Submitted:

27 December 2023

Posted:

29 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental

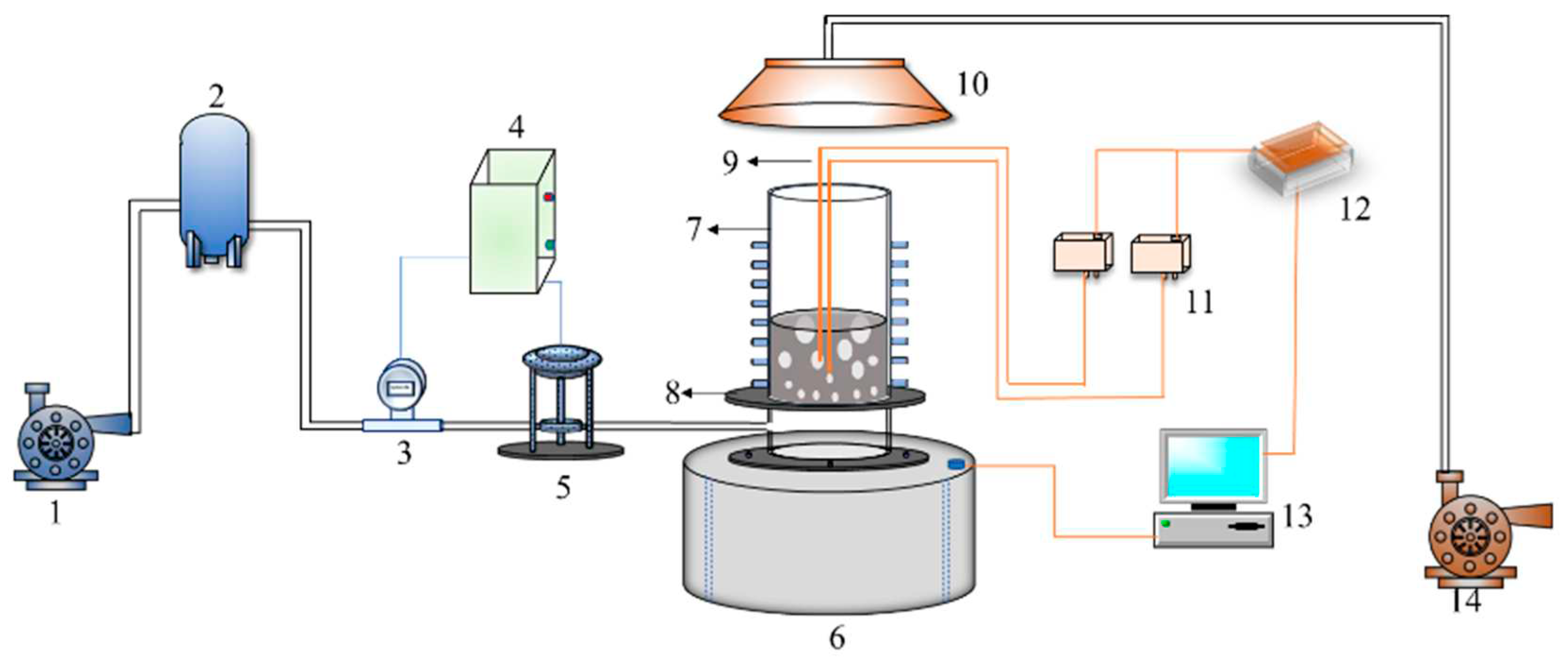

2.1. Vibration Fluidization System

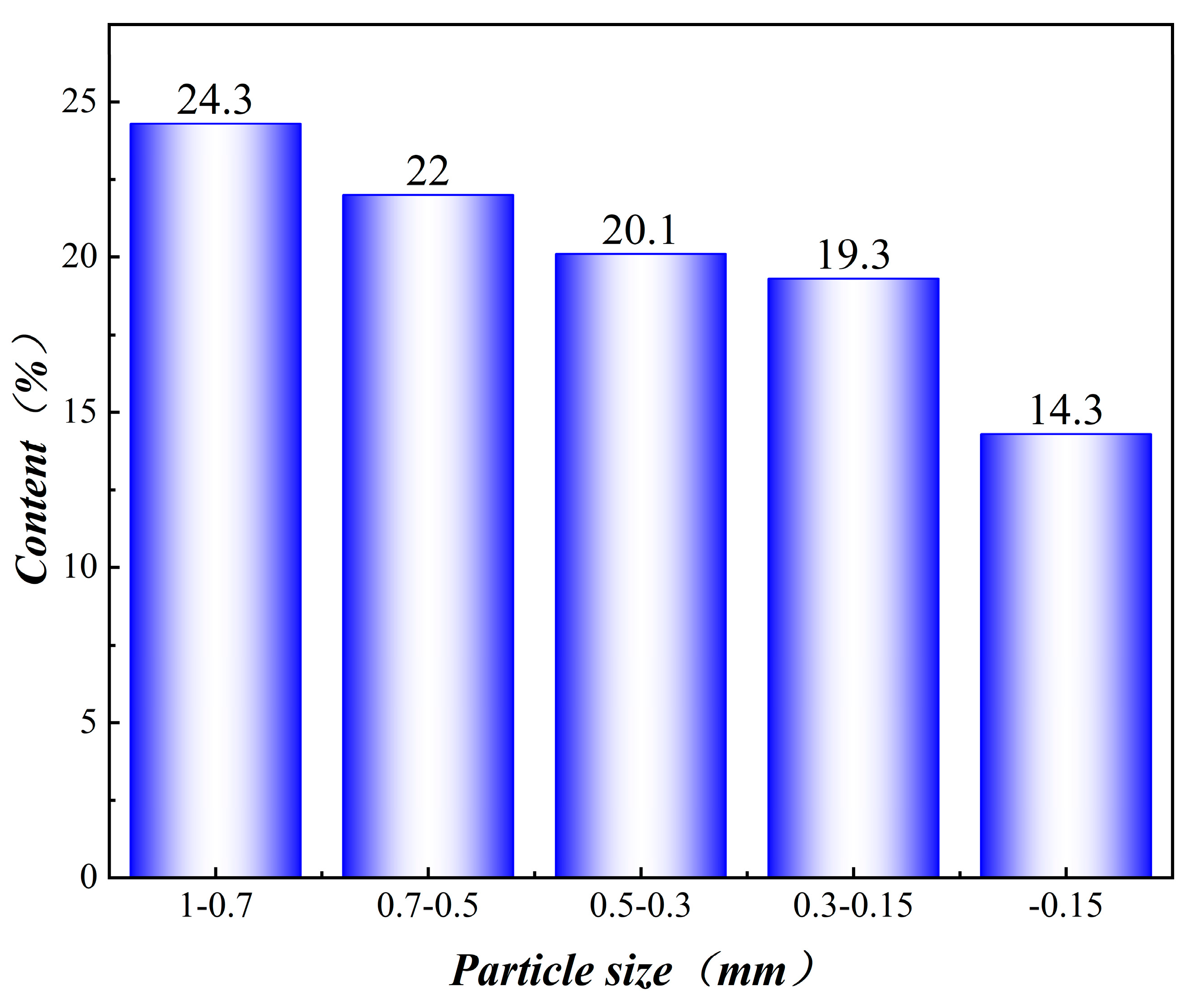

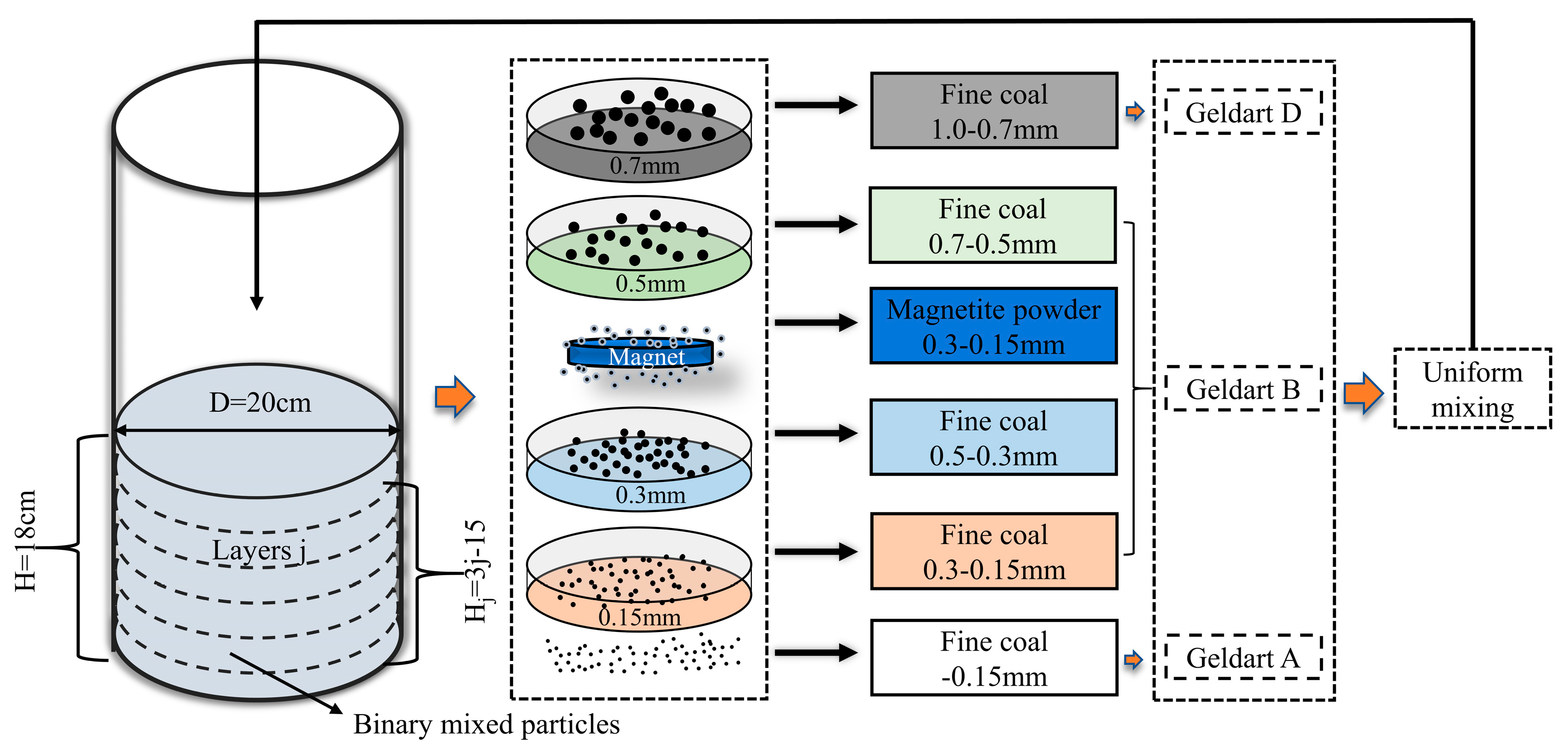

2.2. Material and Experimental Parameter Design

2.3. Evaluation Index

3. Results and Discussion

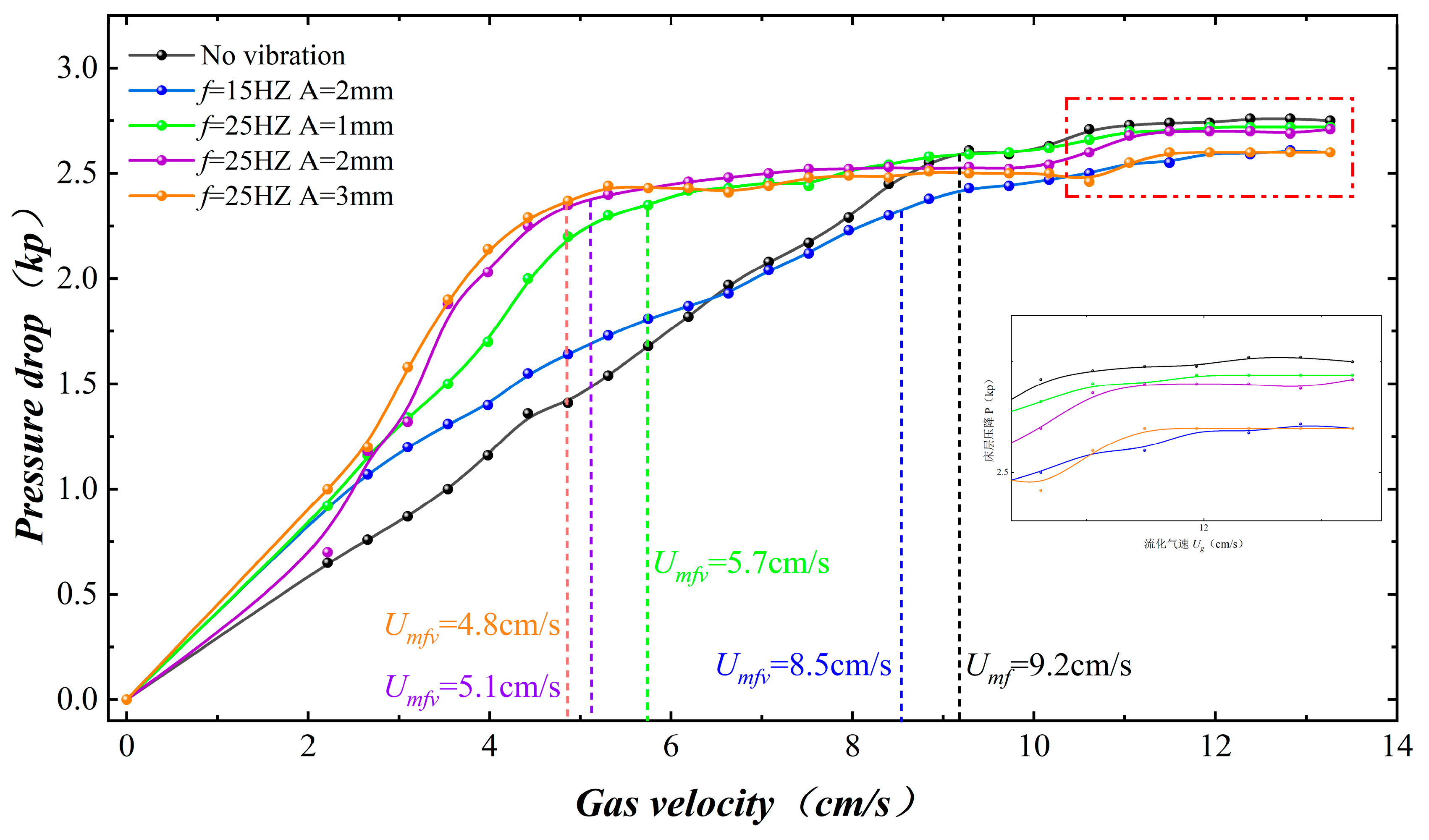

3.1. Vibration Fluidization Characteristics of Wide-Scale Dense Medium

