1. Introduction

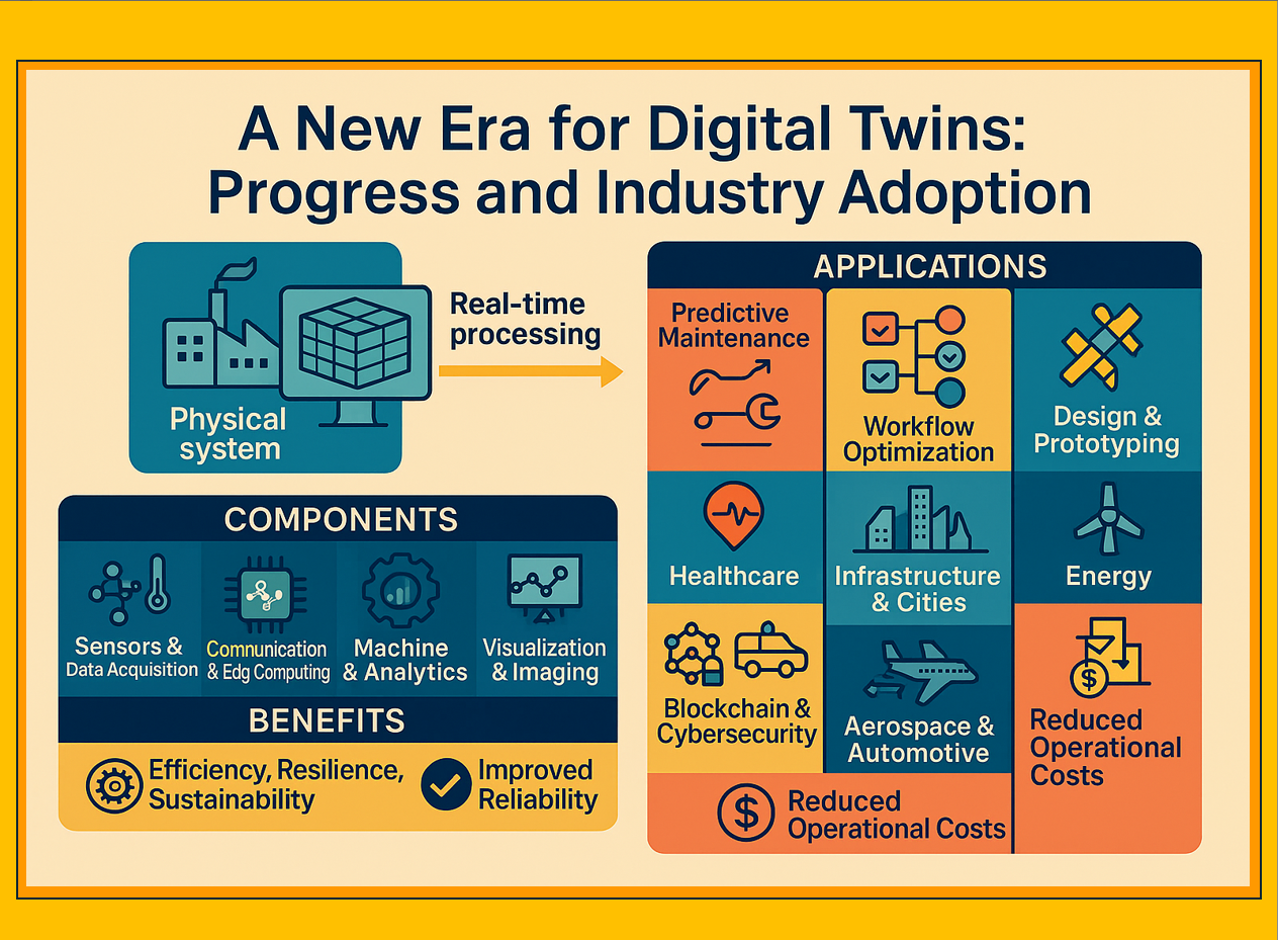

Digital Twin (DT) technology is a transformative innovation that bridges the physical and digital worlds. It creates virtual replicas of real-world systems, enabling real time monitoring, simulation, and optimization. By integrating data with computational models, DT enhances efficiency, sustainability, and resilience across various industrial systems, giving operators full visibility of production processes [

1].

Originally developed for aerospace applications, Digital Twin technology has expanded to offer transformative solutions for complex challenges in numerous sectors, including manufacturing, healthcare, infrastructure and urban planning, energy, logistics, education, transportation, and autonomous systems [

2].

DT technology relies on sensors, data acquisition systems, and computational infrastructures for seamless data collection and real time processing. Machine learning and analytics improve predictive capabilities, allowing for proactive decision-making [

3]. Connectivity solutions ensure smooth data exchange, while visualization tools, high-resolution imaging, and scanning techniques enhance digital modeling accuracy [

4]. Advanced features in modern IoT devices further improve their performance [

5,

6]. To ensure security and data integrity, blockchain and cybersecurity mechanisms play a critical role [

7].

Digital twins offer several key applications, including predictive maintenance, process optimization, design and prototyping, and healthcare advancements. In predictive maintenance, digital twins facilitate the identification of potential system failures before they occur, thereby reducing downtime, extending equipment lifespan, and lowering operational costs [

8]. Process optimization is another significant application, where digital twins streamline workflows and enhance resource allocation, leading to increased efficiency [

7]. Furthermore, design and prototyping benefit from digital twins, as they enable virtual testing, accelerate development cycles, and reduce the need for physical prototypes [

9]. In the healthcare sector, digital twins enable patient-specific modeling, which improves diagnosis, treatment planning, and surgical simulations [

10].

Digital twins also play a crucial role in smart infrastructure and urban planning. Engineers use them to monitor structural health and predict potential failures [

11] , while urban planners utilize them to simulate traffic flow and optimize resource distribution, fostering the development of sustainable cities [

12]. In the energy sector, digital twins enhance grid operations, facilitate the integration of renewable energy sources, and improve system safety [

13]. Furthermore, both renewable and nuclear energy plants employ digital twins for real-time monitoring, efficiency optimization, and risk assessment [

14].

DT also plays a vital role in training and education by providing interactive and immersive simulations that enhance learning and skill development [

15]. It improves autonomous systems by creating high-fidelity virtual environments, allowing for safe algorithm testing before deployment [

16]. In supply chain management, DT improves demand forecasting, route planning, and real-time tracking, thereby increasing operational efficiency [

17]. In manufacturing and aerospace, DT optimizes production quality, monitors equipment performance, and facilitates predictive maintenance, leading to improved safety and productivity [

18].

The impact of DT extends further into energy production and distribution, where it enhances the reliability of utilities and optimizes power management [

19]. In civil engineering, DT supports real-time infrastructure monitoring, improving safety and extending the lifespan of critical structures [

20]. Robotics and automation also benefit from DT, as it enables real-time system optimization and process refinement, improving accuracy and efficiency [

21]. Oil and gas industries utilize DT to optimize workflows, enhance predictive maintenance, and improve risk management [

22]. Similarly, transportation and marine engineering leverage DT for fleet management, route optimization, and operational safety, reducing costs and improving overall system reliability [

23].

Despite its vast potential, DT faces several challenges, including high computational demands, data integration complexity, cybersecurity threats, and a lack of standardization [

24]. To Address these challenges requires collaboration among researchers, industry experts, and policymakers to develop scalable and secure DT implementations [

7]. Future research should focus on AI-driven analytics, hybrid DT models, edge computing for real-time processing, and blockchain-based security solutions [

25]. Establishing standardized frameworks and interdisciplinary training programs will also be essential in driving the widespread adoption of DT across industries.

This systematic review examines the current state of DT technology encompassing commonly integrated elements, its most impactful applications across industries, and future research directions.

This article is structured into six comprehensive sections.

Section 1 introduces digital twin technology and its diverse applications.

Section 2 details the systematic review methodology, including research question formulation, literature search strategies, inclusion and exclusion criteria, study selection procedures, data extraction techniques, and validation methods.

Section 3 delves into the core components and underlying technologies of digital twins.

Section 4 presents a detailed overview of DT applications across various industries.

Section 5 discusses existing technologies, current challenges, and future research directions. Finally,

Section 6 concludes the article, summarizing key findings and implications.

