Submitted:

21 January 2024

Posted:

23 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

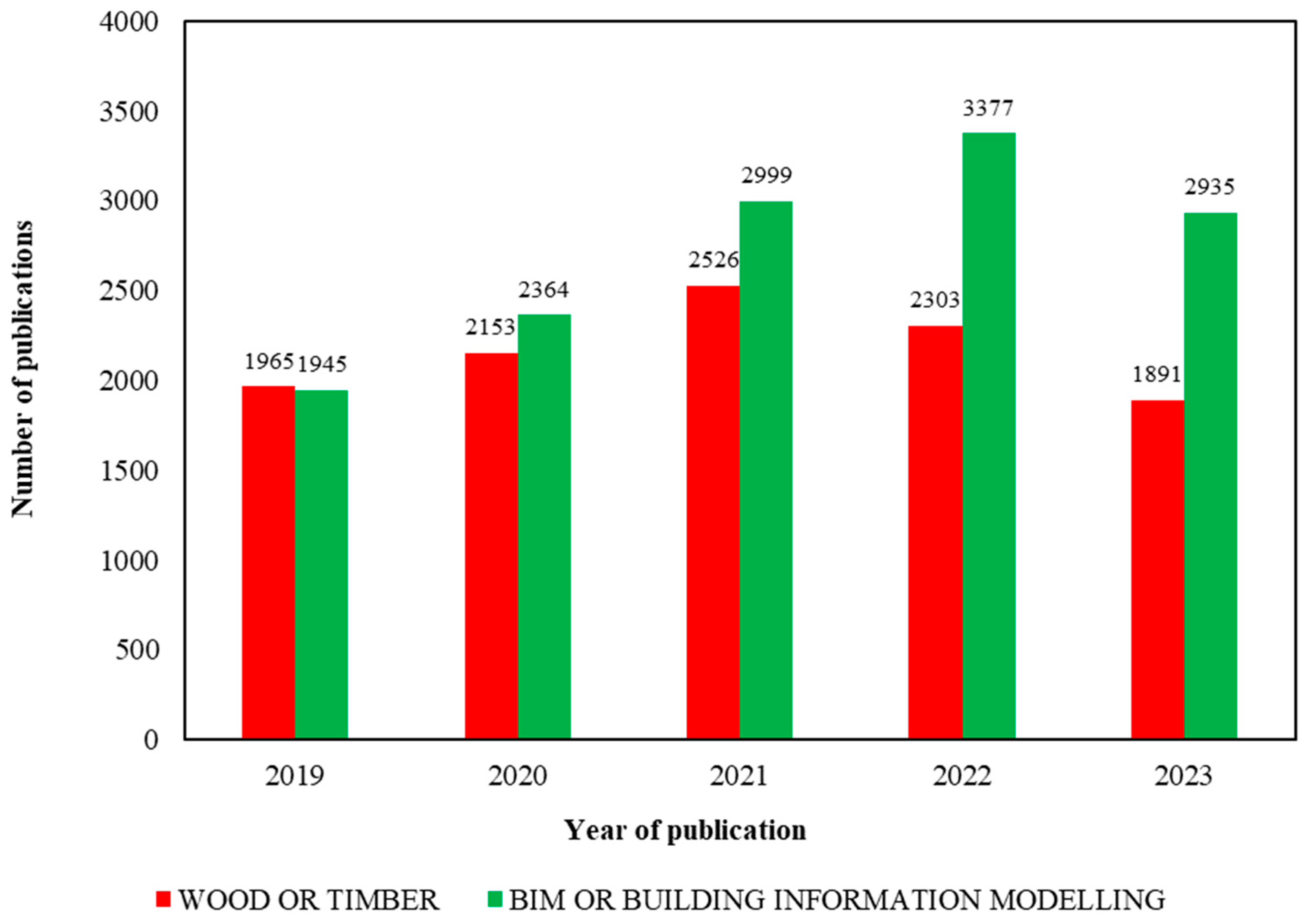

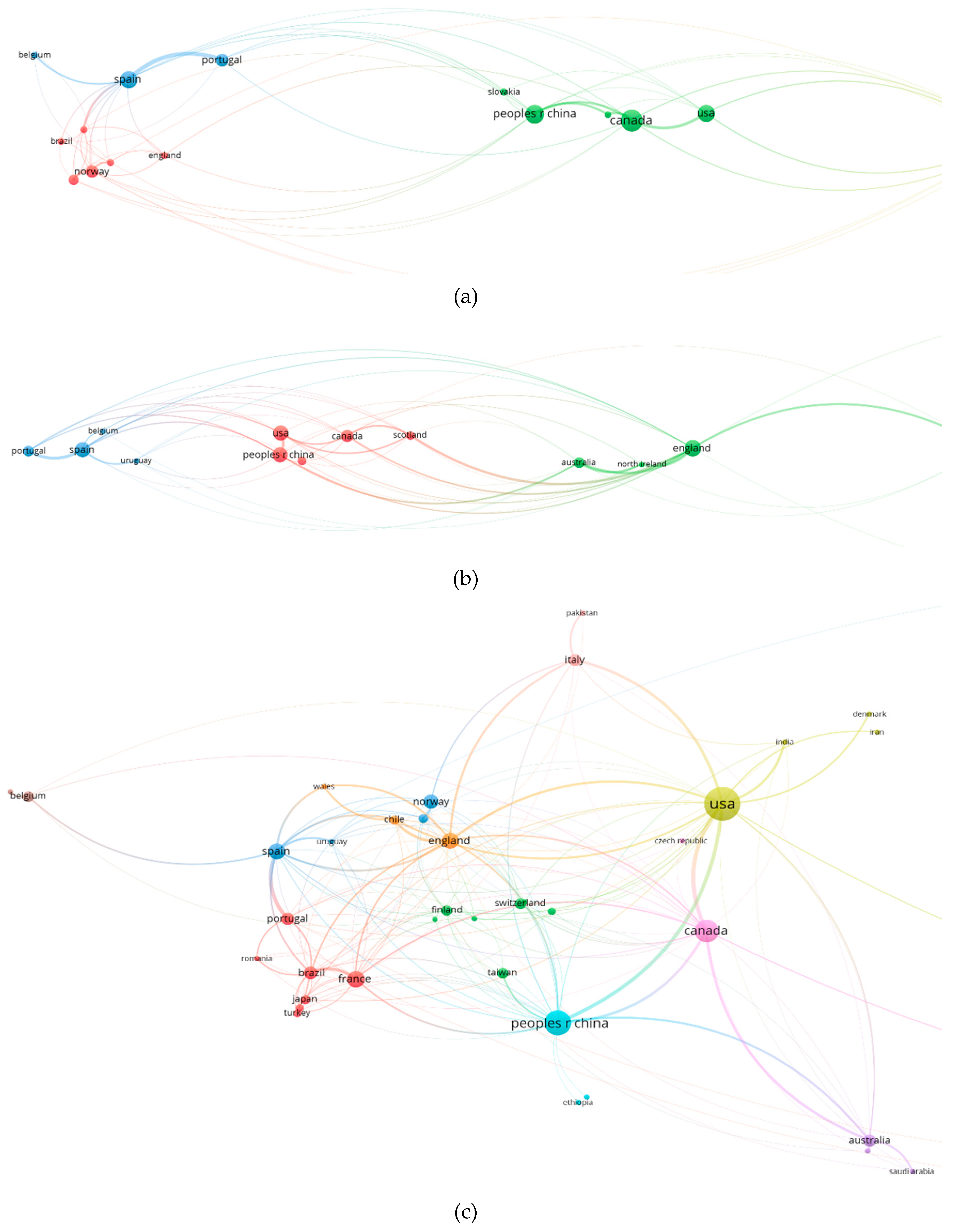

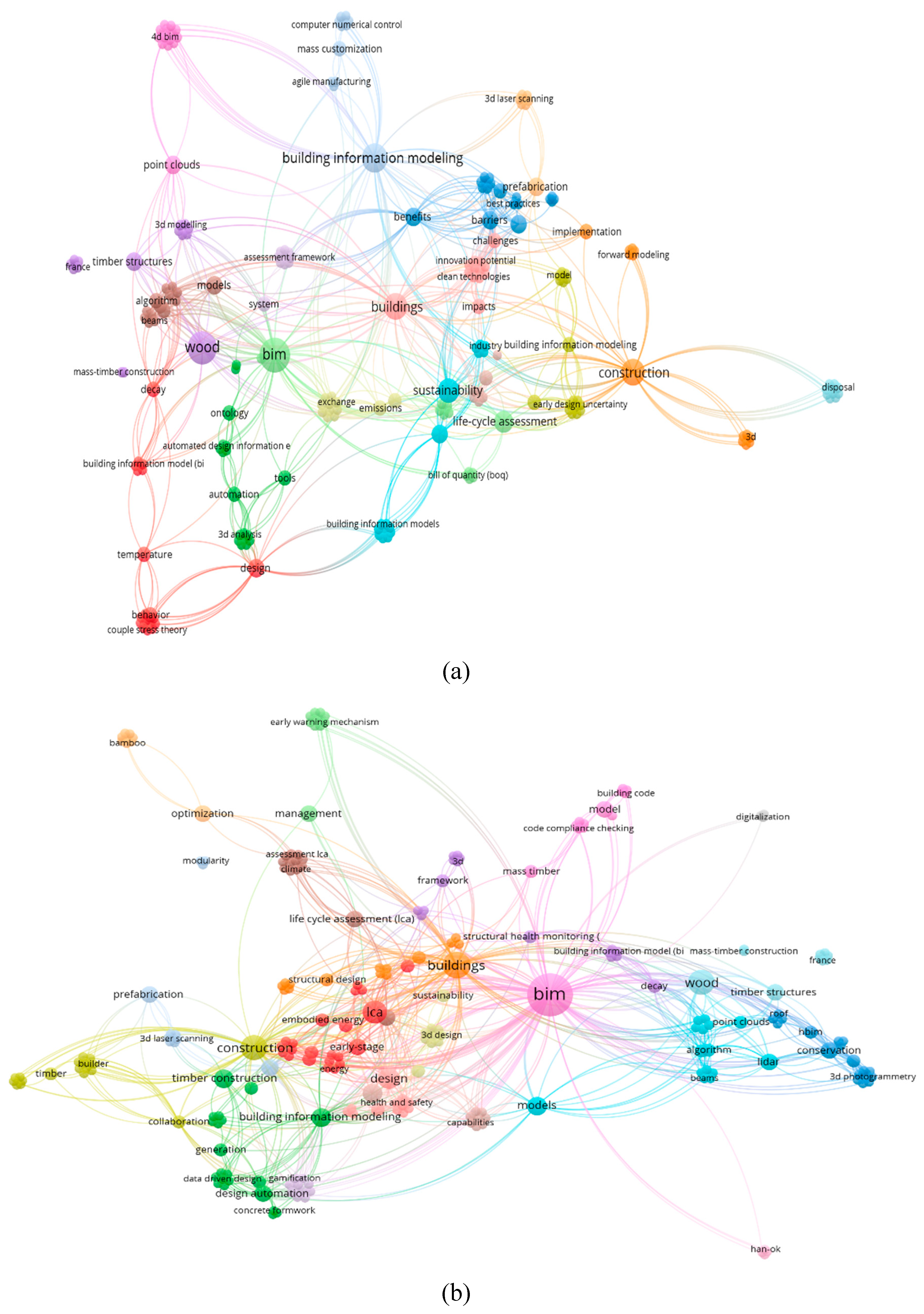

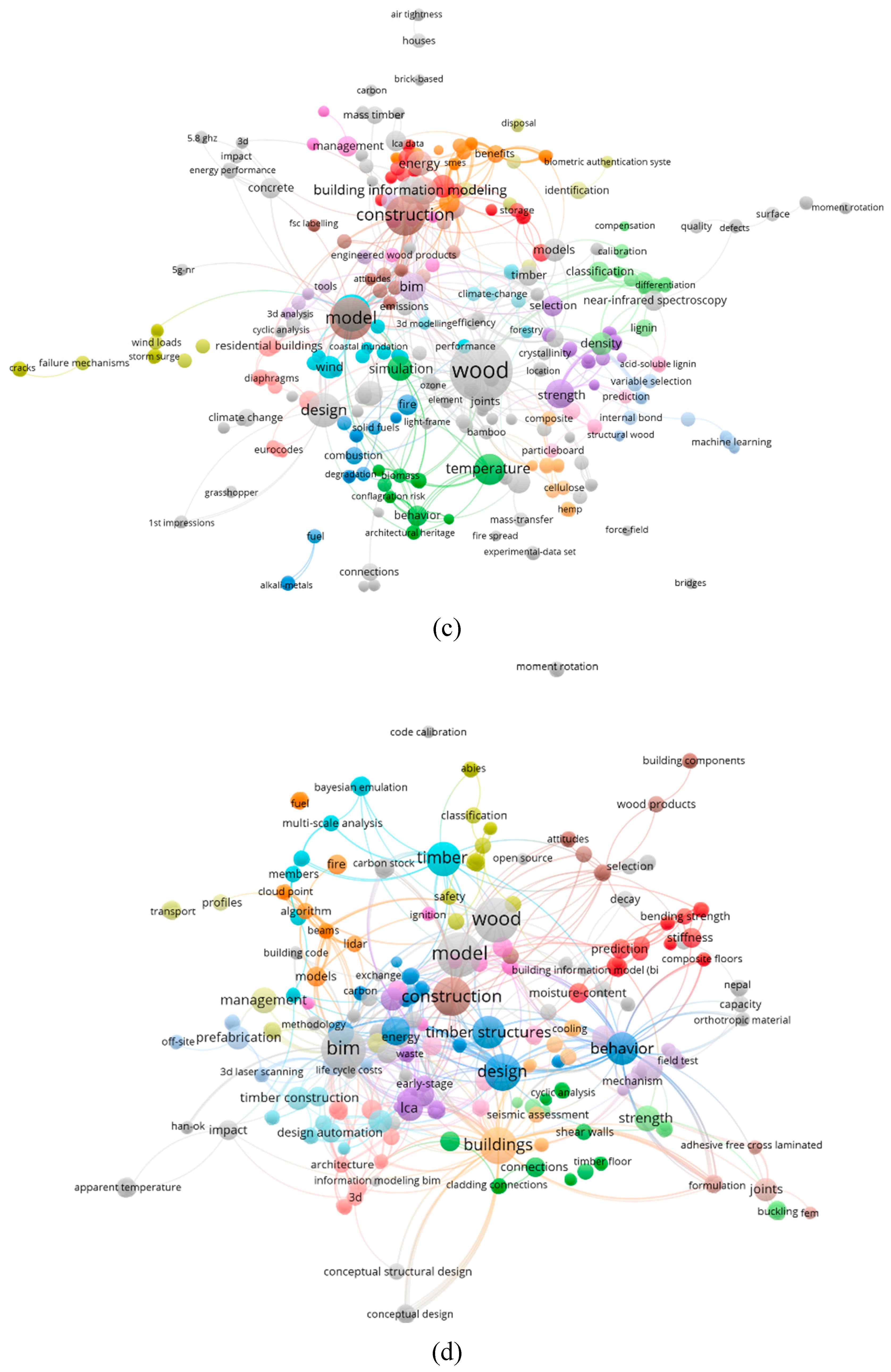

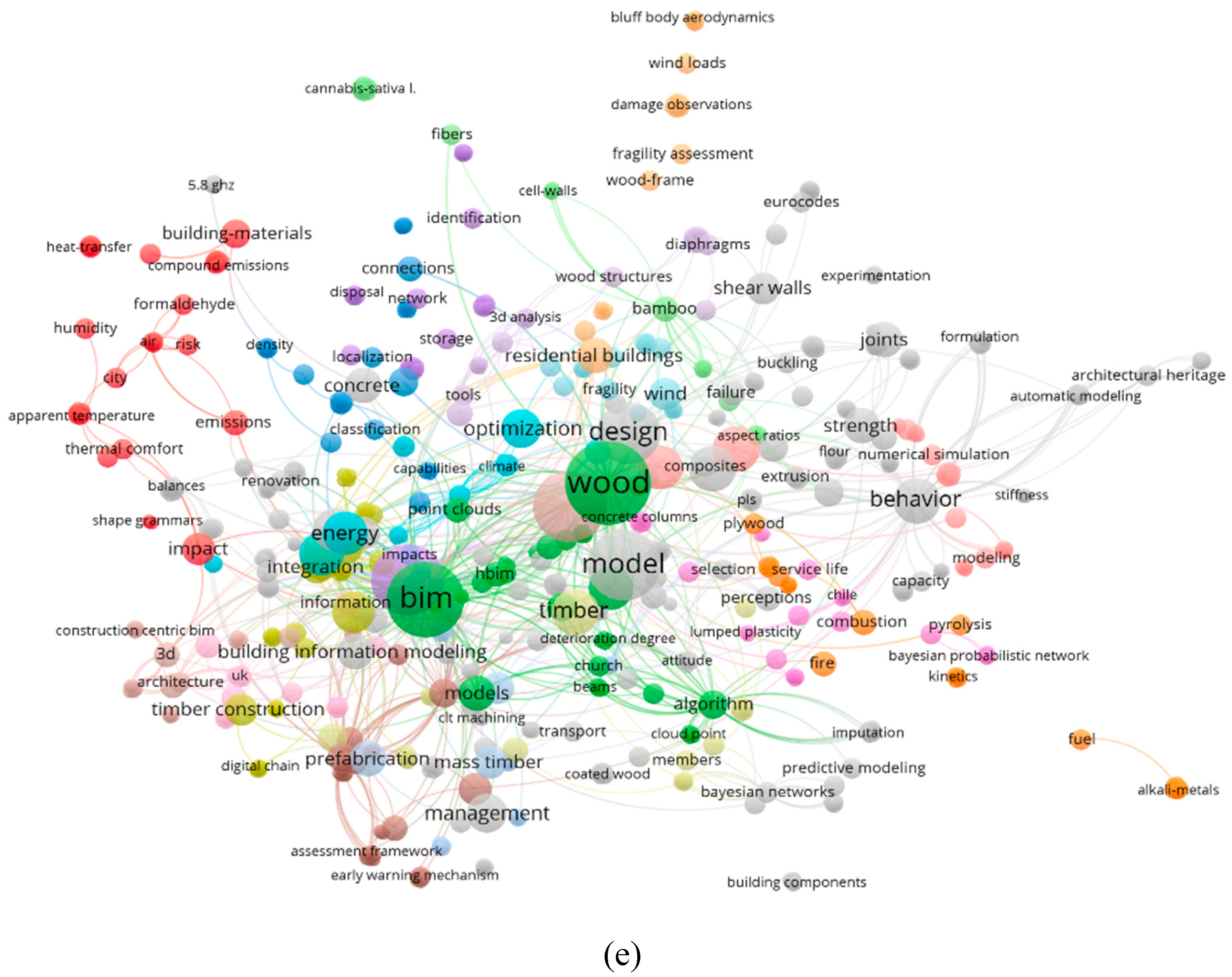

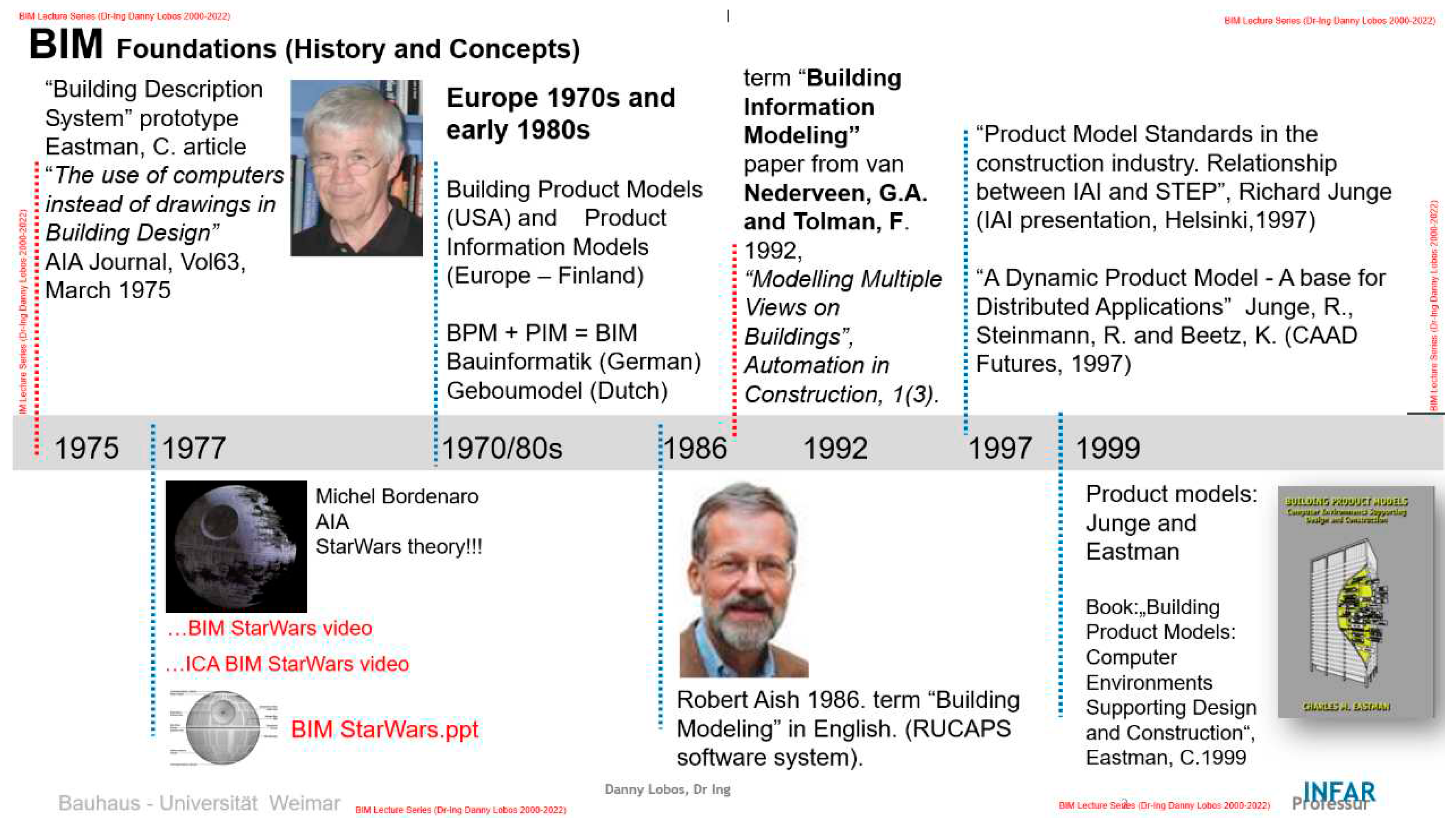

2. BIM situation

Origin of BIM

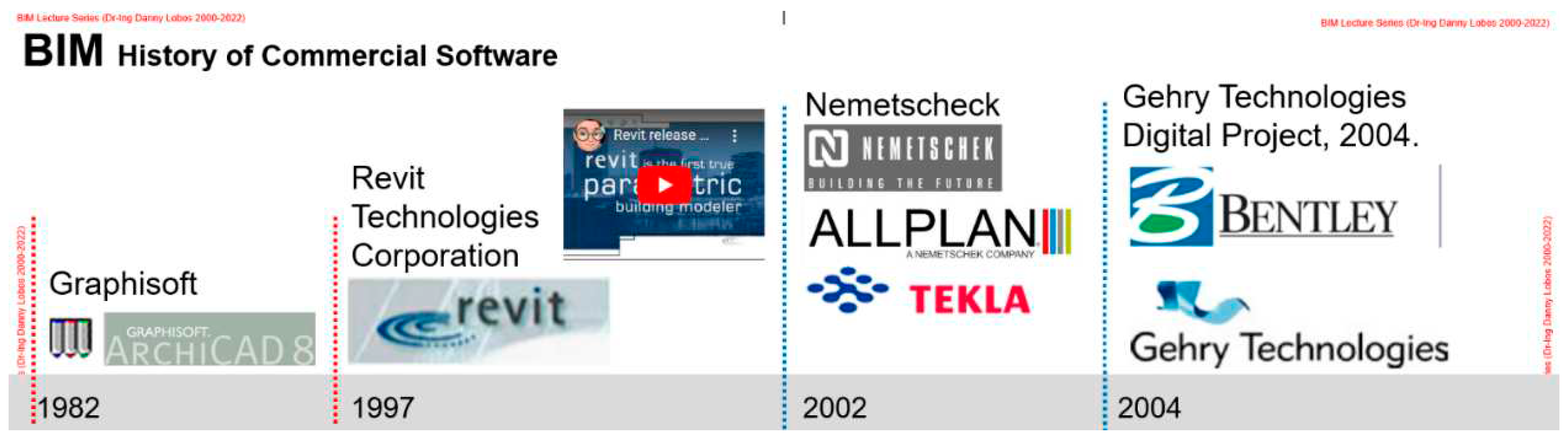

