1. Introduction

Industrial Internet of Things (IIoT) is the next level of Internet of Things (IoT) technology and is unique in its manufacturing transformation [

1,

2,

3]. However, this surge in efficiency and productivity has not come without its ecological repercussions. The simultaneous escalation of energy consumption and carbon emissions has underscored the urgent need for sustainable manufacturing practices that minimize resource utilization, improve energy efficiency [

4,

5], and promote environmentally conscious methodologies. Through a series of meticulously designed experiments conducted on a CNC 5-axis milling machine, this study delves into the intricate interplay between various machining parameters, innovative toolpath planning strategies, and consequential energy consumption patterns.

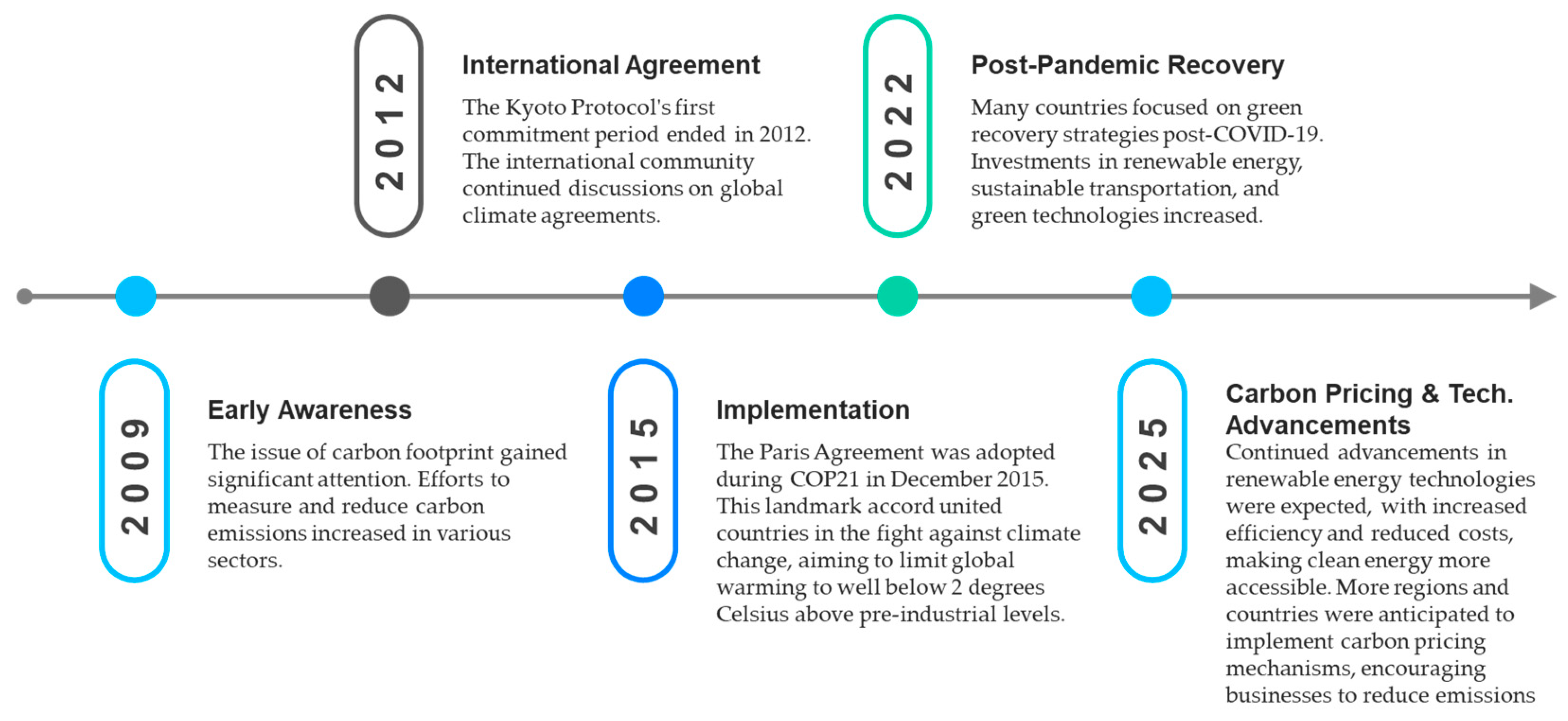

The real-world energy consumption data obtained from these experiments provide the foundation for a nuanced analysis, unraveling the nuanced relationships between process variables and energy utilization as mentioned in

Figure 1.

