Submitted:

20 July 2025

Posted:

22 July 2025

You are already at the latest version

Abstract

Keywords:

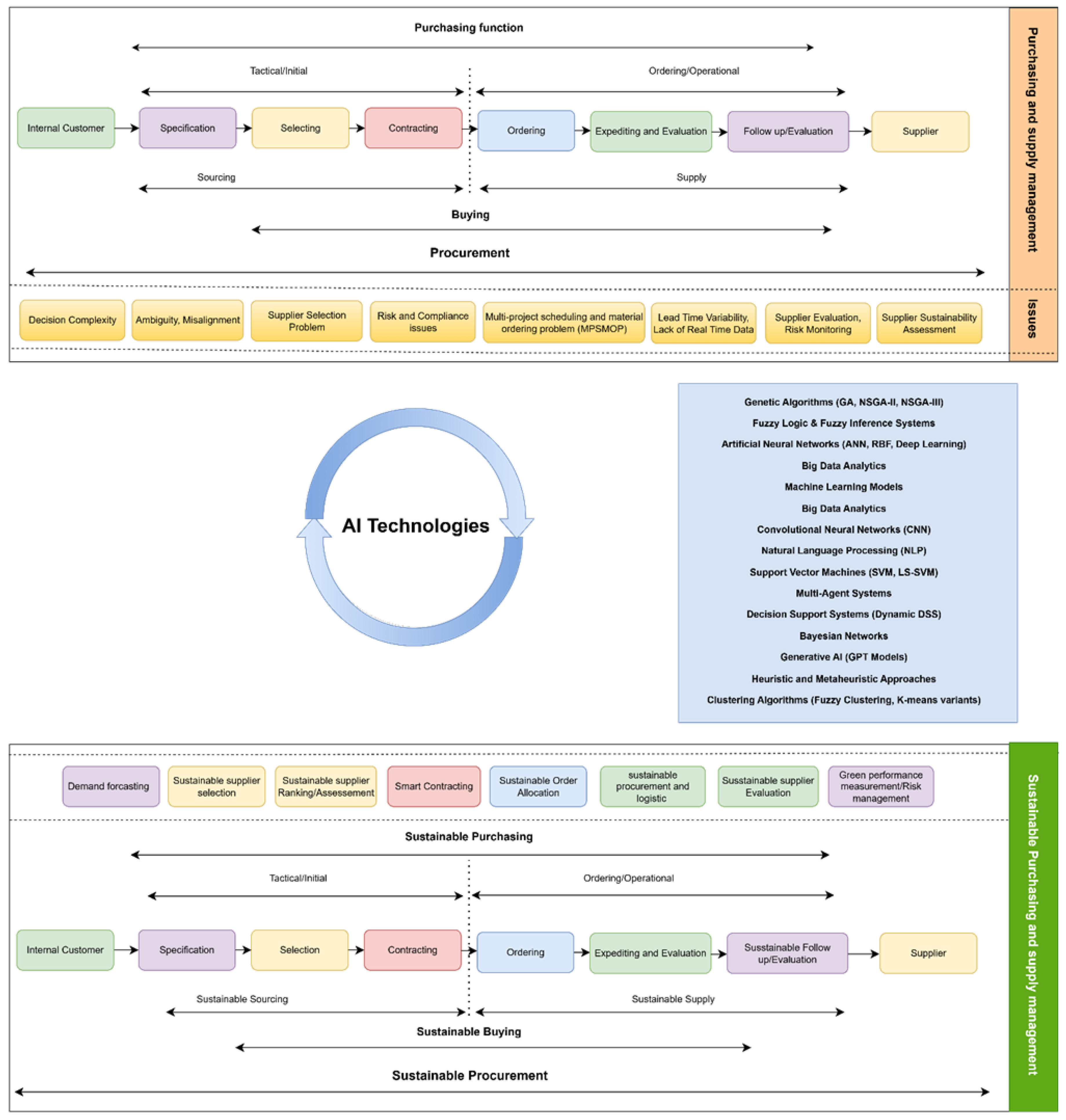

1. Introduction

- Research Question 1 (RQ1): What are the existing trends in the application of artificial intelligence (AI) technologies within sustainable purchasing and supply management (SPSM)?

- Research Question 2 (RQ2): Which AI-integrated technologies are currently utilised in sustainable purchasing and supply management?

- Research Question 3 (RQ3): What are the prospective research directions for advancing the application of AI-integrated technologies in sustainable purchasing and supply management?

