1. Introduction

It is a present certainty that industrial or collaborative robotics [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

23,

24,

25,

28,

29,

30] will have a bright future with increasing integration of artificial intelligence (AI) [

16,

17,

26,

27,

33,

34], which together bring about major changes in business models and implicit production of innovative and highly technological goods.

This is because large technical companies, together with advanced research institutes and other technical SMEs, have aligned themselves with the new conceptual evolution of production called "Industry 4.0."

Incorporating artificial intelligence as a decisive factor for creating added value – high performance and ultra-precision in intelligent robots, as well as embedding AI in the production flows of Industry 4.0 enterprises, unlocks completely new and expanded capabilities for productive intelligent robots and intelligent control and monitoring devices. These advances open a multitude of new possibilities for rethinking the staging and combination of industrial processes, leading to extremely beneficial developments for the competitive industrial environment.

The integration of artificial intelligence (AI) with robotics marks a significant transformation in the manufacturing and service industries. As the world shifts toward Industry 4.0, AI's role has expanded from mere automation to enabling robots to perform complex tasks autonomously, leading to more efficient and adaptive production processes. AI-driven robots are now capable of real-time decision-making, enhanced perception, and predictive capabilities, allowing them to excel in industries ranging from automotive assembly to healthcare and logistics.

One of the most profound impacts of AI on industrial robots is seen in their ability to learn from experience, much like human operators. By utilizing advanced machine learning (ML) algorithms such as deep learning (DL) and reinforcement learning (RL), robots can now adapt to dynamic environments, optimize workflows, and make intelligent decisions based on sensory inputs. For instance, Tesla’s AI-powered robots use convolutional neural networks (CNNs) to detect and classify objects on the assembly line, ensuring precise and efficient production processes.

The growth of cloud computing and big data analytics further supports the rapid advancement of AI in robotics. Through cloud robotics, robots can access vast datasets and processing power remotely, allowing for continuous improvements and updates. This collaborative learning environment enables robots across multiple facilities to share information and learn collectively, enhancing their performance and efficiency. Companies such as Boston Dynamics and BMW have embraced these technologies, pushing the boundaries of what AI-integrated robotics can achieve.

AI's applications in robotics extend beyond manufacturing. In healthcare, AI-driven robots assist in minimally invasive surgeries, as seen with systems like Medtronic’s Da Vinci Surgical Robot, which enhances the precision and control available to surgeons. In logistics, Amazon’s warehouse robots utilize AI to streamline inventory management, reducing errors and optimizing warehouse space.

The convergence of AI and robotics represents a technological leap that is not only automating repetitive tasks but is also enabling robots to perform tasks that require human-like cognition, such as problem-solving, spatial awareness, and intelligent decision-making. The importance of this integration is echoed by industry leaders like Elon Musk, who emphasizes that AI is key to achieving Tesla's goal of full automation, from manufacturing to autonomous vehicles.

Similarly, Marc Raibert of Boston Dynamics highlights how AI has transformed their robots' ability to navigate and perform in dynamic environments, from warehouse automation to disaster relief.

The necessity for a close, seamless collaboration between industrial robots and AI stands at the core of this article as a cornerstone for the sustainable evolution of advanced mass production systems, ensuring a future where innovative, high-quality consumer goods are produced efficiently and sustainably.

2. The Synergy Between Robots and Artificial Intelligence in Competitive and Modern Industrialized Countries

The joint advancement of AI and robotics will persist for many years to come, as numerous foundations and forward-looking scenarios have already been established, providing robust arguments for their successful collaboration and mutual enhancement.

When examining the evolution and future outlook of the synergy between robots and artificial intelligence within the realm of modern competitive activities, particularly in the context of Industry 4.0, several key aspects stand out:

While 3D vision has been a crucial aspect for robots tackling intricate tasks, recent technological advancements over the past five years (2019-2024) have revolutionized this field. For example, breakthroughs in 3D vision technology have occurred, notably with the introduction of LiDAR (Light Detection and Ranging) sensors and advanced depth-sensing cameras. These innovations, alongside the utilization of state-of-the-art algorithms like SLAM (Simultaneous Localization and Mapping) and point cloud processing, have enhanced robots' spatial awareness and object recognition capabilities to unprecedented levels. Furthermore, the rise of AI-powered visual processing tools, including the integration of neural networks for object detection and tracking, has significantly boosted robots' ability to interpret visual data in real-time, allowing for more accurate decision-making and seamless

Enhanced 3D vision systems, such as Intel's RealSense and Nvidia's Deep Learning AI vision capabilities, have made significant strides, enabling robots to execute precise manipulations and tasks based on real-time 3D visual data integration.

The advancement of 3D vision technology is revolutionizing robotic perception and interaction with complex environments. Modern 3D vision systems use sophisticated sensors and algorithms to create accurate models of their surroundings. Technologies like LiDAR (Light Detection and Ranging) and advanced stereo cameras enable robots to navigate, recognize objects, and interact with their environment with high precision. For instance, systems like Intel RealSense and Microsoft Azure Kinect are providing robots with depth-sensing capabilities that facilitate tasks such as object manipulation, inspection, and autonomous navigation. The integration of AI with 3D vision allows for enhanced object recognition and decision-making capabilities, enabling robots to perform a wider variety of complex tasks in dynamic settings.

Progress in cloud robotics is crucial, as AI-driven robotics requires large datasets for deep learning tasks, such as image classification and speech recognition. It is known that cloud robotics allows intelligence to be shared between all robots connected to a given online environment, and in this way, it is possible to reduce the massive memory units necessary for intelligent robots to work properly.

Cloud robotics represents the convergence of robotics and cloud computing, allowing robots to leverage the vast computational power and storage available in the cloud. This technology enables real-time data sharing and processing, facilitating collaborative learning among robots.

For example, Google's Cloud Robotics Platform allows robots to access and share data, which can be used to improve algorithms and performance metrics without needing extensive on-board processing capabilities.

Notable advancements include Google's Robotics as a Service (RaaS) and Amazon Web Services' (AWS) RoboMaker, which provide scalable and robust solutions for cloud-based robotic intelligence.

This evolution not only enhances the individual capabilities of robots but also fosters an ecosystem where robots continuously improve through collective intelligence. This approach streamlines updates and functionality improvements, reducing downtime and maintenance costs.

The emphasis on robot training is expected to grow, with AI simplifying the training process and reducing costs, making it more accessible even for SMEs.

Robots are becoming easier to train thanks to advancements in AI, transforming how industries automate tasks.

One major development is the use of machine learning algorithms that allow robots to learn from demonstrations. These robots can capture and interpret human motions through sensors, converting them into precise robotic actions.

For instance, advanced robots like Boston Dynamics' Spot and ABB's GoFa can now be trained through on-the-fly demonstrations, capturing precise human movements with sensors and translating them into executable robotic actions.

Additionally, by leveraging extensive AI models, these robots can adapt quickly to new and complex operations with improved memory capabilities, further accelerating the transition of various industries toward automated solutions.

Real-world examples, such as the Baxter and Sawyer robots from Rethink Robotics, illustrate the potential for robots to learn tasks by guidance and example.

This evolution ensures robots not only become more versatile but also significantly enhances productivity and lowers the barriers for smaller enterprises to integrate robotic automation into their workflows can be trained to perform tasks via intuitive VR interfaces and multi-sensor systems, significantly reducing the time and cost associated with traditional programming methods.

The future of robotic training is particularly exciting as innovative technologies such as Virtual Reality (VR) interfaces and multi-sensor systems become more integrated into the process.

These tools enable human operators to intuitively program robots by simply demonstrating tasks in real-time scenarios.

These three aspects—3D Vision Development, Cloud Robotics, and Enhanced Robot Training —represent key areas for the ongoing symbiosis between AI and robotics, driving future innovation across both industrial and collaborative applications.

2.1. Technological Analysis of the Evolution of Industrial Robots and AI Integration

The evolution of industrial robots from 2012 to 2024 demonstrates a significant transition driven by advancements in artificial intelligence (AI) [

43,

44,

45,

46,

47,

48,

49,

50,

51]. The most important aspects regarding the synergy between industrial robots and AI, focus on a number of technological innovations that have occurred in a relatively short time, and which have created an important technological leap, marked by the integration of AI in increasingly roles complex, increasing the degree of autonomy and efficiency of robots.

2.1.1. AI Algorithms Enhancing Robotics

One of the critical technological drivers for the evolution of industrial robots is the incorporation of AI algorithms that enhance decision-making, learning, and real-time response. Several AI methodologies have been instrumental:

Reinforcement Learning (RL): Robots utilizing RL can improve their decision-making capabilities by learning from their environment and adapting to new situations. For instance, Boston Dynamics uses RL to enable robots like Spot to navigate complex terrains autonomously. The application of RL in industrial robotics allows robots to adjust to varying production environments and optimize task completion. Similar technologies are employed by Tesla’s assembly line robots, allowing real-time adjustments in a dynamic production environment.

Deep Learning (DL): Deep learning, particularly convolutional neural networks (CNNs), is widely used in robotic vision systems to improve object recognition and manipulation accuracy. Robots powered by DL can distinguish between subtle differences in objects, making them highly effective in assembly lines. Tesla incorporates DL in its manufacturing robots to enhance the precision of automated vehicle assembly. Also, Tesla's robots, for instance, utilize CNNs [

41] to guide assembly tasks with high precision.

Simultaneous Localization and Mapping (SLAM): SLAM algorithms, combined with AI, enable robots to create real-time maps of their environment and position themselves accurately within it. This is essential for autonomous navigation, which is seen in Autonomous Mobile Robots (AMRs) deployed by BMW and Tesla to streamline logistics and material handling processes in their factories.

Recent advancements in artificial intelligence (AI) have significantly enhanced industrial robots' capabilities by improving their autonomy, decision-making, and precision. Various AI algorithms, such as reinforcement learning (RL) and deep learning (DL), play pivotal roles.

Continuous and sustained progress in reinforcement learning (RL) and deep learning (DL) have significantly contributed to enhancing the autonomy and adaptability of robots in complex industrial settings (Krizhevsky et al., 2012; Thrun et al., 2005)[

42,

44].

Tesla's production robots, for instance, leverage convolutional neural networks for precise object recognition and adaptive learning (LeCun et al., 2015; Goodfellow et al., 2016) [

41,

48].

2.1.2. AI Powered Sensors and Robotics Components

AI has revolutionized the efficiency and versatility of industrial robots by enhancing their sensors and actuators. These components, integrated with AI algorithms, significantly improve robots' capability to interact with their environment.