The primary objective of this research is to pave the way for a substantial reduction in the carbon footprint of 5-axis CNC machining processes. The overarching goal is to establish a comprehensive and multifaceted strategy that integrates various elements, ranging from energy calculation and optimization. By adopting this holistic approach, the aim is not only to benefit the environment but also to promote more efficient and responsible manufacturing practices. A key focus of the research lies in predicting and optimizing energy consumption in machining processes. The use of Machine Learning emerges as a robust methodology to understand the intricate and dynamic nature of machining operations [

11,

12]. Advanced algorithms enable the identification of patterns, optimization of parameters, and refinement of predictions, ultimately contributing to more accurate estimations of energy usage. In the field of machining, the research emphasizes that spindle speed plays a central role in determining overall energy consumption, surpassing even cutting energy. This insight becomes pivotal in crafting targeted and impactful strategies for enhancing energy efficiency in machining processes. By incorporating the principles of Taguchi analysis, the research aims to enhance the precision and reliability of energy consumption predictions [

13,

14]. Through comparisons with Decision tree analysis, valuable insights are gained into the factors significantly influencing energy consumption [

15].

Calculating and forecasting energy consumption is very important, especially for the CNC machining process [

16,

17,

18]. It has become obvious that the power consumption changes depending on the tool path as the number of axes on machine tools has risen and the motion of machines has become more sophisticated. Unique cutting circumstances of a machining operation, such as the spindle motor speed and feed rate, as well as its predicted electrical energy consumption and the maximum electrical power in watts during the operation duration, are referred to as the processing mode. They also created a conceptual issue to create an energy-load profile with the goal of reducing the profile length, and they talked about how their method may be used as the foundation for green manufacturing processes. We provide a theoretical framework, mostly using machine learning tools, for processes that are energy efficient in 5-axis machine. On the basis of actual machining data, our system employs energy-load profiles and the processing modes of machine tools.

Machine learning regression techniques have emerged as powerful tools to understand and predicting complex relationships within manufacturing processes [

19,

20,

21,

22,

23]. In the context of CNC machining, these techniques allow us to decipher the intricate connections between various parameters such as spindle speed, feed rate, depth of cut, material properties, and tool characteristics, and the resulting energy consumption. Linear regression, a fundamental technique, assumes a linear relationship between input variables and output (in this case, energy consumption). Provides valuable insight into how changes in individual parameters affect energy use. Lasso regression combines regression analysis with regularization, promoting the selection of important variables while penalizing less significant ones [

24,

25,

26]. This technique is crucial when dealing with datasets where some parameters might have negligible impact. Ridge regression, similar to Lasso, incorporates regularization. It is particularly useful in the presence of multicollinearity, where input variables are highly correlated [

27,

28]. Ridge regression helps mitigate the impact of correlated variables on the model. Decision trees, a nonlinear regression technique, break down the data into hierarchical structures, enabling the modeling of complex relationships. Decision tree regressors are adept at capturing intricate patterns within the data [

29,

30]. The last, like another type of statistic modelling, we know that Random forests, an ensemble technique, utilize multiple decision trees to enhance predictive accuracy. By averaging the output of numerous trees, random forest regressors reduce overfitting and improve the robustness of predictions [

31,

32].

2. Materials and Methods

2.1. Research Methodology

The recent focus on machine learning in various research endeavors underscores the significance of optimizing machining operations. The exploration of optimization methodologies using machine learning gains more attention as the volume of data expands exponentially and the complexity of the model increases [

33]. The essence of future manufacturing lies in incremental optimization that extends from the supply chain to the final products. Critical to cost savings and heightened overall profitability per production run, the optimization of CNC machine tool operations is essential for boosting productivity and minimizing defects in manufactured components. By integrating motion system kinematics, a sophisticated motion-cueing algorithm is developed to improve simulator performance. This algorithm focuses on enhancing the precision of coupled movements by limiting actuator extensions. This restriction plays a crucial role in the refinement of the overall operation, ensuring smoother and more accurate machining processes. As a result, the implementation of this optimal motion-cueing algorithm contributes to increased efficiency and reduction in defects during the manufacturing of components. [

34].