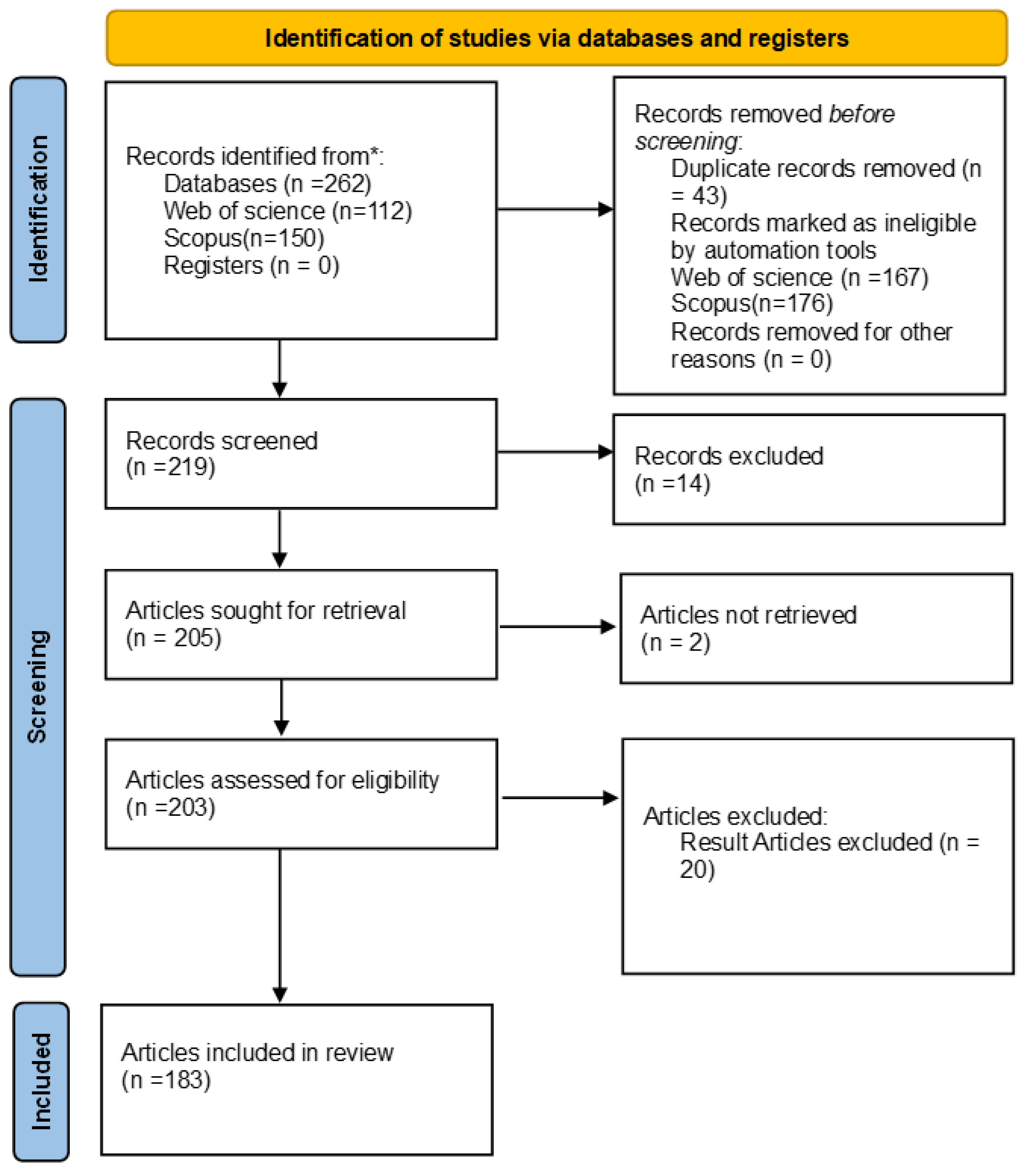

2. Materials and Methods

2.1. Inclusion and Exclusion Criteria

| Boolean search string |

|---|

| ("Artificial Intelligence" OR "Machine Learning" OR "Deep Learning" OR "Neural Network" OR "Decision Tree" OR "Natural Language Processing" OR "Clustering" OR "Genetic Algorithm" OR "Support Vector Machine" OR "Bayesian Network" OR "Back Propagation" OR "Linear Regression" OR "Fuzzy Logic" OR "Logistic Regression" OR "Big Data") AND ("Sustainable Supply Management" OR "Sustainable Procurement" OR "Sustainable Purchasing" OR "Sustainable Sourcing" OR "Green Supplier Selection" OR "Sustainable Supplier Selection") |