LiDAR and Visual Recognition Sensors: Advanced AI-powered sensors, such as LiDAR and depth cameras, have improved robots’ spatial awareness, enabling precise 3D mapping and object recognition. These sensors, coupled with AI, are critical in applications requiring high accuracy, such as precision manufacturing and quality control. BMW and Tesla [

43,

44,

49] have adopted AI-driven visual systems in their robots to ensure flawless component assembly, or tasks like quality control, or welding.

Force and Compression Sensors: AI-enhanced force sensors enable robots to adjust their grip strength in real-time, which is vital in tasks like assembly, welding, or delicate handling. This has led to the development of collaborative robots (cobots) that can work safely alongside humans. Force/torque sensors [

49] are critical in ensuring safe human-robot collaboration, as seen in Universal Robots' cobots, which rely on advanced impedance control algorithms [

47]. Bicchi and Tonietti [

46] into recent research highlights how AI enhances the precision and adaptability of these sensors in real-time. Boston Dynamics has employed force-feedback mechanisms in their robots, allowing them to perform complex, high-precision tasks [

45] with minimal human intervention.

2.1.3. Cloud Robotics and Distributed AI Systems

The future of industrial robotics is increasingly dependent on cloud computing. Cloud robotics allows robots to offload heavy computational tasks to remote servers, which facilitates more efficient data processing and model training.

The integration of cloud robotics and AI is becoming essential for real-time data processing and collaborative learning. Robots can offload complex computations to the cloud, thus reducing on-site hardware requirements.

Real-Time Collaboration: Cloud robotics platforms, such as Google’s Cloud Robotics Platform and Amazon's RoboMaker, enable robots to share data and algorithms, accelerating their collective learning process, continuously improve, and optimize their tasks.. This enhances robots' ability to perform collaborative tasks with increased efficiency across multiple facilities. For instance, Rethink Robotics has leveraged cloud-based AI to improve the capabilities of their cobots, allowing them to access real-time updates and enhanced operational protocols remotely. FANUC's operations in China also uses AI-driven cloud platforms for real-time production adjustments.

Predictive Maintenance: AI-driven cloud platforms can monitor the performance of robots in real-time, providing predictive analytics to anticipate component wear or system failure before they occur. Tesla uses predictive AI models to forecast maintenance needs in its robotic systems, reducing downtime and improving overall production efficiency.

2.1.4. Robotics in Manufacturing and Beyond: AI Powered Solutions

AI-driven robots are now pervasive across various sectors beyond manufacturing, offering enhanced functionality in healthcare, logistics, and service industries. AI's impact on industrial robotics is evident in various sectors. Tesla, Boston Dynamics, and BMW are prime examples of companies that have embraced AI technologies.

Tesla: AI-powered robots on Tesla’s production lines handle precise tasks like part assembly and inspection, ensuring consistent quality.

Boston Dynamics: Known for advanced robotics, Boston Dynamics uses AI for robotic mobility and adaptability in dynamic environments, such as assisting in healthcare and logistics.

Healthcare Robotics: AI-based surgical robots, such as Medtronic’s Da Vinci Surgical System, use machine learning to assist surgeons in performing complex procedures with higher precision. These robots are also capable of learning from each surgery to improve future performance.

Logistics Automation: In the logistics sector, Amazon Robotics utilizes AI to automate warehouse management. Their robots, powered by AI and deep learning, streamline picking, packing, and inventory management tasks, significantly reducing manual labor and errors.

2.1.5. AI training Systems for Robots

Another key advancement is the simplification of robot training through AI. Robots are increasingly trained through machine learning techniques such as imitation learning and demonstration-based training.

Demonstration Learning: Robots, such as Boston Dynamics’ Spot and ABB’s GoFa, can now be trained by imitating human movements. With the help of sensors, these robots capture and process human actions and translate them into robotic tasks. This reduces the need for extensive programming and allows robots to adapt quickly to new tasks, enhancing their versatility in dynamic industrial environments.

2.2. Some Recent Advancements and Implementations of Collaborative Robots (Cobots) with Integrating AI into Modern Digital Robotic Applications in Highly Industrialized Countries – Such as China, Japan, United States, South Korea, Germany, Italy, France and Asia (Excluding China, Japan, and South Korea)

China's advanced manufacturing: is heavily investing in cobots to automate its manufacturing sector. Companies like FANUC and KUKA have established significant operations in China, focusing on integrating AI to enhance precision and efficiency. These cobots are used in automotive manufacturing, electronics, and consumer goods industries.

Robotics and AI are being applied in China's healthcare sector to aid in surgeries and rehabilitation. For example, TMiRob, a Chinese firm, has developed autonomous disinfection robots that use AI for navigation and ensuring thorough cleaning in hospitals.

Japan's automotive industry: Japan, home to robotics giants like FANUC and Yaskawa Electric, utilizes cobots extensively in its automotive manufacturing plants for tasks such as welding, assembly, and inspection. These robots are integrated with AI to optimize production lines and reduce human error.

Japan is also employing cobots and AI in the healthcare sector, particularly in elderly care. Robots like the PARO therapeutic robot and SoftBank's Pepper are designed to interact with and support the elderly, providing companionship and assistance with daily tasks.

United States Manufacturing: In the U.S., companies like Universal Robots and Rethink Robotics have popularized the use of cobots in manufacturing environments. These robots are frequently used for tasks such as assembly, packaging, and quality control. Tesla, for example, uses cobots extensively in its factories, leveraging AI to streamline production lines and improve efficiency.

The healthcare sector in the U.S. is rapidly adopting cobots and AI. Medtronic and Intuitive Surgical develop robotic surgical systems like the da Vinci Surgical System, which use AI for better precision and control during procedures. Additionally, hospitals are using robots for tasks like disinfection and telemedicine.

Logistics: Amazon's warehouses are prime examples of high-level robotic integration. The company uses robots from Kiva Systems to manage inventory, move goods, and streamline logistics with AI guidance for real-time optimization.

South Korea's smart factories: South Korea is advancing towards smart factories with heavy investments in cobots. The government has initiatives to boost the adoption of INDUSTRY 4.0 technologies, including AI-integrated robotics. For example, Doosan Robotics specializes in cobots that work alongside humans in electronics assembly and packaging.

Service robots: Companies like LG Electronics are developing AI-driven service robots used in hospitality and retail to assist customers, manage inventory, and perform cleaning tasks.

Germany Industry 4.0: Germany, a pioneer of INDUSTRY 4.0, has numerous applications of AI-integrated cobots in manufacturing. Companies like Bosch and Siemens are implementing AI-powered robotic systems for predictive maintenance, quality inspection, and seamless human-robot collaboration.

In agriculture, German startups like Agrointelli are developing robots for tasks like harvesting and plant monitoring. These robots use AI to analyze crop health and optimize farming practices.

Advanced manufacturing in Italy: Italian companies are increasingly adopting cobots for tasks such as assembly, packaging, and inspection. Comau, for instance, has developed cobots that integrate AI for adaptive manufacturing processes, enhancing productivity and customization.

The italian food & beverage industry: In the food and beverage sector, cobots are being used for packaging, sorting, and quality control to ensure high standards and efficiency. AI helps optimize these processes by learning and adapting to different product requirements.

France – Aerospace and defense: French enterprises in the aerospace sector, including Airbus, employ cobots for tasks that require high precision, such as drilling and assembling aircraft parts. AI integration ensures these tasks are performed with utmost precision and safety.

France is also pioneering robotic applications in healthcare, with companies like Aldebaran Robotics (SoftBank Robotics) developing AI-driven humanoid robots like Pepper and Nao, which are used in therapy, patient interaction, and assisting medical staff.

Singapore – manufacturing: Singapore is at the forefront of integrating cobots and AI across various sectors as part of its Smart Nation Initiative. In manufacturing, companies are adopting cobots to enhance productivity and flexibility in operations. AI is used for predictive maintenance and quality control.

Singapore’s healthcare sector is increasingly adopting robotic solutions for surgery, elderly care, and hospital management. The Singapore General Hospital uses robots for logistical tasks within the hospital, such as transporting medications and linens.

Urban solutions: As part of its Smart Nation effort, Singapore is also focusing on using robots and AI for urban management. Robots like OTSAW's O-R3 patrol public spaces to enhance security, and autonomous cleaning robots are employed to maintain public hygiene.

India: The rise of cobots is notable in India's manufacturing sector, particularly with companies like Tata and Mahindra using robots in automotive manufacturing. AI integration is also prominent in sectors like pharmaceuticals, where robots assist in drug manufacturing and packaging.

Thailand: The Thai government is promoting the adoption of robotics in agriculture through initiatives that support the development of smart farms. Robots and AI are used for planting, monitoring crop health, and harvesting, thereby optimizing agricultural practices.

Vietnam: Vietnam is emerging as a significant player in electronics manufacturing, with companies integrating cobots and AI to boost productivity and ensure quality. Factories are employing robots for tasks such as PCB assembly and quality inspection.

These all countries illustrate how high - industrialized companies are leveraging cobots and AI to enhance efficiency, precision, and productivity across various sectors, from manufacturing and healthcare to agriculture and services.

3. Analysis on the Evolution of Industrial Robots and Artificial Intelligence. Perspectives

By meticulously examining and delving into the annual reports detailing the utilization of industrial robots [

1,

2,

3,

4,

5,

6,

7,

8,

9,

31,

32], alongside an exhaustive review of the latest scholarly and reputable sources on industrial robotics and artificial intelligence (AI) [

33,

34,

35,

36,

37,

38,

39], the authors of this paper have meticulously crafted a well-researched manuscript focusing on the pivotal themes and current trends shaping the progress of industrial robots and AI from 2012 to 2024 also presenting a short forecast for the near future. This exploration sheds light on the trajectory of robots and artificial intelligence within the landscape of tomorrow, a realm characterized by ambitious pursuits and rapid advancements in engineering paradigms for products and services tailored primarily to industry 4.0. Moreover, this wave extends to groundbreaking technologies such as IoT, Big Data, Cloud computing, Blockchain, Digital Twin, Artificial Intelligence.

