As the problem of uneven spatial and temporal distribution of global water resources is becoming more and more serious, long-distance water conveyance project is an important technical means to satisfy social production. Long-distance pressurized water transmission system with high drop, due to the high terrain drop, usually up to several hundred meters, compared with the low drop gravity flow pressurized water transmission system, the transition process of this water transmission system is more dangerous and complex. The system in the valve operation process generated by the transient flow water hammer phenomenon, often leading to rapid changes in the internal pressure of the pipeline, resulting in the separation of the water column, bridging, pipe burst. Therefore, the study of water hammer effect in water distribution system and the optimization of protection strategy has been an important topic in the field of water distribution engineering. At present, scholars have carried out a large number of studies on water hammer protection measures for long-distance pressurized water transmission systems.Li Jiangyun et al[

1]The water hammer propagation characteristics of long-distance water transmission systems are analyzed, and the combined application of air valves, regulator towers and other protective measures is proposed;Li Jiang et al [

2] verified the effect of end valve closing time on water hammer pressure by numerical simulation, and suggested to use 300s to close the valve at a uniform speed; Lin Xiaozhi et al [

3], as an example, constructed a numerical model of water hammer pressure and evaluated the effect of different protective measures for a water diversion and transfer project in Yunnan Province; and Xu Dawei et al [

4], described in detail the experience of the design of the alteration and expansion of the long-distance and large-height difference water transmission pipeline. Pei Shuangbao [

5], as an example of Shanxi Province Yumenkou water lifting east expansion project, for the complexity of the third section of its gravity flow, according to the basic principles of water hammer calculation, the establishment of the overpressure relief valve, the air tank mathematical model, the use of numerical simulation, respectively, simulate the air valve, the air valve and the overpressure relief valve, the air valve and the air tank joint protection of the working conditions of the change in the pressure of the water hammer; Cai Fulin et al.[