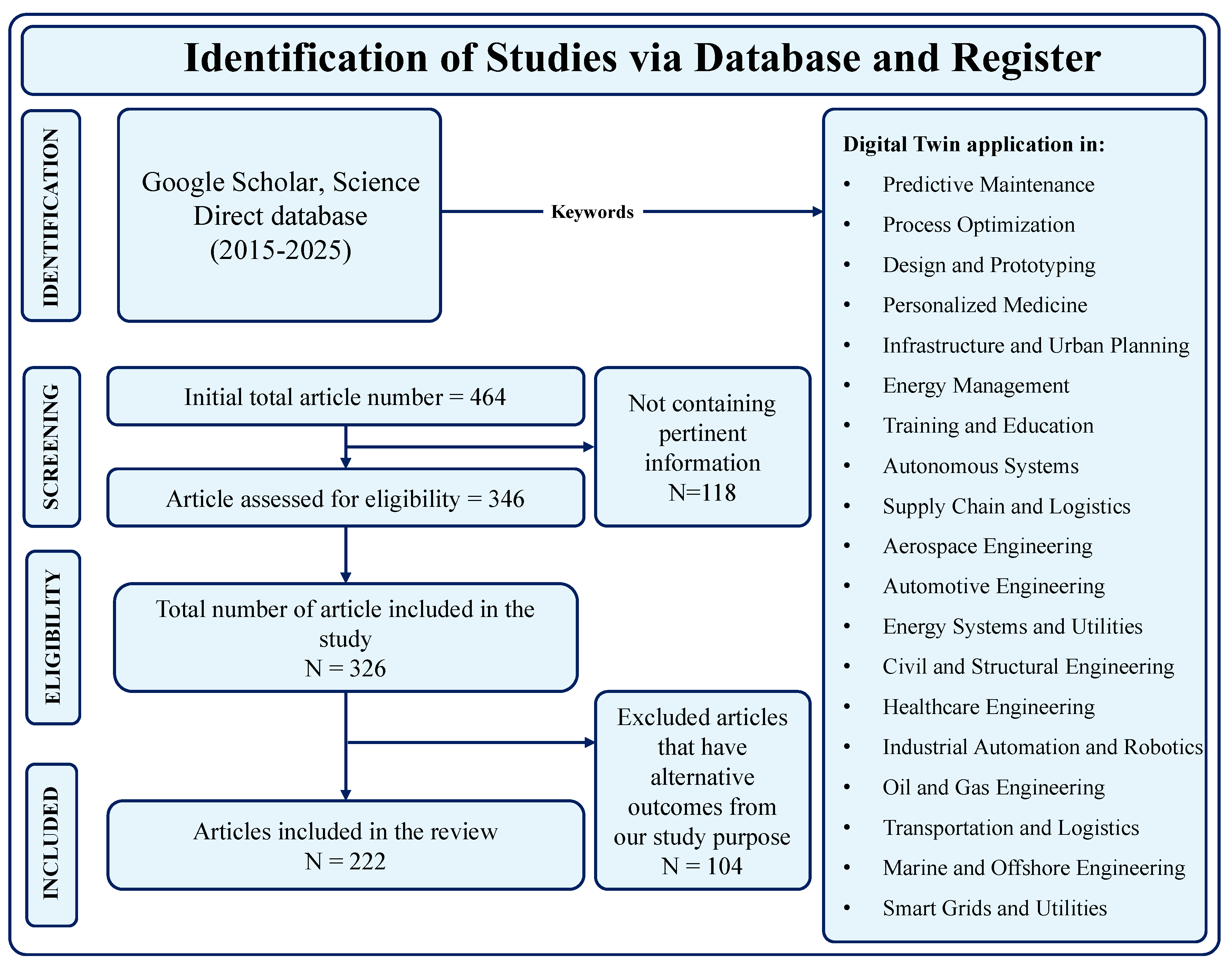

2. Methodology

This systematic review followed a structured and comprehensive approach to examine the structure and application of various types of digital twins across different industries. The review process was conducted in five distinct stages: defining the research questions, identifying relevant studies, selecting studies based on inclusion and exclusion criteria, extracting data, and analyzing the findings.

2.1. Research Question Formulation

This systematic review aimed to synthesize evidence regarding the applications of different types of digital twins. The review addressed the following specific questions:

2.2. Literature Search Strategy

Searches were conducted using the phrase “the elements of a Digital twin” and "the application of Digital twin" in relation to the following areas: Predictive Maintenance, Process Optimization, Design and Prototyping, Personalized Medicine, Infrastructure and Urban Planning, Energy Management, Training and Education, Autonomous Systems, Supply Chain and Logistics, Aerospace Engineering, Automotive Engineering, Energy Systems and Utilities, Civil and Structural Engineering, Healthcare Engineering, Industrial Automation and Robotics, Oil and Gas Engineering, Transportation and Logistics, Marine and Offshore Engineering, and Smart Grids and Utilities. The search was limited to articles published in peer-reviewed journals between 2020 and 2025. To ensure thorough coverage, both backward and forward citation tracking of selected articles was performed.

2.3. Inclusion and Exclusion Criteria

Studies were included/excluded based on the following criteria:

Inclusion criteria:

- -

Studies published between 2020 to 2025.

- -

Studies published in English

- -

Studies that explicitly define or describe the technology being used as a "digital twin".

- -

Application Area: Studies that describe the application of digital twins in one or more of the following areas:

▪ Predictive Maintenance

▪ Process Optimization

▪ Design and Prototyping

▪ Personalized Medicine

▪ Infrastructure and Urban Planning

▪ Energy Management

▪ Training and Education

▪ Autonomous Systems

▪ Supply Chain and Logistics

▪ Aerospace Engineering

▪ Automotive Engineering

▪ Energy Systems and Utilities

▪ Civil and Structural Engineering

▪ Healthcare Engineering

▪ Industrial Automation and Robotics

▪ Oil and Gas Engineering

▪ Transportation and Logistics

▪ Marine and Offshore Engineering

▪ Smart Grids and Utilities

Exclusion criteria:

- -

Editorials, letters to the editor, and opinion pieces

- -

Conferences

- -

Books and book chapters (unless they contain primary research)

- -

Patents

- -

Websites, blogs, and other non-peer-reviewed sources

- -

Language: Studies published in languages other than English

- -

Studies published before 2020

- -

Studies that do not provide a clear definition or description of a digital twin. Studies that use the term "digital twin" loosely or interchangeably with other concepts (e.g., simulation, modeling) without meeting the core components.

- -

Application Area: Studies that do not focus on the specified application areas.

- -

Studies that describe the theoretical concepts of digital twins without empirical data or real-world applications.

2.4. Study Selection

Following database searches, duplicates were removed. Two independent reviewers then screened the titles and abstracts of the remaining studies and subsequently assessed the full-text articles for eligibility based on the inclusion and exclusion criteria. Disagreements were resolved through discussion.

2.5. Data Extraction and Synthesis

For the selected studies, data were extracted on the following parameters: type of digital twin system used, industrial application, technology used. A qualitative synthesis was performed to analyze the findings and categorize the digital twin applications based on their functionality.

2.6. Quality Assessment

The quality of the included studies was evaluated using a modified version of the Newcastle-Ottawa Scale, specifically adapted to assess the methodological rigor and relevance of control system used in rehabilitation research.

2.7. Data Analysis

and practical application as the primary criteria. Out of 385 reviewed articles, 198 were shortlisted for detailed analysis.

Figure 1.

Flow Chart of the Search and Inclusion Process.

Figure 1.

Flow Chart of the Search and Inclusion Process.

3. Key Elements of Digital Twin

Digital twin (DT) technology creates virtual replicas of physical assets, enabling real-time monitoring, simulation, and optimization. A robust DT system relies on several key components. Sensors and IoT devices collect real-time data, while data acquisition and integration systems consolidate information from diverse sources. High-performance computing infrastructure and cloud platforms process and analyze the vast data streams. Simulation and modeling software build accurate virtual models, supported by advanced analytics and machine learning tools that enhance prediction and decision-making.

Visualization tools, including dashboards and 3D simulations, provide intuitive user interaction. Blockchain technology ensures data security and transparency, while cybersecurity frameworks protect DT systems from evolving threats. Edge computing enables low-latency data processing close to the source, and standardized communication protocols ensure seamless interoperability across systems. High-resolution imaging technologies like LiDAR and 3D scanning create detailed models, and advanced databases manage the large and dynamic datasets.

Together, these elements form the foundation of effective digital twin systems, driving innovation and efficiency across industries such as manufacturing, healthcare, infrastructure, and smart cities.

3.1. Sensors and IoT Devices

Sensors and Internet of Things (IoT) devices are essential for Digital Twin (DT) systems. They gather real-time data from physical assets, enabling accurate monitoring and analysis. Key parameters like temperature, pressure, vibration, and environmental conditions are captured by these devices, providing critical inputs for DT models [

24].

Sensors link the physical and digital worlds by transmitting data to DT systems for processing and analysis. For instance, temperature sensors in manufacturing system detect temperature changes, allowing DT models to simulate equipment performance and predict potential issues [

7]. Similarly, the accelerometer can identify unusual patterns in machinery, offering early warnings for mechanical failures [

14].

Accuracy is vital for reliable DT systems. High-quality sensors reduce data errors, ensuring digital models mirror their physical counterparts effectively [

15]. In healthcare, wearable IoT devices track heart rate and blood pressure. These real-time readings help digital twins support timely medical decisions [

10].

Reliability is equally important, especially in safety-critical industries. Faulty sensors can cause incorrect predictions or delays, leading to significant issues. For example, smart city systems use environmental sensors to track air quality. Accurate data enables timely actions like adjusting traffic flows or deploying air-purification measures [

12]. Dependable sensors ensure smooth system operations and informed decision-making [

20].

3.2. Data Acquisition and Integration Systems

Robust data acquisition and integration are fundamental to the operation of Digital Twin (DT) systems. These processes involve consolidating data from diverse sources, including IoT devices, enterprise systems, and historical datasets, each provides essential information for accurate system representation [

1].

IoT devices capture real-time physical-world conditions through sensors, measuring variables like temperature, pressure, and movement. This continuous stream of data enhances the DT's precision in mirroring its physical counterpart and providing up-to-the-minute insights into system performance [

1,

24].

Enterprise systems, such as Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and supply chain management tools, contribute critical operational and transactional data. This integration provides a comprehensive view of an organization's operations, thereby improving efficiency and decision-making [

26,

27].

Historical datasets, containing past records, trends, and performance patterns, further enhance DT capabilities. By supporting predictive analytics, these datasets enable the identification of potential future outcomes. Combining historical data with real-time data strengthens forecasting accuracy and decision support systems [

1,

6].

