1. Introduction

There is little doubt that the space debris problem is rapidly becoming acute - there are currently some 23,000 pieces of space debris exceeding 10 cm in diameter in Earth orbit. In 2021, the decommissioned Russian satellite Cosmos-1408 was deliberately destroyed in an anti-satellite test creating a debris field of 1500 pieces at 485 km altitude, endangering the International Space Station including its two Russian occupants. In 2007, China had conducted a similar anti-satellite test at 865 km altitude in polar orbit increasing the debris population by 25%. The US and India conducted similar tests in 2008 (at approximately 250 km altitude) and 2019 (at 283 km altitude) respectively but these were at much lower altitude to ensure atmospheric removal of the debris. These deliberate destructions join accidental ones such as the collision between the decommissioned Russian Kosmos-2251 with the operational Iridium-33 satellite at 800 km altitude which generated 1800 fragments. SpaceX’s Starlink global fast internet mega-constellation stands at 1892 satellites (in 2021) of which 1732 are operational in low Earth orbit at ~500 km altitude – it is projected to grow to 42,000 satellites. These satellites with their deployed solar panels were bright enough to interfere with astronomical observations including near-Earth asteroid tracking. More recent Starlink satellites have reduced their optical footprints down to magnitude 6.0 by incorporating sunshades. Their altitude is low enough to ensure that atmospheric friction will induce orbit decay and removal soon after their mission lives. Morgan Stanley projects that this sector will comprise 50-70% of the ~

$1 T space economy in 2040. Although they do not contribute to persistent space debris populations, it is expected that space traffic at all main orbits will increase with an attendant growth in orbital collisions. If the Kessler limit is surpassed, a self-perpetuating shroud of debris could partially entomb the Earth. This would not persist for astronomical timescales but for perhaps hundreds of years. To prevent the Kessler limit being attained, the most amenable solution is to remove around 5-10 of the largest pieces of space debris every year [

1]. The most crucial debris targets are Envisat and Zenith 2 rocket upper stages.

Such pieces must be transported either into graveyard orbits which do not interfere with useful orbits or low orbits with high atmospheric friction for effective removal by re-entry. There are several approaches to debris acquisition [

2]

: tentacle capture (e.g. e.Deorbit), single arm capture (e,g, DEOS), multi-arm capture, net capture (e,g. ROGER), tethered gripper (e.g. ROGER) or harpoon (e,g. e.Deorbit). Robotic geostationary orbit restorer (ROGER) was a concept that was realised through RemoveDebris (2018) that demonstrated a tethered harpoon and a capture net mechanism. Robotic arms are most commonly used for versatility by grappling of launch vehicle adapters (most commonly Marman rings) designed for high loads [

3]. Debris removal is also challenging requiring augmentation of the target spacecraft by [

2]: foaming, inflating or wrapping the target to increase drag; electrodynamic tether to generate Lorenz interactions or mechanical tether as a slingshot; solar sail propulsion; contactless interaction by pulsed laser or ion beam shepherding.

The primary obstacle to solving the problem is that no institution is prepared to shoulder the high cost of such a shared public good. The solution is to introduce the prospect for profit by recovering such debris and converting them into assets – salvage. Given that the largest pieces of debris are essentially dysfunctional satellites that have typically run out of station-keeping fuel, we briefly discuss a deconstruction process before addressing the topic of the paper – self-assembly of new spacecraft from modules that may be manufactured in-situ.

2. Salvaging & Refurbishing Spacecraft Debris

We require an orbital salvage handling facility that may itself be constructed from modular trusses, e.g. a robotically-reconfigurable 3D truss structure may be built from a factory floor constructed from tiles onto which are mounted a modular manipulator for connecting trusses, a motorised elevator mechanism for the creation of new floors and in-built guide-rails for truss alignment, so that the truss is built of bars and nodes incrementally from the floor [

4]. The truss may be supported by a Skyworker-type of truss-mobile manipulator for building large space structures [

5]. Skyworker is a conceptual mobile 9 degree of freedom (DOF) manipulator that assembles a growing truss by manipulating the truss components. For this function, it is fitted with locking pliers and walks along the truss at a constant speed. The beams and nodes themselves may be 3D printed from metal wire feedstock using electron beam or other additive manufacturing method. Alternatively, a self-mobile manipulator designed for rectangular strut-and-node truss assembly may be replaced with a re-integrated truss design based on I-beam units forming hexagonal assemblies [

6]. We assume that a freeflying robotic spacecraft onto which one or more grappling manipulators is mounted is employed for acquiring the spacecraft debris targets [

7,

8]. There is a high degree of undesirable dynamic coupling between the spacecraft and its mounted manipulator but the freeflying approach does not suffer the dynamic singularities of the freefloating system [

9]. Freeflyers and truss robots were proposed for assembling large 100 m x 100 m modules for the NASA Solar Power Satellite Reference model [

10]. Another approach is the freeflying intelligent fibre/rope match-maker robot (FIMER) concept that employs a tether between two robot freeflyers to autonomously dock them by reeling the tether [

11] but we suggest that direct manipulation of the target spacecraft is sufficient because complex manipulation tasks are required for the deconstruction process anyway.

Many components of the target debris spacecraft are likely to be degraded and unrecoverable such as spacecraft computers (due to radiation damage) and chemical batteries (due to degraded depth of discharge) while others may be refurbished such as solar panels. Deconstruction of the target spacecraft begins with non-destructive removal of high value items that can be redeployed. This requires the deployment of highly dextrous manipulators to remove the high value items. A test case for such an operation was the Solar Maximum Repair Mission (SMRM 1984) which involved two major repair phases: (a) replacement of an orbital replacement module (ORM) that was designed for servicing using 4 simple single-bolt exchanges [

12]; (b) replacement of a main electronics box (MEB) that was not designed for servicing by exchanging 14 x 10-32 non-capture screws, 4 x 10-32 captive cap screws, and 22 x 4-40 slotted head connector screws after cutting, folding, taping and retaping outer thermal blankets [

13]. These astronaut-executed activities using standard power tools and specialised custom tooling have been laboratory demonstrated through direct robotic teleoperation. Robotic on-orbit servicing has been progressing by applying the lessons of the Solar Maximum Repair Mission and Hubble Space Telescope Servicing Mission by astronauts to large space telescope and solar power satellite assembly [

14].

Deployables such as solar panels, antenna and thermal radiators may be recovered

in toto through disassembly from the mounting spacecraft. During this process, it is likely that motor drives of deployment mechanisms may be compromised but their magnets and coils should be recovered.

Motors often suffer from stiction with long term exposure to space and the lubrication challenges in space would have to be resolved in recovering motor units. Solar panels as high value items may be refurbished using laser annealing at ~1200

oC close to the melting point of Si to eliminate defects [

15]. Thermal blankets may be recovered through unfolding, cutting, refolding and taping (as performed in the SMRM 1984 MEB exchange). The wiring harness is also highly valuable and can be re-used – it is typically wrapped internally within the spacecraft and secured by mounting brackets.

It is an open question whether propulsion systems can be recovered and refuelled – conventional propulsion comprise a mix of thruster assemblies, fuel lines and tankage and the currently envisaged non-cryogenic chemical fuel sources include hydrogen peroxide or hydrazine which must be resupplied (though H2O2 could be synthesised from water resources). Ion engines require more exotic fuels but ion engines would constitute high value items if they have not suffered erosive degradation through sputtering. An alternative propulsion system that might be manufacturable in-situ include sails of reflective aluminium on Mylar though this would require advanced processing capabilities on-orbit.

High value internal components include cameras/telescopes, GPS receivers, star sensors, gyroscopes, motors, magnetometers, travelling wave tubes, etc if they can be recovered intact – if not, high value parts such as magnets and cathodes (from vacuum tube devices such as travelling wave tube amplifiers and magnetrons) should be salvaged. Useful parts of the structure may be recovered such as structural faceplates that can potentially be welded into desired configurations. Once mined for high value parts, the spacecraft comprises a structural husk filled with secondary structure and unusable components which may be subjected to several processes (

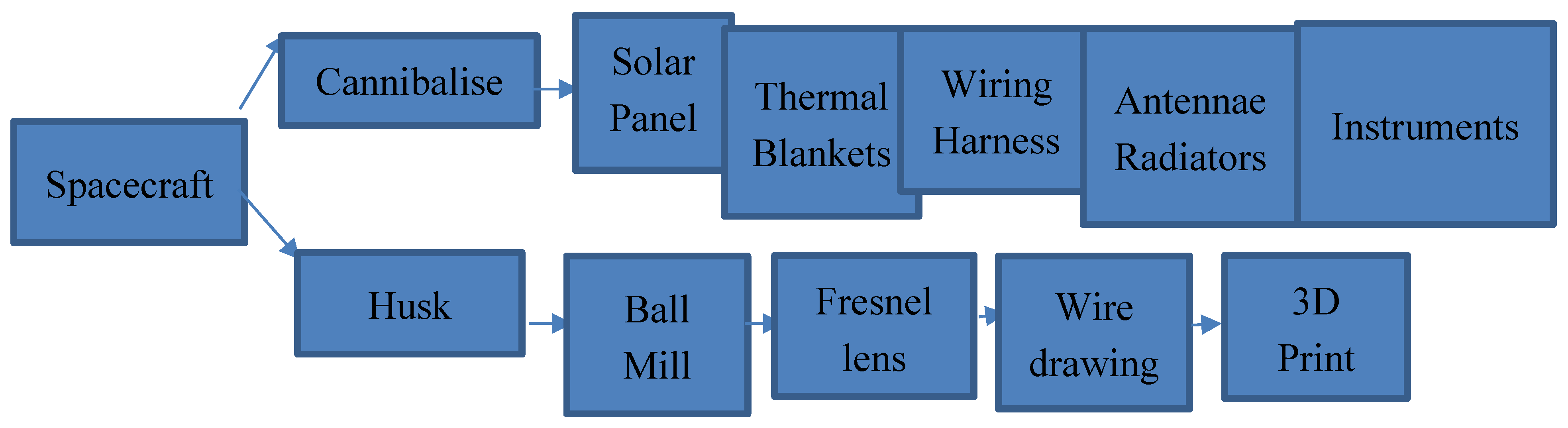

Figure 1).