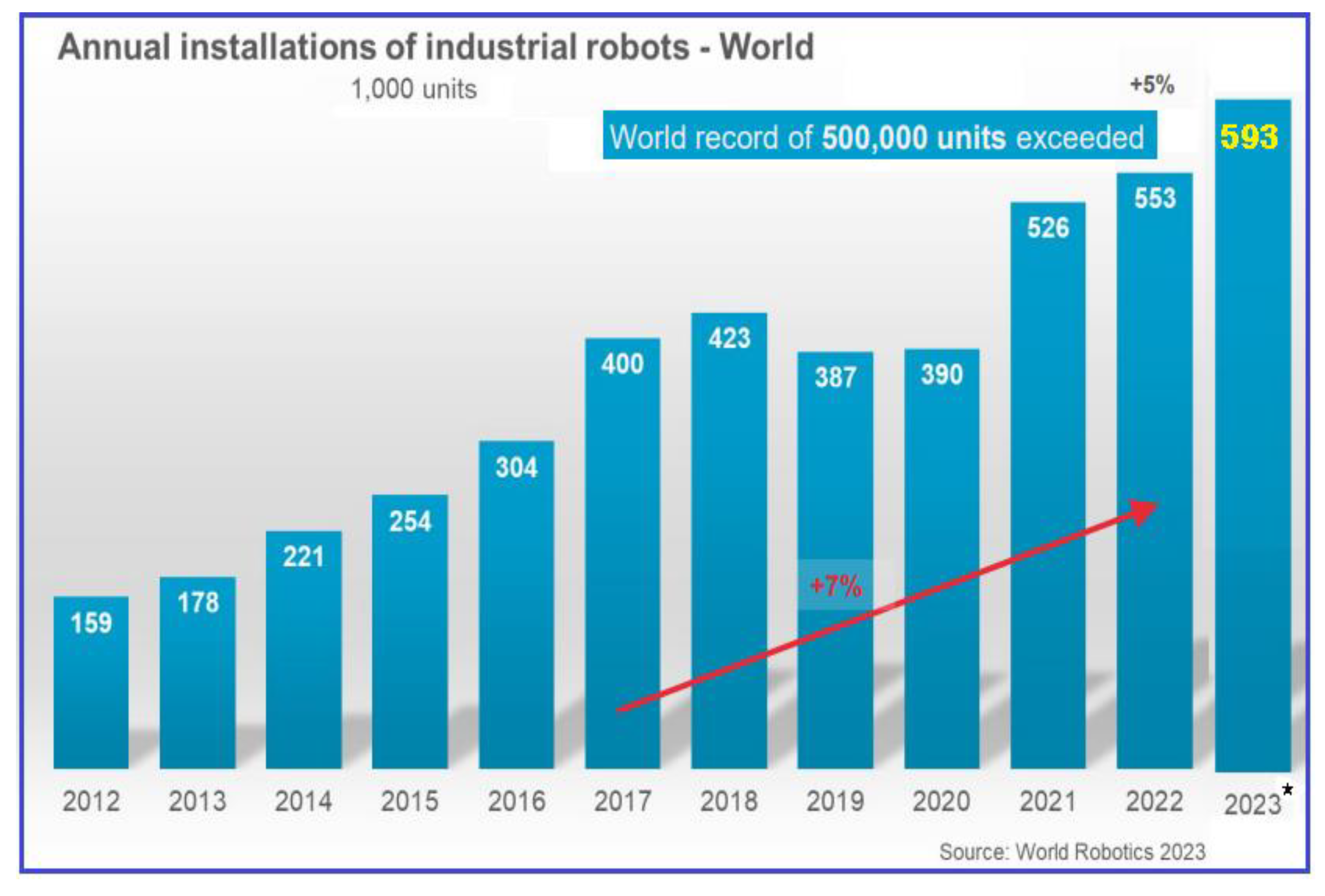

Despite the challenges posed by the global pandemic, the sales of new robots saw a modest uptick of 0.63%, with a meager 526,000 units being delivered worldwide in 2021.

As of 2022, the integration of artificial intelligence into industrial robots has reached unprecedented levels, with a staggering over 3,5 million such robots seamlessly operating in factories worldwide - something more than 7% increase from previous figures.

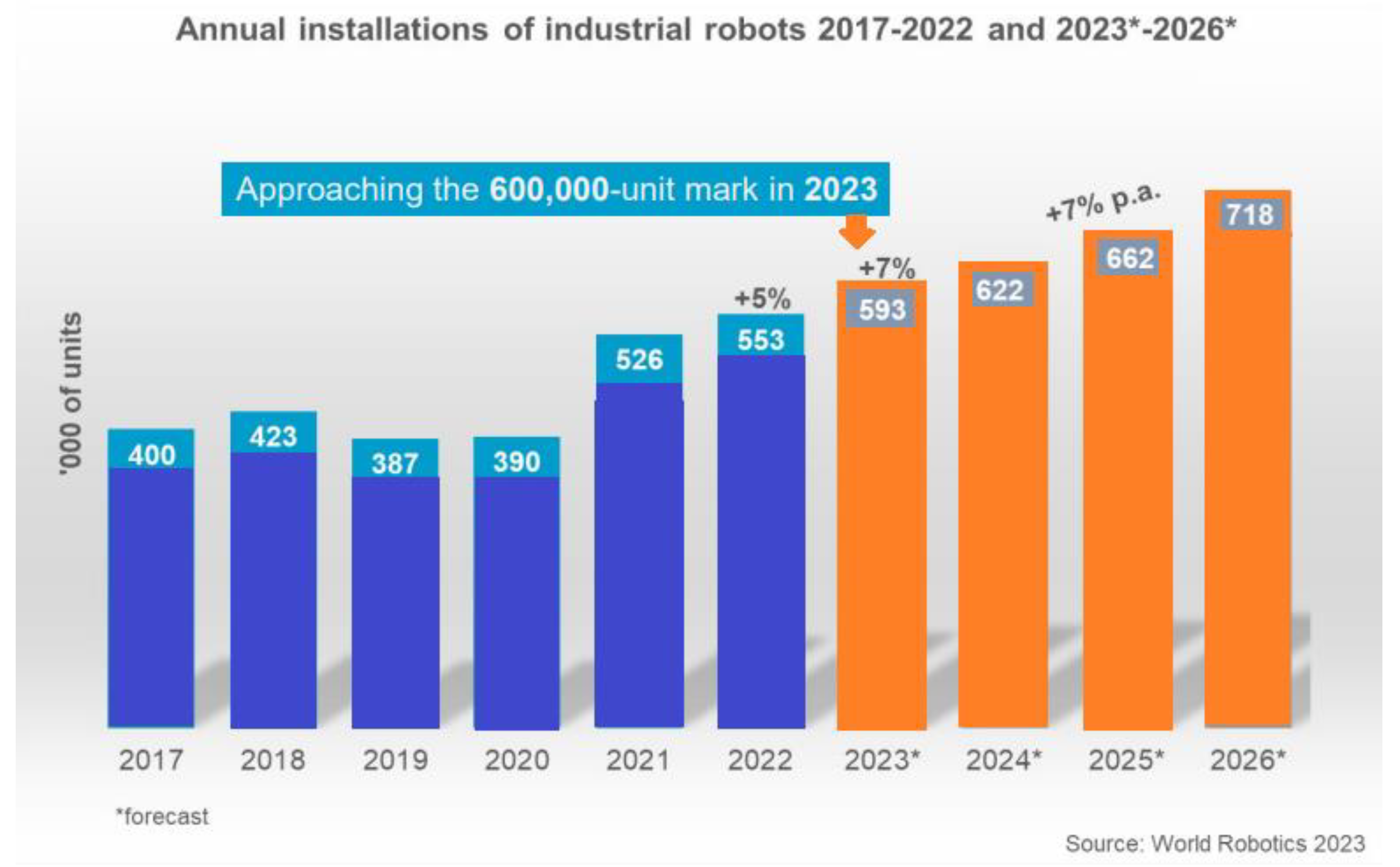

Worldwide industrial robot shipments amounted to some 553,000 unit in 2022, just a slight increase compared to 2021 (526,000 unit). It is projected that industrial robot shipments will increase significantly in the coming years on to 662,000 unit in 2025 year. It is expected that in 2026, global industrial robot shipments will amount to about 718,000 unit.

Figure 1.

Annual installations of industrial robots – worldwide, for 2012-2023.

Figure 1.

Annual installations of industrial robots – worldwide, for 2012-2023.

The forecast for 2023-2026 years, about annual installations of industrial robots with integrated AI to a lesser or greater extent, is presented in

Figure 2, below.

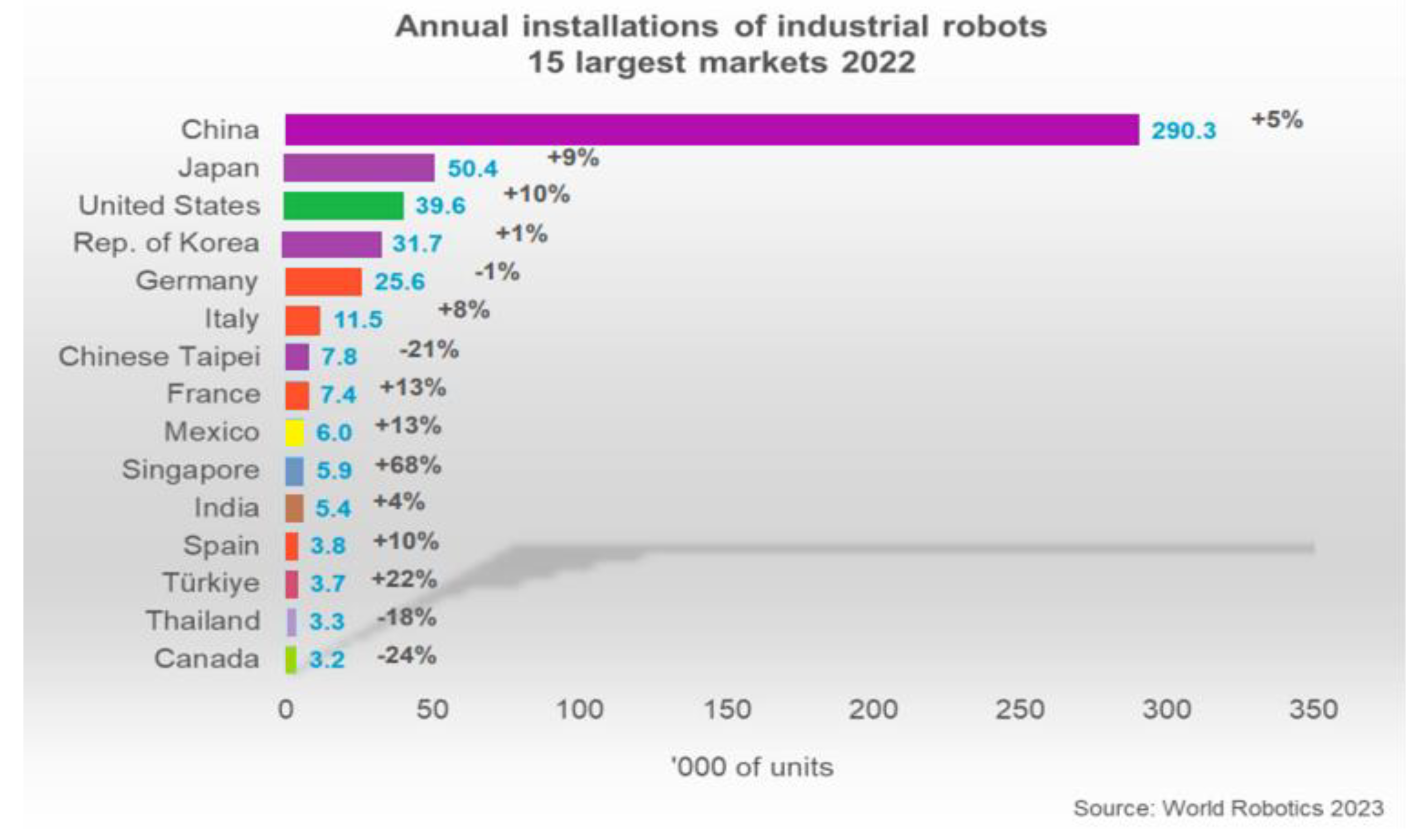

Leading industrial robot markets include China, Japan, the United States, South Korea, and Germany, which are among the top five globally (see

