1. Introduction

CFRP is increasingly used in aerospace, shipbuilding, and automotive industries due to its advantages of high specific strength and stiffness, lightweight, and long fatigue life [

1,

2]. For example, in recent years, more than 50% of the structural weight of most aircraft is made of CFRP, which reduces the total weight and fuel consumption of the aircraft [

3]. CFRP is an orthotropic material made of carbon-fiber cloth layer by layer. Compared with isotropic materials, CFRP is prone to complex and inconspicuous damage forms during use [

4], such as delamination, matrix cracking, and fiber rupture [

5]. In addition, to meet the needs of various engineering applications, CFRP is usually made into different types of structures, such as tube, beam [

6], winglet [

7], and bending structures [

8]. The bending part is a common aircraft structure [

9], such as rectangular and C-shaped wing beams. The vulnerability of CFRP bending structures has been demonstrated [

10]. Due to the structural characteristics of bent CFRP, stress/strain concentration is easily induced in the bending area. As a result, the shape distortion and uneven distribution of carbon fibers occur in the bending area, ultimately leading to the appearance of damage. Delamination is the most common and extremely harmful failure mode of CFRP bending structures [

11,

12]. Delamination usually occurs covertly within the CFRP structure. The occurrence and development of delamination significantly reduce the stiffness, strength, and load-bearing capacity of the structure. The bending CFRP structure will suffer serious overall failure when the delamination size reaches a critical value [

13]. Therefore, the detection of the bending feature area to achieve the quantification of the delamination is crucial for the safe and reliable operation of the bending CFRP structure during the service life.

As an active detection method, Lamb wave has the advantages of long propagation distance, small long-distance propagation attenuation, large coverage area, and high damage sensitivity [

14]. Compared with other damage detection methods, Lamb wave has the characteristics of propagation along the plate and unique advantages for detecting bending plate damages. Lamb wave detection technology has proven to be one of the most promising methods in non-destructive assessment applications and can be used to detect various types of damage (delamination, holes, etc.) in CFRP structures [

15,

16]. Lamb wave has two modes of symmetry and anti-symmetry due to its dispersion characteristics. Lamb wave components with different mode frequencies have unique sensitivities to delamination damage due to their propagation characteristics. When Lamb waves encounter delamination damage in the CFRP plate structure, phenomena such as scattering, transmission, and mode conversion will occur [

17,

18]. The Lamb waves propagate in each sub-layer above and below the layer, and sub-layers with different lay-up methods have different propagation velocities [

19]. The propagation velocity, phase, and peak amplitude of Lamb wave will change due to the existence of delamination damage [

20], and delamination damage with different sizes has different effects on Lamb wave propagation characteristics. Based on these properties of Lamb waves, quantitative detection of delamination damage can be achieved. Xianping Zeng et al. [

21] detected the damage of large composite laminates using lamb wave. The proposed damage contour algorithm using the convex envelope of damage reflection points and maximum inscribed n-polygon can accurately determine the quantitative damage size. Jiahui Guo et al. [

22] extracted the precise time-of-flight (ToF) of the Lamb wave using the matching pursuit decomposition algorithm. The scattering source is identified on the elliptical trajectory obtained by the ToF of each sensing path. The Gaussian kernel probability density distribution of the scattering source can accurately characterize the damage size.

Generally speaking, the fundamental symmetric S0 and anti-symmetric A0 Lamb modes were used for practical detection [

23]. Lamb waves in A0 mode and S0 mode have different propagation characteristics. At the same excitation frequency, the A0 mode Lamb wave has a lower propagation velocity and shorter wavelength than the S0 mode Lamb wave. Consequently, the A0 mode Lamb wave is more sensitive to damage [

24,

25,

26]. However, it is difficult to analyze the signal of the A0 mode Lamb wave because it has higher dispersion and propagation attenuation than the S0 mode Lamb wave [

27,

28]. Ramadas et al. [

29] investigated the interaction of A0 mode Lamb waves with the delamination in the middle plane of CFRP laminates. The research shows that the A0 mode Lamb wave is converted into an S0 mode Lamb wave at the leading edge of the delamination. The S0 mode Lamb wave only exists within the sub-layer of the delaminated region and converts back to the A0 mode Lamb wave when leaving the delaminated region.

In addition, extracting information carried by Lamb waves based on time domain features was challenging. As a result, various signal analysis methods were applied to Lamb waves to extract signal features. Guoqi Zhao et al. [

30] employed PZT piezoelectric sensor to excite and receive A0 mode Lamb waves to detect the delamination damage of the composite double cantilever beam. The A0 mode Lamb wave signal was processed by Hilbert transform, Fourier transform and continuous wavelet transform, and the effective A0 mode Lamb wave parameters were extracted to characterize the delamination damage length. Pillarisetti et al. [

31] obtained the power spectral density of the A0 and S0 mode Lamb wave signals by performing a fast Fourier transform and quantified the damage degree of CFRP based on the stress wave factor extracted from the power spectral density distribution.

To analyze the quantitative detection ability of A0 and S0 mode Lamb waves on CFRP delamination damage, this paper introduces SDC to evaluate the sensitivity of A0 and S0 mode Lamb waves to delamination damage and quantify the delamination damage. The linear array PZT phase time-delay method was employed to realize the control and enhancement of single-mode Lamb wave. The quantitative detection ability of single-mode Lamb waves to delamination damage is investigated by simulation. The A0 mode Lamb wave was excited by the developed one-dimensional LCT, which was employed to conduct the detection experiment on the CFRP bending plate with different delamination damage sizes. The relationship between the delamination damage size and SDC obtained by the finite-element simulation data can accurately quantify the delamination damage.

2. Signal Processing Methods

The characteristics of the Lamb wave signal are altered due to the presence of damage. In this article,

SDC was employed to evaluate the damage sensitivity of the Lamb wave. At the same time, the damage size can be evaluated based on the

SDC between the signal with damage information and the non-damage baseline signal.

SDC is defined as

where m is the length of the signal sequence.

Sdi and

Sri are the damage signal and the baseline signal correspondingly,

μSd and

μSr are the mean values of the corresponding signals, respectively. If there is no damage, the two signals are the same, and the

SDC is 0. If the phases of the two signals are opposite, the

SDC is close to 1.0.

To obtain the ToF of the Lamb wave, the continuous wavelet transform coefficients (

CWTC) of the Lamb wave signal are obtained through the application of wavelet transform. The wavelet transform is defined as:

where

t is time.

S(

t) is the signal sequence.

is the wavelet basis function, where a is the scale factor, and its value is inversely proportional to the frequency. The small-scale factor can distinguish the high-frequency components of the signal sequence, and the large-scale factor can distinguish the low-frequency components of the signal sequence. And b is the displacement factor, which represents the time range in which a signal sequence of a certain frequency appears.

3. Finite-Element Simulation

The finite-element simulation technology can accurately calculate the propagation characteristics of Lamb waves in CFRP [

32,

33]. The three-dimensional finite-element analysis of Lamb wave propagation in CFRP was conducted in the Abaqus software environment.

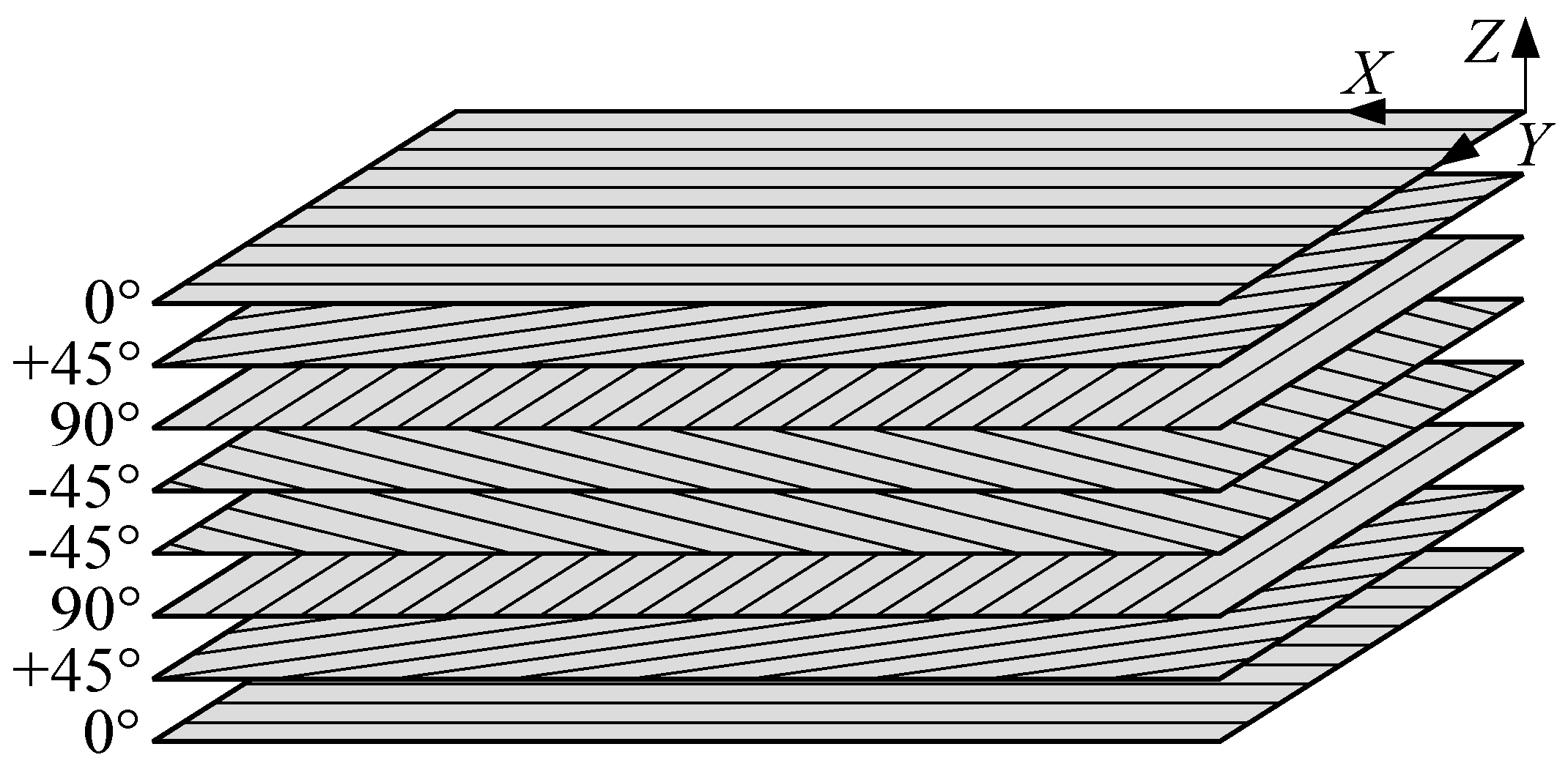

3.1. Finite-Element Simulation Model

In this paper, the detection effect of A0 mode and S0 mode Lamb waves on delamination damage in CFRP bending plates was investigated by finite-element analysis. The numerical simulation of [0°/45°/90°/−45°]

s quasi-isotropic CFRP was carried out. The relationship between the ply direction and the coordinate axis is shown in

Figure 1, and the CFRP material properties are listed in

Table 1.