3.2. Influence Law of Vibration on Axial Mixing of Wide-Grained Dense Medium

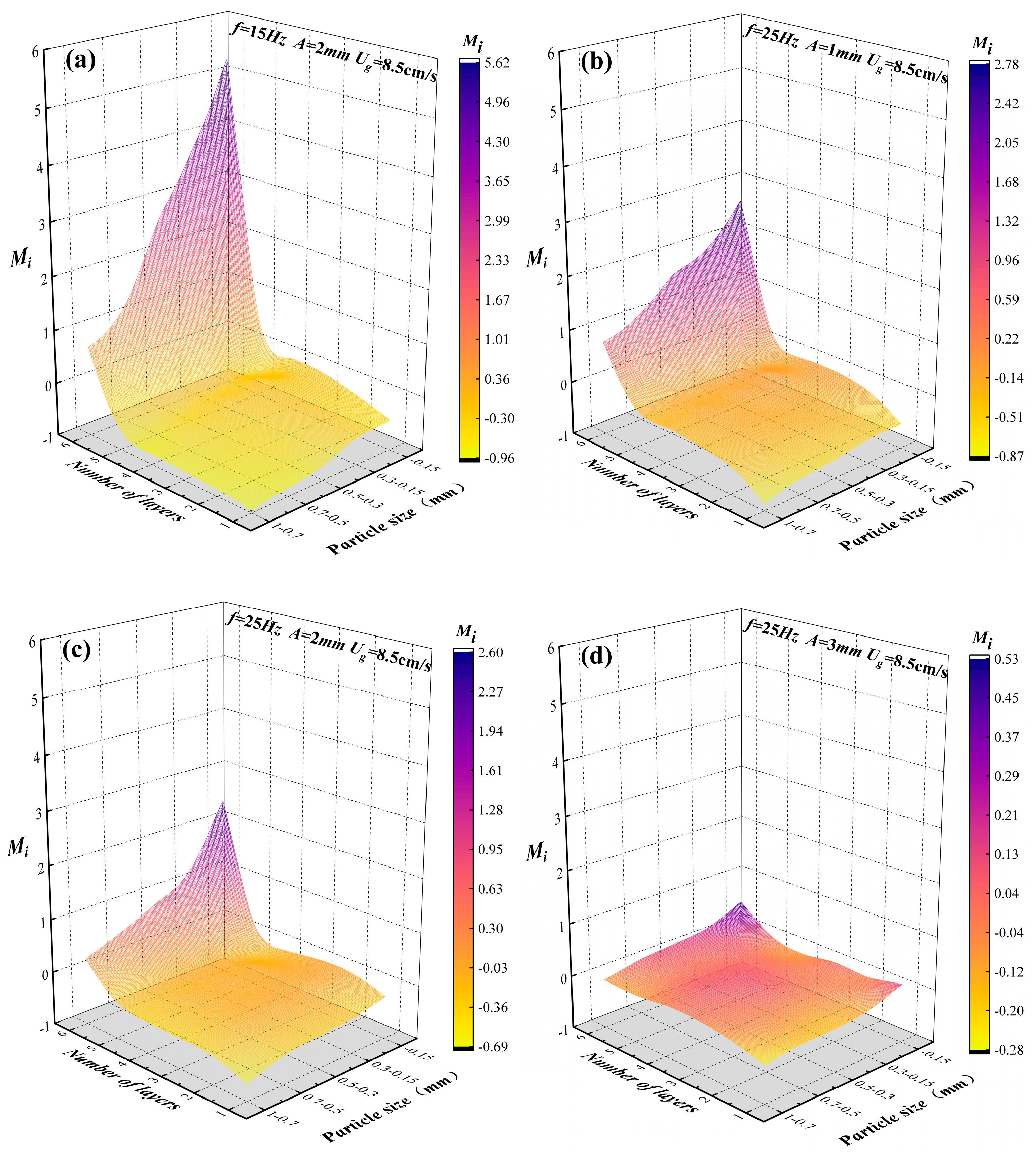

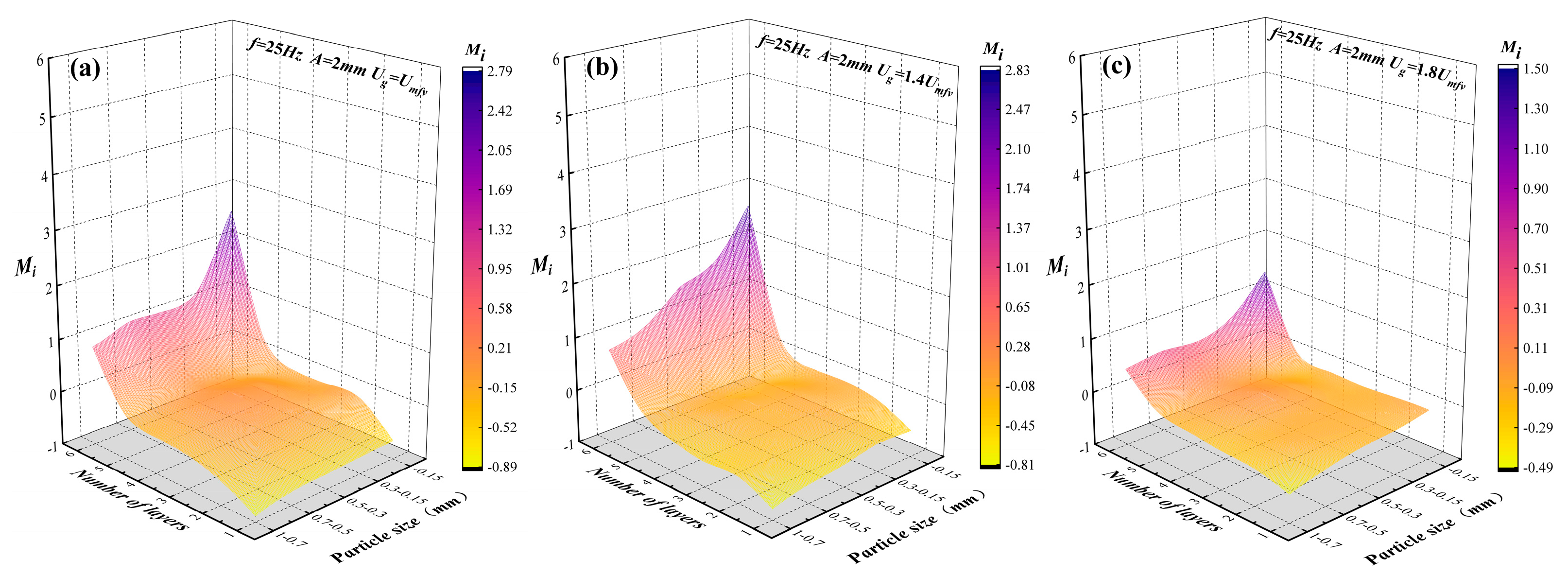

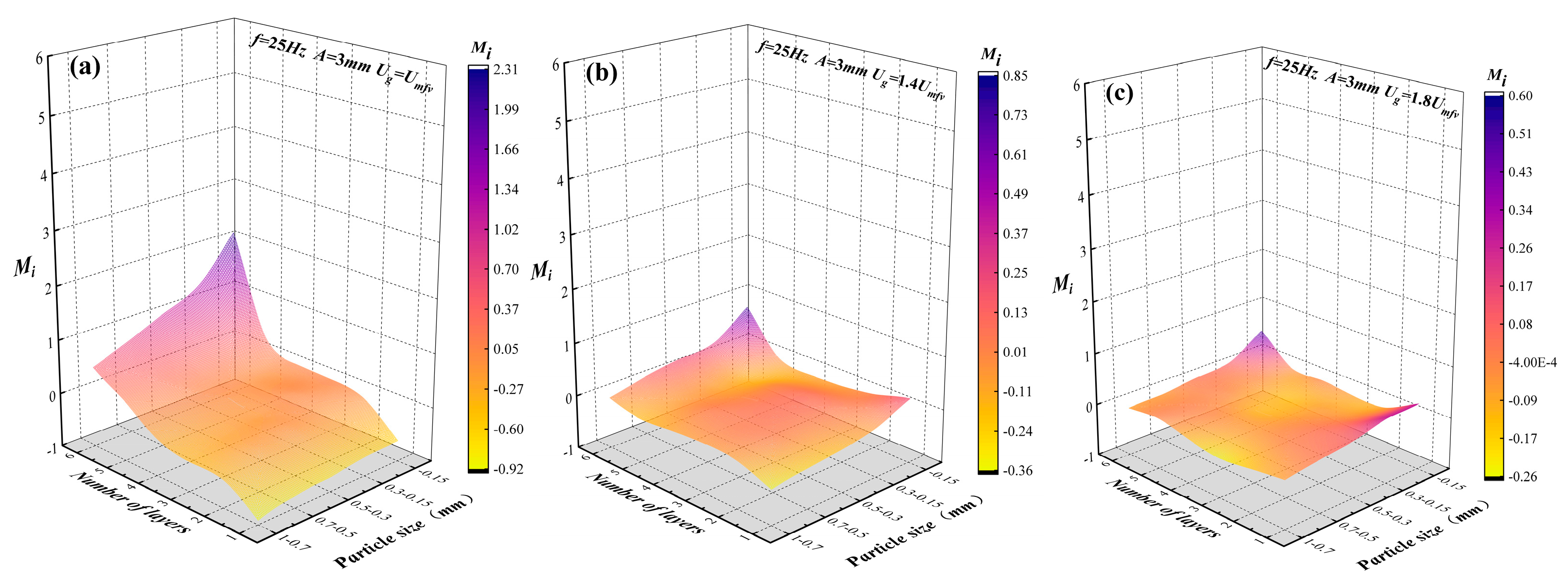

3.2.1. Effect of Vibration on the Local Mixing Indices

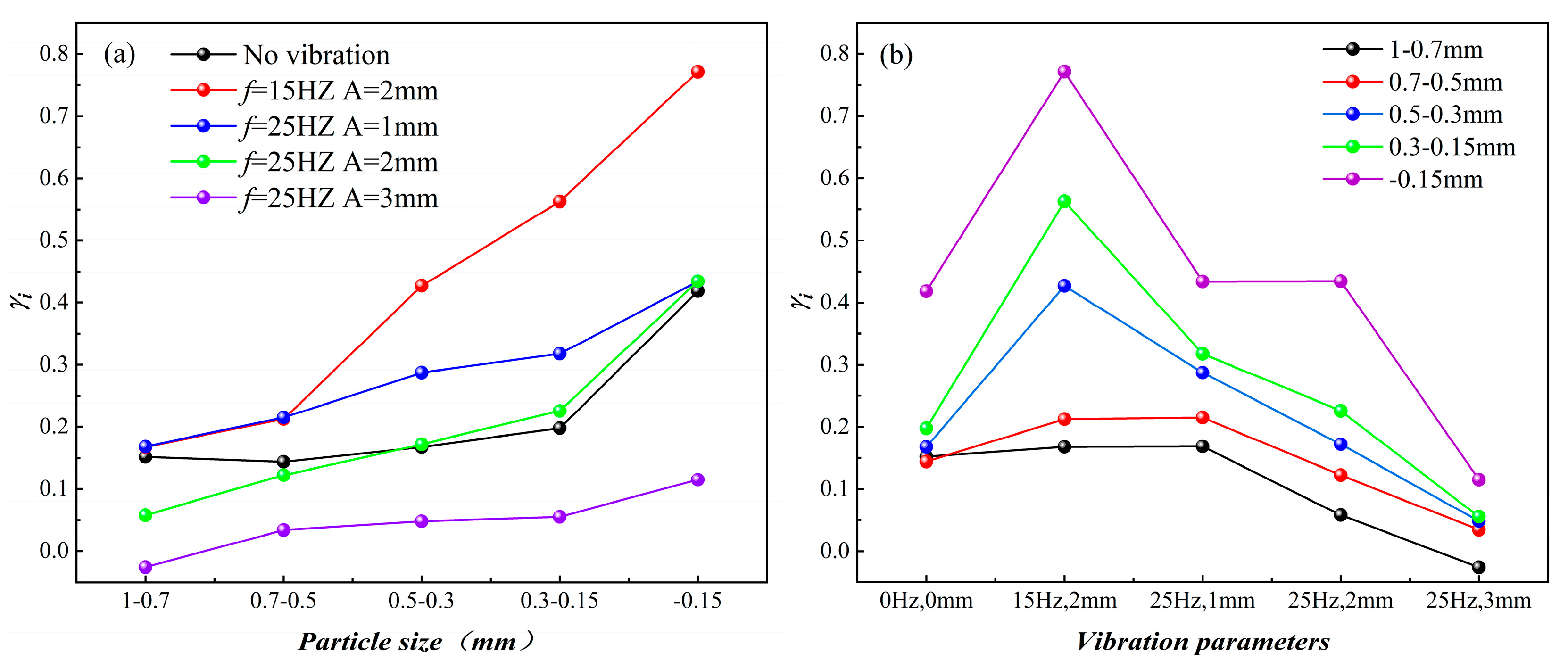

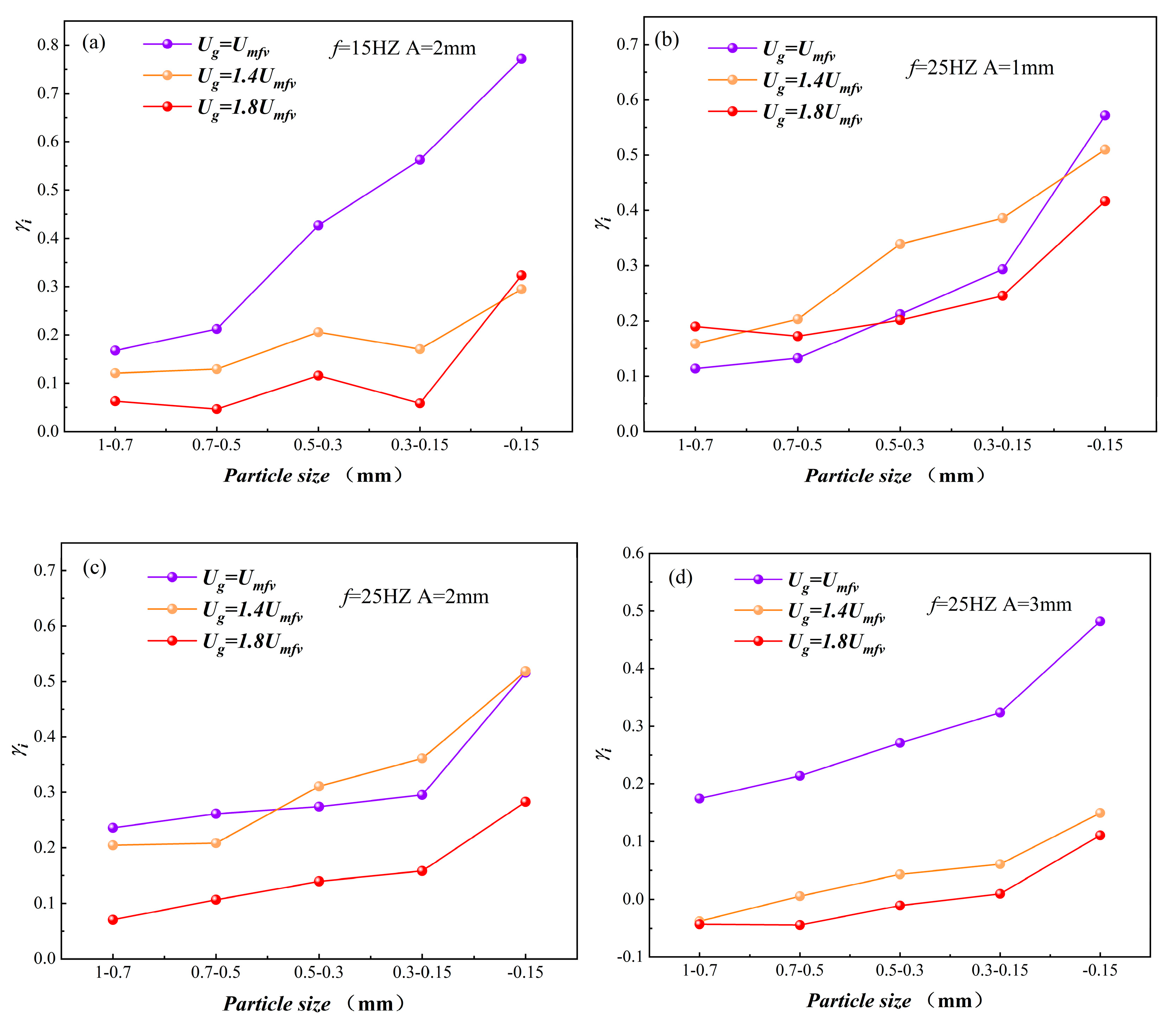

3.2.2. Effect of Vibration on Density Segregation of Pulverized Coal at All Levels

3.3. Influence Law of Gas Velocity on Axial Mixing of Wide-Grained Dense Medium