Figure 3). In emerging manufacturing markets, growth is largely fueled by rising wages, making machines a more attractive alternative to human labor. Industrial robots are increasingly used for a variety of tasks across numerous industries. While the highly automated car manufacturing sector remains one of the largest users of electro-mechanical machines, the electrical and electronics industry actually installed the most industrial robots in 2020. It's important to note that robotics is also a subset of another industry: the electrical/electronics industry that installed the most industrial robots in 2020.

It has to be noted that the field of robotics is a part of another industry: the automation market. This industry is comprised of a variety of products and services, including relays, switches, sensors and drives, machine vision and control systems, as well as industry software development and services. Conglomerates like Siemens, Mitsubishi Electric or General Electric are the major vendors of industrial automation and industry software. The key players in the industrial robot market include ABB, KUKA, Fanuc, Kawasaki, and Yaskawa.

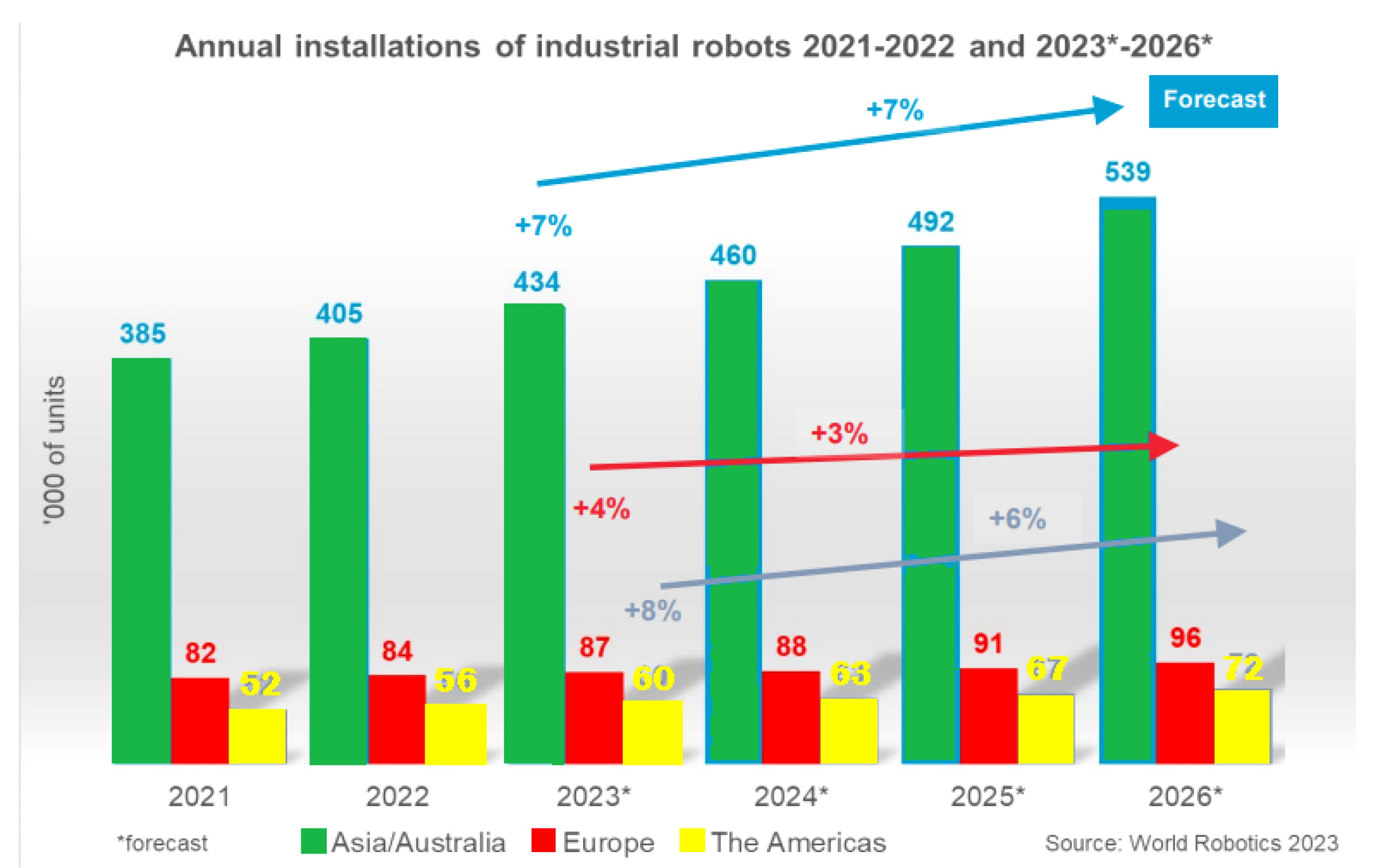

According to the World Robotics 2023 Report, here’s a breakdown of robot installations across these regions:

Asia leads the way, with 73% of newly deployed robots installed in this region. China continues to dominate with an accelerated pace of robot installations, year-on-year growth. Major investments by tech giants like Huawei and Alibaba in AI and robotics emphasize the shift towards a highly automated industrial landscape. China's plans to further expand its AI and robotics capabilities are evident in its latest 5-year plan, aiming for global leadership in advanced manufacturing technologies.

China, in particular, stands out as the world’s largest market, with annual installations reaching 290,258 units in 2022.

Despite economic challenges, Japan maintains its position as a leading robotics market, with a forecasted 10% growth in 2024. Companies such as Fanuc and Kawasaki are pioneering advancements in robotics, focusing on enhancing AI applications to develop smarter manufacturing solutions.

Japan and the Republic of Korea also contributes significantly to Asia's robust growth in this domain.

Europe accounts for 15% of global robot installations. The European Union remains the second-largest market, with countries like Germany, Italy, and France actively adopting industrial robots. Germany, with a market share of 36% within the EU, is a key player.

The Americas represent 10% of robot installations. The United States leads the way, accounting for 71% of installations in the region. The automotive industry has been a major growth driver, with surging installations in recent years.

The U.S. leads with substantial investments in AI-integrated robots across various sectors, including automotive and electronics. Recent industrial reports highlight a substantial 20% increase in intelligent robot deployments, driven by innovations from companies like Tesla and General Motors, integrating advanced robotics to enhance production efficiency. Another important example, Ford has implemented AI-driven robots to improve precision in its assembly lines, reducing waste and increasing overall productivity.

Overall, the global installed capacity of industrial robots reached a record high of 553,000 units in 2022, demonstrating the remarkable vitality of robotics across North America, Asia, and Europe. These technological advances are shaping the future of manufacturing and automation worldwide.

Based on extensive analysis of highly relevant data, including information directly from leading players in the high-performance industrial robot market, it is projected that installations of high-performance robots in North America will increase by approximately 6%, reaching around 63,000 units (

Figure 4) by the end of 2024. In comparison, the growth in Europe is expected to be about 3%, or around 88,000 units by the same period. An extended forecast for the installation of intelligent robots in Asia and Australia points to a slightly higher figure, exceeding 460,000 units (

Figure 4) in 2024—an increase of about 7% from the previous year. Across all Asia/Australia markets, robot usage is estimated to surpass 492,000 units in 2025.

Asia leads globally in the adoption of industrial robots, making it the largest market in the world. Installations of intelligent robots in China, the region's largest integrator, have seen significant growth to 52% of world installations (delivered and installed units). Thus 290,258 units of all newly installed industrial robots in 2022 were installed in China. This country has reached the highest recorded value for a single country in terms of industrial robot installations (see

Figure 3). This rapid growth highlights the accelerated pace of robotization in China, as well as the country's openness to digitalization and technologies like Industry 4.0 and artificial intelligence.

Japan (

Figure 3) remains the second-largest market for industrial robots after China, despite the severe impact of the Covid-19 pandemic on its economy. In 2020, sales in Japan dropped by 23%, with only 38,653 units installed. This marked the second consecutive year of decline, following a peak of 55,240 units in 2018.

The year 2022 brought to Japan a revival and a strong increase in the implementation of industrial robots to a maximum value of 55,240 units, with real prospects for expansion in the future. In contrast to China, demand from the electronics and automotive industries in Japan has been more weak.

Revenue in the industrial robotics in Japan market is projected to reach US$ 1,241.00m in 2024. Here, automotive industry robotics dominates the market with a projected market volume of US$ 682.90m in 2024. Revenue is expected to show an annual growth rate (CAGR 2024-2029) of -0.64%.

Demand for Japanese robotics is based on already identified and loyal export destinations. Thus, 36% of Japanese exports of robotics and automation technology went to China, but another 22% of exports were shipped to the United States.

The Republic of Korea (

Figure 3) can be considered the fourth largest robot market in terms of annual installations, after China, Japan, and the USA. The export-oriented economy has coped remarkably well with the pandemic so far. Revenue in the robotics market is projected to reach US

$ 0.97bn in 2024, in Korea. Here, service robotics dominates the market with a projected market volume of US

$ 0.60bn in 2024. Revenue is expected to show an annual growth rate (CAGR 2024-2029) of 4.00%, resulting in a market volume of US

$ 1.18bn by 2029, for this country. In a global total comparison, most revenue will be generated only in the United States – US

$ 9,421.00m in 2024.