Integrating these diverse data sources necessitates advanced integration tools. These tools ensure seamless communication and data flow between different components, minimizing delays and bottlenecks to facilitate real-time data processing [

27]. A key aspect of this integration is data harmonization, which standardizes varying data formats from different systems to ensure compatibility and accessibility for analysis. This process enhances interoperability across platforms and devices [

28].

The ability to perform real-time data analysis, enabled by seamless integration, is crucial for DT performance. This capability allows for the immediate detection of anomalies, prediction of failures, and optimization of operations. This is particularly valuable in industries like manufacturing, healthcare, and logistics, where timely decisions can significantly impact efficiency and safety [

29].

Finally, effective data acquisition and integration, achieved through the consolidation of data from IoT devices, enterprise systems, and historical records, provides organizations with a comprehensive, real-time view of their operations. Advanced integration tools are essential in this process, facilitating efficient analysis and informed decision-making [

30].

3.3. Computational Infrastructure

High-performance computing (HPC) infrastructure plays a vital role in managing the enormous volumes of data generated by digital twin (DT) systems. These systems produce and analyze data at an extraordinary rate, making robust computing capabilities indispensable [

31]. HPC provides the processing power required to handle such large-scale operations efficiently, ensuring the effective simulation, analysis, and optimization of complex systems [

32].

Cloud computing platforms, including widely recognized services such as Amazon Web Services (AWS), Microsoft Azure, and Google Cloud, offer significant advantages in addressing these computational demands [

33]. These platforms are designed to provide scalable resources for both data storage and analysis [

34]. Their scalability is a key feature, as it allows organizations to expand their computational capacity on demand without the need for substantial upfront investment in physical infrastructure [

35]. This flexibility enables businesses to adapt to varying workloads and operational requirements, making cloud solutions an attractive option for supporting DT systems [

36].

In addition to storage and analysis, cloud platforms provide a wide array of advanced tools and services. These include machine learning capabilities, data visualization tools, and specialized analytics engines, which enhance the ability of organizations to extract actionable insights from their data [

37]. With these resources, businesses can streamline operations, improve decision-making, and achieve higher levels of efficiency in managing DT systems [

38].

3.4. The Role of Simulation and Modeling Software in Digital Twin Systems

Simulation and modeling software are essential for digital twin (DT) systems. These tools create virtual replicas of physical assets, enabling detailed analysis, real time simulations, and performance monitoring [

4]. By accurately replicating real world objects, they help organizations to optimize operations, reduce costs, and enhance decision-making [

24]. Their integration is crucial for ensuring DT systems deliver reliable and valuable insights [

32]

Popular platforms in this domain include ANSYS, Siemens NX, and MATLAB [

39]. Each offers unique capabilities suited to various industries. ANSYS provides extensive simulation tools for structural analysis, fluid dynamics, and thermal simulations [

34]. Siemens NX supports product design, engineering, and manufacturing, making it popular in automotive and aerospace industries [

4]. MATLAB excels in numerical computing, data analysis, and system modeling, making it valuable for research and development.

A major strength of these platforms is their ability to combine physics-based models with data-driven approaches [

24]. Physics-based models simulate real-world phenomena using established scientific principles [

15]. They help understand system behaviors, such as stress distribution in materials or fluid flow in pipelines [

39]. However, real-world systems are complex, requiring additional insights beyond physics alone [

6].

Data-driven techniques complement traditional modeling methods by incorporating machine learning and artificial intelligence. These tools analyze large volumes of historical and real-time data, identifying patterns, trends, and anomalies that may not be visible through conventional simulations [

9]. This integration of physics-based accuracy with data-driven insights enhances predictive capabilities, improving the reliability of DT systems.

Real-time simulation capabilities are another key feature of these tools [

1]. By linking digital models to live data from sensors and IoT devices, organizations can continuously monitor physical assets [

40]. This real-time connectivity supports proactive decision-making, allowing early detection and resolution of potential issues before they escalate [

24]. For example, real-time simulations can identify equipment wear, optimize maintenance schedules, and minimize downtime [

32].

Simulation and modeling software also play a critical role in product design and testing [

15]. Virtual prototypes enable engineers to explore different designs, materials, and configurations without the cost and time associated with physical prototyping [

32]. This speeds up the development process and encourages innovation by allowing the testing of unconventional solutions [

6].

3.5. Analytics and Machine Learning (ML) Tools

Advanced analytics and machine learning (ML) tools are essential for processing data derived from digital twin (DT) models. These tools transform raw data into actionable insights through advanced computational techniques [

9]. ML algorithms can accurately identify patterns within data, detect anomalies for early issue identification, and predict future outcomes based on historical trends and real-time inputs [

24]. These capabilities enhance decision-making and operational efficiency in various industries.

The ability to uncover patterns in data provides immense value across multiple sectors. By analyzing complex datasets, ML algorithms reveal trends that may not be immediately apparent through traditional methods, enabling evidence-based decision-making [

32]. Additionally, detecting anomalies in operational data allows organizations to proactively address potential risks or inefficiencies, reducing downtime and improving system reliability [

41].

Predictive maintenance is one of the most impactful applications of ML tools in digital twin environments. ML models use data from DT simulations to anticipate equipment failures before they occur, enabling organizations to schedule maintenance at optimal times [

15]. By understanding the conditions under which failures are likely to happen, businesses can minimize disruptions to operations, extend the lifespan of machinery, and reduce maintenance costs by avoiding unnecessary repairs [

40].

Another key application of these tools is the process optimization. ML algorithms analyze data from digital twins to identify inefficiencies in workflows, resource allocation, or system configurations [

4]. By providing data-driven recommendations, these tools help organizations streamline operations, reduce waste, and improve productivity. This is particularly crucial in industries where precision and efficiency determine competitiveness and profitability [

37].

Operational efficiency is further enhanced by ML-driven analytics. Continuous real-time data analysis offers organizations a clear view of current performance, helping optimize resource utilization, support informed decision-making, and adapt quickly to changing conditions [

42]. By leveraging these capabilities, businesses can ensure sustained operational excellence and long-term success [

1].

Advanced analytics and ML tools are foundational for getting predictive and prescriptive insights from digital twin models. Their ability to identify patterns, detect anomalies, and predict outcomes with high accuracy makes them indispensable across various applications [

9]. Whether improving predictive maintenance, optimizing processes, or enhancing operational efficiency, these tools empower organizations to maximize the value of their data. By harnessing ML-enhanced analytics, businesses can achieve greater reliability, efficiency, and performance in their operations [

27].

3.6. Visualization Tools

Visualization tools are essential for intuitive interaction with digital twin (DT) models, bridging the gap between complex datasets and actionable insights [

23]. These tools simplify data interpretation, enabling informed decision-making through user-friendly interfaces [

43,

44].

Key features include dashboards, which consolidate data streams into a single view for real-time monitoring, anomaly identification, and efficiency evaluation [

32,

45,

46]. 3D simulations, which replicate physical systems in virtual environments for in-depth analysis and risk-free experimentation [

9,

15,

47,

48].

Augmented reality (AR) interfaces enhance interaction by overlaying digital information onto the physical world, improving efficiency in operations [

1,

43,

49]. Platforms like Unity, Unreal Engine, and specialized AR frameworks support these advanced visualization capabilities. Unity and Unreal Engine are used for realistic 3D simulations in industries like manufacturing and automotive [

39,

45,

50]. Specialized AR platforms integrate with IoT devices for visually engaging, real-time insights, enhancing situational awareness [

1,

49,

51].

The ability to visualize system performance has broad implications across industries. In manufacturing, it improves production line monitoring; in healthcare, it advances training and surgical simulations [

48,

49] and in infrastructure management, it aids in planning and maintenance [

47].

In conclusion, visualization tools transform complex data into actionable insights via dashboards, 3D simulations, and AR interfaces [

45]. Platforms like Unity, Unreal Engine, and specialized AR frameworks empower effective user engagement with virtual environments [

49]. These tools enhance decision-making, streamline operations, and drive innovation across industries, with their role expanding as technology evolves [

9,

52].

3.7. Blockchain Technology

Blockchain enhances data security and transparency in digital twin (DT) systems by creating immutable transaction records, ensuring data integrity [

53,

54,

55].

Blockchain secures sensitive data in sectors like healthcare and supply chain management, preventing unauthorized access [

55,

56,

57,

58]. It also provides transparency through a decentralized ledger, allowing stakeholders to trace data history [

55,

59]. This is valuable in collaborative environments like smart energy grids [

60].

By providing a single source of truth and verifying transactions through consensus mechanisms, blockchain enhances trust and accountability [

55,

58,

61]. Its immutability creates a robust audit trail, useful in supply chains for resolving disputes [

61]. Smart contracts can automate processes, such as payment release upon delivery verification, streamlining operations [

58,

62,

63].

In conclusion, blockchain improves data security, transparency, trust, and accountability in DT systems. Its immutable records and decentralized nature support secure, efficient, and trustworthy operations across diverse industries [

54,

55,

62].

3.8. Cybersecurity Frameworks

As connectivity grows, cybersecurity is a vital concern for digital twin (DT) systems, which are vulnerable to cyber threats due to constant data exchange, [

44,

63]. Robust cybersecurity measures are essential to ensure their reliability and safety [

45], A comprehensive security framework is crucial for protecting DT systems and ensuring data confidentiality and integrity [

65,

66,

67].

