Submitted:

23 January 2024

Posted:

23 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

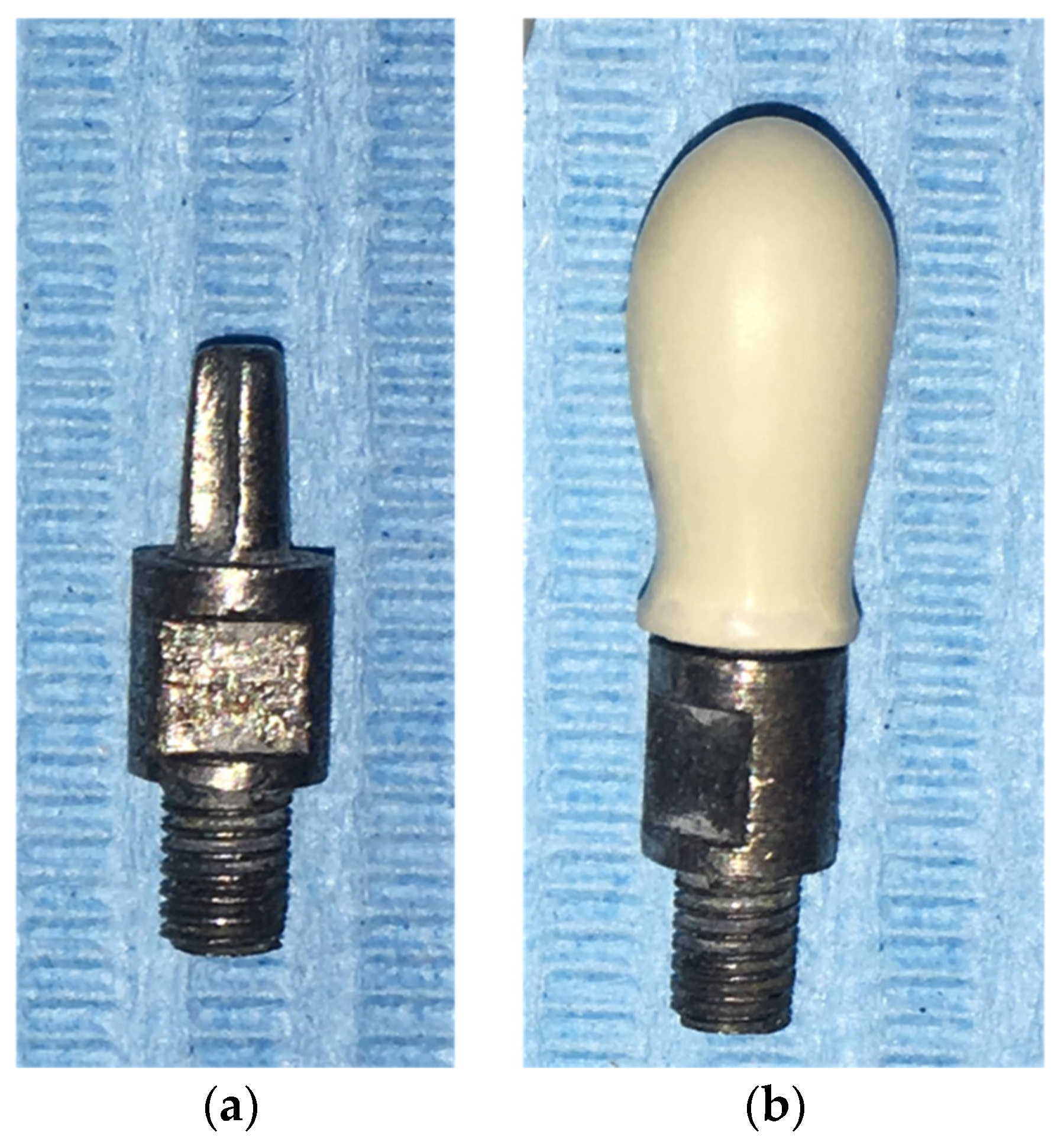

2.1. Sample crowns

