Submitted:

12 January 2024

Posted:

15 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Theoretical Background

2. Materials and Methods

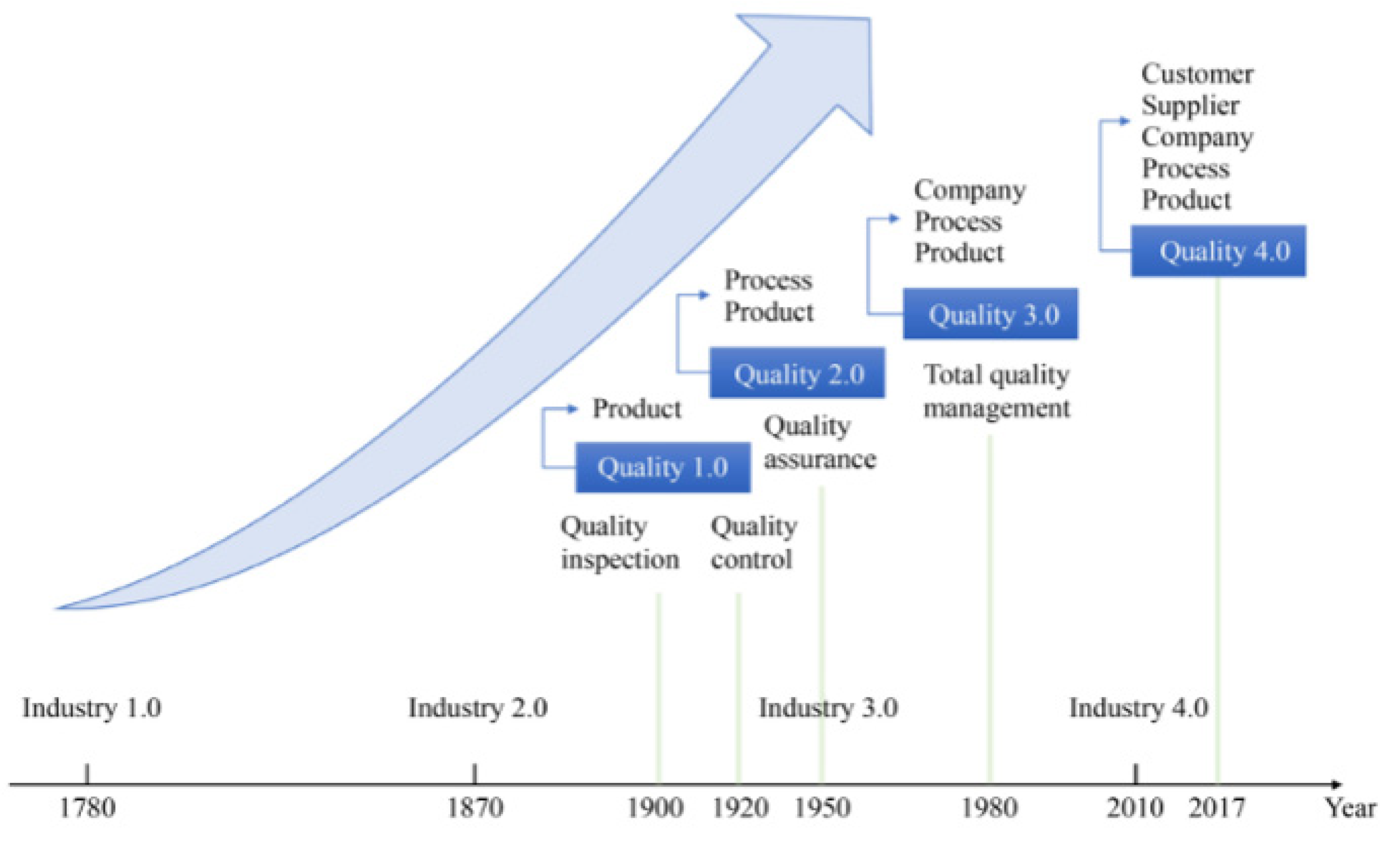

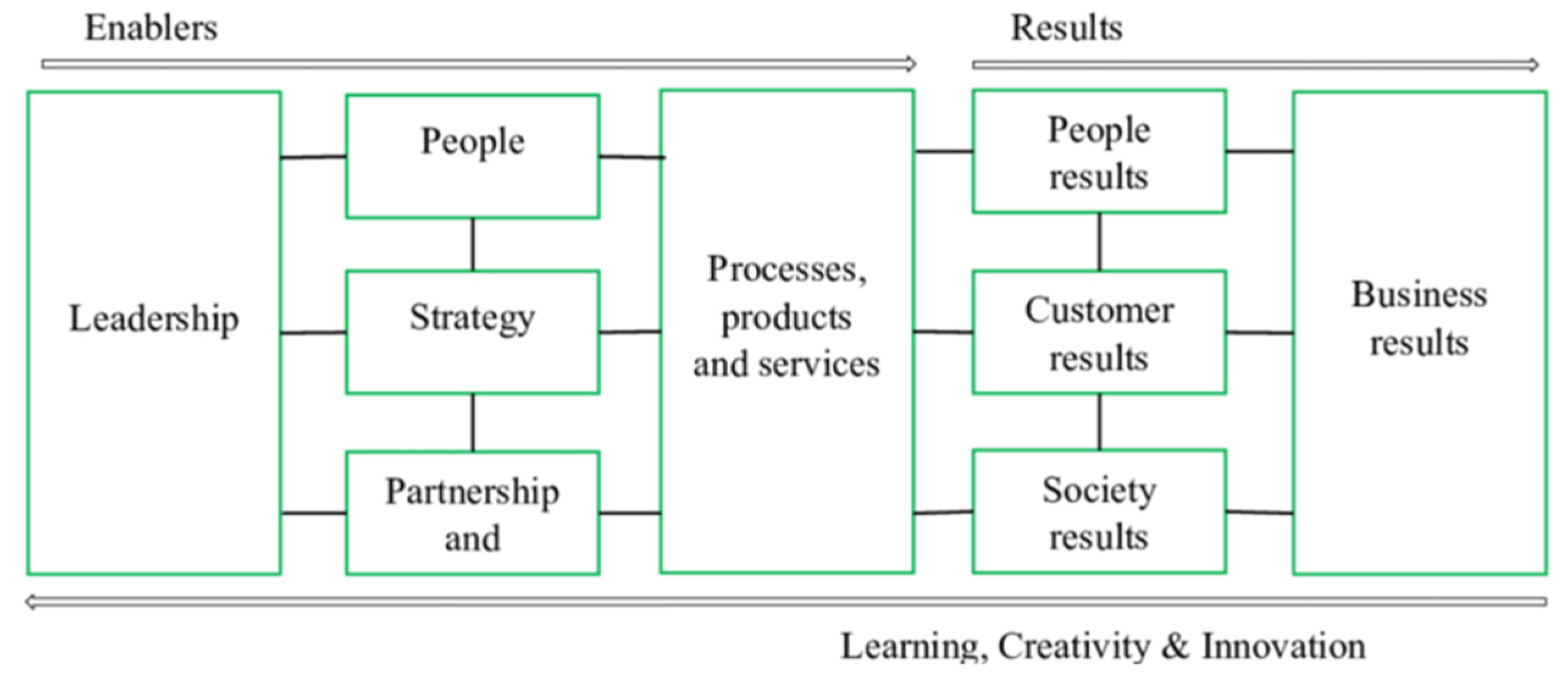

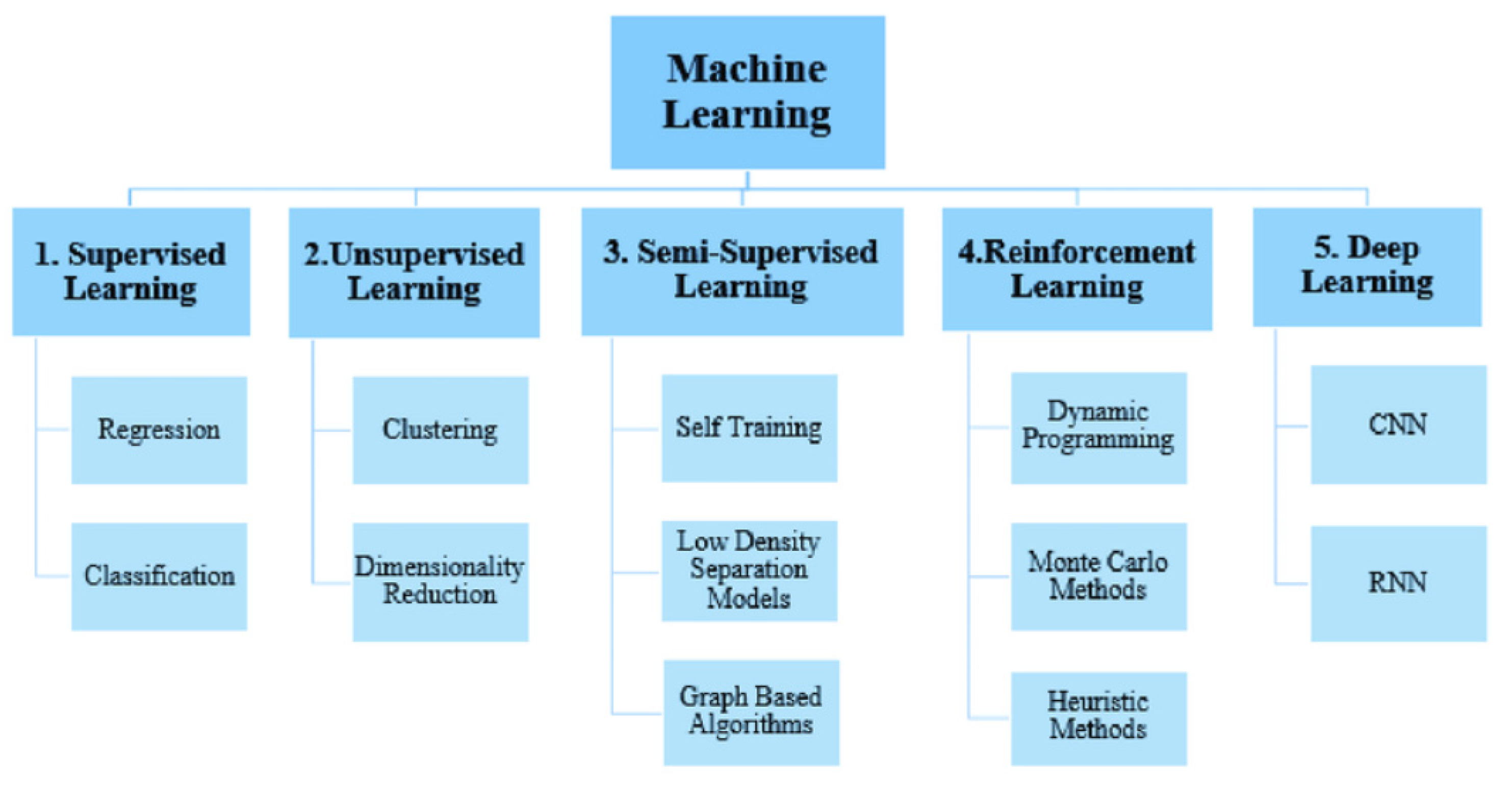

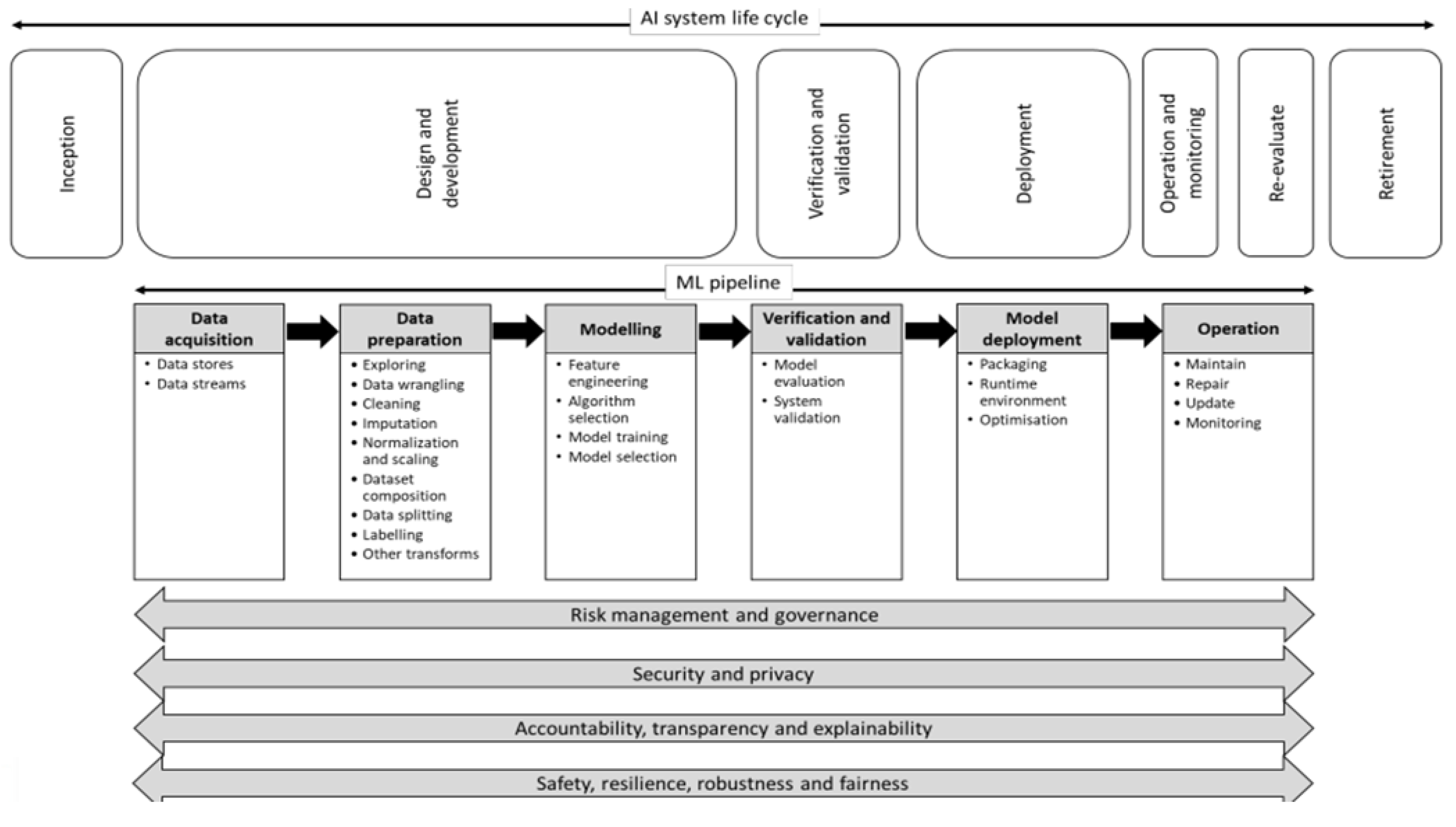

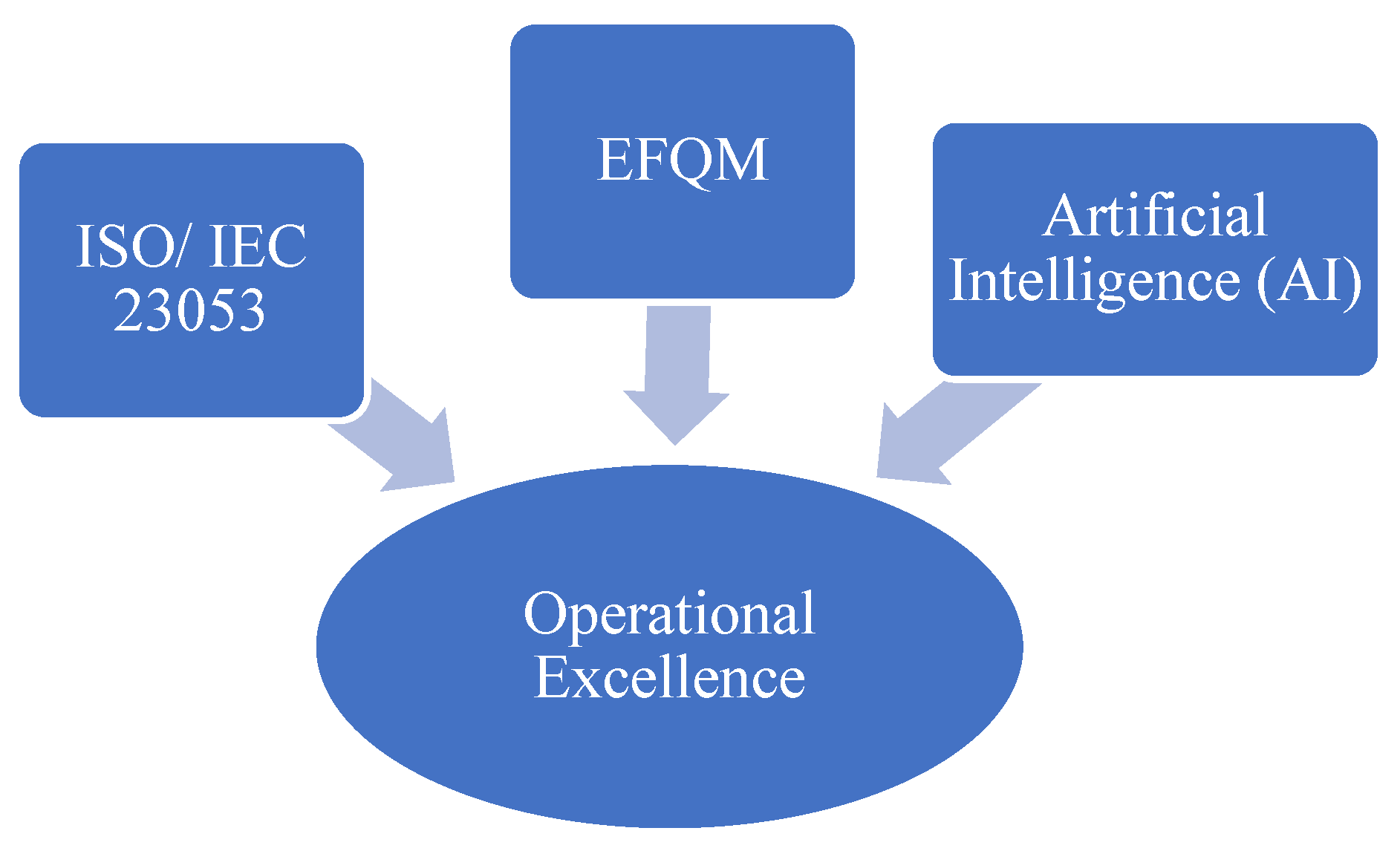

2.1. Concepts Overview

- EFQM framework is made up of the following main principles as described in [28];

- Result orientation;

- Customer orientation;

- Leadership and consistency of objectives;

- Management by processes and facts;

- Development and involvement of people;

- Development of partnerships;

- Social responsibility of the organizations.

- It makes more advanced use of AI [36];

- Machine learning features like accuracy and explainability are interpreted and set in an international frame [37];

- It gives AI standardization for policing software explored [38].

- Enriches the knowledge body by injecting AI into business excellence models (EFQM);

- Enhances operational excellence;

- Is applied to any sector worldwide;

- Saves time and money before applying to EFQM excellence award.