2.2. Bibliometric Analysis

2.3. Thematic Mapping and Topic Modeling

3. Result

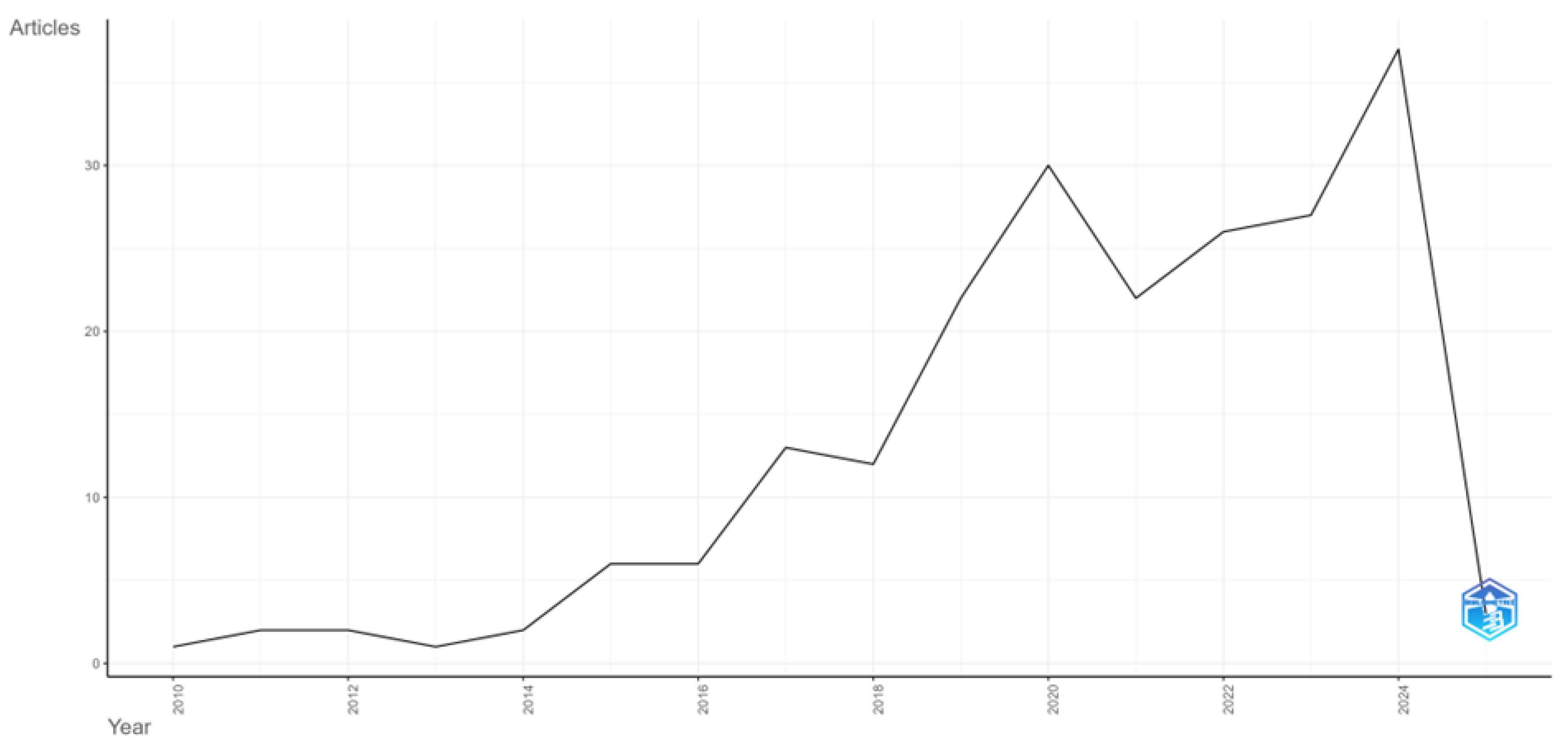

3.1. Bibliometric Analysis

3.1.1. Annual Scientific Production

3.1.2. Top Contributing Journals

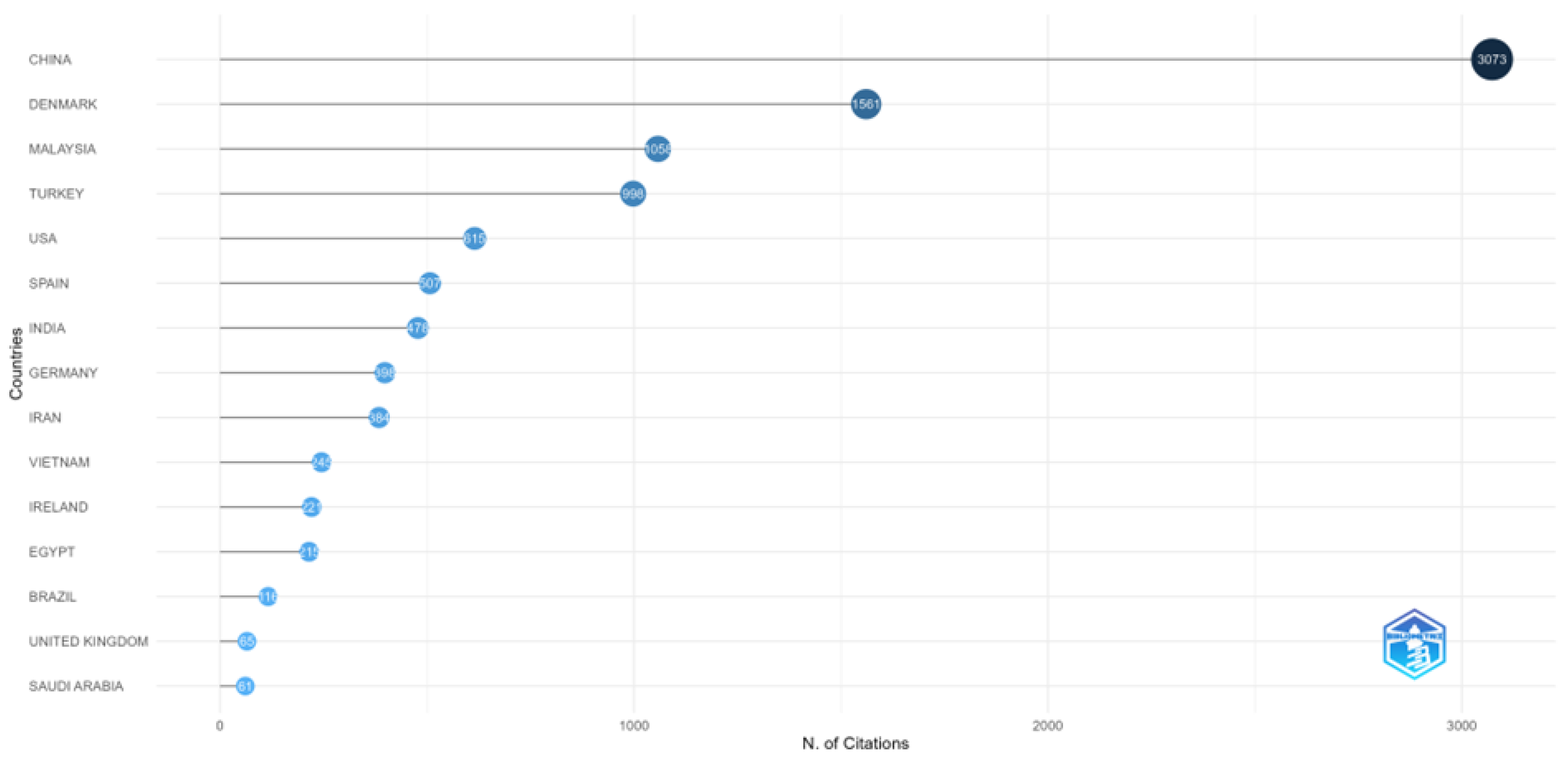

3.1.3. Top Countries

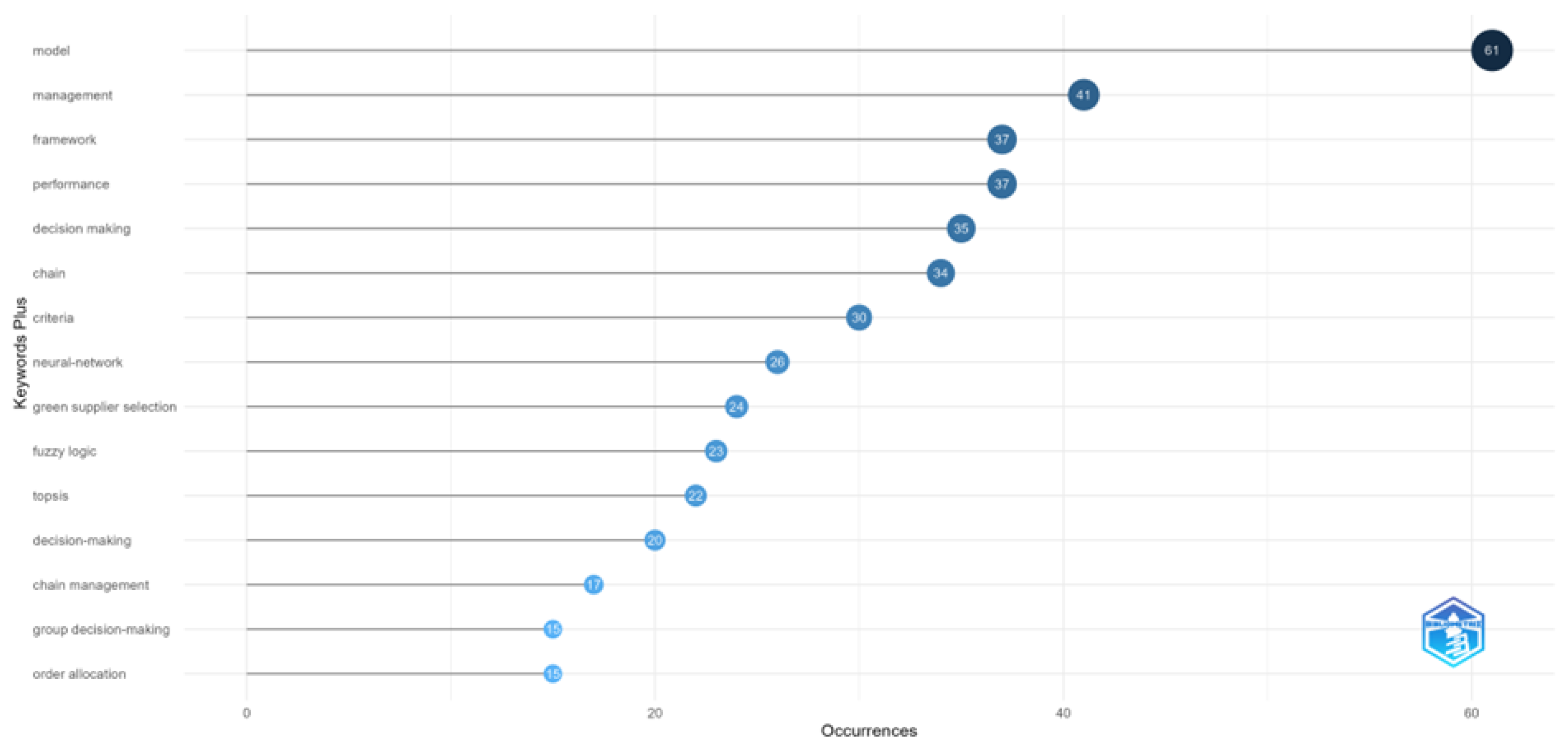

3.2. Most Frequent Keywords

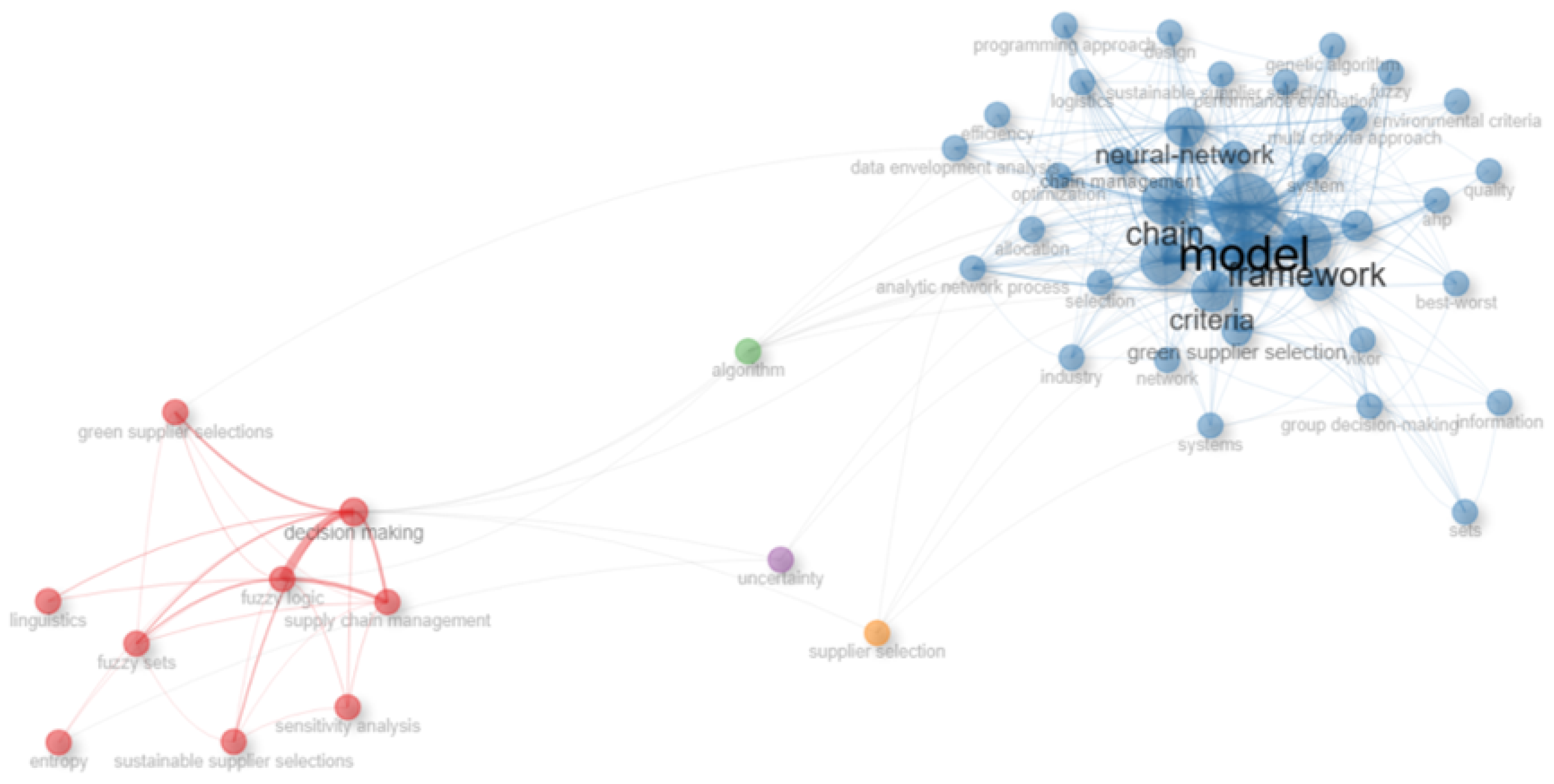

3.3. Keyword Co-Occurrence Networks

3.3.1. Thematic Evolution

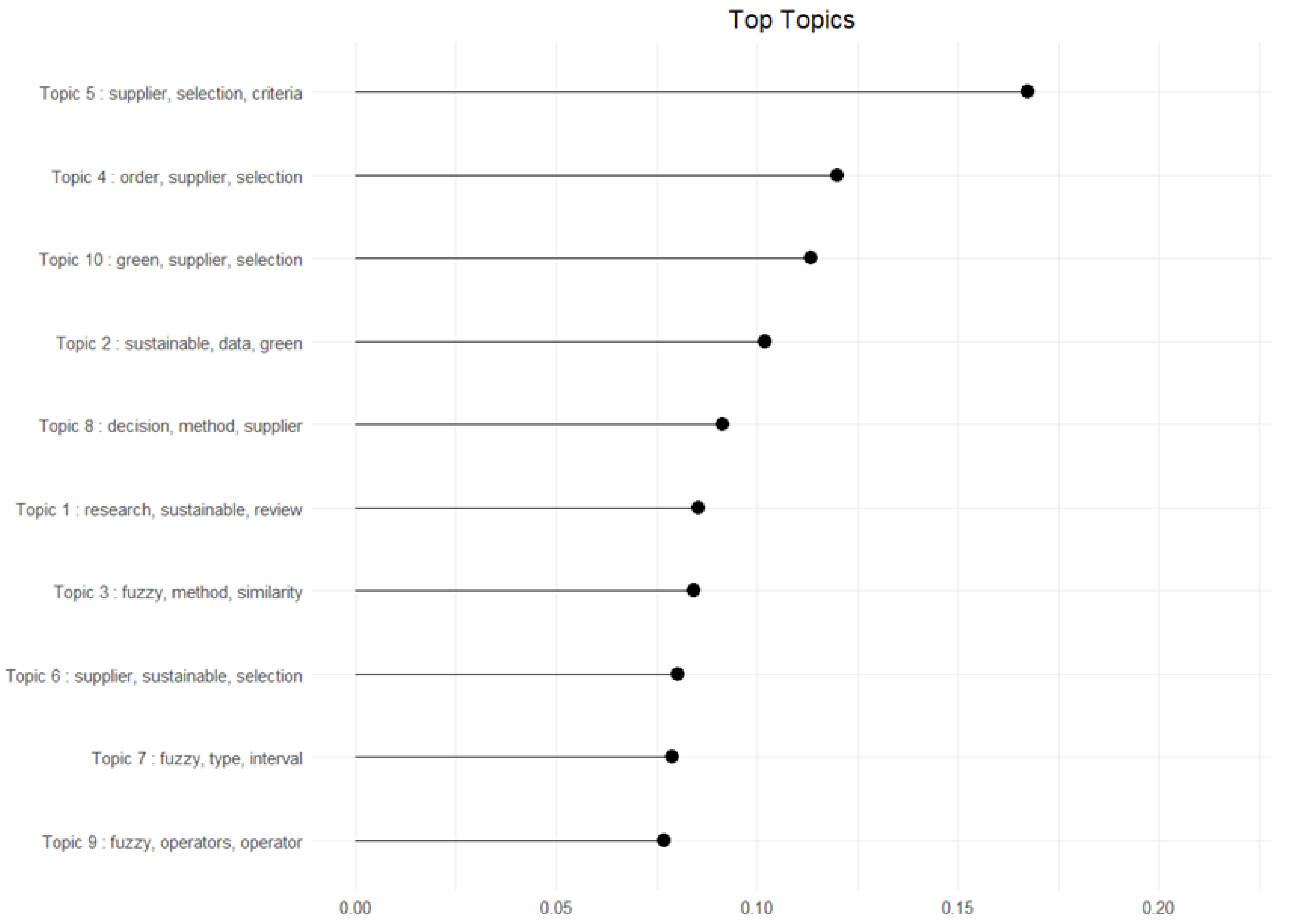

