Submitted:

03 January 2024

Posted:

04 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Raw Materials

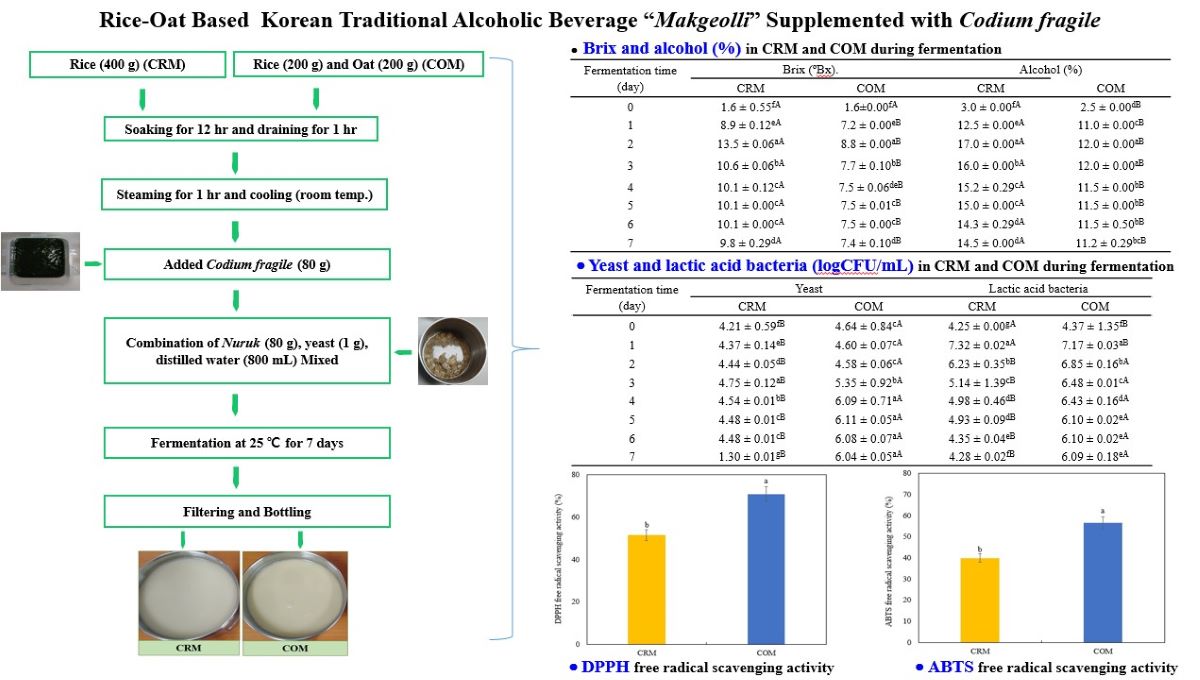

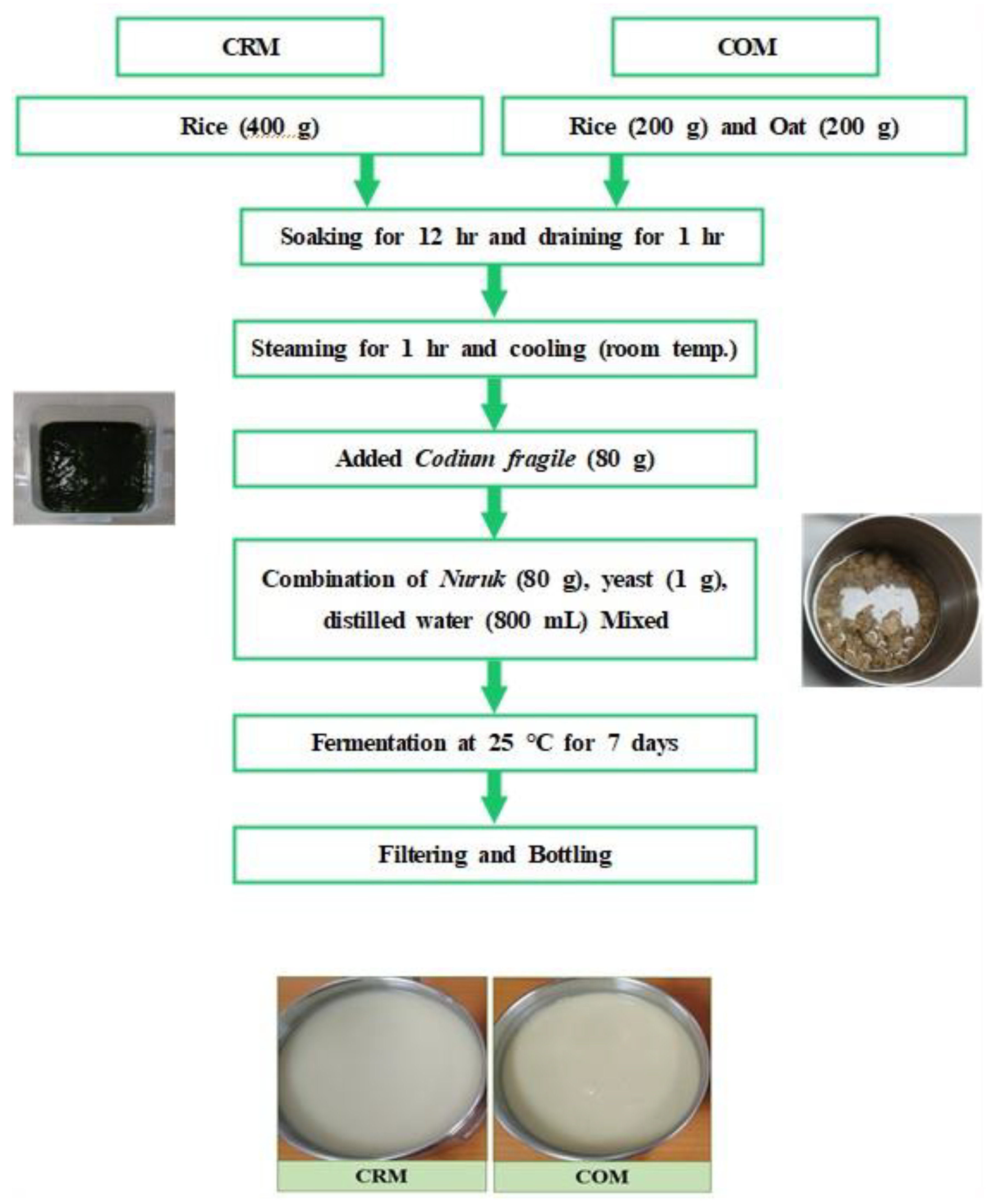

2.2. Production of Rice-Oat Makgeolli with Cf

2.3. Analysis of Physicochemical Quality Characteristics

2.3.1. pH Value and Acidity

2.3.2. Brix and Alcohol Content

2.4. Analysis of Microbiological Quality Characteristics

2.5. Analysis of Antioxidant Quality Characteristics

2.5.1. DPPH Radical Scavenging Ability

2.5.2. ABTS Radical Scavenging Ability

2.6. Sensory Characteristics

2.7. Statistical Analysis

3. Results and Discussion

3.1. Changes in pH and Total Acid Content During Fermentation