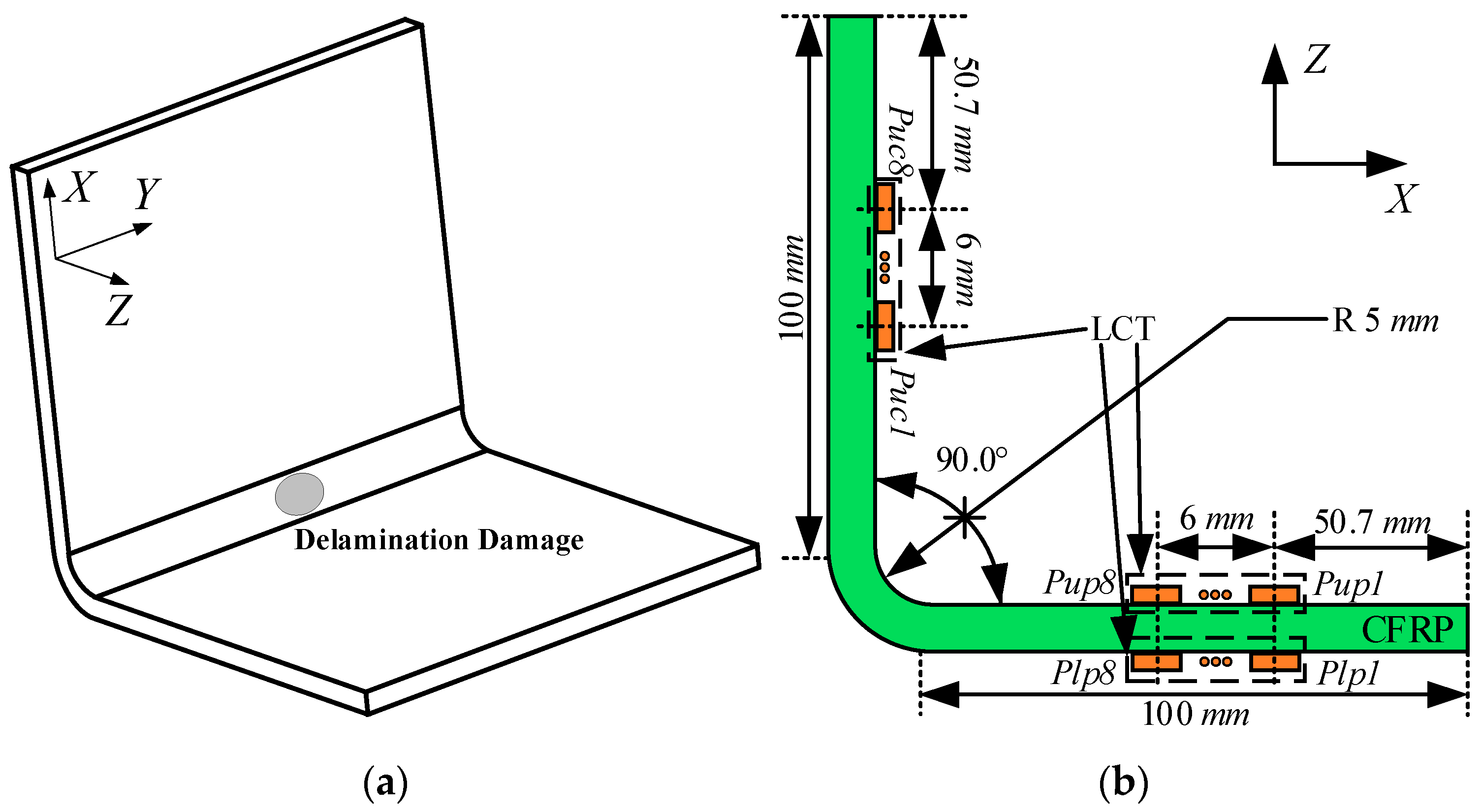

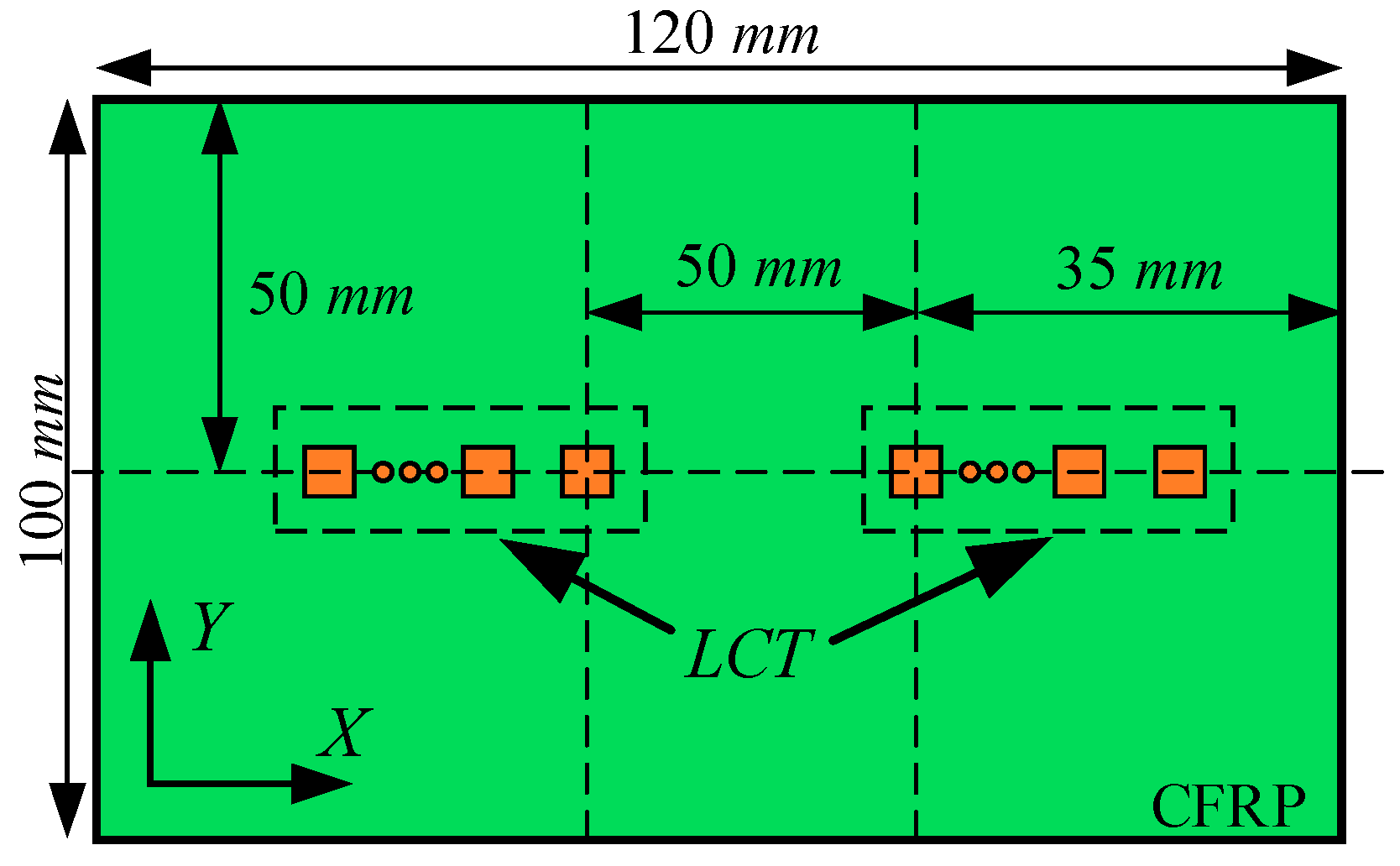

As shown in

Figure 2a, the delamination damage is located at the center of the CFRP bending plate. The structural dimensions of the CFRP bending plate and the position of LCT on the CFRP bending plate are shown in

Figure 2b. The bending radius R of the CFRP bending plate is 5.0 mm and the thickness is 2.0 mm. As shown in

Figure 2b, the LCT used to excite the Lamb wave was pasted on the upper and lower sides of the CFRP plate. The excitation elements of the LCT pasted to the upper side of the CFRP plate were numbered from

Pup1 to

Pup8. The excitation elements of the LCT pasted to the lower side of the CFRP plate were numbered from

Plp1 to

Plp8. The LCT used to receive Lamb waves was pasted on the upper side of the CFRP plate, and the receiving elements of the LCT were numbered from

Puc1 to

Puc8.

PZT-5H was used as the excitation element and the receiving element, and its density is 7500.0 kg/m

3. The stiffness coefficient, piezoelectric coefficient, and relative dielectric constant of PZT-5H are listed in

Table 2,

Table 3 and

Table 4, respectively, and the absolute dielectric constant is 8.854 × 10

-12 F/m.

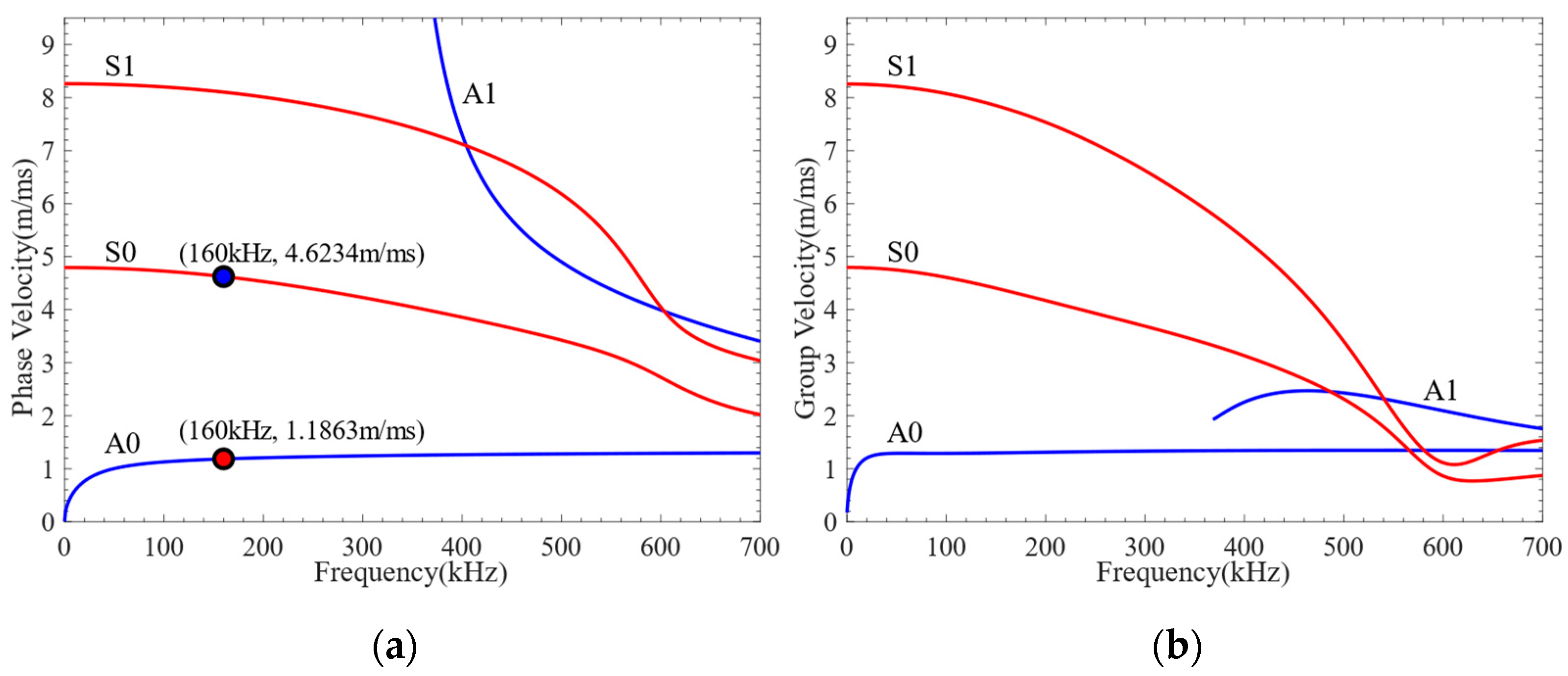

3.2. Selection of Excitation Signal Frequency

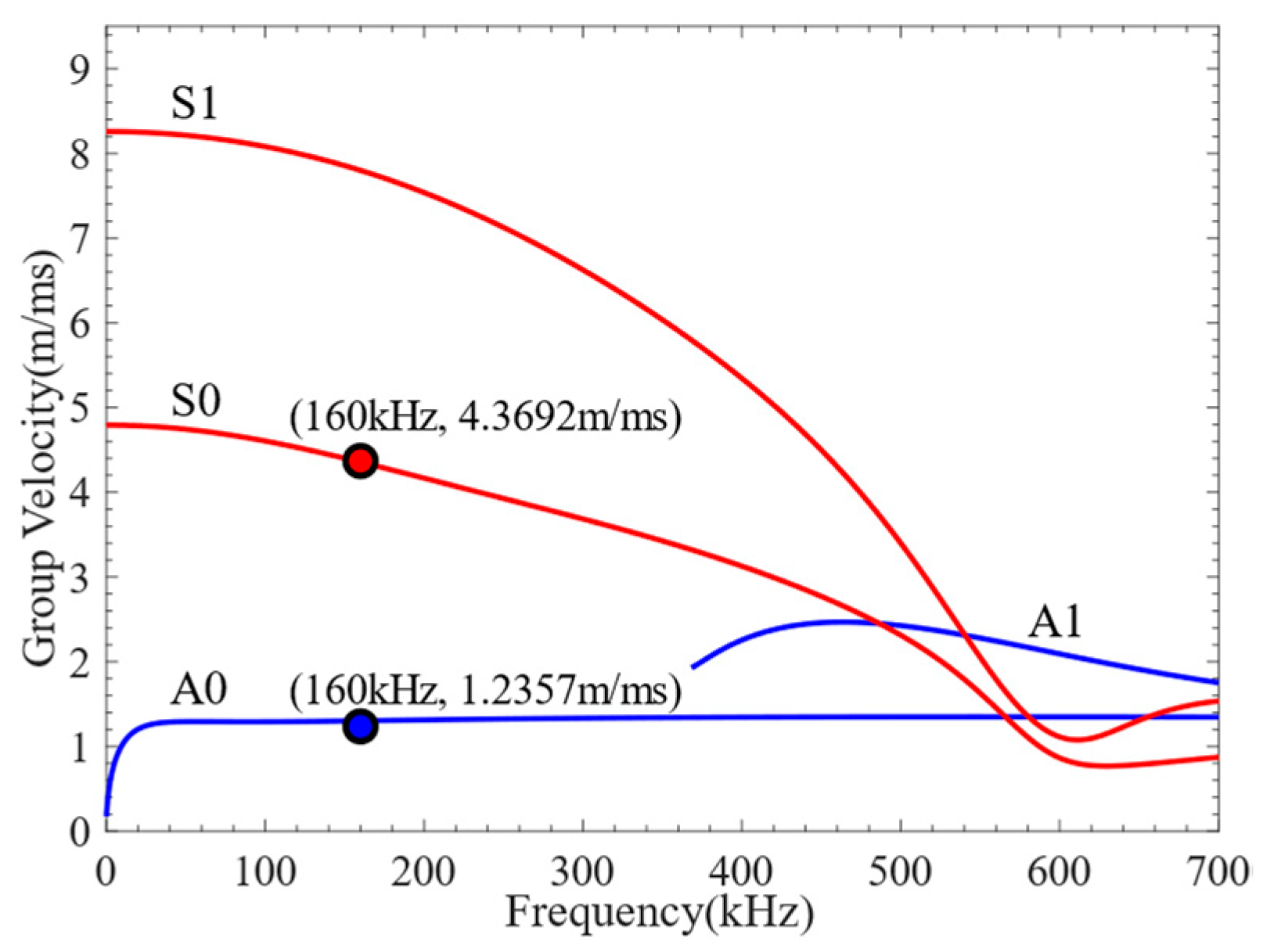

Lamb waves exhibit varying levels of sensitivity to damage at different frequencies. Before conducting damage detection, it is necessary to understand the dispersion characteristics of Lamb waves and select a more reasonable excitation frequency. However, there is no analytical solution to the dispersion equation for multilayer quasi-isotropic materials. The Dispersion Calculator [

34] was used to calculate the phase velocity and group velocity dispersion curves of CFRP, as shown in

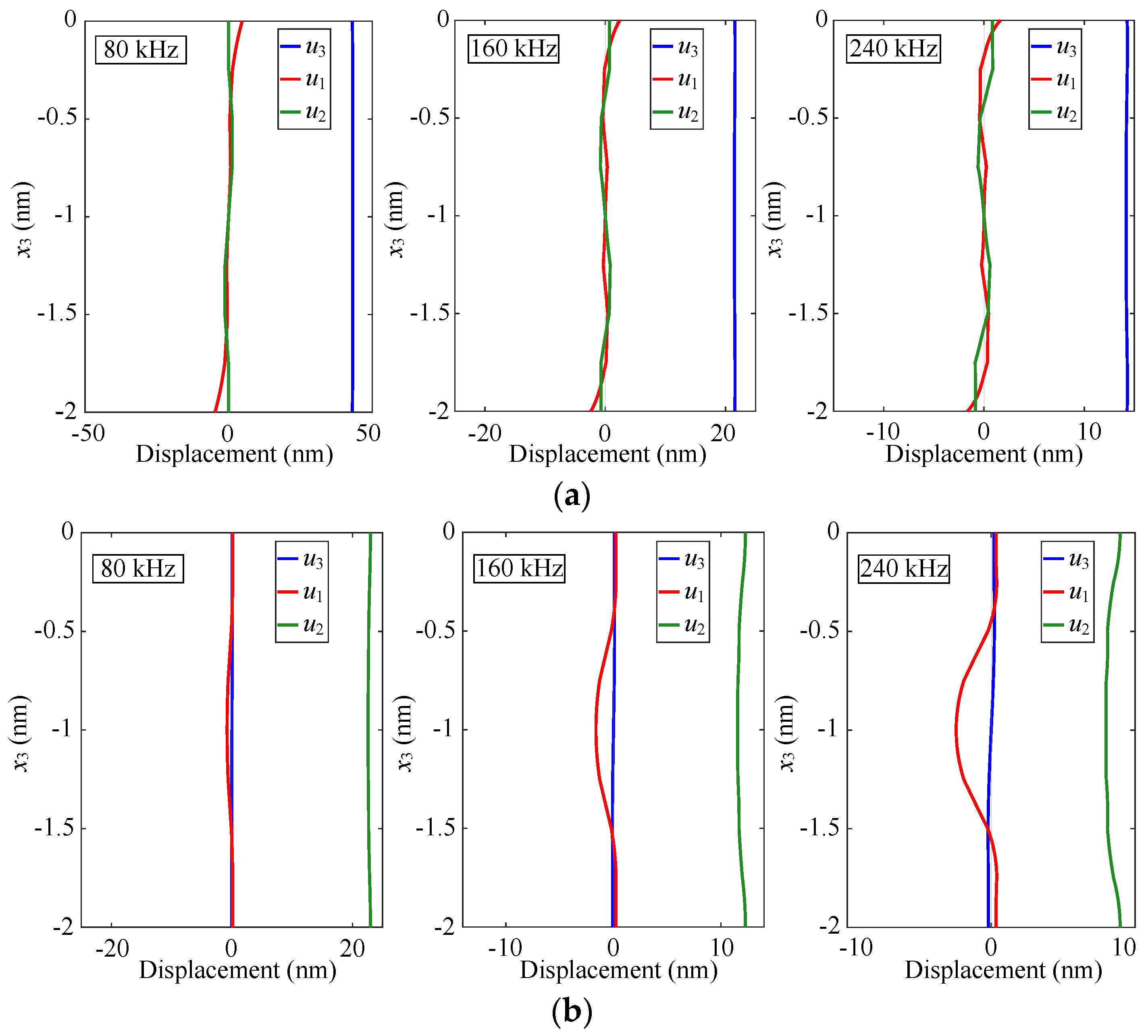

Figure 3. The through-thickness displacement profiles of Lamb waves propagating in CFRP at frequencies of 80 kHz, 160 kHz, and 320 kHz are shown in