3.1. The Impact of Artificial Intelligence and Robotics on Modern Industrial Manufacturing and Global Supply Chains. A Focus on China and Its Leading Competitors

In countries like China, Japan, South Korea, Singapore, and the United States, factories equipped with AI-driven systems and advanced robotics have revolutionized industrial manufacturing. These highly automated facilities, such as those in Shenzhen, feature robots embedded with sophisticated sensors and guided by AI to perform intricate tasks like soldering circuits and assembling complex components with remarkable precision. This fusion of AI and robotics has not only accelerated production but has also significantly reduced human error and manufacturing costs by minimizing defects and rework.

The role of AI in these factories extends far beyond the use of physical robots. In China, for instance, Shenzhen’s factories have embraced the "Digital Twin" concept, wherein virtual replicas of machines, components, and processes are created to mirror their physical counterparts. These digital twins [

12,

14,

15,

22] constantly gather and relay real-time data, enabling factory managers to closely monitor operations, predict equipment failures, and fine-tune production processes. By simulating various scenarios, managers can preemptively address issues to ensure optimal factory performance. This concept has gained traction in Japan, South Korea, and the U.S., where manufacturers are using digital twins to reduce downtime and boost operational efficiency.

Another essential aspect of modern manufacturing is the integration of the Internet of Things (IoT). Sensors embedded across machines and the factory environment collect a wide array of data, ranging from temperature and vibration levels to humidity and lighting conditions. When this data is analyzed by AI algorithms, patterns emerge that would otherwise remain unnoticed. For example, in a highly automated car manufacturing facility in South Korea, an AI system might identify that production efficiency decreases slightly when ambient temperatures exceed a specific threshold. Such seemingly minor insights can have substantial long-term impacts on productivity and energy conservation.

In addition to enhancing machine operations, AI is reshaping the roles of human workers in these high-tech factories. No longer viewed merely as part of the production line, workers are now supervisors, decision-makers, and problem solvers. Augmented reality (AR) glasses powered by AI, for example, are guiding workers through intricate assembly processes by overlaying digital instructions onto physical components. Workers can instantly access data on machine performance and inventory levels, enabling them to make informed, real-time decisions.

Safety, a crucial concern in manufacturing, has also seen significant advances with AI integration. Predictive maintenance algorithms can forecast when machines are likely to fail, thus preventing potential accidents. AI-enhanced surveillance systems also continuously monitor factory floors, detecting safety hazards or protocol breaches and alerting management before incidents occur.

AI’s influence doesn’t stop within the walls of the factory. The supply chain—vital to the manufacturing process—has undergone a transformation in AI-powered facilities like those in Shenzhen. AI algorithms now predict the need for raw materials, optimize inventory management, and streamline procurement to reduce waste and costs. On the logistics side, AI-powered systems ensure that finished products are delivered efficiently through the use of drones, autonomous vehicles, and smart tracking solutions. These advancements reduce shipping times and enhance customer satisfaction.

Despite the clear benefits, there are challenges. The high costs associated with integrating AI technology, the need for specialized workforce training, and concerns over job displacement due to automation are significant hurdles that countries like China and the United States must address. Furthermore, as data plays an integral role in AI operations, securing this data against breaches and maintaining privacy are critical issues that continue to arise.

Ultimately, robots, IoT devices, and AI-powered software working in tandem across supply chains create an unprecedented amount of structured and unstructured data. This has led to the development of machine learning solutions that process this data, turning it into actionable insights for industries to stay competitive in the rapidly evolving global market.

3.2. Revolutionizing the Standards of Digitized Manufacturing 4.0. by AI in Quality Control

In the world of manufacturing, "quality" is a basic principle, a distinction between success and failure. Therefore, quality control has traditionally been a rigorous process involving manual inspections, random sampling, and often considerable investment of time and resources.

In the digitized and high-performing factories - like China, Japan, United State, South Korea - with the integration of Artificial Intelligence, the field of quality control has moved to a higher level through a transformative and extremely beneficial change.

By infusing intelligence into systems, AI is setting new benchmarks for manufacturing standards, ensuring that products rolling off assembly lines are not just good, but exceptional.

At the heart of AI's impact on quality control is its ability to process large amounts of data quickly and accurately. Where human inspectors might struggle to spot inconsistencies or minor defects, especially after hours of repetitive work, AI-powered systems maintain constant vigilance. Equipped with advanced sensors, cameras and algorithms, these systems can detect anomalies that might escape the human eye.

For example, in electronics manufacturing, AI can identify tiny solder defects or microscopic cracks in chips, ensuring that only flawless products reach the end customer (this is already happening consistently in the five heavily industrialized 4.0 countries).

3.3. Predictive Analytics with AI - Just-in-Time Inventory Management and Supply Chain Forecasting

Predictive analytics, a confluence of statistical algorithms, machine learning and big data, is transforming industries from China, Japan and United State and other similar countries, but its impact on forecasting and inventory management in supply chains [

11,

13,

19,

20,

21] is particularly notable. At the intersection of mathematics and technology, this tool promises a new era of efficiency, foresight and agility, enabling companies to navigate the complexities of global commerce with unparalleled precision.

The influx of variables such as geopolitical events and sudden market shifts has made forecasting increasingly complex in today's rapidly changing global economy. Rather than merely extending trends from historical data, predictive analytics powered by AI delves deeper, examining vast datasets to identify subtle patterns and correlations. By integrating real-time data from diverse sources—such as sales figures, social media trends, market news, and weather forecasts—it offers a dynamic and continuously updated perspective on future needs.

This capability allows companies to anticipate market changes proactively, strategically positioning themselves to tackle upcoming challenges and seize opportunities. This sophisticated tool, which utilizes AI-generated predictive analytics, is particularly invaluable in inventory management.

Inventory, often a company's largest asset, poses both potential rewards and significant risks. Overstocking leads to high holding costs, potential depreciation, and resource wastage, while insufficient inventory can result in lost sales, dissatisfied customers, and strained business relationships. Striking the right balance is a constant challenge for businesses, and today, predictive analytics with AI provides an effective, efficient, and competitive long-term solution.

Accurate demand forecasting through predictive analytics allows companies to maintain ideal inventory levels. AI algorithms examine various data sets, including historical sales, seasonal trends, promotional schedules, and external factors like economic conditions and competitor activities. This extensive data enables the creation of precise demand forecasts over specific time periods. Consequently, businesses can make well-informed decisions regarding procurement, production planning, and storage requirements.

Furthermore, AI-driven predictive analytics delves into every significant and complex aspect of the supply chain, offering insights into possible bottlenecks or disruptions. For instance, if analyses suggest that the cost of a specific raw material might increase due to geopolitical issues in a supplier country, companies can explore alternative options or take measures to mitigate expected price hikes. Similarly, if AI predicts a potential labor strike at a key logistics location, businesses can adjust shipment routes to maintain operations and ensure customer satisfaction.

Beyond forecasting, predictive analytics significantly impacts inventory placement. Global enterprises with numerous warehouses or retail points face intricate decision-making processes in inventory distribution. By evaluating factors such as transportation expenses, local demand patterns, and storage costs, predictive models assist in making optimal inventory placement choices. This strategy not only ensures product availability where it is most needed but also reduces transportation and storage expenses.

A significant advantage of predictive analytics lies in its capability for continuous self-improvement. Machine learning models, fundamental to predictive analytics, are consistently refined. As they process more data and receive feedback on forecast accuracy, these models adapt their algorithms, enhancing their predictive capacity. Over time, this iterative learning process results in increasingly precise forecasts that better align with actual market conditions.

However, predictive analytics, like any powerful tool, presents its own challenges. Prediction accuracy is heavily dependent on the quality of the data being utilized. Inferior data quality or outdated information can lead to inaccurate forecasts and misguided decisions. To mitigate this, ongoing attention to the data being fed into these powerful AI tools is essential.

AI's impact on the industry is evident in reduced costs and increased revenues, stemming from its integration into supply chains. This inclusion results in minimized logistics expenses, decreased inventory levels, and substantial cost savings. Consequently, it is no surprise that the supply chain industry is rapidly embracing AI and machine learning technologies.

Recent research predicts that the global AI market for supply chains will grow significantly, from $527.5 million in 2017 to an anticipated $10,110.2 million by 2025.

4. The Evolution of the Symbiosis Between Artificial Intelligence (AI) and Industrial Robots Throughout the Period 2021 - 2030 and Future Forecasts

To highlight the significant impact and rapid expansion of artificial intelligence (AI) in various industrial sectors, the authors of this article conducted a thorough and well-supported analysis of the primary factors driving the development of AI. Their goal was to provide an in-depth overview of pertinent data on the remarkable progress of AI over the specified time frame. The analysis includes relevant graphical visualizations that outline current trends and future predictions of the role of AI in the modern world, especially in high-performance, highly automated industries in various countries where AI-equipped robots play a direct role.

By examining the salient metrics and trajectories associated with AI implementation and adoption, the authors aim to offer a deeper insights into the transformative potential of this pervasive technology. Through a rigorous, data-driven approach, the authors seek to better understand the multifaceted drivers shaping the accelerating growth and diversification of AI applications across a wide spectrum of industrial and societal domains.