3.2. Changes in the Sugar Content during Fermentation

3.3. Changes in Alcohol Content during Fermentation

3.4. Changes in the Number of Yeast and Lactic Acid Bacteria during Fermentation

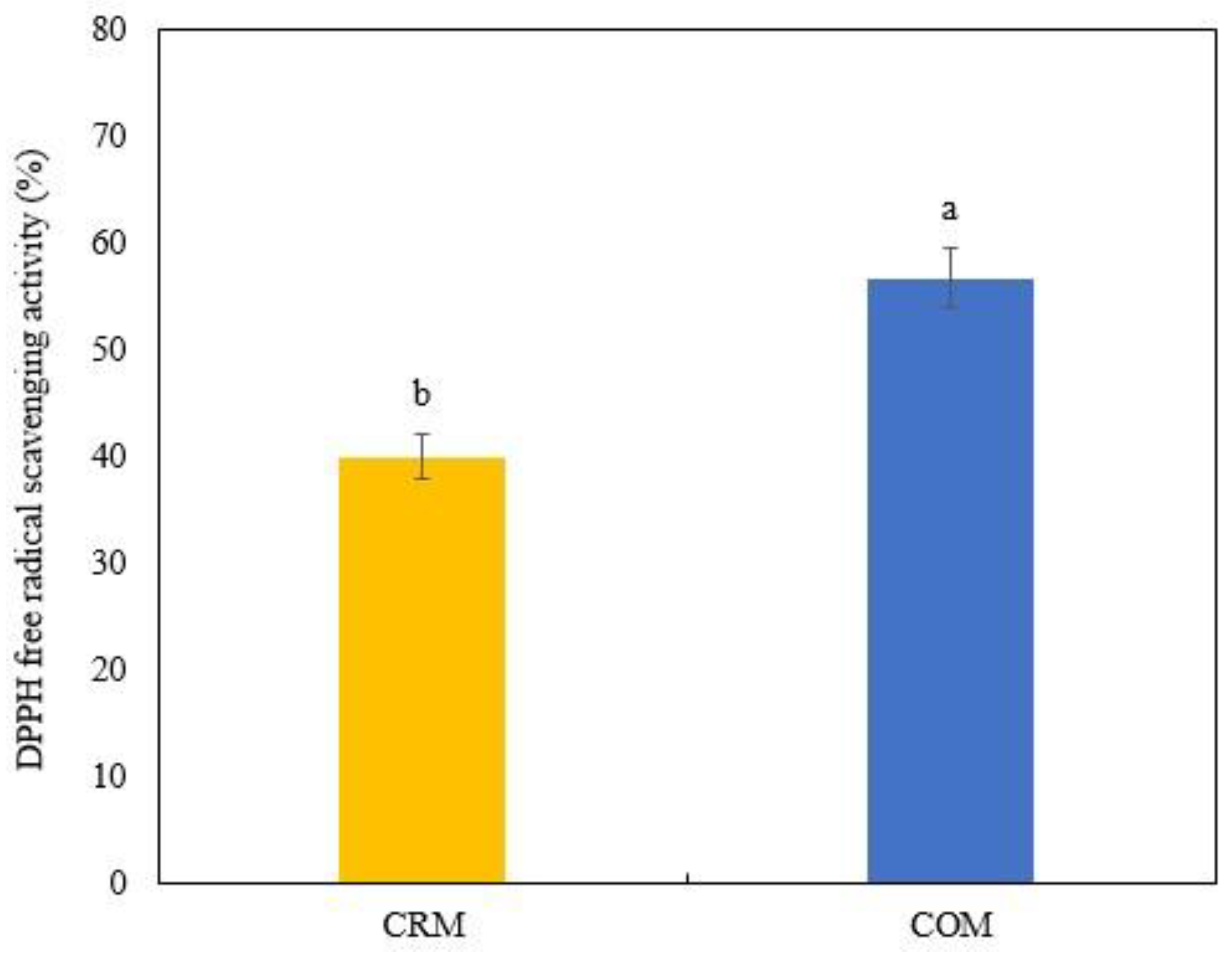

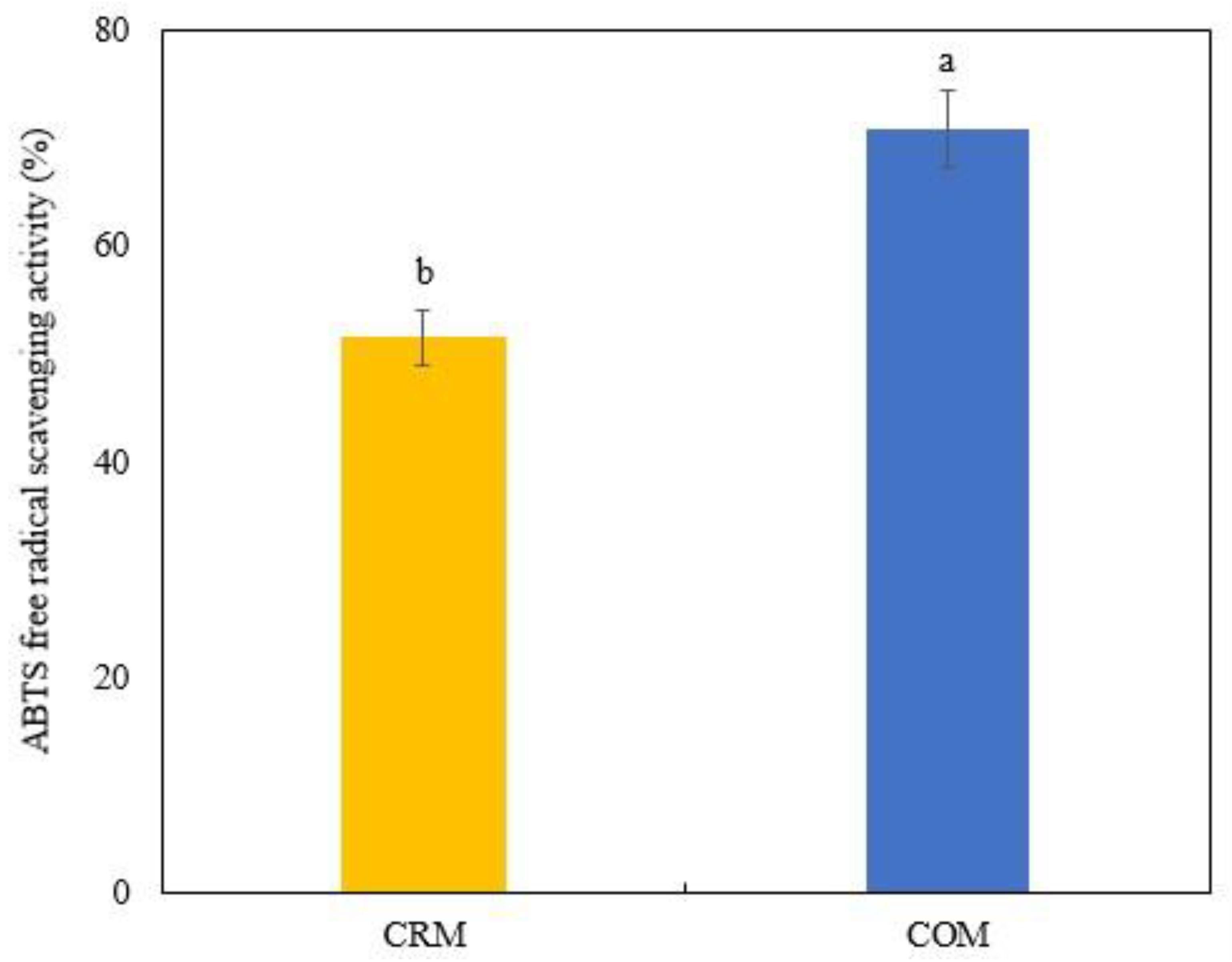

3.5. Changes in Antioxidant Activity (DPPH/ABTS Radical Scavenging Activity) during Fermentation

3.6. Sensory Evaluation

4. Conclusions

References

- Koo, HyunMi. 2012. Quality characteristics of Makgeolli added with polygonatum odoratum. Ph.D. thesis, University of Myongji, Seoul, Korea, August.

- Jun, E.B.; Choi, M.S.; Park, S.Y. Quality and antioxidant effects of the Korean traditional rice wine Makgeolli supplemented with