The primary and secondary structure of aluminium alloy is dominant but there will be small amounts of other minor metals such as lithium from batteries. The remaining material may be ground into powder using ball mills followed by pyrolysis to evaporate polymeric material into a syngas-like vapour – syngas forms the basis for radiation-tolerant silicone plastic (siloxanes) manufacture (Rochow process) which may be 3D printed into components using polymer extrusion. This aluminium-dominated alloy powder may be melted and drawn into wire that provides the feedstock for 3D printers to construct new structures on-demand. We have demonstrated the use of Fresnel lenses as solar concentrators to melt aluminium chips (

Figure 2A and 2B). There are several 3D printer technologies suited to this task including selective laser sintering/melting and electron beam additive manufacturing [

16]. Although it can be envisaged that new spacecraft structures can be manufactured in-situ supplemented by salvaged high-value components, the creation of new functional spacecraft requires more sophisticated capabilities.

We focus on reconfigurable systems that possess the advantage of modularity for ease of assembly. Each module is an encapsulated robotic unit comprising structure, sensors, actuators and connectors. Connectors are typically complex as they must be mechanically robust yet readily reversible, provide electric power and data connection, accommodate thermal pathways. It is crucial that latching is rigid as well as reversible requiring actuators. For space application, self-alignment mechanisms for mechanical connector are essential to accommodate errors. Internal sensors are employed for controlling actuation, e.g. potentiometers, encoders, Hall sensors and/or strain sensors. External sensors detect neighbouring modules such as infrared sensors. There are two types of actuator – a large actuator for relative movement of modules and latch actuators for connectors. Shape memory alloys (SMA) are often used as latching actuators due to high force/torque output despite their short stroke ~5% maximum strain. Other options include permanent or electropermanent magnet latching but these tend to be weak. Large actuators are usually DC motors or electromagnets.

There are different scales of reconfigurability – inter-reconfigurability in which modules are the unit of reconfigurability and intra-reconfigurability in which internal components such as actuators, sensors, etc may be reconfigured with a module [

17]. A combination of both constitutes nested reconfigurability. Most approaches to reconfigurable robotics are of the former form but here we invite the potential for the latter approach. There are two specific applications that we are concerned with here: (i) space-based reconfigurable robotic manipulators that comprises a single DOF motorised joint between two identical link structures mounted with connectors; (ii) self-deploying large area structures such as lunar bases. This paper addresses how nested reconfigurability might be explored.

We envisage on-orbit manufacture of reconfiguration modules using either feedstock launched from Earth and/or larger pieces of spacecraft debris. The mainstay of such a facility will be 3D printing. We discuss how 3D printing may be employed to manufacture complex devices on-orbit as an integral part of a self-assembly process. Most self-assembling systems are comprised of pre-existing pre-manufactured modules. Our goal is to build robotic systems that manufacture and assemble other robotic systems by exploiting the versatility of 3D printing. Most 3D printing has focussed on the manufacture of structures, especially intricate structures that cannot be manufactured by other means. Robotic 3D printing can minimise assembly complexity to as few steps as possible by 3D printing complex electromechanical systems. 4D-printing introduces a time dimension to the 3D printing process. There has been little consideration of 3D printing of mechatronic elements. Stereolithographically 3D printed structures with cavities and mechanical joints for inserted prefabricated electronics, actuators and sensors permit building simple mobile robots [

18]. These components were not 3D printed. We address this gap by demonstrating 3D printing of electric motors within a self-assembly context. Our goal here is to aim for 3D printing complete self-assembling robots – structure, electronics, sensors and actuators. We have demonstrated a 3D printed DC electric motor. The only parts that were not 3D printed are the coiled wiring and the motor shaft (this has subsequently been achieved but not in a self-assembly context [

19]. We have incorporated our 3D printed motor with 3D printed TRIGON panels to form a TRIGON self-assembling system. The 3D printed motorised panel system demonstrates that the motor aspect of robotic self-assembling machines is amenable to 3D printing. What this implies is that self-assembly can be extended to include self-manufacture. Before discussing this in detail, we shall review self-assembling/self-reconfiguring modular systems.

3. Modular Spacecraft

Modular spacecraft and robotic manipulators are the target for both the space manufacturing facility and the re-furbished spacecraft fashioned from space debris. Manual assembly of the ISS involved 160 astronaut EVAs amounting to ~1000 hours. Robotic on-orbit assembly involves several capabilities – automatic rendezvous and docking, robotic manipulation, maintenance and repair. Self-assembly is a highly desirable capability for construction [

20]. Self-assembly involves automatically assembling modular components into specific configurations. Modules offer reusability, reconfigurability and self-repair capability. Comprehensive reviews of spacecraft modularity and its application to on-orbit servicing and spacecraft reconfigurability are given in [

14,

21,

22]. Modularity is the key to dealing with complexity. Modules must be standardised and exhibit standardised interfaces for interchangeability. The multimission modular spacecraft (MMS) was a modular spacecraft design of six modules mounted onto a triangular prism-based truss (1975). There were seven spacecraft configured from MMS including the Solar Maximum Mission (1982). The HST (1990) was a modular design comprising a primary mirror, a secondary mirror, a scientific instrument suite, a service module and solar arrays. It was designed to be serviced and underwent five servicing missions including a first repair and upgrade mission (1993). Spacecraft for the universal modification of orbits (SUMO 2004) was a spacecraft that demonstrated autonomous rendezvous and docking through capture by robotic arms. Orbital Express (2007) was a successful two-spacecraft servicing demonstration similar to ETS-VII (1997).

Self-reconfigurable machines comprise multiple mechanical modules (usually homogeneous) that connect to each other and alter their morphology. A few reconfigurable modules can generate a wide variety of space structures for different applications. Enhanced system reliability is achieved at low cost. These modules can include joints with integrated motors, serially or parallel connected links, a set of end-effector tooling that is compatible with a standard wrist plate, sensors, signal processing electronics, etc. The modules can be configured into spacecraft/manipulator platforms for different roles. Such a system could provide the basis of large spacecraft structures and/or formations to perform coordinated functions.

On-orbit assembly of large composite spacecraft comprised of modules is essential for constructing large space structures [

23]. Traditionally, on-orbit assembly operations have required the use of astronauts but robotic self-assembly is now feasible. Self-assembly may be implemented at any scale with a common requirement that components must be mobile and interact via weak forces to control them. Static self-assembly finds configurations with global or local equilibrium while dynamic self-assembly dissipates energy to generate stable but dynamic patterns [

24,

25]. Static assembly is commonly adopted in engineering applications (as here), but dynamic assembly is exploited by biological molecular self-assembly subject to random external forces. Macroscopic self-assembly requires a source of external propulsion unlike Brownian motion inherent in microscopic self-assembly [

26,

27]. The use of environment-supplied perturbations to macroscopic self-assembly has limited practicality. There will be few sources of random environmental perturbation that can be exploited in space so external sources of actuation will be required. One option to eliminate thrusters for station-keeping and manoeuvring is to employ compact structurally connected modules without the need for formation flying [

28,

29]. This eliminates station keeping issues though additional problems such as structural vibration suppression become important. There are four approaches to self-assembly of spacecraft: (i) a set of modular building blocks that can be constructed and configured into different formations – a cellular approach; (ii) self-assembly of modules that are assembled and configured by a manipulator; (iii) a small set of modular building blocks for constructing functionally diverse structures through self-folding; (iv) tug-based based assembly [

30].

We consider aspects of each approach (except the fourth) insofar as it illustrates our central theme of actuators and motors. We first address the issue of connecting interfaces between spacecraft modules.

4. Active Connectors between Modules

Many self-assembling and reconfigurable systems adopt joining through either (electro)magnetic coupling and/or mechanically actuated attachment (which, if motorised, also involve magnetic components). We first consider magnetic connections which have dominated small-scale self-assembly. The electropermanent magnet comprises an electromagnet whose magnetic field changes the effective magnetisation of a permanent magnet – the permanent magnet has a fixed magnetic field while the magnetically soft material responds with variable magnetism. By controlling the alignment of the soft magnetisation vector, the overall magnetic configuration can be tailored. This may be applied to self-building structures which then use remanent magnetism of the permanent magnets for stability of the final assembly. This permanent magnetic coupling can also be modulated by activating the electromagnets. Electromagnets have been used to move non-magnetic electrically conductive metal (such as aluminium) objects without contact [

31,

32]. Time-varying magnetic fields induce eddy currents which interact with the magnetic field and generate mechanical forces. These mechanical forces can be controlled through arrays of rotating dipole magnetic fields along any axis.

ElectroVoxel is a cube-based reconfigurable robot that reconfigures itself by pivoting along its edges [

33]. It uses electromagnets embedded in its edges to create mutually attractive or repulsive magnetic forces between cubes. Pivoting maneouvres by controlling electromagnetic repulsion either side of the attractive electromagnetic hinge allow the cubes to re-position themselves relatively into 2D and 3D structures. A variation on this is non-contacting magnetic flux pinned revolute joints implemented by high temperature superconductors [

34]. These electromagnetic connections are not as reliable as mechanical connectors. Most approaches for spacecraft require mechanical, electrical and thermal interfaces. Self-assembly of large optical structures from smaller modules can dock using a set of electromagnets coupled to probe-and-drogue mechanisms in a 120

o configuration (Kelvin clamps) [

35,

36]. This is an example of using both electromagnetic and mechanical interfacing.