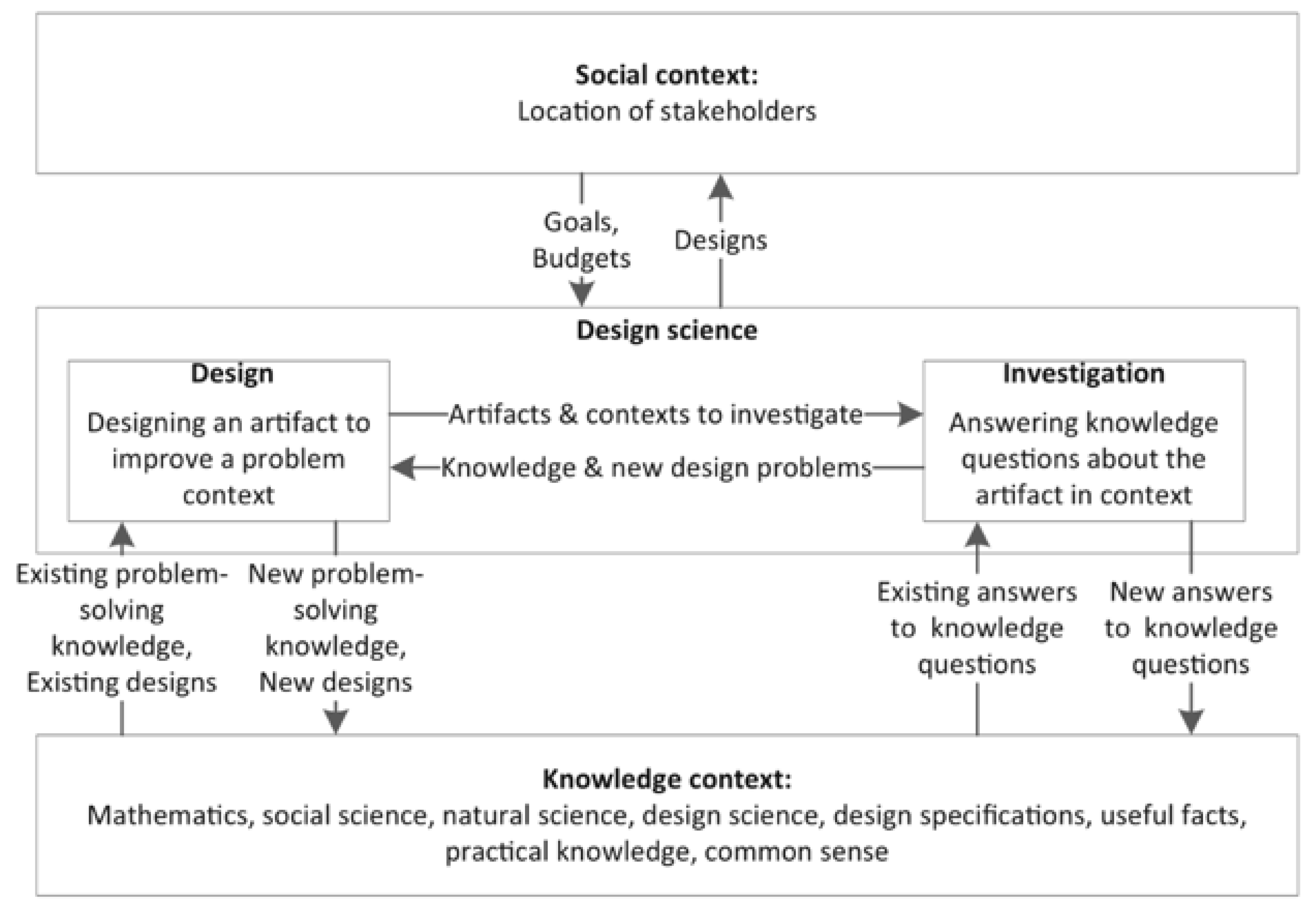

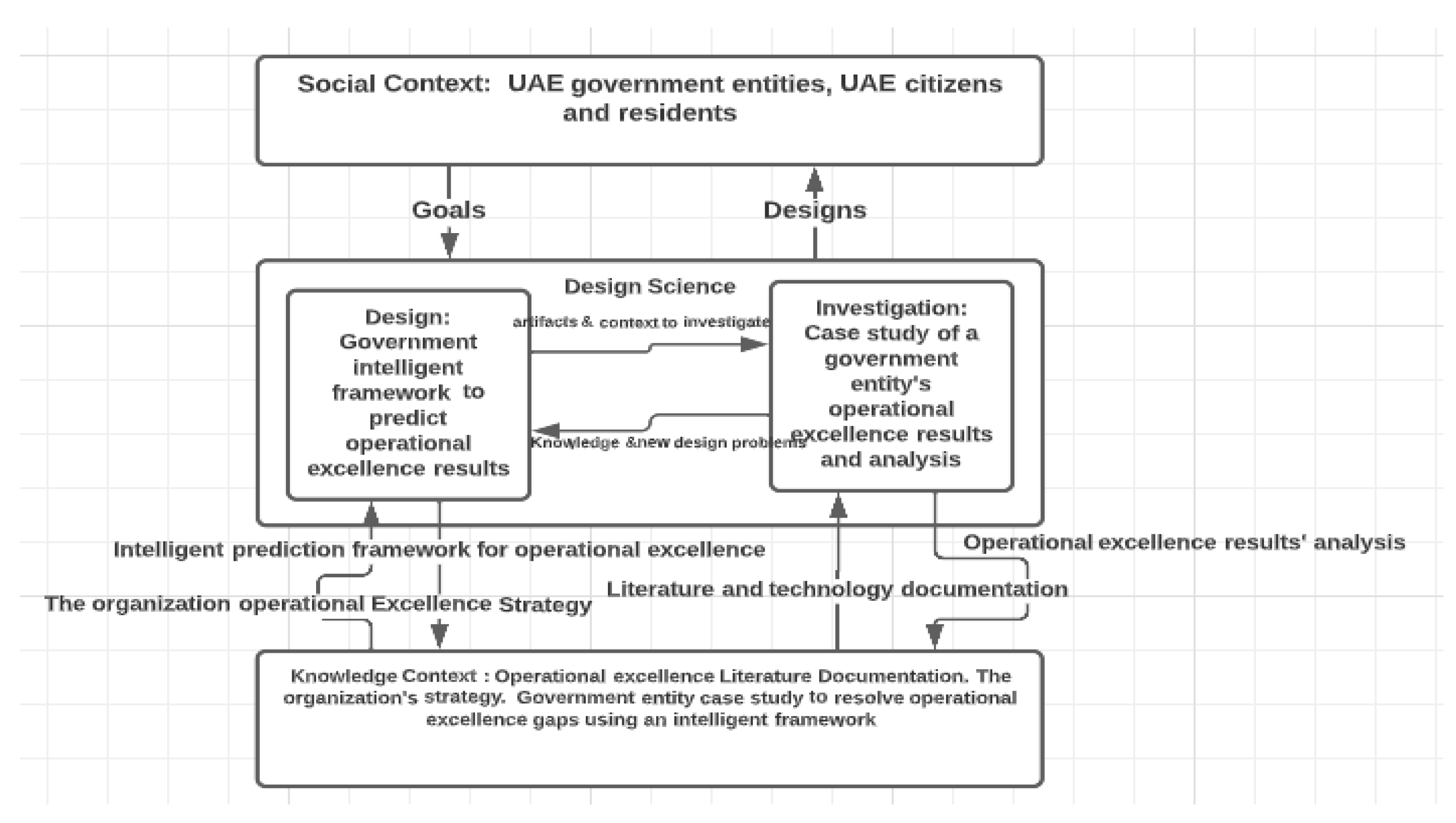

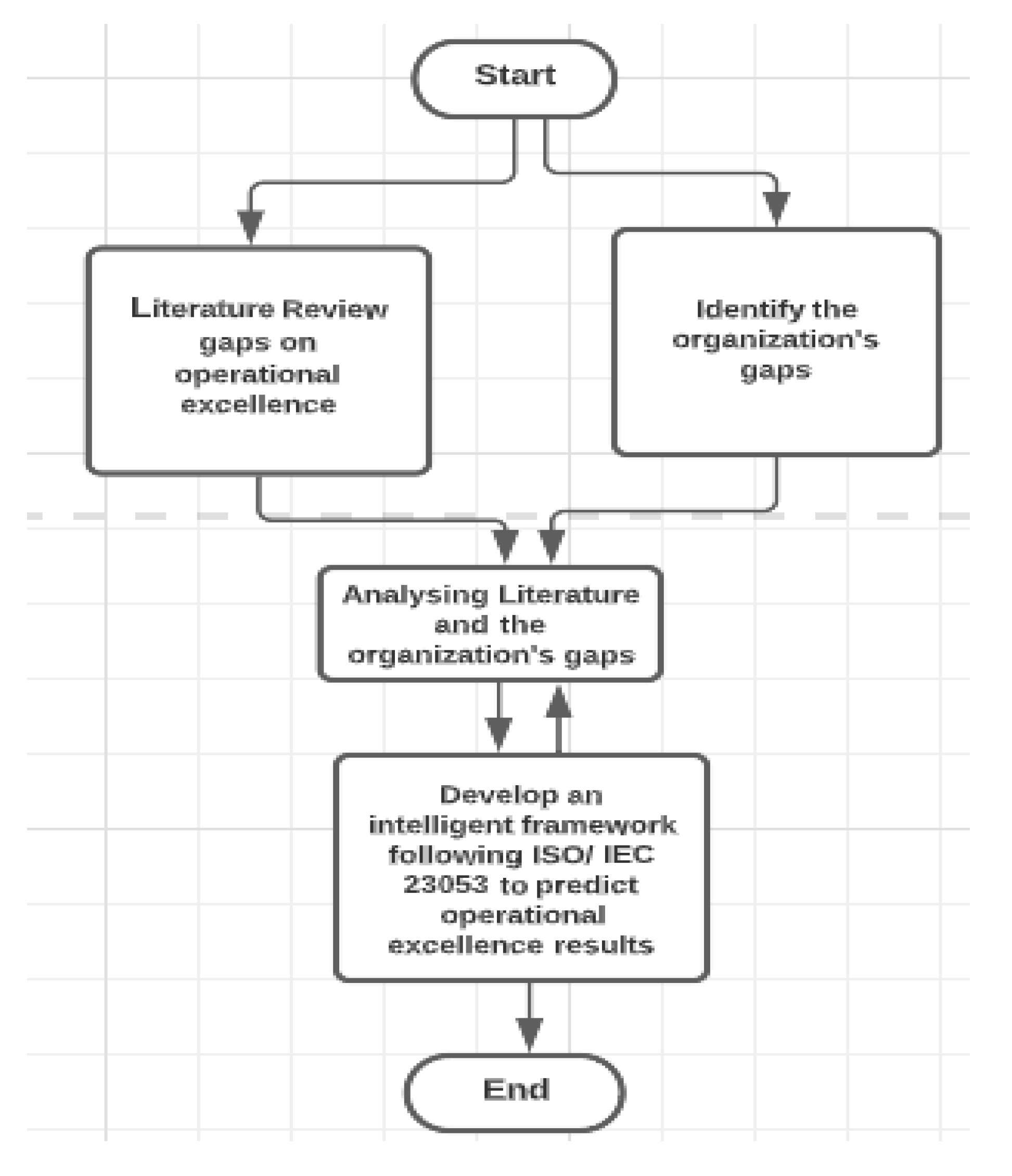

2.2. Research Methodology

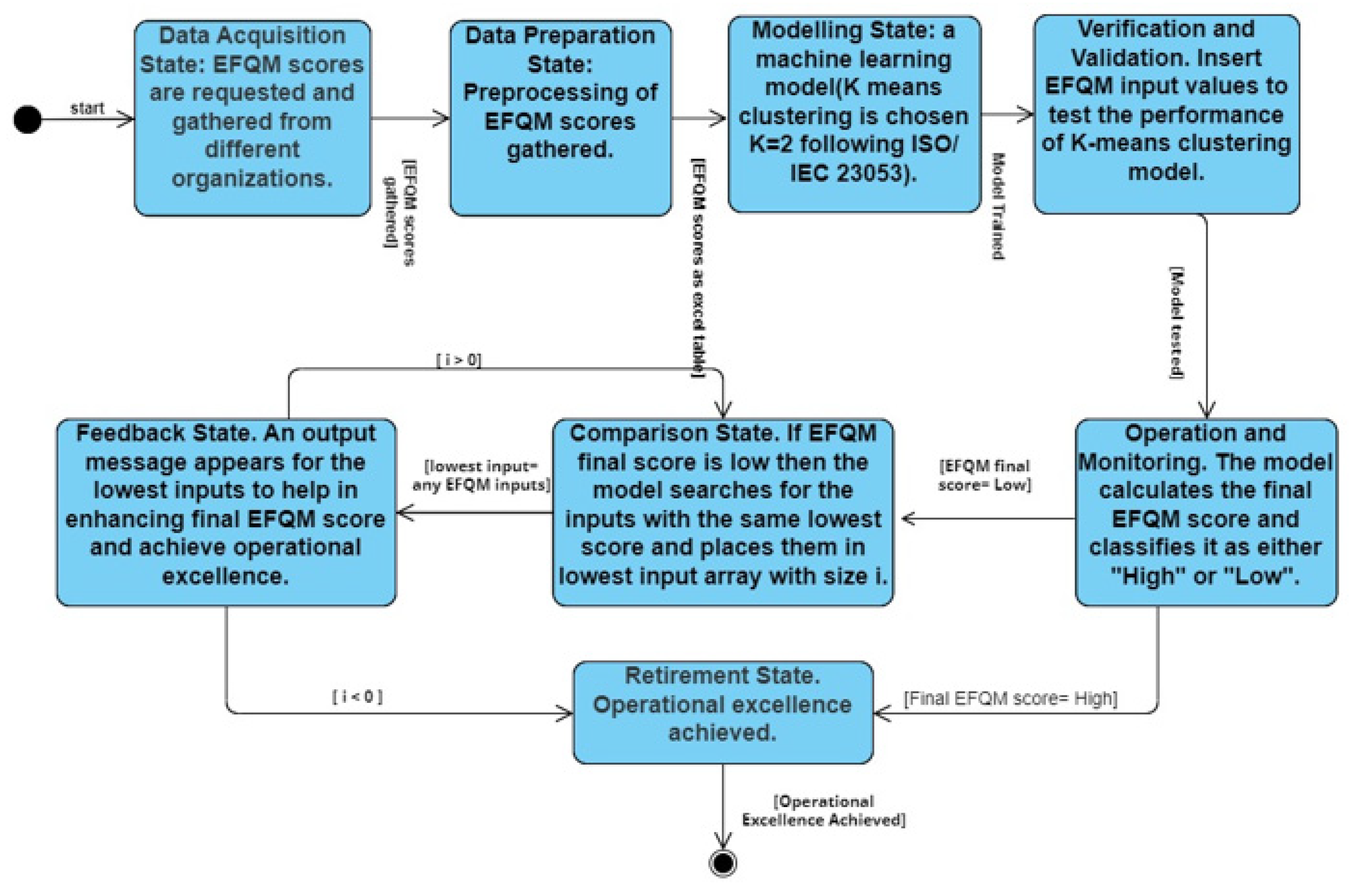

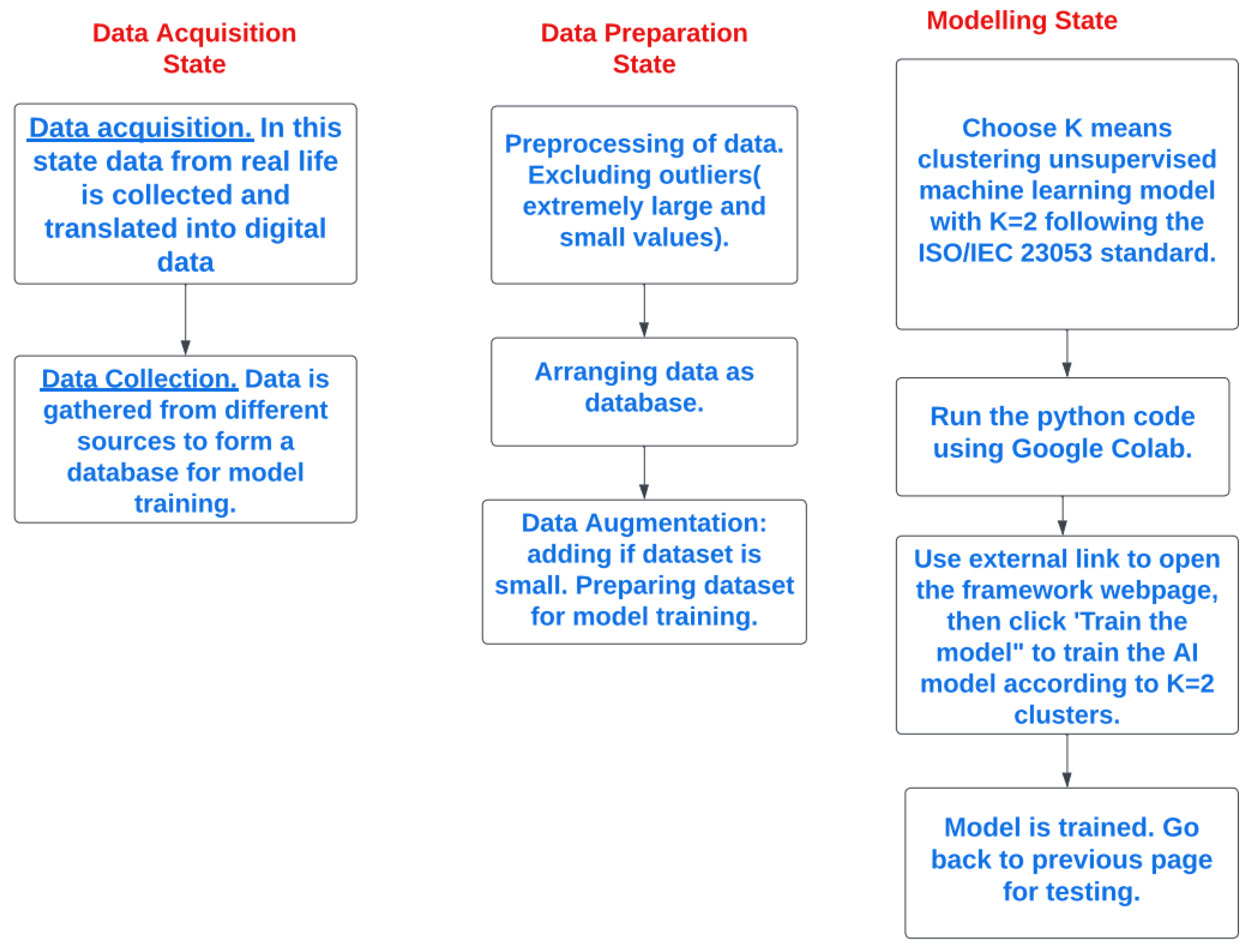

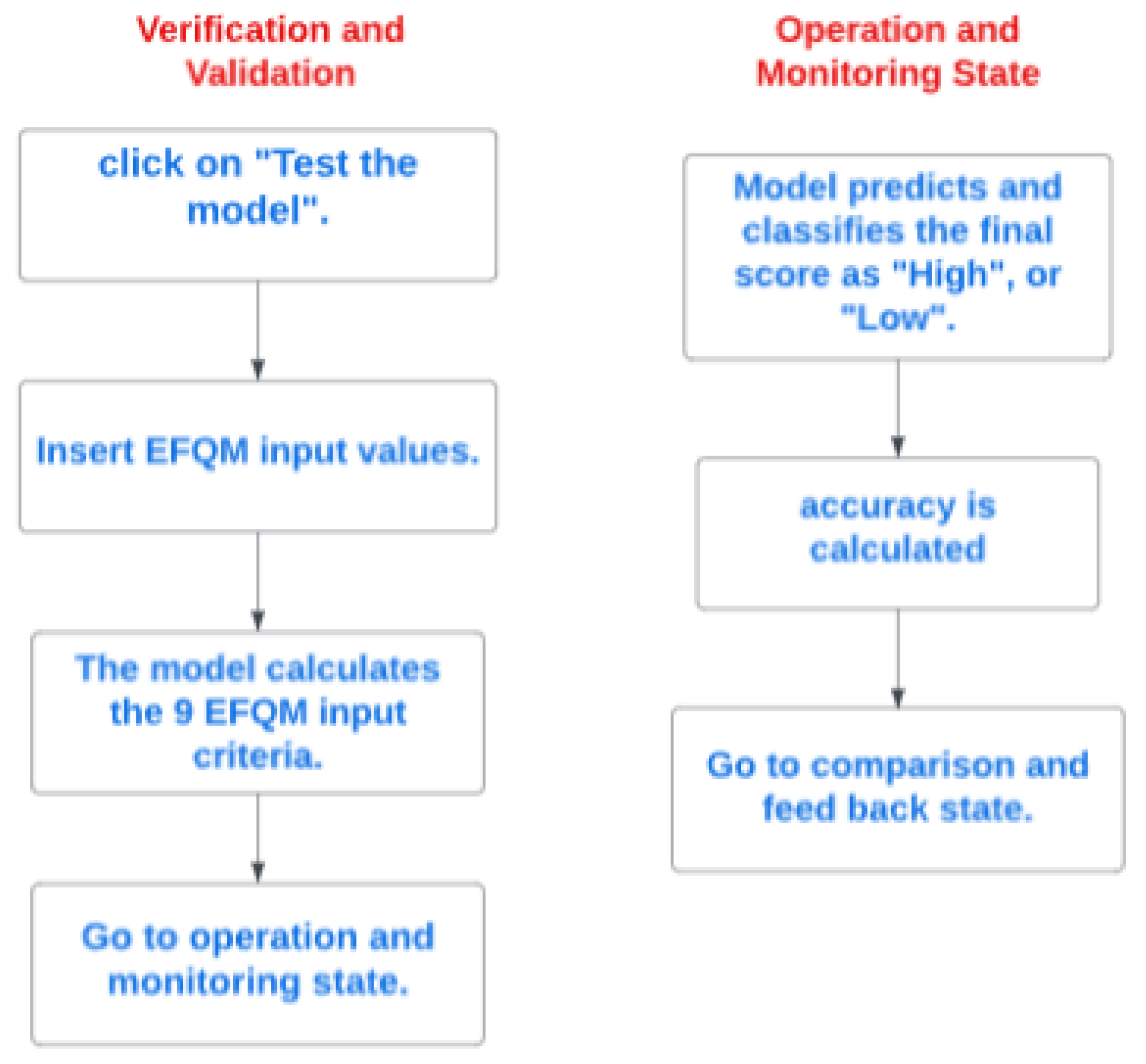

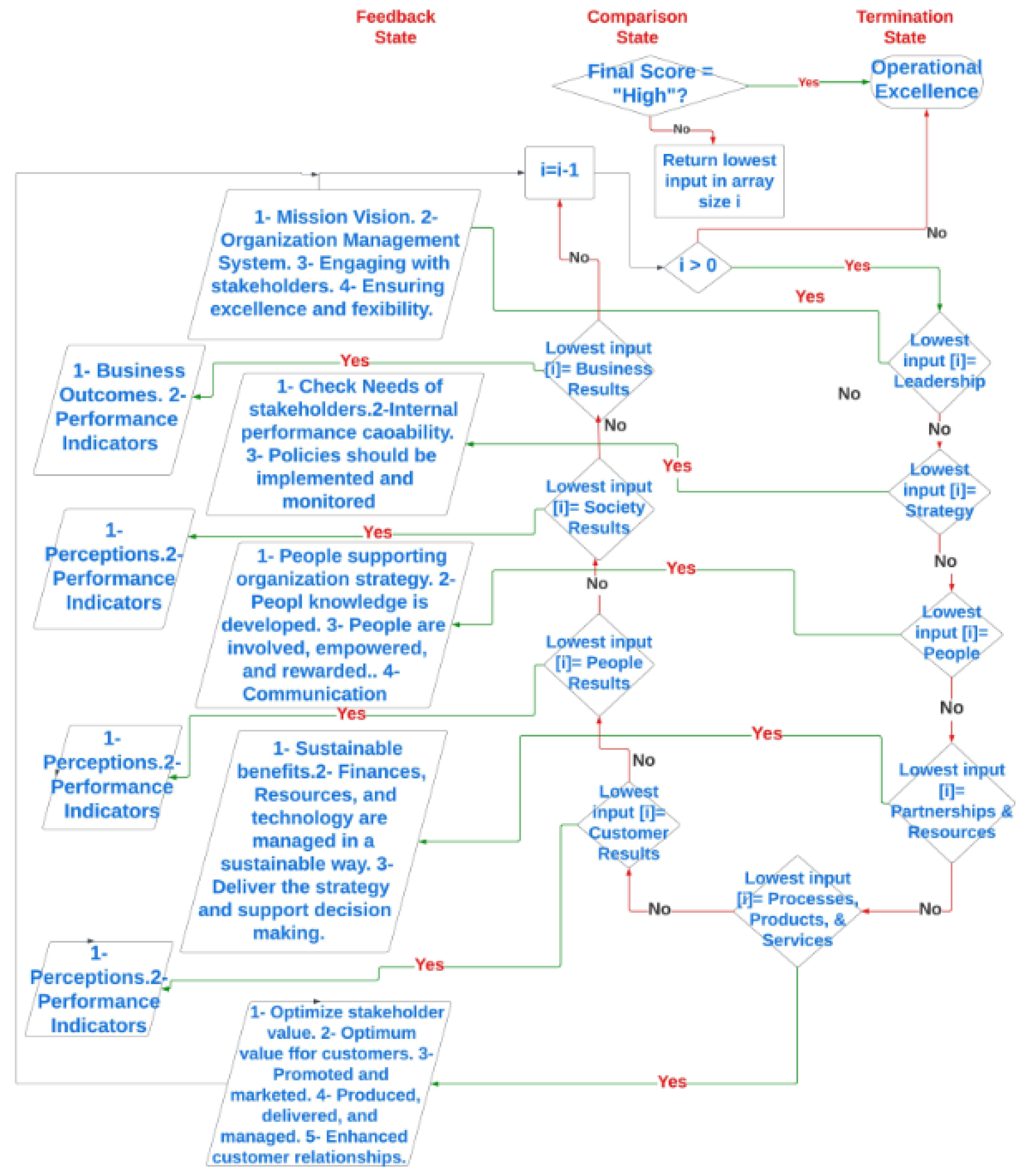

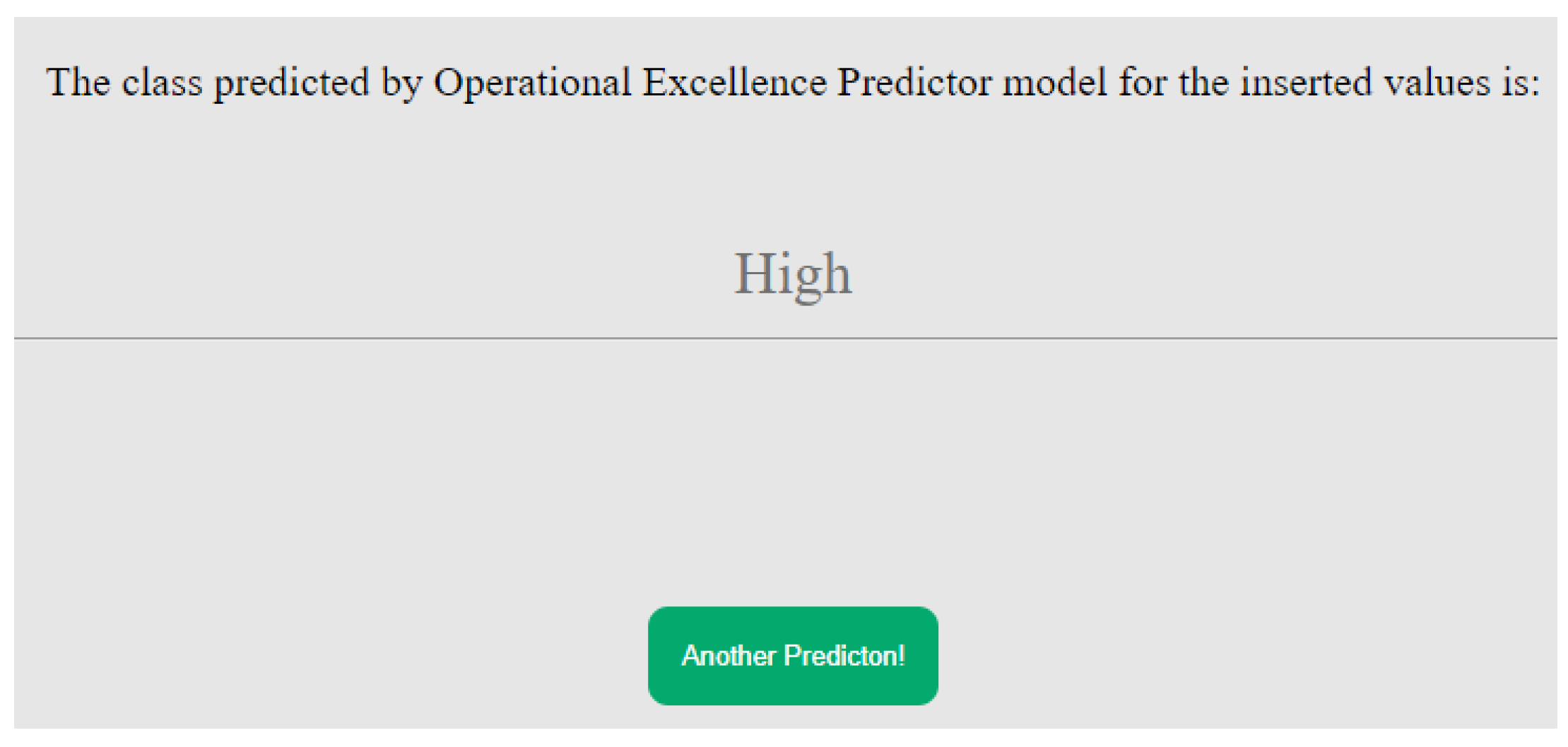

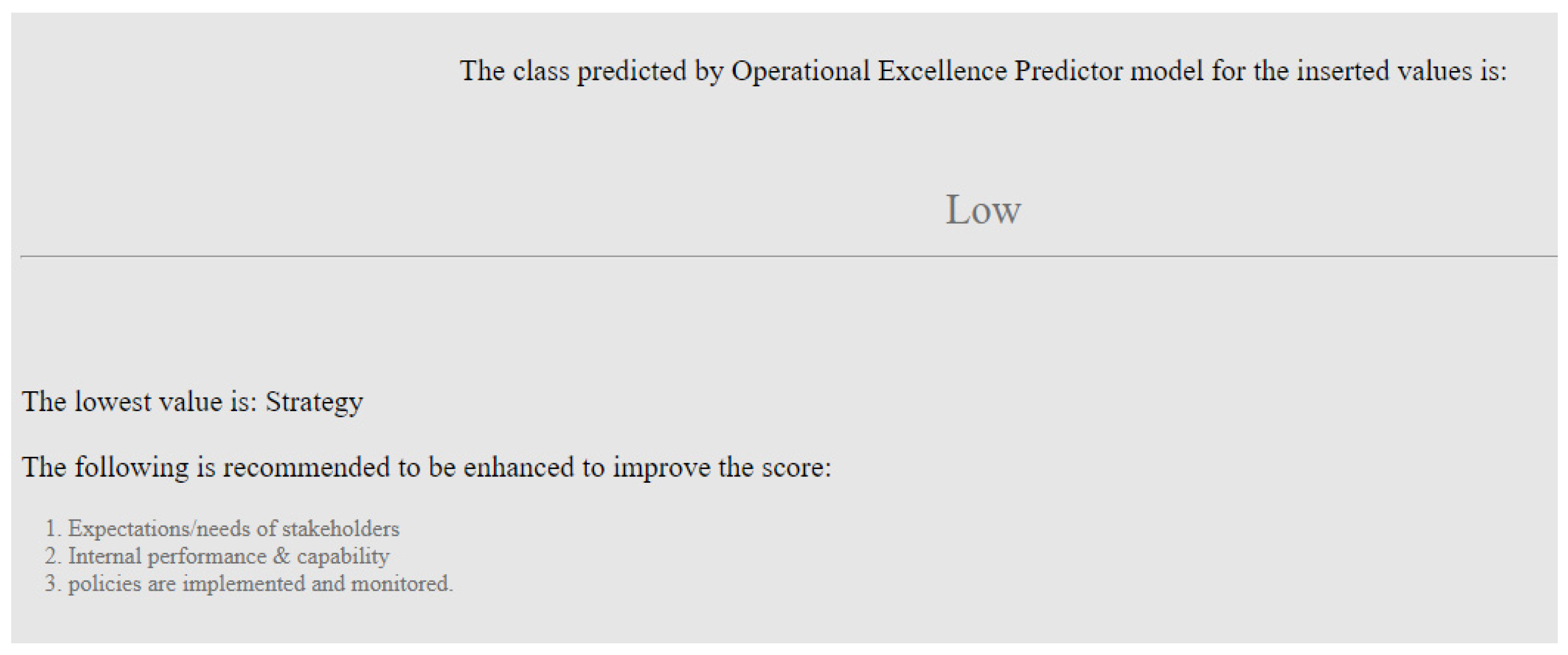

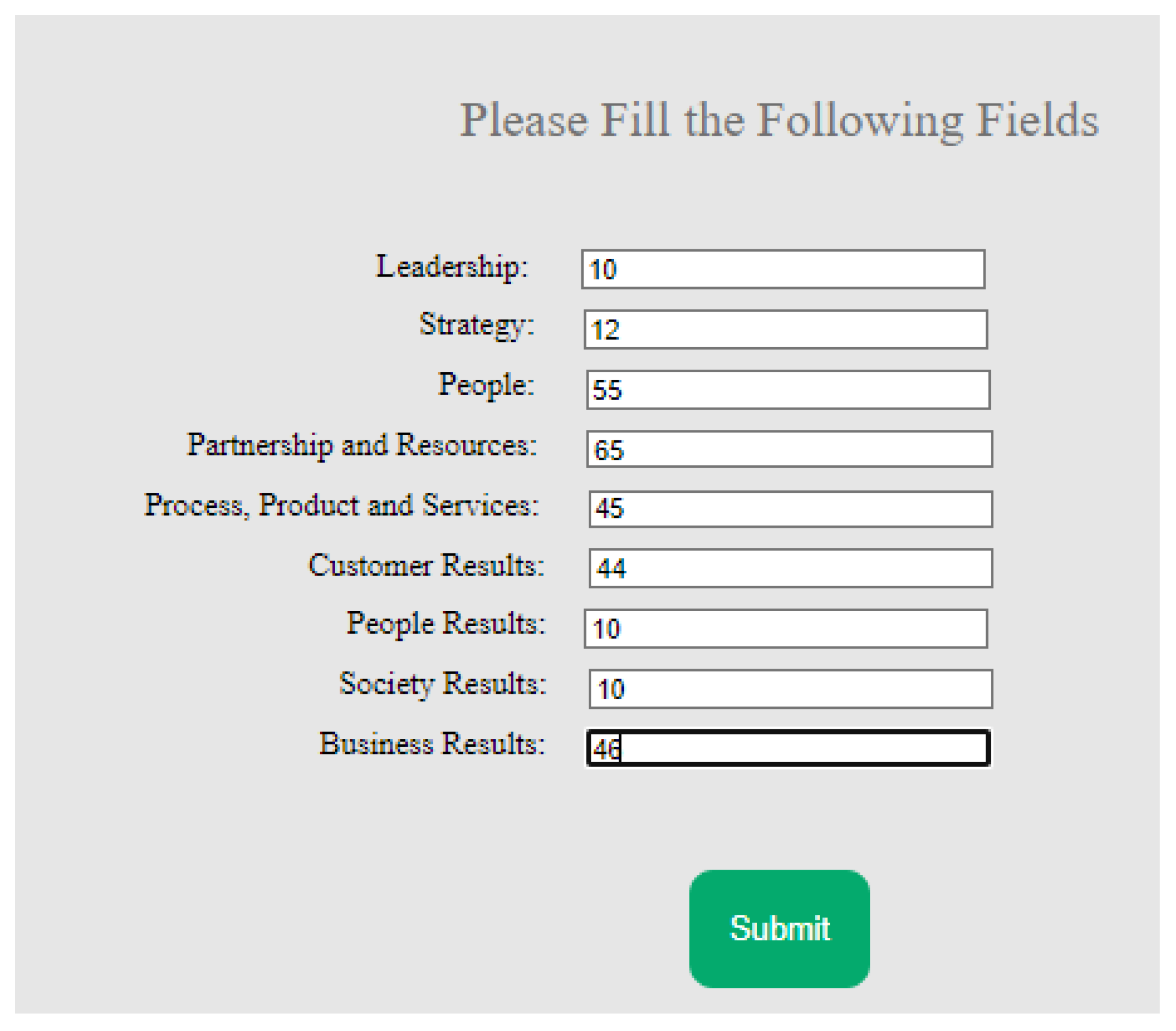

2.3. The integrated AI framework

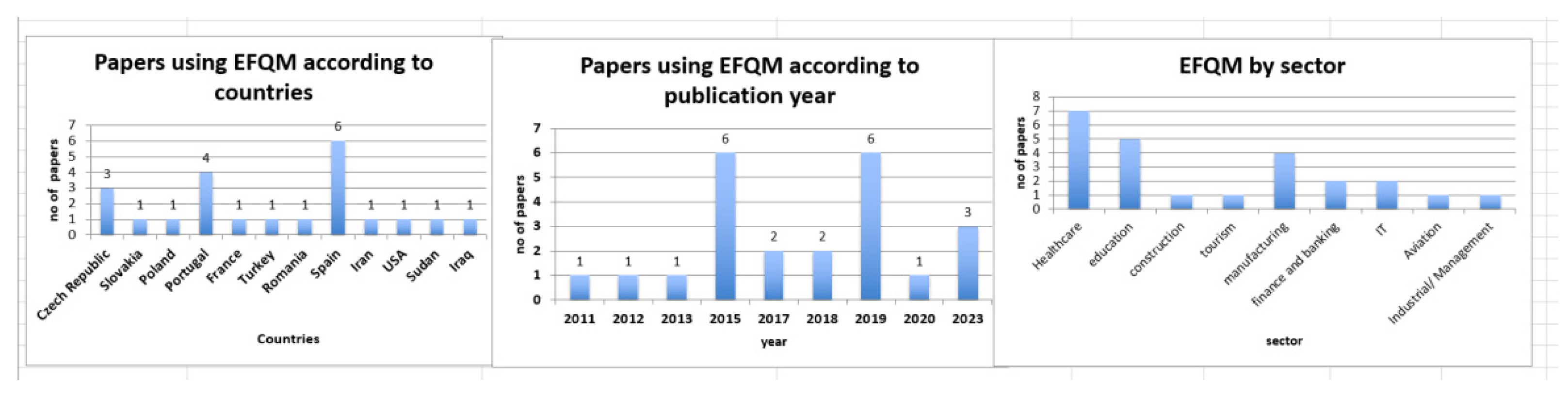

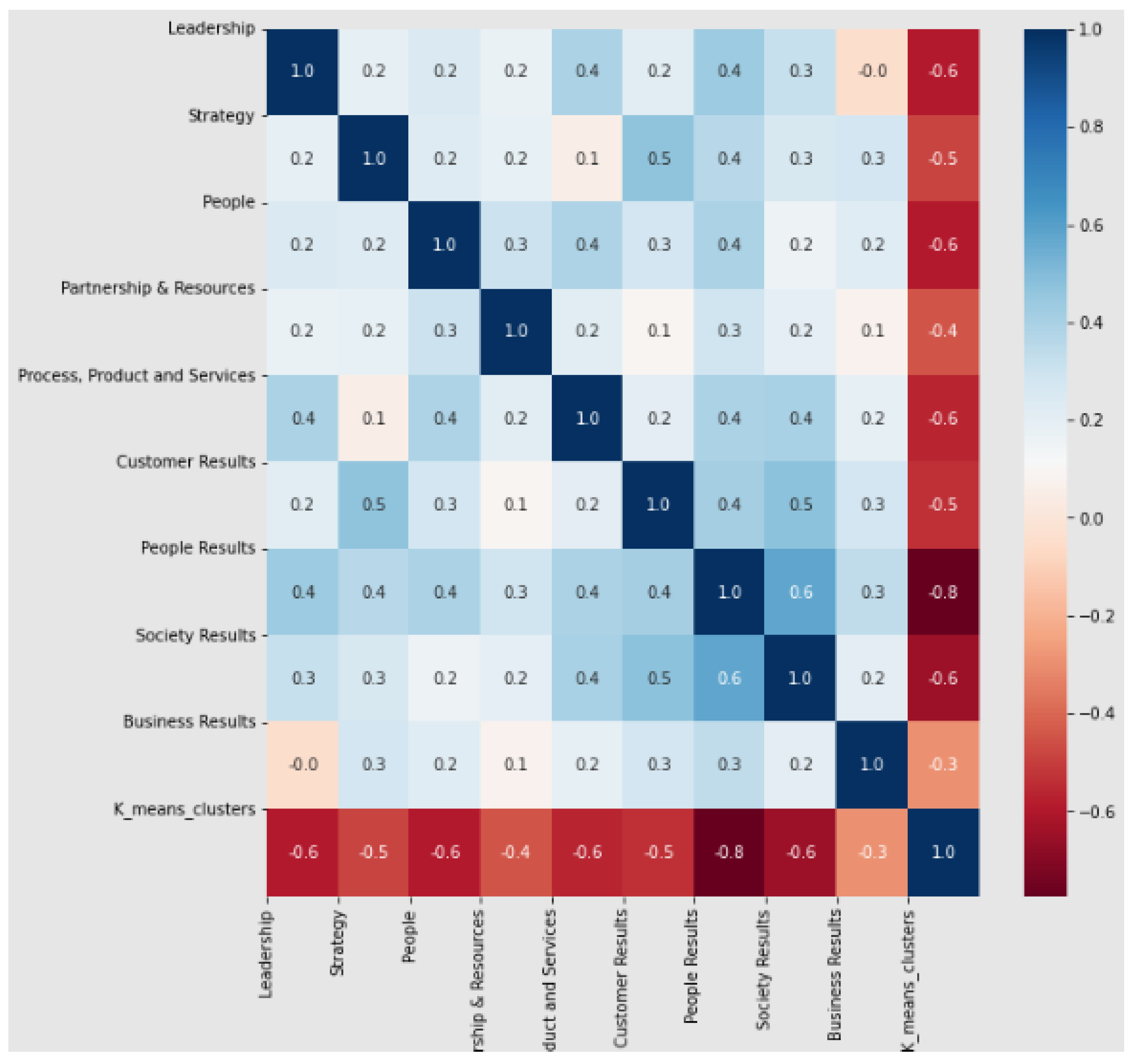

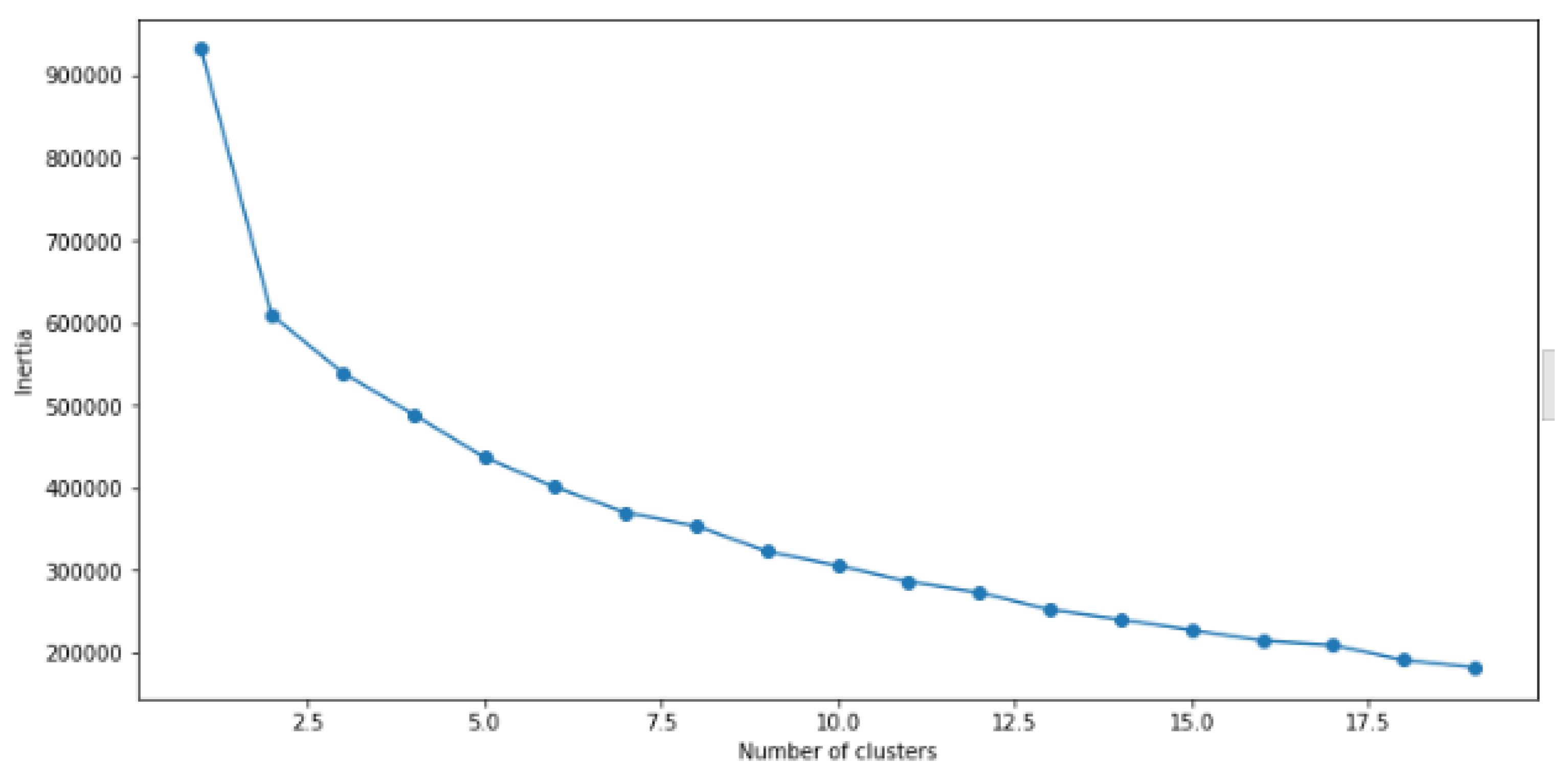

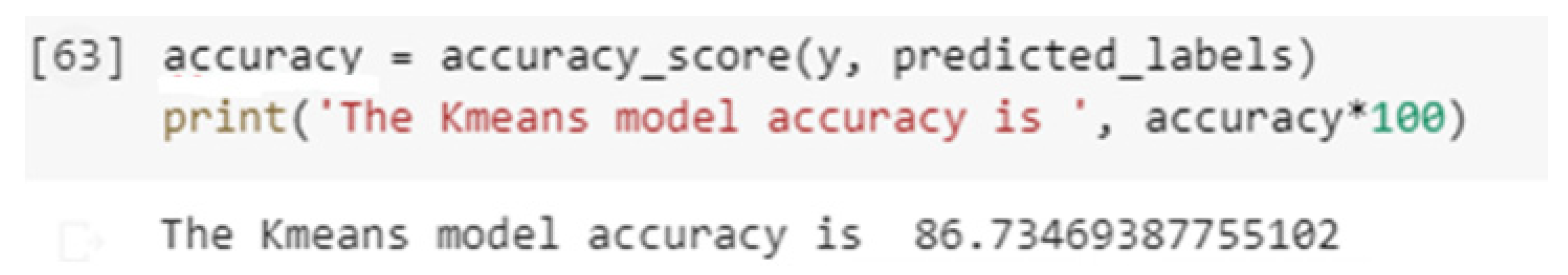

3. Results and Discussions

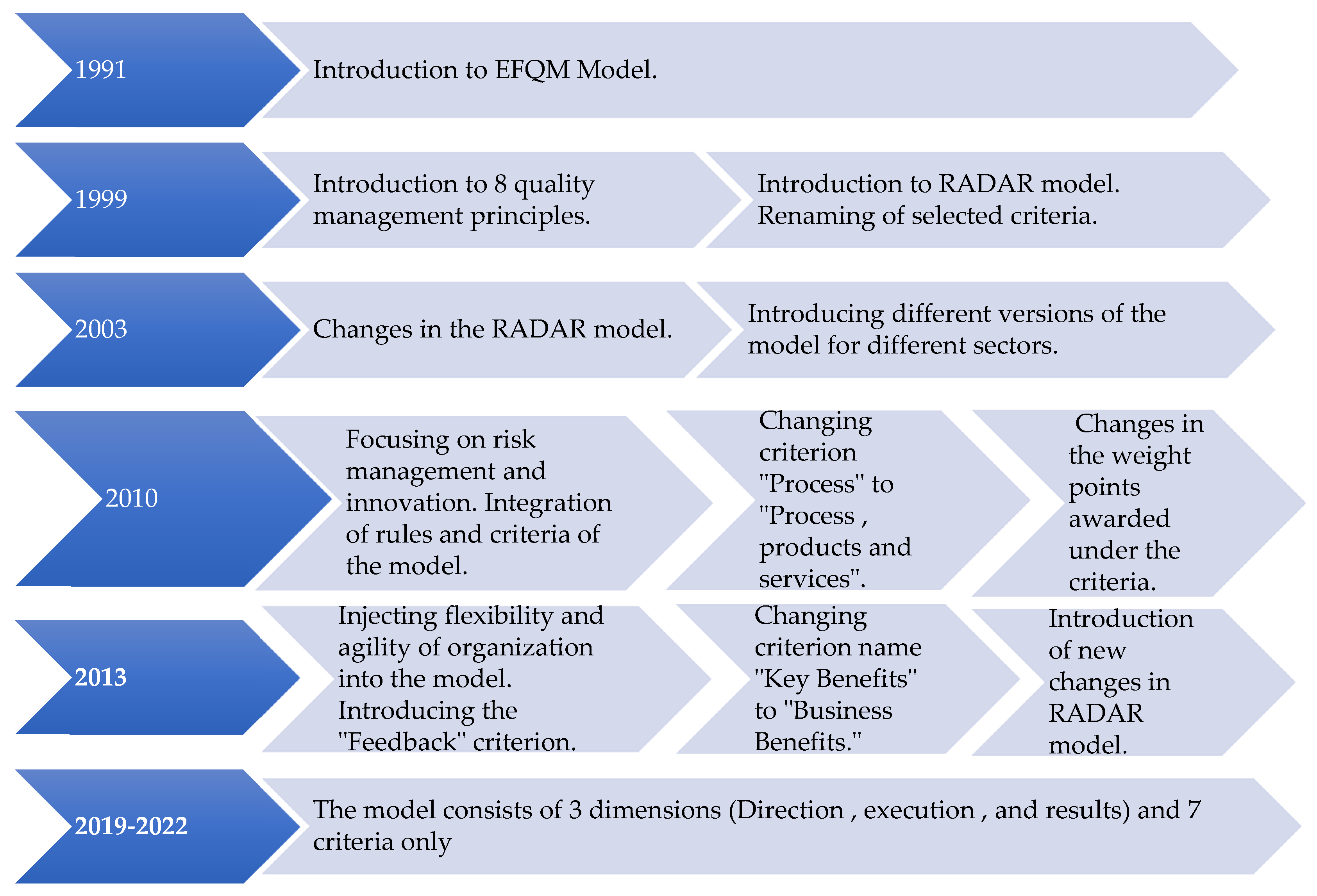

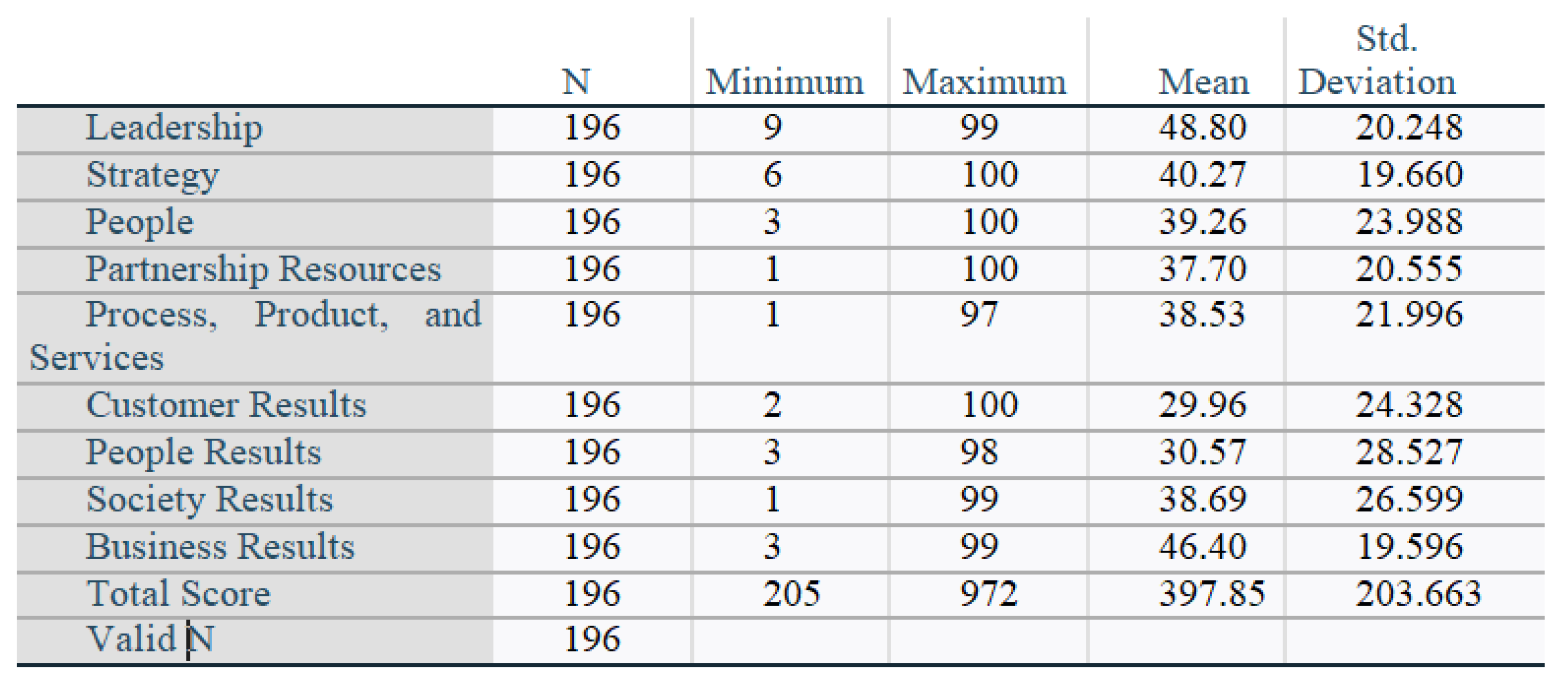

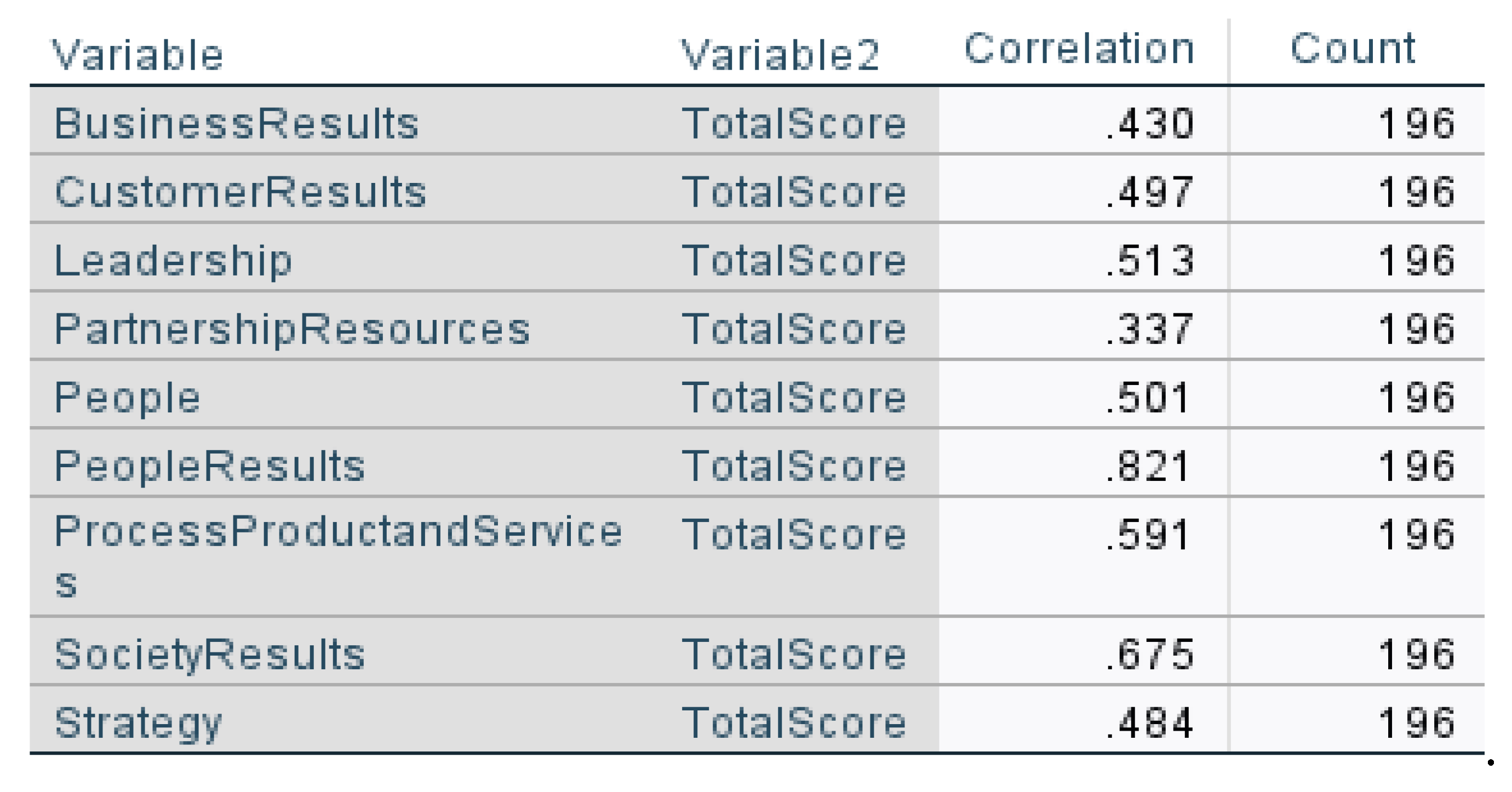

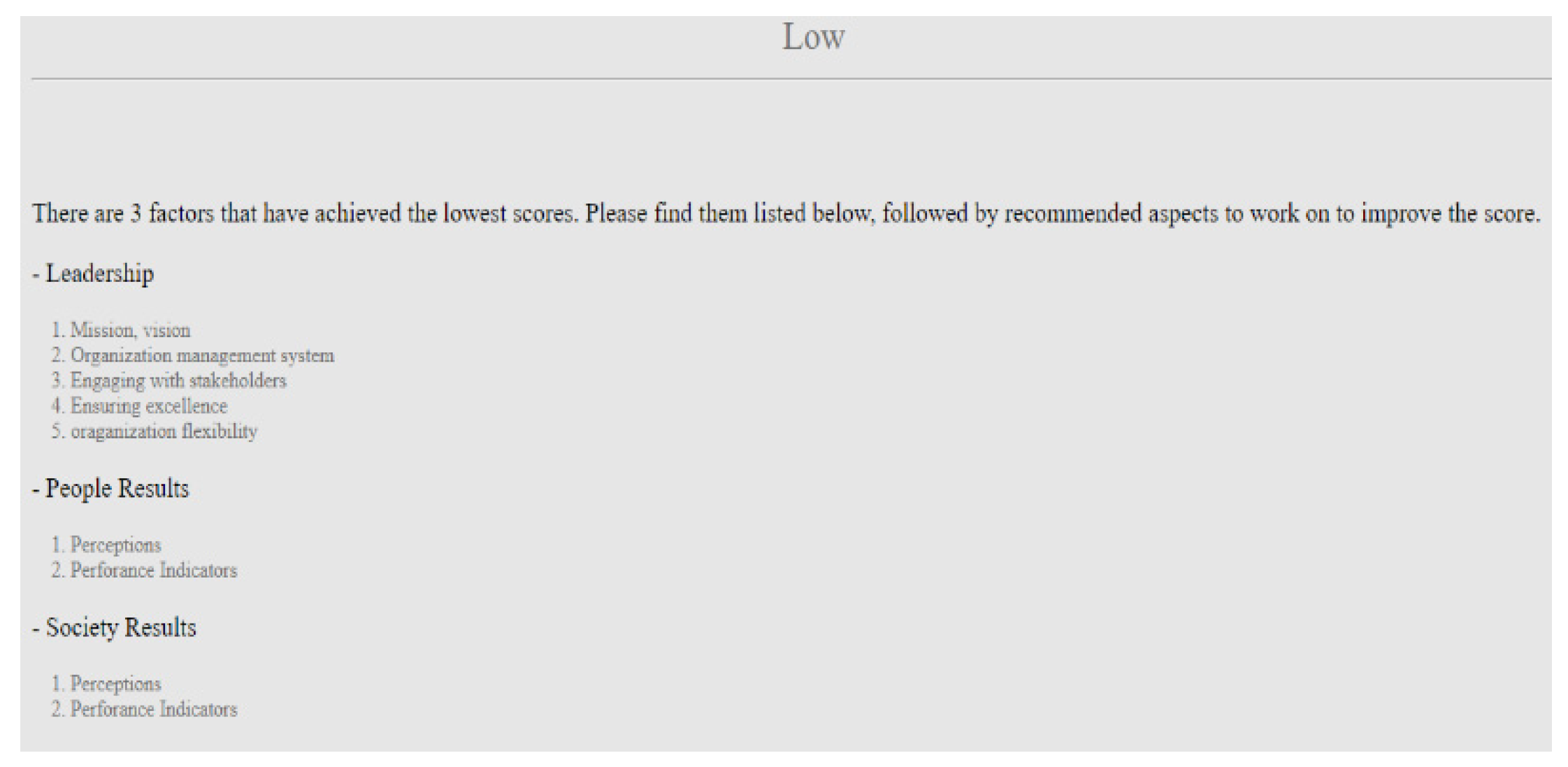

3.1. Old EFQM Model Results

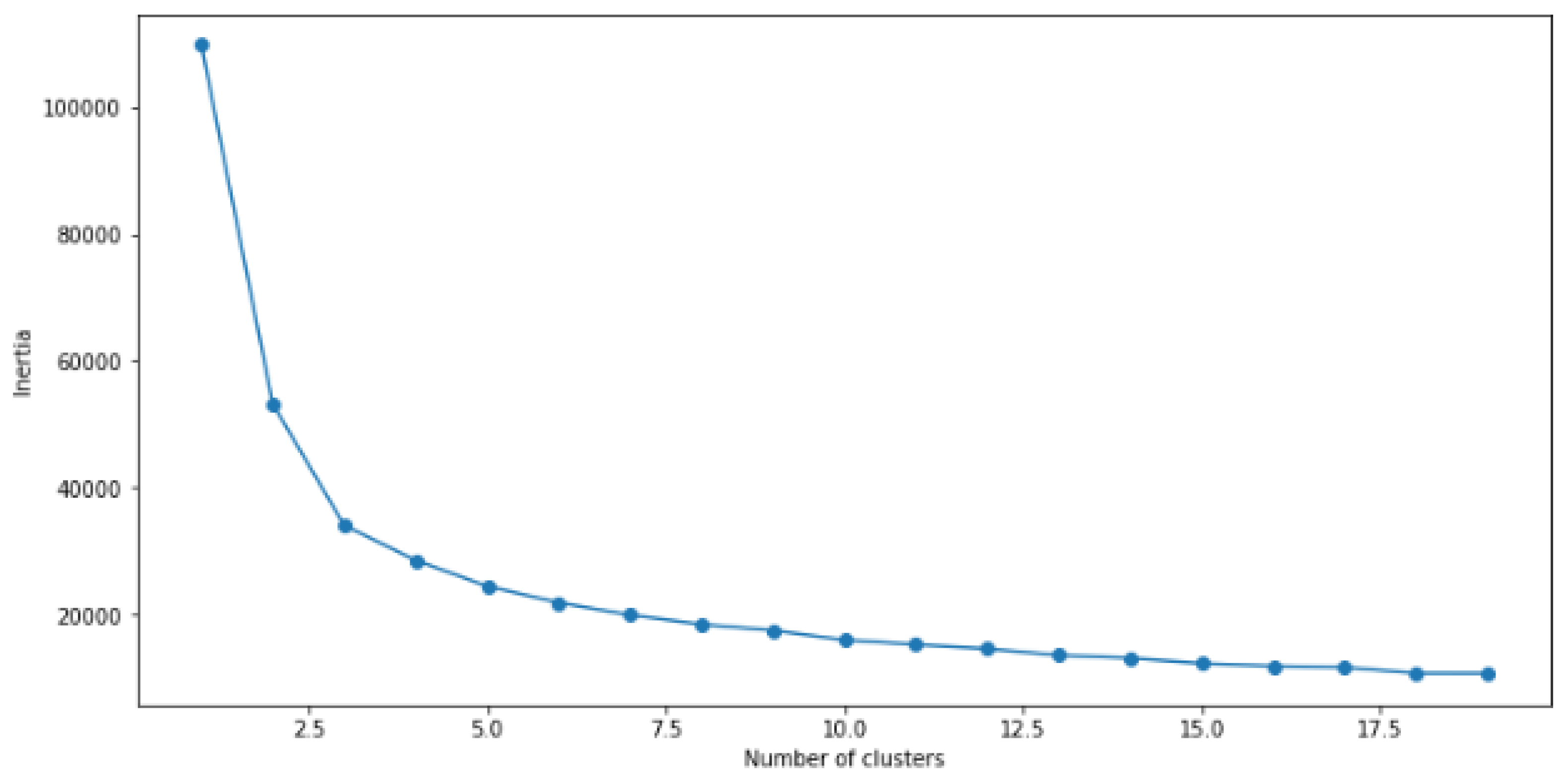

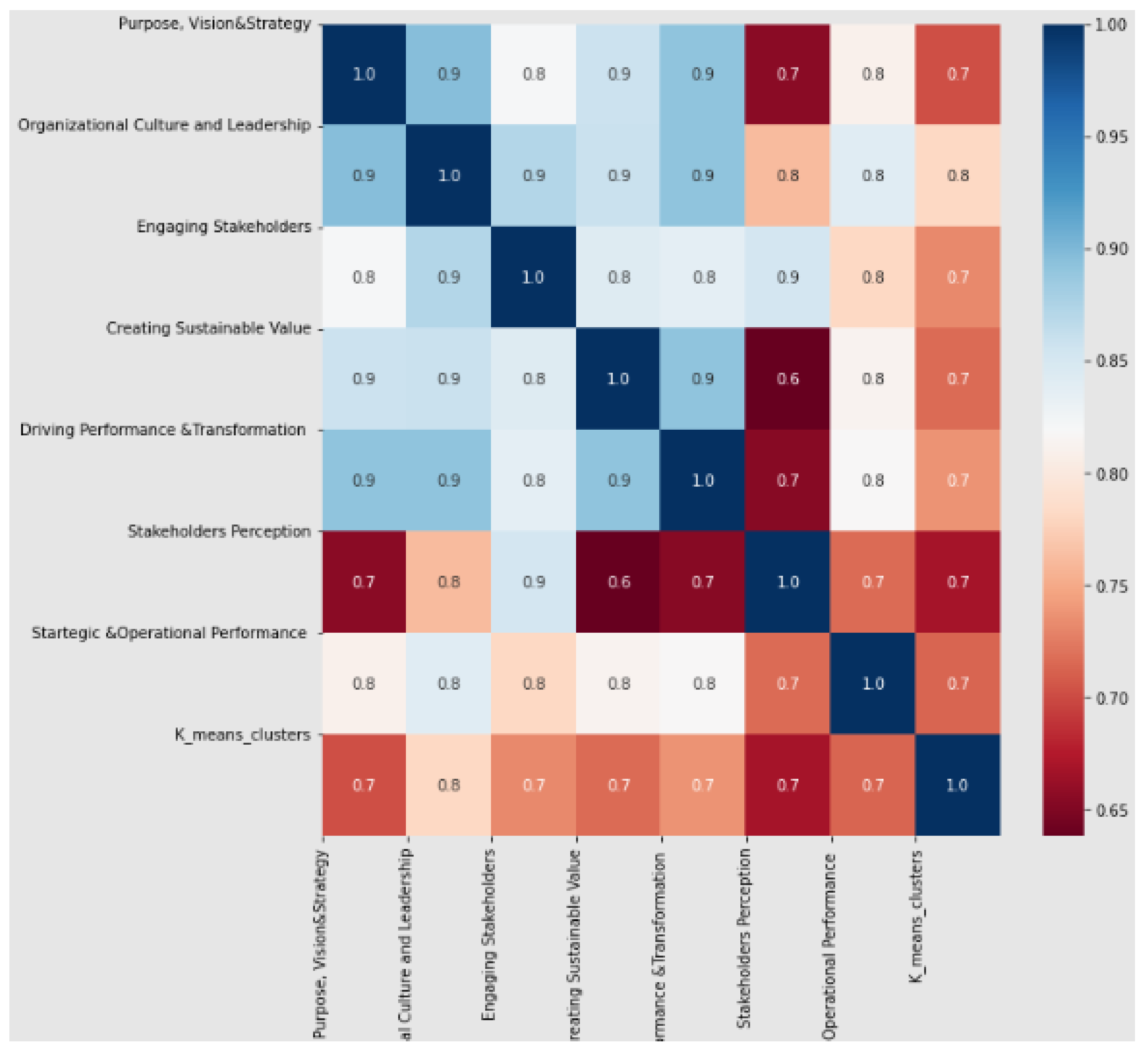

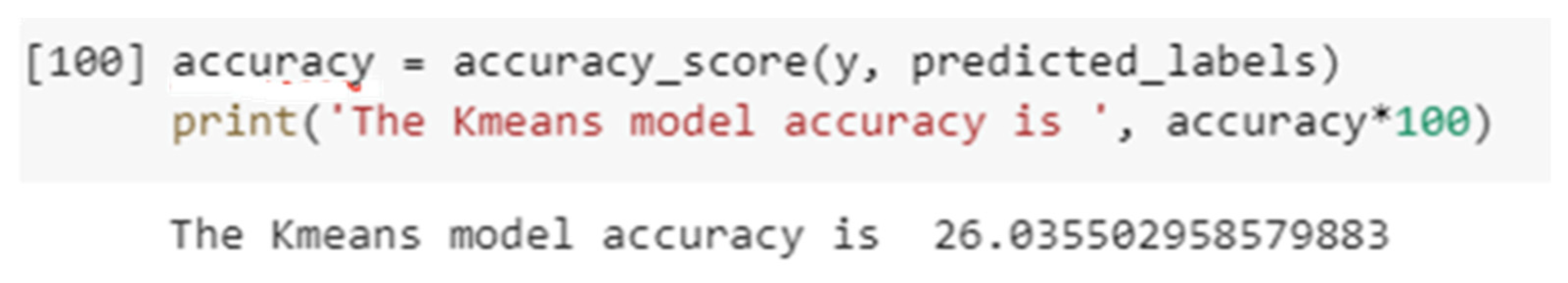

3.2. New EFQM Model Results