Codium fragile during fermentation. Korean J. Fish. Aquat. Sci. 2019, 52, 224–231. [Google Scholar] [CrossRef]

- Lee, T.J.; Hwang, D.Y.; Lee, C.Y.; Song, H.J. Changes in yeast cell number, total acid and organic acid during production and distribution processes of Makgeolli, traditional alcohol of Korea. Korean J. Microbiol. 2009, 45, 391–396. [Google Scholar]

- Cho, H.K.; Lee, J.Y.; Seo, W.T.; Kim, M.K.; Cho, K.M. Quality characteristics and antioxidant effects during Makgeolli fermentation by purple sweet potato-rice Nuruk. Korean J. Food Sci. Technol. 2012, 44, 728–735. [Google Scholar] [CrossRef]

- Yeo, S.H.; Jeong, Y.J. Current trends and development a plan in the Korean Makgeolli industry. Food Sci. Ind. 2010, 43, 55–64. [Google Scholar]

- Kim, Y.J.; Jeong, E.S.; Choi, E.S.; Gal, S.W.; Choi, Y.J. Studies of antioxidant activity and inhibition of nitric oxide synthesis from Codium fragile. J. Sci. 2006, 5, 788–793. [Google Scholar] [CrossRef]

- Oh, S.W.; Kim, S.K.; Jung, K.J.; Pham, T.N.A.; Yang, S.W.; Ahn, B.J. Potential prebiotic and anti-obesity effects of Codium fragile extract. Appl. Sci. 2022, 12, 959. [Google Scholar] [CrossRef]

- Park, D.B.; Lee, Y.J.; Rho, J.W.; Kim, W.S.; Park, S.J.; Kim, Y.T. Comparison of antioxidant and physiological activities of different solvent extracts from Codium fragile. Korean J. Fish. Aquat. Sci. 2022, 55, 858–866. [Google Scholar]