We now address mechanical connections which dominate large-scale self-assembling systems. Self-assembly implies the ability of modules to form a single composite configuration. An example is okuriari, the Japanese art of carpentry that adopts joints without nails, screws or adhesive to construct a specific assembly configuration. They are not generally reconfigurable. Self-assembly may also be implemented through connecting mechanisms between modules. If the modular components are standardised and interchangeable, reconfigurability is implemented by rearranging those modules. The ability to reconfigure into multiple assemblies from modular units affords significant advantages - manufacturing efficiency, versatility of implementation, robustness of redundancy and low cost due to economies of scale. Reconfigurability involves adjusting kinematic connectivity of multiple modules to the task at hand. For self-reconfigurable robots, each module must be self-contained and interconnectable with each other. Interconnectable modularity ensures that self-reconfigurable robots may be configured to their specific tasks.

Mechanical coupling is much stronger than magnetic coupling, offering rigid connections suitable for space application. However, active connectors provide electromechanical rather than just mechanical connections, i.e. they involve actuation. Robotic assembly requires manipulation of two parts and joining them with standardised fastening mechanisms. Each module must make/break connections with other modules, i.e. a docking interface with high mechanical strength and stiffness, precise alignment with compliance to misalignment. Assembly and docking requires well-defined tolerances in relative positioning and orientation and a controlled relative velocity. Connectors should have alignment features such as fixture pins to ensure correct alignment with a “soft-latch” prior to a full positive lock, especially in microgravity where gravity cannot assist. Mechanical, electrical, optical and thermal interfaces must be tolerant of misalignment and self-aligning.

Connector design must be rigidisable, reversible and re-usable. Docking mechanisms are the most complex mechanical part of modules. Mechanical connectors must be robotically and reliably mated/demated – this eliminates bayonet-style connectors unless a ratchet tool is adopted. Docking fixtures are a variation on the peg-in-hole task for which the remote-centre compliance (RCC) linkage was designed [

37]. Modular robotics has evolved from automatic quick-change tooling using standardised connections. CEBOT adopted a probe-and-drogue docking mechanism. The ESA latch is a development of this approach [

38]. It requires a target capture pin while the hooked latching levers possess a ball at each end to engage a circumferential groove around the grapple pin. If the control pin is pushed further into the pin by its single motor, the levers open to disengage the pin. Latchability implies the requirement for actuation. A common approach is to adopt hooks actuated by shape memory alloys or electric motors, the former being popular [

39].

One requirement is the necessity to reversibly lock connectors in a specific configuration to prevent relative movement [

40]. Locks are mechanical, frictional or singularity-based. Mechanical locks rely on mechanical obstruction between parts and include latches, ratchets, dog clutches and cam-locks. Latches comprise of a receiving hook and a pawl to lock either in a single or in multiple positions. Ratchets comprise a toothed gear and a pivoting pawl that engages the teeth. A dog clutch comprises two interlocking parts that only rotate with respect to each other when disengaged. A cam-lock is a cam-based device exploits a cam to engage/disengages a lock cyclically, e.g. the Geneva drive. Mechanical locks are small and require little energy. Frictional locks rely on friction to prevent relative motion and include electromagnetic brakes, overrunning clutch, non-backdrivable gearing, self-amplifying brakes and piezo-actuated brakes [

40]. Non-backdrivable gearing such as work drives have poor efficiency. Electromagnetic brakes exploit attraction between a permanent magnet and an electromagnet, e.g. brake discs. A piezo-actuated brake is similar except it uses a piezoelectric stack for actuation but suffers from a small stroke. Self-amplifying brakes such as the capstan exploits friction between a cable and pulley to brake the cable as it tightens – this is used in the Barratt robotic arm. Frictional locks are easier to unlock than mechanical locks but have limited locking torque but high energy consumption. Singularity locks possess a singular position with infinite locking torque such as the four-bar linkage – it has a singular position in which three of the four joints are aligned which can only be perturbed by an actuator. Singularity locks are bulky but have low energy consumption with high locking torque and ease of unlocking. A highly valuable capability would be that of force/torque sensing feedback of contact forces/torques to modulate the connection according to applied loads.

Robotic interface mechanisms have four fundamental physical properties [

41]: (i) a specific geometry to provide rapid, self-aligning docking and release; (ii) latching stiffness, stability and robustness with high load strength and impact tolerance without buckling; (iii) data, electric power and thermal transfer interface with low power during state transition and unpowered in-state; and (iv) low mass and small parts count for ease of assembly and maintenance. The latch should support disconnection from both sides which suggests a genderless connection scheme. SpaceFibre is a complement to the SpaceWire electronics standard for data routing that is compatible with modular configurations.

The universe of connectors is large so we describe two foundational and influential connectors that illustrate well issues in connector design applicable to space application. The DRAGON connector for self-reconfiguring robots can self-align and connect with a high strength-to-weight ratio [

42]. It comprises three components: (i) guide with two funnels and two mating cones to align the connectors with a tolerance of 45

o and 20% diameter offsets; (ii) thin load-bearing Al outer shell; (iii) steel latching spring to lock the mated connectors inside the shell. The latching spring is actuated by a shape memory alloy wire along the inside of the spring which compresses the spring to release the mated connector. Two infrared emitters within each guiding cone act as beacons and two infrared receivers on the funnels provide optically isolated electrical connections for data transfer. Within the connector, 12 thick spring-loaded copper contacts provide a power conduit. The ACOR (active connector for robotic systems) connector has both a male pin and a female receptacle for mechanical and electrical interfacing [

43]. The pin and receptacle contain many flexible lamellae for connecting to the opposite gender lamellae with high shear strength. A shape memory alloy actuator wrapped around the lamellae displaces the ends of the lamellae for disconnection. Either pin or receptacle sides may be activated to release the connection. The pin/receptacle provides the electrical power connection while the lamellae provide the data connection. The ACOR universal connector with its side-by-side male and female connectors is effectively genderless. Both of these connectors for self-reconfigurable robotics utilise shape memory alloy actuators to mediate connection.

5. Self-Assembling Modular Systems

We review some selected research in the broad field of self-assembly with particular focus on actuation to illustrate the implications of 3D printing electric motors and other magnetic devices. Only a few foundational examples of the “yet another modular robot” are discussed as they suffice to illustrate the principles of self-assembly. Self-reconfigurable modules offer adaptability, robustness and self-repair [

44]. The cube and the dodecahedron are the only platonic solids that can construct space-filling shapes. The Proteo assembly system uses dodecahedral modules that may assemble into any topology including branched structures [

45]. Each module can communicate only with its immediate neighbours. They roll relative to each other’s outer surfaces by following pheromone trails to control their morphology. The simpler cubic structure is more common for reconfigurable robotic modules and cubes can build arbitrary structures. Self-assembling systems such as M-TRAN, CONRO, PolyBot, Swarm-bot, fractum and Super mechano-colony involve identical general-purpose modules that can be adapted for multiple functions [

46]. Reconfigurable systems may be classified into three architecture – lattice architectures in which modules are arranged into cubic or hexagonal grids (e.g. Crystalline and Molecules), chain/tree architectures in which modules are connected serially into open or closed kinematic chains/trees (e.g. CONRO/PolyBot), and hybrid chain/lattice architectures (e.g. M-TRAN and ATRON) [

47,

48]. To this, we may add trusses and freeforms [

49]. These architectures can be reconfigured either deterministically or stochastically. They are self-propelled on Earth but could be adapted as space freeflyers with appropriate propulsion systems or utilize relative module pivoting.

CONRO is a homogeneous cubical module with three DOF that can autonomously connect using connectors on each facet to generate different morphological configurations such as multiple sub-robots, caterpillar-like loops, snake-like chains and tree-like multi-branched trees [50-52]. A CONRO module comprises a motorised one degree-of-freedom joint connecting two links. Multiple modules can be assembled into different morphologies. CONRO employs radiofrequency communication links for messaging but each module incorporates a self-contained microprocessor with ADC, two servomotor actuators, onboard Li battery power, four connectors and four infrared LED/sensors for communication. In each module, two motors provide two rotary degrees of freedom of 90o pitch and 30o yaw. The CONRO module had docking pins at each end. Each docking pin had a spring-loaded latch to lock the pins and shape memory alloy actuators to release the pins. CONRO exhibited bidirectional infrared transmitter/receiver interfaces for communication between modules.

PolyBot is similar to CONRO in being a homogeneous cubic module-based reconfigurable robot [

53,

54]. Each module with one DOF actuation enables it to link up into legged, tread-based and snake-like locomotion systems. Power is supplied to each module through a tether. Each cubic module comprises a single DOF motorised joint with a DC motor/harmonic drive supported by multiple sensors – proximity sensors, contact sensors, joint encoder and force/torque sensors. An embedded PowerPC processor communicates over a CAN-bus. Two end plates either side of the joint incorporate mechanical/electrical connectors. The hermaphrodite connectors comprise four grooved pins and four chamfered receptacles with infrared sensor feedback. The pins and receptacles provide stability. A shape memory alloy actuator holds modules together with active current opening the latch. The upgraded G3 module is smaller than the G2 module due to the adoption of a pancake motor/harmonic drive. Polybot has self-assembled a manipulator from 6 PolyBot G3 modules.

