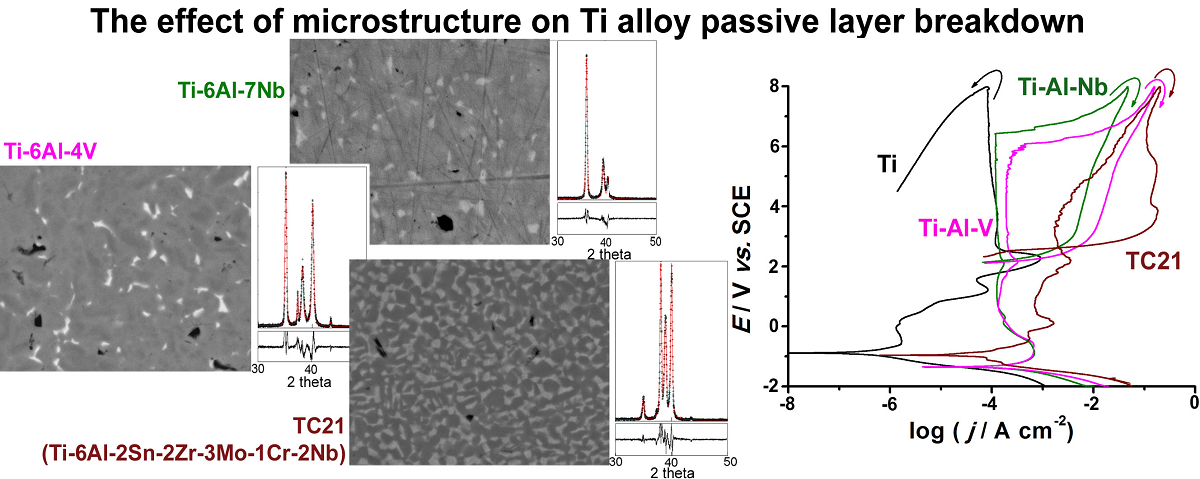

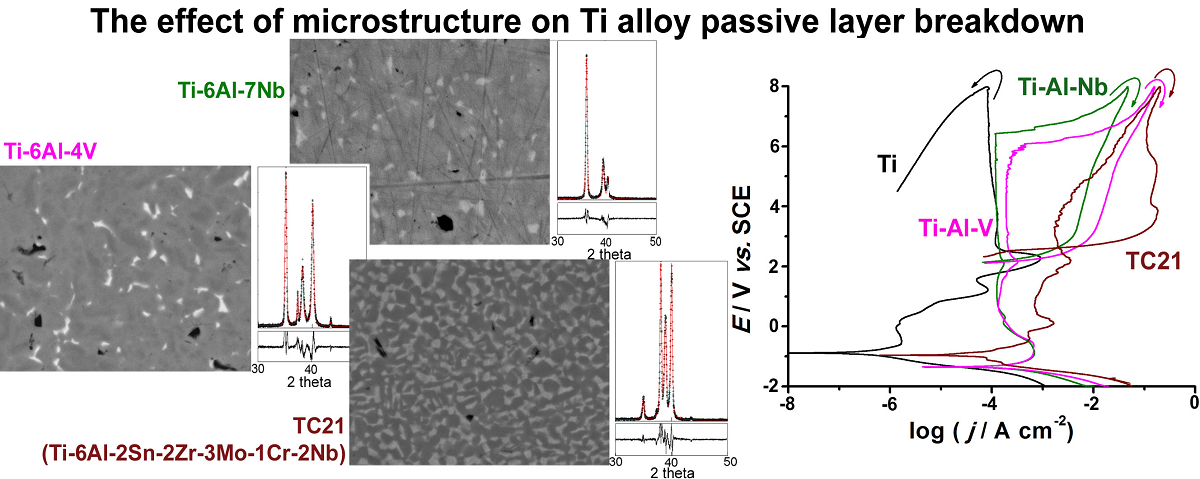

The effect of microstructure and chemistry of passive films on the kinetics of passive layer growth and passivity breakdown of some Ti-based alloys, namely Ti-6Al-4V, Ti-6Al-7Nb and TC21 alloys was studied. The rate of pitting corrosion was evaluated using cyclic polarization measurements. Chronoamperometry was applied to assess the passive layer growth kinetics and breakdown. Microstructure influence on the uniform corrosion rate of these alloys was also investigated employing Tafel extrapolation and dynamic electrochemical impedance spectroscopy. Corrosion studies were performed in 0.9% NaCl solution at 37 oC, and the obtained results were compared with ultrapure Ti (99.99%). The different phases of the microstructure were characterized by X-ray diffraction and scanning electron microscopy. Chemical composition and chemistry of the corroded surfaces were studied using X-ray photoelectron analysis. For all studied alloys, the microstructure consisted of α matrix, which was strengthened by β phase. The highest and the lowest values of the β phase’s volume fraction were recorded for TC21 and Ti-Al-Nb alloys, respectively. The uniform corrosion rate and pitting corrosion resistance (Rpit) of the studied alloys were enhanced following the sequence: Ti-6Al-7Nb < Ti-6Al-4V << TC21. The corrosion resistance of Ti-Al-Nb alloy approached that of pure Ti. The obvious changes in the microstructure of these alloys, together with XPS findings, were adopted to interpret the pronounced variation in their corrosion rates.