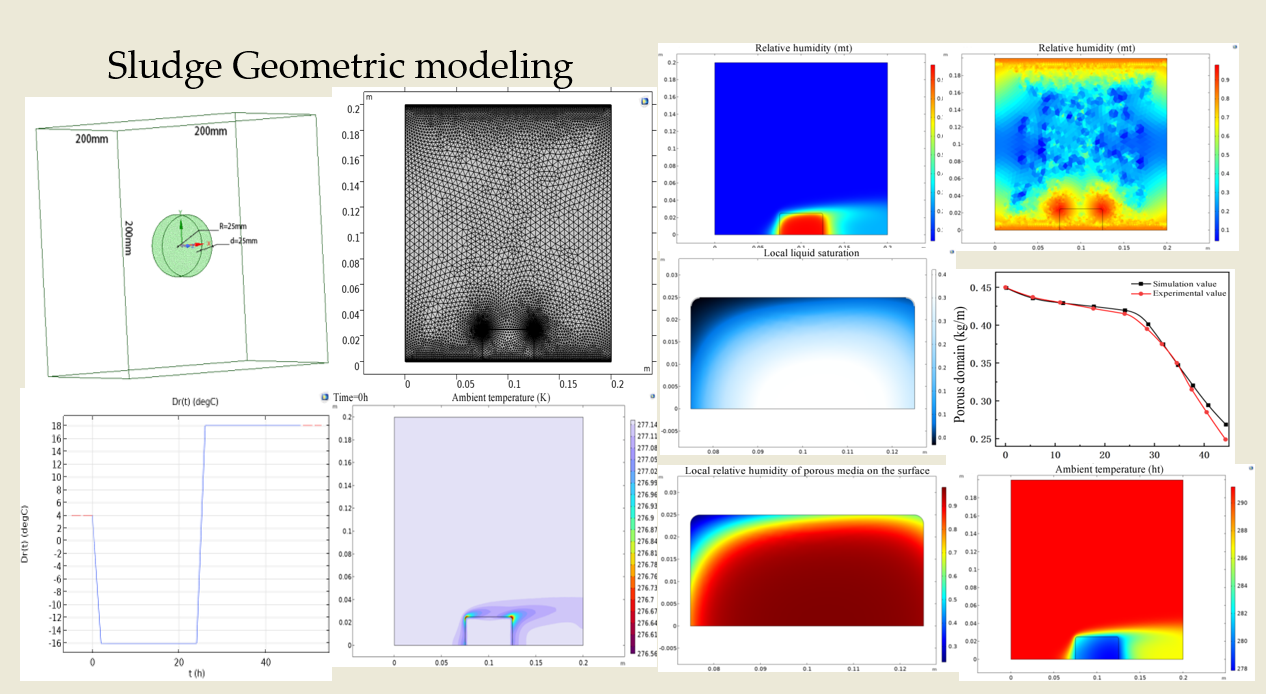

2.1. Experimental Design Scheme

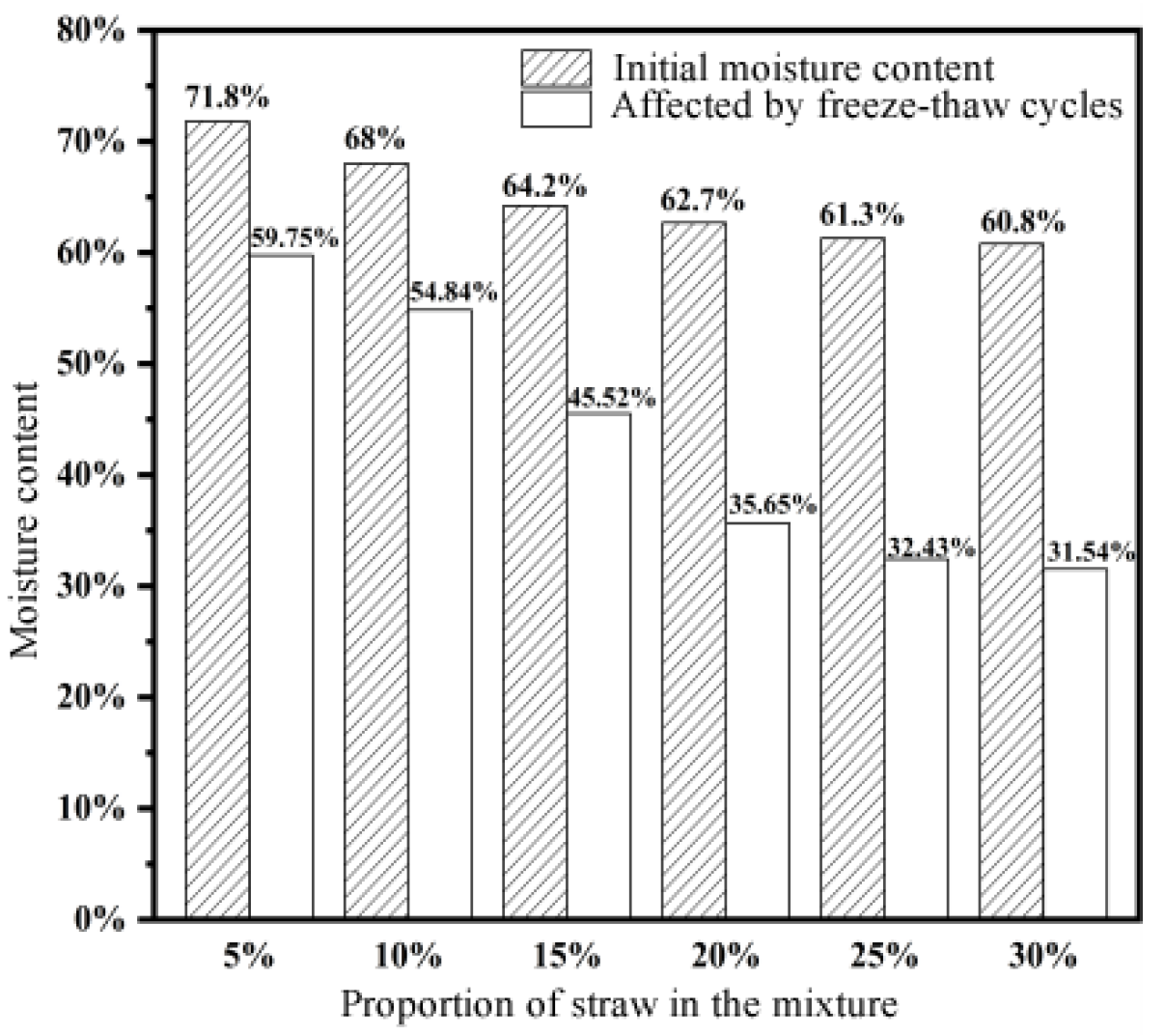

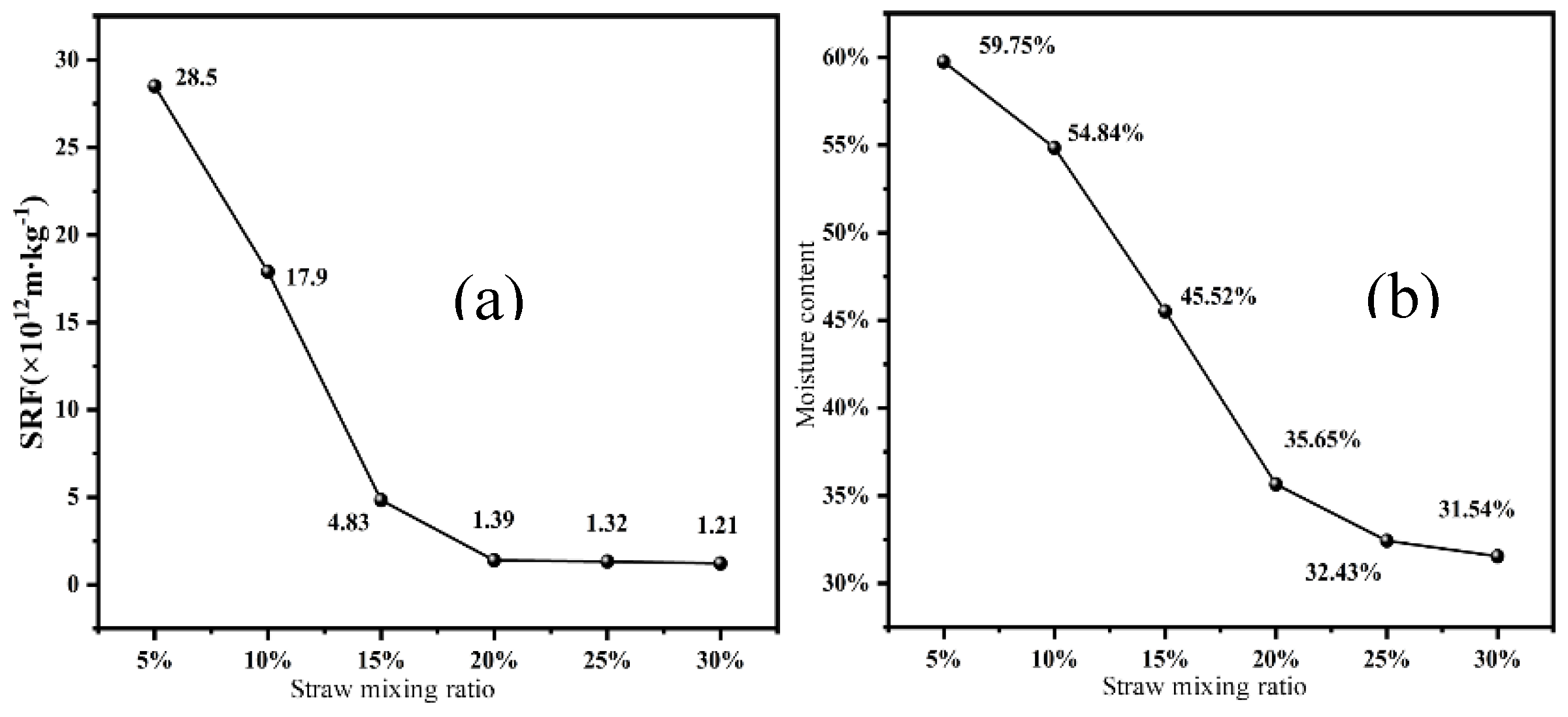

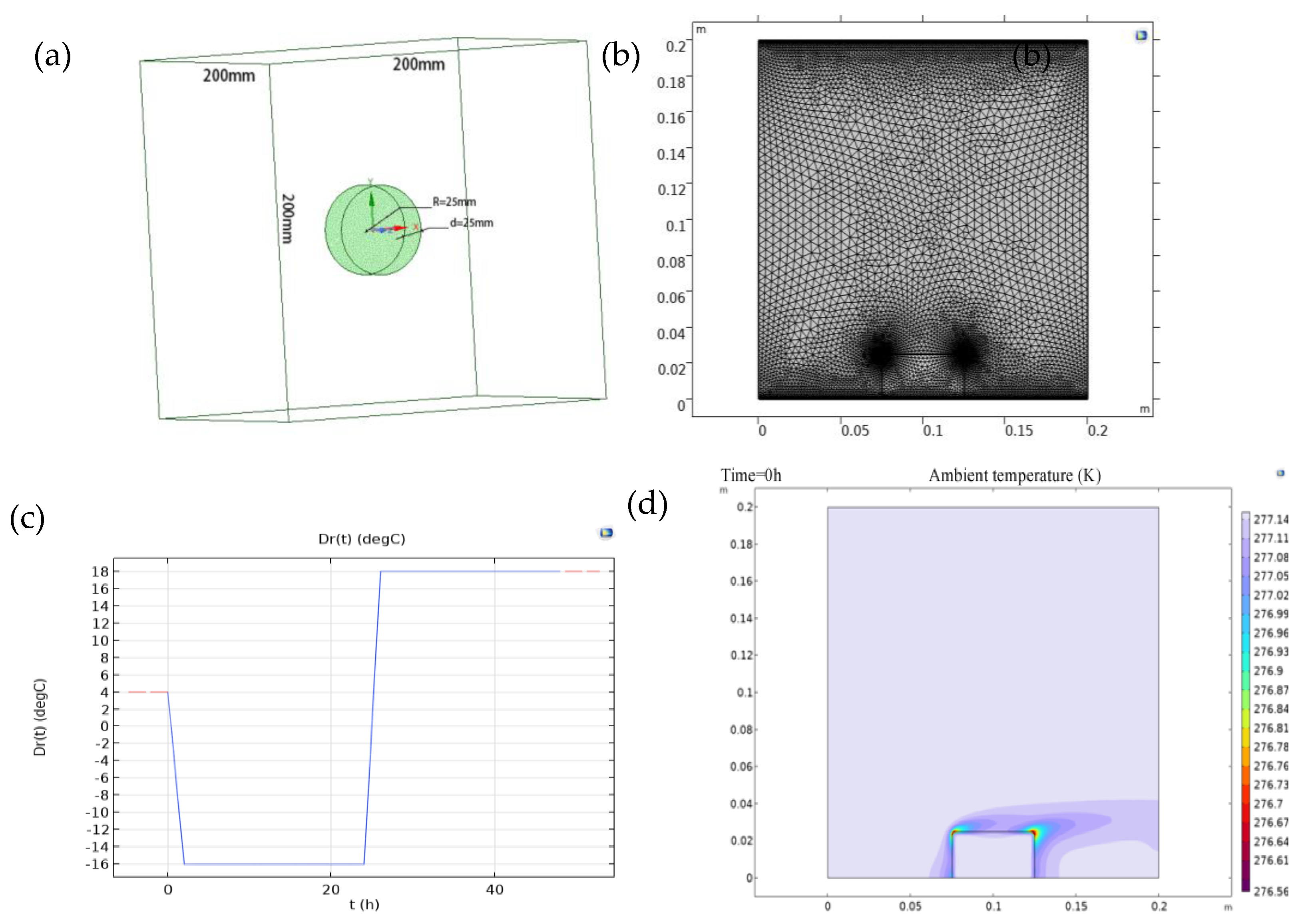

The experimental design for investigating the synergistic effects of straw conditioning on sludge dewatering during freeze-thaw (F/T) cycles was structured using a rigorous framework combining preliminary trials and response surface methodology (RSM). Initial experiments were conducted to identify baseline parameters that maximized moisture reduction in untreated sludge, revealing optimal F/T conditions of −16°C freezing temperature, 14-hour freezing duration, and 20 cycles. Building upon these findings, the study expanded its scope to incorporate straw as a conditioning agent, aiming to quantify its impact on moisture content dynamics and establish an optimized operational window for mixed sludge-straw systems. It illustrated the impact of the straw blending ratio on the moisture content of the sludge under specific freeze-thaw conditions (

Figure 1).

The moisture content of the sludge decreases as the straw blending ratio increases. At a straw blending ratio of 20%, the sludge's moisture content measures 35.65%, marking a 40.35% reduction compared to the original sewage sludge and a 4.75% decrease compared to freeze-thaw cycles without straw conditioning under identical freeze-thaw conditions. This negative correlation between the sludge's moisture content and the