Both CONRO and Polybot are chain-based self-reconfigurable robots that can form track-like loops, snakes and hexapod legs for locomotion [

55,

56] with space applications [

57]. While many self-reconfigurable modules comprised single joints for chain structures, the reconfigurable Tetrabot module used a multi-link spherical joint allowing the construction of modular trusses with an arbitrary number of struts [

46]. There are other modular robots that have more than a single DOF joint. MTRAN (modular transformer) comprises a set of two DOF joint modules that can be reconfigured as a hybrid chain and lattice system [58-61]. Each module comprises two cubic sections connected by a servomotor link supported by a power supply circuit, pulse generator circuit, embedded microprocessor and digital communications bus. Passive connection plates use permanent rare earth magnets – a stronger magnetic force acts against a weaker nonlinear spring. Detachment is mediated by two antagonistic shape memory alloy springs [

62]. Two pairs of electrodes provide for electrical power while one electrode serves serial communications. Self-assembling modular robot (Sambot) is a chain-based modular reconfigurable robot connected through physical docking interfaces with some functional similarities to M-TRAN [

63]. Its docking mechanism comprises a single motorised curved pyramidal docking hook interface and four passive docking interfaces on its other sides.

SuperBot adopts 3 DOF cubical modules based on the earlier MTRAN modules for self-reconfigurability [

64]. They comprise two modules connected via a link acting as roll joint. AT end each, the cubes are mounted at each end through a yaw joint and a pitch joint respectively. Each cube incorporated electronics for sensors, motors and batteries. One genderless connector on each of the six sides transmit power and data communications. The genderless SINGO connector provided compliance to accommodate misalignments [

54]. SuperBot implemented the digital hormone control system developed for CONRO for reconfiguration [

65]. An alternative is robotic enzymes representing simulated linking between two modules [

66]. Modules have active sites (connectors) which attempt to attach to other modules in a simulated environment.

The 4 DOF Molecube module comprises two atoms attached by a perpendicular connection (bond) similar to MTRAN [

67,

68]. Each atom has five intermolecular connection sites and two motorised DOF. One DOF rotates 180

o around its bond axis and the other rotates 180

o at right angles to its bond axis. A gripper links the molecules together with a bond of superior rigidity to previously adopted electromagnetic bonds. Each molecule houses motors, motor driver circuits and a microprocessor to support RS-485 serial connections. The L-shaped molecule robot can configure into 2D tilings (tilings can be stacked into 3D structures) by moving with respect to each other. They can also self-assemble into locomotive or manipulative structures [

69].

6. Self-Assembling Spacecraft

There are several space-based reconfigurable concepts in which reconfigurability offers robustness and adaptability including expandability and upgradability [

21]. iBOSS (intelligent building blocks for on-orbit servicing and assembly) is a DLR-led programme for developing cubic modules (iBLOCKS) of 40 cm x 40 cm x 40 cm with standardised interfaces including freespace optics that can be reconfigured into multiple architectures. The spacecraft modules have functional specialisation within standardized cubical structures and interfaces for docking, power, thermal and data interconnnection that can be assembled robotically into integrated spacecraft [

70]. The cubic building blocks implement subsystem functions and attach to a central structure via the standard androgynous interfaces. Intelligent space system interface (iSSI) of iBOSS is a standardised lightweight and compact but robust modular interface protocol that builds on a legacy of European interface developments such as the gendered SIROM (standard interface for robotic manipulation) and the androgynous HOTDOCK [

71]. Deployables are attached as external elements. The functional modules of carbon fibre reinforced polymer frames and sandwich panels mounted on aluminium corner nodes are coated with low α/ε ratios to minimise thermal transmission. The disk-shaped interface provides a data connector at its core surrounded by a robust mechanical coupling ring surrounded by an electrically conducting annulus flanked by an outer thermal annulus of high thermal conductivity. Spacecraft servicing involves replacement of iBOSS modules.

MOSAR (modular spacecraft assembly and reconfiguration) is a European programme to develop modular building blocks for both on-orbit assembly and on-orbit servicing of reconfigurable satellites [

72]. MOSAR is similar to iBoss but exploits a manipulator to assemble its module boxes. Its manipulator is a symmetric end-over-end walking manipulator of 7 degrees of freedom that can relocate itself to different attachment points. Its kinematic configuration is generated from high level action plans [

73]. Different skills – attach module, detach module and move module - invoke different kinematic geometries through inverse kinematic regression. To minimise the search space of assembly sequences, previously machine-learned assembly constraints may be transferred to new assembly configurations via a graph neural network representation of semantic relations [

74]. The manipulator manipulates cubical spacecraft modules of dimensions 30-40 cm which may be assembled and/or replaced by virtue of their interconnectability. The standardised interfaces provide mechanical connection, thermal management, electric power distribution and data communications. The manipulator assembles a fully functional spacecraft from the different subsystem modules. MOSAR is thus an example that affords reconfigurable modular manipulators that are addressed in the next section. On-orbit self-assembly is a route to the manufacture of large structures such as astronomical telescopes ~15-20 m diameter which have traditionally been limited by launch fairing size, payload mass and financial costs.

Many self-reconfiguring/self-assembling spacecraft concepts revolve around very large aperture space telescope missions up to 100 m diameter, e.g. next next generation space telescope (NNGST) is conceived as comprising 126 hexagonal segments to be assembled into a 20 m diameter primary mirror. Beyond 20 m diameter, formation flying is favoured to prevent structural resonance higher than the 1 Hz limit imposed by control system cycles – for example, a set of 4 single gimbal control moment gyroscopes may be employed to suppress vibration of a large space structure using a steering law with null space motion [

75]. Docking involves contact dynamics that may be modelled as Hertzian spring-damper systems with impedance control. The robotically assembled modular space telescope (RAMST) adopts a six-legged crawler robot (hexbot) to assemble and service a set of hexagonal truss structural modules forming a 100 m diameter spherically curved primary mirror [

76]. Prior to assembly, multiple mirror modules are bolted onto each of the truss modules. The prototype of an ultra-large structure assembly robot (PULSAR) is a European project for precise assembly of a large primary segmented mirror by autonomous robotics that analysed different interface protocols for power, data, thermal and mechanical load including the iSSI interface of iBOSS [

77]. The autonomous assembly of a reconfigurable space telescope (AAReST) is a Surrey Satellite Technology Ltd mission concept for a self-assembling spacecraft using three smallsats into larger space systems such as large aperture telescopes [

35,

78]. Two independently propelled cubesats mount 10 cm diameter deformable mirror tiles which are docked electromagnetically with a kelvin clamp of three probe-and-drogue mechanisms. A set of modular solar arrays and antennas with standardised connectors are brought together with an inchworm robotic manipulator mounted onto a main micro-satellite base with a focal plane camera instrument.

7. Reconfigurable Modular Manipulators

Robotic manipulators may be employed for spacecraft assembly but may themselves be self-assembled from modules. There are many common features with more generic self-assembly of modules. Robotic manipulators are general purpose machines that can perform many manipulative functions if mounted with a robotic hand. However, such anthropomorphic configurations are not optimal for many specialised tasks. The rationale for modular manipulators is that different tasks are best performed by different kinematic configurations. Reconfigurable robotics is an active approach to implementing versatility in robotics using modules assembled into different kinematic configurations [

79]. The set of modules may have different or identical functions with latter the advantage of simple self-repair. Reconfigurable robots comprise heterogeneous modules (typically, a set of different structural link and motor-driven joint units) that are based on standard electrical, data, mechanical and power interfaces [80–83]. Reconfigurable assemblies are a variation on the “Plug-and-play” Concept in which a small set of modules may be configured using well-defined reversible interfaces into an open or closed kinematic chain.

There are six fundamental joint mechanisms (revolute, prismatic, double-revolute universal, cylindrical, ball-and-socket and planar) but they all can be represented by combinations of one DOF revolute and prismatic joints [

85]. Prismatic joints are rarely adopted in space systems, so revolute joints are the most commonly seen form for space robotic joints. The heterogeneous modules of modular manipulators must include actuator-driven and unpowered joints, nominally, lower-pair prismatic and revolute joints. Standardised joint systems (perhaps with dual drive for redundancy) are equipped with dedicated electronics – microcontrollers, CAN bus interfaces, rotary encoders, tachometers, accelerometers, torque sensors, motor controllers, brakes, signal conditioning, etc), standardised structure and standardised interfaces offer off-the-shelf modules [

84]. Powered modules can incorporate a DC motor, motor drivers, gearing (such as harmonic drives) encoder and brake integrated within a connecting link [

80]. It is desirable that links have circular cross-section to minimise bending stresses and torsional loads. Shape memory alloy actuators are used for opening latches/connectors between modules. A mix of fixed and variable modules may be adopted – a fixed module comprises motorised joints with integrated motor, sensors, controller and interfaces (prismatic, revolute and spherical joints) while variable modules are rigid links of different sizes. Robotic mechanisms constructed from modular components will have a variable kinematic geometry. To support longitudinal and perpendicular mechanical connections, a 45

o connection to the main axis of the module with a 180

o rotation between connecting modules represents a compact approach. Rather than review the ever-expanding range of reconfigurable robots, we shall focus on a select few foundational examples that highlight principles relating to motorised joints.

There are two forms of motor - large motors for high torque output near the base of a modular manipulator and smaller motors near the wrist with lower torque output. To reduce the loading on the outboard links, all prime movers are installed at the shoulder. A set of bevel-geared cable drives is an option but this suffers from large torsional and longitudinal deformations. The manipulator wrist comprises separate roll-pitch-yaw joints intersecting at a common focus. A revolute jointed 6 DOF manipulator similar to the PUMA 560 may be constructed from such modules. A modular reconfigurable design may be optimised for a specific set of tasks. The tasks are determined by the required end effector workspace, end effector velocity/acceleration, maximum end effector deflection and external forces/moments on the end effector. A multipurpose high load precision connector based on a single-turn threaded collar was designed for nuclear applications to enable 6 DOF modular maintenance robots to be built manually [

85].