4. Conclusion

4.1. Significance

4.2. Future Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sila, I. Investigating changes in TQM’s effects on corporate social performance and financial performance over time. Total Quality Management Business Excellence 2020, 31, 210–229. [Google Scholar] [CrossRef]

- Liu, H.C.; Liu, R.; Gu, X.; Yang, M. From total quality management to Quality 4.0: A systematic literature review and future research agenda. Frontier of Engineering Management 2023, 10, 191–205. [Google Scholar] [CrossRef]

- Sadeh, E.; Arumugam, V.C.; Malarvizhi, C.A. Integration of EFQM framework and quality information systems. Total Quality Management & Business Excellence 2013, 24, 188–209. [Google Scholar] [CrossRef]

- Laurett, R.; Mendes, L. EFQM model’s application in the context of higher education: A systematic review of the literature and agenda for future research. International Journal of Quality & Reliability Management 2019, 36, 257–285. [Google Scholar] [CrossRef]

- Quintero-Garzón, M.L.; Carrión-García, A.; Jordá-Rodríguez, M.A.; Rodríguez-Córdoba, M. Corporate social responsibility and the EFQM excellence model as a frame work for integration of management systems in organizations. Ingeniería y competitividad 2015, 17, 9–22. [Google Scholar] [CrossRef]

- Arezki, S.; Elhissi, Y. Toward an IT Governance Maturity Self-assessment model using EFQM and COBIT. In Proceedings of the International Conference on Geo informatics and Data Analysis - ICGDA ’18, 20 April 2018.

- Pimentel, L.; Ramos Pires, A. The impact of EFQM awards on organizational management. 20th Excellence in Services University of Verona International Conference, Verona, Italy, 2017.

- Asif, M.; Searcy, C.; Garvare, R.; Ahmad, N. Including sustainability in business excellence models. Total Quality Management & Business Excellence 2011, 22, 773–786. [Google Scholar] [CrossRef]

- Rosak-Szyrocka, J.; Roszak, M. The role of the EFQM model in precepting quality in Polish enterprises. Multidisciplinary Aspects of Production Engineering MAPE 2019, 2, 399–406. [Google Scholar] [CrossRef]