straw blending ratio implies that raising the straw blending ratio benefits the sludge's dewatering efficiency. Beyond a 20% straw blending ratio, the decline in sludge moisture content persists, albeit with diminishing returns. As the straw blending ratio rises, the dry straw absorbs some moisture, hindering the sludge from expelling water under lower pressure and increasing the workload of sludge treatment. Hence, it can be inferred that in this experiment, a higher straw blending ratio does not necessarily yield superior results. The optimal range of straw blending ratio influencing the dewatering performance of sludge during freeze-thaw cycles is 5% to 20%.

As revealed by the response surface experiments, the freezing temperature during sludge freeze-thaw cycles exerts a comparatively minor influence when contrasted with the freezing-thawing duration and frequency. Consequently, during the design of the straw-conditioned sludge freeze-thaw cycle experiments, the optimal freezing temperature (approximately -16°C) was initially ascertained. Following this, parameters including freezing-thawing duration, frequency, and straw blending ratio were chosen in accordance with this temperature. Varied proportions of screened straw were incorporated into the sludge for the freeze-thaw cycle experiments (5%, 10%, 15%, 20%).

A three-factor, three-level Box-Behnken design (BBD) was employed under the RSM framework, selected for its efficiency in exploring nonlinear interactions while minimizing experimental runs compared to full factorial designs. The independent variables included:

Freezing-Thawing Duration (X₁): Ranging from 4 to 24 hours, this parameter governs ice crystal growth and structural disruption of sludge flocs.

F/T Cycle Frequency (X₂): Tested between 5 and 20 cycles, this factor determines the cumulative mechanical stress imposed on the sludge matrix.

Straw Mixing Ratio (X₃): Varied from 5% to 20% (w/w), representing the proportion of dried straw (particle size < 2 mm) blended into the sludge.

Subsequently, these ranges were transformed into low and high-level values, coded according to their respective factors, while maintaining central level values at 14, 12.5, and 12.5 for each coded factor.

2.2. ANOVA with the Establishment of the Regression Equation

A regression model was developed and validated to ascertain the optimal parameters. Based on the BBD response surface experimental design, a total of 12 experiments at varying levels were performed, including 5 repetitions. Eventually, the optimal experimental conditions that influenced the moisture content of straw-conditioned sludge after freeze-thaw cycles were identified as follows: freezing at -16°C for 24 hours, 12.5 freeze-thaw cycles, and a 20% straw blending ratio. Under these circumstances, the moisture content of the sludge decreased from 62.7% to 35.9%, resulting in a 3.4% reduction compared to the sludge without straw conditioning in the same conditions.