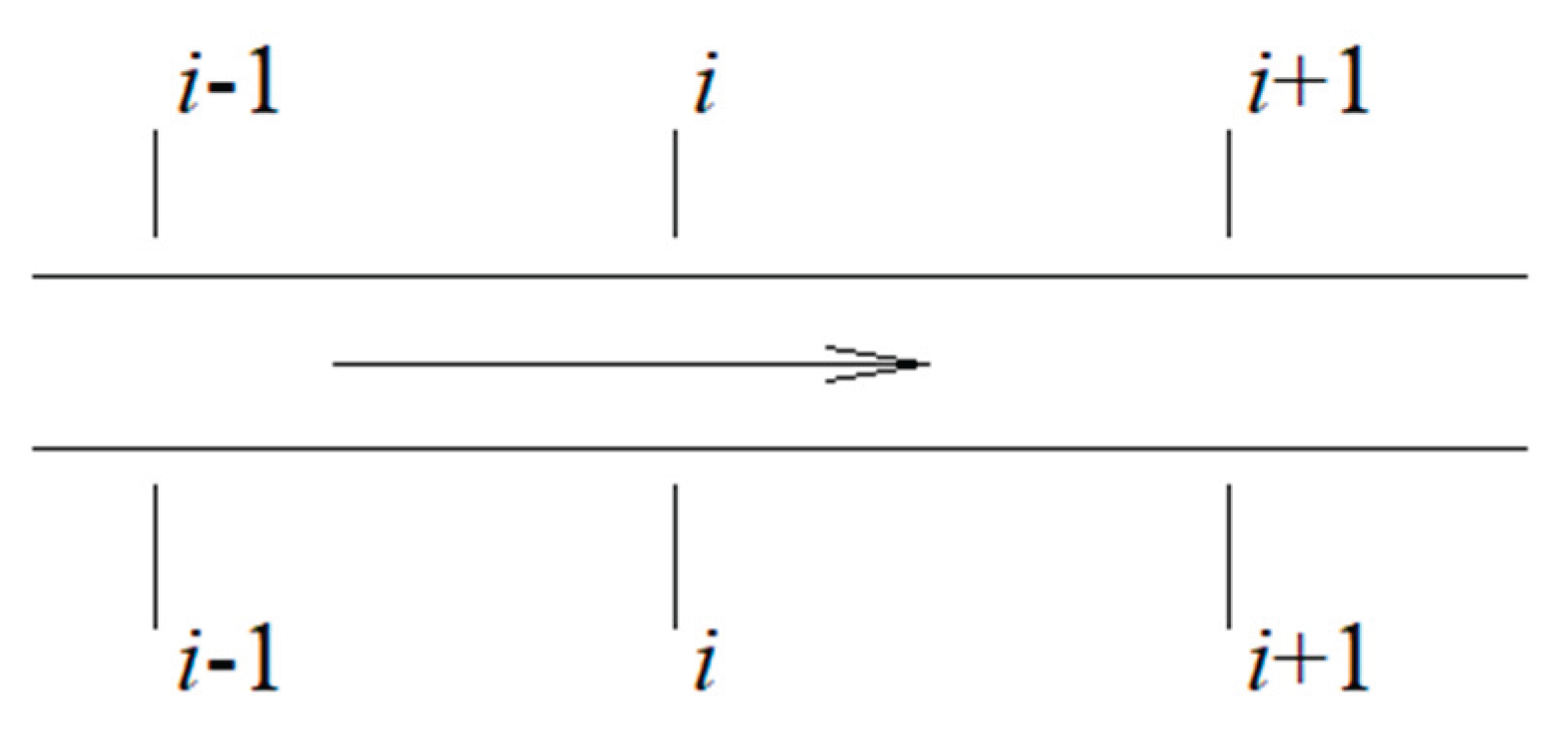

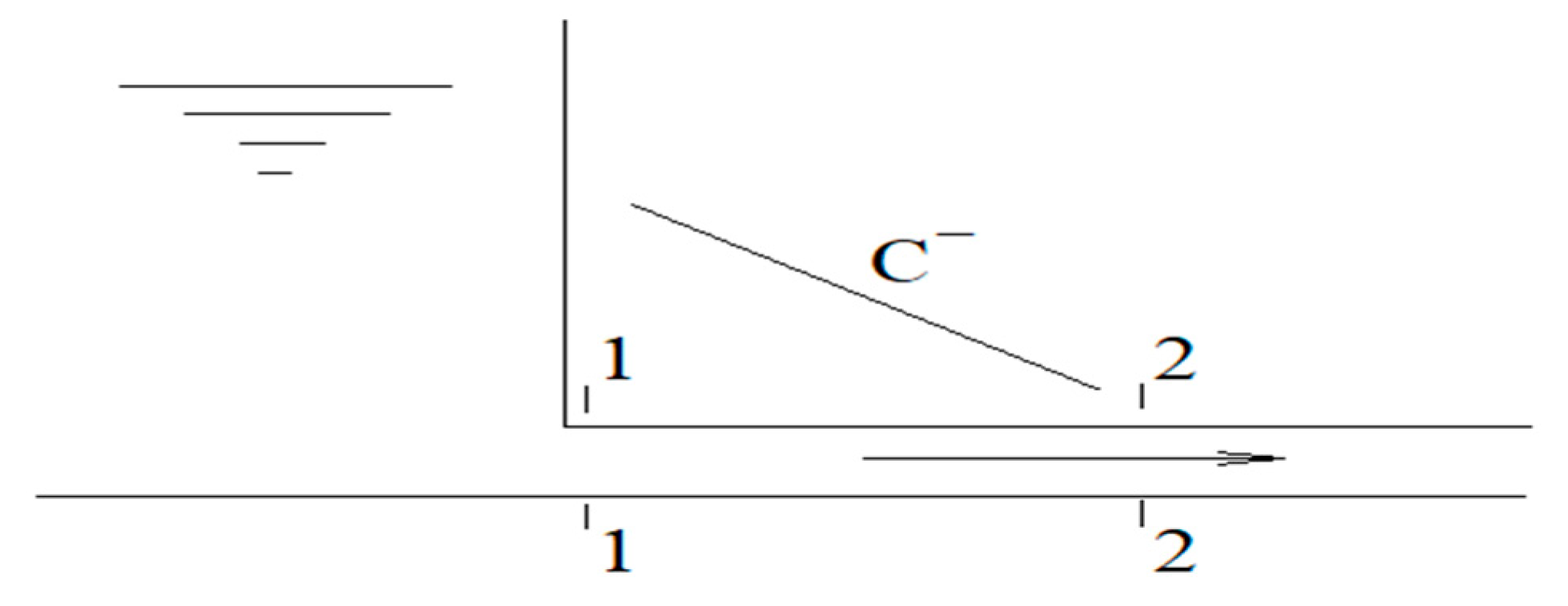

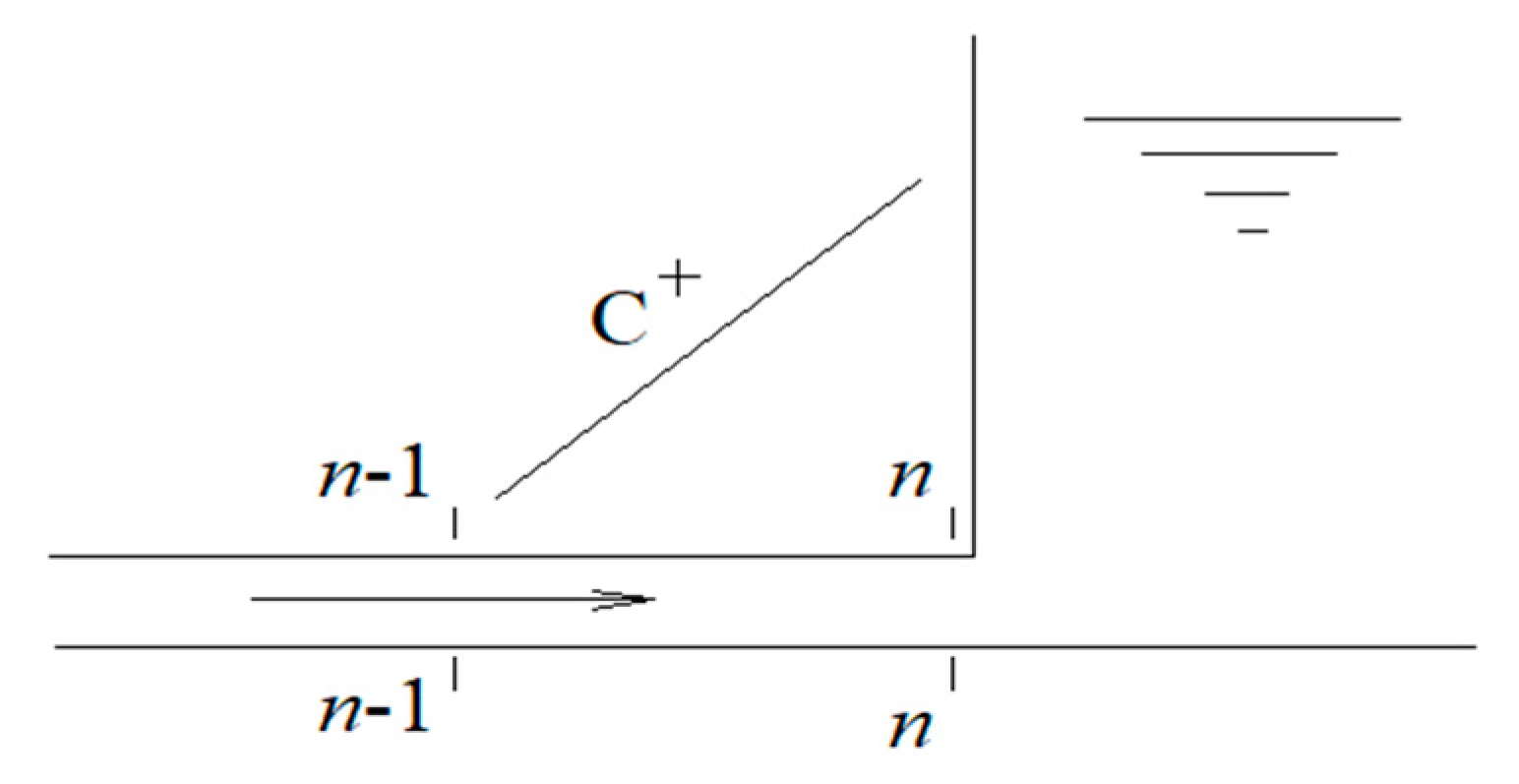

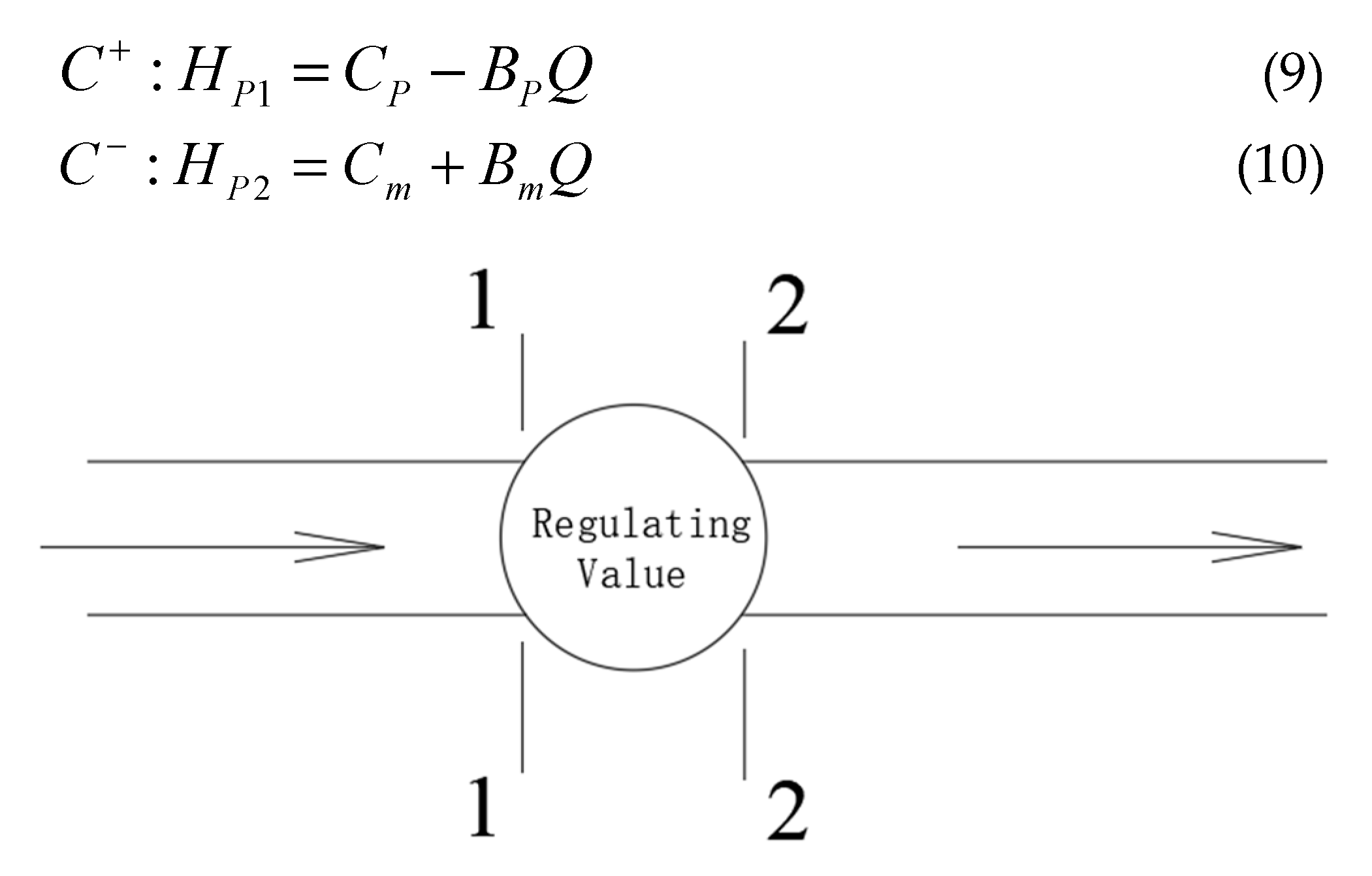

6] established a mathematical model of water transmission system transition process calculation based on transient flow analysis of the eigenline method, and investigated the water hammer problem when the long-distance multi-branch pressurized water transmission system, which contains gravity flow transmission pipeline and pumping station pressurized lifting pipeline, is opened; Chen Minghui et al.[

7] investigated the local water hammer characteristics of the intermediate bulge pipeline section and its protection against water hammer with the arrangement of the hump-type pipeline long water transmission system. Elucidated the one-way regulator tower on the hump type long distance water pipeline protection mechanism, and deduced the one-way regulator tower set the height of the approximate analytical formula; LiPengYu, etc. [