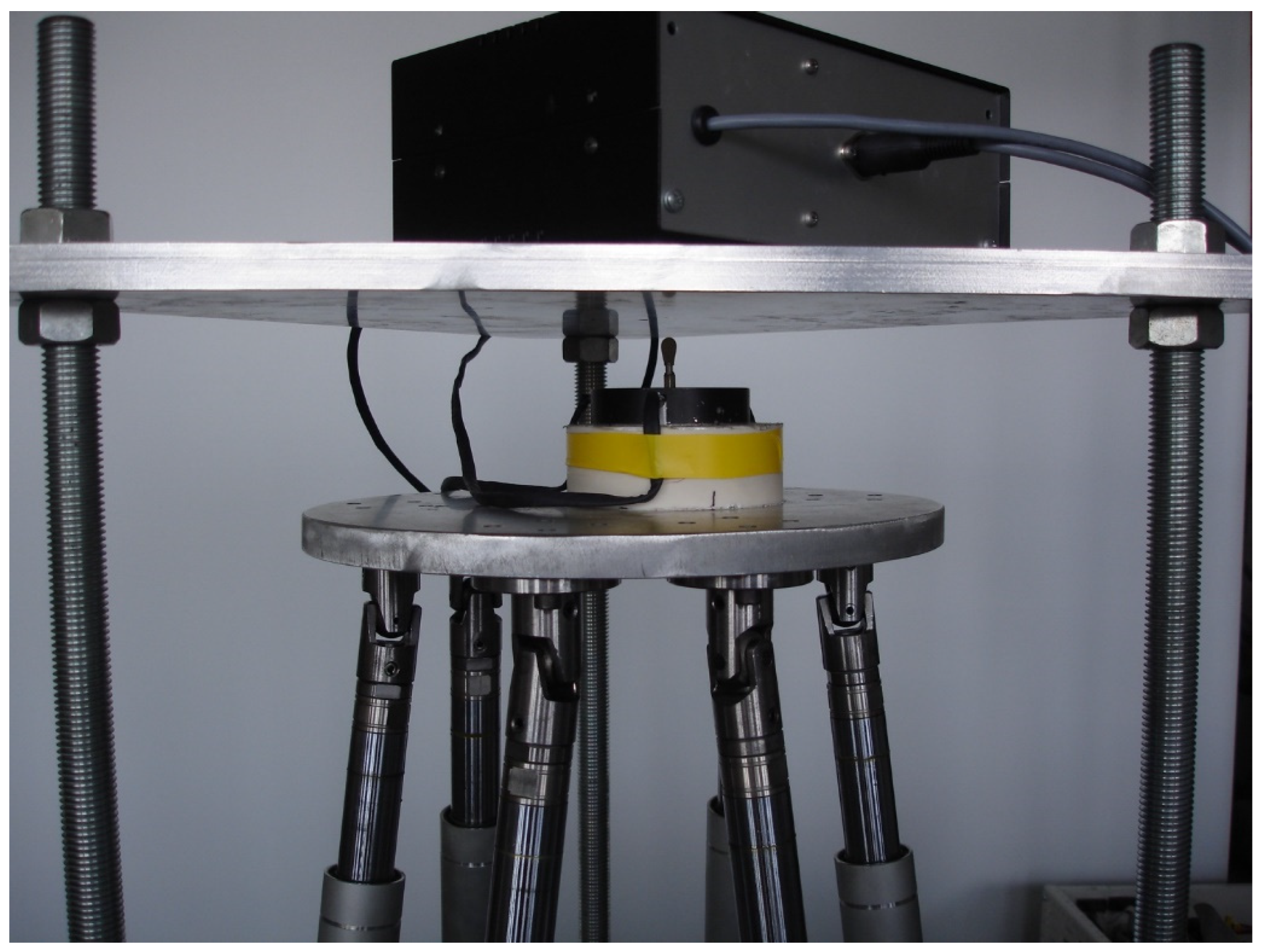

2.2. Test set-up

2.3. Statistical analysis

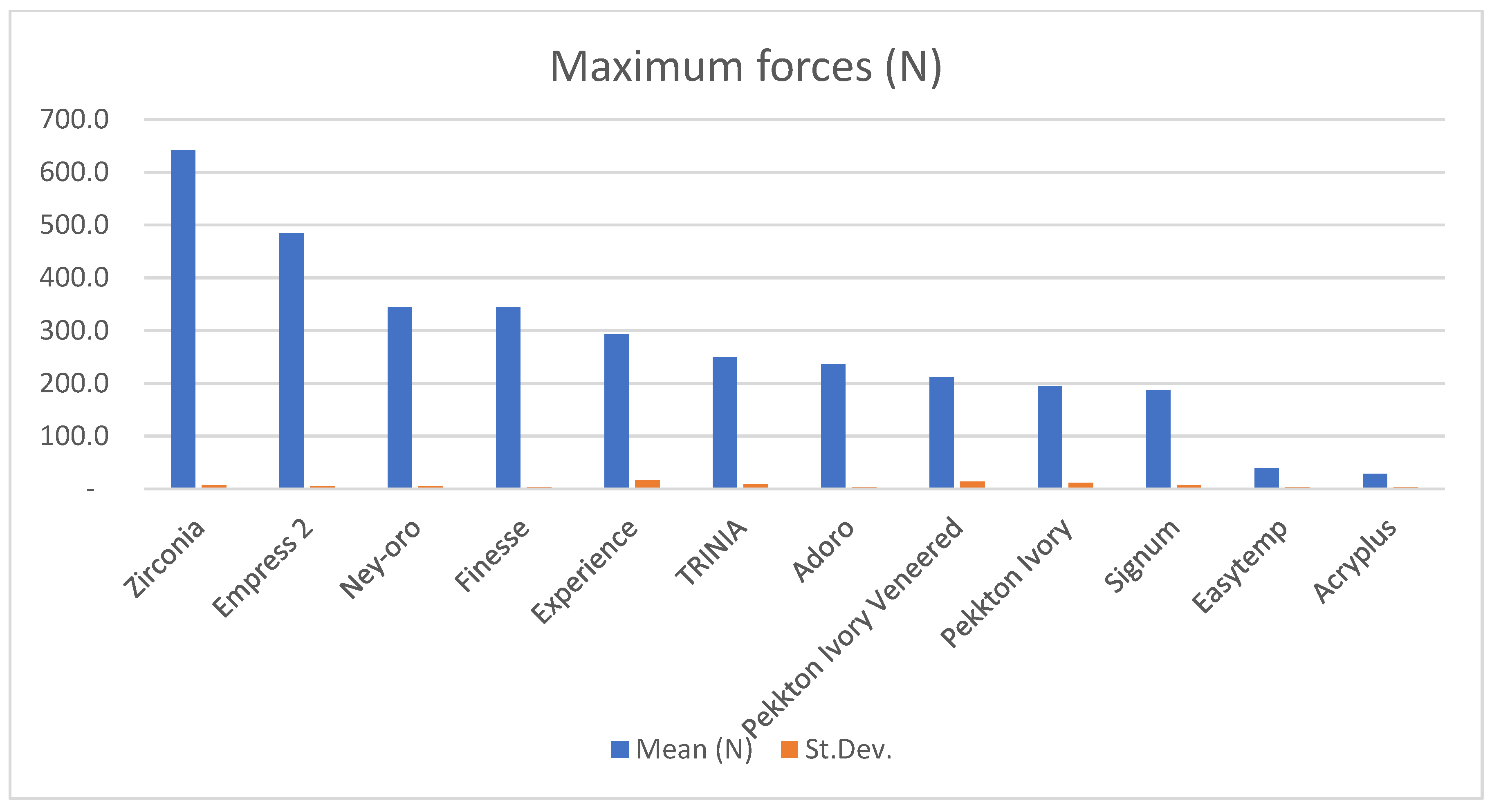

3. Results

| Sample | Pekkton® ivory | Pekkton® ivory veneered | TRINIATM | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean ± SD (N) | min (N) | MAX (N) | Mean ± SD (N) | min (N) | MAX (N) | Mean ± SD (N) | min (N) | MAX (N) | |

