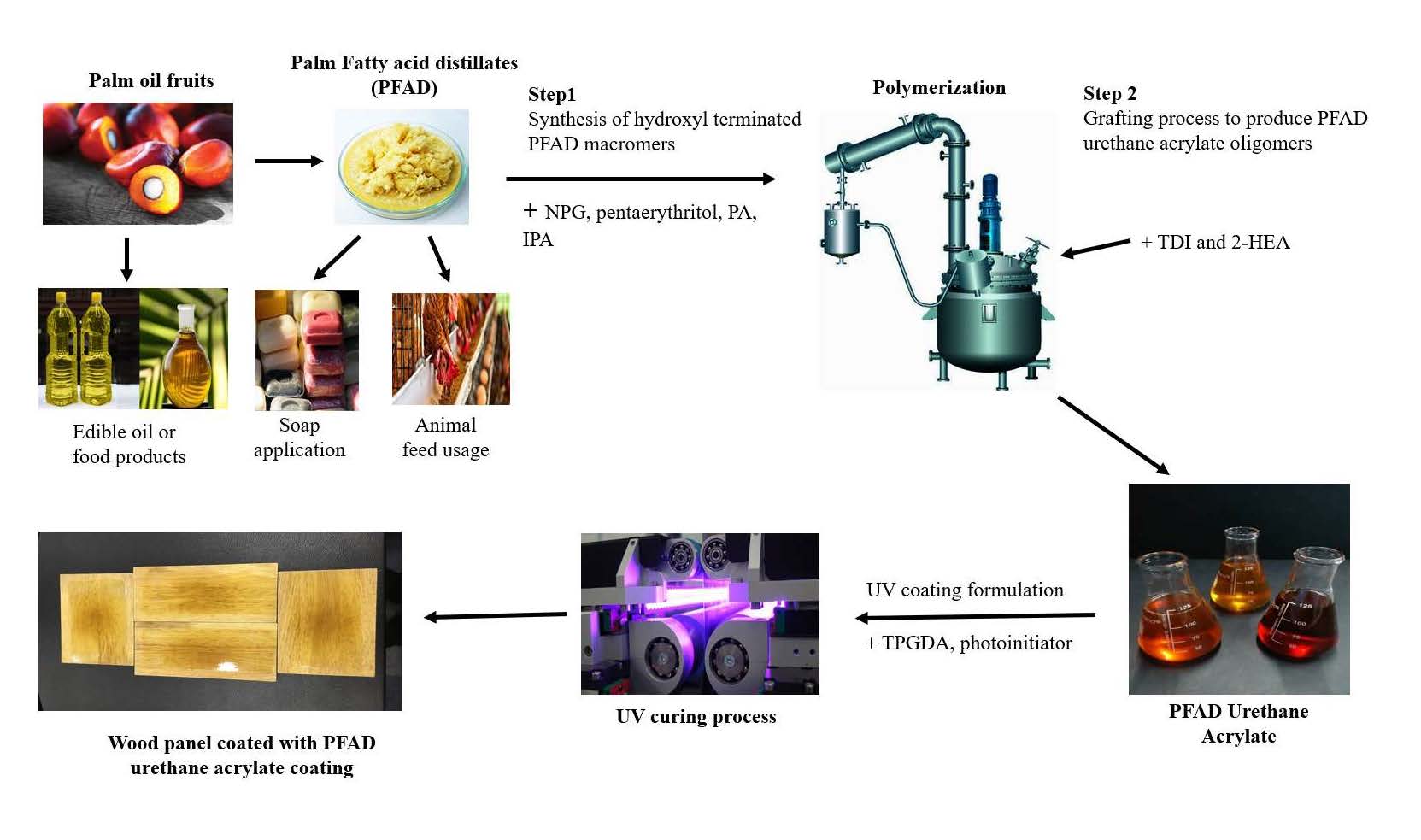

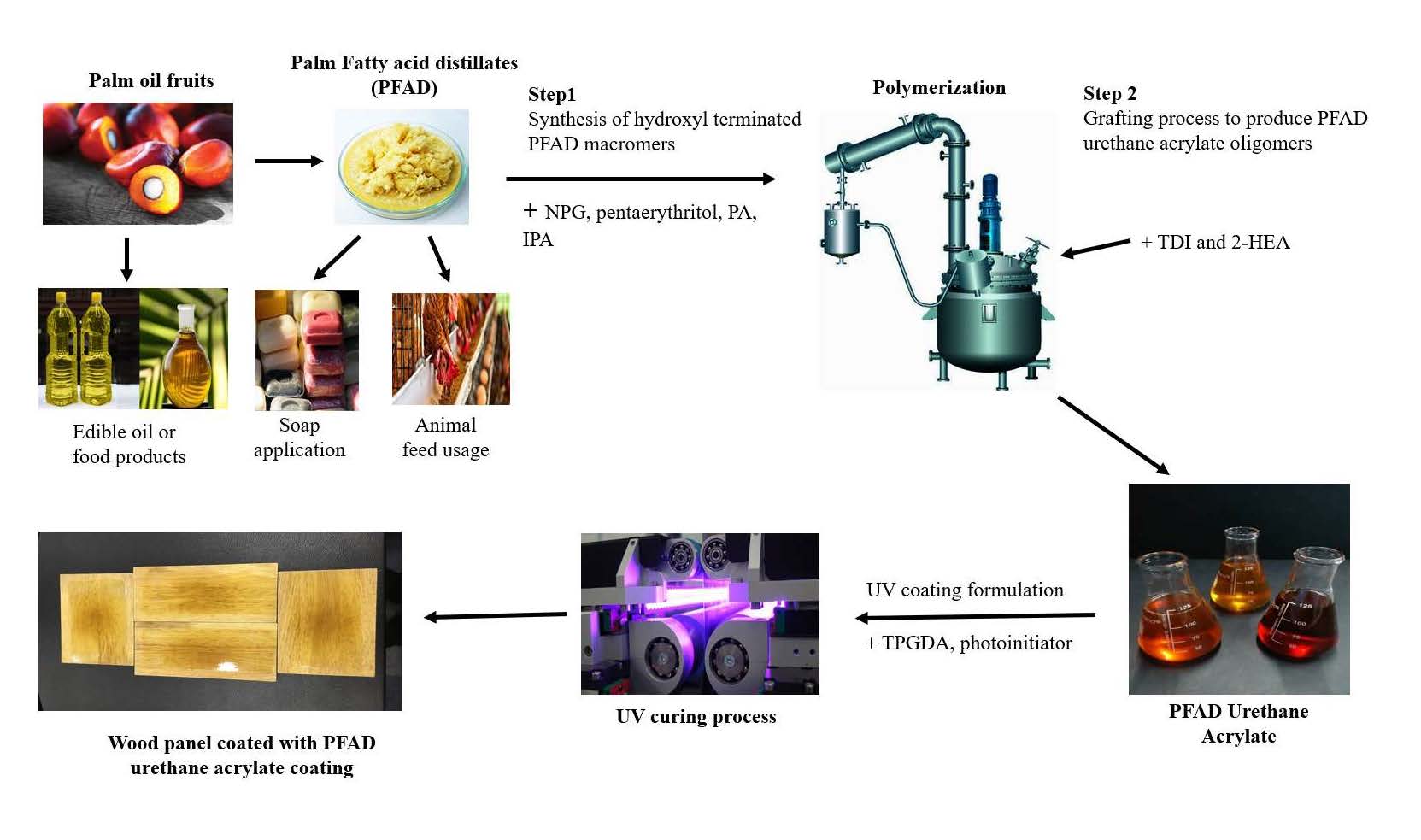

Palm fatty acid distillate (PFAD) is a by-product from the refining of crude palm oil. It comprises mainly of free fatty acids, having around 45% of palmitic and 33% oleic acids as the major components. Ultra-violet (UV) curable urethane acrylate (UA) oligomers could be synthesized from PFAD by the following procedure. A hydroxyl terminated macromer was first prepared by reacting PFAD with a mixture of isophthalic acid, phthalic anhydride, neopentagylcol (NPG) and pentaerythritol. The macromer is then reacted with 2-hydroxylethylacrylate (2HEA) and toluene diisocynate (TDI) to generate a resin containing acrylate side chains for UV curable application. A series of UA resins were prepared by using 15, 25, 45, 55 and 70% of PFAD respectively. The UA resin has Mw in the range of 3200 to 27,000. They could be cured by UV irradiation at intensity of 225mW/cm2. Glass transition temperature (Tg) of the cured film was measured by differential scanning calorimeter (DSC), and hardness of the film was determined by pendulum hardness tester according to ASTM4366. The resins were used in wood coating application. All of the cured films showed good adhesion, hardness and chemical resistant for resins using up to 55% PFAD; however the resin at 70% did not cure properly.