BIM software industry

BIM in Government

BIM in AEC Industry

Typical use of BIM software

3. Traditional design and construction in wood for modern buildings

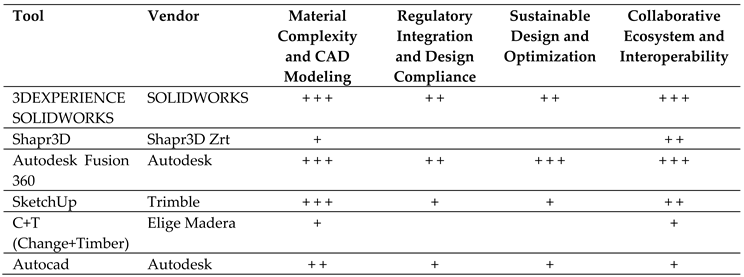

4. CAD tools for wood design

Material Complexity and CAD Modeling

Regulatory Integration and Design Compliance

Sustainable Design and Optimization

Collaborative Ecosystem and Interoperability

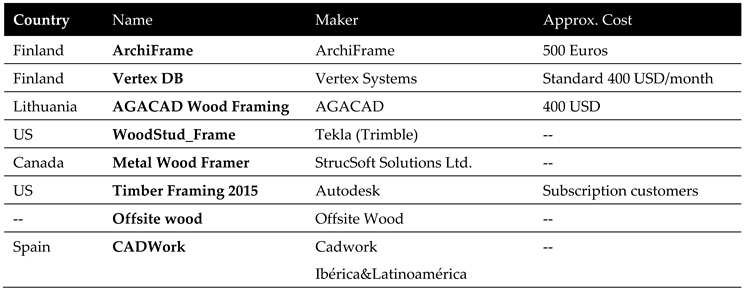

5. BIM for Wood

5.1. Transversal function of BIM tool for wood

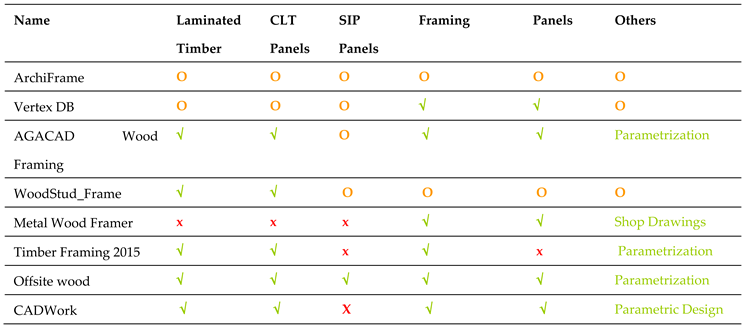

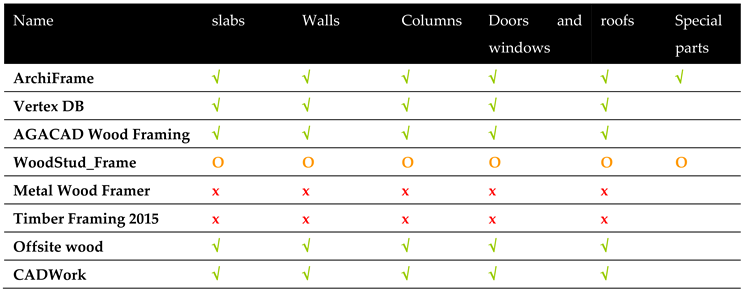

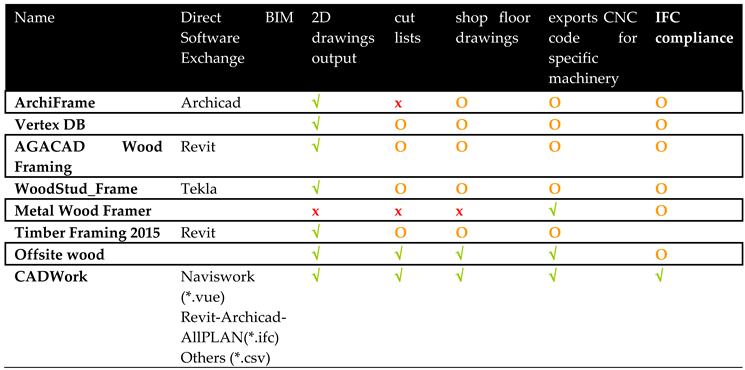

5.2. Specific functions for BIM in wood

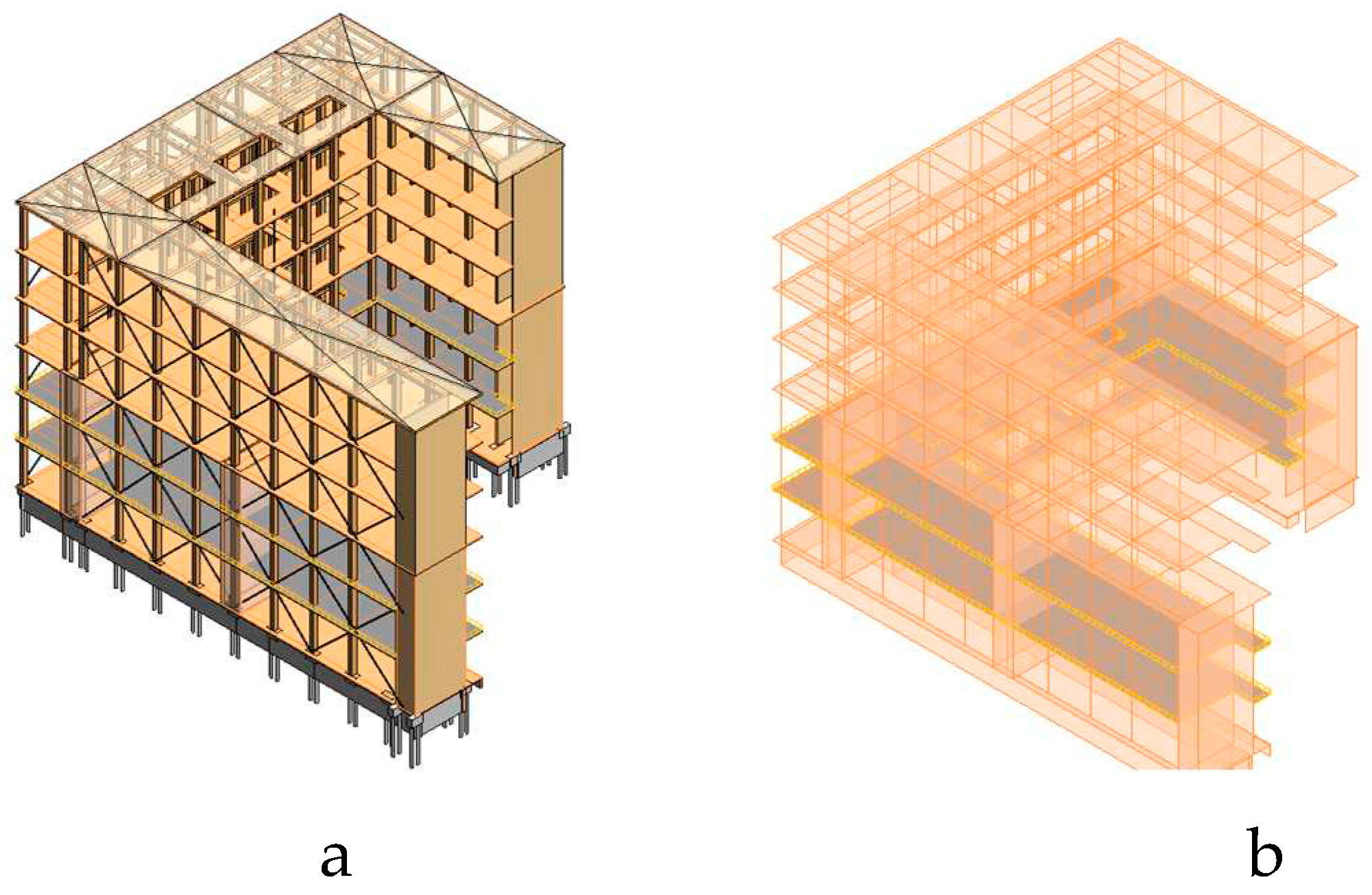

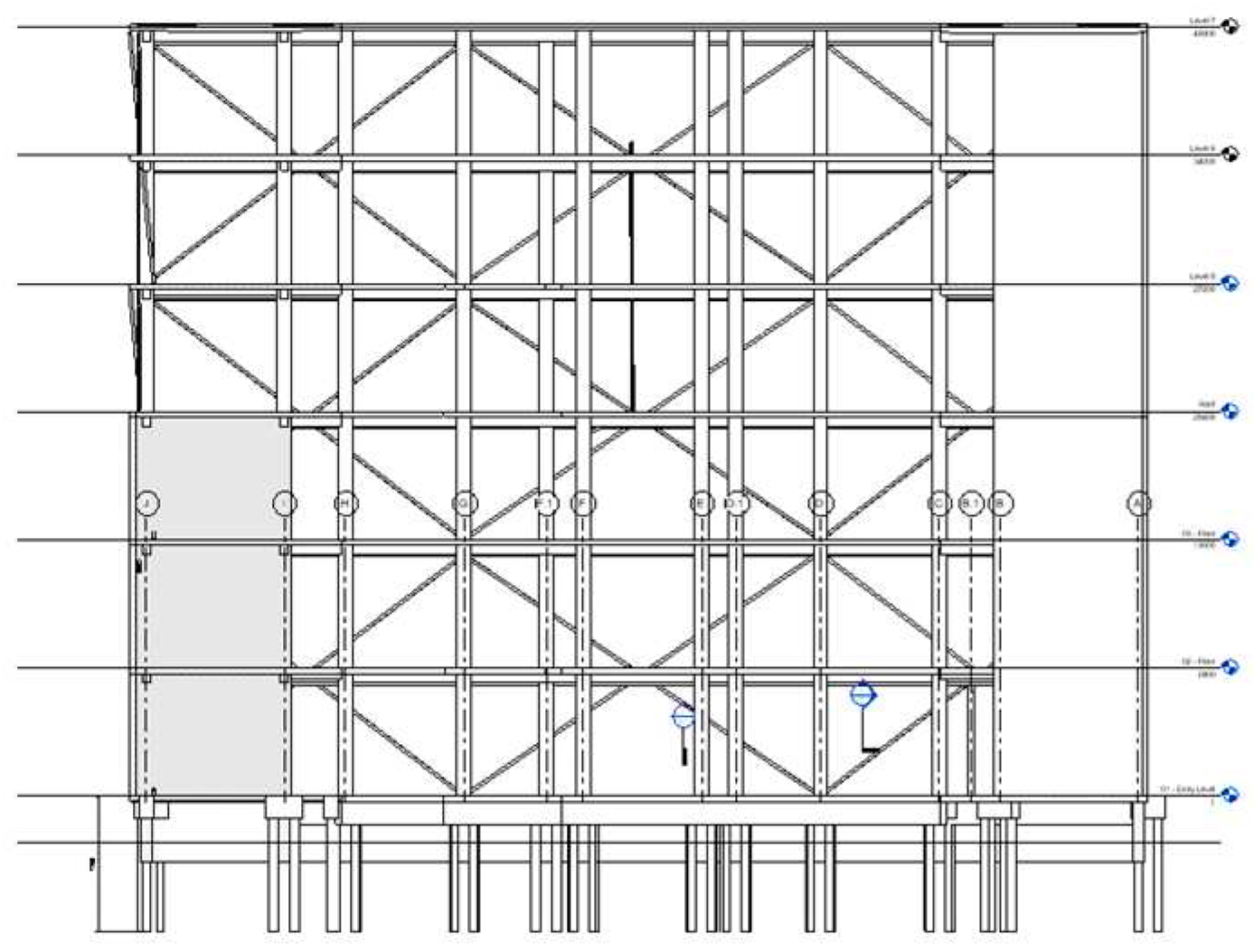

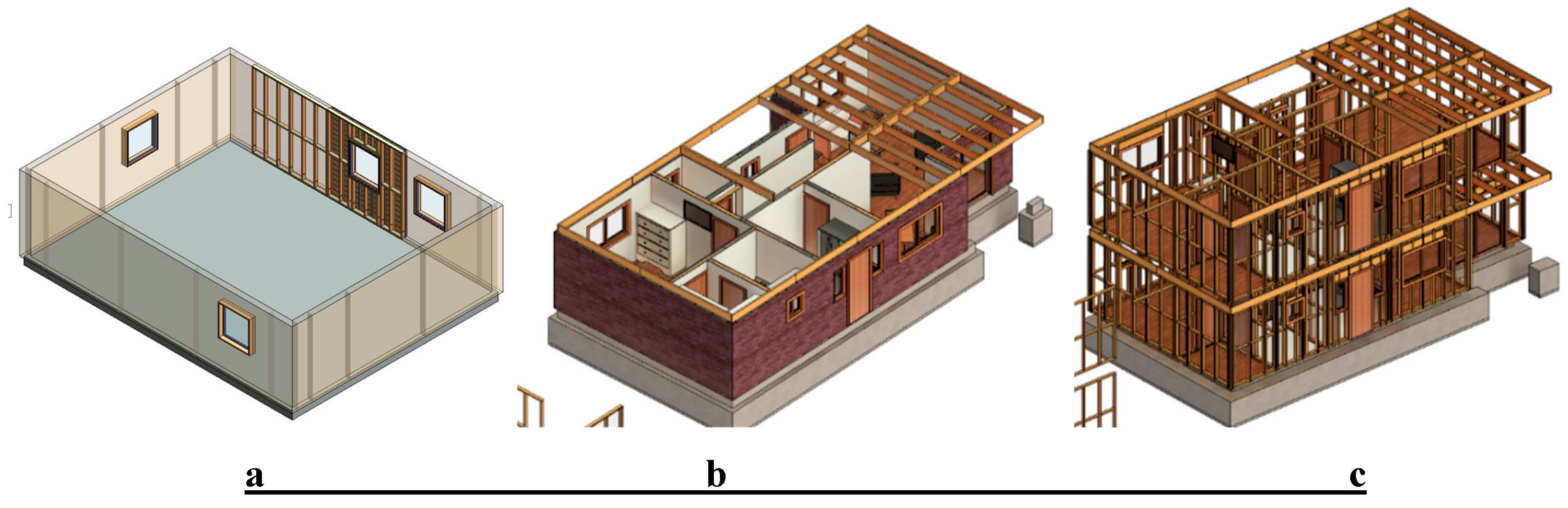

- A multilayer system: where the design of a wood construction is characterized by having a multilayer system (interior lining, sheathing, structural component, exterior siding, nailers, etc.). This allows that each of the layers to be configured, created, and generated with high precision and a certain flexibility, as well as each of its elements to be controlled, in addition to the whole.