- Soliman, G.M.; Abou-El-Enien, T.H. Terrorism Prediction Using Artificial Neural Network. Rev. d’Intelligence Artif. 2019; 33, 81–87. [Google Scholar] [CrossRef]

- Keshtegar, A. ; Ghasemi, M. ; Hosseini, A. ; Ahang, A, F. ; Ghaffari, H. The impact of business intelligence on enablers of EFQM excellence model with mediating role of knowledge sharing ARTICLE INFO 48. International Journal of Human Capital in Urban Management, 2021. [CrossRef]

- Nassif, A.B.; Shahin, I.; Attili, I.; Azzeh, M.; Shaalan, K. Speech recognition using deep neural networks: a systematic revie. IEEE Access 2019, 1–1. [Google Scholar] [CrossRef]

- Cruz, J.A.; Wishart, D.S. Applications of machine learning in cancer prediction and prognosis. Cancer informatics 2006, 2, 117693510600200030. [Google Scholar] [CrossRef]

- Bunker, R.P.; Thabtah, F. A machine learning framework for sport result prediction. Applied Computing and Informatic, ScienceDirect 2019, 15. [Google Scholar] [CrossRef]

- Schwalbe, N.; Wahl, B. Artificial intelligence and the future of global health. The Lancet, Elsevier 2020, 395, 1579–158. [Google Scholar] [CrossRef]

- Gao, N.; Liu, Y.; Mai, Y. WITHDRAWN: Manufacturing service innovation platform based on 5G network and machine learning. 2020,103448. [CrossRef]

- Dirican, C. The impacts of robotics artificial intelligence on business and economics. Procedia - Social Sciences and Behavioral 2015, 195, 564–573. [Google Scholar] [CrossRef]

- Masum, A.K.M.; Beh, L.S.; Azad, M.A.K.; Hoque, K. Intelligent human resource information system (i-HRIS): a holistic decision support framework for HR excellence. Int. Arab J. Inf. Technol. 2018, 15, 121–130. [Google Scholar]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technological Forecasting and Social Change 2021, 163, 120420. [Google Scholar] [CrossRef]

- Griner, T.E.; Thompson, M.; High, H.; Buckles, J. Artificial intelligence forecasting census and supporting early decision. Nursing Administration Quarterly 2020, 44, 316–328. [Google Scholar] [CrossRef] [PubMed]

- Rizvi, A.T.; Haleem, A.; Bahl, S.; Javaid, M. Artificial intelligence (AI) and its applications in Indian manufacturing: a review. Current Advances in Mechanical Engineering: Select Proceedings of ICRAMERD 2020, 2021. [CrossRef]

- Arpaci, I.; Huang, S.; Al-Emran, M.; Al-Kabi, M.N.; Peng, M. Predicting the COVID-19 infection with fourteen clinical features using machine learning classification algorithms. Multimedia Tools and Applications 2021, 80, 11943–11957. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Weng, Y.; Lund, J. Applications of explainable artificial intelligence in diagnosis and surgery. Diagnostics 2022, 12, 237. [Google Scholar] [CrossRef]

- Huang, M.H.; Rust, R.T. A strategic framework for artificial intelligence in marketing. Journal of the Academy of Marketing Science, Springer 2021, 49, 30–50. [Google Scholar] [CrossRef]

- Cotton, P. ; Patel, M.; Wei, W. Information technology — artificial intelligence — artificial intelligence concepts and terminology. ISO/IEC 22989:2022(E), 2022.