| 1 | 194.664 ± 2.037 | 191.547 | 207.656 | 214.274 ± 2.143 | 210.955 | 224.221 | 240.685 ± 1.890 | 237.622 | 251.655 |

| 2 | 201.490 ± 1.961 | 197.282 | 213.019 | 229.910 ± 1.777 | 226.891 | 239.053 | 257.446 ± 2.415 | 253.766 | 273.020 |

| 3 | 174.865 ± 4.254 | 169.962 | 194.329 | 216.873 ± 2.010 | 211.908 | 227.352 | 245.492 ± 3.960 | 240.717 | 274.793 |

| 4 | 198.381 ± 2.060 | 195.554 | 211.475 | 193.914 ± 1.951 | 189.975 | 205.977 | 260.094 ± 3.805 | 255.703 | 286.513 |

| 5 | 202.872 ± 2.306 | 199.964 | 217.816 | 203.231 ± 1.878 | 197.737 | 212.133 | 247.298 ± 2.254 | 243.770 | 262.483 |

| Mean | 194.454 ± 10.544 | 169.962 | 217.816 | 211.640 ± 12.437 | 189.975 | 239.053 | 250.203 ± 7.954 | 237.622 | 286.513 |

4. Discussion

Author Contributions

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Delucchi, F.; De Giovanni, E.; Pesce, P.; Bagnasco, F.; Pera, F.; Baldi, D.; Menini, M. Framework Materials for Full-Arch Implant-Supported Rehabilitations: A Systematic Review of Clinical Studies. Materials (Basel) 2021, 14. [Google Scholar] [CrossRef]

- Pera, F.; Pesce, P.; Solimano, F.; Tealdo, T.; Pera, P.; Menini, M. Carbon fibre versus metal framework in full-arch immediate loading rehabilitations of the maxilla - a cohort clinical study. J Oral Rehabil 2017, 44, 392–397. [Google Scholar] [CrossRef]

- Collaert, B.; De Bruyn, H. Immediate functional loading of TiOblast dental implants in full-arch edentulous maxillae: a 3-year prospective study. Clin Oral Implants Res 2008, 19, 1254–1260. [Google Scholar] [CrossRef]

- Arshad, M.; Hassantash, S.; Chinian, S.; Sadr, A.; Habibzadeh, S. Fracture strength and three-dimensional marginal evaluation of biocompatible high-performance polymer versus pressed lithium disilicate crowns. J Prosthet Dent 2023, 130, 132 e131–132 e139. [Google Scholar] [CrossRef] [PubMed]

- Elashmawy, Y.; Elshahawy, W.; Seddik, M.; Aboushelib, M. Influence of fatigue loading on fracture resistance of endodontically treated teeth restored with endocrowns. J Prosthodont Res 2021, 65, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Jovanovic, M.; Zivic, M.; Milosavljevic, M. A potential application of materials based on a polymer and CAD/CAM composite resins in prosthetic dentistry. J Prosthodont Res 2021, 65, 137–147. [Google Scholar] [CrossRef] [PubMed]

- Alqurashi, H.; Khurshid, Z.; Syed, A.U.Y.; Rashid Habib, S.; Rokaya, D.; Zafar, M.S. Polyetherketoneketone (PEKK): An emerging biomaterial for oral implants and dental prostheses. J Adv Res 2021, 28, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Han, K.H.; Lee, J.Y.; Shin, S.W. Implant- and Tooth-Supported Fixed Prostheses Using a High-Performance Polymer (Pekkton) Framework. Int J Prosthodont 2016, 29, 451–454. [Google Scholar] [CrossRef] [PubMed]

- Klur, T.; Hasan, I.; Ottersbach, K.; Stark, H.; Fichte, M.; Dirk, C.; Bourauel, C. PEKK-made indirect temporary crowns and bridges: a clinical pilot study. Clin Oral Investig 2019, 23, 771–777. [Google Scholar] [CrossRef] [PubMed]