CEBOT (cellular robot) was the first modular reconfigurable robot to adapt its kinematic configuration to conduct specific tasks [86-89]. Hexagonal modules were connected into different configurations by pairs of hook/receptor interfaces to dock and undock modules (cells). The modules were heterogeneous for performing specialised functions including rotary and telescopic joint modules for manipulators, a hand module for end effectors and mobile modules with wheels. Although heterogeneous, all the modules had the same dimensions (90 mm width by 50 mm (height) in a narrow mass range of 1.1-1.3 kg incorporating the same motors, processors and network communications bus. The mobile module specialized for transport and alignment using infrared and ultrasonic sensors to detect modules. CEBOT autonomously and dynamically configured its optimal morphology for a given task defined by: (i) end effector kinematic coordinates; (ii) end effector force/torque limits; (iii) position accuracy; (iv) manipulator world coordinates; (v) class of end effector for the task; (vi) workspace volume. Simple rules with cooperative module negotiation provided autonomous reconfiguration plans [

90]. CEBOT adopted a genetic knowledge production algorithm to derive its distributed rules for reconfiguration [

91]. A network of single tasks represented a task plan. This task plan was implemented as a synaptic weighting matrix connecting modular rules so that any task can be represented as a task weighting matrix.

I-Cubes was a self-reconfigurable robot that comprised cubic link modules to form a three DOF manipulator to position and orient its links to attach/detach to other links [

92]. The three DOF manipulator motors were sited at: (i) a 360

o rotation axis at the base of the first link; (ii) a 270

o elbow pitch halfway along the length of the middle link; (iii) a 360

o rotation axis along the end of the final link. The final link accommodated a cross-shaped twist-and-lock attachment to any cubical module with mechanical, electrical and data interfaces. Many of the mechanical components of the cubes and links were 3D printed.

The rapidly reconfigurable modular manipulator system (RMMS) reconfigured into a variety of specialised manipulators from a set of different types of link and joint modules [80-82]. The modules had standard interfaces that could be assembled into different kinematic configurations for different tasks. Each module incorporated a DC motor, harmonic drive, motor amplifier, brake, resolver and tachometer sensors, microcontroller, ADC/DAC circuits, RS-485 and RS-232 drivers and VME-based communication interface. Power and data distribution was implemented through a six-wire harness. There were four module types: (i) a manipulator base, (ii) a link module and two types of joint module – (iii) pivot for perpendicular offset configurations and (iv) rotary module for parallel inline configurations. The base and link modules had zero degrees of freedom while the joint modules had a single DOF. A quick-coupling mechanism based on a locking ring at the male end drove a cam to grip keyed flanges on male/female ends. A guide collar with six alignment pins ensured accurate alignment. The male connector with its 30 electrical power and data pins fitted into the corresponding female connectors.

The RMMS task-based design determined the manipulator kinematic and dynamic configuration from the cartesian trajectory of the task. Kinematic design begins from the minimum number of DOF, the kinematic parameters of the pose and the initial base position. Geometric modelling may be implemented through the Denavit-Hartenburg parameters. The most common kinematic formulations are Denavit-Hartenburg (DH) matrices and variants, product-of-exponentials and unified robot description format (which is similar to the DH convention except in representing rotation through roll-pitch-yaw) [

93]. The forward kinematic model reflects the physical assembly of the robot. The solution to the inverse kinematics is determined through the Newton-Raphson method. From the inverse kinematics, path interpolation through cubic splines provides smooth joint trajectories. This determines the task-defined kinematic structure specified as a joint velocity trajectory over a Cartesian path. The Cartesian velocity trajectory is transformed into joint velocities through the Moore-Penrose pseudo-inverse with constraints imposed as kinematic limits and energy minimisation. The space of kinematic configurations is impractically large so they must be pruned. Pruning the search space can be implemented through kinematic constraints. This yields joint position, velocity and acceleration as inputs to the recursive Newton-Euler dynamics computation of joint torques [

94]. Motor PID control requires a global computed torque control system. These algorithmic techniques can be readily adapted to space application using a space freeflyer modification [

9].

From a task statement of reachability over the trajectory with constraints imposed by a dexterity measure, singularity avoidance and workspace obstacle avoidance, the robot configuration required to perform a particular function is an optimisation problem. The mapping between task and manipulator design may be subjected to a genetic algorithm (GA) search over relative manipulability (dexterity) measure. The ant colony system solution applied to the travelling salesman problem as a graph search relies on indirect cooperation of a population of agents via pheromone-mediated communication [

95,

96]. Pheromone updating assigns greater pheromone intensity to shorter routes communicated through stigmergy. As a parallel search algorithm, it is superior to evolutionary algorithms. To obviate against the high computational cost of using GAs or other similar approaches, the geometry may be determined in terms of pre-defined substructures such as “Shoulder”, “Elbow”, “Wrist”, etc – the human arm and variants has evolved to perform a multitude of tasks. For parallel manipulators, the Stewart platform constrains the kinematics problem. It is essential that a calibration process (such as Tsai’s algorithm [

97]) be undertaken to ensure accurate geometric modelling particularly in view of kinematic errors. Assembly of the control software re-uses reconfigurable software components from a software library. Task-based design has been applied to a Space Shuttle tile servicing robot comprising a 7 degree-if-freedom robot manipulator with a spherical wrist [

98]. RMMS is suitable for a fault tolerant satellite docking system [

99]. Beyond this, the manipulator itself may be configured to perform a variety of tasks in spacecraft refurbishment including assembly of modules.

8. 3D Printing Electric Motors

Autonomous self-assembly of macroscopic modules into assemblies assume pre-existing modules incorporating microprocessors, sensors and actuators [

28]. A review of on-orbit assembly programmes is given by [

100] including Made in Space’s Archinaut which comprises three robotic arms for assembly of 3D printed parts which bears some resemblance to the concept presented here. A step toward this is the Refabricator onboard ISS which was to recycle plastic waste and obsolete plastic products as feedstock (though it failed operationally). We describe attempts to 3D print shape memory alloy actuators and DC electric motors which are crucial to reconfigurable module manufacture. This may be regarded as an exploration of the feasibility of sophisticated manufacture of components by a space manufacturing facility (though without regard to microgravity).