- Lee, J.H.; Kim, B.A. A study on seaweed sea staghorn (Codium fragile) ethanol extract for antioxidant. J. Converg. Cul. Technol. 2019, 5, 467–472. [Google Scholar] [CrossRef]

- Choi, M.S.; Jeon, E.B.; Kim, J.Y.; Park, S.Y. Quality and antioxidant activity of soybean curd supplemented with Codium fragile. Korean J. Fish. Aquat. Sci. 2020, 53, 816–822. [Google Scholar] [CrossRef]

- Lee, D.H.; Jeon, E.B.; Kim, J.Y.; Song, M.G.; Kim, Y.Y.; Park, S.Y. Quality characteristics and antioxidant effects of bread containing Codium fragile powder. Korean J. Fish. Aquat. Sci. 2021, 54, 890–895. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, B.G.; Lee, B.W.; Kim, H.J.; Park, J.Y.; Han, S.I.; Lee, Y.Y. Evaluation of bioactive compounds and antioxidant activity of roasted oats in different extraction solvents. Korean J. Food Sci. Technol. 2018, 50, 111–116. [Google Scholar] [CrossRef]

- Seo, SangHyun. 2019. Abenanthramide, a substance containing oats, is effective in preventing dementia. Korea farmers and fishermen newspaper, December 10, p. 7. http://www.agrinet.co.kr/news/articleView.html?idxno=173406. 10 December.

- Lee, J.H.; Son, Y.R.; Lee, B.G.; Lee, B.W.; Kim, H.J.; Park, J.Y.; Lee, H.S.; Kim, J.S.; Park, H.H.; Han, O.K.; Han, S.I.; Lee, Y.Y. Analysis of total polyphenol content and antioxidant activity in puffed oats. Korean J. Food Sci. Technol. 2018, 50, 117–121. [Google Scholar]

- National institute of food science, agricultural promotion agency. 2017. Diversification of food materials for new demands in domestic oat. PJ010508. Wanju, Korea: National Institute of Agriculture Sciences.

- Lee, S.I.; An, W.H.; Kim, S.H. Formulating strategy to strengthen global competitiveness for Korean Makgeolli industry. J. Int. Trade & Commer. 2015, 11, 171–193. [Google Scholar]

- Yeo, S.H.; Jeong, Y.J. Current trends and development a plan in the Korean Makgeolli industry. Food Sci. Ind. 2010, 43, 55–64. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, J.H.; Lee, J.S. Effect of pears on the quality and physiological functionality of Makgeolli. Korean J. Food Nutr. 2009, 22, 606–611. [Google Scholar]

- Kim, S.Y.; Kim, E.K.; Yoon, S.J.; Jo, N.J.; Jung, S.K.; Kwon, S.H.; Chang, Y.H.; Jeong, Y.H. Physicochemical and microbial properties of Korean traditional rice wine, Makgeolli, supplemented with cucumber during fermentation. J. Korean Soc. Food Sci. Nutr. 2011, 40, 223–228. [Google Scholar] [CrossRef]

- Jeon, M.H.; Lee, W.J. Characteristics of blueberry added Makgeolli. J. Korean Soc. Food Sci. Nutr. 2011, 40, 444–449. [Google Scholar] [CrossRef]

- Kim, S.H.; Jeon, E.B.; Song, M.G.; Park, S.Y. Quality characteristics and antioxidant activity of the traditional Korean rice wine Makgeolli containing lotus leaf Nelumbo nucifera powder during fermentation. Korean J. Fish. Aquat. Sci. 2022, 55, 769–776. [Google Scholar] [CrossRef]

- Jeon, E.B.; Song, M.S.; Kim, S.H.; Choi, J.S.; Lee, J.S.; Park, S.Y. Quality characteristics and antioxidant activities of Korean traditional rice and quinoa-based wine “Makgeolli”. Cereal Chem. 2023, 100, 473–483. [Google Scholar] [CrossRef]

- Kim, M.H.; Lee, M.H. Quality changes during alcohol fermentation of Takju using oat. J. Soc. Sci. 2022, 7, 213–225. [Google Scholar] [CrossRef]