- Quintero-Garzón, M.L.; Carrión-García, A.; Jordá-Rodríguez, M.A.; Rodríguez-Córdoba, M. Corporate social responsibility and the EFQM excellence model as a framework for integration of management systems in organizations. Ingeniería y competitividad 2015, 17, 9–22. [Google Scholar] [CrossRef]

- Hıdıroğlu, D. Self- assessment performance measurement in construction Companies: An Application of the EFQM Excellence Model on Processes and Customer stages. Procedia Computer Science 2019, 158, 844–851. [Google Scholar] [CrossRef]

- Suárez, E.; Calvo-Mora, A.; Roldán, J.L; Periáñez-Cristóbal, R. Quantitative research on the EFQM excellence model: A systematic literature review (1991–2015). European Research Management Business Economics, 2017; 23, 147–156. [Google Scholar] [CrossRef]

- Fonseca, L. Relationship between ISO 9001 certification maturity and EFQM business excellence model results. Quality Innovation Prosperity 2015, 19, 85–102. [Google Scholar] [CrossRef]

- Mukherjee, A.; Pal, A.; Misra, P. Data analytics in ubiquitous sensor- based health information systems. In Proceeding of 6th International Conference Next Generation Mobile Application Services Technology (NGMAST), 12 September 2012. [Google Scholar] [CrossRef]

- Franc, V.; Hlavac, V. Multi-class support vector machine. 2002 International Conference on Pattern Recognition, Quebec City, QC, Canada, 11 August 2002. [CrossRef]

- Rojas, R. Unsupervised learning and clustering algorithms in neural networks. Springer, 1996, 99–121. [CrossRef]

- Sharma, P. The most comprehensive guide to k-means clustering you’ll ever need. 2019. URL: https://www. Analytics vidhya. com/blog/2019/08/comprehensive guide-k-means-clustering.

- Meng, S.; Zhang, X.; Xu, M.; Pignatari, M.; Gallino, R.; Heil, M. 3rd International Conference on Automation, Control and Robotics Engineering (CACRE 2018). 2018 3rd International Conference on Automation, Control and Robotics Engineering (CACRE 2018), 2018.

- Thurzo, A.; Strunga, M.; Urban, R.; Surovková, J.; Afrashtehfar, K.I. Impact of artificial intelligence on dental education: a review and guide for curriculum update. EducationSciences 2023, 13, 150. [Google Scholar] [CrossRef]

- Stark, L.; Greene, D.; Hoffmann, A.L. Critical perspectives on governance mechanisms for AI/ML systems. The cultural life of machine learning: An incursion into critical AI studies, 2021, 257-280. [CrossRef]

- Trenta, F.; Battiato, S.; Ravì, D. An Explainable Medical Imaging Framework for Modality Classifications Trained Using Small Datasets. International Conference on Image Analysis and Processing. Cham: Springer International Publishing, 2022. [CrossRef]

- Bertassi, E. Considerations on Predictive Policing Software. Bulletin-Volume 2018, 3. [Google Scholar]

- Wieringa, R. J. Design science methodology for information systems and software engineering. Springer, 2014. [CrossRef]

- Wieringa, R. Relevance and problem choice in design science. In International Conference on Design Science Research in Information Systems, Berlin, Heidelberg: Springer Berlin Heidelberg, Germany, 4 June 2010. [CrossRef]

- Zhao, W. Artificial Intelligence and ISO 26000 (Guidance on Social Responsibility). In AI and Learning Systems-Industrial Applications and Future Directions. IntechOpen, 2021. [CrossRef]

- Tidjon, N.L; Khomh, F. Never trust, always verify: a roadmap for Trustworthy AI? arXiv preprint arXiv:2206.11981, 2022. [CrossRef]

- Thirumalai, C. ; Duba, A. ; Reddy, R. Decision making system using machine learning and Pearson for heart attack. 2017 International conference of Electronics, Communication and Aerospace Technology (ICECA). IEEE, 20 April 2017.

- Abedelgadir, M.I.O.; Mohammad, R. Operational excellence and performance measurement tool for organization self-assessment in the Sudanese aviation industry. Journal of Advanced Research in Business and Management Studies 2023, 30, 34–44. [Google Scholar] [CrossRef]

- Jaeger, A.; Matyas, K. Transformation of the EFQM approach from business towards operations excellence. Production Engineering 2016, 10, 277–291. [Google Scholar] [CrossRef]

- Ahire, S.L.; Landeros, R.; Golhar, D.Y. Total quality management: A literature review and an agenda for future research. Production Operations Management 1995, 4, 277–306. [Google Scholar] [CrossRef]

- AurelMihail, T.I.T.U.; Stanciu, A.; Tarnu, L. Improving the quality of the decision-making process for management and implementation of shared artificial intelligence platforms. In Proceedings of the international management conference, Faculty of Management, Academy of Economic Studies, Bucharest, Romania; 2020. [Google Scholar]

- Lee, C.; Kim, H.; Lee, S. Analysis of safety considerations for application of artificial intelligence in marine software systems. Journal of the Korean Society of Navigation and Port Studies 2022, 46, 269–279. [Google Scholar]

- Cortes, L.L.; Silva, C.F. Artificial intelligence models for crime prediction in urban spaces. Machine Learning and Applications: An International Journal (MLAIJ) 2021, 8. [Google Scholar] [CrossRef]

- Wahyudi, R.E.; Permanasari, V.Y. Analysis of the quality of nursing services according to hospital accreditation 2012 Version, Reviewed from Baldrige Malcolm Criteria in Pasar Minggu Jakarta Selatan Hospital in 2017. KnE Life Sciences 2017, 4, 232. [Google Scholar] [CrossRef]

- Ghufli, A.A. Implementation of business excellence model: A case study of UAE public sector organization. PhD paper, Faculty of Humanities University of Manchester, 2012.

- Goonan, K.J.; Stoltz, P.K. Leadership and management principles for outcomes-oriented organizations. Medical Care Supply 2004, 42, 31–38. [Google Scholar] [CrossRef]

- Schlesinger, M. I.; Hlavác, V. Supervised and unsupervised learning in ten lectures on statistical and structural pattern recognition. Springer Science & Business Media, 2013.

- Hong, S.J.; Choi, D.; Chae, J. Exploring different airport users’ service quality satisfaction between service providers and air travelers. Journal of Retailing and Consumer Services 2020, 52. [Google Scholar] [CrossRef]

- Brueckner, J.K.; Flores-Fillol, R. Market structure and quality determination for complementary products: Alliances and service quality in the airline industry. International Journal of Industrial Organization 2020, 68, 102557. [Google Scholar] [CrossRef]

- Kiraz, A.; Açikgöz, N. A fuzzy-logic-based approach to the EFQM model for performance enhancement. Sādhanā 2021, 46. [Google Scholar] [CrossRef]

- Lee, S.; Choi, K.S.; Kang, H.Y.; Cho, W.; Chae, Y.M. Assessing the factors influencing continuous quality improvement implementation: Experience in Korean hospitals. International Journal of Quality Health Care 2002, 14. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.T.; Wang, S.; Britton, T.; Abebe, R. Reimagining the machine learning life cycle to improve educational outcomes of students. Proceedings of the National Academy of Sciences 2023, 120, e2204781120. [Google Scholar] [CrossRef]

- Mejbel, M.K.; Abdullah, S.A.; Hussein, I.A. Evaluating the performance of people in the central bank of Iraq (Cbi) According to the European excellence model. Int.J. Prof. Bus. Rev. 2023, 8, 1. [Google Scholar] [CrossRef]

- Metaxas, I.N.; Koulouriotis, D.E. Business excellence measurement: a literature analysis (1990–2016). Total Quality Management & Business Excellence 2019, 30, 1189–1218. [Google Scholar] [CrossRef]

- Miller, J.; Parast, M.M. Learning by applying: The case of the Malcolm Baldrige national quality award. IEEE Transactions on Engineering Management 2018, 66, 337–353. [Google Scholar] [CrossRef]

- Minkman, M.; Ahaus, K.; Huijsman, R. Performance improvement based on integrated quality management models: what evidence do we have? A systematic literature review. International journal for quality in health care 2007, 19, 90–104. [Google Scholar] [CrossRef]

- Nenadál, J. The New EFQM Model: What is Really New and Could Be Considered as a suitable tool with respect to Quality 4.0 concept? Quality Innovation Prosperity 2020, 24, 17–28. [Google Scholar] [CrossRef]

- Parasuraman, A.; Zeithmal, V.A.; Berry, L. SERVQUAL: A multiple-item scale for measuring consumer perceptions of service quality. Journal of Retailing 1988, 64, 12–40. [Google Scholar]

- Parasuraman, A.; Zeithaml, V.A.; Berry, L.L. Reassessment of expectations as a comparison standard in measuring service quality: implications for further research. Journal of marketing 1994, 58, 111–124. [Google Scholar] [CrossRef]

- Zhao, W. Improving social responsibility of artificial intelligence by Using ISO 26000. IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering, 3rd International Conference on Automation, Control and Robotics Engineering (CACRE 2018), Chengdu, China, 19-22 July 2018.

- Zhang, Q.; Yang, L.T.; Chen, Z.; Li, P. A survey on deep learning for big data. Information Fusion, Elsevier 2018, 42, 146–157. [Google Scholar] [CrossRef]

| Name of paper | Country/Year | Author/ Publisher |

General Description | Applied Area/Field |

Strengths of applied technique/ Method |

Challenges/ Limitation |

|---|---|---|---|---|---|---|

| 1-The Impacts of Robotics, Artificial Intelligence on Business and Economics [17]. | Turkey, 2015 | (Dirican C., 2015), Elsevier | Injecting AI concepts into economical concepts | Economics | Enhance different economical perspectives. | Increased unemployment |

| 2- Decision Making System using Machine Learning and Pearson for Heart Attack [41]. | India, 2017 | (Thirumalai C., et al., 2017), IEEE | Using machine learning to predict heart attacks of patients. SPSS used for data validation | Healthcare | Get predicted medical results from scanning directly on phone application, so helps in decision making |

N/A |

| 3- Intelligent human resource information system (i-HRIS): A holistic decision support framework for HR excellence [18]. | Malaysia, 2018 | (Masum M., et al., 2018), Researchgate | Integrating intelligent HR with intelligent decision making with knowledge discovery database | Human Resources, Artificial intelligence. | Improve structured, semi-structured, and unstructured HR decision making process. | Data can be used to predict suitable AI techniques to be used. The model can be broader by using wireless protocols. |

| 4- Artificial intelligence and the future of global health [15]. | USA, 2020 | (Schwalbe N., and Wah B., 2020), Elsevier | AI into global health categories | Healthcare | Accelerate sustainability. Improved health outcomes |

No ethical considerations |

| 5-Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities [19]. | South Africa, 2020 | (Bag S., et al, 2020), Elsevier | Description of reasons why firms use AI into manufacturing. | Manufacturing | Enhance sustainable manufacturing and develop circular economy. | Low skill level |

| 6-A strategic framework for artificial intelligence in marketing [24]. | Taiwan, USA, 2020 | (Huang M., and Rust R., 2020), Springer | Injecting AI techniques into strategic marketing planning | Marketing | Enhance strategic marketing process | Biased, less human intervention |

| 7- Artificial Intelligence Forecasting Census and Supporting Early Decisions [20]. | USA, 2020 | (Griner T., et al., 2020), Wolters Kluwer Health | Alex is an AI technique that helps nurses for occupancy prediction and decision making. | Healthcare, Nursing. | Enhance operational excellence, and safety | N/A |

| 8-Manufacturing service innovation platform based on 5 G network and machine learning [16] | China, 2020 | (Gao N., et al., 2020), Elsevier | Using AI to organize innovation and achieve organizational excellence | Manufacturing, services. | Enhance customer satisfaction, service innovation, and organizational performance. | N/A |

| 9- Artificial Intelligence (AI) and Its Applications in Indian Manufacturing: A Review [21] | India, 2021 | (Rizvi A., et al., 2021), Springer | AI integrated into manufacturing firms in India | Manufacturing | Improve quality and reduce errors | High installation cost and maintenance. |

| 10- Predicting the COVID-19 infection with fourteen clinical features using machine learning classification algorithms [22]. | China, 2021 | (Arpaci I., Huang S., Al-Emran M., Al-Kabi M, 2021), Springer | AI model is used to predict COVID 19 from 14 criteria with limited testing resources | Medicine, Healthcare |

Predict COVID 19 cases ahead of time when RT-PCT kids are limited. | Low sample size. Unavailable data about COVID 19 symptoms in predicting the infection. |

| 11- Applications of Explainable Artificial Intelligence in Diagnosis and Surgery [23]. | China, UK,2022 | (Zhang, Y.;Weng, Y.; Lund, J.,2022), Diagnostics | Apply AI in surgeries | Medicine, Healthcare | Usage of AI in surgeries | N/A |

| 12-Impact of Artificial Intelligence on Dental Education: A Reviewand Guide for Curriculum Update [35]. | (Thurzo, A.; Strunga, M.; Urban, R.; Surovková, J.; Afrashtehfar, K.I., 2023), Education Sciences | Usage of AI in dentistry | Medicine , Dentistry | Usage of AI in new fields in medicine. | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).