Key components include encryption, which secures data during transmission and storage [

44,

68,

69], and access control, which defines and manages user access through methods like role-based access controls and multi-factor authentication [

63,

65,

70]. Real-time threat detection using machine learning and AI is also essential for identifying and responding to potential threats [

66,

67,

69,

70].

The importance of cybersecurity spans industries, including manufacturing, healthcare, and energy, where cyberattacks could have severe consequences [

65,

66,

70].

Implementing strong cybersecurity measures also builds trust among stakeholders, which is essential for the adoption and growth of DT technologies [

63,

67].

In conclusion, cybersecurity is critical for DT systems. Robust frameworks with encryption, access control, and real-time threat detection are necessary to protect data, ensure reliable operations, and foster trust. The importance of strong security measures will only increase as cyber threats evolve [

44,

65]

3.9. Edge Computing Devices

Edge computing devices process data locally, reducing reliance on centralized cloud infrastructure and improve response times for real-time applications [

71,

72].

DT systems with real-time processing needs benefit from edge computing, which processes data closer to its source (sensors, IoT devices) instead of relying on a centralized cloud [

71,

73]. This reduces latency, which is crucial for applications like autonomous vehicles, industrial automation, and healthcare monitoring [

9,

71,

73]. Edge computing also alleviates network strain and reduces data transfer, enhancing efficiency and lowering costs [

71]. Edge solutions can operate in areas with limited connectivity [

71].

Cloud computing handles large-scale data storage and long-term trend monitoring, while edge computing provides immediate processing and low-latency responses [

71,

72]. This combination allows organizations to maximize their DT systems' potential [

9].

3.10. Digital Communication Protocols

Standardized communication protocols are essential for effective interoperability among digital twin (DT) system elements [

76]. They facilitate seamless data exchange between physical assets, IoT devices, and digital models across diverse platforms [

77]. This efficient communication enhances the scalability and flexibility of DT implementations [

77]. Standardized protocols create a common language for data exchange [

78], which is crucial because DT ecosystems often comprise systems from various manufacturers and frameworks [

79]. Without standardization, these systems may struggle to communicate, leading to inefficiencies or compatibility issues [

80]. Protocols like MQTT, OPC UA, and REST APIs bridge this gap, enabling effortless sharing among components [

51]. The following section reviews the commonly used digital communication protocols used in digital twin systems.

MQTT (Message Queuing Telemetry Transport) is widely recognized for its lightweight design and efficiency [

81]. It is particularly well-suited for IoT environments where bandwidth and resource constraints are common [

82]. MQTT operates on a publish-subscribe model, which enables devices to share data with minimal latency [

83]. This makes it an ideal choice for DT applications requiring real-time updates, such as monitoring equipment performance or tracking environmental conditions [

51].

OPC UA (Open Platform Communications Unified Architecture) is another key protocol for DT systems. Known for its versatility, OPC UA provides a robust framework for integrating industrial systems and devices [

80]. It supports platform independence, ensuring that components can exchange data regardless of the underlying hardware or software [

84]. Additionally, OPC UA offers built-in security features, such as encryption and authentication, making it a reliable choice for industries with strict security requirements [

85].

REST APIs (Representational State Transfer Application Programming Interfaces) further enhance interoperability by providing a standardized way for systems to interact over the web [

84]. REST APIs use simple HTTP methods to enable seamless communication between applications, devices, and DT modules [

85]. Their widespread adoption and simplicity make them an excellent choice for integrating modern DT systems with cloud services and third-party platforms [

51].

Standardized communication protocols are essential for effective interoperability among digital twin (DT) systems [

76]. They facilitate seamless data exchange between physical assets, IoT devices, and digital models across diverse platforms [

77] .This efficient communication enhances the scalability and flexibility of DT implementations [

77]. Standardized protocols create a common language for data exchange [

78], which is crucial because DT ecosystems often comprise systems from various manufacturers and frameworks [

79]. Without standardization, these systems may struggle to communicate, leading to inefficiencies or compatibility issues [

80]. Protocols like MQTT, OPC UA, and REST APIs bridge this gap, enabling effortless information sharing among components [

51].

Standardized protocols contribute to the scalability of DT implementations, allowing for the addition of new elements without major overhauls [

84]. They also provide flexibility for DT systems to adapt to changing requirements, integrate new technologies, and support evolving business needs [

85,

89,

90].

3.11. High-Resolution Imaging and Scanning Equipment

Technologies like LiDAR, 3D scanners, and high-resolution cameras are crucial for creating detailed virtual models, which are fundamental to digital twin (DT) systems [

91,

92]. These tools capture the physical attributes of objects, spaces, and environments, enabling the development of accurate and reliable virtual representations [

90].

LiDAR uses laser beams to measure distance and build clear 3D models, even when lighting conditions changes [

92,

93,

94,

95].

3D scanners use laser or structured light to create detailed 3D models, which are essential in manufacturing industries for applications such as reverse engineering and quality control [

90], [

91,

96,

97].

High-resolution cameras capture visual details like texture and color, enhancing the realism of virtual models, particularly in applications like VR simulations [

90].

In infrastructure modeling, LiDAR and 3D scanners aid in visualizing projects and optimize designs, contributing to cost savings and efficiency [

98,

99]. In healthcare, 3D scanning is revolutionizing diagnostics and treatment planning by enabling the creation of detailed models of the human body [

100,

101].

These technologies also benefit other industries. LiDAR is used in entertainment and gaming to develop lifelike digital environments, while 3D scanners help preserve artifacts in archaeology and enable virtual try-on experiences in retail [

99].

In conclusion, LiDAR and 3D scanners are essential for developing detailed virtual models by capturing precise physical attributes. Their role in creating realistic and reliable digital representations is transforming industries and driving innovation [

90].

3.12. Advanced Databases

Advanced database systems are essential for managing the vast datasets required by digital twin (DT) systems and support their complex operations [

102]. Modern databases offer features like scalability, reliability, and performance to handle the diverse data demands of DT systems.

Distributed databases, such as Cassandra and MongoDB, are commonly used in DT implementations for their ability to handle large data volumes across multiple servers, ensuring scalability and fault tolerance [

103,

104,

105,

106,

107]. Cassandra is well-suited for high availability and write-heavy workloads, like those in IoT-based DT systems [

103,

104]. MongoDB offers a flexible schema design for handling diverse datasets, simplifying the mapping of physical assets to virtual models [

91,

108,

109,

110]. Time-series databases, like InfluxDB, are crucial for DT systems that rely on real-time data, such as sensor monitoring [

111,

112]. They efficiently handle time-stamped data, which is essential for DT systems monitoring dynamic environments [

102,

112]. The integration of distributed and time-series databases supports hybrid storage solutions, optimize the performance of DT systems [

102,

109,

111].

Advanced databases contribute to the scalability and flexibility of DT systems and support analytics and visualization tools, enabling stakeholders to gain actionable insights [

104,

108,

110], [

111,

112,

113]. This integration enhances decision-making, operational efficiency, and system reliability across industries [

113,

114].

4. Comprehensive Applications of Digital Twins

Digital twin technology is reshaping industries by creating virtual models of physical assets. It enables real-time monitoring, simulation, and predictive analytics. Key applications include predictive maintenance to reduce failures and downtime, and process optimization to boost efficiency in manufacturing, healthcare, and logistics.

In design and prototyping, digital twins allow rapid testing before production, cutting costs and improving quality. Healthcare uses them for personalized treatments, improving outcomes. Urban planning and infrastructure benefit through better traffic flow, city layouts, and public service management.

Energy management leverages digital twins for smarter, cleaner, and more resilient systems. They also support risk-free training in fields like healthcare and aviation. Autonomous systems, such as self-driving cars and robotics, rely on digital twins for learning and operational improvements.

Supply chain and logistics use digital twins for real-time tracking, forecasting, and inventory control. Aerospace and automotive industries apply them for design, structural assessments, and maintenance. Utilities improve grid stability and efficiency with their help.

In engineering fields, digital twins strengthen building resilience, hospital operations, and industrial automation. They also enhance operations in oil and gas, marine engineering, transportation, and smart grids, driving better monitoring, maintenance, and performance.