- Kim, O.S.; Park, S.S.; Sung, J.M. Antioxidant activity and fermentation characteristics of traditional black rice wine. J. Korean Soc. Food Sci. Nutr. 2012, 41, 1693–1700. [Google Scholar] [CrossRef]

- Baek, C.H.; Choi, J.H.; Choi, H.S.; Jeong, S.T.; Kim, J.H.; Jeong, Y.J.; Yeo, S.H. Quality characteristics of brown rice Makgeolli produced under differing conditions. Korean J. Microbiol. Biotechnol. 2013, 41, 168–175. [Google Scholar] [CrossRef]

- Shin, D.S.; Choi, Y.J.; Jeong, S.T.; Sim, E.Y.; Lee, S.K.; Kim, H.J.; Woo, K.S.; Kim, S.J.; Oh, S.K.; Park, H.Y. Quality characteristics of mixed Makgeolli with barley and wheat. Korean J. Food Nutr. 2016, 29, 565–572. [Google Scholar] [CrossRef]

- Chen, Ying. ; Hwang, J.N.; Chang, Y.H. Quality characteristics of Makgeolli added with red bean. Korean J. Food Cook. Sci. 2013, 29, 777–784. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, H.Y. pH, acidity, color, amino acids, reducing sugars, total sugars, and alcohol in puffed millet powder containing millet Takju during fermentation. Korean J. Food Sci. Technol. 2010, 42, 727–732. [Google Scholar]

- Cho, H.K.; Lee, J.Y.; Seo, W.T.; Kim, M.K.; Cho, K.M. Quality characteristics and antioxidant effects during Makgeolli fermentation by purple sweet potato-rice Nuruk. Korean J. Food Sci. Technol. 2012, 44, 728–735. [Google Scholar] [CrossRef]

- Choi, J.S.; Seo, H.J.; Lee, Y.R.; Kwon, S.J.; Moon, S.H. Characteristics and in vitro anti-diabetic properties of the Korean rice wine, Makgeolli fermented with Laminaria japonica. Prev. Nutr. Food Sci. 2014, 19, 98–107. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.H.; Ko, S.H.; Kim, H.L.; Lee, H.L.; Hyun, T.H.; Kim, Y.S.; Oh, J.M.; Kim, H.C.; Ko, S.B.; Lee, S.J.; Jo, J.W. Design of marketing contents for functional rice wine from Ecklonia cava. Korea Acad. Ind. Coop. Soc. 2010, 49–52. [Google Scholar]

- Kim, J.Y.; Jeon, E.B.; Choi, M.S.; Park, S.Y. Effect of Enteromorpha prolifera on quality characteristics and antioxidants activities of the Makgeolli (Korean traditional rice-based wine). Korean J. Fish. Aquat. Sci. 2020, 53, 231–236. [Google Scholar]

- Kang, D.H.; Park, E.M.; Kim, J.H.; Kim, J.W. Bioactive compounds and antioxidant activity of Jeju camellia mistletoe (Korthalsella japonica Eng1). J. Life Sci. 2016, 26, 1074–1081. [Google Scholar] [CrossRef]

- Choi, K.W.; Jun, K.L.; Jo, H.J.; Lee, K.J.; Yoon, J.A.; An, J.H.; Chung, K.H. Fermentation characteristics of Makgelli made with loquat fruits (Eriobotrya Japonica Lindley). J. Korean Soc. Food Sci. Nutr. 2013, 42, 975–982. [Google Scholar] [CrossRef]

- Jeong, J.W.; Park, K.J.; Kim, M.H.; Kim, D.S. Quality characteristics of Takju fermentation by addition of chestnut peel powder. Korean J. food preserv. 2006, 13, 329–336. [Google Scholar]

- Kim, H.S.; Choi, J.S.; Yu, S.H.; Kim, M.K.; Lim, B.R.; Jeong, S.T. Change is quality characteristics of ‘Makgeolli’ prepared by independent two-step fermentation during storage. Korean J. Food Preserv. 2020, 27, 685–693. [Google Scholar] [CrossRef]

- Park, M.J.; Kim, H.K.; Choi, K.K.; Koo, B.J.; Lee, S.K. Fermentation characteristics of Makgelli containing Aronia (Aronia melanocarpa, Black chokoberry). Korean J. Food Sci. Technol. 2016, 48, 27–35. [Google Scholar] [CrossRef]