Figure 4. It can be seen from the figure that the through-thickness displacement profile of CFRP is approximately the same below the frequency of 240 kHz. Consequently, a three-period narrowband Tone-Burst with a central frequency of 160 kHz modulated by the Hanning window was selected as the excitation signal [

35]. The excitation signal is defined as:

where the excitation frequency is

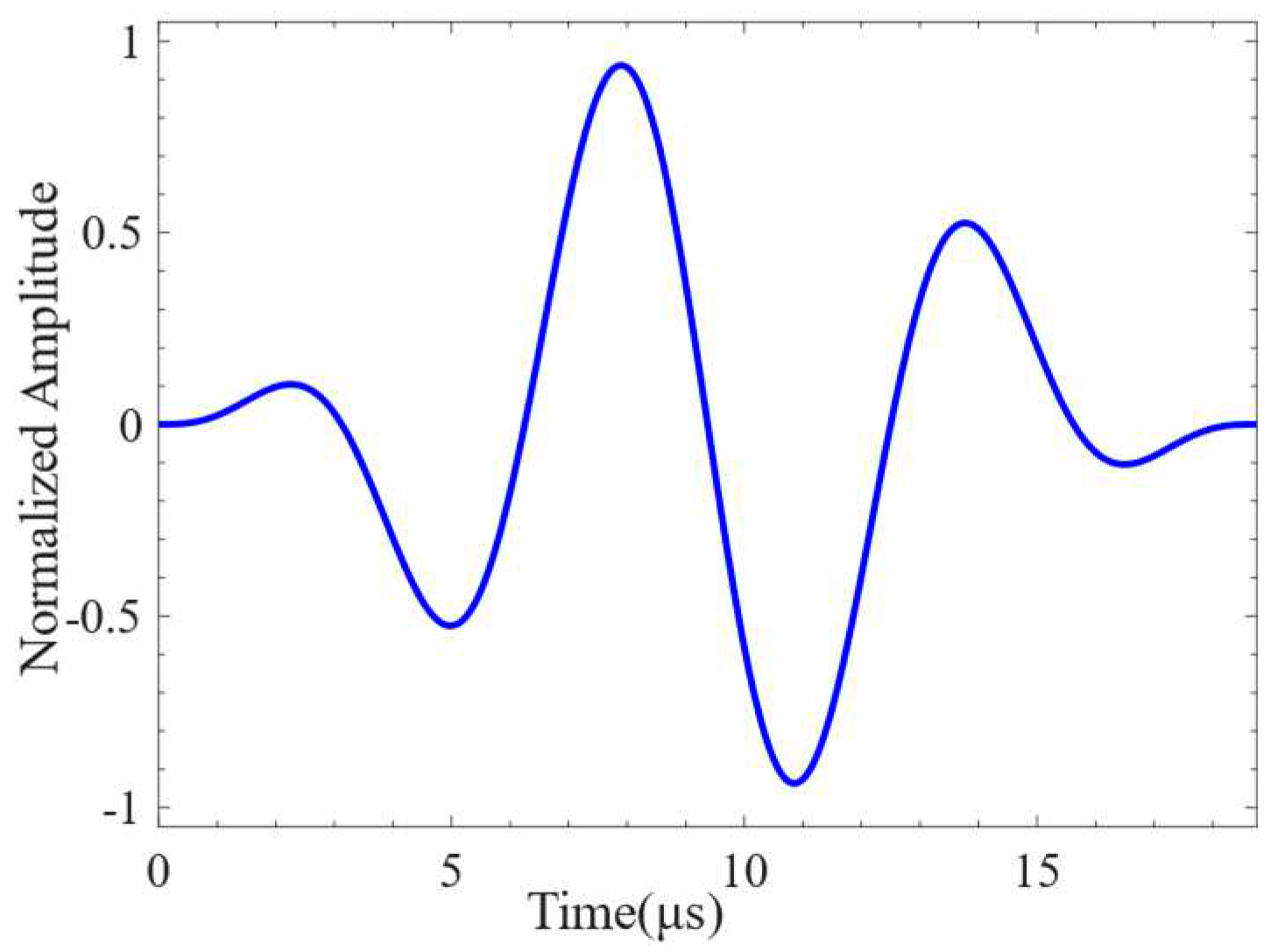

f = 160 kHz. The waveform of the excitation signal is shown in

Figure 5.

3.3. Selection of Mesh Element Size

The accuracies of finite-element simulation results and computer time consumption are closely related to the mesh size. Theoretically, the smaller the mesh element size, the more accurate the calculation results will be, but the longer the computer time consumption [

36,

37]. To balance the contradiction between calculation accuracy and computer time-consuming, it is meaningful to select the most suitable mesh element size for finite-element simulation.

The CFRP plate calculation model is shown in

Figure 6. Since the independence verification of the mesh element size only focuses on the dependence of the Lamb wave on the mesh element size during the propagation process, the Lamb wave excitation and reception method based on displacement loading was applied in the flat plate finite-element simulation. The excitation signal defined by Formula (3) was loaded at point P1, and the Lamb wave signals were received at point P2.

In this paper, the mesh element type of CFRP was set to C3D8R. Four levels of mesh element size of 0.12 mm, 0.16 mm, 0.2 mm, and 0.4 mm were considered to verify the mesh element size independence of the finite-element simulation results. The ABAQUS/Explicit dynamic analysis solver was used to calculate the computational model with a total duration of 150 μs. The fixed time step for finite-element calculation was 10 ns.

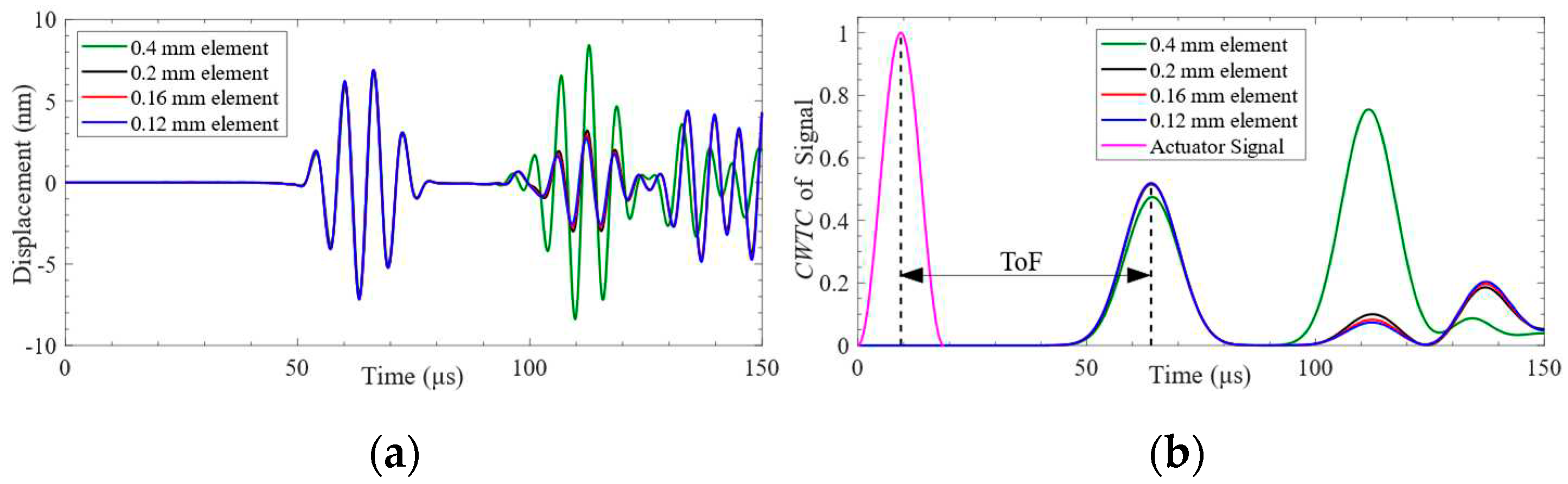

The received time-domain signals and their

CWTC are shown in

Figure 7. It can be seen from the figure that the time-domain waveform and

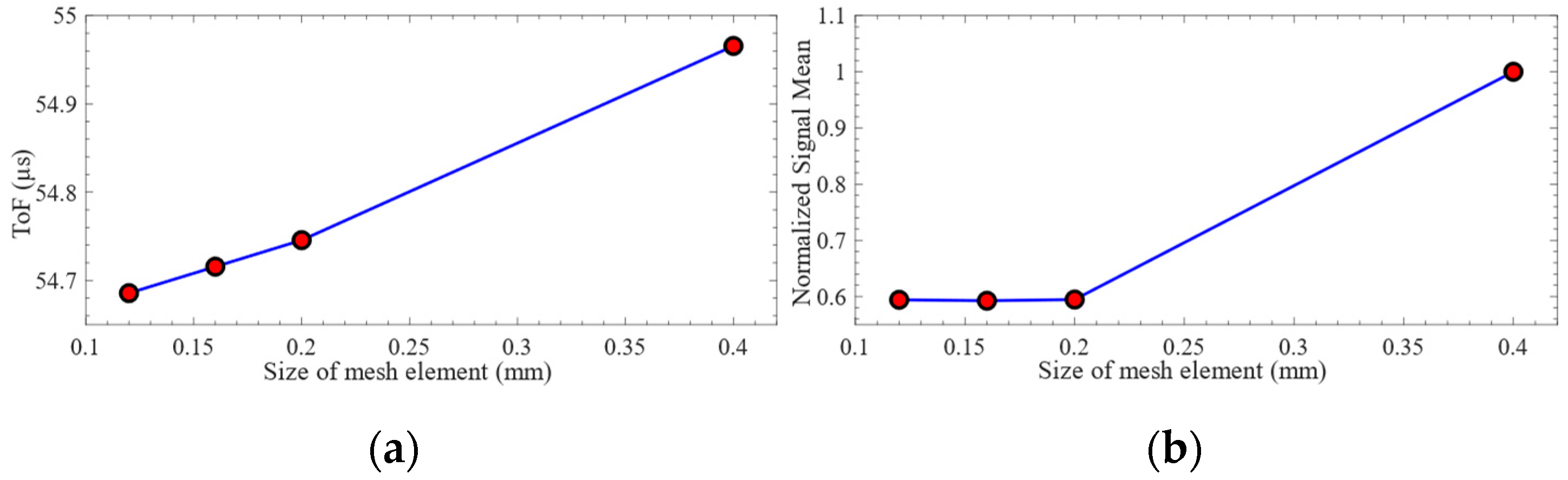

CWTC of the mesh element size of 0.4 mm are very different from those of other mesh element sizes. The characteristics of the time-domain waveforms with mesh element sizes of 0.12 mm, 0.16 mm, and 0.2 mm are very similar. The characteristics of Lamb waves under different mesh element sizes is shown in

Figure 8. It can be seen from the figure that the difference between the ToF obtained under each mesh element size is very small. Selecting the appropriate mesh element size was challenging based on the variation in ToF. The difference in the mean value of the signal obtained under the mesh element sizes of 0.4 mm and 0.2 mm is 68.2%. And the difference in the mean value of the signal obtained under the mesh element sizes of 0.2 mm and 0.16 mm is 0.4%. Consequently, the mesh element with a size of 0.16 mm was selected in this paper to complete the subsequent research.

3.4. Modal Verification of Lamb Wave

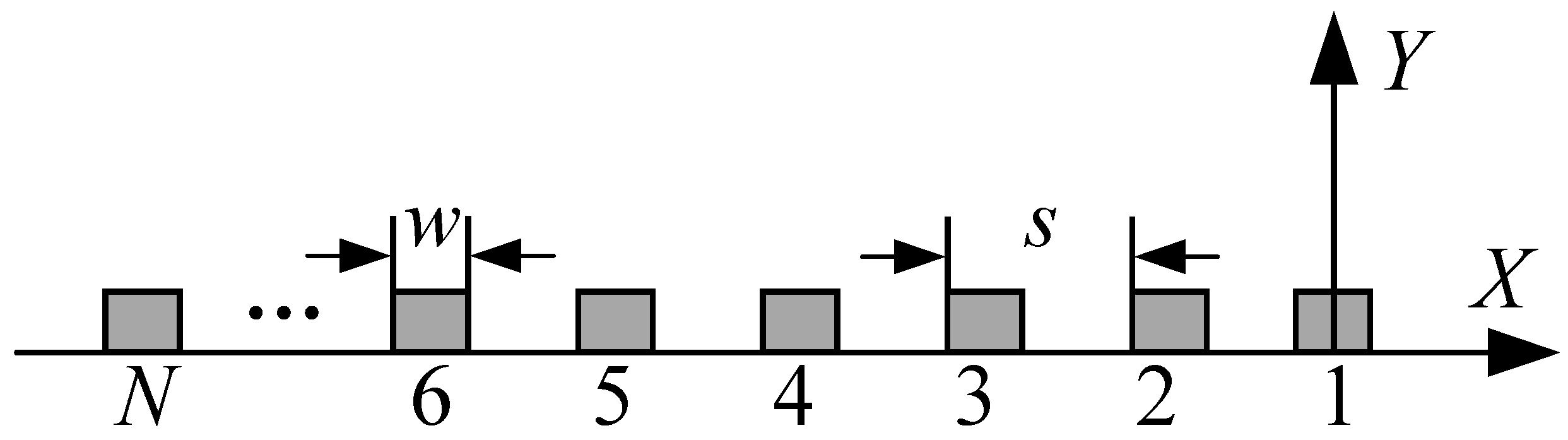

Lamb wave mode control can be achieved using LCT. As shown in

Figure 9, LCT consists of a group of PZT array elements arranged in parallel at certain intervals. Lamb wave mode control was achieved by adding phase time-delay to the excitation signal of each PZT array element of the LCT. Assume that the LCT contains

N PZT array elements. The distance between PZT array elements is

s, and the width of PZT array elements is

w. If the Lamb wave propagates along the negative direction of the

X-axis, the phase time-delay of the PZT array element numbered

N is:

where

t0 =

s/

cp, represents the phase time-delay added between adjacent PZT array elements. And

cp is the phase velocity of the Lamb wave, which can be obtained by calculating the phase velocity dispersion curve.

Each probe of the LCT developed in this article has 8 PZT array elements. The distance between PZT array elements s = 0.8 mm, and the width of PZT array elements w = 0.4 mm. According to the phase velocity dispersion curve, the phase velocities of the A0 mode and S0 mode at 160 kHz can be obtained as 4623.4 m/s and 1186.3 m/s correspondingly. The phase time-delay t0 added between adjacent PZT array elements of the LCT is 674.4 ns in the A0 mode and 173.0 ns in the S0 mode.