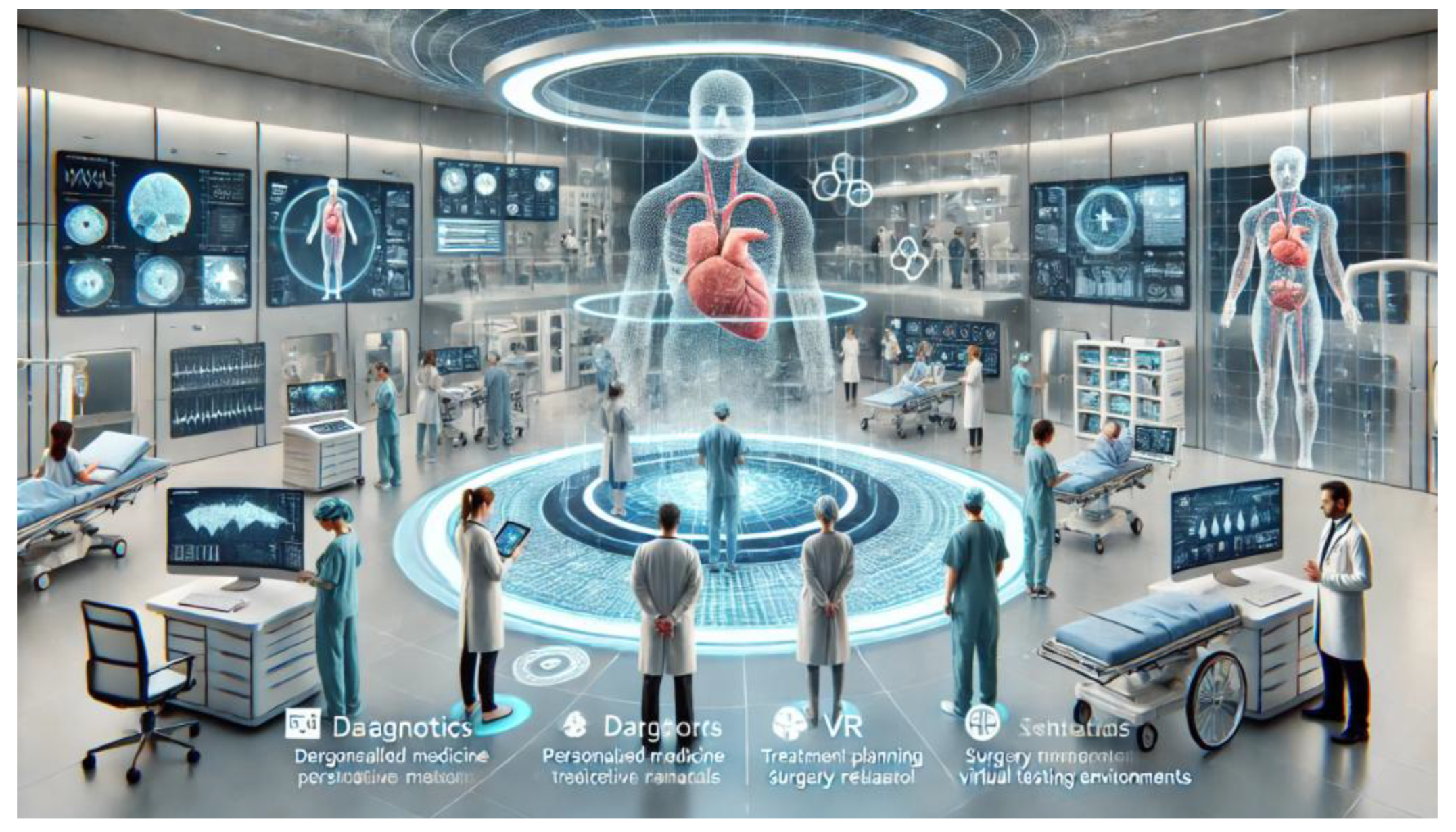

4.1. DT in Personal Medicine

Digital Twins (DTs) are transforming healthcare by creating dynamic virtual replicas of physical entities. These models integrate real-time data, simulations, and predictive analytics to improve medical outcomes. They play a key role in personalized medicine, clinical decision-making, and public health management. This study explores DTs by examining their applications, underlying technologies, benefits, and challenges. By analyzing these aspects, we aim to understand their impact on modern healthcare and their potential to improve patient care.

Figure 2 shows how DT is used to present the personalized medicine.

Applications of DT in Personal Medicine

Digital Twins (DTs) have found diverse applications across healthcare, fundamentally transforming approaches from individualized patient care to public health interventions. Kamel Boulos & Zhang discuss DTs' potential in personalized diagnostics and preventive medicine, demonstrating their effectiveness through real-time integration of data from electronic health records (EHRs), genomics, wearable devices, and environmental sensors [

124]. This integrative approach enables accurate silico simulations to predict disease progression and tailor treatment outcomes effectively.

Papachristou et al. extend this application scope by introducing Digital Human Twins (DHTs), which are detailed virtual representations of individual physiological characteristics [

125]. They underscore DHTs' practical utility in precision cardiology, diabetes management, and virtual surgical planning, enhances both safety and precision. Similarly, Sahal et al. discuss Personal Digital Twins (PDTs), emphasize their unique integration of biological, mental, physical, and social data [

131]. PDTs demonstrate significant advantages in COVID-19 management, osteoporosis prevention, and cancer treatment through improved diagnostic accuracy and disease prevention.

Okegbile et al. explore Human Digital Twins (HDTs), focusing on proactive disease diagnosis, personalized treatment regimens, and surgical simulations [

132]. They underline the importance of proactive health monitoring and individual care. Complementing these insights, Venkatesh et al. highlight how HDTs extend beyond personal care into virtual clinical trials and public health management, notably in addressing public health crises like COVID-19 [

133].

Underlying DT Technologies used in Personal Medicine

Digital Twins rely on advanced technological infrastructure, including artificial intelligence (AI), big data analytics, the Internet of Things (IoT), cloud computing, and virtual reality (VR). Armeni et al. and Cellina et al. specifically recognize AI and big data analytics as crucial elements enhancing DTs' predictive accuracy and simulation capabilities [

128,

137]. These technologies enable applications such as virtual clinical trials which significantly reduce reliance on human participants and address related ethical concerns.

Gaebel et al. introduced a modular, multi-layered approach employing natural language processing (NLP) and machine learning (ML) for integrating heterogeneous medical data [

127]. This technology significantly improves the scalability and flexibility of clinical decision support systems (CDSS). Similarly, Papachristou et al. emphasize the importance of IoT, cloud computing, and VR in real-time data collection and analysis within DHTs, enhance the effectiveness of these digital representations [

125].

Additionally, Sahal et al. and Okegbile et al. highlight blockchain technology alongside AI and IoT for secure data management [

131,

132]. They stress ultra-reliable, low-latency communications (URLLC) as vital for real-time synchronization between physical and virtual entities, ensure accuracy and timeliness in data-driven healthcare decisions.

Benefits of Using DT in Personal Medicine

Digital Twins offer extensive benefits, prominently improving clinical decision-making, patient outcomes, and public health management. Sun et al. highlight DTs' significant impact on clinical decision-making by simulating disease progression accurately and predicting treatment outcomes, thus enabling more timely and effective interventions [

115]. This capability enhances patient outcomes and reduces overall healthcare costs.

Abd Elaziz et al. further underscore DTs’ role in disease prediction, early diagnosis, and optimized treatment strategies [

116]. These capabilities lead to improved patient engagement, substantial cost savings, and higher-quality care. Moreover, Papachristou et al. note the use of DTs in surgical planning, reducing complications through virtual simulations, thus enhance patient safety [

125].

DTs also improve patient engagement by offering individualized health insights, fostering proactive health management. Venkatesh et al. emphasize the role of DTs during public health crises such as COVID-19, highlighting how DTs enable better resource allocation and effective risk assessment [

133]. Furthermore, Sahal et al. emphasize the holistic advantages of PDTs, delivering actionable insights for mental and nutritional health, ultimately contributing to overall well-being [

131].

Challenges Involved in the Use of DT in Personal Medicine

Despite their promising benefits, the adoption and implementation of Digital Twins in healthcare face numerous challenges. One of the most significant is data privacy, a critical issue consistently raised across the references reviewed. Kamel Boulos & Zhang, Papachristou et al., and Sahal et al. identify substantial privacy and ethical concerns related to digital representations of patients, data ownership, and biases in AI algorithms [

124,

125,

131]. Armeni et al. specifically warn of risks associated with inequitable healthcare delivery due to biases inherent in AI training datasets [

137].

Integration complexities and the lack of standardized data protocols are additional significant barriers. Okegbile et al. and Venkatesh et al. stress these integration challenges, noting the difficulty of managing heterogeneous data streams and ensuring seamless interoperability [

132,

133]. Additionally, computational demands and the need for robust technological infrastructure represent major technical hurdles. Meijer et al. emphasize the challenges in data standardization and management, highlighting the requirement for significant advancements in non-invasive data collection, computational modeling, and high-throughput analytics [

117].

Financial considerations also pose challenges, as Cellina et al. note the high costs associated with developing and maintaining DT infrastructures [

128]. Furthermore, evolving regulatory landscapes and clinical acceptance issues add complexity. Venkatesh et al. highlight concerns among clinicians regarding AI transparency and algorithmic reliability, stressing the importance of building clinician trust and developing robust regulatory frameworks [

133].

Digital Twins (DTs) hold significant promise for transforming healthcare through personalized medicine, clinical decisions, and public health. Their diverse applications and benefits position them as vital tools. However, realizing this potential requires addressing challenges like data privacy, integration, computational needs, and regulations. Overcoming these barriers through collaboration, research, and strong regulations is crucial for the successful adoption of DTs to improve patient outcomes and healthcare delivery.