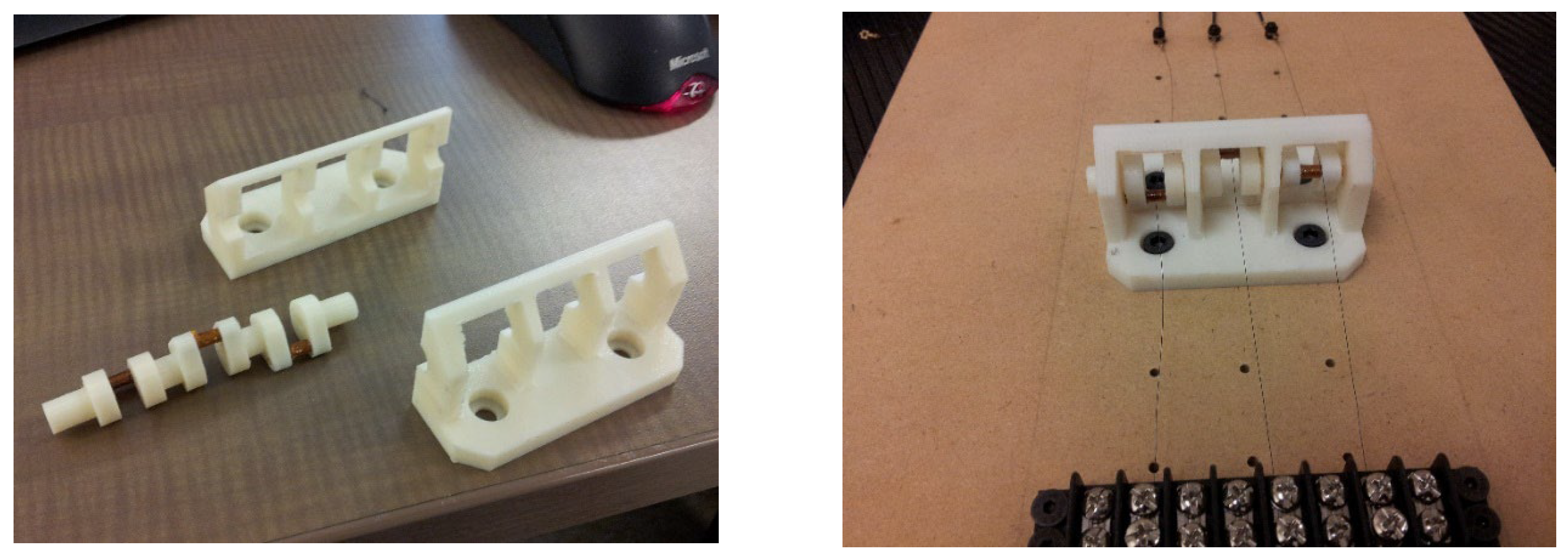

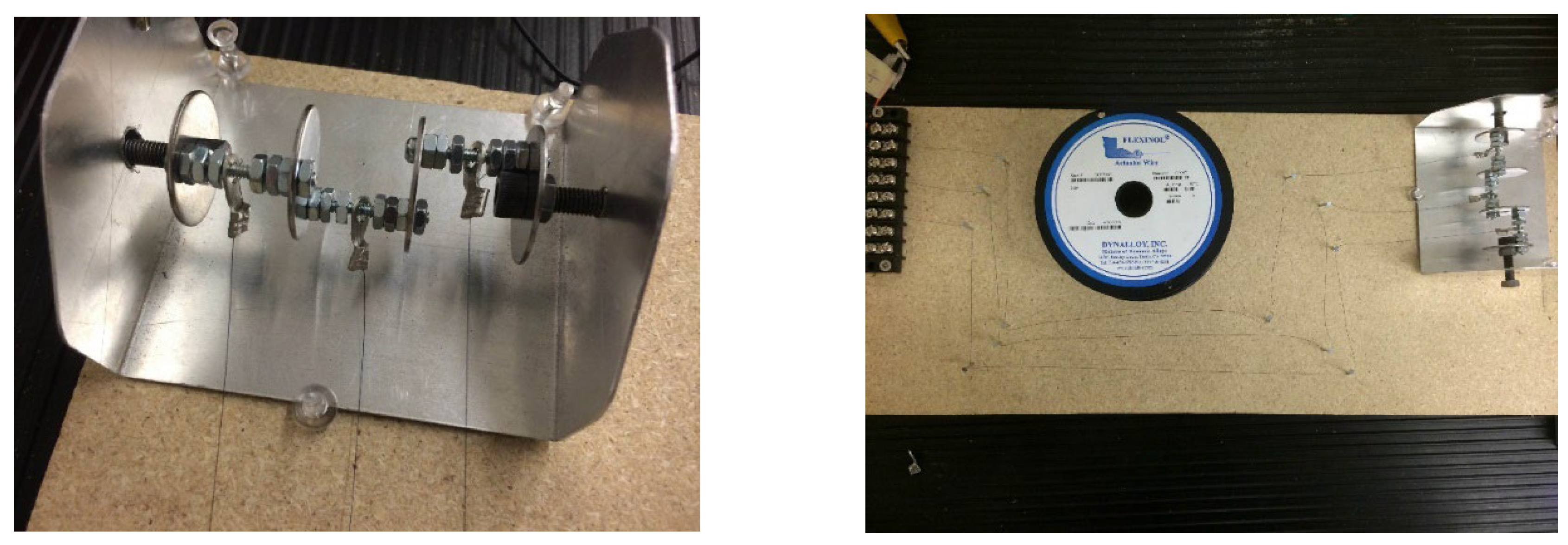

Most modules of self-assembling systems incorporate shape memory alloy actuators within their connectors where only short strokes are necessary. We have used shape memory alloy wire as artificial “Muscles” Based on nitinol (NiTi) alloy which can generate practical strains of 4% through self-heating electrical resistance [

101,

102]. We adopted a complex configuration to demonstrate the limits of such artificial muscles. The first prototype motor was based on nitinol (Flexinol) artificial muscles operating in agonist/antagonistic fashion through a 3D printed cam-based assembly to convert linear contraction into rotary motion similar to a piston engine (

Figure 3).

This design worked but was not efficient. The primary problem was high friction between the working ABS plastic parts. This was due to the staircasing artifact of coarse 3D printing. The extrusion motor (and the discharge nozzle size) of the 3D printer determines the resolution of the layering. The MakerBot Replicator offers higher 100 μm resolution than our Prusa i3 3D printer. Although this would reduce the staircasing effect, it would not eliminate it. A second design was built from steel to eliminate this problem to demonstrate the design concept of shape memory alloy wire actuators (

Figure 4).

The design worked effectively but the 4% stroke required an excessively long nitinol wire length to drive the cam. This is a characteristic property of most bio-inspired linear actuators - poor stroke despite good output torque. The heating/cooling cycle of nitinol alloy limited the cam revolution frequency to around 1 Hz. Preliminary results suggest that four sectors to the motor would improve performance over the current three but would not substantially affect the general conclusions. Nevertheless, shape memory alloys are ideal for actuating connectors which are not sensitive to their short stroke and making/breaking connection frequency is not hindered by their thermal response time constants.

We maximise our manufacturing capabilities by focussing on on-orbit manufacturing multifunctional components that are readily adapted across multiple subsystems – we focus on electric motors and electronic circuitry onboard a spacecraft [

103,

104]. Electric motors have multiple uses across subsystems: (i) deployment and orientation mechanisms; (ii) counter-rotating flywheels to substitute for chemical batteries for power storage; (iii) gyroscopic attitude sensors; (iv) reaction wheels, momentum wheels or control moment gyroscopes for attitude actuation; (v) memory read/write heads. Electronics innervates all spacecraft subsystems through several forms: (i) electric power conversion, regulation and distribution electronics; (ii) onboard computer (data processing and storage), buses and software; (iii) radiofrequency electronics including travelling wave tube amplifiers; (iv) electronic sensors and sensor processing; (v) electric resistance heaters. The recovered wiring harness provides the basis for electrical buses to link electronic components. Although passive electrical components are of simple construction (enabling electrical heaters, potentiometer sensors and simple signal processing), active components are more complex. The prospect of manufacturing solid state electronics on-orbit represents a considerable challenge – we do not address it here but, in passing, suggest that recovered silicon chips may be refurbished by razing surface microcircuitry through surface micromachining, zone refining of the remaining bulk silicon to re-purify it [

105] and implementing electron beam lithography to write new surface circuitry [

106]. We have an intriguing possibility of uploading spacecraft designs consistent with the constraints we have briefly discussed to be printed in-situ and assembled from space debris without the need for launch.

A neglected area is manufacturability of spacecraft modules and their components. The ability to 3D print magnets (both soft electromagnets to hard permanent magnets) and magnetic devices such as electric motors are crucial components for imparting actuation in 3D printed self-assembling systems. Such offers the prospect for 3D printing complete modular robots including their mechatronic components (though 3D printing electronics and sensors are not addressed here). Whereas 3D printed structures are typically static, 4D printing involves 3D printing of dynamic structures that morph their shape over time - such 3D printed structures are typically smart materials which respond to environmental stimuli such as shape memory materials and origami-type configurations [

107]. Shape memory polymers may be 3D printed through extrusion-based fused deposition modelling. Polymers may be printed into thin sheets with shape memory polymers at the joints to form actuated Origami-type structures. Shape memory alloys respond to thermal stimuli which may be generated on-demand by electrical means. The shape memory alloy NiTi may be 3D printed into artificial muscle wire/ribbon form. Our approach to 4D printing involves 3D printing layer-by-layer followed by the ability to alter shape such as folding using motorised hinges. We have not addressed 3D printing under microgravity specifically here but observe that it has been demonstrated in space [

108]. One example of 4D printing is Bitbloxes, small plastic blocks of several different types (including battery and microcontroller types) capable of automatically interconnecting both mechanically and electrically using 12 press-fit connectors actuated by electromagnets to form reconfigurable assemblies in preconfigured geometries (digital materials) [

109]. Nevertheless, only the plastic structure was 3D printed.

All modular reconfigurable robots must have a form of locomotion such as truss traversal to reconfigure themselves through self-assembly. There is a good reason why electric motors dominate actuation mechanisms – they are compact, have high stroke and high torque output. Electric motors have complex construction involving multiple functional materials rendering them challenging to 3D print. A complete motor system is comprised of the actuator, gearing, control electronics and sensors as well as its variety of structural members in a complex configuration. It would considerably widen the applications of 3D printing beyond plastic or metal structures if mechatronic components could be 3D printed.

Our electric motor was partially 3D printed through fused deposition modelling (FDM) using a Prusa i3 3D printer. We selected rotary electric motors as our actuator of choice because they offer: (i) good speed/torque characteristics with high stroke output; (ii) compact volume; (iii) robustness of performance. We selected the brushed DC electric motor as our test platform as it re[resents the most fundamental motor design in that all other motors are derived from it (including the constituent parts of AC motors). As in all DC electric motors, it comprises four main components – a rotor, a stator, copper wiring and a brush/commutator assembly. Both the rotor and the stator were 3D printed from commercially available ProtoPasta

TM which comprises 50% by mass magnetic iron particles in a 50% by mass PLA (polylactic acid) matrix (

Figure 5).

Both the rotor and stator soft magnets were wire wound to form electromagnets. The rotor windings were connected through wire brushes of 24 MAG copper wire to the commutator. Hence, this motor was a series wound self-excited DC motor. The commutator was a simple set of four thin contact copper sheets mounted onto the motor shaft. The rotor was wound with 70 wire turns per pole while the stator was wound with 100 wire turns per pole using an automatic wire winder. The copper wire coils and the steel motor shaft were the only parts not 3D printed (though the thicker output shaft was 3D printed polylactic acid). The motor was driven by a 30 Vdc power supply. PLA could be produced from corn syrup as a side-product of closed ecological life support systems-based agriculture on the Moon or on-orbit. However, PLA is susceptible to UV-degradation so silicone-based plastics (siloxanes) derived from CO2 and H2O via syngas (Rochow process) would be more suitable. Although we have not 3D printed silicone, it is suitable for FDM extrusion using specialized FDM 3D printers.

Although the motor was assembled manually, robotisation of the assembly process will require a sophisticated 3D printer capable of simultaneous metal/ceramic/plastic printing to reduce (though not eliminate) the assembly requirements with a wrist/gripper head to perform assembly operations. A question that is not explored here regards the trade between using a wire winder of drawn/extruded wire against (3D) printing wires directly by deposition on a rotary work platform. Wire may be drawn and extruded from a nozzle resembling an FDM nozzle. A simple wire coil winding machine can be constructed from a rotary knife sharpener and a circular part with three right-angle brackets for holding the coil in place [

110]. A simple coil winder can also be constructed from the standard modular Meccano parts [

111]. A more complex coil winding machine can also be readily constructed with universal wire gauges [

112]. We contend that this equipment is simpler than printing wires using lithography, deposition or laminated object manufacturing. The ability to manufacture electric motors on-orbit using modest equipment suggests that in-situ manufacture of rotary joints, one of the major components of many solar power satellite designs [

155], is feasible if the source materials are available. More generally, it provides an integral part of general purpose self-assembly of reconfigurable modules.