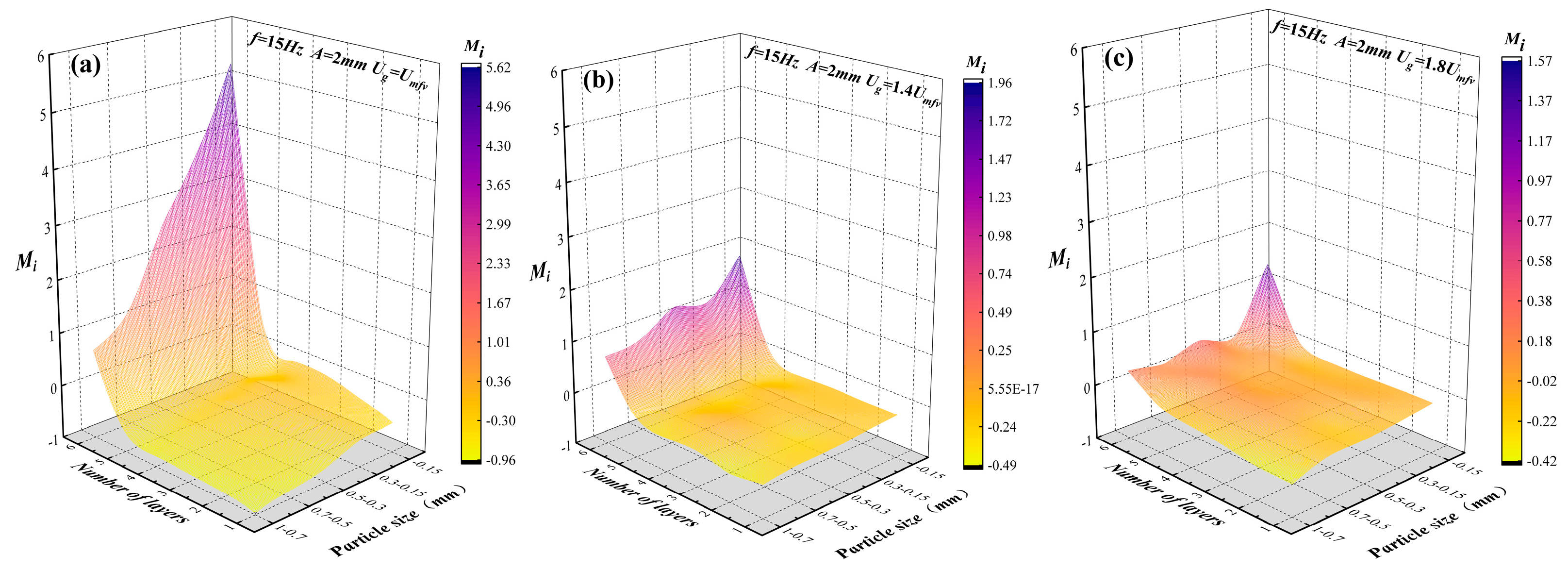

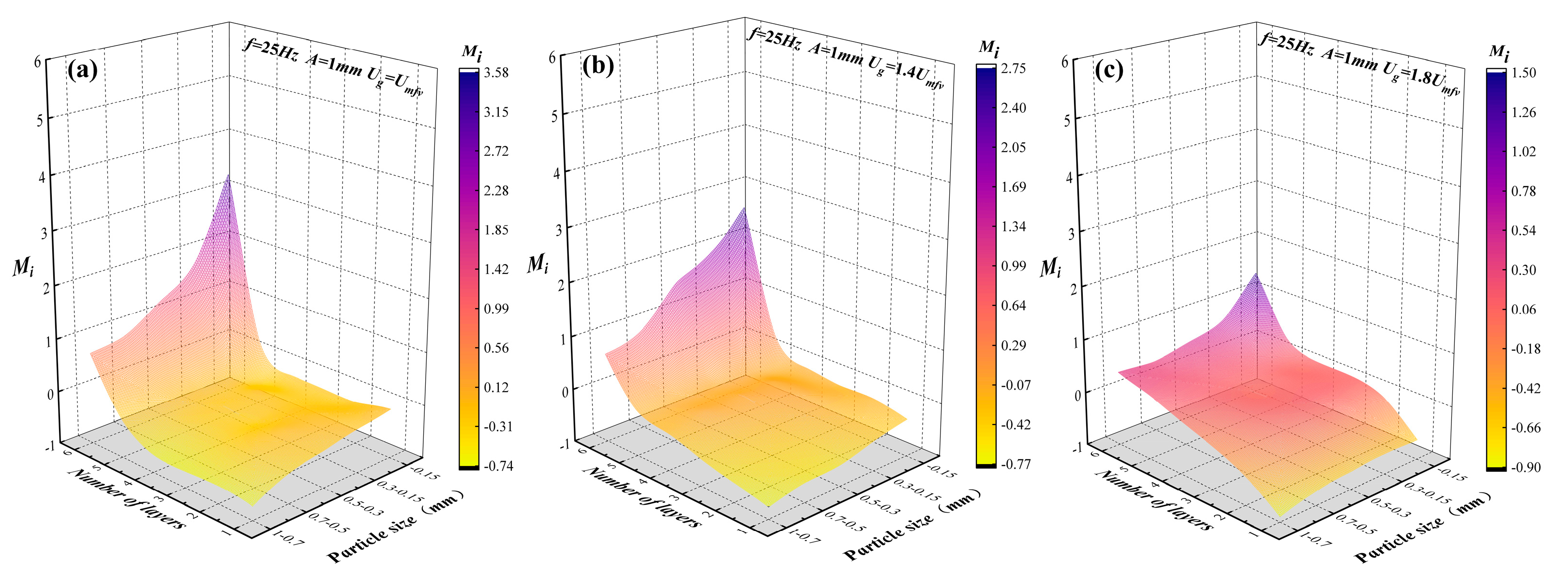

3.3.1. Effect of Gas Velocity on Local Mixing Indices

3.3.2. Effect of Gas Velocity on Density Segregation of Pulverized Coal at All Levels

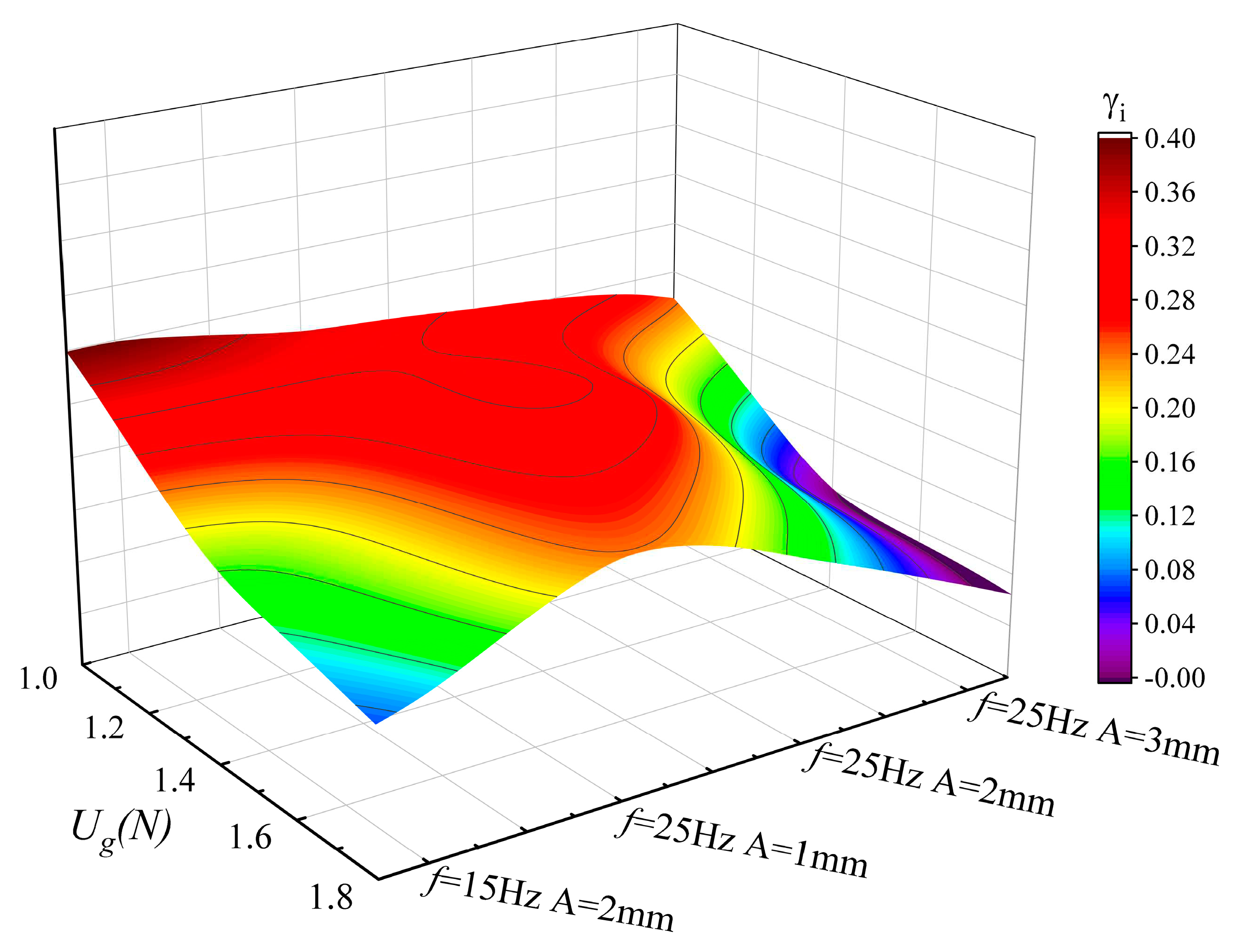

3.4. Bed Density Segregation Patterns under Interaction

4. Conclusions

References

- Zhou, C.; Liu, X.; Zhao, Y.; Yang, X.; Li, Y.; Dong, L.; Duan, C.; Rao, Z. Recent progress and potential challenges in coal upgrading via gravity dry separation technologies. Fuel 2021, 305, 121430. [CrossRef]