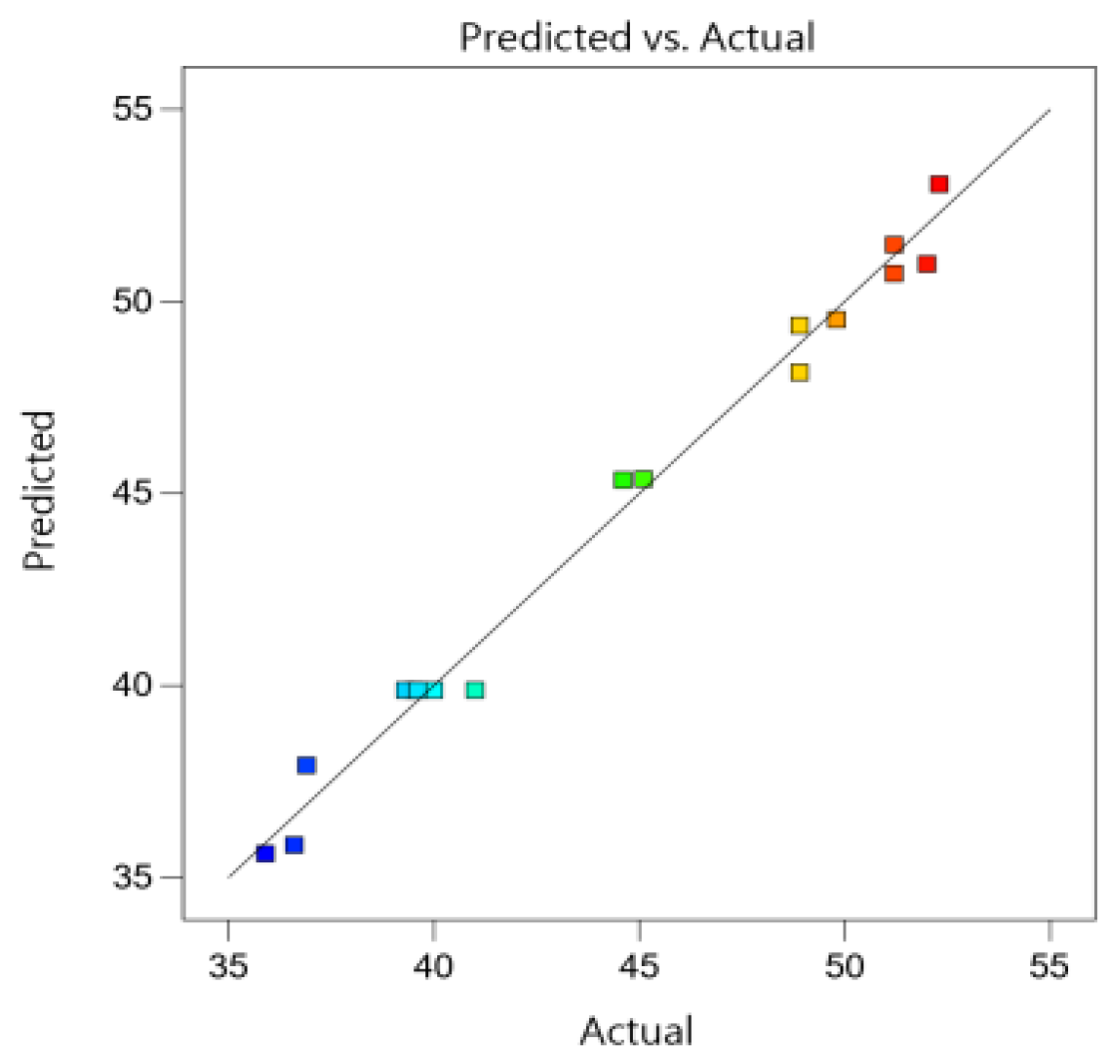

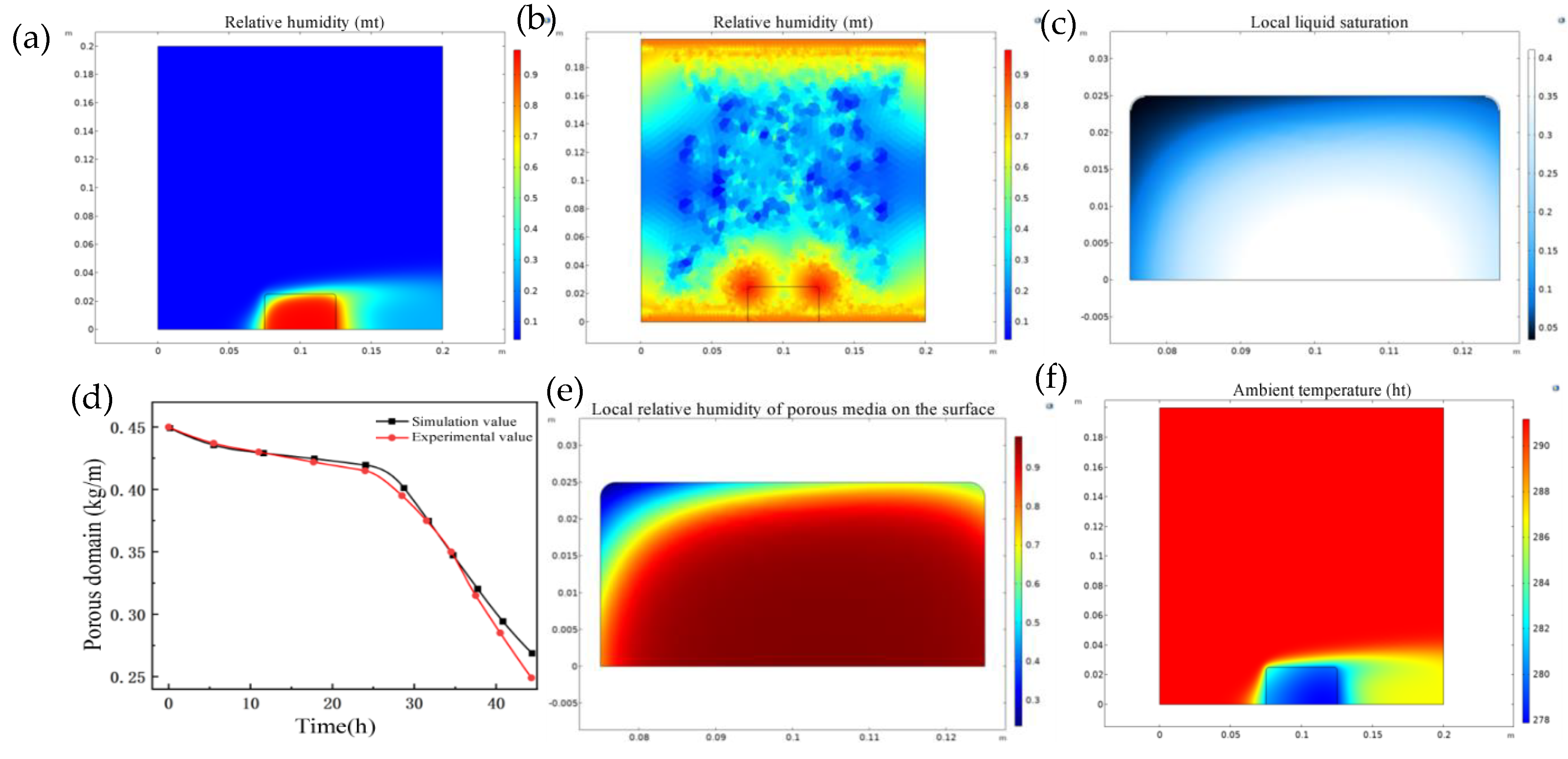

The experimental results underwent a variance analysis using Design-Expert 13.0 software. The sludge moisture content model had a significant F-value of 63.83, a fitted R^2 of 0.9880, and a correlation p-value < 0.0001, all of which suggest the model's importance, accuracy, and usefulness in analyzing and predicting the effects of individual factors and interaction terms on sludge moisture content. Furthermore, a lack of fit can serve as an indicator of model adequacy [

12]. The p-value for the moisture content model's lack of fit was 0.1183, exceeding the 0.05 significance level, indicating a non-significant lack of fit. In addition, the signal-to-noise ratio was 26.9581, surpassing 4, indicating the model's reliability and repeatability to a certain degree [

13]. The experimental actual values were distributed around the predicted values, which confirms the accuracy of the model fit by demonstrating close agreement between actual and predicted values (

Figure 2).

Equation (1) displays the fitted equation for sludge moisture content (Y) under varying factor conditions (X

1, X

2, X

3). The positive sign (+) preceding an influencing factor represents a promotion effect on sludge moisture content, while a negative sign (-) signifies a reduction effect on sludge moisture content.