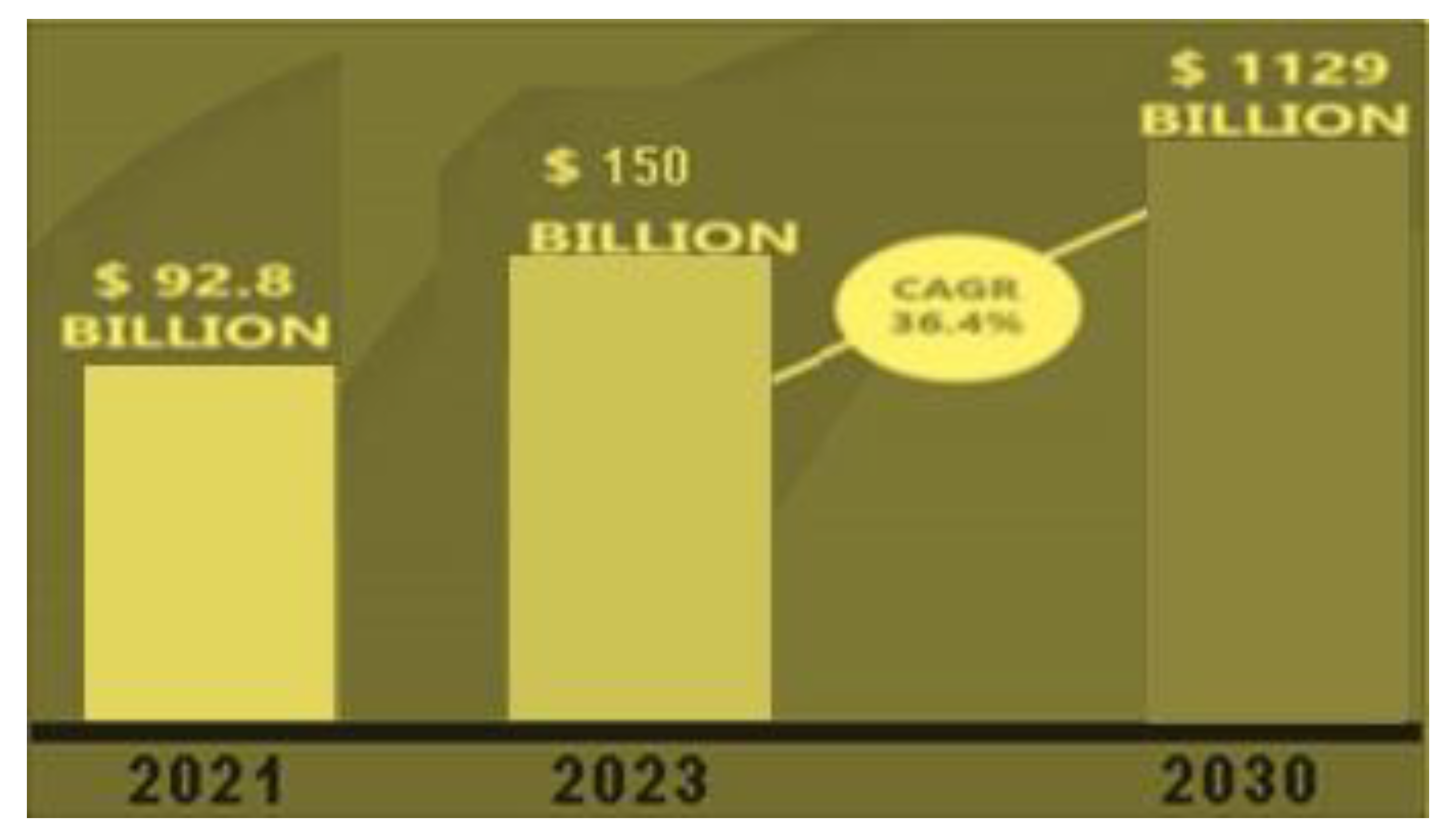

This graph (

Figure 5) shows the exponential growth of the global AI market, from approximately

$150 billion in 2023 to a projection of over

$1.3 trillion by 2030.

This impressive growth reflects the rapid adoption of AI technologies across various industries and confirms the trends mentioned earlier, such as the democratization of AI and its integration into industrial processes.

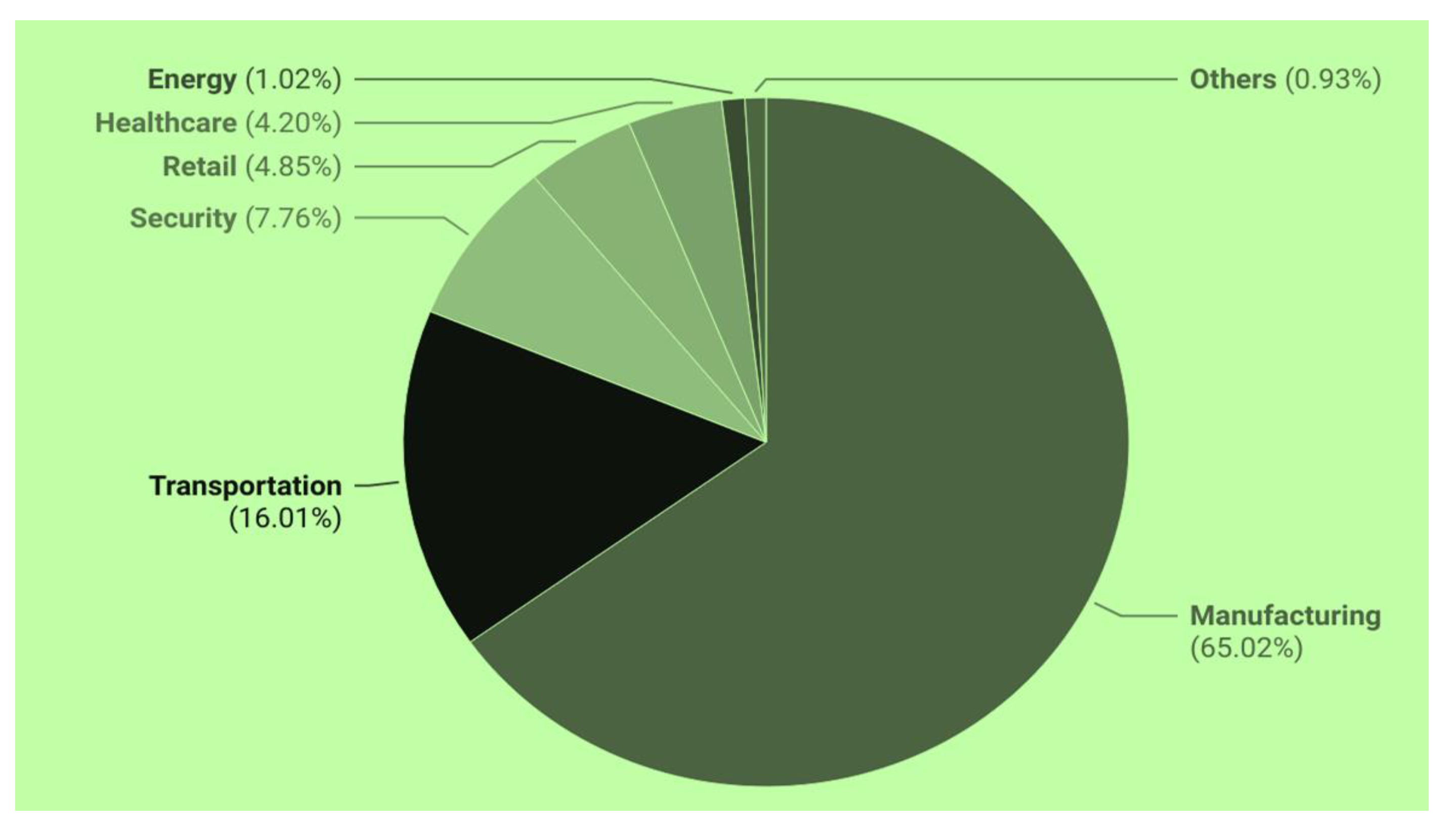

The AI robotics market is experiencing significant growth across various industries. In 2022, manufacturing dominated with a 65.02% market share (

Figure 6), followed by transportation (16.01%) and security (7.76%). Projections indicate substantial expansion in multiple sectors: the defense industry is expected to reach

$61 billion by 2027, agricultural AI robotics may hit

$703.4 million by 2025, and the logistics market could grow to

$40.9 billion in the same year. Healthcare is poised to become the second-largest AI robotics market by 2024, with a 19% share. Additionally, environmental monitoring applications are forecasted to generate

$79.9 million in revenue by 2025, highlighting the diverse and rapidly evolving landscape of AI robotics across industries.market is experiencing significant growth across various industries.

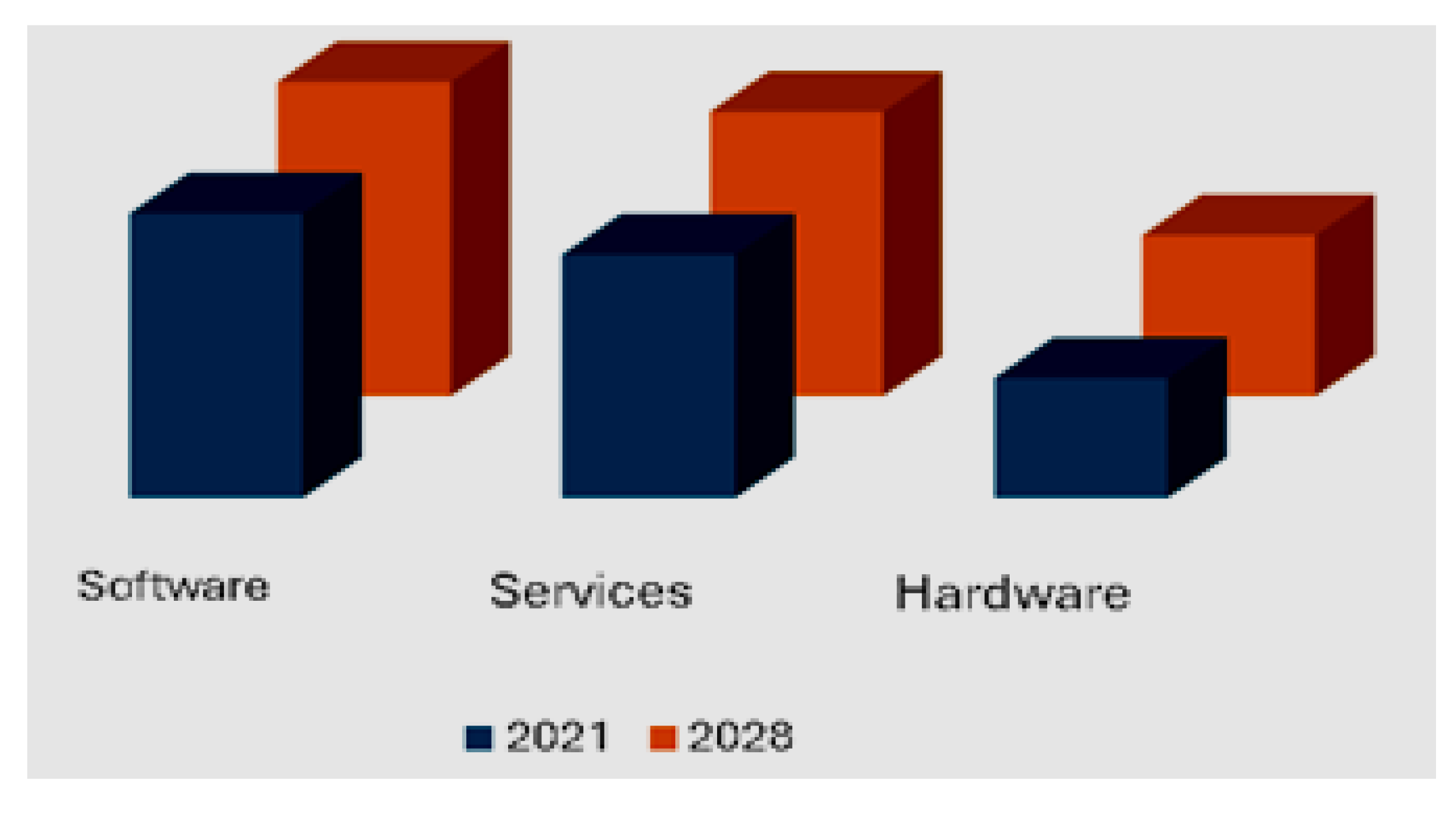

According to the recent report titled "Artificial intelligence market size and forecast" by the experts at Verified Market Research [

34], who have analyzed credible and extensive international data for the report, we can observe a balanced growth across the AI market segments. The global AI market is projected to experience relatively proportionate growth across its main segments - hardware, services, and software - during the period 2021-2028 (

Figure 7).