- Configuration and automated generation of frames: where the design tools allow their components to be defined (studs, panels, siding, beams, nogging, etc.), configuring the dimensional parameters (squaring, thickness, heights, etc.) and location (distancing, angle, etc.) and then generating them automatically. In case of changes to the architectural and/or structural design, the frames and their components are automatically updated. Furthermore, it is possible also configure the connections between studs in L, T, or other connections, which allows flexible modelling and easy handling of complex situations. In a large project, including several wooden buildings, it is possible to design multiple frameworks automatically.

- Configuration and generation of documentation: where sheets are generated automatically with different views that show one or more layers of a component (vertical frame, horizontal frame, roof framework) as predefined in the design. The documentation process becomes automated and rapid, ideal for the preparation of assembly and manufacturing plans, which is usually a long and tedious process.

5.3. Benefits and advantages of BIM-Wood tools

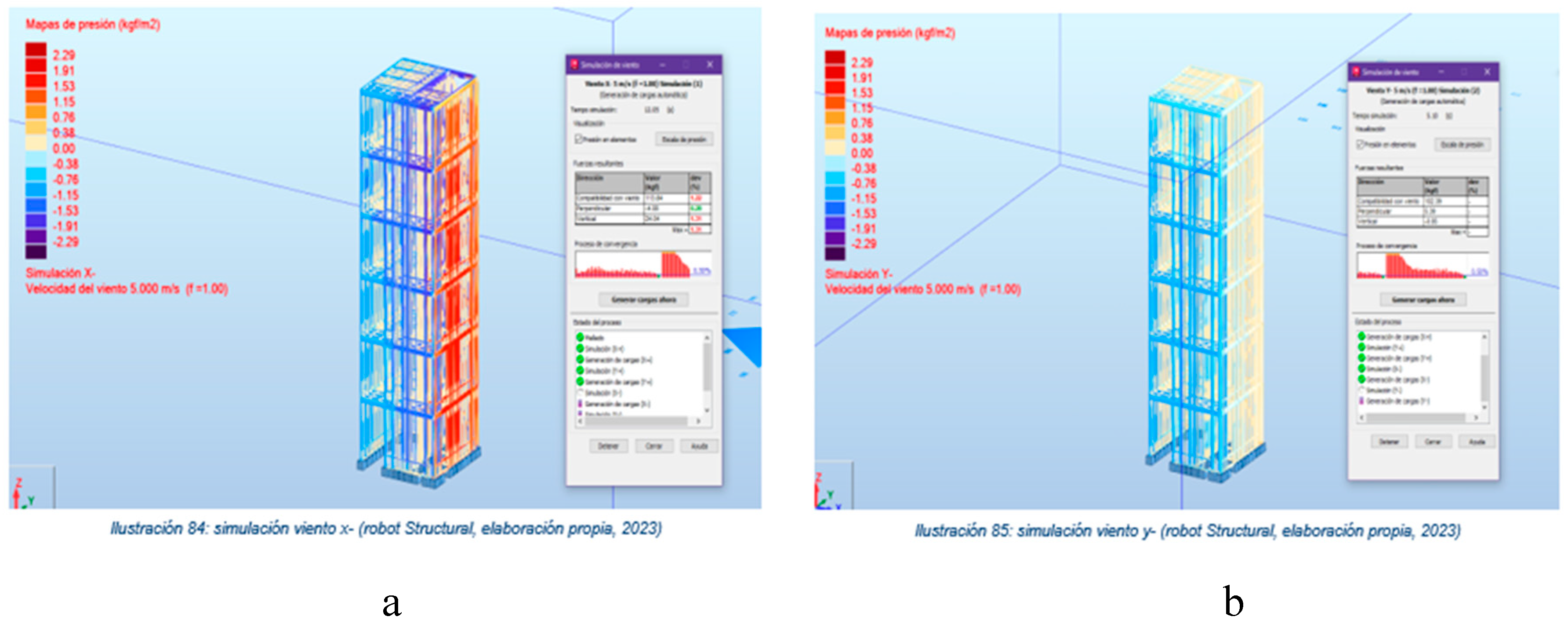

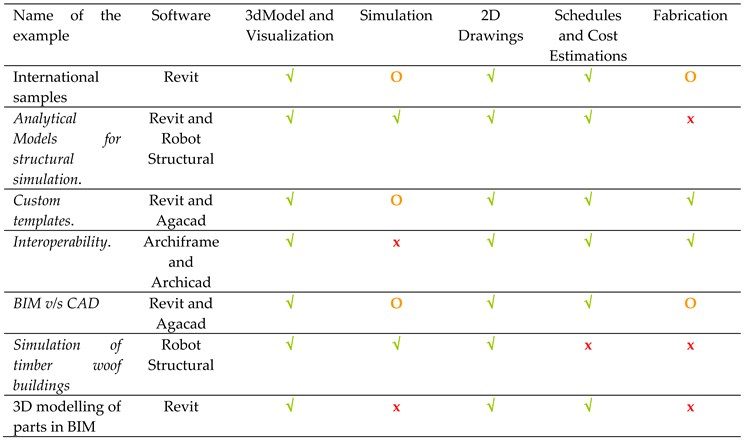

6. Cases around the world

International samples

Academic experiences

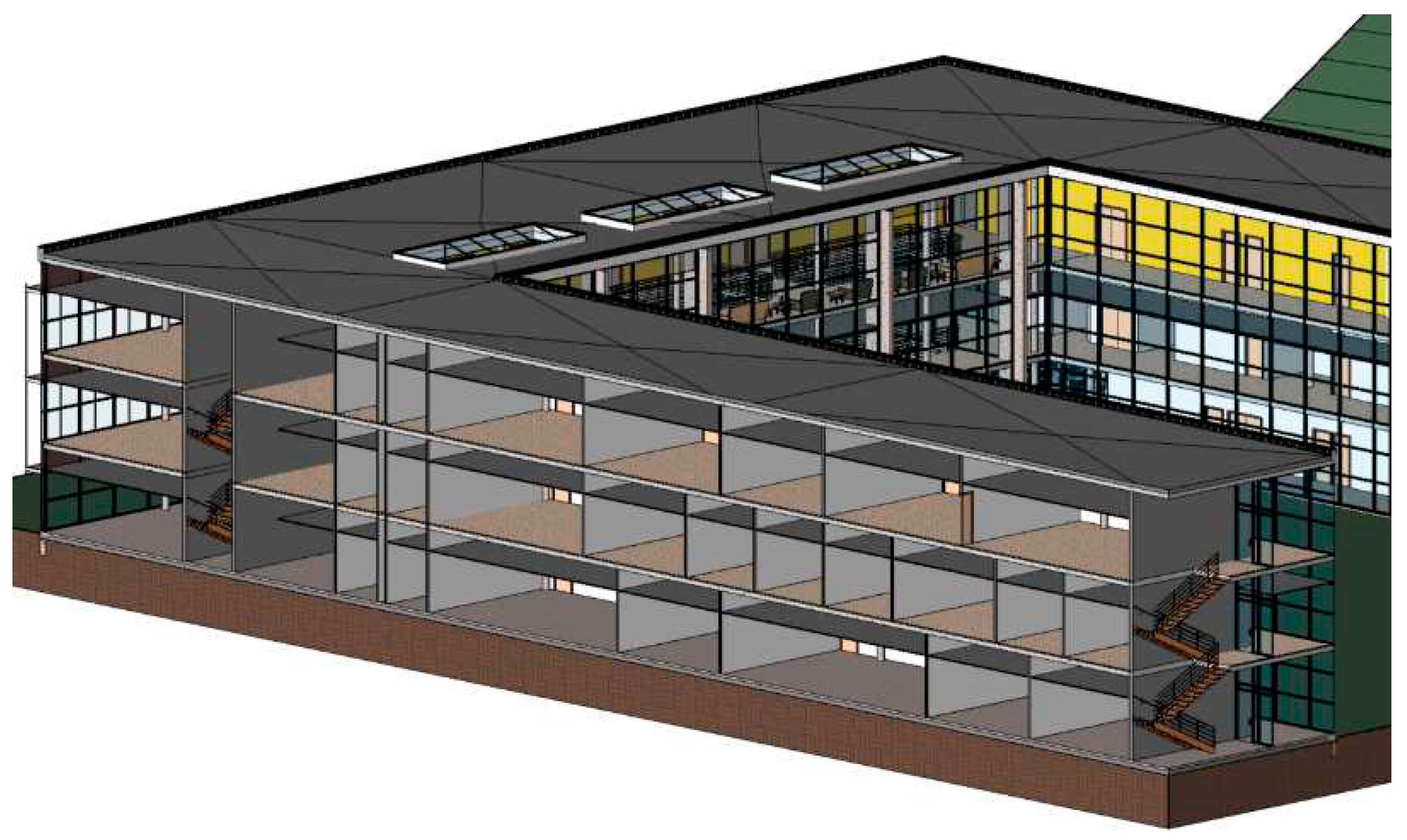

- 3dModel: the complete building is derived from BIM-Wood Model, it has more advantages in comparison to traditional CAD approach that shows just parts of the real building.