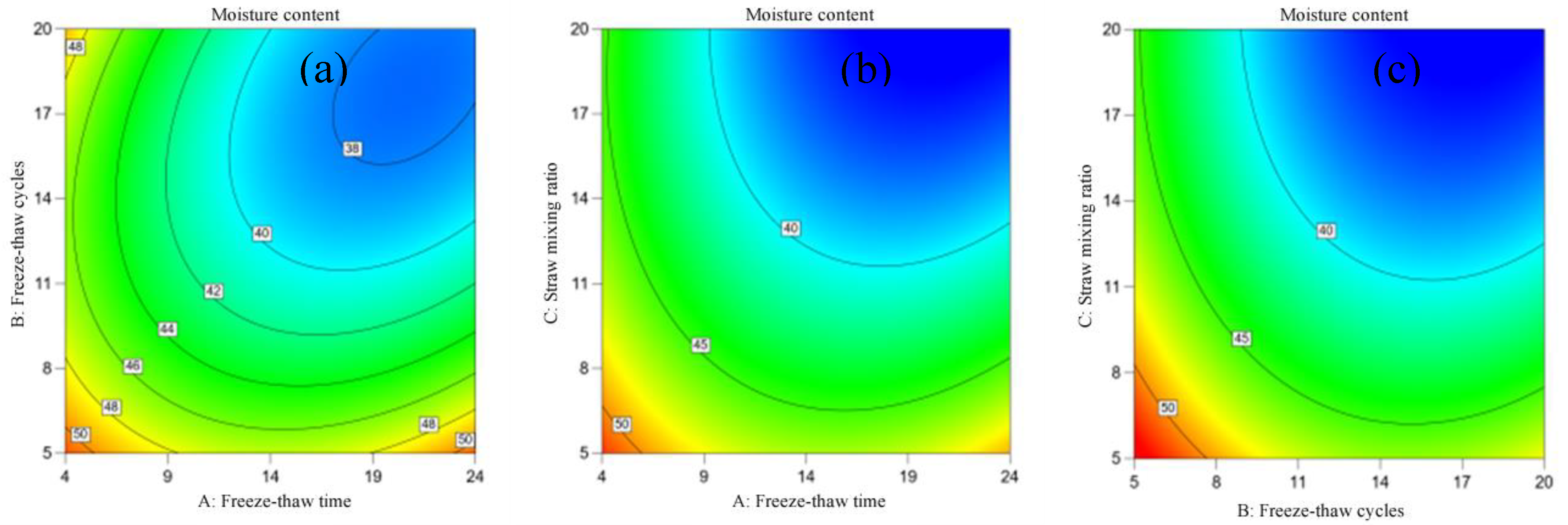

2.3. Experimental Analysis of Response Surface Method Using Sludge Water Content as an Evaluation Index

By conducting a significance test on the model coefficients, an analysis of the sludge moisture content demonstrated that the p-values for each individual influencing factor, namely X1 (freeze-thaw duration), X2 (freeze-thaw frequency), and X3 (straw mixing ratio), were all found to be less than 0.0001. These results indicate that the effects of freeze-thaw duration, frequency, and straw mixing ratio on the sludge moisture content are all highly significant. Moreover, the negative signs preceding X1, X2, and X3 signify that an increase in freeze-thaw duration, frequency, and straw mixing ratio leads to a decrease in the sludge moisture content. The order of influence of the independent variables on the response value, as determined by the F-values of X1, X2, and X3, is as follows: straw mixing ratio (X3) > freeze-thaw frequency (X2) > freeze-thaw duration (X1). This section elaborates on the mechanistic interpretation of factor effects, interaction dynamics, and validation experiments, supported by contour plots, perturbation analyses, and empirical verification.