Critical for advancing the precision and efficiency of CNC machining operations in component manufacturing, optimization procedures for both machine tool performance and machining parameters become indispensable [

35]. The utilization of artificial intelligence and machine learning with real-time production data facilitates automated optimization, consequently increasing the accuracy of machined components and the productivity of part manufacturing through optimized machining parameters [

36]. A comprehensive method for optimizing multi-response machining processes is established, utilizing a combination of machine learning and genetic algorithms. The incorporation of a multi-objective evolutionary algorithm during CNC machining operations enhances both convergence speed and part production performance [

37]. Employing machine learning to enhance parallel metaheuristics on the shop floor during CNC machining operations is a strategy aimed at increasing efficiency in part production processes. An in-depth analysis is conducted on the utilization of machine learning in optimizing CNC machine tools, with the aim of improving the stability of component production and reducing the likelihood of unforeseen failures.

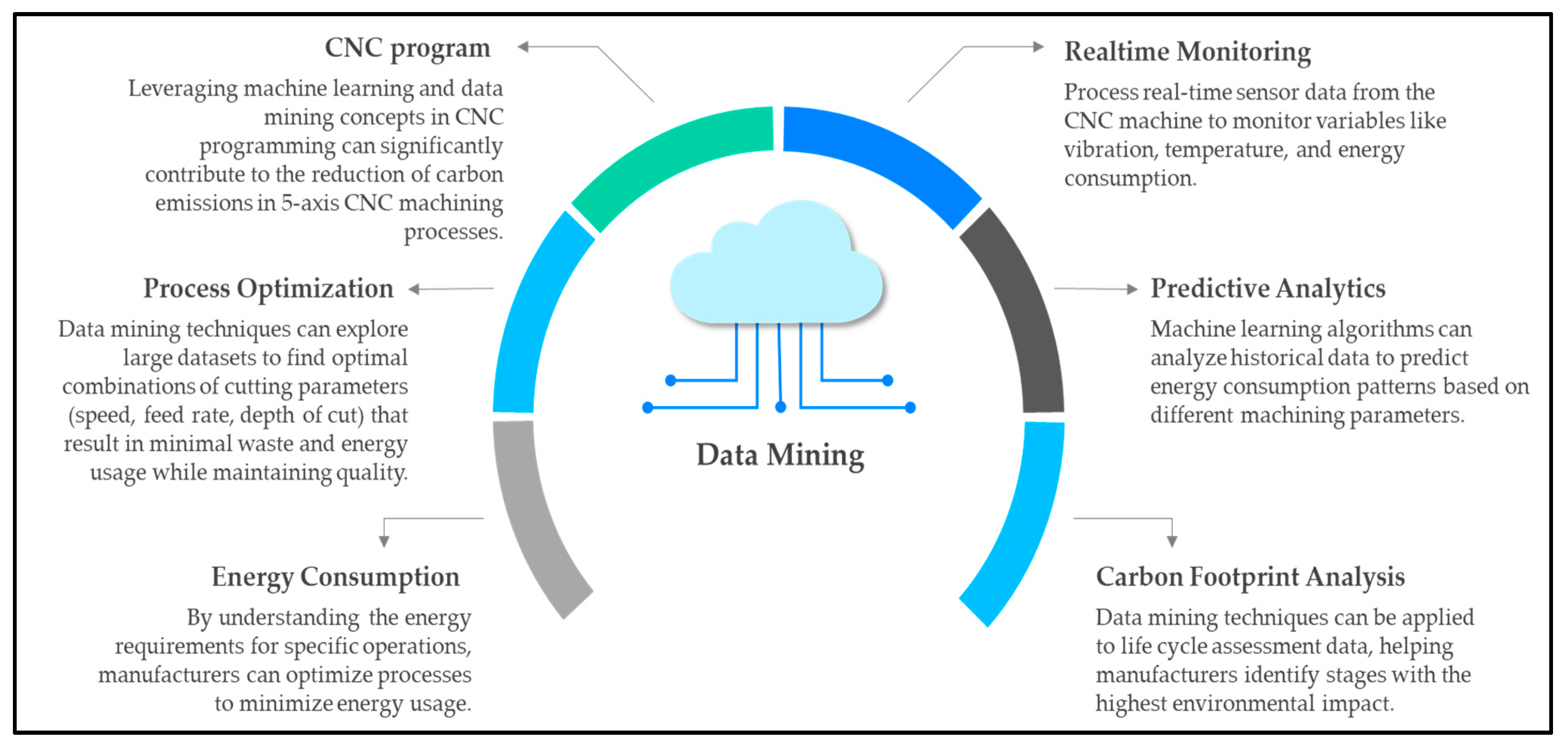

Machine learning algorithms can analyze historical data to identify optimal tool paths for specific materials and geometries. By minimizing unnecessary movements and optimizing cutting strategies, these algorithms reduce machining time and subsequently lower energy consumption, contributing to a decrease in carbon emissions [

38,

39]. Therefore, our design can be shown in

Figure 2.

Linear regression models build the relationship between independent variables or factors that explain or influence a phenomenon

(predictors) and a dependent variable

through the equation:

In this context, ϵ is understood as random observational error or fluctuations. When measurements are performed

n times, producing

n values of

for n sets of

, the model for each observation (

i-th observation) can be expressed as:

In this formulation

is the observed value of the dependent variable for the

i-th set of observations.

are the parameters to be estimated.

is the

i-th observation of the

j-th predictor variable.

represents the unobserved random error for the

i-th observation. Ridge and Lasso regression methods offer regularization of estimated coefficients, addressing some drawbacks of the Ordinary Least Squares (OLS) estimator, particularly in scenarios with a large number of predictors relative to the sample size (

> n) [

40]. In situations where the relationship between variables is nearly linear and the number of predictors is significantly less than the sample size (