- Fan, X.; Ren, Y.; Dong, L.; Zhou, C.; Zhao, Y. Optimization of coal size for beneficiation efficiency promotion in gas–solid fluidized bed. Part. Sci. Technol. 2022, 41, 151–162. [CrossRef]

- Li, G.; Wang, D.; Liu, Q.; Zhao, Y.; Duan, C. Separation performance of 0.5–1 mm fine coal in a gas–solid fluidized bed without dense medium. Fuel 2022, 318, 123645. [CrossRef]

- Wang, S.; Yang, Y.; Yang, X.; Zhang, Y.; Zhao, Y. Dry beneficiation of fine coal deploying multistage separation processes in a vibrated gas-fluidized bed. Sep. Sci. Technol. 2018, 54, 655–664. [CrossRef]

- Dong, L.; Zhao, Y.; Duan, C.; Luo, Z.; Zhang, B.; Yang, X. Characteristics of bubble and fine coal separation using active pulsing air dense medium fluidized bed. Powder Technol. 2014, 257, 40–46. [CrossRef]

- Fan, M.; Chen, Q.; Zhao, Y.; Luo, Z. Fine coal (6–1 mm) separation in magnetically stabilized fluidized beds. Int. J. Miner. Process. 2001, 63, 225–232. [CrossRef]