- Visualization: automatic orthogonal views, perspective views, 3d Sections, renders, are derived from BIM-Wood Model, it has more advantages in comparison to traditional CAD approach that requires creation of another model for such view.

- Drawings: automatic floor plans, sections, elevation, details are derived from BIM-Wood Model, it has more advantages in comparison to traditional CAD approach that requires creation of each drawing separately and unconnected.

- Schedules and Cost Estimations, automatic schedule and cost estimation are derived from BIM-Wood Model, it has more advantages in comparison to traditional CAD approach that requires creation of separated spreadsheets creation, which are unconnected to drawings.

- Fabrication: automated shop drawings and machine formats are available; it has more advantages in comparison to traditional CAD approach that requires creation of new files for fabrication.

7. Conclusions

- Use of BIM software and plug-ins in English would improve competitiveness in international markets.

- Introduction of BIM methodologies and plug-ins in the academic curricula of Architecture, Engineering, and Construction (AEC) degrees. Such as the UC and UBB Timber Certification courses.

- Creation of national standards for using BIM that include the use of wood.

- Creation of training for AEC professionals, such as workshops, courses, or certification courses.

- Partnerships with wood producers for construction, where standardizations of products for BIM platforms can be discussed.

- Dissemination seminars supported by the industry organizations involved: College/Associations of Architects, Constructor and Engineers.

Author Contributions

Conflict of Interest

References

- E. Fleury and M. Chiche, “LE BOIS DANS LA CONSTRUCTION,” 2006.

- J. Hildebrandt, N. Hagemann, and D. Thrän, “The contribution of wood-based construction materials for leveraging a low carbon building sector in europe,” Sustain Cities Soc, vol. 34, 2017. [CrossRef]

- H. Sakata and Y. Yamazaki, “Challenges in High-rise Wooden Structures and the Seismic Design in Japan,” International Journal of High-Rise Buildings, vol. 11, no. 3, 2022. [CrossRef]

- K. R. Gunawardena, M. J. Wells, and T. Kershaw, “Utilising green and bluespace to mitigate urban heat island intensity,” Science of the Total Environment, vol. 584–585, 2017. [CrossRef]

- Banco Mundial, H. C. Terraza, R. Donoso, F. Victorero, and D. Ibanez, “The Construction of Timber Houses in Chile: A Pillar of Sustainable Development and the Agenda for Economic Recovery,” 2020.

- E. Hurmekoski, J. Kunttu, T. Heinonen, T. Pukkala, and H. Peltola, “Does expanding wood use in construction and textile markets contribute to climate change mitigation?,” Renewable and Sustainable Energy Reviews, vol. 174, 2023. [CrossRef]

- A. Roos et al., “Beliefs on environmental impact of wood construction,” Scand J For Res, vol. 38, no. 1–2, 2023. [CrossRef]

- P. M. Diaz, “Analysis of Benefits, Advantages and Challenges of Building Information Modelling in Construction Industry,” Journal of Advances in Civil Engineering, vol. 2, no. 2, pp. 1–11, Mar. 2016. [CrossRef]

- A. Okakpu, A. GhaffarianHoseini, J. Tookey, J. Haar, and A. Ghaffarian Hoseini, “An optimisation process to motivate effective adoption of BIM for refurbishment of complex buildings in New Zealand,” Frontiers of Architectural Research, vol. 8, no. 4, 2019. [CrossRef]

- R. M. Borjeghaleh and J. M. Sardroud, “Approaching Industrialization of Buildings and Integrated Construction Using Building Information Modeling,” in Procedia Engineering, 2016. [CrossRef]

- P. Wu, R. Jin, Y. Xu, F. Lin, Y. Dong, and Z. Pan, “The analysis of barriers to bim implementation for industrialized building construction: A China study,” Journal of Civil Engineering and Management, vol. 27, no. 1, 2021. [CrossRef]

- B. Malgıt, Ü. Işıkdağ, G. Bekdaş, and M. Yücel, “A generative design-to-BIM workflow for minimum weight plane truss design,” Revista de la Construccion, vol. 21, no. 2, 2022. [CrossRef]

- S. A. Biancardo, A. Capano, S. G. de Oliveira, and A. Tibaut, “Integration of BIM and procedural modeling tools for road design,” Infrastructures (Basel), vol. 5, no. 4, 2020. [CrossRef]

- A. Kamari, B. M. Kotula, and C. P. L. Schultz, “A BIM-based LCA tool for sustainable building design during the early design stage,” Smart and Sustainable Built Environment, vol. 11, no. 2, 2022. [CrossRef]

- T. Ahmad, A. Aibinu, and M. J. Thaheem, “BIM-based Iterative Tool for Sustainable Building Design: A Conceptual Framework,” in Procedia Engineering, 2017. [CrossRef]

- C. Llatas, R. Quiñones, and N. Bizcocho, “Environmental Impact Assessment of Construction Waste Recycling versus Disposal Scenarios Using an LCA-BIM Tool during the Design Stage,” Recycling, vol. 7, no. 6, 2022. [CrossRef]

- S. Gaur and A. Tawalare, “Investigating the Role of BIM in Stakeholder Management: Evidence from a Metro-Rail Project,” Journal of Management in Engineering, vol. 38, no. 1, 2022. [CrossRef]

- A. N.hasan and S. M. Rasheed, “The Benefits of and Challenges to Implement 5D BIM in Construction Industry,” Civil Engineering Journal (Iran), vol. 5, no. 2, 2019. [CrossRef]

- A. Z. Sampaio, P. Sequeira, A. M. Gomes, and A. Sanchez-Lite, “BIM Methodology in Structural Design: A Practical Case of Collaboration, Coordination, and Integration,” Buildings, vol. 13, no. 1, 2023. [CrossRef]

- B. Ilhan and H. Yaman, “Green building assessment tool (GBAT) for integrated BIM-based design decisions,” Autom Constr, vol. 70, 2016. [CrossRef]

- M. A. van Eldik, F. Vahdatikhaki, J. M. O. dos Santos, M. Visser, and A. Doree, “BIM-based environmental impact assessment for infrastructure design projects,” Autom Constr, vol. 120, 2020. [CrossRef]

- V. W. Tam, Y. Zhou, L. Shen, and K. N. Le, “Optimal BIM and LCA integration approach for embodied environmental impact assessment,” J Clean Prod, vol. 385, 2023. [CrossRef]

- J. K. W. Wong and J. Zhou, “Enhancing environmental sustainability over building life cycles through green BIM: A review,” Automation in Construction, vol. 57. 2015. [CrossRef]

- M. Marrero, M. Wojtasiewicz, A. Martínez-Rocamora, J. Solís-Guzmán, and M. D. Alba-Rodríguez, “BIM-LCA integration for the environmental impact assessment of the urbanization process,” Sustainability (Switzerland), vol. 12, no. 10. 2020. [CrossRef]

- R. Santos, A. Aguiar Costa, J. D. Silvestre, and L. Pyl, “Development of a BIM-based Environmental and Economic Life Cycle Assessment tool,” J Clean Prod, vol. 265, 2020. [CrossRef]

- L. Wilhelm, A. Donaubauer, and T. H. Kolbe, “Integration of bim and environmental planning: The citygml envplan ade,” Journal of Digital Landscape Architecture, vol. 2021, no. 6, 2021. [CrossRef]

- R. Junge, R. Steinmann, and K. Beetz, “A Dynamic Product Model,” Dordrecht, 1997, pp. 617–634.

- Graphisoft, ArchiCAD. 2007. [CrossRef]

- ArchiSolutions Oy/Ltd, “Archiframe”.

- B. Soust-Verdaguer, C. Llatas, and A. García-Martínez, “Critical review of bim-based LCA method to buildings,” Energy and Buildings, vol. 136. 2017. [CrossRef]

- L. Khemlani, “BIM Evaluation Study Report, For the AIA Large Firm Round Table (LFRT) CEO Committee,” 2010.

- CIC Research Group, Computer Integrated Construction Research Program, and Penn State CIC Research Team, “BIM Project Execution Planning Guide and Templates – Version 2.1,” buildingSMART alliance, 2011.

- N. Gu and K. London, “Understanding and facilitating BIM adoption in the AEC industry,” Autom Constr, vol. 19, no. 8, 2010. [CrossRef]

- C. Jobim, M. Stumpf, R. Edelweiss, and A. Kern, “Análisis de la implantación de tecnología BIM en oficinas de proyecto y construcción en una ciudad de Brasil en 2015,” Revista ingeniería de construcción, vol. 32, no. 3, 2017. [CrossRef]

- McGraw Hill Construction, The business value of BIM for construction in major global markets. 2014.

- ISO, “BS ISO 29481-1 : 2010 - Building information modelling - Information delivery manual - Part 1: Methodology and format,” ISO, 2010.

- A. Agirbas, “Teaching construction sciences with the integration of BIM to undergraduate architecture students,” Frontiers of Architectural Research, vol. 9, no. 4, 2020. [CrossRef]

- S. Levin et al., “Plan BIM Chile,” Economic History Review, vol. 73, no. 1, 2019.

- CORFO and PMG, “Hoja de Ruta PyCS 2025,” Programa Estratégico de Productividad y Sustentabilidad en la Construcción, 2016.

- C. Eastman, P. Teicholz, R. Sacks, and K. Liston, BIM handbook: A Guide to building Information Modeling for owners, managers, designers, Engineers and contractors (2nd edition ed.): Wiley Publishing. 2011.

- D. Lobos and M. Trebilcock, “Building performance information and graphs approach for the design of floor plans,” Arquiteturarevista, vol. 10, no. 1, 2014. [CrossRef]

- C. S. Ogueta and M. C. Sweden, “Object Interaction Query: A Context Awareness Tool for Evaluating BIM Components’ Interactions,” 2014. [CrossRef]

- R. and G. L. Eastman, C., Teicholz, P. Sacks, BIM Handbook - A Guide to Building Information Modelling for Owners, Designers, Engineers, Contractors, and Facility Managers. 2018.