9. Self-Assembling Panel Systems

Deployable structures are self-assembling structures using pre-connected actuated modules. They are either rigid segments connected by discrete joint actuators or flexible membranes with continuous shape control actuation but both are complementary [

113]. Mesh structures are commonly constructed from pre-tensioned knitted tungsten wires ~20 µm diameter coated with nickel. However, such structures suffer from the pillowing effects of pre-tensioning. Shell membranes are commonly constructed from carbon fibre reinforced silicone without pre-tensioning. Silicone exhibits high flexibility, very low outgassing, and radiation and temperature tolerance. Membranes may be folded with Miura folding [

114]. Continuous shape control of flexible membranes is commonly implemented with cables to transmit tensile forces but they are not compressible. Spring-like elastomers such as shape memory alloys or piezoelectric polymers can be integrated into structures and are compressible. Embedded fibre optic strain sensors can measure distributed strains to feedback into shape control including active damping. Here, we focus on deployables as actuated rigid segments, the daisy flower-type of deployment being well-established [

115]. A genderless automated coupling mechanism has been designed that disengages once a predefined force is exceeded [

116]. It was a 2D structure with origami-type hinges for folding with a shape memory alloy spring that can retract the slider coupling. An origami-inspired crawling robot has been constructed by autonomously self-folding a flat sheet of paper with embedded electronics using bistable shape memory composite (pre-stressed polystyrene) flexures that bend along creases when heated [

117]. The design included a bar linkage with hinge joints to generate walking.

Deployment mechanisms for deployable structures may be planar or spatial. Bar linkages with kinematic pair joints may be driven by electric motors typically or, more rarely, by smart materials. For kinematic linkages, the Grubler-Kutzbach criterion describes degrees of freedom resulting from over-constrained closed kinematic chains of revolute joints in deployable structures – 4-bar linkages and Sarrus 6-bar linkages are commonly adopted. Printed circuit microelectromechanical systems (PC-MEMS) manufacturing can fabricate mm to cm-scale 3D structures with complex topologies through several stages [

118]. 1-250 µm layers of flexible and rigid material are constructed by sequential laminated object manufacture and subtractive micromachining through several steps, followed by the addition of discrete electronic and other components and then folded at flexural joints into origami-inspired 3D pop-up shapes and locked into position [

119]. Such dynamic reconfigurability to different tasks is analogous to biological metamorphosis [

120]. Embedded shape memory alloy wires can act as actuators to deform the silicone skins whilst acting as proprioceptive sensors (which may also be implemented with piezoelectric sensors).

We have coupled our 3D printed motor to panel structures for space and planetary applications. In-space control solutions to self-folding may be derived from those of space manipulators [

7,

9]. Deciding the minimum number of tiles that can be assembled into a given shape (minimum tile set problem) is NP-hard. There are polynomial time solutions that exist under certain constraints [

121] but the number of panels may be pre-determined by design as here. Assembly tasks involve the mating of assembled parts subject to contact forces. Positional entropy is a measure of uncertainty in part position and/or orientation that dictates these contact forces [

122]. Positional entropy quantifies the probability distribution of the position/orientation of parts through repeated assembly tests. However, positional entropy can be reduced using grippers, fixtures, jigs and sensory feedback. In flat-pack systems that unfold, the constraints of the flat-pack configuration reduces part entropy by effectively adding structure to the environment. The flat-pack itself acts as a combined fixture/gripper requiring only motor sensors for feedback.

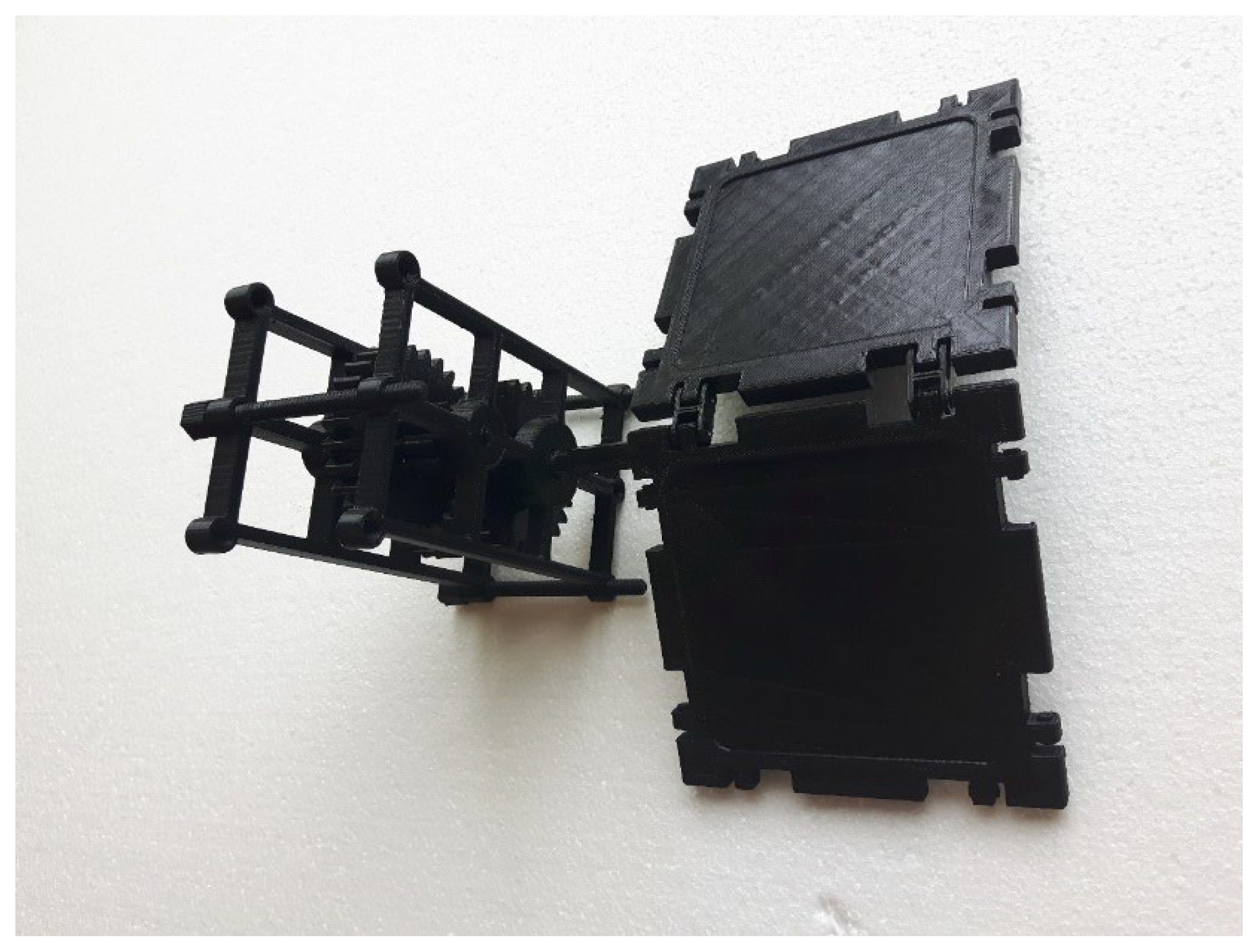

Hence, we have 3D printed a motorised TRIGON panel system. TRIGON is a versatile robotic construction system comprising a set of modular parts that are designed to self-assemble into trusses, habitats, rovers, factories, etc [

123,

124]. Our perceived application is in “stitching” recovered solar panels from different debris sources together using on-demand 3D printed motor hinges to form adaptive structures. TRIGON builds structures through self-assembly from a finite set of modules which are panels. Each TRIGON part is a face with motors integrated along the panel edges to form a hinge linking to other panels [

125]. The polygonal panels can accommodate arbitrary payloads at their centre.