3.4. Text Analytics Using STM

| No. | Topic Label | Keywords | FREX | Lift |

|---|---|---|---|---|

| 1 | Literature Review on Green and Sustainable Supply Chains | research, sustainable, review, supply, green, analysis, study, literature, management, chain | sss, dynamic, hesitant, mean, rapid, exhibit, explored, select, affecting, combined | advancing, avenues, bibliometric, blockchain, depth, journal, journals, papers, publications, science |

| 2 | Big Data in Sustainable Public Procurement | sustainable, data, green, procurement, big, public, sustainability, study, purchasing, supply | promoting, among, ahp, risk, germany, machine, hesitant, presented, reducing, represents | across, ecofriendly, marketing, samples, regression, hypotheses, user, explores, participants, equation |

| 3 | Fuzzy MCDM Methods for Green Supplier Selection | fuzzy, method, similarity, green, topsis, supplier, preference, can, ranking, grey | ahp, impact, mean, time, two, ambiguous, chains, prospect, relations, evolves | multiplicative, grey, picture, moora, similarity, measures, relational, code, computed, conceptual |

| 4 | Supplier Selection and Order Allocation | order, supplier, selection, allocation, model, multiobjective, algorithm, optimization, green, genetic | improvement, contribution, mean, hesitant, another, demonstrate, vendors, ensuring, numbers, pythagorean | multiperiod, multiproduct, scheme, shortage, parties, times, discount, scenario, allocate, quantities |