Regarding the interaction effects between different factors, the p-values for X1X2 (freeze-thaw duration and frequency), X1X3 (freeze-thaw duration and straw mixing ratio), and X2X3 (freeze-thaw frequency and straw mixing ratio) are 0.0008, 0.0058, and 0.0541, respectively. Based on the F-values of the interaction terms, which are 31.66 and 15.36, respectively, we can conclude that the interaction effect of X1X2 has a greater impact on the sludge moisture content compared to X1X3.

By representing the interrelationships between different factors as contour plots,

Figure 3(a) reveals that the sludge moisture content decreases rapidly with an increase in freeze-thaw duration and frequency, thus indicating a synergistic effect between these two factors on the sludge moisture content. With regard to the relationship between freeze-thaw duration and straw mixing ratio, as well as freeze-thaw frequency and straw mixing ratio,

Figure 3(b) and (c) reveal that as the straw mixing ratio increases, an increase in freeze-thaw duration and frequency can result in a reduction in the sludge moisture content within a certain range.

In light of the experimental findings, it was prognosticated that the optimal experimental parameters would entail a freeze-thaw duration of 24 hours, a freeze-thaw frequency of 20 cycles, and a straw mixing ratio of 20%.Under these specified conditions, the model envisaged a sludge moisture content of 33.93%.To validate the predicted value, three parallel experiments were executed under the anticipated optimal conditions, yielding experimental results of 31.92%, 31.26%, and 30.83% correspondingly. The projected outcomes fell within 5% of the actual results [

14], suggesting the viability of utilizing response surface methodology to optimize the physicochemical characteristics of straw-conditioned sludge during freeze-thaw cycles, thereby enhancing its dewatering efficiency.

The dewatering performance of sludge is generally subpar, and depending solely on mechanical methods has limited efficacy in enhancing its dewatering capabilities [

15]. Hence, to further decrease the moisture content of sludge and bolster its dewatering performance, conditioning agents can be incorporated for treating the sludge. In this investigation, straw was employed as a conditioning agent primarily due to its capacity to absorb residual moisture in the sludge, consequently diminishing its moisture content and enhancing its dewatering performance [

16]. Moreover, this treatment method demonstrates consistent outcomes and facilitates the utilization of straw resources.

By comparing the F-values of the sludge moisture content model, it becomes apparent that the proportion of straw mixing in the independent variables has the most substantial effect on the response variable. Hence, the impact of the straw mixing ratio on sludge dewatering performance is examined and evaluated, as illustrated in

Figure 4. It is evident that after undergoing freeze-thaw cycle pretreatment, the residual sludge's specific resistance to filtration (SRF) diminishes as the straw mixing ratio increases. With the gradual increase of added straw, both SRF and cake moisture content display a notable downtrend. The optimal straw mixing ratio amounts to 20%, at which juncture both SRF and cake moisture content can be minimized to their respective lowest values of 1.30×10

12 m/kg and 35.65%. However, when the straw mixing ratio keeps surging, alterations in SRF and moisture content of the sludge become sluggish, leading to a limited effect on its dewatering efficiency.