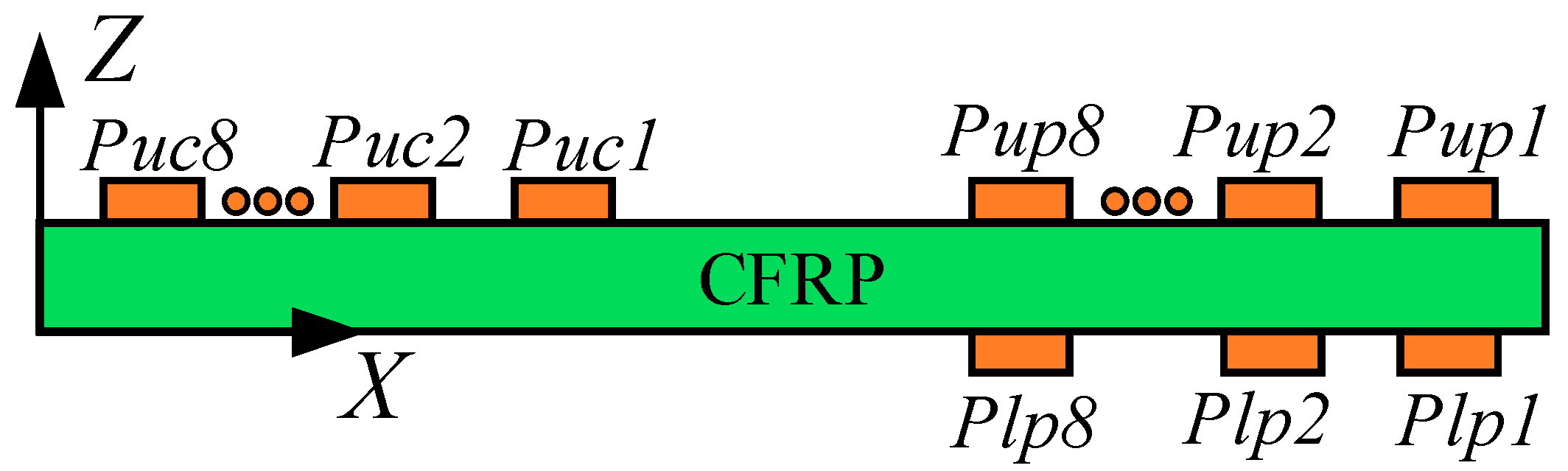

To verify the effectiveness of the Lamb wave mode control method in this article, the Abaqus implicit-explicit co-simulation technology was used to calculate the flat plate model, as shown in

Figure 10. The paste position of the PZT array element of LCT on the CFRP plate is shown in

Figure 11. The total duration of finite-element calculation was 70 μs. The fixed time step of the finite-element calculation was 10 ns. The mesh element type of PZT-5H was set to C3D8E in this article.

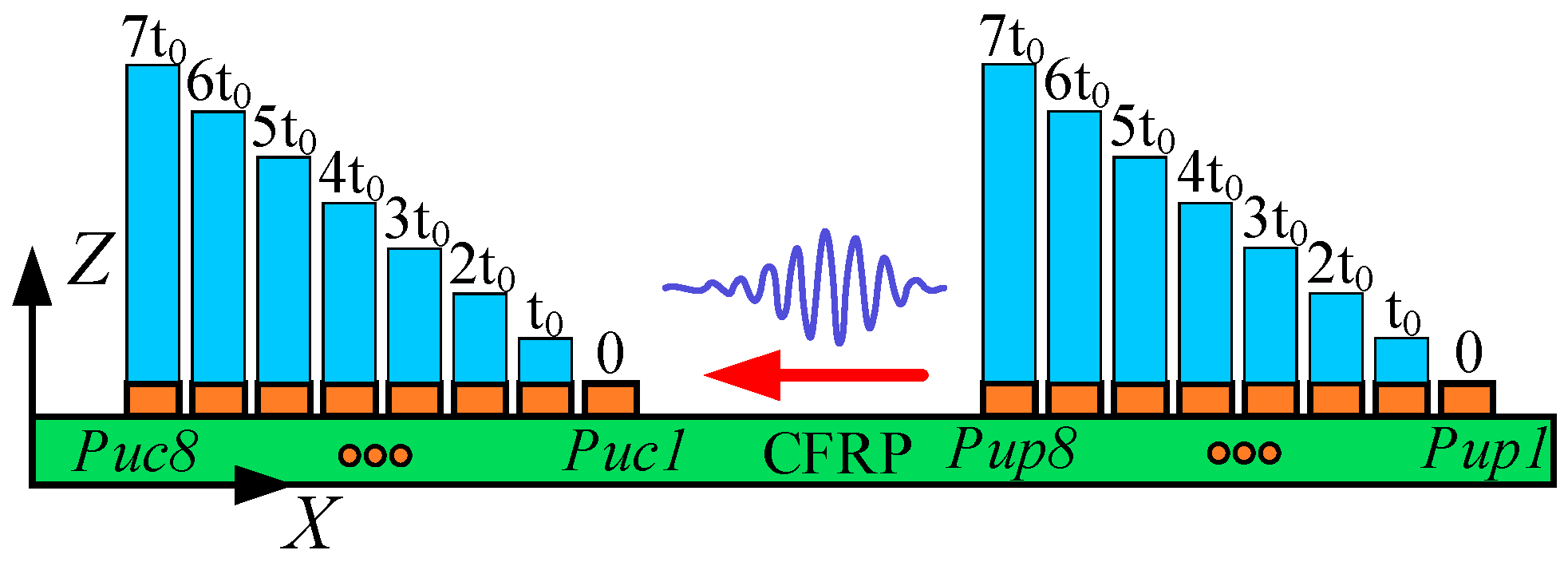

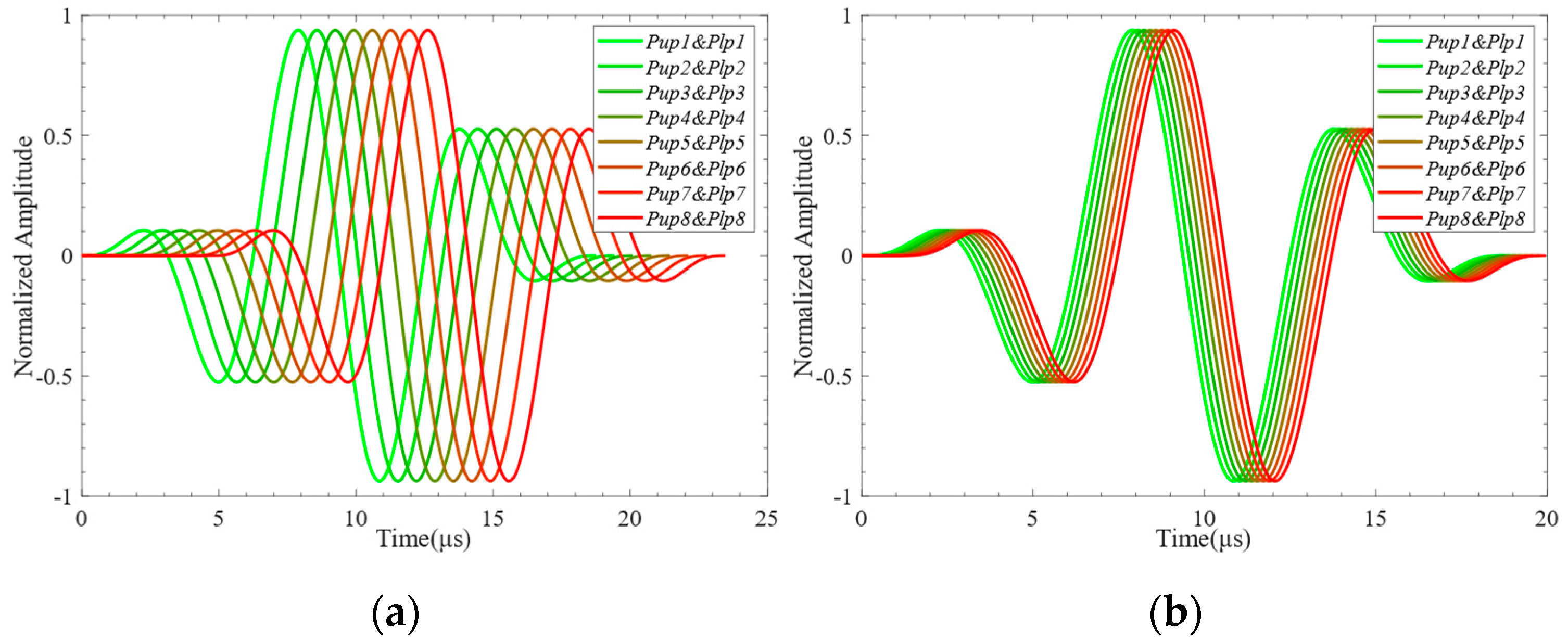

The surfaces of the excitation element and the receiving element in contact with the CFRP were set as zero potential surfaces. The surfaces of the excitation elements parallel to the zero potential surfaces were set as the excitation surfaces for loading voltage. The surfaces of the receiving elements parallel to the zero potential surfaces were set as the receiving surfaces of the voltage. The phase time-delay of each excitation element and the receiving element is shown in

Figure 12. The phase time-delay of the loading voltage of the excitation element with the same

X-axis coordinates and pasted on the upper and lower sides of the CFRP is the same. When the A0 mode Lamb wave was generated by controlling the phase time-delay of the LCT, the excitation signals loaded on each excitation element pasted on the upper and lower sides of the CFRP are shown in

Figure 13a. The voltage of the excitation surfaces of the excitation elements numbered

Pup1 to

Pup8 and numbered

Plp1 to

Plp8 was set to 500.0 V. When the S0 mode Lamb wave was generated by controlling the phase time-delay of the LCT, the excitation signals loaded on each excitation elements pasted on the upper and lower sides of the CFRP are shown in

Figure 13b. The voltage of the excitation surfaces of the excitation elements numbered

Pup1 to

Pup8 was set to 500 V, and the voltage of the excitation surfaces of the excitation elements numbered

Plp1 to

Plp8 was set to -500.0 V.

The signal propagation of the A0 mode Lamb wave generated by LCT excitation at 27 μs is shown in

Figure 14a. The signal propagation of the S0 mode Lamb wave generated by LCT excitation at 16.5 μs is shown in

Figure 14b. It can be seen from the figure that the Lamb wave signals can be aggregated in the desired direction by controlling the LCT phase time-delay. The change of phase time-delay will produce different Lamb wave signal propagation phenomena. The wavelength of the S0 mode Lamb wave generated by LCT excitation is longer than that of the A0 mode Lamb wave.