- Ha, S.J.; Yang, S.K.; In, Y.W.; Kim, Y.J.; Oh, S.W. Changes in microbial and physicochemical properties of single-brewed Makgeolli by high hydrostatic pressure treatment during fermentation. J. Korean Soc. Food Sci. Nutr. 2012, 41, 1176–1181. [Google Scholar] [CrossRef]

- Kwon, Y.H.; Lee, A.R.; Kim, J.H.; Kim, H.R.; Ahn, B.H. Changes of physicochemical properties and microbial during storage of commercial Makgeolli. Korean J. Mycol. 2012, 40, 210–214. [Google Scholar] [CrossRef]

- Kim, M.H.; Lee, M.H. Quality changes during alcohol fermentation of Takju using oat. J. Sci. 2022, 7, 213–225. [Google Scholar] [CrossRef]

- National institute of agricultural science. Food standards and standards notification. https://koreanfood.rda.go.kr/eng/fctFoodSrchEng/list (accessed on 10 August 2023).

- Kim, E.K.; Chang, Y.H.; Ko, J.Y.; Jeong, Y.H. Physicochemical and microbial properties of Korean traditional rice wine, Makgeolli, supplemented with mulberry during fermentation. J. Korean Soc. Food Sci. Nutr. 2013, 42, 1682–1689. [Google Scholar] [CrossRef]

- Kim, I.H.; Park, W.S.; Koo, Y.J. Comparison of fermentation characteristics of Korean traditional alcoholic beverages prepared by different brewing methods and their quality changes after aging. Korean J. Diet. Cult. 1996, 11, 4. [Google Scholar]

- Park, MiJung. 2015. Fermentation characteristics of Makgeolli containing Aronia (Black chokeberry). Ph.D. thesis, University of Konkuk, Seoul, Korea, February.

- Ham, H.M.; Woo, K.S.; Lee, B.W.; Park, J.Y.; Sim, E.Y.; Kim, B.J.; Lee, C.W.; Kim, S.J.; Kim, W.H.; Lee, J.S.; Lee, Y.Y. Antioxidant compounds and activities of methanolic extracts from oat cultivars. J. Korean Soc. Food Sci. Nutr. 2015, 44, 1660–1665. [Google Scholar] [CrossRef]

- Lee, D.H.; Jeon, E.B.; Kim, J.Y.; Song, M.G.; Kim, Y.Y.; Park, S.Y. Quality characteristics and antioxidant effects of bread containing Codium fragile powder. Korean J. Fish. Aquat. Sci. 2021, 54, 890–895. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, J.Y.; Jeon, E.B.; Song, M.G.; Park, S.Y. Quality and antioxidant activity of soybean curd supplemented with Gloiopeltis furcata juice. J. Korean Soc. Fish. Mar. Edu. 2021, 33, 1326–1334. [Google Scholar] [CrossRef]

- Kim, Y.J.; Jeong, I.S.; Choi, E.S.; Gal, S.W.; Choi, Y.J. Studies on antioxidant activity and inhibition of nitric oxide synthesis from Codium fragile. J. Life Sci. 2006, 16, 788–793. [Google Scholar] [CrossRef]

- Kim, M.S.; Kim, K.M.; Han, D.H.; Ko, K.W.; Kim, S.S. Antibacterial activity and other functions of Codium fragile and Chaenomeles sinensis extracts by extraction meth. Korean Soc. Biotechnol. Bioeng. 2018, 33, 89–94. [Google Scholar]

- Lee, J.H.; Lee, B.K.; Lee, B.W.; Kim, H.J.; Park, J.Y.; Han, S.I.; Lee, Y.Y. Evaluation of bioactive compounds and antioxidant activity of roasted oats in different extraction solvents. Korean J. Food Sci. Technol. 2018, 50, 111–116. [Google Scholar] [CrossRef]

- Kim, E.J.; Choi, J.Y.; You, M.L.; Kim, M.Y.; Lee, S.H.; Lee, B.H. Total polyphenols, total flavonoid contents, and antioxidant activity of Korean natural and medicinal plants. Korean J. Food Sci. Technol. 2012, 44, 337–342. [Google Scholar] [CrossRef]