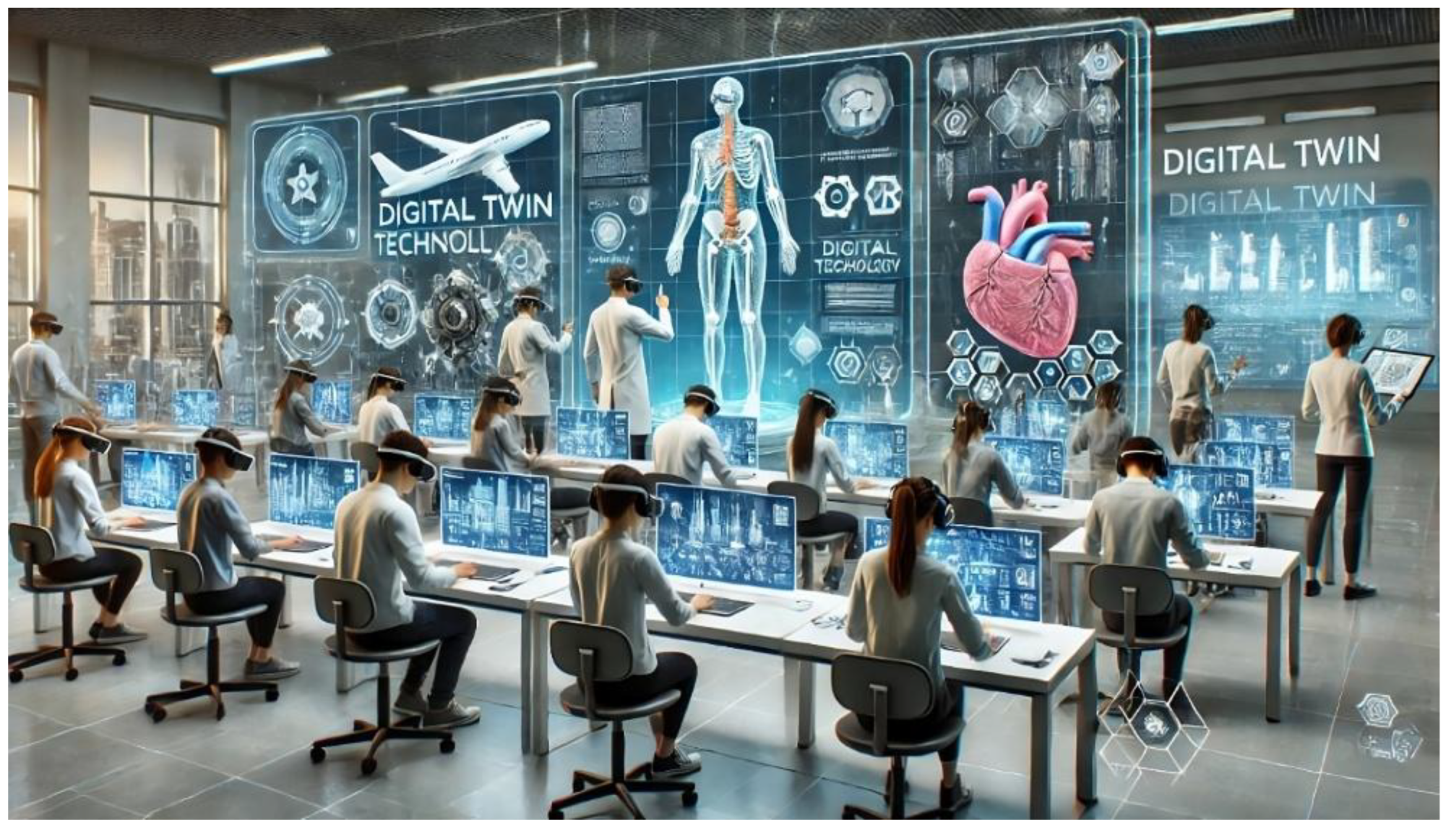

4.2. Applications of DT in Training and Education

Digital Twin (DT) technology is being widely adopted across diverse fields, including education, training, cybersecurity, and industry. While its primary goal is to improve efficiency, learning, and security, its implementation varies across domains. In education, DTs enhance hands-on learning experiences, while in safety training and cybersecurity, they strengthen preparedness and threat mitigation. Additionally, the integration of Augmented Reality (AR) and Virtual Reality (VR) further expands DT capabilities, creating immersive and interactive environments. The following study explores the different approaches to DT adoption, highlighting their role in advancing knowledge, security, and operational effectiveness.

Figure 3 shows the use of DT in immersive learning.

Educational Applications of Digital Twin

Zhou et al. and Kuhn et al. explore the role of DT in education and training, using different methodologies and target audiences [

118,

119]. Zhou et al. investigate how AR enhanced chemical engineering education by allowing students to visualize and interact with complex chemical processes [

118]. The integration of AR and Computational Fluid Dynamics (CFD) simulations helps in understanding airflow dynamics and internal structures of laboratory equipment. The study highlights that AR-driven learning improves engagement, reduces safety risks, and enhances students' technical proficiency.

In contrast, Kuhn et al. focus on a modular DT training system designed to bridge the digital skills gap for non-technical individuals in industrial environments [

119]. Their framework uses low-cost, hands-on training modules equipped with microprocessors, sensors, and actuators, helping participants learn data analysis, real-time monitoring, and system optimization. Unlike Zhou et al., which integrates AR for immersive learning, Kuhn et al. emphasize a progressive learning approach, allowing users to gradually build DTs using open-source tools like Unity and Node-Red [

118,

126]. Both studies highlight DT’s educational benefits, Zhou et al. is more focused on visualization, whereas Kuhn et al. offers a structured, hands-on approach for broader digital competency development [

118,

119].

Digital Twin for Safety and Training

Speiser & Teizer and Martínez-Gutiérrez et al. focus on DT applications in training, particularly in safety-critical environments [

120,

121]. Speiser & Teizer present the Digital Twin for Construction Safety (DTCS) framework, which generates personalized safety training environments using real-time construction data [

120]. The system automatically updates training scenarios to match evolving site conditions, allowing trainers to tailor safety lessons based on specific risks present at the worksite. The study emphasizes the importance of hazard recognition and risk-based decision-making in dynamic construction environments.

Martínez-Gutiérrez et al. explore the combination of DT and VR for industrial operator training [

121]. Their study assesses how VR-based training compares with traditional equipment-based training and computer-based training. Results show that while real-equipment training provides the highest skill improvement (47%), VR-based training achieves a significant 38% improvement while reducing costs and safety risks. VR enhances situational awareness and allows workers to practice in high-risk scenarios without real-world dangers.

The key difference is that Speiser & Teizer apply DT to dynamically update and personalize training, while Martínez-Gutiérrez et al. focus on VR as a cost-effective alternative to physical equipment training [

120,

121].

Cybersecurity Applications in Digital Twin

Unlike the other studies that focus on education and training, Kandasamy et al. investigates DT’s role in cybersecurity research [

122]. Their study introduces the EPIC DT, a digital replica of an electric power microgrid designed for cybersecurity testing. Traditional physical testbeds are expensive and difficult to scale, whereas the EPIC DT provides a cost-effective alternative for simulating cyberattacks, testing defense mechanisms, and developing intrusion detection systems (IDS). Developed platform supports multiple communication protocols, including MMS, GOOSE, MQTT, and Modbus, allowing researchers to evaluate vulnerabilities across different smart grid components.

A key contribution of this study is the development of tools like the Attack Designer (AD) and Attack Launcher (AL), which systematically deploy cyberattacks, such as man-in-the-middle (MITM) attacks, to assess the resilience of smart grid security measures. The study highlights how DTs enable extensive cybersecurity research without risking live infrastructure.

Unlike the other references, which focus on improving education, workforce skills, or safety, Kandasamy et al. emphasize DT’s application in cyber defense, demonstrating its significance in securing critical infrastructure [

122].

Key Differences in Implementation and Technologies Among the Representative Articles

Each study integrates different technological solutions to enhance DT’s effectiveness in its respective applications. Zhou et al. incorporates AR and CFD simulations to improve visualization in education, while Kuhn et al. focus on a hands-on modular learning approach using IoT-based tools [

118,

119]. Speiser & Teizer use real-time construction data and game engine technology (Unity) to create personalized training scenarios, whereas Martínez-Gutiérrez et al. leverage VR for immersive learning experiences [

120,

121].

Kandasamy et al. take a completely different approach, focusing on cybersecurity and using DT to simulate real-world cyberattacks [

122]. Their study integrates cybersecurity-specific tools like the Attack Designer and various communication protocols, making it the only reference that applies DT to security and infrastructure protection rather than education or training.

Another notable contrast is in automation and real-time adaptation. Speiser & Teizer and Kandasamy et al. emphasize automation, with the former dynamically generating training environments and the latter simulating real-time cyberattacks [

120,

122]. In contrast, Zhou et al. and Kuhn et al. focus more on structured learning experiences, with predefined exercises and step-by-step training approaches [

118,

119].

While all studies explore DT applications, their focus areas and technological implementations vary significantly. Some studies emphasize immersive technologies like AR (Zhou et al.) and VR (Martínez-Gutiérrez et al.), while others prioritize hands-on training for digital literacy (Kuhn et al.) or real-time hazard awareness (Speiser & Teizer) [

118,

119,

120,

121]. Kandasamy et al. stands out by focusing on cybersecurity, demonstrating DT’s potential beyond training and education [

122].

Despite these differences, all studies highlight the transformative potential of DT technology in their respective fields. Whether improving education, enhancing safety, training workers, or securing infrastructure, DT continues to be a versatile tool driving innovation across industries. Future research may explore the convergence of these applications, such as integrating cybersecurity awareness into DT-based training or using VR-enhanced DT models for both industrial education and security testing.

4.3. Applications of DT in Design and Optimization

Digital twin technology in design and optimization leverages AI, IoT, simulation, and cloud computing to create virtual replicas of physical systems. It enables real-time performance analysis, predictive simulations, and iterative design improvements, reduce development time and costs. By integrating data-driven insights, digital twins optimize product lifecycles, structural integrity, and energy efficiency. These applications enhance decision-making, streamline manufacturing, and drive innovation across various industries. The following sections analyze the application of DT in design and optimization from different prospectives.