- Villefort, R.F.; Diamantino, P.J.S.; Zeidler, S.; Borges, A.L.S.; Silva-Concilio, L.R.; Saavedra, G.; Tribst, J.P.M. Mechanical Response of PEKK and PEEK As Frameworks for Implant-Supported Full-Arch Fixed Dental Prosthesis: 3D Finite Element Analysis. Eur J Dent 2022, 16, 115–121. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.S.; Shin, J.H.; Kim, J.E.; Kim, J.H.; Lee, W.C.; Shin, S.W.; Lee, J.Y. Corrigendum to "Biomechanical Evaluation of a Tooth Restored with High Performance Polymer PEKK Post-Core System: A 3D Finite Element Analysis". Biomed Res Int 2017, 2017, 7196847. [Google Scholar] [CrossRef]

- Lee, K.S.; Shin, J.H.; Kim, J.E.; Kim, J.H.; Lee, W.C.; Shin, S.W.; Lee, J.Y. Biomechanical Evaluation of a Tooth Restored with High Performance Polymer PEKK Post-Core System: A 3D Finite Element Analysis. Biomed Res Int 2017, 2017, 1373127. [Google Scholar] [CrossRef]

- Qian, B.; Ji, K.; Lu, W.; Wu, G.; Tan, B.; Jing, J.; Ji, J. Polyetherketoneketone, a high-performance polymer for splinting mobile teeth: A clinical report. J Prosthet Dent 2023. [Google Scholar] [CrossRef]

- Salem, M.T.; El-Layeh, M.; El-Farag, S.A.A.; Salem, A.S.; Attia, A. Clinical assessment of different implant-supported esthetic crown systems fabricated with semi-digital workflow: Two-year prospective study. J Esthet Restor Dent 2022, 34, 1247–1262. [Google Scholar] [CrossRef]

- Turksayar, A.A.D.; Atsu, S.S. Fracture Resistance of Zirconia, Polyetheretherketone, and Polyetherketoneketone Implant Abutments After Aging. Int J Oral Maxillofac Implants 2021, 36, 332–340. [Google Scholar] [CrossRef]

- Fuhrmann, G.; Steiner, M.; Freitag-Wolf, S.; Kern, M. Resin bonding to three types of polyaryletherketones (PAEKs)-durability and influence of surface conditioning. Dent Mater 2014, 30, 357–363. [Google Scholar] [CrossRef]

- Lommen, J.; Schorn, L.; Sproll, C.; Haussmann, J.; Kubler, N.R.; Budach, W.; Rana, M.; Tamaskovics, B. Reduction of CT Artifacts Using Polyetheretherketone (PEEK), Polyetherketoneketone (PEKK), Polyphenylsulfone (PPSU), and Polyethylene (PE) Reconstruction Plates in Oral Oncology. J Oral Maxillofac Surg 2022, 80, 1272–1283. [Google Scholar] [CrossRef] [PubMed]

- Menini, M.; Pesce, P.; Bevilacqua, M.; Pera, F.; Tealdo, T.; Barberis, F.; Pera, P. Effect of Framework in an Implant-Supported Full-Arch Fixed Prosthesis: 3D Finite Element Analysis. Int J Prosthodont 2015, 28, 627–630. [Google Scholar] [CrossRef]

- Menini, M.; Conserva, E.; Tealdo, T.; Bevilacqua, M.; Pera, F.; Signori, A.; Pera, P. Shock absorption capacity of restorative materials for dental implant prostheses: an in vitro study. Int J Prosthodont 2013, 26, 549–556. [Google Scholar] [CrossRef]

- Conserva, E.; Menini, M.; Tealdo, T.; Bevilacqua, M.; Pera, F.; Ravera, G.; Pera, P. Robotic chewing simulator for dental materials testing on a sensor-equipped implant setup. Int J Prosthodont 2008, 21, 501–508. [Google Scholar] [PubMed]