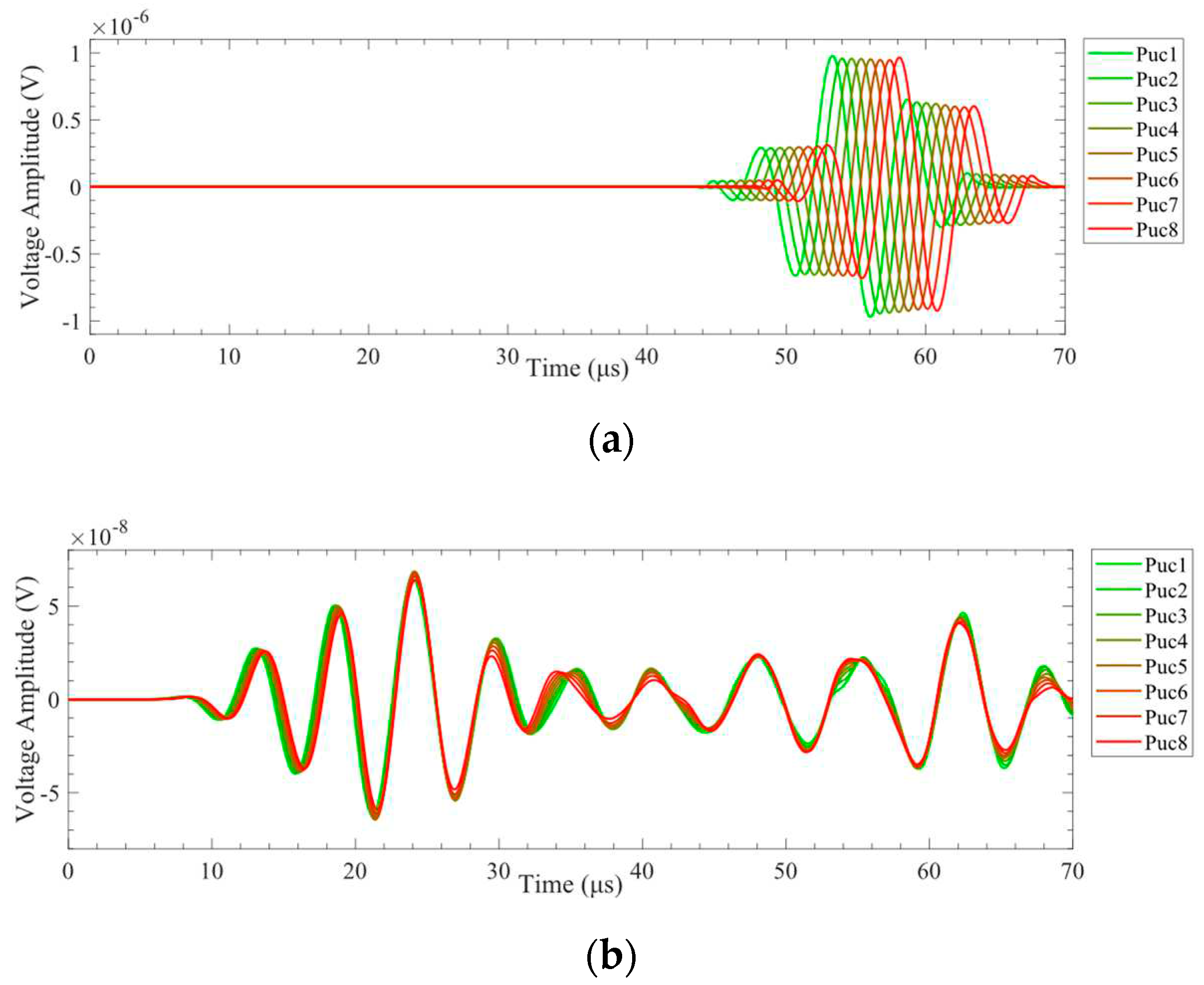

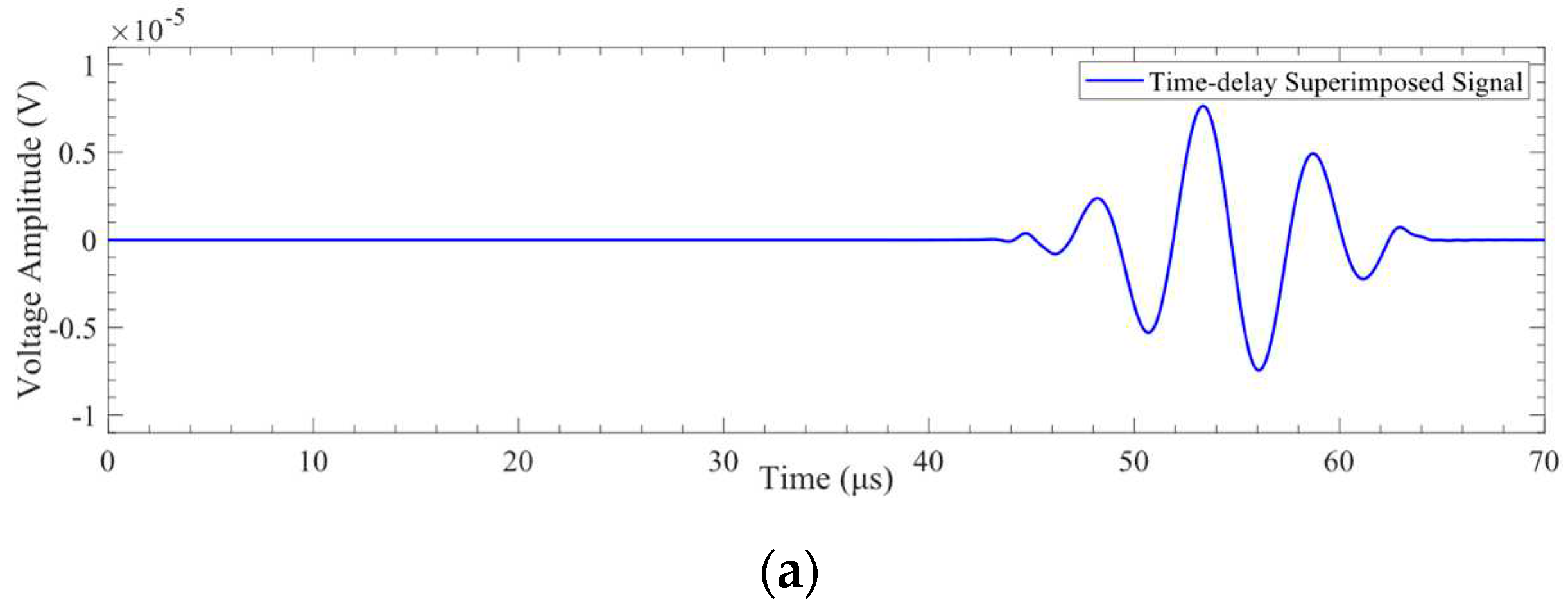

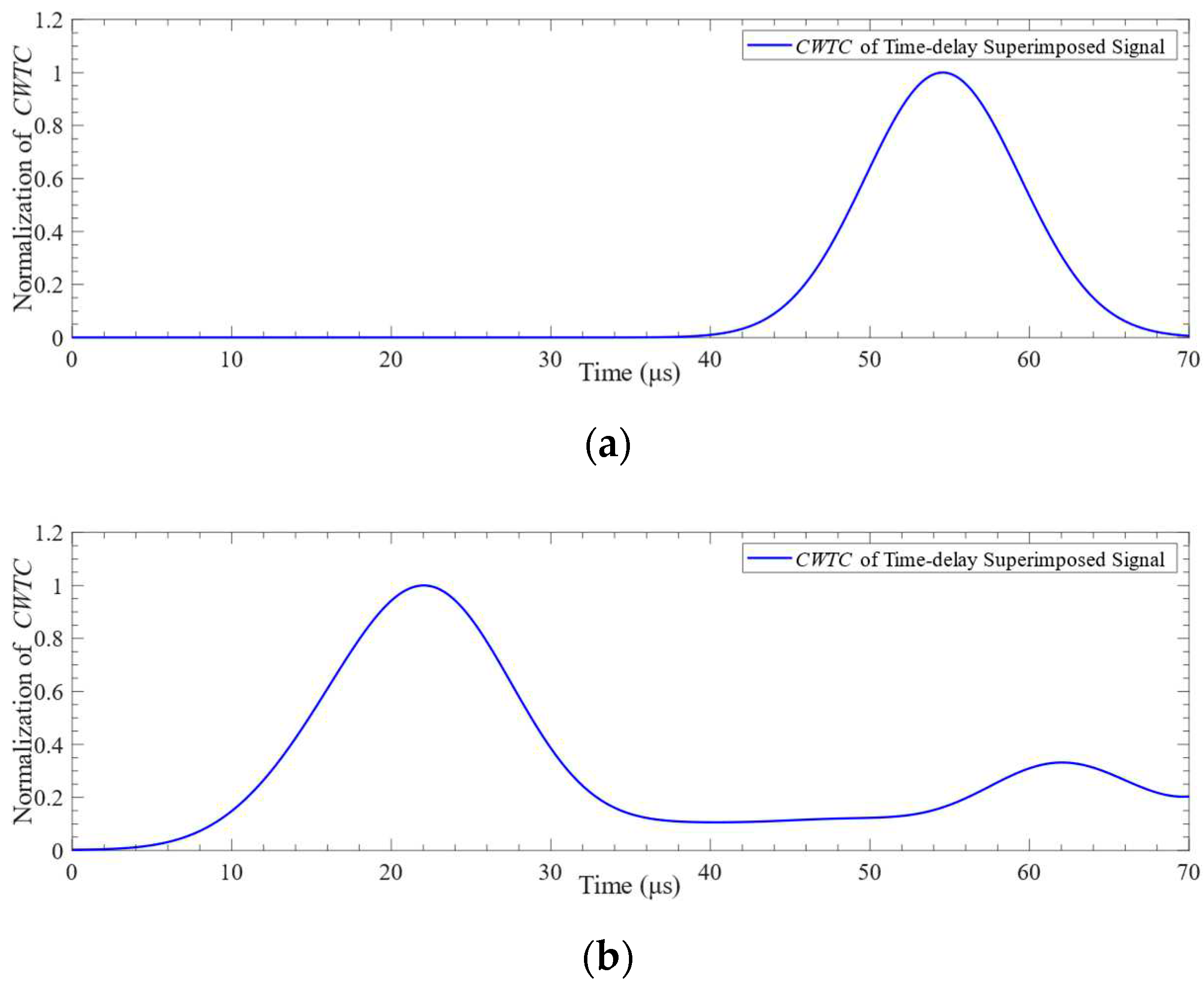

The A0 mode and S0 mode Lamb waves were generated by LCT excitation, and the surface average voltage signals received by each receiving element are shown in

Figure 15. The time-delay superimposed processing of the surface average voltage signal received by the receiving element was carried out, and the time-delay superimposed voltage signal of A0 mode and S0 mode Lamb wave was obtained, as shown in

Figure 16. It can be seen from

Figure 15 and

Figure 16 that different Lamb wave signals can be excited by changing the phase time-delay of the excitation element. The time-domain distribution and amplitude of the Lamb wave signal were changed due to the different phase time-delay. The continuous wavelet transform was applied to the time-delay superimposed voltage signals, and the

CWTCs of the time-delay superimposed voltage signals were obtained as shown in

Figure 17. The ToF of Lamb wave propagation was obtained using the calculation method of

Section 3.3, and the group velocity of the Lamb wave was calculated according to the propagation distance of the Lamb wave. As shown in

Figure 18, the group velocities of A0 mode and S0 mode Lamb waves obtained by finite-element simulation were 1235.7 m/s and 4369.2 m/s at the frequency of 160 kHz, respectively. The group velocities of A0 mode and S0 mode Lamb waves calculated theoretically were 1302.1 m/s and 4359.4 m/s, respectively. As shown in

Table 5, the absolute errors between the simulation results and theoretical calculation results of the group velocities of A0 mode and S0 mode Lamb waves were 66.4 m/s and 9.8 m/s, respectively, with percentage errors of 5.1% and 0.2%. The error between the simulation results and the theoretical calculation results was within the acceptable range. The LCT can be employed to accurately excite A0 mode and S0 mode Lamb waves proved by finite-element simulation.

3.5. Delamination Damage Detection of CFRP Bending Plate

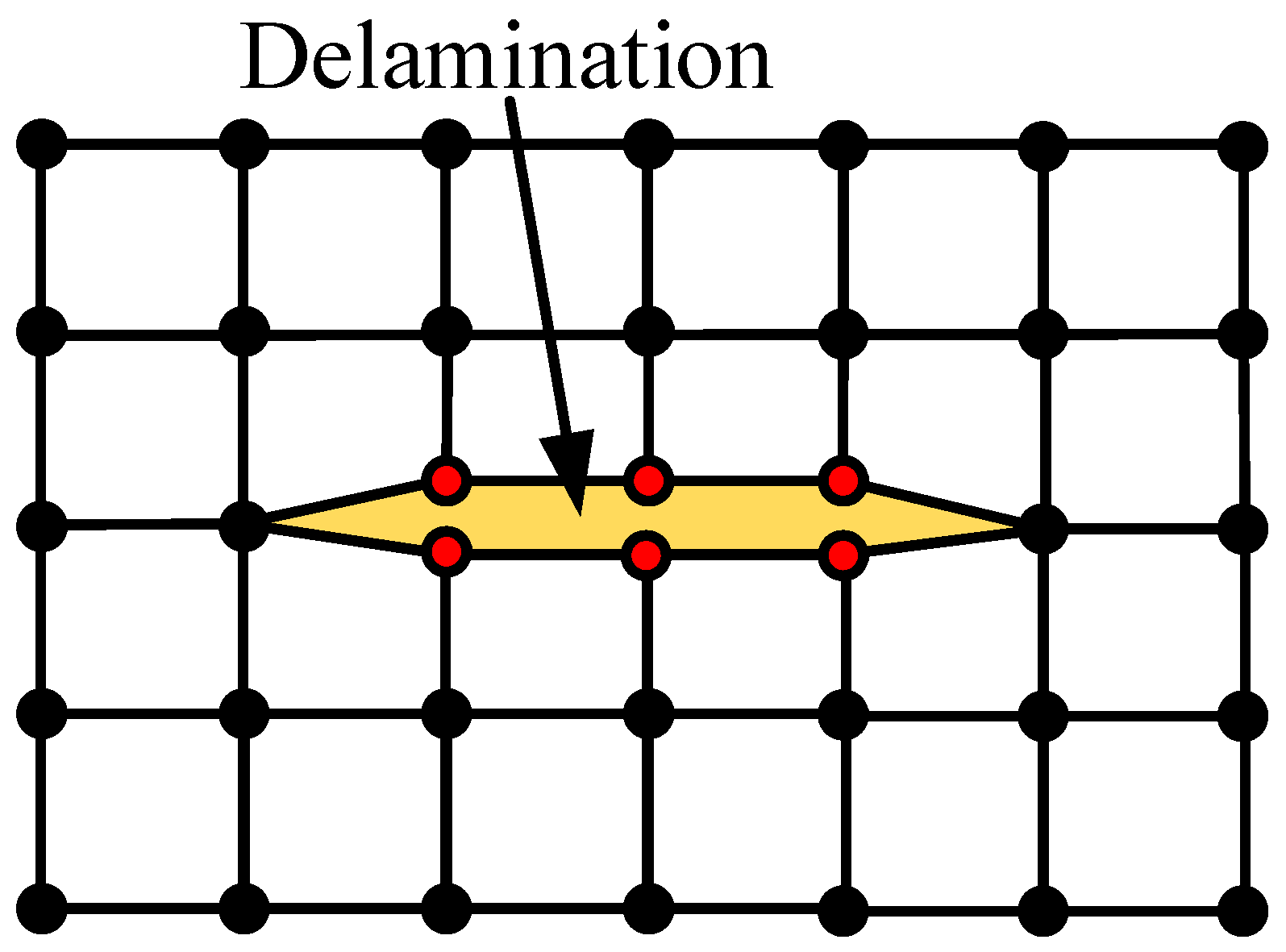

The finite-element calculation was carried out for the model shown in

Figure 2. As shown in

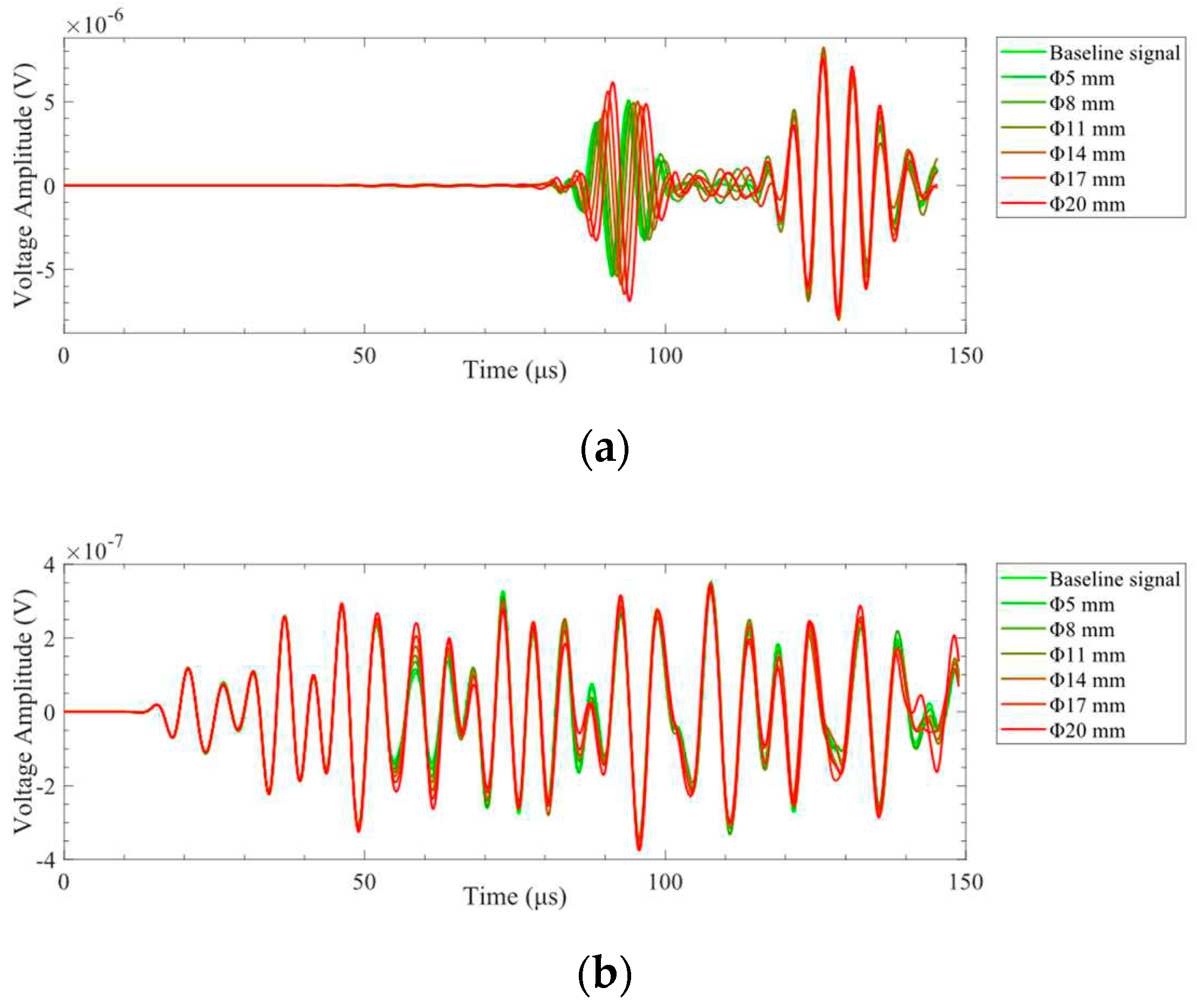

Figure 19, the detaching mesh node method was employed to generate delamination damage in the middle layer of the CFRP bending plate. A node was detached into two unrelated nodes at the same position to generate zero-volume delamination damage. The sizes of delamination damage were Φ5.0 mm, Φ8.0 mm, Φ11.0 mm, Φ14.0 mm, Φ17.0 mm and Φ20.0 mm, respectively. The CFRP bending plate without delamination damage was used as a reference. The time-domain signal of the CFRP bending plate without delamination damage was obtained by finite-element calculation as the reference signal.