8] to an actual long distance gravity flow water transmission project as an example, simulate the end of the valve transition process, analyze the water hammer pressure of the system under the different shut-off rules, verify the gravity flow shut-off valve water hammer characteristics and theoretical formulas, and on the basis of the proposed sub-phase On the basis of this, the selection method of valve closing rate and folding point opening is proposed. Ma Yiyang[

9]took a long-distance gravity flow water transfer project in Shanxi Province as an example, established a hydraulic transient calculation model, and based on the model developed an optimization program of valve shut-off curve and valve arrangement scheme using genetic algorithm. The results show that the multi-stage valve shut-off program is significantly better than the one-stage valve shut-off program; in addition, Dang Zhiliang[

10] explored the optimization method of the number of decompression tank stages and the arrangement location.Bian Shaokang et al. [

11] established a calculation model for the hydraulic transition process of a certain project based on the Porter method, analyzed the valve closing law without protective measures, compared the protective effects of traditional ordinary air valves and three-acting air valves, and discussed the influence of the three-acting air valve combined with the two-stage valve closing scheme on the valve closing water hammer. Guo Weiqi et al. [

12] used computer simulation to simulate multiple protective measures such as linear valve closing, two-stage valve closing, and combined overpressure relief valves. Zhang Yousheng et al. [

13], based on the overall layout plan of the pipeline network and the characteristics of water usage, adopted a hydraulic mathematical model and water hammer calculation method to analyze the hydraulic transition process of the water transmission pipeline under different operating conditions, and simulated the influence of valve opening and closing at different times on the pressure and water hammer changes along the pipeline. Huang Wei et al. [

14], taking actual engineering as an example, conducted numerical simulations of pump stop water hammer under four water hammer protection schemes: air valve protection, combined protection of air valve and end valve, combined protection of air valve, end valve and overflow pipe, and combined protection of air valve and air valve pressure regulating chamber. Sun Yiming et al. [

15] established a water hammer calculation model using PIPENET and conducted a protection study on the water hammer phenomenon that occurs in pressurized water supply pipelines when pumps stop due to accidents through a combined protection method of multi-functional hydraulic control valves, gas injection micro-discharge valves, and air tanks. Zhang Dongjun et al. [

16] conducted a water HAMMER simulation analysis of a long-distance water transmission project based on the Bentley HAMMER V8i water hammer calculation software. By setting different working states, they carried out calculation and analysis around the maximum pressure value, the reverse rotation of the water pump and the vacuum degree of the pipeline to explore the technical measures for protecting against water hammer. A water hammer elimination scheme combining "multi-functional water hammer pump control valve + air valve + pressure-holding and pressure-relief valve" was derived. Shi Lin et al. [

17] proposed a water hammer protection scheme combining an air tank and an outlet overflow pool for some water supply projects with special terrain conditions in this paper, and established a mathematical model of the outlet overflow pool. Wang Shunsheng et al. [

18] studied the water hammer protection effect when the airbag air tank is used in combination with the multi-functional water pump control valve and air valve, as well as the influence of the tank volume and the preset pressure of the airbag on the water hammer protection effect. The research results show that installing airbag-type air tanks in high-head and medium-flow water conveyance projects can achieve a good water hammer protection effect. Zhou Tianchi et al. [

19] used the hydraulic transition process simulation calculation software Hysimcity for modeling and calculation analysis to carry out the water hammer protection design of the entire water transmission system. It was finally determined to install an overpressure relief valve with a diameter of 1 meter in front of the Linping, Renhe, Hongpan and Tangxi water plants, as well as a combined water hammer protection scheme of one-section linear closure of the valves of each water plant. This effectively solved the water hammer problem of the multi-user gravity flow water supply system. Tan Zhen et al. [

20] established a finite volume method Godunov scheme hydraulic transient mathematical model for the combined pressure-unpressure flow and inverted siphonic pressurized flow in a long-distance water transmission system, and conducted a simulation study on the operational hydraulic characteristics. Bian Shaokang et al. [

21] established a calculation model for the hydraulic transition process of a certain actual project based on the Baud property method. The valve closing rule without protective measures was studied. The protective effects of traditional ordinary air valves and three-action air valves were compared. The sensitivity analysis of the air valve diameter parameters was conducted. The influence of two-stage valve closing + air valve combined protection on valve closing water hammer was investigated. Zhu Sheng [

22], taking the pre-built gravity flow water transmission pipeline in a mountainous county in the southeast as an example, selected the reservoir water level, pipeline flow rate and valve closing point as variables, obtained 12 operating conditions, simulated the hydraulic transition process of these conditions under various valve closing durations, and analyzed the influence of three variables on valve closing water hammer. Song Naishuo et al. [

23], through the application of large drop gravity water conveyance in the water supply project of Mengga Town, Mangshi City, Yunnan Province, introduced the pressure water hammer protection measures for pressure reduction and energy dissipation, the layout of exhaust valves and precautions in the design of large drop gravity flow pipeline water conveyance.