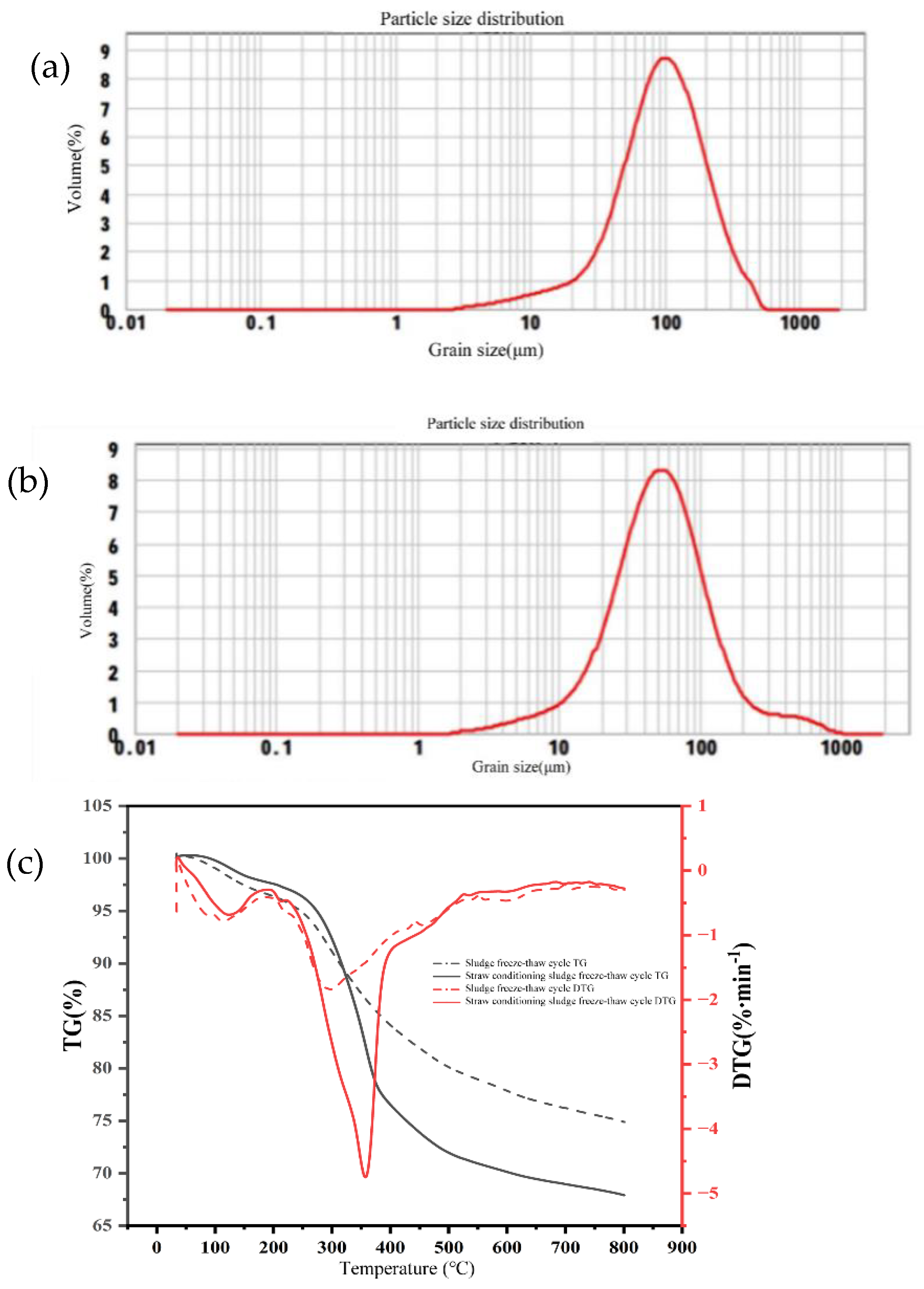

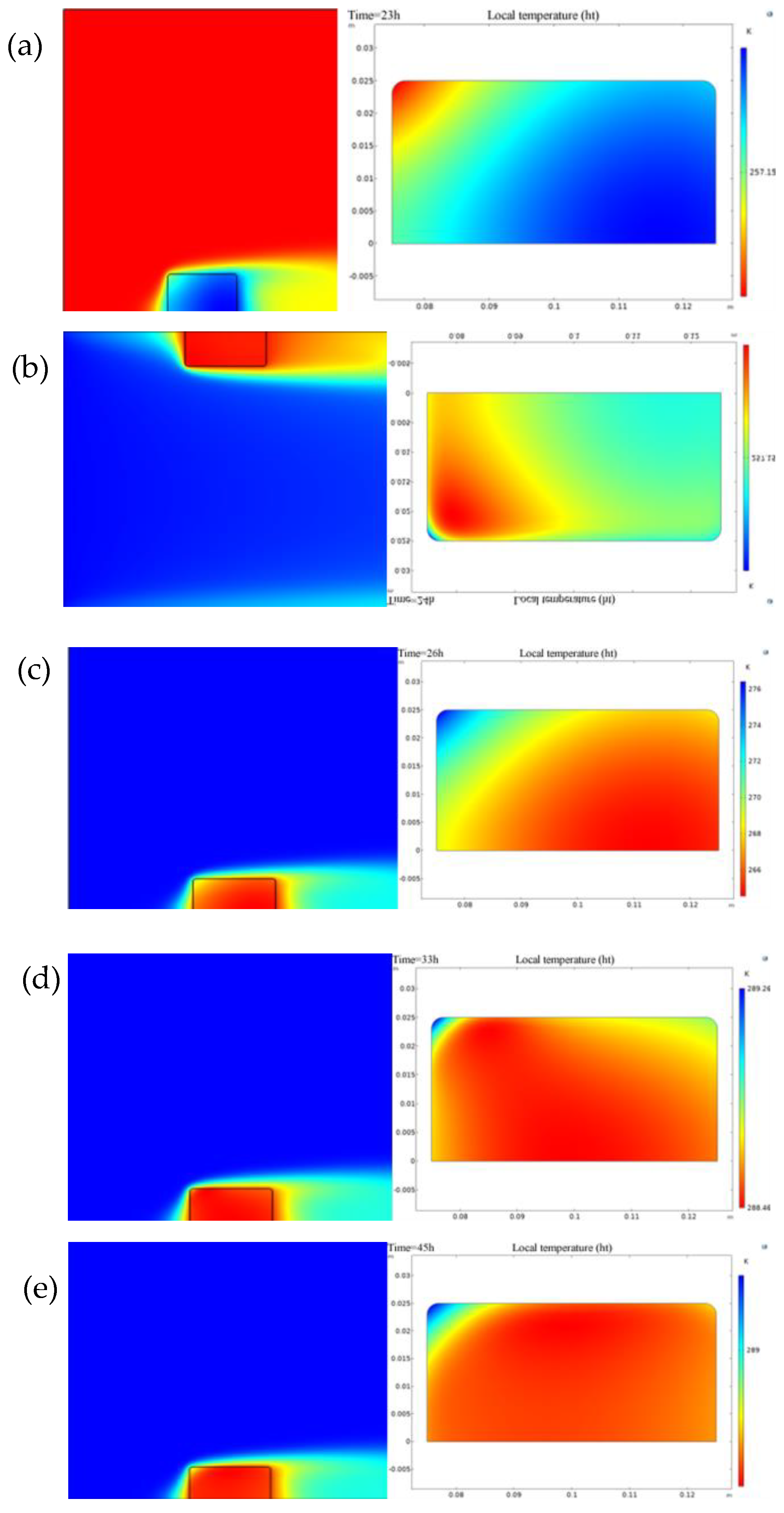

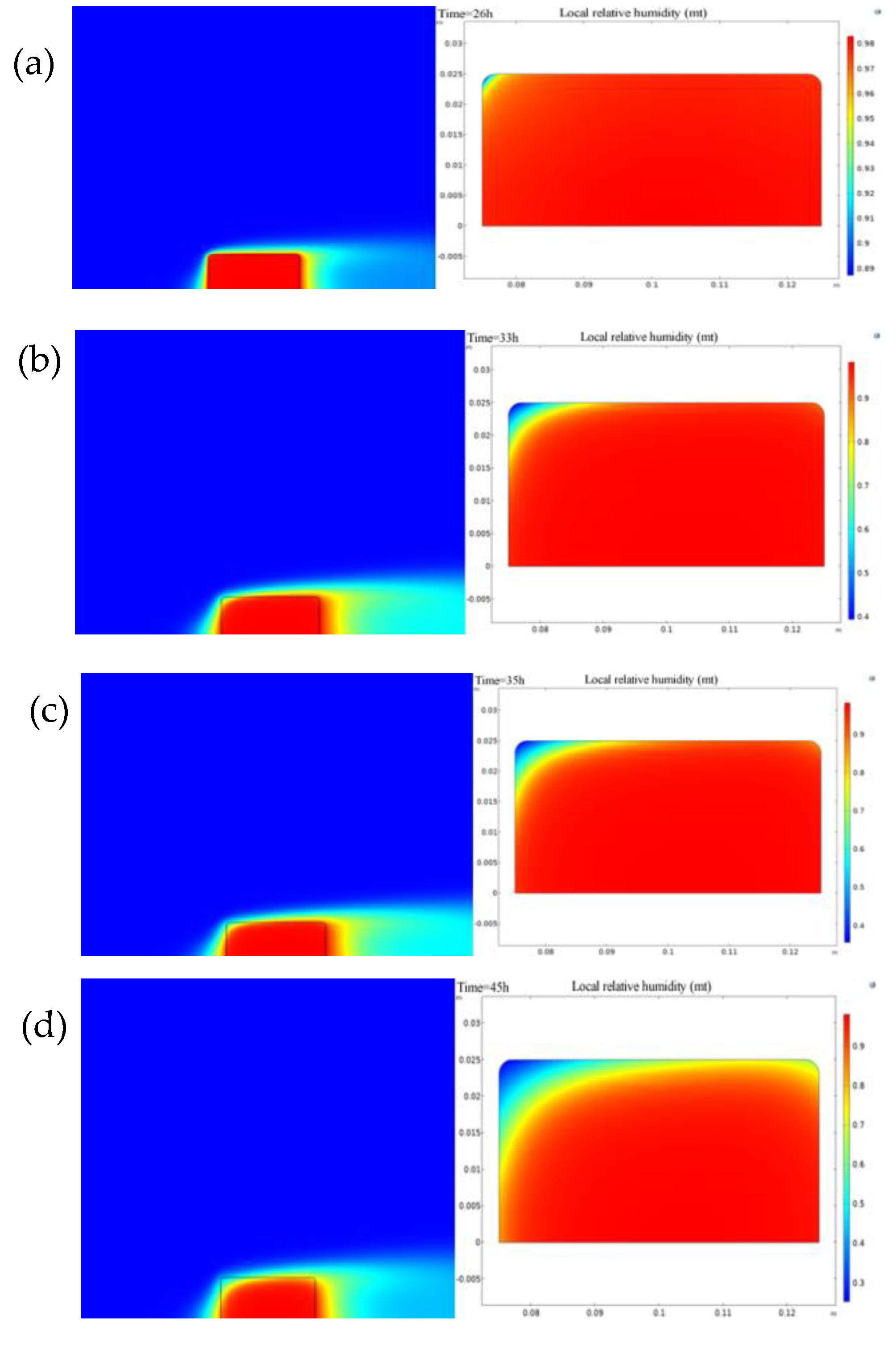

In order to delve deeper into the impact of straw conditioning on the thermal-mass transfer characteristics of sludge and analyze the mechanism through which straw affects the flocculent structure of sludge, the particle size distribution of the sludge floc before and after straw conditioning is depicted in

Figure 5a and b. During the experiment, utilizing straw as a conditioner can induce varying degrees of alteration in the particle size of sludge flocs. Thus, by scrutinizing the particle size distribution of sludge flocs, the underlying mechanism of the experiment can be elucidated more effectively. The particle size distribution of sludge within the 0-1000 μm range was investigated, and it was observed that the particle size distribution exhibited a predominantly normal pattern. Following the straw conditioning, the sludge exhibited a notable leftward displacement in comparison to the particle size distribution curve of the frozen-thawed pretreated sludge. In order to provide a more intuitive depiction of the alterations in sludge particle size, the mean particle size of sludge flocs was selected as the principal criterion for analysis. Upon the introduction of straw into the sludge, the average particle size of the sludge diminished from 116.4 μm to 74.96 μm. This occurs because introducing straw leads to the expansion of sludge flocs, thus facilitating the development of dehydration pores. Furthermore, the collaborative influence of freeze-thaw cycles augments the requisite channels for dehydration, subsequently enhancing the efficiency of sludge dewatering.

Utilizing TG-DTG curves of sludge samples subjected to varying freezing temperatures, this study investigates the impact of straw conditioning on the thermal mass transfer in sludge during freeze-thaw cycles. In order to facilitate comparison, the thermogravimetric curves of both untreated and straw-conditioned sludge samples after undergoing freeze-thaw cycles were acquired at a heating rate of 20℃/min, as depicted in