- Conserva, E.; Menini, M.; Tealdo, T.; Bevilacqua, M.; Ravera, G.; Pera, F.; Pera, P. The use of a masticatory robot to analyze the shock absorption capacity of different restorative materials for prosthetic implants: a preliminary report. Int J Prosthodont 2009, 22, 53–55. [Google Scholar]

- Kelkar, K.C.; Bhat, V.; Hegde, C. Finite element analysis of the effect of framework materials at the bone-implant interface in the all-on-four implant system. Dent Res J (Isfahan) 2021, 18, 1. [Google Scholar] [PubMed]

- Hoque, M.E.; Showva, N.N.; Ahmed, M.; Rashid, A.B.; Sadique, S.E.; El-Bialy, T.; Xu, H. Titanium and titanium alloys in dentistry: current trends, recent developments, and future prospects. Heliyon 2022, 8, e11300. [Google Scholar] [CrossRef] [PubMed]

- Dantas, T.A.; Pinto, P.; Vaz, P.C.S.; Silva, F.S. Design and optimization of zirconia functional surfaces for dental implants applications. Ceramics International 2020, 46, 16328–16336. [Google Scholar] [CrossRef]

- Kondo, T.; Komine, F.; Honda, J.; Takata, H.; Moriya, Y. Effect of veneering materials on fracture loads of implant-supported zirconia molar fixed dental prostheses. J Prosthodont Res 2019, 63, 140–144. [Google Scholar] [CrossRef] [PubMed]

- Papaspyridakos, P.; Lal, K. Computer-assisted design/computer-assisted manufacturing zirconia implant fixed complete prostheses: clinical results and technical complications up to 4 years of function. Clin Oral Implants Res 2013, 24, 659–665. [Google Scholar] [CrossRef] [PubMed]

- Tiossi, R.; Gomes, E.A.; Faria, A.C.L.; Rodrigues, R.C.S.; Ribeiro, R.F. Biomechanical behavior of titanium and zirconia frameworks for implant-supported full-arch fixed dental prosthesis. Clin Implant Dent Relat Res 2017, 19, 860–866. [Google Scholar] [CrossRef] [PubMed]

- Abdulmajeed, A.A.; Lim, K.G.; Narhi, T.O.; Cooper, L.F. Complete-arch implant-supported monolithic zirconia fixed dental prostheses: A systematic review. J Prosthet Dent 2016, 115, 672–677 e671. [Google Scholar] [CrossRef] [PubMed]

- Vallittu, P.K. An overview of development and status of fiber-reinforced composites as dental and medical biomaterials. Acta Biomater Odontol Scand 2018, 4, 44–55. [Google Scholar] [CrossRef]

- Menini, M.; Pesce, P.; Pera, F.; Barberis, F.; Lagazzo, A.; Bertola, L.; Pera, P. Biological and mechanical characterization of carbon fiber frameworks for dental implant applications. Mater Sci Eng C Mater Biol Appl 2017, 70, 646–655. [Google Scholar] [CrossRef]

- Pesce, P.; Lagazzo, A.; Barberis, F.; Repetto, L.; Pera, F.; Baldi, D.; Menini, M. Mechanical characterisation of multi vs. uni-directional carbon fiber frameworks for dental implant applications. Mater Sci Eng C Mater Biol Appl 2019, 102, 186–191. [Google Scholar] [CrossRef]

- Liebermann, A.; Wimmer, T.; Schmidlin, P.R.; Scherer, H.; Loffler, P.; Roos, M.; Stawarczyk, B. Physicomechanical characterization of polyetheretherketone and current esthetic dental CAD/CAM polymers after aging in different storage media. J Prosthet Dent 2016, 115, 321–328 e322. [Google Scholar] [CrossRef]

- Omaish, H.H.M.; Abdelhamid, A.M.; Neena, A.F. Comparison of the strain developed around implants with angled abutments with two reinforced polymeric CAD-CAM superstructure materials: An in vitro comparative study. J Prosthet Dent 2022, 127, 634 e631–634 e638. [Google Scholar] [CrossRef]