| 5 | Sustainable Supplier Selection Based on Evaluation Criteria | supplier, selection, criteria, suppliers, sustainable, fuzzy, sustainability, supply, environmental, chain | take, models, via, impact, hesitant, mean, prominent, copyright, purpose, conduct | phase, philosophy, scm, pressures, ahptopsis, mabac, border, resolve, transparency, era |

| 6 | Sustainable Supply Chain Systems and Performance | supplier, sustainable, selection, system, supply, chain, sustainability, model, performance, fuzzy | ahp, risk, hesitant, recent, methodology, comprehensive, selecting, numbers, pythagorean, presence | alterations, compete, correspond, globally, pharmaceutical, benchmarking, extends, dynamics, variable, efforts |

| 7 | Fuzzy Interval Approaches for Decision Making | fuzzy, type, interval, approach, method, sets, uncertainty, decision making, mcdm, proposed | ahp, presented, hesitant, time, present, chains, ordering, unique, practices, select | rise, choquet, interaction, space, interval, type, utility, methodologies, dairy, pattern |

| 8 | Group Decision Making in Sustainable Supply Chain | decision, method, supplier, selection, making, group, proposed, model, green, based | risk, ahp, substantial, time, mean, theoretical, better, practices, methodology, significant | medium, reaching, reputation, trust, consensus, mechanism, generated, types, assessments, verified |

| 9 | Fuzzy Operators and Aggregation | fuzzy, operators, operator, aggregation, weighted, mean, linguistic, pythagorean, supplier, proposed | ahp, among, makes, time, impact, systems, chains, rank, significant, practices | dombi, heronian, valued, operator, aos, tconorm, operators, orthopair, tnorm, qrung |

| 10 | Green and Sustainable Supplier Selection Approaches | green, supplier, selection, criteria, model, sustainable, fuzzy, suppliers, supply, approach | products, ahp, identify, mean, dss, strategic, twostage, comparing, another, decisionmaker | assignment, deployment, qfd, gmbh, springerverlag, heuristic, prioritize, side, envelopment, footprint |

- Topic 1: Literature Review on Green and Sustainable Supply Chains

- Proposition 1: Future research should investigate the integration of social sustainability measures into existing sustainable supply chain models.

- Proposition 2: Future studies should explore how different supply chain configurations (e.g., closed, open, or hybrid structures) impact suppliers’ ability to engage in sustainability driven supply chains.

- Proposition 3: There is a need to empirically examine the role of non-traditional third-party actors such as NGOs, social enterprises, and public institutions in shaping sustainability outcomes.

- Proposition 3: There is a need to empirically examine the role of non-traditional third-party actors such as NGOs, social enterprises, and public institutions in shaping sustainability outcomes.

- Topic 2: Big Data Applications in Sustainable Public Procurement

- Proposition 1: Future research should explore the use of AI and predictive analytics in real-time fraud detection across domain specific public procurement datasets.

- Proposition 2: There is a critical need to investigate the trade-offs between transparency, data privacy, and competitive strategy in public e-procurement systems, especially in the context of open data platforms.

- Proposition 3: Future studies should develop and validate modular, cognitive procurement analytics platforms that integrate dashboard visualization, real-time risk scoring, and scenario-based policy modeling to support sustainable and adaptive decision-making.

- Topic 3: Fuzzy Multi-Criteria Decision-Making (MCDM) Methods for Green Supplier selection

- Proposition 1: Future research should conduct empirical, industry-specific case studies that combine fuzzy MCDM methods with practical data sources to validate model effectiveness and ensure decision relevance.

- Proposition 2: There is a need to integrate sensitivity analysis and behavioral decision making dimensions into fuzzy MCDM models for green supplier evaluation.

- Proposition 3: Future studies should expand the methodological diversity in fuzzy MCDM applications by comparing traditional approaches (e.g., fuzzy TOPSIS, BWM) with advanced or hybrid methods like fuzzy ANP, fuzzy SWARA, ELECTRE, or metaheuristic optimization models.

- Topic 4: Supplier Selection and Order Allocation Using Metaheuristic Optimization

- Proposition 1 (Future Direction): Future research should incorporate social sustainability dimensions into supplier selection and order allocation models.

- Proposition 2 (Future Direction): There is a need to develop adaptive metaheuristic optimization models that address real-time uncertainty, supply disruptions, and contextual risks.

- Proposition 3 (Future Direction): Future studies should perform cross-sectoral of metaheuristic-based supplier selection models where sustainability factors and disruption risks differ.

- Topic 5: Sustainable Supplier Selection Based on Evaluation Criteria and Sub-Criteria

- Proposition 1: Future research should develop and continuously update a domain-specific for sustainable supplier selection (SSS), incorporating new and evolving environmental, economic, and social criteria.

- Proposition 2: Further research is required to incorporate advanced fuzzy based MCDM techniques (e.g., IT2FNs, fuzzy PROMETHEE, grey linguistic models) to better manage uncertainty and social complexity in green supplier selection.