Figure 5c.

Through a comparison of the characteristic curves between individual sludge samples and sludge-straw mixed samples, it becomes evident that the combustion performance of both sludge and straw was thoroughly accounted for during the entire process. The composition of straw encompasses crude protein, cellulose, hemicellulose, lignin, and various other components. Hemicellulose, one of these components, possesses an irregular amorphous structure characterized by low thermal stability, with a decomposition temperature ranging from 220 to 315℃.Cellulose molecules are linked together by glycosidic bonds and possess a non-branching structure that makes them resistant to decomposition. The decomposition temperature of cellulose is documented to fall within the range of 315 to 400℃ [

17]. Conversely, lignin exhibits high stability and is resistant to degradation. Its combustion range can span from room temperature up to 850℃ (without achieving complete combustion) [

18]. Evidently, during the second stage, the combustion of straw is predominantly governed by the presence of hemicellulose and cellulose.

The stages of volatilization and combustion represent the periods wherein the maximum weight loss rate is most prone to manifest during the combustion of sludge and straw. Nevertheless, the maximum weight loss rate of the sludge mixed sample following straw conditioning surpasses that of sludge-only combustion, rising from 1.84% to 4.75%. This observation suggests that the freeze-thaw cycles experienced by straw-conditioned sludge can augment the maximum weight loss rate, thereby intensifying the volatilization and combustion stages of the sample. Furthermore, as a result of straw conditioning, the weight loss temperature associated with sludge pyrolysis correspondingly rises. This phenomenon is likely attributed to the fact that straw conditioning expedites the combustion of volatile components within the sludge, facilitating the premature reaction between unburned organic matter in the sludge and environmental oxygen, thereby decomposing it into more combustible substances.