Forecasts indicate that the software segment will remain the largest component of the AI market, with an average annual growth rate of approximately 36% in the 2021-2028 interval. However, the hardware and services segments will advance at comparable annual rates, between 32-34%, showcasing a balanced development of the entire AI ecosystem.

This trend reflects how the demand for AI solutions materializes at all levels - from the hardware infrastructure powering advanced algorithms, to innovative software applications and implementation/maintenance services. This harmonious growth among the key components ensures a sustainable and durable expansion of the global AI market as a whole.

While some segments may record slightly higher or lower rates, the data suggests that the AI industry as a whole is developing in a balanced and coordinated manner, without excessive dominance of any particular technological aspect. This diversity and equilibrium are essential to ensuring a solid and long-term evolution of the entire artificial intelligence sector globally.

4.1. Several Major Trends Can Already Be Identified Regarding the Development of Artificial Intelligence (AI) in Correlation with the Implementation of Industrial and Even Service Robots (for the 2024-2028 Period), Including:

– Generative AI: Beyond automating routine tasks, Generative AI focuses on creativity by generating new content from existing data. Models like GPT-4.0 or GPT Plus and DALL-E are currently capable of creating text, images, and more. In the near future, we will see an increase in the use of Generative AI to create synthetic data for various business purposes. This innovative approach to AI will revolutionize content creation, artistic expression, and problem-solving by leveraging artificial creativity. The integration of generative capabilities and creativity into the behavior of robots could transform how they interact with their environment. By 2028, robots may be able to create unique artistic works or find innovative solutions to complex challenges in fields such as medicine (where significant progress in cancer research with AI has already been reported), design, or entertainment.

– Intelligent process automation: Advances in intelligent process automation could enable industrial robots to perform complex and varied tasks with increased efficiency. By 2028, these intelligent robots could manage entire factories or large-scale industrial operations without constant supervision, significantly increasing productivity and quality, tending towards extended autonomy.

– Self-developing AI: The integration of the ability to autonomously learn and evolve in intelligent robots could lead to highly adaptable and versatile systems. By 2028, we can anticipate that robots will gain the ability to continuously improve their own skills and performance, rapidly adapting to the changing demands of their work environment.

– Augmented working: The integration of robots and smart machines in the workplace will become more common by 2023. This includes AR-enabled headsets, real-time data access, and AI-powered virtual assistants to enhance productivity and safety. Working alongside intelligent machines will be an increasingly valuable skill in the evolving workplace, empowering employees to collaborate effectively with AI technologies and navigate the changing landscape of work.

– Sustainable AI: As companies aim to reduce their carbon footprint, AI can both consume resources and offer solutions for sustainability. Efforts in 2023 will focus on implementing green energy-powered infrastructure and using AI to address environmental challenges such as deforestation and illegal activities. By leveraging AI for sustainability initiatives, businesses can optimize their operations while contributing significantly to environmental conservation, leading the way toward a more sustainable future powered by intelligent innovation.

– The ongoing democratization of AI: AI will reach its full potential when it becomes accessible to everyone. In 2023, there will be a growing number of apps that make AI functionality available to users of all technical levels, empowering individuals to create AI-powered solutions without requiring coding knowledge. This democratization of AI will not only help bridge the skills gap but also democratize decision-making processes across various sectors, ushering in a new era of inclusivity and innovation.

– Autonomous vehicles: The existing advancements in autonomous vehicles globally provide concrete evidence of the significant potential that can be developed and refined, bringing major societal benefits. Autonomous robots, especially in the transportation and delivery sectors, are expected to revolutionize these industries by 2028, ensuring efficient and safe operations without the need for human intervention.

– Ethical and explainable AI: Trust in AI is crucial, especially when dealing with sensitive data. Efforts in 2023 will focus on making AI systems more transparent and ethical, ensuring that decisions are explainable and free of bias. Organizations will prioritize eliminating bias and unfairness in automated decision-making processes. By fostering transparency and ethical standards, AI can gain public trust and drive responsible innovation, laying the foundation for a more ethical and accountable future in AI development and deployment.

5. Conclusions

The evolution of AI and robotics signifies an inevitable transformation in industrial practices, emphasizing the need to adapt to new technological advancements. While increasing efficiency, these technologies also challenge existing labor structures, necessitating technological retraining and skill development among workers.

The future underscores a collaborative engagement between AI-driven robots and human ingenuity to achieve unprecedented industrial productivity and innovation.

The integration of robots and artificial intelligence (AI) in industrialized countries, particularly in China, Japan, South Korea, and the United States, has ushered in a new era of advanced manufacturing. These technologies have revolutionized production lines by exponentially increasing efficiency, minimizing errors, and drastically cutting costs. In regions like Shenzhen, China, AI-powered robotics and the "Digital Twin" concept have become central to smart manufacturing, allowing real-time monitoring, predictive maintenance, and production optimization.

Countries such as Japan and South Korea, which are recognized for their leadership in robotics and electronics, have embraced similar technologies. Japan, home to pioneers like FANUC and Kawasaki, has heavily invested in automated systems, while South Korea's tech giants like Samsung have implemented advanced AI and robotics to maintain their competitive edge. The United States, though slightly behind in robotic density, has made significant strides in integrating AI-driven technologies in the automotive and aerospace sectors.

Furthermore, the use of IoT (Internet of Things) devices and data-driven approaches has become widespread, enhancing operational efficiency and reducing downtime. AI-powered augmented reality (AR) is also gaining ground, transforming human roles in factories from repetitive tasks to more supervisory and decision-making functions. However, these tools are still in the early stages of broader deployment.

While the benefits of AI in manufacturing are clear, concerns are emerging. Experts like Elon Musk and Stephen Hawking have expressed fears about the unchecked rise of AI. Musk, in particular, has warned about the dangers of AI surpassing human intelligence, potentially leading to job displacement and greater social inequality.

Researchers and economists have echoed similar sentiments, particularly in regard to the potential disruption of employment in industries that become increasingly automated. As the automation trend continues, industries face the challenge of upskilling their workforce to remain relevant in this changing landscape.

Critics also point out that the high initial cost of integrating AI, along with concerns about data privacy and security, must be addressed before widespread adoption is achieved. Andrew Yang, a former U.S. presidential candidate, has also voiced concerns about AI’s impact on the labor force, advocating for policies to manage the disruption caused by automation.

In conclusion, AI has fundamentally transformed the robotics industry, enabling the development of highly autonomous, intelligent, and adaptive robots. Through the integration of cutting-edge AI algorithms and sensors, robots are now capable of performing complex tasks across various industries with unprecedented precision and efficiency. Companies like Tesla, Boston Dynamics, and BMW lead this AI-driven revolution, utilizing advanced machine learning models and AI-powered sensors to improve robotic functionality.

AI's integration into robotics has opened new frontiers in autonomous navigation, force control, and predictive maintenance, as demonstrated by leaders like Tesla and Boston Dynamics (Nguyen et al., 2020; Raibert & Craig, 1981) [

49,

50]. The future of AI-driven robots, with their growing capability to learn from their environments and improve through cloud collaboration, promises significant advances in industrial efficiency and flexibility (Zhu et al., 2019) [

45].

The future of industrial robotics will increasingly depend on advances in AI, particularly in areas like cloud robotics, where real-time data sharing and collaboration among robots will further enhance productivity. As AI continues to evolve, the next generation of robots will likely exhibit even greater autonomy, learning capabilities, and adaptability, positioning AI-powered robots at the forefront of the industrial landscape.

By expanding the AI and technological focus of this research, the paper highlights the ongoing advancements in the integration of AI and robotics, setting a solid foundation for future innovations and applications.

Looking ahead, AI’s role in robotics is poised to expand significantly. Emerging technologies such as Generative AI, which enables robots to create new designs or solutions autonomously, and self-developing AI, where robots continuously learn from their environment, are likely to define the next phase of industrial automation.

By 2030, we expect to see robots that not only perform tasks but also proactively find innovative ways to optimize production processes, reduce costs, and increase overall efficiency. AI-driven autonomous robots will further evolve into systems capable of managing entire manufacturing lines with minimal human intervention.

Author Contributions

Conceptualization, M.I.S., U.L.M. and V.V.; methodology, M.I.S., U.L.M. and V.V.; formal analysis, M.I.S. and U.L.M.; investigation, M.I.S., U.L.M. and V.V.; resources, M.I.S., U.L.M. and V.V.; data curation, M.I.S. and V.V.; writing—original draft preparation, M.I.S.; writing—review and editing, M.I.S. and U.L.M.; visualisation, M.I.S.; supervision, U.L.M.; project administration, M.I.S.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National University of Science and Technology POLITEHNICA Bucharest, grant GNAC ARUT-2023 number 150.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data substantiating the conclusion of this study are included. Other primary datasets are available, upon reasonable request, from the author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gusan, V.; Țîțu, A.M.; Bogorin-Predescu, A.; Tertereanu, P.; Bâlc, D.; Pop, A.B. From Industrial Robots to Collaborative Robots: Exploring the Transformation in the Collaborative Work Environment. New Technol. Dev. Appl. VII 2024, 1069, 32–41. [Google Scholar]

- Titu, A.M.; Gusan, V. The Influence of Collaborative Robots on the Quality, Efficiency and Effectiveness of Automotive Manufacturing Flows. New Technol. Dev. Appl. V 2022, 472, 58–67. [Google Scholar]

- Velásquez Villagrán, N.; Pesado, P.; Estevez, E. Cloud Robotics for Industry 4.0 - A Literature Review. Cloud Comput. Big Data Emerg. Topics 2020, 1291, 1–14. [Google Scholar]

- Schmidbauer, C.; Komenda, T.; Schlund, S. Teaching Cobots in Learning Factories – User and Usability-Driven Implications. Procedia Manuf. 2020, 4, 398–404. [Google Scholar] [CrossRef]

- Saccuti, A.; Monica, R.; Aleotti, J. A Comparative analysis of collaborative robots for autonomous mobile depalletizing tasks. In Proceedings of the 2022 Sixth IEEE International Conference on Robotic Computing (IRC); pp. 34–38.