Li Pengyu et al. [

24], taking a certain actual long-distance gravity flow water transmission project as an example, simulated the end valve closing transition process, analyzed the water hammer pressure of the system under different valve closing rules, verified the water hammer characteristics and theoretical calculation formulas of gravity flow valve closing, and on this basis, proposed a selection method for phased valve closing rates and breakpoint opening degrees. Tong Baolin et al. [

25], aiming at the selection problem of the flow characteristics of the end flow regulating valve in a gravity flow system under large amplitude flow, based on one-dimensional water hammer theory, adopted numerical simulation methods and combined with engineering examples, A comparative study is conducted on three types of flow characteristics, namely linear type, parabolic type and equal percentage type, from three aspects: the influence of the flow characteristics of the flow regulating valve on the steady-state operation opening degree, the determination of the most unfavorable flow condition of water hammer when the flow regulating valve is closed, and the influence of the flow characteristics of the flow regulating valve on the water hammer when the valve is closed. Gu Yuanhao et al. [

26] established the corresponding water hammer calculation model using KY PIPE2022 software. Through numerical simulation, they explored the entire process of water hammer hydraulic transition in the water delivery system when the pump was stopped, and discussed the influence laws of different closing procedures of two-stage slow-closing check valves and different arrangements of airbag air tanks on the water hammer protection effect. Zhang Yong et al. [

27], using Bentley Hammer software, established a mathematical model of the dual-pump parallel unit in the pumping station water delivery system, and studied the influence of pipeline optimization before and after different valve closing schemes in two stages on the most unfavorable water hammer parameters such as water hammer pressure and unit speed. Wang Zhiyang et al. [

28] adopted the characteristic line method and utilized water hammer numerical simulation software to establish a basic model for water hammer calculation in long-distance water transmission pipelines. The water hammer phenomenon and its variation laws under four working conditions of the stable operation state, adjusted operation state, operation state of the maintenance and pipe cutting section and pipe burst of the water conveyance pipeline system from Huangchi Gou water distribution hub to Banqiao Water outlet of the north main line of the second phase of the Han Water to Wei Water diversion project were analyzed and studied. Dou Pinxin et al. [

29] pointed out that for underwater water supply pipelines, conventional waterproof hammer measures could not be adopted. Instead of the air valve, a single-outlet style waterproof hammer air valve and a pressure regulating pipe were used to meet the waterproof hammer requirements of the pipeline. The calculation results of the closed valve water hammer, open valve water hammer and flow regulation water hammer of the water supply pipeline under different working conditions were analyzed and studied by the characteristic line method. Qu Ningling [

30] Taking the water supply project of County A as an example, based on the basic principle of water Hammer and the characteristic line method, the model calculation and analysis of the water hammer condition when the pump stops in this project were carried out by using the unique model system of the Bently Hammer software. The simulation results show that after the pump group of the three-stage series pumping station in County A stops due to an accident, multiple pipelines are facing the hazards of overpressure and negative pressure. Based on the simulation results, targeted water hammer protection design is carried out for the water transmission system.

At present, the research on the water hammer protection measures of long-distance pipeline water transmission system focuses on the control strategy of opening and closing of low-drop valves and the application of different water hammer protection measures, and there are fewer research studies on the water hammer protection of long-distance high-drop water transmission system when it is opened and closed.

This paper takes a reservoir water transmission project as the research object, for the water hammer protection problem of long-distance high drop water transmission network, adopts the characteristic line method to construct the hydraulic transition process simulation model, and calculates the hydraulic transition process of long-distance high drop pressurized water transmission system when it is opened and closed. Through comparative analysis, the impact of different valve opening and closing control strategies on water hammer is investigated, and the synergistic protection strategy of “multi-stage decompression tank + air valve” is proposed. It provides theoretical basis and engineering reference for similar projects.