| Fermentation Time (day) | pH | Acidity (%) | ||

|---|---|---|---|---|

| CRM | COM | CRM | COM | |

| 0 | 5.28 ± 0.00aA | 4.85 ± 0.00aB | 0.20 ± 0.00eA | 0.19 ± 0.00eB |

| 1 | 5.08 ± 0.01bA | 4.69 ± 0.00bB | 0.27 ± 0.03fA | 0.19 ± 0.05eB |

| 2 | 3.57 ± 0.01fB | 3.63 ± 0.01efA | 0.86 ± 0.01aA | 0.82 ± 0.02aB |

| 3 | 3.54 ± 0.02gB | 3.62 ± 0.01fA | 0.86 ± 0.01aA | 0.82 ± 0.02aB |

| 4 | 3.58 ± 0.01fB | 3.64 ± 0.01eA | 0.80 ± 0.02abA | 0.77 ± 0.01bB |

| 5 | 3.62 ± 0.02eB | 3.66 ± 0.00dA | 0.78 ± 0.01bcA | 0.71 ± 0.01cB |

| 6 | 3.69 ± 0.01cB | 3.67 ± 0.01dA | 0.72 ± 0.00cdA | 0.67 ± 0.02dB |

| 7 | 3.66 ± 0.03dB | 3.69 ± 0.01cA | 0.68 ± 0.02dA | 0.65 ± 0.01dB |

| Fermentation Time (day) | Brix (ºBx). | Alcohol (%) | ||

|---|---|---|---|---|

| CRM | COM | CRM | COM | |

| 0 | 1.6 ± 0.55fA | 1.6±0.00fA | 3.0 ± 0.00fA | 2.5 ± 0.00dB |

| 1 | 8.5 ± 0.12eA | 7.2 ± 0.00eB | 12.5 ± 0.00eA | 11.0 ± 0.00cB |

| 2 | 13.5 ± 0.06aA | 8.8 ± 0.00aB | 17.0 ± 0.00aA | 12.0 ± 0.00aB |

| 3 | 10.6 ± 0.06bA | 7.7 ± 0.10bB | 16.0 ± 0.00bA | 12.0 ± 0.00aB |

| 4 | 10.1 ± 0.12cA | 7.5 ± 0.06deB | 15.2 ± 0.29cA | 11.5 ± 0.00bB |

| 5 | 10.1 ± 0.00cA | 7.5 ± 0.01cB | 15.0 ± 0.00cA | 11.5 ± 0.00bB |

| 6 | 10.1 ± 0.00cA | 7.5 ± 0.00cB | 14.3 ± 0.29dA | 11.5 ± 0.50bB |

| 7 | 9.8 ± 0.29dA | 7.4 ± 0.10dB | 14.5 ± 0.00dA | 11.2 ± 0.29bcB |

| Fermentation Time (day) | Yeast | Lactic Acid Bacteria | ||

|---|---|---|---|---|

| CRM | COM | CRM | COM | |

| 0 | 4.21 ± 0.59fB | 4.64 ± 0.84cA | 4.37 ± 0.00eA | 4.20± 1.35fB |

| 1 | 4.37 ± 0.14eB | 4.60 ± 0.07cA | 7.32 ± 0.02aA | 7.17 ± 0.03aB |

| 2 | 4.44 ± 0.05dB | 4.58 ± 0.06cA | 6.23 ± 0.35bB | 6.85 ± 0.16bA |

| 3 | 4.75 ± 0.12aB | 5.35 ± 0.92bA | 5.14 ± 1.39cB | 6.48 ± 0.01cA |

| 4 | 4.54 ± 0.01bB | 6.09 ± 0.71aA | 4.98 ± 0.46dB | 6.43 ± 0.16dA |

| 5 | 4.48 ± 0.01cB | 6.11 ± 0.05aA | 4.93 ± 0.09dB | 6.10 ± 0.02eA |

| 6 | 4.48 ± 0.01cB | 6.08 ± 0.07aA | 4.35 ± 0.04eB | 6.10 ± 0.02eA |

| 7 | 1.30 ± 0.01gB | 6.04 ± 0.05aA | 4.28 ± 0.02fB | 6.09 ± 0.18eA |

| Properties | Taste Tests | ||||

|---|---|---|---|---|---|

| Color | Smell | Taste | Appearance | Overall Acceptability | |

| CRM | 3.81 ± 0.75b | 4.31 ± 0.48b | 5.06 ± 0.25b | 4.94 ± 0.68a | 4.93 ± 0.68b |

| COM | 5.37 ± 0.50a | 5.88 ± 0.50a | 6.00 ± 0.52a | 5.50 ± 0.89a | 6.06 ± 0.44a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).