- Grover, A.K.; Ashraf, M.H. Leveraging autonomous mobile robots for Industry 4.0 warehouses: a multiple case study analysis. Int. J. Logist. Manag. 2024, 35(4), 1168–1199. [Google Scholar] [CrossRef]

- Benotsmane, R.; Dudás, L.; Kovács, G. Collaborating robots in Industry 4.0 conception. IOP Conf. Ser.: Mater. Sci. Eng. 2018, 448. [Google Scholar] [CrossRef]

- Gonzalez, A.G.; Alves, M.V.; Viana, G.S.; Carvalho, L.K.; Basilio, J.C. Supervisory Control-based navigation architecture: A new framework for autonomous robots in Industry 4.0 environments. IEEE Trans. Ind. Inform. 2017, 14(4), 1732–1743. [Google Scholar] [CrossRef]

- Malý, I.; Sedláček, D.; Leitao, P. Augmented reality experiments with industrial robot in industry 4.0 environment. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN); pp. 176–181.

- Nomura, T.; Kanda, T.; Yamada, S. Measurement of moral concern for robots. In Proceedings of the 2019 14th ACM/IEEE International Conference on Human-Robot Interaction (HRI); pp. 540–541.

- Falayi, A.; Ayeni, A.; Adebayo, B.; Abdullahi, A. Towards digitalization of fruits and vegetables supply chain: Digital Twins and Internet of Things Approach. Glob. J. Res. Eng.: G. Ind. Eng. 2024, 24(1), Version 1.0. [Google Scholar]

- Agalianos, K.; Ponis, S.T.; Aretoulaki, E.; Plakas, G.; Efthymiou, O. Discrete event simulation and digital twins: review and challenges for logistics. Procedia Manuf. 2020, 51, 1636–1641. [Google Scholar] [CrossRef]

- Assaqty, M.I.S.; Gao, Y.; Hu, X.; Ning, Z.; Leung, V.C.M.; Wen, Q.; Chen, Y. Private Blockchain-Based Industrial IoT for Material and Product Tracking in Smart Manufacturing. IEEE Network 2020, 34(5), 91–97. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert García, R.E.; RamírezMoreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.D.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14(6), 1335. [Google Scholar] [CrossRef]

- Bhatti, G.; Mohan, H.; Singh, R.R. Towards the Future of Smart Electric Vehicles: Digital Twin Technology. Renew. Sustain. Energy Rev. 2021, 141, 110801. [Google Scholar] [CrossRef]

- Yinong, C. IoT, Cloud, Big Data and AI in interdisciplinary domains. Simulation Modelling Practice and Theory 2020, 102, 102070. [Google Scholar] [CrossRef]

- Gill, S.S.; Xu, M.; Ottaviani, C.; Patros, P.; Bahsoon, R.; Shaghaghi, A.; Golec, M.; Stankovski, V.; Wu, H.; Abraham, A.; et al. AI for Next Generation Computing: Emerging Trends and Future Directions. Internet Things 2022, 19, 100514. [Google Scholar] [CrossRef]

- Lim, K.Y.H.; Zheng, P.; Chen, C.-H. A State-of-the-Art Survey of Digital Twin: Techniques, Engineering Product Lifecycle Management and Business Innovation Perspectives. J. Intell. Manuf. 2020, 31, 1313–1337. [Google Scholar] [CrossRef]

- Prasad, R.; Rohokale, V.; Prasad, R.; Rohokale, V. Internet of Things (IoT) and Machine to Machine (M2M) Communication. In Cyber Security: The Lifeline of Information and Communication Technolog; 2020; pp. 125–141. [Google Scholar]

- Rejeb, A.; Rejeb, K.; Zailani, S.; Treiblmaier, H.; Hand, K.J. Integrating the Internet of Things in the Halal Food Supply Chain: A Systematic Literature Review and Research Agenda. Internet Things 2021, 13, 100361. [Google Scholar] [CrossRef]

- Sarker, I.H.; Khan, A.I.; Abushark, Y.B.; Alsolami, F. Internet of Things (IoT) Security Intelligence: A Comprehensive Overview, Machine Learning Solutions and Research Directions. Mob. Netw. Appl. 2022, 1–17. [Google Scholar] [CrossRef]

- Wenfeng, L.; Fan, H.; Lei, C.; G., W.; W., Z.; Y., P. Digital Twin-Driven Proactive-Reactive Scheduling Framework for Port Multi-Equipment under a Complex Uncertain Environment. Simul. Model. Pract. Theory 2024, 2024. [Google Scholar] [CrossRef]

- Şahan, A.; Kathiravan, S.; Lokesh, M.; Raffik, R. Role of Cobots over Industrial Robots in Industry 5.0: A Review. In Proceedings of the 2023 2nd International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA); pp. 1–5.

- Albinowski, M.; Lewandowski, P. The Impact of ICT and Robots on Labour Market Outcomes of Demographic Groups in Europe. SSRN Electron. J. 2023.

- Bachmann, R.; Gonschor, M.; Lewandowski, P.; Madoń, K. The Impact of Robots on Labour Market Transitions in Europe. SSRN Electron. J. 2024.

- El-Gendy, S. IoT Based AI and Its Implementations in Industries. In Proceedings of the 2020, 15th International Conference on Computer Engineering and Systems (ICCES); 2020; pp. 1–6. [Google Scholar]

- Kumar, A.; Nadikattu, R. Influence of Artificial Intelligence on Robotics Industry. Engineering 2021.

- Toniolo, L.C.; Camarotto, J.A.; Tonin, L.A.; Silva, S.L. Practices Related to Industry 4.0 and Its Applications in the Field of Ergonomics: Analysis of Applications of Collaborative Robots (Cobots) and Exoskeletons. Rev. Ação Ergonômica 2021. [Google Scholar] [CrossRef]

- Pazienza, A.; Macchiarulo, N.; Vitulano, F.; Fiorentini, A.; Cammisa, M.; Rigutini, L.; Iorio, E.D.; Globo, A.; Trevisi, A. A Novel Integrated Industrial Approach with Cobots in the Age of Industry 4.0 through Conversational Interaction and Computer Vision. ArXiv Presented at the Italian Conference on Computational Linguistics. 2024, arXiv:abs/2402.10553. [Google Scholar]

- R, R.; Sathya, R.R.; V, V.; S, B.; N, J.L. Industry 5.0: Enhancing Human-Robot Collaboration through Collaborative Robots – A Review. In Proceedings of the 2023 2nd International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA), 2023; pp. 1–6.

- International Federation of Robotics. Available online: https://ifr.org/img/worldrobotics/2023_WR_extended_version.pdf (accessed on 2 September 2024).

- International Federation of Robotics - World Robotics 2023 Report: Asia Ahead of Europe and the Americas. Available online: https://ifr.org/ifr-press-releases/news/world-robotics-2023-report-asia-ahead-of-europe-and-the-americas (accessed on 2 September 2024).

- AI in Robotics Statistics. Available online: https://www.coolest-gadgets.com/ai-in-robotics-statistics/ (accessed on 3 September 2024).

- Global artificial intelligence market size and forecast. Available online: https://www.verifiedmarketresearch.com/product/global-artificial-intelligence-market-size-and-forecast/ (accessed on 4 September 2024).

- 150+ Artificial intelligence statistics for October 2024 - Techopedia. Available online: https://www.techopedia.com/artificial-intelligence-statistics (accessed on 5 September 2024).

- 24 Top AI Statistics And Trends In 2024 - Forbes. Available online: https://www.forbes.com/advisor/business/ai-statistics (accessed on 3 September 2024).

- AI Statistics for 2024: Growth, Usage and Adoption. Available online: https://mspoweruser.com/ro/ai-statistics (accessed on 4 September 2024).

- 57 New artificial intelligence statistics (Oct 2024) - Exploding Topics. Available online: https://explodingtopics.com/blog/ai-statistics (accessed on 4 September 2024).

- Artificial Intelligence (AI) in the U.S. - Statistics & Facts. Available online: https://www.statista.com/topics/7923/artificial-intelligence-ai-in-the-us (accessed on 6 September 2024).

- Artificial Intelligence (AI) Worldwide - Statistics & Facts. Available online: https://www.statista.com/topics/3104/artificial-intelligence-ai-worldwide (accessed on 7 September 2024).

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. E. ImageNet classification with deep convolutional neural networks. Advances in neural information processing systems 2012, 25, 1097–1105. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics: Modelling, planning, and control; Springer Science & Business Media, 2010. [Google Scholar]

- Thrun, S.; Burgard, W.; Fox, D. Probabilistic robotics; MIT press, 2005. [Google Scholar]

- Zhu, Q.; Liu, B.; Chen, C. H.; Zheng, P. An overview of the smart manufacturing paradigm with emphasis on AI in the production process. IEEE Access 2019, 7. [Google Scholar]

- Bicchi, A.; Tonietti, G. Fast and "soft-arm" tactics in robot control. IEEE Robotics and Automation Magazine 2004, 11(2), 22–33. [Google Scholar] [CrossRef]

- Hogan, N. Impedance control: An approach to manipulation: Part II—implementation. Journal of Dynamic Systems, Measurement, and Control 1985, 107(1), 8–16. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep learning; MIT press, 2016. [Google Scholar]

- Nguyen, H.; Pham, M.; Nguyen, D.; Vu, L. AI-powered force control in industrial robotics. Journal of Robotics and Automation Systems 1034, 128, 1023–1034. [Google Scholar]

- Raibert, M. H.; Craig, J. J. Hybrid position/force control of manipulators. Journal of Dynamic Systems, Measurement, and Control 1981, 102(2), 126–133. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Artificial intelligence, machine learning and deep learning in advanced robotics, a review. Cognitive Robotics 2023, 3, 54–70. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).