- Xu, X.; Yang, L.; Fu, Y.; Zhao, Y.; Chen, Z.; Song, S.; Dong, L. Enhanced fluidization of solid particles in an oscillating acoustic field. Adv. Powder Technol. 2022, 33. [CrossRef]

- Zhou, E.; Zhang, Y.; Zhao, Y.; Luo, Z.; Yang, X.; Duan, C.; Dong, L.; Fu, Z. Effect of vibration energy on fluidization and 1–6 mm coal separation in a vibrated dense medium fluidized bed. Sep. Sci. Technol. 2018, 53, 2297–2313. [CrossRef]

- Boylu, F.; Talı, E.; Çetinel, T.; Çelik, M. Effect of fluidizing characteristics on upgrading of lignitic coals in gravity based air jig. Int. J. Miner. Process. 2014, 129, 27–35. [CrossRef]

- Yang, X.; Wang, S.; Zhang, Y.; Zhao, Y.; Luo, Z. Dry beneficiation of fine coal using planar air jets. Powder Technol. 2018, 323, 518–524. [CrossRef]

- Zhou, E.; Lu, J.; Wang, Q.; Lv, G.; Zhao, Y.; Dong, L.; Duan, C. Mixing and migration rule of binary medium in vibrated dense medium fluidized bed for fine coal separation. Adv. Powder Technol. 2020, 31, 3420–3432. [CrossRef]