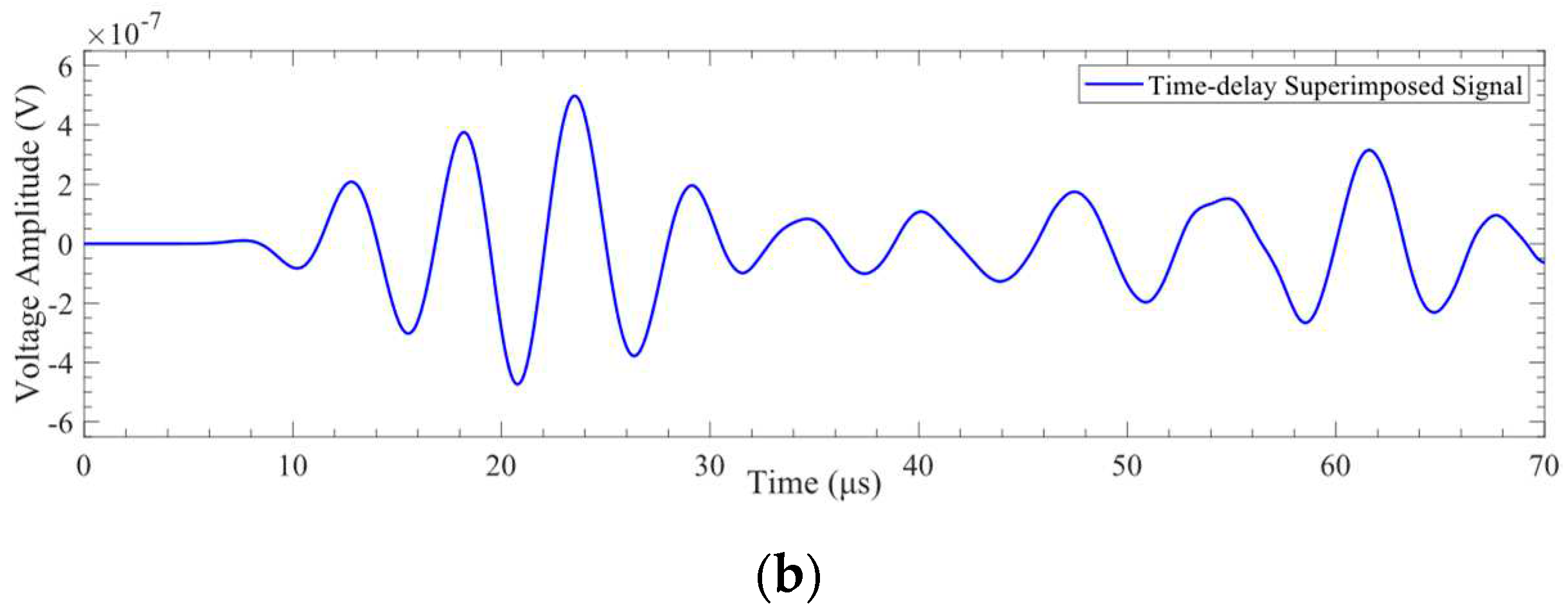

The time-delay superimposed voltage signals of different sizes of delamination damage obtained by finite-element calculation are shown in

Figure 20. It can be seen from the figure that when A0 mode Lamb waves were used to detect delamination damage, the change in the size of layered damage had a significant impact on the time-delay superimposed voltage signal. The phase and amplitude of the time-delay superimposed voltage signal had changed due to the different sizes of the delamination damage. When the S0 mode Lamb waves were employed to detect the delamination damage, the influence of the delamination damage size on the time-delay superimposed voltage signal was non-significant.

The

SDC values of time-delay superimposed voltage signals with different sizes of delamination damage are shown in

Figure 21. It can be seen from the figure that both in the A0 mode and in the S0 mode, the

SDC value increases with the increase of the delamination damage size. Delamination damage can be quantified by analyzing the variation rule of

SDC values with the size of the delamination damage. In addition, as shown in

Figure 21, when the A0 mode Lamb wave was employed for delamination damage detection, the

SDC value remained relatively constant in case the size of the damage was less than 5.0 mm or greater than 17.0 mm. This meant that the

SDC value did not significantly change with an increase in the size of the delamination damage within this range. In cases where the delamination damage size is less than 5.0 mm, the A0 mode Lamb wave is insensitive to the delamination damage because its wavelength is larger than the size of the damage. In cases where the delamination damage size is greater than 17.0 mm, the A0 mode Lamb wave cannot completely cover the large-scale delamination damage due to the small size of the PZT array element and its short distance from the delamination damage. When the size of delamination damage is between 5.0 and 17.0 mm, the

SDC value increases significantly with the increase of delamination damage size, increasing from 0.013 to 0.51. The relationship between

SDC value and delamination damage size is different in S0 mode and A0 mode.

In the case of delamination damage detection using S0 mode Lamb wave, when the delamination damage size is less than 20.0 mm, the SDC value gradually increases from 0.0 to 0.05 with the increase of the delamination damage size. This is because the S0 mode Lamb wave is poorly sensitive to delamination damage size due to its longer wavelength and faster wave velocity. According to the variation of SDC value with the size of delamination damage, it can be concluded that the A0 mode Lamb wave is more sensitive to delamination damage identification.

At the same time, considering that the amplitude of the time-delay superimposed voltage signal of the S0 mode was nearly 100 times lower than that of the A0 mode, the signal-to-noise ratio of the S0 mode Lamb wave signal excited in the experiment may be small. As a result, obtaining available S0 Lamb wave data during the experiment was challenging. Therefore, the A0 mode Lamb wave was excited for the quantitative experiment of delamination damage.

Figure 21.

The SDC value of the time-delay superimposed voltage signal: (a) SDC value of A0 mode Lamb wave; (b) SDC value of S0 mode Lamb wave.

Figure 21.

The SDC value of the time-delay superimposed voltage signal: (a) SDC value of A0 mode Lamb wave; (b) SDC value of S0 mode Lamb wave.

4. Experiment

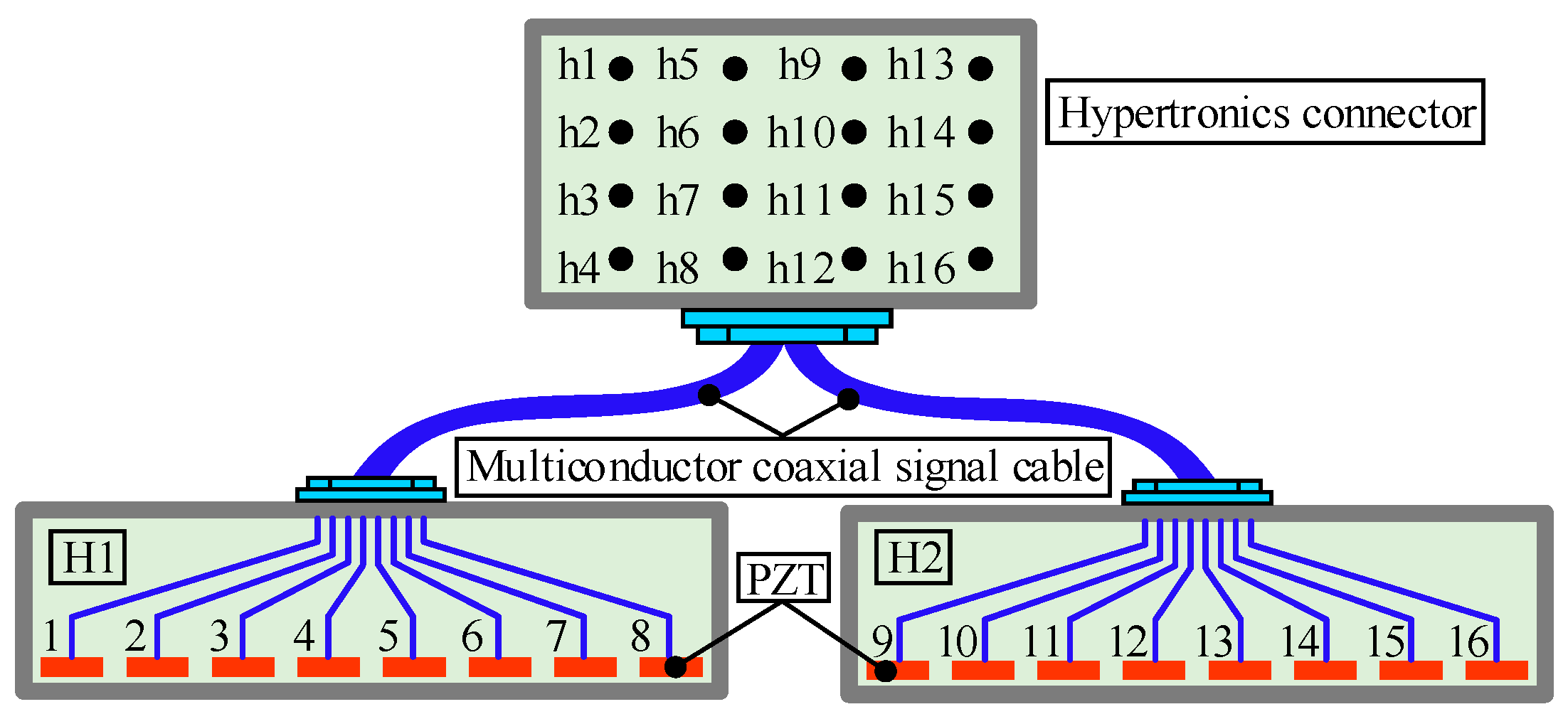

A miniaturized LCT was developed to excite and receive Lamb waves of expected modes in experiments. The structure diagram of the LCT is shown in

Figure 22. The width of the PZT array element and the distance between adjacent array elements were the same as the size set in the simulation. Hypertronics served as a connector for LCT, with pins numbered from h1 to h16. The two probes of the developed LCT share a Hypertronics connector. The two probes of LCT were numbered H1 and H2, respectively, and each probe contains 8 PZT elements. The PZT array elements of probe H1 were numbered 1 to 8, and probe H2 were numbered 9 to 16. Probe H1 was used to excite Lamb waves, while probe H2 was used to receive them. The PZT array elements numbered 1 to 8 were connected to the pins numbered h1 to h8, respectively. Similarly, the PZT array elements numbered 9 to 16 were connected to the pins numbered h9 to h16, respectively. Each array element can individually excite and receive Lamb signals without mutual influence. The miniaturized LCT produced is shown in

Figure 23. The length × width of the probe is 16.0 mm × 12.0 mm.

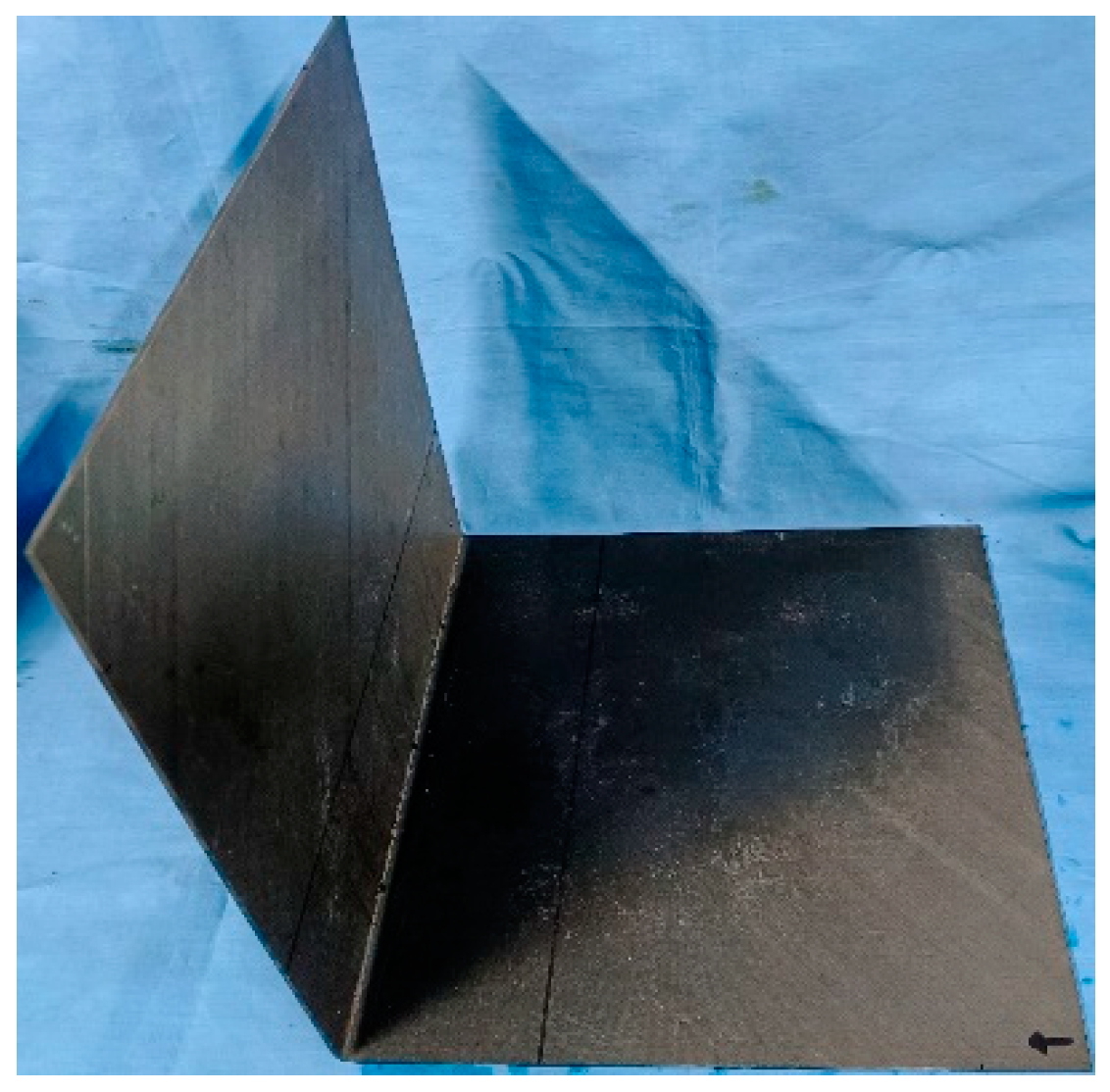

The prepared CFRP bending specimen is shown in

Figure 24. The bending angle of the specimen is 90 °, the bending radius is 5.0 mm, and the length × width of the plate area of the CFRP bending plate is 300.0 mm × 300.0 mm, with a thickness of 2.0 mm. Delamination damage with dimensions of Φ6.0 mm, Φ10.0 mm, and Φ15.0 mm were prefabricated in CFRP bending plate specimens, respectively. Delamination damage was established by filling anti-sticking paper in the middle layer of CFRP bending plate specimens.