- Proposition 3: Future studies should empirically validate and compare AHP integrated frameworks (e.g., AHP-TOPSIS, AHP-VIKOR) across diverse industrial sectors and over time.

- Topic 6: Sustainable Supply Chain Systems and Performance

- Proposition 1: Future research should examine how sustainable supply chain management (SSCM) practices impact social and innovation performance.

- Proposition 2: The influence of stakeholder pressure on SSCM should be explored by distinguishing between different stakeholder types and incorporating contextual risk factors.

- Proposition 3: Future studies should employ dyadic and longitudinal designs to explore how internal (e.g., leadership, digitalization) and external (e.g., customer, supplier, societal) actors co-create sustainable performance in supply chain systems.

- Topic 7: Fuzzy Interval Approaches for Decision Making

- Proposition 1: There is a need to integrate fuzzy interval decision-making models with AI techniques to enable real-time, adaptive evaluation in dynamic environments.

- Proposition 2: Future research should conduct a comparative analysis of fuzzy interval approaches versus other uncertainty-handling methods (e.g., hesitant fuzzy sets, rough sets).

- Proposition 3: Future research should explore dynamic fuzzy interval models that evolve over time, capturing changes in decision-maker preferences and contextual factors.

- Topic 8: Group Decision Making in Sustainable Supply Chain

- Proposition 1: Future research should develop dynamic GDM models that adapt to evolving stakeholder preferences and changing sustainability objectives.

- Proposition 2: There is a need to investigate the behavioral and psychological aspects of group decision making in SSCM, such as trust, influence, and conflict resolution.

- Proposition 3: Further studies should explore the integration of digital platforms and AI in facilitating real-time, multi-stakeholder consensus building in sustainable supply chains.

- Topic 9: Fuzzy Operators and Aggregation

- Proposition 1: Future research should explore hybrid fuzzy operators that combine classical aggregation with AI or machine learning for improved decision adaptability.

- Proposition 2: Comparative studies are needed to benchmark new fuzzy operators (e.g., elliptical, Dombi-based) against traditional ones in various decision-making environments.

- Proposition 3: Researchers should investigate the role of fuzzy aggregation in dynamic and real-time group decision-making systems, particularly under high uncertainty.

- Topic 10: Green and Sustainable Supplier Selection Approaches

- Proposition 1: Future research should develop and empirically validate integrated supplier selection models that simultaneously consider environmental, social, and economic criteria.

- Proposition 2: Future studies should explore how real-time data from digital technologies (e.g., IoT, blockchain, environmental sensors) can be integrated into supplier selection models.

- Proposition 3: Future research should develop advanced GSES models that integrate modern uncertainty theories such as probabilistic linguistic sets, interval-valued neutrosophic sets, or fuzzy rough sets to effectively manage incomplete, vague, or heterogeneous supplier performance data.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production. 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics. 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–40. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production. 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production. 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production. 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–40. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics. 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Bozdogan, H. Supply Chain Integrity: A Key to Sustainable Supply Chain Management. Journal of Business Logistics 2018, 39, 38–56. [Google Scholar] [CrossRef]

- Morgane, M.C.P.D. Sustainable Supply Chain Management. Responsible Consumption and Production Encyclopedia of the UN Sustainable Development Goals [Internet]. 2019 Jan 1 [cited 2025 May 26]; Available online: https://www.academia.edu/40249916/Sustainable_Supply_Chain_Management.

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management – A textile case. Journal of Cleaner Production 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. International Journal of Production Economics 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics. 2012, 140, 330–340. [Google Scholar] [CrossRef]

| Source | h_index | g_index | m_index | TC | NP | PY_start |

|---|---|---|---|---|---|---|

| JOURNAL OF CLEANER PRODUCTION | 15 | 16 | 0.938 | 3134 | 16 | 2010 |

| SUSTAINABILITY | 6 | 11 | 0.857 | 139 | 12 | 2019 |

| ENVIRONMENTAL SCIENCE AND POLLUTION RESEARCH | 5 | 5 | 1 | 131 | 5 | 2021 |

| INTERNATIONAL JOURNAL OF PRODUCTION RESEARCH | 5 | 5 | 0.455 | 734 | 5 | 2015 |

| SOFT COMPUTING | 5 | 6 | 0.833 | 389 | 6 | 2020 |

| APPLIED SOFT COMPUTING | 4 | 6 | 0.286 | 560 | 6 | 2012 |

| COMPUTERS & INDUSTRIAL ENGINEERING | 4 | 5 | 0.364 | 428 | 5 | 2015 |

| EXPERT SYSTEMS WITH APPLICATIONS | 4 | 4 | 0.267 | 326 | 4 | 2011 |

| INTERNATIONAL JOURNAL OF PRODUCTION ECONOMICS | 4 | 6 | 0.5 | 349 | 6 | 2018 |

| PLOS ONE | 4 | 8 | 1 | 72 | 8 | 2022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).