- M. Loyola and F. Lopez, “An evaluation of the macro-scale adoption of Building Information Modeling in Chile: 2013-2016,” REVISTA DE LA CONSTRUCCION, vol. 17, no. 1, pp. 158–171, Apr. 2018. [CrossRef]

- McGraw Hill Construction, “The Business Value of BIM for Construction in Major Global Markets,” 2014.

- J. Messner et al., “BIM Project Execution Planning Guide-Version 2.2.”.

- C. Eastman, P. Teicholz, R. Sacks, and K. Liston, BIM handbook: a guide to building information modeling for owners, managers, designers, engineers, and contractors, 2nd ed. New York: John Wiley, 2011.

- C. Eastman, P. Teicholz, R. Sacks, and K. Liston, BIM Handbook. A guide to Building Information Modeling for Owners Managers, Designers, Engineers, and Contractors, 1st ed. New Jersey: John Wiley & Sons, Inc., 2008.

- P. M. Diaz, “Analysis of Benefits, Advantages and Challenges of Building Information Modelling in Construction Industry,” Journal of Advances in Civil Engineering, vol. 2, no. 2, pp. 1–11, Mar. 2016. [CrossRef]

- T. Dzambazova, G. Demchak, and E. Krygiel, Mastering TM Revit Architecture 2008, vol. 53. 1989.

- V. Y. Alpatov, A. V. Atamanchuk, and M. I. Balzannikov, “Economic effectiveness of traditional building materials in modern conditions,” in IOP Conference Series: Materials Science and Engineering, 2019. [CrossRef]

- J. Švajlenka and M. Kozlovská, “Perception of user criteria in the context of sustainability of modern methods of construction based on wood,” Sustainability (Switzerland), vol. 10, no. 2, 2018. [CrossRef]

- J. Švajlenka and M. Kozlovská, “Elements of the Fourth Industrial Revolution in the Production of Wood Buildings,” Tehnički glasnik, vol. 14, no. 3, 2020. [CrossRef]

- T. W. Pribadi, M. S. Arif, S. I. Wahidi, and I. W. Maditiara, “Modular system construction for laminated wooden fishing vessel industry,” in IOP Conference Series: Earth and Environmental Science, 2021. [CrossRef]

- H. Salamah and T. Kang, “Review of timber construction manual in designing traditional building,” in The 2022 Structures Congress (Structures22), Seoul, Korea, Aug. 2022.

- D. Domljan and L. Janković, “Design of Sustainable Modular Wooden Booths Inspired by Revitalization of Croatian Traditional Construction and New User Needs Due to COVID-19 Pandemic,” Sustainability (Switzerland), vol. 14, no. 2, 2022. [CrossRef]

- B. Kim, “Proportions of Wood Members in Japanese Traditional Architecture—A Comparison of the Kiwari-Sho and Measurements of Building Remains,” Sustainability (Switzerland), vol. 15, no. 7. 2023. [CrossRef]

- A. Erarslan, “An example of traditional timber building techniques from Anatolia. Granary structures in the region of the Eastern Black Sea, Turkey; serender,” International Wood Products Journal, vol. 12, no. 1, 2021. [CrossRef]

- B. Wrightsman, “A Critical Investigation of the Wood Frame System: The Case for the Neil Astle House,” Journal of Architectural Education, vol. 75, no. 1, 2021. [CrossRef]

- F. Lindblad, “Växjö municipality’s planning strategy to increase the construction ofwooden multi-family buildings,” Sustainability (Switzerland), vol. 12, no. 12, 2020. [CrossRef]

- Fredrik Lindblad, “A Case Study of Växjö Municipality’s Actions to Increase the Construction of Wooden Multi-family Buildings,” Journal of Civil Engineering and Architecture, vol. 16, no. 5, 2022. [CrossRef]

- X. Lu, Y. Wei, X. Hu, and J. Fang, “A Research on the Architectural Design and its Implementing of Dong Nationality in Northern Guangxi,” IOP Conf Ser Earth Environ Sci, vol. 525, no. 1, 2020. [CrossRef]

- Y. Bai, J. Gao, A. Pitts, Y. Gao, W. Bai, and Z. Tao, “Improving the sustainability of traditional dwellings in Yunnan, China: Seismic resistance testing of wood-frame and earth-built wall dwellings,” Sustainability (Switzerland), vol. 11, no. 4, 2019. [CrossRef]

- S. Fernando, E. Hansen, R. Kozak, and A. Sinha, “Organizational cultural compatibility of engineered wood products manufacturers and building specifiers in the Pacific Northwest,” Architectural Engineering and Design Management, vol. 14, no. 5, 2018. [CrossRef]

- M. K. Kuzman and D. Sandberg, “Engineered wood products in contemporary architectural use – a concise overview,” Wood Mater Sci Eng, vol. 18, no. 6, pp. 2112–2115, Nov. 2023. [CrossRef]

- T. Herzog, J. Natterer, R. Schweitzer, M. Volz, and W. Winter, Timber Construction Manual. Basel: Birkhäuser Architecture, 2004.

- A. Fallahi, E. A. Poirier, S. Staub-French, J. Glatt, and N. Sills, “Designing for Pre-Fabrication and Assembly in the Construction of UBCäó» s Tall Wood Building,” Modular and Offsite Construction (MOC) Summit Proceedings, 2016.

- U. J. Udosen, “Evaluation and improvement of dvorak keyboard layout using CADwork,” in Advanced Materials Research, 2009, pp. 585–591. [CrossRef]

- M. Abushwereb, H. Liu, and M. Al-Hussein, “A knowledge-based approach towards automated manufacturing-centric BIM: wood frame design and modelling for light-frame buildings,” Modular and Offsite Construction (MOC) Summit Proceedings, pp. 100–107, 2019.

- B. Ceranic, D. Latham, and A. Dean, “Sustainable Design and Building Information Modelling: Case Study of Energy Plus House, Hieron’s Wood, Derbyshire UK,” Energy Procedia, vol. 83, pp. 434–443, 2015. [CrossRef]

- A. Alwisy, S. Bu Hamdan, B. Barkokebas, A. Bouferguene, and M. Al-Hussein, “A BIM-based automation of design and drafting for manufacturing of wood panels for modular residential buildings,” International Journal of Construction Management, vol. 19, no. 3, pp. 187–205, May 2019. [CrossRef]

- H. Deng, “Application of BIM Technology in the Seismic Performance of ‘wood Weaving’ Structure of Wooden Arcade Bridges,” Shock and Vibration, vol. 2022, 2022. [CrossRef]

- L. L. Dong, Y. H. Lu, and G. Chen, “The Modern Green Technology Innovation of Bayu Traditional Wooden Building,” Adv Mat Res, vol. 1065–1069, 2014. [CrossRef]

- F. Bianconi and M. Filippucci, “Digital Wood Design: Innovative Techniques of Representation in Architectural Design,” Springer, vol. 24, no. January, 2019.

- F. Bianconi and M. Filippucci, “WOOD, CAD AND AI: Digital modelling as place of convergence of natural and artificial intelligent to design timber architecture,” in Lecture Notes in Civil Engineering, vol. 24, 2019, pp. 3–60. [CrossRef]

- F. Neri, R. Cognoli, G. Palmieri, and R. Ruggiero, “Robotic assembly of a wooden architectural design,” in Mechanisms and Machine Science, 2023, pp. 426–433. [CrossRef]

- A. Adelzadeh, H. Karimian-Aliabadi, K. Åhlund, and C. Robeller, “ReciprocalShell A hybrid timber system for robotically-fabricated lightweight shell structures.”.

- C. Boton and D. Forgues, “Construction industrialization and IT integration: how tall wood buildings can show the right path towards construction 4.0,” Modular and offsite construction (MOC) summit proceedings, 2017.

- E. Hurmekoski, R. Jonsson, and T. Nord, “Context, drivers, and future potential for wood-frame multi-story construction in Europe,” Technol Forecast Soc Change, vol. 99, pp. 181–196, 2015. [CrossRef]

- S. An, P. Martinez, M. Al-Hussein, and R. Ahmad, “BIM-based decision support system for automated manufacturability check of wood frame assemblies,” Autom Constr, vol. 111, Mar. 2020. [CrossRef]

- O. Wong Chong, J. Zhang, R. M. Voyles, and B. C. Min, “BIM-based simulation of construction robotics in the assembly process of wood frames,” Autom Constr, vol. 137, May 2022. [CrossRef]

- B. Ben Mahmoud, N. Lehoux, P. Blanchet, and C. Cloutier, “Barriers, strategies, and best practices for BIM adoption in Quebec prefabrication small and medium-sized enterprises (SMEs),” Buildings, vol. 12, no. 4, Apr. 2022. [CrossRef]

- H. V. Dang, “Using sustainable timber in architecture in Vietnam,” in E3S Web of Conferences, 2023. [CrossRef]

- O. Bucklin, A. Menges, F. Amtsberg, O. Krieg, H. Drexler, and A. Rohr, “Mono-Material Wood Wall : Digital Fabrication of Performative Wood Envelopes,” Journal of Facade Design and Engineering, vol. 9, no. 1, 2021. [CrossRef]

- A. Ruuska and T. Häkkinen, “Efficiency in the Delivery of Multi-story Timber Buildings,” Energy Procedia, vol. 96, pp. 190–201, 2016. [CrossRef]

- A. A. M. Ali, “An integrated analysis with life cycle assessment, building information modeling, and environmental performance for window materials: Assiut university hospital clinic as a case study,” JES. Journal of Engineering Sciences, vol. 48, no. 6, pp. 1024–1050, 2020.

- P. Schneider-Marin, H. Harter, K. Tkachuk, and W. Lang, “Uncertainty analysis of embedded energy and greenhouse gas emissions using BIM in early design stages,” Sustainability, vol. 12, no. 7, p. 2633, 2020.