- He, J.; Zhu, L.; Bu, X.; Liu, C.; Luo, Z.; Yao, Y. Intensification of waste gangue removal from 6–1 mm fine-sized iron ores based on density-based dry vibrated separation and upgrading. Chem. Eng. Process. - Process. Intensif. 2019, 138, 27–35. [CrossRef]

- Macpherson, S.; Iveson, S.; Galvin, K. Density based separations in the Reflux Classifier with an air–sand dense–medium and vibration. Miner. Eng. 2010, 23, 74–82. [CrossRef]

- Zhou, E.; Zhang, Y.; Zhao, Y.; Tian, Q.; Chen, Z.; Lv, G.; Yang, X.; Dong, L.; Duan, C. Influence of bubbles on the segregated stability of fine coal in a vibrated dense medium gas–solid fluidized bed. Particuology 2021, 58, 259–267. [CrossRef]

- Zhou, E.; Shan, Y.; Li, L.; Shen, F.; Byambajav, E.; Zhang, B.; Shi, C. Study on the Fluidization Quality Characterization Method and Process Intensification of Fine Coal Separation in a Vibrated Dense Medium Fluidized Bed. ACS Omega 2021, 6, 14268–14277. [CrossRef]

- Luo, Z.; Fan, M.; Zhao, Y.; Tao, X.; Chen, Q.; Chen, Z. Density-dependent separation of dry fine coal in a vibrated fluidized bed. Powder Technol. 2008, 187, 119–123. [CrossRef]

- Zhang, Y.; Li, Y.; Dong, L.; Zhao, Y.; Gao, Z.; Duan, C.; Liu, Q.; Yang, X. Characterization of temporal and spatial distribution of bed density in vibrated gas-solid fluidized bed. Adv. Powder Technol. 2018, 29, 2591–2600. [CrossRef]

- Zhang, Y.; Huang, L.; Yuan, J.; Zhao, Y.; Duan, C.; Yang, X.; Dong, L.; Chen, Z. Study on the suppression of bubble behavior by the synergistic effect of vibration and airflow based on pressure and particle collision signals. Powder Technol. 2022, 410. [CrossRef]

- Zhou, E.; Zhang, Y.; Zhao, Y.; Luo, Z.; Duan, C.; Yang, X.; Dong, L.; Zhang, B. Collaborative optimization of vibration and gas flow on fluidization quality and fine coal segregation in a vibrated dense medium fluidized bed. Powder Technol. 2017, 322, 497–509. [CrossRef]

- Zhou, E.; Zhang, Y.; Zhao, Y.; Luo, Z.; He, J.; Duan, C. Characteristic gas velocity and fluidization quality evaluation of vibrated dense medium fluidized bed for fine coal separation. Adv. Powder Technol. 2018, 29, 985–995. [CrossRef]

- Yang, X.; Zhao, Y.; Zhou, E.; Luo, Z.; Fu, Z.; Dong, L.; Jiang, H. Kinematic properties and beneficiation performance of fine coal in a continuous vibrated gas-fluidized bed separator. Fuel 2015, 162, 281–287. [CrossRef]

- Yang, X.; Zhang, Y.; Wang, S.; Wu, W. Parametric evaluation and performance optimization of fine coal separation in a vibrated gas-fluidized bed using response surface methodology. Part. Sci. Technol. 2019, 38, 652–658. [CrossRef]

- Rose, H.E., A suggested equation relating to the mixing of powders and its application to the study of the performance of certain types of machine. 1959.

- Xie, Z.-A.; Wu, P.; Zhang, S.-P.; Chen, S.; Jia, C.; Liu, C.-P.; Wang, L. Separation patterns between Brazilian nut and reversed Brazilian nut of a binary granular system. Phys. Rev. E 2012, 85, 061302. [CrossRef]

- Li, L.; Wu, P.; Abdul, R.; Wang, L.; Zhang, S.; Xie, Z.-A. Energy-dissipation correlated size separation of granular matter under coupling vibration and airflow. Powder Technol. 2017, 307, 84–89. [CrossRef]

- Zhou, E.; Fan, X.; Dong, L.; Zhao, Y.; Yang, X.; Duan, C.; Liu, Q. Process optimization for arsenic removal of fine coal in vibrated dense medium fluidized bed. Fuel 2018, 212, 566–575. [CrossRef]

- Oshitani, J.; Hino, M.; Oshiro, S.; Mawatari, Y.; Tsuji, T.; Jiang, Z.; Franks, G.V. Conversion air velocity at which reverse density segregation converts to normal density segregation in a vibrated fluidized bed of binary particulate mixtures. Adv. Powder Technol. 2022, 33. [CrossRef]

- Cano-Pleite, E.; Hernández-Jiménez, F.; Acosta-Iborra, A.; Tsuji, T.; Müller, C. Segregation of equal-sized particles of different densities in a vertically vibrated fluidized bed. Powder Technol. 2017, 316, 101–110. [CrossRef]

- Menbari, A.; Hashemnia, K. Effect of vibration characteristics on the performance of mixing in a vertically vibrated bed of a binary mixture of spherical particles. Chem. Eng. Sci. 2019, 207, 942–957. [CrossRef]

- Menbari, A.; Hashemnia, K. Studying the particle size ratio effect on granular mixing in a vertically vibrated bed of two particle types. Particuology 2020, 53, 100–111. [CrossRef]

- Su, D.; Luo, Z.; Lei, L.; Zhao, Y. Segregation modes, characteristics, and mechanisms of multi-component lignite in a vibrated gas-fluidized bed. Int. J. Min. Sci. Technol. 2018, 28, 251–258. [CrossRef]

| Material | Particle size range mm |

Geldart particle type |

True density g/cm3 |

Stack density kg/m3 |

Content % |

| Fine coal | 1-0.7 | D | 1705 | 909 | 2.5 |

| 0.7-0.5 | B | 1714 | 981 | 2.0 | |

| 0.5-0.3 | B | 1680 | 944 | 2.0 | |

| 0.3-0.15 | B | 1708 | 934 | 2.0 | |

| -0.15 | A | 1802 | 961 | 1.5 | |

| Magnetite powder | 0.3-0.15 | B | 4530 | 2571 | 90 |

| Vibration frequency Hz |

Amplification mm |

Air speed Ug(cm/s) |

| 15 | 2 | Umfv 1.4Umfv 1.8Umfv |

| 25 | 1 | Umfv 1.4Umfv 1.8Umfv |

| 25 | 2 | Umfv 1.4Umfv 1.8Umfv |

| 25 | 3 | Umfv 1.4Umfv 1.8Umfv |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).