Figure 4 shows the use of DT for Design and optimization in various sectors.

Application Domains of DT in Design and Optimization

The selected references present diverse applications of Digital Twin (DT) technology tailored to specific industry needs and objectives. Bellalouna focuses on product design optimization, aiming to reduce material usage and improve structural efficiency through precise stress simulations in an arbor press [

123]. Conversely, Kalantari et al. apply DT in architectural design prototyping, aiming to bridge physical creativity with digital analytics through their Ph2D system, enhancing spatial understanding and energy performance [

124].

In facility management, Asare et al. utilize DT for predictive maintenance, integrated Building Information Modeling (BIM) and Internet of Things (IoT) to enhance decision-making, reduce costs, and improve maintenance efficiency [

125]. Sreedharan et al. target mining automation, employing DT and Industrial IoT (IIoT) to address safety, connectivity, and productivity challenges in mining operations, particularly in remote sites [

126].

Bellavista et al. explore adaptive DTs for digital factories, aiming to improve flexibility, resilience, and operational efficiency in Industry 4.0 environments [

127]. Sifat et al. focus on electric grid management, developing a DT framework for enhancing grid stability, predictive maintenance, and cybersecurity through advanced analytics [

128]. Lee et al. emphasize user-centric DT applications in building management, prioritizing occupant comfort, energy efficiency, and personalized environmental control [

129].

Innovations of DT in Design and Optimization

Selected studies employ specific technological frameworks that highlight DT versatility. Bellalouna integrates IoT platforms and Finite Element Analysis (FEA) to enable accurate real-time data collection and structural simulations [

123]. In contrast, Kalantari et al. leverage 3D printing, modular tiles, and digital analytical tools for real-time synchronization of physical and digital architectural prototypes [

124].

Asare et al. compare Autodesk Tandem and Unreal Engine combined with Microsoft Azure, evaluating their effectiveness in real-time data management and advanced visualization for facility maintenance [

125]. Sreedharan et al. adopt Business Process Modeling Notation (BPMN), mesh networking and simulation analytics to ensure reliable data transmission and robust decision-making support in harsh mining environments [

126].

Bellavista et al. implement micro-services architecture coordinated by Kubernetes, using patterns like microkernel, sidecar, ambassador, and adapter to enhance scalability and adaptability in digital factories [

127]. Sifat et al. employ cloud platforms, machine learning algorithms, and bi-directional communication systems for dynamic grid optimization [

128]. Lee et al. integrate 3D visualization, AI-driven recommendations, and intuitive interfaces, significantly enhancing building management and occupant interactions [

129].

Challenges and Implementation Considerations of DT in Design and Optimization

Despite significant benefits, each reference identifies specific implementation challenges. Bellalouna emphasizes challenges related to sensor placement accuracy and data reliability crucial for effective structural optimizations [

123]. Kalantari et al. express concerns over simplifying complex architectural details and recommend refining digital functionalities for broader usability [

124].

Asare et al. highlight difficulties in system integration, scalability, data security, and managing costs associated with deploying advanced DT platforms in facility management [

125]. Sreedharan et al. note significant challenges due to poor connectivity, extreme environmental conditions, and integrating automated systems with traditional mining practices [

126].

Bellavista et al. acknowledge difficulties in managing real-time data processing and complexity in rapidly changing industrial contexts [

127]. Sifat et al. mention challenges in accurately modeling complex electric grid subsystems and ensuring robust cybersecurity measures [

128]. Lee et al. address challenges related to data privacy, intuitive user interface design, and balancing occupant comfort with energy efficiency in democratized building management systems [

129].

This comparative analysis among the prominent innovations emphasizes Digital Twins' extensive applicability, technological diversity, significant performance improvements, and implementation challenges across varied industries. Overcoming these challenges through innovative solutions and interdisciplinary collaboration will be critical to harness the full potential of Digital Twin technologies and promoting their broader adoption.

4.4. DT in Infrastructure and Urban Planning

Digital twin technology in infrastructure and urban planning employs IoT, AI, GIS, and simulation models to construct virtual replicas of cities and infrastructure systems. It enables real-time monitoring, predictive maintenance, and optimized resource management for smart cities and sustainable urban development. Applications include traffic flow optimization, energy efficiency planning, and disaster response simulations to enhance urban resilience. By integrating real-time data and analytics, digital twins improve decision-making and support the creation of more efficient, livable, and sustainable urban environments.

Application Domains of DT in Infrastructure and Urban Planning

The selected references cover diverse applications of Digital Twin (DT) technology across various urban and infrastructure domains. Wan et al. focus on city-level DT development, emphasizing policy-driven approaches and cross-sector data integration, particularly for smart infrastructure and urban planning [

130]. Their study, centered around Cambridge, highlights DT’s role in improving policy coordination across transport, housing, energy, and environmental sectors. Similarly, Abdeen et al. prioritize citizen engagement through Citizen-Centric Digital Twins (CCDTs), aiming to foster transparency and inclusivity in urban governance [

131].

In stormwater management, Sharifi et al. utilize AI-enhanced DTs to predict system performance and proactively optimize operations, demonstrate how DT can contribute to address urban environmental challenges [

132]. Bellalouna applies DT in product design optimization, notably in an arbor press, improving material efficiency and structural performance [

123]. Meanwhile, Gürdür Broo et al. and Marai et al. discuss DTs in smart infrastructure and road infrastructure management respectively, focusing on real-time monitoring and predictive maintenance to enhance resilience and operational efficiency [

133,

134]. Lastly, Ye et al. emphasize community resilience through human-centered Urban Digital Twins (UDTs), particularly for climate adaptation planning in vulnerable coastal areas [

135].

Figure 5 shows how DT can be used to facilitate the Infrastructure and Urban Planning.

Technological Specifications of DT in Infrastructure and Urban Planning

The selected references integrate various technological frameworks into their DT implementations. Wan et al. leverage data science and machine learning, complementing traditional urban theories, to enhance predictive capabilities [

130]. Abdeen et al. employ volunteered geographic information (VGI), remote sensors, machine learning algorithms, and Application Programming Interfaces (APIs) for dynamic, interactive management [

131]. Sharifi et al. utilize AI, machine learning (ML), deep learning (DL), and IoT sensors to enable accurate stormwater predictions and real-time system adjustments [

132].

Bellalouna incorporates IoT platforms, computer-aided design (CAD), and finite element analysis (FEA) for structural optimization, while Gürdür Broo et al. implement a multi-layered DT framework integrating sensors, data analytics, and visualization tools [

123,

133]. Marai et al. rely on IoT devices, edge computing, and advanced object detection algorithms for real-time road infrastructure monitoring [

134]. Ye et al. propose integrating big data, AI, and multi-agent interaction models within human-centered UDT frameworks to enhance decision-making and resilience [

135].

Benefits and Outcomes of DT in Infrastructure and Urban Planning

Implementing DT technology yields numerous benefits across these studies. Wan et al. demonstrate DT's effectiveness in identifying systemic urban risks and facilitating policy experimentation [

130]. Abdeen et al. report improved urban infrastructure governance through enhanced citizen participation and real-time responsiveness [

131]. Sharifi et al. highlight improved stormwater management, optimized resource allocation, and proactive maintenance through AI-enhanced DTs [

132].

Bellalouna achieves significant material reductions and structural efficiency improvements, emphasizing sustainability [

123]. Gürdür Broo et al. enhance infrastructure resilience, operational efficiency, and predictive maintenance through real-time data analytics [

133]. Marai et al. note improved road safety, optimized traffic management, and reduced operational risks, while Ye et al. emphasize enhanced community resilience and improved adaptation planning capabilities for climate risks [

134].

Challenges and Implementation Considerations of DT in Infrastructure and Urban Planning

Despite their advantages, these DT implementations face significant challenges. Wan et al. stress the necessity of aligning technical development with governance frameworks [

130]. Abdeen et al. highlight challenges related to data interoperability, crowd-sourced data quality, and advanced AI integration [

131]. Sharifi et al. discuss issues in data integration, model accuracy, and standardization within AI-powered DTs [

132].

Bellalouna emphasizes precise sensor placement, data synchronization, and real-time monitoring as critical challenges [

123]. Gürdür Broo et al. note data quality, system integration, and multidisciplinary collaboration as significant barriers [

133]. Marai et al. point out cybersecurity risks, high deployment costs, and limitations in detection accuracy under poor conditions [

134]. Ye et al. underline the complexity of integrating socio-environmental data, ensuring data privacy, and developing standardized methodologies [

135].

This comparative analysis among the selected articles highlights the diverse applications, robust technological frameworks, significant benefits, and notable challenges associated with Digital Twins across various urban infrastructure domains. Addressing these challenges through innovative approaches and interdisciplinary collaboration is essential for maximizing DT potential and fostering broader adoption in urban planning and infrastructure management.

4.5. DT in Transportation and Logistics

Digital twin technology in transportation and logistics integrates IoT, AI, and simulation models to optimize operations and decision-making. It enables real-time tracking of fleets, predictive maintenance of vehicles, and route optimization to reduce delays and fuel consumption. In logistics, digital twins enhance warehouse automation, supply chain resilience, and demand forecasting through data-driven simulations. These applications improve efficiency, reduce costs, and enhance sustainability in transportation networks.

Figure 6 presents the applications of DT in Transportation and Logistics.