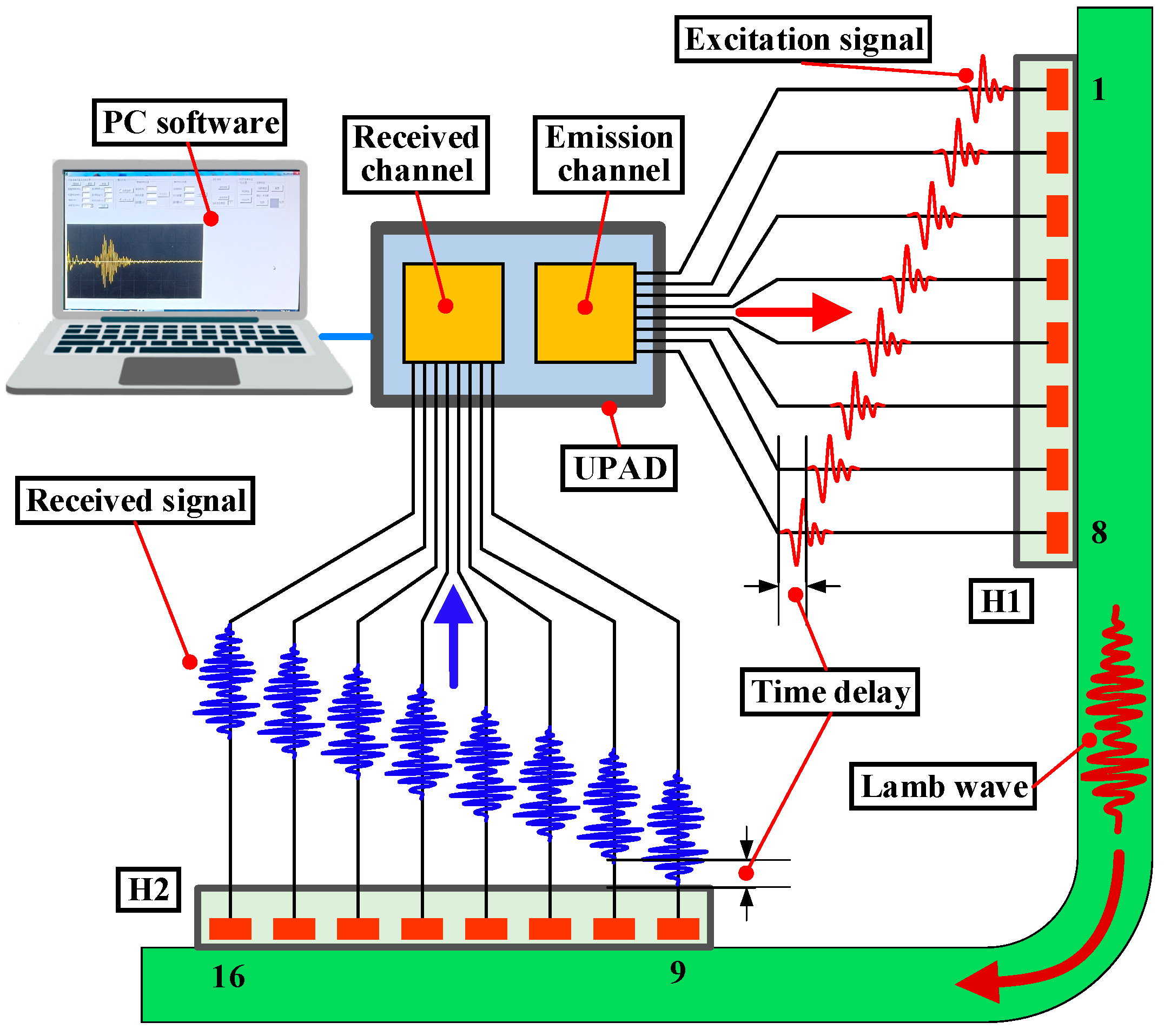

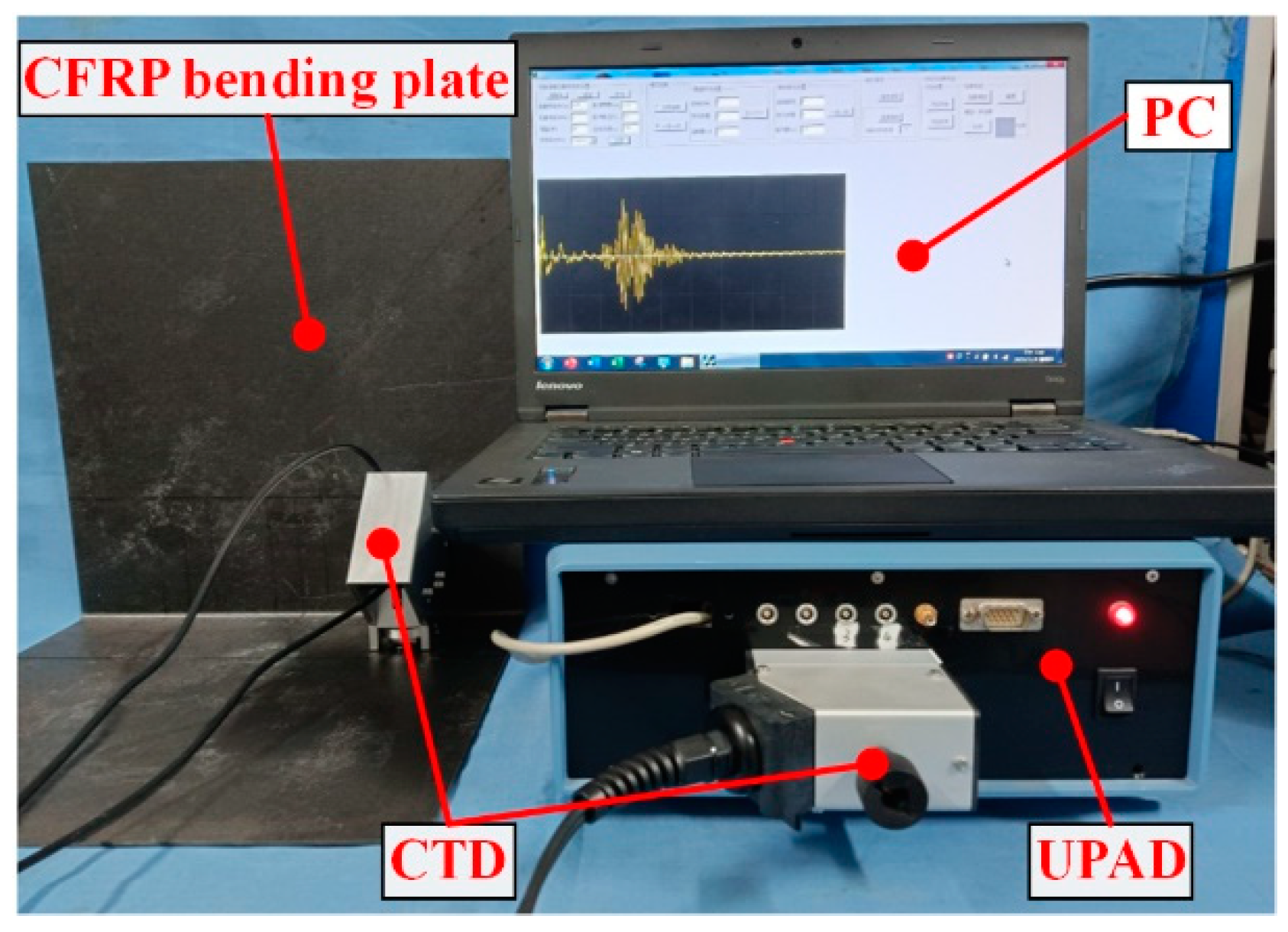

The Lamb wave phased array detection system was employed for verification experiments on the CFRP bending plate specimens with prefabricated delamination damage. The Lamb wave phased array detection system is shown in

Figure 25. The Lamb wave phased array detection system consists of an ultrasonic phased array detector (UPAD) with 32 channels, a PC, LCT (including a clamping device), and a CFRP bending plate specimen. PC interacts with UPAD through the USB interface, which can control the time delay of each array element and transmit Lamb wave signal data. The verification experiment was carried out using the pitch-catch method. The 1st to 8th channels of UPAD were controlled by PC to generate the excitation signal with a set time delay, which was employed to excite the 1st to 8th array elements of probe H1. The Lamb waves excited by probe H1 propagated in the CFRP bending plate and were then perceived by probe H2. The Lamb wave signals were received by channels 9 to 16 of UPAD with a set time delay. The A0 mode Lamb wave signal after phase-controlled mode focusing was obtained.

The experimental system is shown in

Figure 26. The A0 mode Lamb wave was excited to detect delamination damage in the CFRP bending plate. The sampling rate of UPAD was 30.0 MHz, and the sampling duration of the Lamb wave signal was 150 μs. During the experiment, the data were collected ten times for averaging to eliminate noise interference. The experiment of array elements without time delay was carried out to verify the effectiveness of the LCT controlling Lamb wave mode, and the time delay of all excitation and receiving array elements of the LCT was set to 0.0.

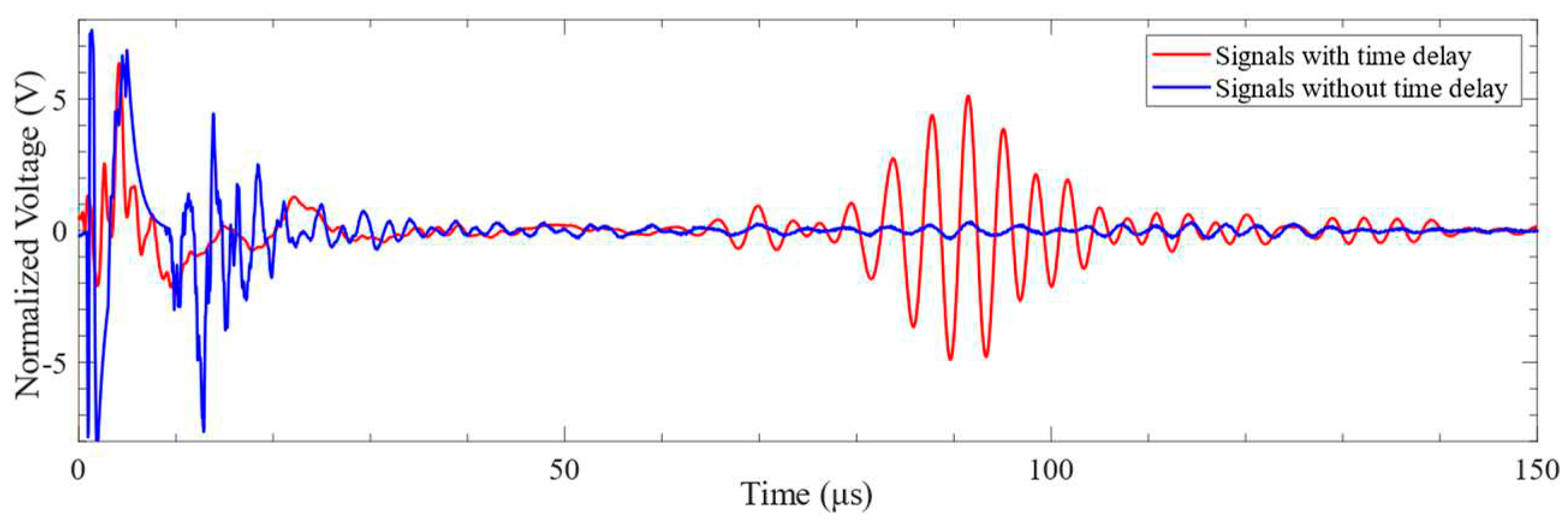

The signals generated by LCT with and without time delay are shown in

Figure 27. It can be seen from the figure that the signals generated by the LCT with time delay were superimposed into the A0 mode Lamb wave in the time range of 70 to 120 μs. The signals generated by the LCT without time delay were not superimposed into a fixed mode Lamb wave throughout the time domain. It has been proven that LCT can effectively control the mode of Lamb waves by adding time delay.

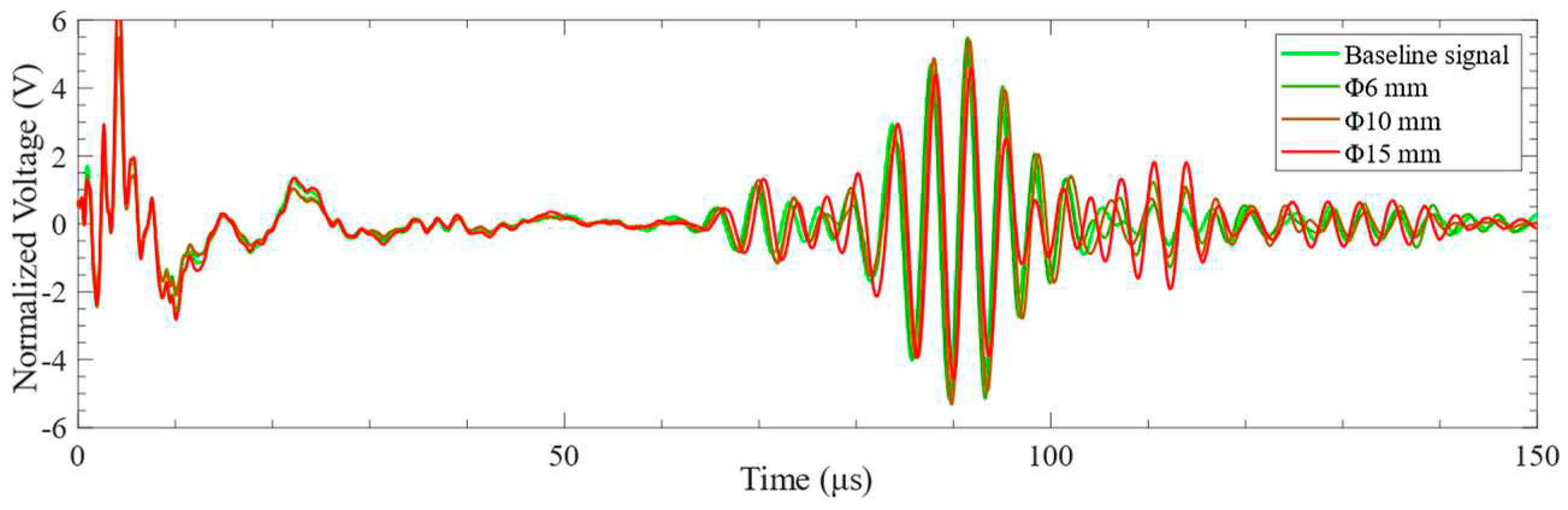

The A0 mode Lamb wave signals of different delamination damage sizes were obtained in the experiment, as shown in

Figure 28. It can be seen from the figure that the characteristics of the Lamb wave signal are insignificantly affected by the delamination damage size. The phase and amplitude of the Lamb wave signal are essentially constant under different delamination damage sizes. Therefore, the

SDC was used to evaluate the difference of signals. The Lamb wave signals from 60 μs to 140 μs were processed to obtain the