- Suzaki, N.; Yamaguchi, S.; Hirose, N.; Tanaka, R.; Takahashi, Y.; Imazato, S.; Hayashi, M. Evaluation of physical properties of fiber-reinforced composite resin. Dent Mater 2020, 36, 987–996. [Google Scholar] [CrossRef]

- Gracis, S.E.; Nicholls, J.I.; Chalupnik, J.D.; Yuodelis, R.A. Shock-absorbing behavior of five restorative materials used on implants. Int J Prosthodont 1991, 4, 282–291. [Google Scholar] [CrossRef]

- Elkabbany, A.; Kern, M.; Elkhadem, A.H.; Wille, S.; Amer, A.A.; Chaar, M.S. Retention of metallic and non-metallic double-crown-retained mandibular overdentures on implants: An in-vitro study. J Prosthodont Res 2020, 64, 384–390. [Google Scholar] [CrossRef]

- Nishihara, H.; Haro Adanez, M.; Att, W. Current status of zirconia implants in dentistry: preclinical tests. J Prosthodont Res 2019, 63, 1–14. [Google Scholar] [CrossRef]

- Song, C.H.; Choi, J.W.; Jeon, Y.C.; Jeong, C.M.; Lee, S.H.; Kang, E.S.; Yun, M.J.; Huh, J.B. Comparison of the Microtensile Bond Strength of a Polyetherketoneketone (PEKK) Tooth Post Cemented with Various Surface Treatments and Various Resin Cements. Materials (Basel) 2018, 11. [Google Scholar] [CrossRef] [PubMed]

- Alsadon, O.; Wood, D.; Patrick, D.; Pollington, S. Fatigue behavior and damage modes of high performance poly-ether-ketone-ketone PEKK bilayered crowns. J Mech Behav Biomed Mater 2020, 110, 103957. [Google Scholar] [CrossRef] [PubMed]

- Schwitalla, A.D.; Spintig, T.; Kallage, I.; Muller, W.D. Flexural behavior of PEEK materials for dental application. Dent Mater 2015, 31, 1377–1384. [Google Scholar] [CrossRef] [PubMed]

- Dawson, J.H.; Hyde, B.; Hurst, M.; Harris, B.T.; Lin, W.S. Polyetherketoneketone (PEKK), a framework material for complete fixed and removable dental prostheses: A clinical report. J Prosthet Dent 2018, 119, 867–872. [Google Scholar] [CrossRef] [PubMed]

- Katzenbach, A.; Dorsam, I.; Stark, H.; Bourauel, C.; Keilig, L. Fatigue behaviour of dental crowns made from a novel high-performance polymer PEKK. Clin Oral Investig 2021, 25, 4895–4905. [Google Scholar] [CrossRef]

- Shash, Y.H.; El-Wakad, M.T.; El-Dosoky, M.A.A.; Dohiem, M.M. Evaluation of stresses on mandible bone and prosthetic parts in fixed prosthesis by utilizing CFR-PEEK, PEKK and PEEK frameworks. Sci Rep 2023, 13, 11542. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.S.; Shin, S.W.; Lee, S.P.; Kim, J.E.; Kim, J.H.; Lee, J.Y. Comparative Evaluation of a Four-Implant-Supported Polyetherketoneketone Framework Prosthesis: A Three-Dimensional Finite Element Analysis Based on Cone Beam Computed Tomography and Computer-Aided Design. Int J Prosthodont 2017, 30, 581–585. [Google Scholar] [CrossRef] [PubMed]

| Material property | TRINIATM | Pekkton®ivory |

|---|---|---|

| Flexural Strength | 393 MPa | 200 MPa |

| Flexural Modulus of Elasticity | 18.8 GPa | 5.1 GPa |

| Tensile Strength | 169 MPa | 119 MPa |

| Compressive Strength | 339 MPa | 246 MPa |

| Rockwell Hardness (R-Scale) | 870 HV | 33 HV |

| Density | 1.68 g/cm3 | 1.4 g/cm3 |

| Fracture strength | 9.7 MPa m1/2 | 115 MPa |

| Water absorption | 0.03 % | 8.7 μg/mm3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).