Application Domains of DT in Transportation and Logistics

The selected references demonstrate diverse applications of Digital Twin (DT) technology across various logistics and manufacturing domains, addressing specific operational challenges and objectives. Cuñat Negueroles et al. focus on logistics and transportation, integrating blockchain with DT to improve data security, traceability, and operational efficiency in vehicle fleet management and supply chain processes [

136]. Z. Zhang et al. target open production logistics, using DT and blockchain to enhance trusted synchronization and dynamic decision-making in manufacturing environments [

137].

L. Zhang et al. address crowdsourcing logistics, combining DT with a four-party evolutionary game model to optimize logistics operations amongst e-commerce growth [

138]. Hong et al. aim to improve cross-enterprise synchronization in production-delivery processes, leveraging DT to coordinate manufacturers and third-party logistics providers (3PLs) effectively [

139]. Zhao et al. apply DT to production logistics resource allocation, introduce dynamic spatial-temporal knowledge graphs to enhance efficiency [

137]. Coelho et al. focus on in-house logistics, employing DT combined with simulation-based decision support tools to optimize warehousing, material handling, and order picking [

140]. Greif et al. concentrate on construction site logistics, specifically bulk material supply, proposing a lightweight DT model to improve operational efficiency and resource management [

141].

Technological Specifications of DT in Transportation and Logistics

Each selected reference employs distinct technological frameworks within their DT implementations. Cuñat Negueroles et al. integrate blockchain technology with DT, using FIWARE, Ethereum-based Canis Major, Orion Context Broker, and KrakenD API Gateway to ensure secure data flow and immutability [

136]. Z. Zhang et al. combine blockchain for secure resource management with DT for real-time monitoring and control, utilizing analytical target cascading (ATC) for synchronization decisions [

142].

L. Zhang et al. integrate DT with evolutionary game theory and multi-agent reinforcement learning, employing blockchain for data transparency and predictive analytics for strategic decision-making [

138]. Hong et al. develop a DT-based bidirectional interactive synchronization mechanism, including distributed decision-making models and optimization algorithms for dynamic cross-enterprise collaboration [

139]. Zhao et al. utilize DT technology with dynamic spatial-temporal knowledge graphs powered by deep neural networks, enabling real-time resource tracking and optimized allocation [

137].

Coelho et al. apply DT through simulation-based decision support using Simio software, creating virtual replicas of logistics systems for real-time monitoring and analysis [

140]. Greif et al. introduce lightweight DT models integrated with decision support systems (DSS) for continuous monitoring, predictive analytics, and optimized resource allocation in construction logistics [

141].

Benefits and Outcomes DT in Transportation and Logistics

DT implementations across these studies deliver substantial performance improvements. Cuñat Negueroles et al. demonstrate enhanced operational efficiency, reduced delays, and improved decision-making in freight transportation through blockchain-enabled DTs [

136]. Z. Zhang et al. report improved reliability, operational cost reductions, and increased adaptability in production logistics synchronization [

142].

L. Zhang et al. achieve system stability and efficiency in crowdsourcing logistics, discouraging dishonest behavior and improving logistics performance through predictive insights [

138]. Hong et al. highlight improved production-delivery coordination, cost efficiency, and system resilience under dynamic conditions, favoring bidirectional collaboration over traditional unidirectional models [

139]. Zhao et al. demonstrate optimized travel routes, reduced waiting times, and enhanced operational efficiency in production logistics resource allocation [

137].

Coelho et al. validate improved decision-making, bottleneck identification, and resource allocation accuracy in in-house logistics, enhancing operational productivity [

140]. Greif et al. show significant cost reductions, improved logistics planning, and enhanced sustainability in construction logistics through DT-based strategies, achieving a 25% decrease in truck-related costs [

141].

Implementation Considerations of DT in Transportation and Logistics

Despite their advantages, these DT implementations encounter various challenges. Cuñat Negueroles et al. emphasize scalability and data validation issues in centralized systems, highlighting the importance of blockchain integration [

136]. Z. Zhang et al. identify the need for interoperability and optimization of dynamic decision algorithms within complex logistics systems [

137].

L. Zhang et al. face challenges in refining incentive mechanisms and preventing behaviors like collusion and false reporting in crowdsourcing logistics [

138]. Hong et al. discuss difficulties related to data privacy, synchronization mechanisms, and dynamic disruption management between collaborating enterprises [

139]. Zhao et al. highlight challenges in real-time performance enhancement and dynamic disturbance incorporation in spatial-temporal logistics models [

137].

Coelho et al. recognize limitations due to reliance on simulated data and the need for integration with real-time systems and sustainability aspects in in-house logistics [

140]. Greif et al. acknowledge challenges in extending lightweight DT frameworks to broader low-tech industries and enhancing predictive analytics for dynamic decision-making [

141].

This comparative analysis among the selected articles underscores the transformative potential of Digital Twin technology across logistics and manufacturing sectors. Each study reveals significant operational improvements, highlighting DT's capability to enhance efficiency, security, and decision-making. Addressed implementation challenges through technological innovation, interdisciplinary collaboration, and advanced algorithm development will be crucial for maximizing DT's impact and achieving widespread industrial adoption.

4.6. DT application in Process Optimization

The selected references illustrate the extensive range of Digital Twin (DT) applications across diverse sectors, each targeting specific industrial or operational challenges. Zhou et al. focus on ironmaking, employing DT integrated with self-adaptive genetic algorithms (SAPGAs) to optimize blast furnace operations by reducing coke consumption and enhancing operational efficiency [

143]. Bellalouna applies DT to product design optimization, specifically for an arbor press, aiming to achieve material efficiency and precise structural performance through real-time operational data [

123]. Zheng et al. utilize DT technology to optimize oil and gas production, integrating real-time data, physical models, and intelligent algorithms to enhance production efficiency, reduce energy consumption, and extend asset life [

1].

Bayer et al. explore DT's potential in bioprocessing, combining digital twins with model-based design of experiments (DoE) to maximize bioprocess yields efficiently [

144]. Davies et al. implement DT for predictive maintenance of engineering assets, focusing on component degradation monitoring and maintenance optimization [

145]. Liu et al. adopt DT for process planning in manufacturing, emphasizing the reuse and real-time evaluation of machining processes [

146]. Lim et al. highlight DT's application in product family design and optimization, integrating context awareness to support dynamic industrial environments [

147].

Figure 7 shows the use of DT for Real-Time Supply Chain and Industrial Process Optimization.

Technological Specifications of DT in Process Optimization

The references exhibit diverse technological integrations within their DT frameworks. Zhou et al. (2020) combine SAPGAs with autoregressive moving average (ARMA) models, leveraging cloud-based platforms like Apache Spark for real-time analytics [

143]. Bellalouna integrates IoT sensors, computer-aided design (CAD), and finite element analysis (FEA) for structural optimization and material reduction [

123]. Zheng et al. employ multi-disciplinary, multi-scale models combined with IoT, artificial intelligence, and virtual/augmented reality to simulate and optimize oilfield operations [

1].

Bayer et al. utilize hybrid modeling techniques, combining mechanistic and data-driven approaches with iterative model validation for bioprocess optimization [

144]. Davies et al. incorporate simulation-based digital twins with mathematical degradation models and MATLAB-based dashboards for maintenance decision-making [

145]. Liu et al. implement a Digital Twin-based Process Knowledge Model (DT-PKM), integrating geometric information, process constraints, and real-time equipment data for dynamic process evaluation [

146]. Lim et al. propose a three-layer digital twin architecture comprising cyber-physical interaction, data processing, and knowledge computation layers. This architecture integrates IoT sensors, cloud computing, and big data analytics to enable context-aware product design. [

147].

Benefits and Outcomes of DT in Process Optimization

DT implementations across these studies demonstrate substantial performance improvements. Zhou et al. achieve a reduction in coke consumption during ironmaking by approximately 14 kg per ton of iron. This improvement enhances both the economic and environmental performance of the process. [

143]. Bellalouna achieves a 60% reduction in material use for an arbor press, enhancing design efficiency and sustainability [

123]. Zheng et al. report increased oilfield efficiency, reduced energy costs, and improved production predictions through digital twin optimization [

1].

Bayer et al. demonstrate efficient bioprocess optimization, significantly reduces experimental efforts from twenty-seven to nine experiments while maximizing yields [

144]. Davies et al. effectively predict the remaining useful life (RUL) of engineering components, supporting proactive maintenance and reduced downtime [

145]. Liu et al. enhance manufacturing efficiency, tripling process planning speed and increasing process knowledge reuse by over 60% [

146]. Lim et al. enhance operational safety and efficiency in smart manufacturing by implementing context-aware asset optimization. This approach effectively addresses supply chain and operational disruptions [

147].

Implementation Considerations of DT in Process Optimization

Despite these benefits, the references identify various challenges. Zhou et al. highlight occasional deviations due to abnormal conditions and the need for robust anomaly handling in optimization frameworks [

143]. Bellalouna emphasizes challenges in precise sensor placement and data synchronization for accurate DT operation [

123]. Zheng et al. note challenges in model accuracy, data integration, and adapting complex digital twins to diverse oilfield conditions [

1].

Bayer et al. discuss challenges related to model bias and reliability in higher-dimensional design spaces for bioprocessing [

144]. Davies et al. acknowledge limitations due to reliance on simulated data, suggesting the need for validation with real-world assets [

145]. Liu et al. identify limited application scope and the requirement for robust data acquisition systems [

146]. Lim et al. point out challenges associated with cyber-physical synchronization and the transition from lab-based simulations to real-world applications [

147].