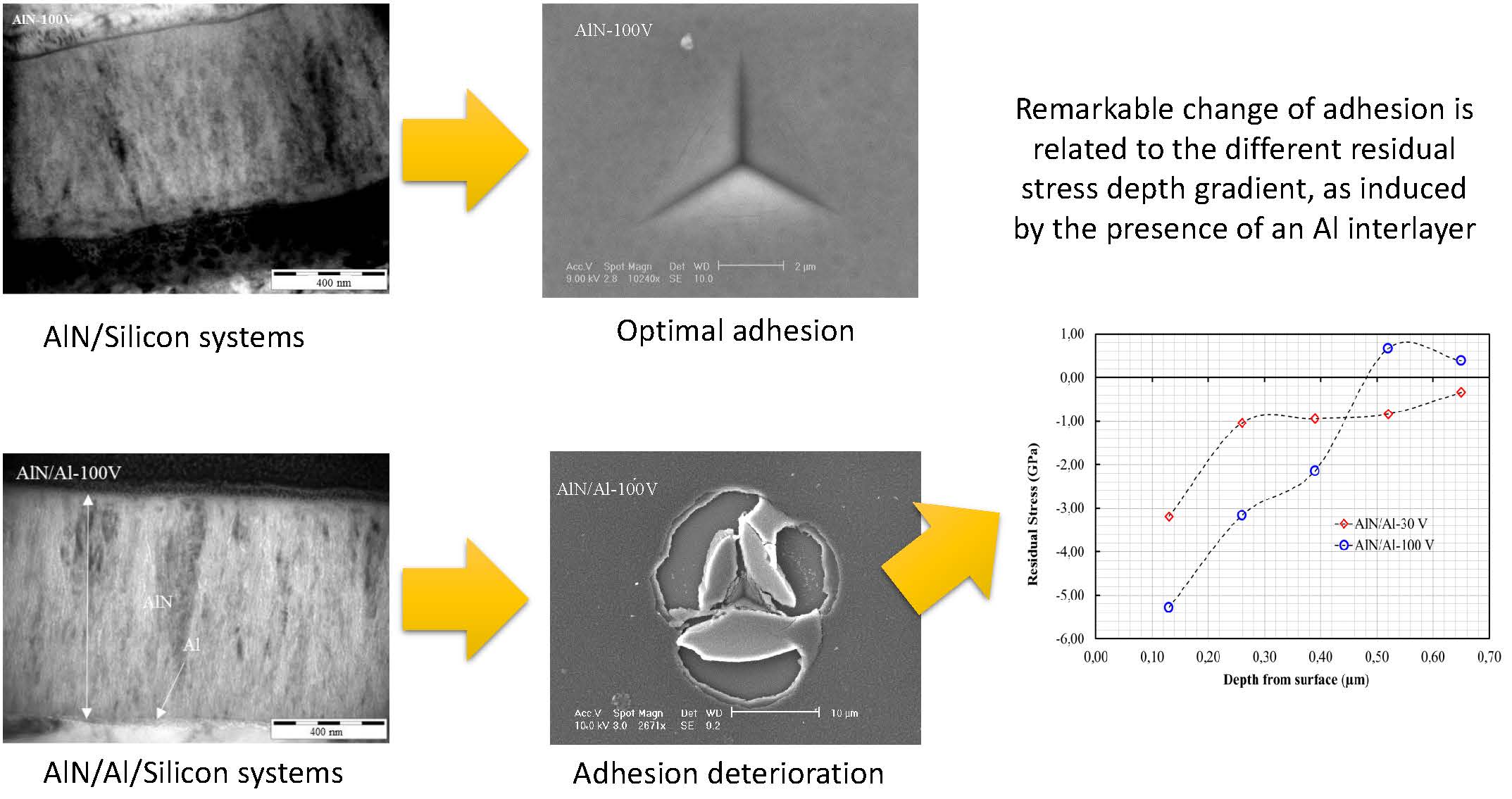

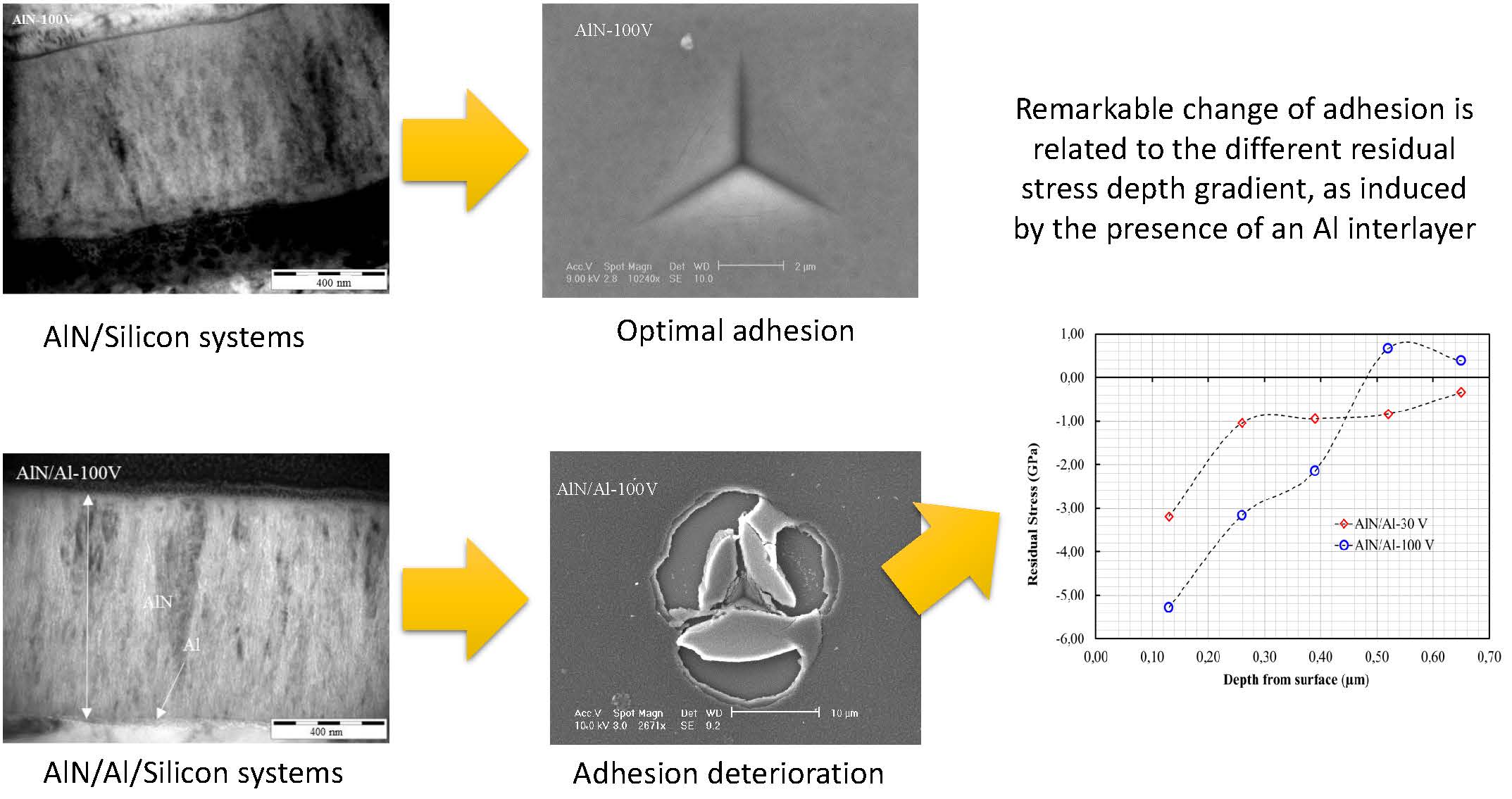

Compressive residual stresses in thin films can inhibit crack propagation under normal or sliding contact loading, with associated enhancement of the coating apparent toughness, load bearing capacity and wear resistance. This study investigates the influence of residual stress distributions on the thin film/substrate adhesion using a nanoindenter coupled with scanning electron microscope (SEM) investigations of indentation induced failure modes. Reactive and un-reactive magnetron sputtering with ion plating was used to coat a (100) silicon substrate with aluminum nitride (AlN) with and without an aluminum (Al) adhesion layer. The presence of an Al bond layer gives additional interfacial tensile stress because of the difference in thermal expansion coefficient. Additionally, a different magnitude of residual stresses in the AlN coating was achieved by changing the applied bias voltage onto the substrate. Wafer curvature method and incremental focused ion beam (FIB) milling, combined with high-resolution in situ scanning electron microscopy (SEM) imaging and full field strain analysis by digital image correlation (DIC), were used to measure the average and in-depth stress residual stress distribution in the produced coatings. The adhesion energy was then quantified by using a nanoindentation based model. Results demonstrate that the additional tensile residual stress in the aluminum adhesion layer decrease significantly the coating adhesion, even in presence of a higher compressive stress state in the AlN top-layer. Therefore, the coatings without Al-layer showed better adhesion because of a more homogeneous compressive residual stress in comparison with the coating having Al layer, even though both groups of coatings are produced under same bias voltage. Results are discussed, and some general suggestions are made on the correlation between coating/substrate property combination and the adhesion energy of multilayer stacks. The results suggested that Al bond-layer and inhomogeneous residual stresses affected the adhesion of AlN negatively to a substrate like silicon.