- B. Soust-Verdaguer, C. Llatas, and L. Moya, “Comparative BIM-based Life Cycle Assessment of Uruguayan timber and concrete-masonry single-family houses in design stage,” J Clean Prod, vol. 277, p. 121958, 2020.

- S. R. Shukla and S. Viswanath, “Comparative study on growth, wood quality and financial returns of teak (Tectona grandis Lf) managed under three different agroforestry practices,” Agroforestry systems, vol. 88, pp. 331–341, 2014.

- Q. Zheng, K. Yang, Q. Xu, C. Zhang, and L. Wang, “Pattern recognition of wood structure design parameters under external interference based on artificial neural network with BIM environment,” Journal of Intelligent and Fuzzy Systems, vol. 39, no. 6, pp. 8723–8729, 2020. [CrossRef]

- A. Alwisy, S. Bu Hamdan, B. Barkokebas, A. Bouferguene, and M. Al-Hussein, “A BIM-based automation of design and drafting for manufacturing of wood panels for modular residential buildings,” International Journal of Construction Management, vol. 19, no. 3, 2019. [CrossRef]

- H. Takabayashi, K. Kado, and G. Hirasawa, “Versatile Robotic Wood Processing Based on Analysis of Parts Processing of Japanese Traditional Wooden Buildings,” in Robotic Fabrication in Architecture, Art and Design 2018, 2019. [CrossRef]

- N. Rogeau, V. Tiberghien, P. Latteur, and Y. Weinand, “Robotic Insertion of Timber Joints using Visual Detection of Fiducial Markers,” in Proceedings of the 37th International Symposium on Automation and Robotics in Construction, ISARC 2020: From Demonstration to Practical Use - To New Stage of Construction Robot, 2020. [CrossRef]

- J. Peronto, J. Komp, and A. Fernandez, “Tall mass timber present and future - 2 case studies,” in 20th Congress of IABSE, New York City 2019: The Evolving Metropolis - Report, 2019. [CrossRef]

- H. Liu, G. Singh, M. Lu, A. Bouferguene, and M. Al-Hussein, “BIM-based automated design and planning for boarding of light-frame residential buildings,” Autom Constr, vol. 89, pp. 235–249, May 2018. [CrossRef]

- A. Bakchan, B. C. Guerra, K. M. Faust, and F. Leite, “BIM-based estimation of wood waste stream: the case of an institutional building project,” in Computing in Civil Engineering 2019: Visualization, Information Modeling, and Simulation - Selected Papers from the ASCE International Conference on Computing in Civil Engineering 2019, 2019, pp. 185–192. [CrossRef]

- M. Darwish, F. Alsakka, S. Assaf, and M. Al-Hussein, “Automated BIM-based CNC file generator for wood panel framing machines in construction manufacturing,” in 2022 Moc Summit: Edmonton, Alberta, Canada, 2022, pp. 98–105. [CrossRef]

- S. Al-Qahtani et al., “Development of photoluminescent translucent wood toward photochromic smart window applications,” Ind Eng Chem Res, vol. 60, no. 23, pp. 8340–8350, 2021. [CrossRef]

- J. C. Rose, A. Kicherer, M. Wieland, L. Klingbeil, R. Töpfer, and H. Kuhlmann, “Towards automated large-scale 3D phenotyping of vineyards under field conditions,” Sensors (Switzerland), vol. 16, no. 12, Dec. 2016. [CrossRef]

- A. Kaiser, M. Larsson, and U. A. Girhammar, “From file to factory: Innovative design solutions for multi-storey timber buildings applied to project Zembla in Kalmar, Sweden,” Frontiers of Architectural Research, vol. 8, no. 1, 2019. [CrossRef]

- R. L. Yuvita and A. Budiwirawan, “Analysis of the Advantages and Disadvantages of Using Autodesk Revit for the Dean Building of the Faculty of Education, Universitas Negeri Semarang,” Jurnal Teknik Sipil dan Perencanaan, vol. 24, no. 2, pp. 91–98, Oct. 2022. [CrossRef]

- J. D. Manrique, M. Al-Hussein, A. Bouferguene, and R. Nasseri, “Automated generation of shop drawings in residential construction,” Autom Constr, vol. 55, pp. 15–24, Jul. 2015. [CrossRef]

- L. Loffer, “The Advantages of Wood as a Building Material,” Wagner Meters, 2020.

- R. and G. L. Eastman, C., Teicholz, P. Sacks, BIM Handbook - A Guide to Building Information Modelling for Owners, Designers, Engineers, Contractors, and Facility Managers. 2018.

- Z. Maqsood, P. S. Rao, and T. Abdullah, “CAD/CAM with New Trends and Advancements, using Machine Learning: A Review,” International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES), vol. 5, no. 5, 2019.

- C. Eastman, P. Teicholz, R. Sacks, and K. Liston, BIM handbook: A Guide to building Information Modeling for owners, managers, designers, Engineers and contractors (2nd edition ed.): Wiley Publishing. 2011.

- J. Westover, P. Lam, and J. Houck, “Using BIM for Wood Framed Construction Projects,” Structure Magazine, p. 40, Sep. 2018. Accessed: Jan. 17, 2024. [Online]. Available:. https://www.structuremag.org/?p=13711.

- C. Paskoff, C. Boton, and P. Blanchet, “BIM-Based Checking Method for the Mass Timber Industry,” Buildings, vol. 13, no. 6, 2023. [CrossRef]

- S. Staub-French et al., “Building Information Modeling (BIM) and Design for Manufacturing and Assembly (DfMA) for Mass Timber Construction,” Vancouver, Nov. 2018. Accessed: Jan. 17, 2024. [Online]. Available:. https://www.naturallywood.com/resource/bim-and-design-for-manufacturing-and-assembly-for-mass-timber-construction/.

- O. Wong Chong, J. Zhang, R. M. Voyles, and B. C. Min, “BIM-based simulation of construction robotics in the assembly process of wood frames,” Autom Constr, vol. 137, 2022. [CrossRef]

- S. An, P. Martinez, M. Al-Hussein, and R. Ahmad, “BIM-based decision support system for automated manufacturability check of wood frame assemblies,” Autom Constr, vol. 111, 2020. [CrossRef]

- NBS, “What is BIM? (Building Information Modelling) - NBS National BIM Library,” NBS national library.

- NBS, “National BIM Report 2019,” National BIM Report 2019 :The definitive industry update, 2019.

- H. Wenzel, “Stora Enso baut Wellpappengeschäft aus,” Lebensmittel Zeitung, vol. 75, no. 2, 2023. [CrossRef]

- S. Meschini, K. Iturralde, T. Linner, and T. Bock, “Novel applications offered by Integration of Robotic Tools in BIM-based Design Workflow for Automation in Construction Processes,” CIB* IAARC W199 CIC 2016 Workshop, 2016.

- A. Agirbas, “Teaching construction sciences with the integration of BIM to undergraduate architecture students,” Frontiers of Architectural Research, vol. 9, no. 4, 2020. [CrossRef]

- D. Lobos, F. Pino, C. Codron, V. Nuñez, and A. Sierra, “BIM and wood integration. New possibilities for AEC industry,” in WCTE 2018 - World Conference on Timber Engineering, 2018.

- E. Souza, “Using BIM to Deliver Low-Carbon Wood Buildings,” ArchDaily. Accessed: Jan. 17, 2024. [Online]. Available:. https://www.archdaily.com/974772/using-bim-to-deliver-low-carbon-wood-buildings.

- P. Eversmann, F. Gramazio, and M. Kohler, “Robotic prefabrication of timber structures: towards automated large-scale spatial assembly,” Construction Robotics, vol. 1, no. 1–4, 2017. [CrossRef]

- R. He, M. Li, V. J. L. Gan, and J. Ma, “BIM-enabled computerized design and digital fabrication of industrialized buildings: A case study,” J Clean Prod, vol. 278, 2021. [CrossRef]

- O. Skidmore and L. Merrill, “Timber tower research project - SOM,” STRUCTURE magazine, no. May, 2013.

- S. Le Roux, F. Bannier, E. Bossanne, and M. Stieglmeier, “Investigating the interaction of building information modelling and lean construction in the timber industry,” in WCTE 2016 - World Conference on Timber Engineering, 2016.

- British Woodworking Federation Ltd (BWF), “What is BIM?.,”. https://www.bwf.org.uk/toolkit/what-is-bim/.

- Y. Matsunaka, “Stunning Wooden Architecture in Japan Exemplifies How BIM Helps Construction,”. https://www.autodesk.com/design-make/articles/how-bim-helps-construction.

- Naturaly Wood, “University of British Columbia’s, Centre for Interactive Research on Sustainability (Nov, 2017). Brock Commons: Construction Modelling Case Study,”. https://www.naturallywood.com/wp-content/uploads/brock-commons-construction-modelling_case-study_naturallywood.pdf.

- A. Menges and J. Knippers, “BUGA Wood Pavilion 2019 | Institute for Computational Design and Construction | University of Stuttgart,” ICD Research Buildings / Prototypes.

- O. Merino, “Estudio exploratorio sobre la edificación con madera en 3 pisos en Chile y su vinculación con metodología BIM Building Information Modeling. (In spanish),” Master Thesis, Pontificia Universidad Católica de Chile, Santiago de Chile, 2014.

- McGraw Hill Construction, The business value of BIM for construction in major global markets. 2014.

- C. Codrón, “Análisis de las Herramientas de las Tecnologías BIM que Permiten Mejorar la Etapa de Diseño en la Elaboración de los Proyectos de Construcción en Madera (In spanish).,” Master Thesis, Pontificia Universidad Católica de Chile, Santiago de Chile, 2018.

- C. H. Yang, T. H. Wu, B. Xiao, and S. C. Kang, “Design of a robotic software package for modular home builder,” in Proceedings of the 36th International Symposium on Automation and Robotics in Construction, ISARC 2019, 2019. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).