SDC values of different delamination damage sizes, as shown in

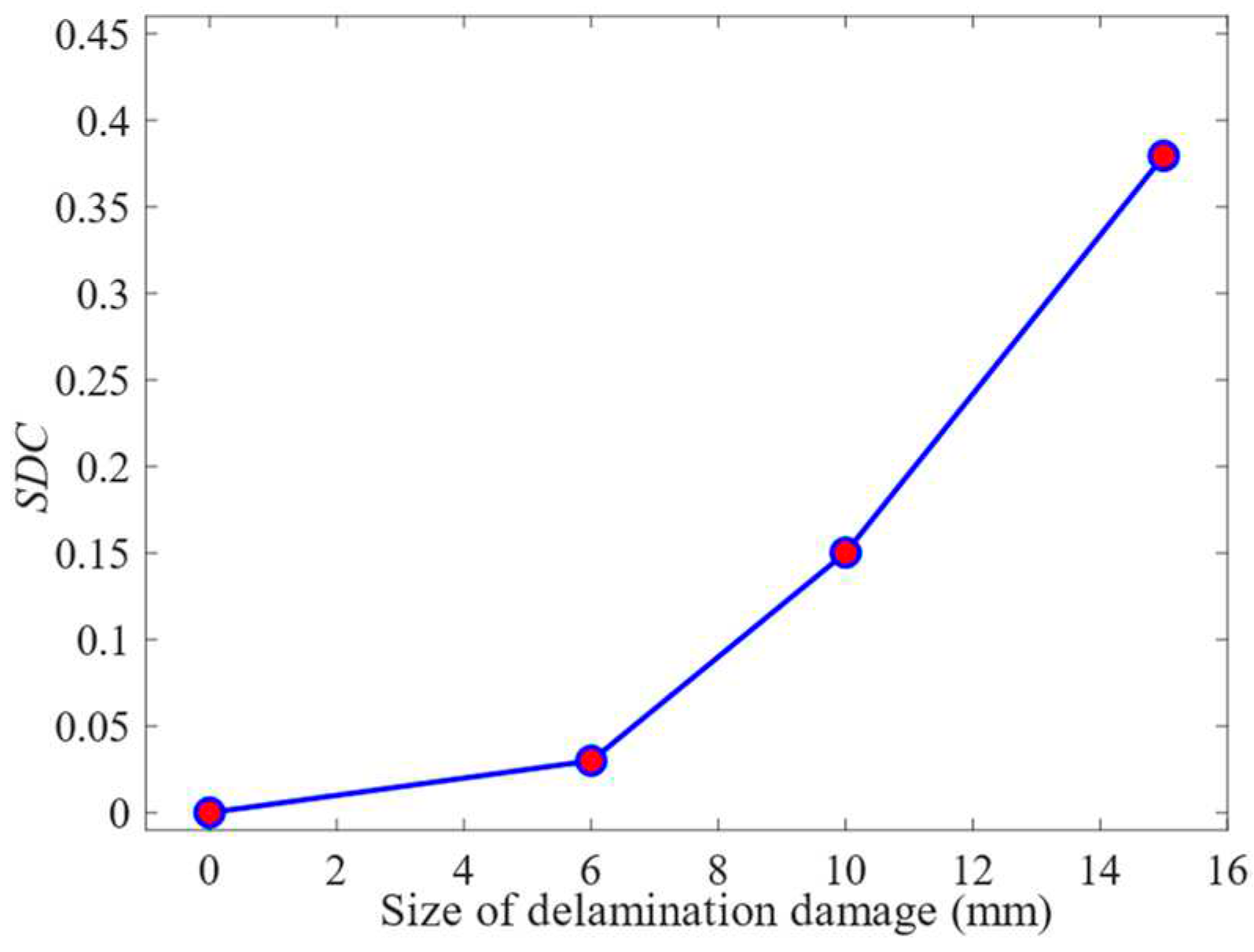

Figure 29. It can be seen from the figure that the

SDC value increases with the increase of the delamination damage size. The results of comparison experiments and simulations show that the finite-element method can accurately simulate the propagation of Lamb waves in CFRP bending plates. Delamination damage can be quantified according to the variation rule of

SDC values with the size of the delamination damage.

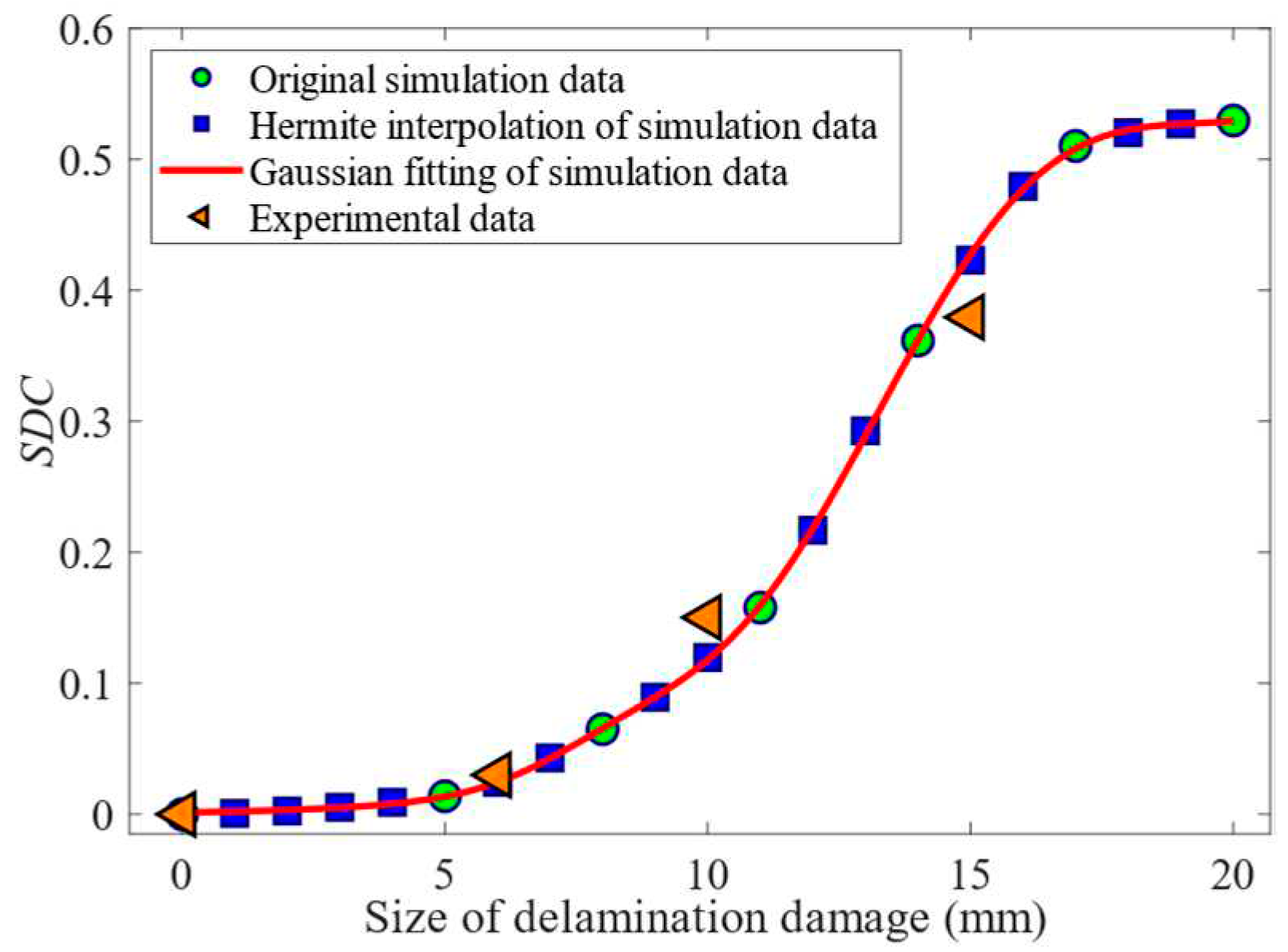

5. Quantification of Delamination Damage

Only seven kinds of

SDC values of delamination damage sizes were provided by finite-element simulation. To better understand the law of

SDC values with the delamination damage sizes, more sample data were required for analysis. Piecewise cubic Hermite interpolation was applied to simulation data to obtain more

SDC values of delamination damage. The Hermite interpolation results of the simulation data are shown in

Figure 30. Based on the Hermite interpolation results of simulation data, a Gaussian function was employed to fit the relationship between the delamination damage sizes and

SDC value. The fitting expression is shown in equation (5), where

x represents the delamination damage size, and

y represents the

SDC value of the delamination damage signal. The fitting accuracy parameter

R2 is 0.99992, and the fitting curve is shown in

Figure 30.

To verify the accuracy of the fitting expression for the quantification of delamination damage, the difference between the calculation results of the fitting expression and the experimental data was analyzed. The absolute and percentage errors of the delamination damage quantification using the fitting expression are shown in

Table 6. It can be seen from the table that the absolute error of the delamination damage quantification with fitting expression is not larger than 0.8 mm, and the percentage error is not more than 8%. This study indicates that the A0 mode Lamb wave can accurately quantify delamination damage.

Figure 30.

The relationship between delamination damage size and SDC values.

Figure 30.

The relationship between delamination damage size and SDC values.

Author Contributions

Conceptualization, Q.Y. and S.Z.; methodology, Q.Y.; validation, Q.Y. and Y.C.; formal analysis, Q.Y. and S.Z.; investigation, Q.Y. and Y.C.; resources, S.Z.; data curation, Q.Y., Y.C. and Y.D.; writing—original draft preparation, Q.Y.; writing—review and editing, Q.Y., S.Z. and J.H.; visualization, Q.Y.; supervision, S.Z. All authors have read and agreed to the published version of the manuscript.

Figure 1.

Ply direction of CFRP.

Figure 1.

Ply direction of CFRP.

Figure 2.

The structure of the CFRP bending plate and the location of delamination damage: (a) Location of delamination damage; (b) Structure size and location of LCT.

Figure 2.

The structure of the CFRP bending plate and the location of delamination damage: (a) Location of delamination damage; (b) Structure size and location of LCT.

Figure 3.

The dispersion curve of CFRP: (a) Phase velocity; (b) Group velocity.

Figure 3.

The dispersion curve of CFRP: (a) Phase velocity; (b) Group velocity.

Figure 4.

The through-thickness displacement profiles of Lamb waves propagating in CFRP: (a) A0 mode Lamb wave; (b) S0 mode Lamb wave.

Figure 4.

The through-thickness displacement profiles of Lamb waves propagating in CFRP: (a) A0 mode Lamb wave; (b) S0 mode Lamb wave.

Figure 5.

Excitation signal.

Figure 5.

Excitation signal.

Figure 6.

The computational model of mesh independence verification.

Figure 6.

The computational model of mesh independence verification.

Figure 7.

Lamb wave signal received at point P2: (a) Time-domain signal; (b) CWTC of the signal.

Figure 7.

Lamb wave signal received at point P2: (a) Time-domain signal; (b) CWTC of the signal.

Figure 8.

The characteristics of Lamb waves under different mesh element sizes: (a) ToF of the signal; (b) Normalized signal mean.

Figure 8.

The characteristics of Lamb waves under different mesh element sizes: (a) ToF of the signal; (b) Normalized signal mean.

Figure 9.

Schematic diagram of PZT array element distribution of LCT.

Figure 9.

Schematic diagram of PZT array element distribution of LCT.

Figure 10.

Computational model for Lamb wave mode control.

Figure 10.

Computational model for Lamb wave mode control.

Figure 11.

The paste schematic diagram of LCT.

Figure 11.

The paste schematic diagram of LCT.

Figure 12.

Phase time-delay of excitation element and receiving element.

Figure 12.

Phase time-delay of excitation element and receiving element.

Figure 13.

The excitation signals loaded on each excitation element: (a) The excitation signals were used to excite the A0 mode Lamb wave; (b) The excitation signals were used to excite the S0 mode Lamb wave.

Figure 13.

The excitation signals loaded on each excitation element: (a) The excitation signals were used to excite the A0 mode Lamb wave; (b) The excitation signals were used to excite the S0 mode Lamb wave.

Figure 14.

Propagation of Lamb wave signal: (a) A0 mode Lamb wave; (b) S0 mode Lamb wave.

Figure 14.

Propagation of Lamb wave signal: (a) A0 mode Lamb wave; (b) S0 mode Lamb wave.

Figure 15.

The surface average voltage signal received by the receiver: (a) A0 mode; (b) S0 mode.

Figure 15.

The surface average voltage signal received by the receiver: (a) A0 mode; (b) S0 mode.

Figure 16.

Time-delay superimposed signal: (a) A0 mode; (b) S0 mode.

Figure 16.

Time-delay superimposed signal: (a) A0 mode; (b) S0 mode.

Figure 17.

CWTC of time-delay superimposed voltage signal: (a) A0 mode; (b) S0 mode.

Figure 17.

CWTC of time-delay superimposed voltage signal: (a) A0 mode; (b) S0 mode.

Figure 18.

Verification of group velocity.

Figure 18.

Verification of group velocity.

Figure 19.

Schematic diagram of zero-volume delamination damage modeling method. (Two new red nodes are generated by the original node in the delamination damage area, and the volume of the delamination damage is exaggerated to highlight the two new red nodes.).

Figure 19.

Schematic diagram of zero-volume delamination damage modeling method. (Two new red nodes are generated by the original node in the delamination damage area, and the volume of the delamination damage is exaggerated to highlight the two new red nodes.).

Figure 20.

Time-delay superimposed voltage signal of delamination damage: (a) Delamination damage time-delay superimposed voltage signal in A0 mode; (b) Delamination damage time-delay superimposed voltage signal in S0 mode.

Figure 20.

Time-delay superimposed voltage signal of delamination damage: (a) Delamination damage time-delay superimposed voltage signal in A0 mode; (b) Delamination damage time-delay superimposed voltage signal in S0 mode.

Figure 22.

The structure diagram of the LCT.

Figure 22.

The structure diagram of the LCT.

Figure 23.

The miniaturized LCT product.

Figure 23.

The miniaturized LCT product.

Figure 24.

CFRP bending plate specimens.

Figure 24.

CFRP bending plate specimens.

Figure 25.

The Lamb wave phased array detection system.

Figure 25.

The Lamb wave phased array detection system.

Figure 26.

Experimental system.

Figure 26.

Experimental system.

Figure 27.

Signals with and without time delay.

Figure 27.

Signals with and without time delay.

Figure 28.

Time domain signals of A0 mode Lamb waves with different delamination damage sizes.

Figure 28.

Time domain signals of A0 mode Lamb waves with different delamination damage sizes.

Figure 29.

The SDC values of different delamination damage sizes.

Figure 29.

The SDC values of different delamination damage sizes.

Table 1.

The properties of CFRP materials in the numerical simulation study.

Table 1.

The properties of CFRP materials in the numerical simulation study.

|

E1(GPa) |

E2 = E3(GPa) |

G12 = G13(GPa) |

G23(GPa) |

ν12 = ν13

|

ν23

|

ρ(kg/m3) |

| 280.0 |

10.0 |

4.0 |

2.0 |

0.28 |

0.45 |

1639.0 |

Table 2.

The stiffness coefficient of PZT-5H.

Table 2.

The stiffness coefficient of PZT-5H.

|

D1111 = D2222(MPa) |

D3333(MPa) |

D1122(MPa) |

D1133 = D2233(MPa) |

D1212 = D1313(MPa) |

D2323(MPa) |

| 127205.0 |

117436.0 |

80212.2 |

84670.2 |

22988.5 |

23474.2 |

Table 3.

The piezoelectric coefficient of PZT-5H.

Table 3.

The piezoelectric coefficient of PZT-5H.

|

d3 11 = d3 22(10−12C/N) |

d3 33(10−12C/N) |

d2 12 = d1 13(10−12C/N) |

| -274.0 |

593.0 |

741.0 |

Table 4.

The relative dielectric constant of PZT-5H.

Table 4.

The relative dielectric constant of PZT-5H.

|

D11

|

D22

|

D33

|

| 1704.4 |

1704.4 |

1433.6 |

Table 5.

The simulation results and theoretical calculation results of group velocity.

Table 5.

The simulation results and theoretical calculation results of group velocity.

| |

A0 |

S0 |

| simulate group velocity (m/s) |

1235.7 |

4369.2 |

| theoretical group velocity (m/s) |

1302.1 |

4359.4 |

| absolute error (m/s) |

66.4 |

9.8 |

| percentage error (%) |

5.1 |

0.2 |

Table 6.

The error of the fitting expression to the delamination damage quantification.

Table 6.

The error of the fitting expression to the delamination damage quantification.

Delamination Damage Size

(mm) |

Measured Value

(mm) |

Absolute Error

(mm) |

Percentage Error

(%) |

| 6.0 |

6.3 |

0.3 |

5.0 |

| 10.0 |

10.8 |

0.8 |

8.0 |

| 15.0 |

14.3 |

0.7 |

4.7 |