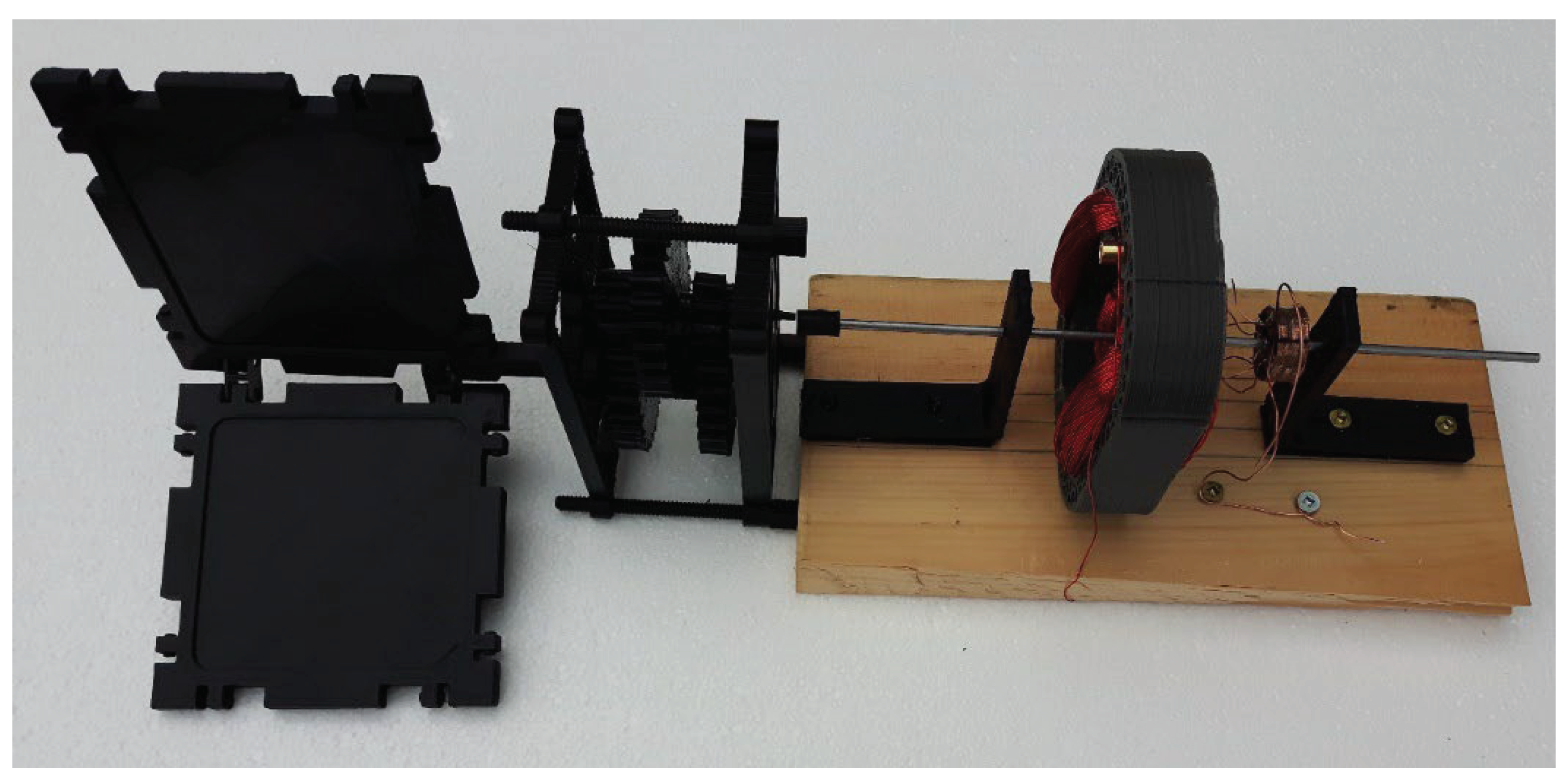

There are two types of self-assembling panels - triangle and square. We have built a dual set of motorised hinged square TRIGON panels with 3D printed motor offset from the panels. Our TRIGON panels, however, are smaller desktop versions of the full-sized panels for demonstration purposes. The 3D printed square TRIGON panels, 1:27 reducing gears and motor shafts are constructed from PLA extruded from a Prusa i3 3D printer. The hinged TRIGON panels were connected to the motor assembly via the reduction gear. It successfully demonstrated opening and closing of the panels (

Figure 6). Albeit a simple demonstration, this shows that a fully motorised self-deploying system can be 3D printed using FDM (less electrical wiring).

TRIGON panels are flat-packs that construct 3D enclosures in two ways: (i) unfolding of panels from a pre-configured stowed configuration; (ii) self-assembly in which an integrated manipulator maneouvres panels together for linkage. The latter capability is unique to TRIGON compared with other flat-pack concepts. A pair of panel connector “arms” may be mounted on each edge to act as manipulators for linking two neighbouring panels together. Controllers with feedback sensors permit sophisticated manipulation including rolling panels over an existing structure edge-over-edge to relocate into a growing structure [

126].

Further developments to our 3D printed TRIGON system involve the incorporation of integrated connector motors with gearing. This would require significant miniaturisation of both motor and gearing for these panel sizes but the TRIGON panels are envisaged to be significantly larger. For full sized panels, harmonic drive gearing would be preferrable to direct drive motors due to their higher torque-weight ratio, high reduction ratio within a single stage (1:320), negligible backlash, high accuracy and repeatability, and high transmission efficiency of ~90%. Further developments might incorporate reconfigurable manipulator arms with motor/gearing at each joint to deploy the TRIGON panels. We have yet to implement these more challenging configurations. Our deployment of a 3D printed geared motor with panels demonstrates that more challenging assemblies are feasible. It is envisaged that TRIGON panels may potentially be deployed to construct a “cassette factory” manufacturing cell based on 3D printing [

127], a major leap toward a self-replicating machine [

128] beyond current developments [

129,

130].

TRIGON is an extension of the PETSAT satellite concept of multiple panels assembled into different spacecraft configurations. PETSAT comprises a set of hinged, deployable panels, each mounting a specific integrated spacecraft subsystem, that self-assemble via connectors into an integrated spacecraft [

131]. Each panel is a standardised structure with integrated heat pipe and graphite insulation for thermal control. The connector interface implements mechanical latching, electrical interfaces and thermal coupling. The 50 kg Sohla-2 satellite was designed as a PETSAT but was not flown [

132].

Self-folding/unfolding provides a mechanism for automated assembly of 3D structures from 2D flat-packs using origami [

133]. Origami-type structures offer efficient mechanisms from a packaged state to the deployed state for applications such as origami bellows that expand into space habitats [

134]. Miura-Ori tessellated crease patterns offer axial and radial expansion while Kresling patterns offer only axial expansion but both are suitable for expandable space habitats. Rather than being inflated, they may be actuated with just two actuators. Miura-Ori patterns may also be employed for physical reservoir computing to implement morphological body computing as peristaltic locomotion [

135]. For example, self-folding machines may be constructed. A flat polymer sheet with embedded resistive circuits activates elastic shape memory polymer hinges to create a crawling robot [

117]. Locomotion was enabled by two single-actuator driven chassis, each comprising an eight-bar linkage that alternately drive forward and aft legs.

Direct ink write assembly with wet-folding origami can construct 3D shapes [

136]. Inks with TiH

2 particles loaded in an organic solvent may be extruded through a nozzle and deposited to form a partially dried ink with elasticity for folding into origami structures such as a crane. Magnetically controlled microbots of soft material have been developed that exploit self-folding to morph into different shapes according to the applied magnetic field [

137,

138]. They comprise magnetised flat panels connected by flexible hinges so the applied magnetic field affects how the panels configure themselves. The microbots were manufactured using electron beam lithography by forming arrays of nanoscale cobalt permanent magnets on thin flexible Si

3N

4 substrates. Thinner nanomagnets require higher applied fields to magnetise them permitting tailoring of their magnetic responses. This can be exploited to create sequences of applied magnetic fields for sophisticated self-assembling structures of modular flat panels such as an origami crane capable of flapping and locomoting. Other reconfigurable robots are locomotor robot units – s-bots, uni-rovers, JL-I and millibots and amoeba [

139].

Contraction/expansion is a variation on folding/unfolding. The “crystalline molecule” is a cubic module in which four faces expand or contract by ±2 cm in a plane around a central core which houses Li batteries and a microcontroller [140-142]. Two faces have active connectors while two have passive connection slots to form rigid connections between modules. Expansion/contraction supports dynamic shifting morphological structures of any 3D cellular grid with modules relocating through the structure itself. A distributed cellular automata control algorithm reconfigures the crystal robot into different shapes [

143]. Telecubes comprises cubic modules with six prismatic DOF to expand similar to the crystal robot but in 3D [

144]. The metamorphic robot system is an extreme version with modules that are deformable planar six-bar linkages that dynamically reconfigure themselves [

145]. The linear actuators in these expandable modular systems may be implemented as 3D printed solenoids which is simpler than our 3D printed rotary motors.

10. Control of Self-Assembly

Assembling modules into kinematic structures requirse kinematic and dynamic analysis to find the optimal structure for the required task [

146]. Multiple metrics may be employed including kinematic error metrics, manipulability measure, joint excursions, torque limits, etc [

147]. The Grubler equation defines the number of constraints in a closed loop chain:

where n=total number of links, j=total number of joint, f

i=number of degrees of freedom per joint i (1 in the case of manipulator joints), λ=dimensions of the task space (3 for planar and spherical mechanisms and 6 for spatial mechanisms). The number of force equations is given by

. These determine whether the mechanism is determined (

Table 1):

A single task constitutes a cartesian trajectory but the assembly of m parts by a manipulator of n DOF generates a C-space of m+n DOF, i.e. assembly requires a path search through the m+n dimensional space. The search for configuration patterns matched to the constraints of a specific task involves an exponentially growing search space with the number of modules. Hence, planning of a path from an initial to final configuration is, in general, NP-hard so hierarchical decomposition is required to impose further constraints [

148]. This implies the use of evolutionary search strategies. GAs can search through a small inventory of components to find a kinematic configuration to realize a specific task constrained by design rules to prune the search space [

83,

149]. GAs can search for an optimal assembly using the manipulability measure

as an assembly fitness function [

150]. The kinematic search space can be reduced by applying physical rules to eliminate unfeasible solutions [

83], e.g. serial link chains only, end effector terminates chains, etc for the GA [

151]. The GA may encode a tree-based representation of an ontogeny that defines an assembly plan of sequential procedures for constructing a 3D organism constrained by environmental physics [

152]. A two-level GA can search for the optimal kinematic configuration from a task specification [

153]. The upper-level GA determines the overall topology while the lower level GA determines the inverse kinematics based on the Denavit-Hartenburg matrix representation. The fitness function may be expanded to incorporate six criteria:

where w

i=weights,

=end effector reachability to task, l

i=link i length, d

j=task j distance from base, n=maximum number of DOF, m=number of subtasks,

=translation distance to goal,

=angular distance to goal,

=penalty function,

=collision penalty if there is an obstacle within a safe area, otherwise c

ij=0, d

ij=link i distance from obstacle j, s

i=security distance, o=number of obstacles,

=minimum complexity measure, r

i=1 if joint i is R but 0 otherwise, e=distance of end effector from base,

=dexterity measure,

=manipulability index. In CEBOT for example, the optimal minimal criteria for assembly is given by [

87]:

where w

i=weights, m=total number of task points j, e

j=position error at task j as a function of link and joint rigidity, T

j=end effector force/torque required to support payload and outboard links at task j, D(j+1)

drive function transform from task j to j+1, C=cost parameter such as joint torque or energy consumed by motor. This fitness function is a performance measure for self-assembly. Such task-based design was used to design a manipulator for Space Shuttle tile servicing on-orbit [

98].

11. Conclusions