<< n), OLS may perform well. However, when k is not substantially smaller than n, estimates obtained through Ordinary Least Squares (OLS) are prone to high variance and diminished accuracy. Regularization techniques, such as Ridge and Lasso come into play when dealing with high-dimensional data. They effectively mitigate the problem of high variance in OLS estimates by introducing a controlled amount of bias, which ultimately leads to improved prediction accuracy. In cases where the number of predictors exceeds the sample size (

> n), OLS fails to produce a unique solution, resulting in infinite estimate variance. Regularization methods help stabilize and enhance predictive performance in such situations.

A classification technique, often referred to as a classifier, is a systematic method for creating classification models based on a provided input dataset [

41,

42,

43]. Different examples of classification techniques encompass decision tree classifiers, rule-based classifiers, neural networks (NN), SVM, and naïve Bayes classifiers. The initial strategy explicitly computes the generalization error taking into account both the training error and a penalty term addressing the complexity of the model. This resulting generalization error serves as a pessimistic assessment of the effectiveness of the model. As illustration, consider

n(

t), which denotes the number of training records classified by node

t, and

e(

t), representing the count of incorrectly categorized data entries. The pessimistic error estimate, denoted as

(

T), for a decision tree

T is calculated as follows:

Here, represents the number of leaf node, e(T) denotes the overall training error of the decision tree, represents the number of training record, and Ω(ti) signifies the penalty term attributed to each node ti.

The machine tool requires a foundational energy input for its operation and overall readiness. This encompasses the essential energy for the machinery’s functionality and ensuring it is ready for operation. The preparatory stage requires energy to position the tool and workpiece in optimal cutting positions, while also setting the spindle speed. Subsequently, during the actual material removal process, cutting energy becomes imperative. The assignment of a numerical value to this enables the modeling of the corresponding emissions.

where the total power consumption of a machine tool, denoted as

, is determined by the specific cutting energy for a given workpiece material, represented by

, multiplied by the material removal rate (

Q) and the cutting time (

).

encompasses the energy consumption of the spindle, accounting for the energy needed for material removal from the workpiece.

pertains to the energy consumption associated with axis feed, while

refers to the energy consumption during tool changes.

corresponds to the energy usage of the coolant equipment, and

is indicative of the energy consumption of the fan motor and servo system.

2.2. Experimental Setup

2.2.1. Electrical connection

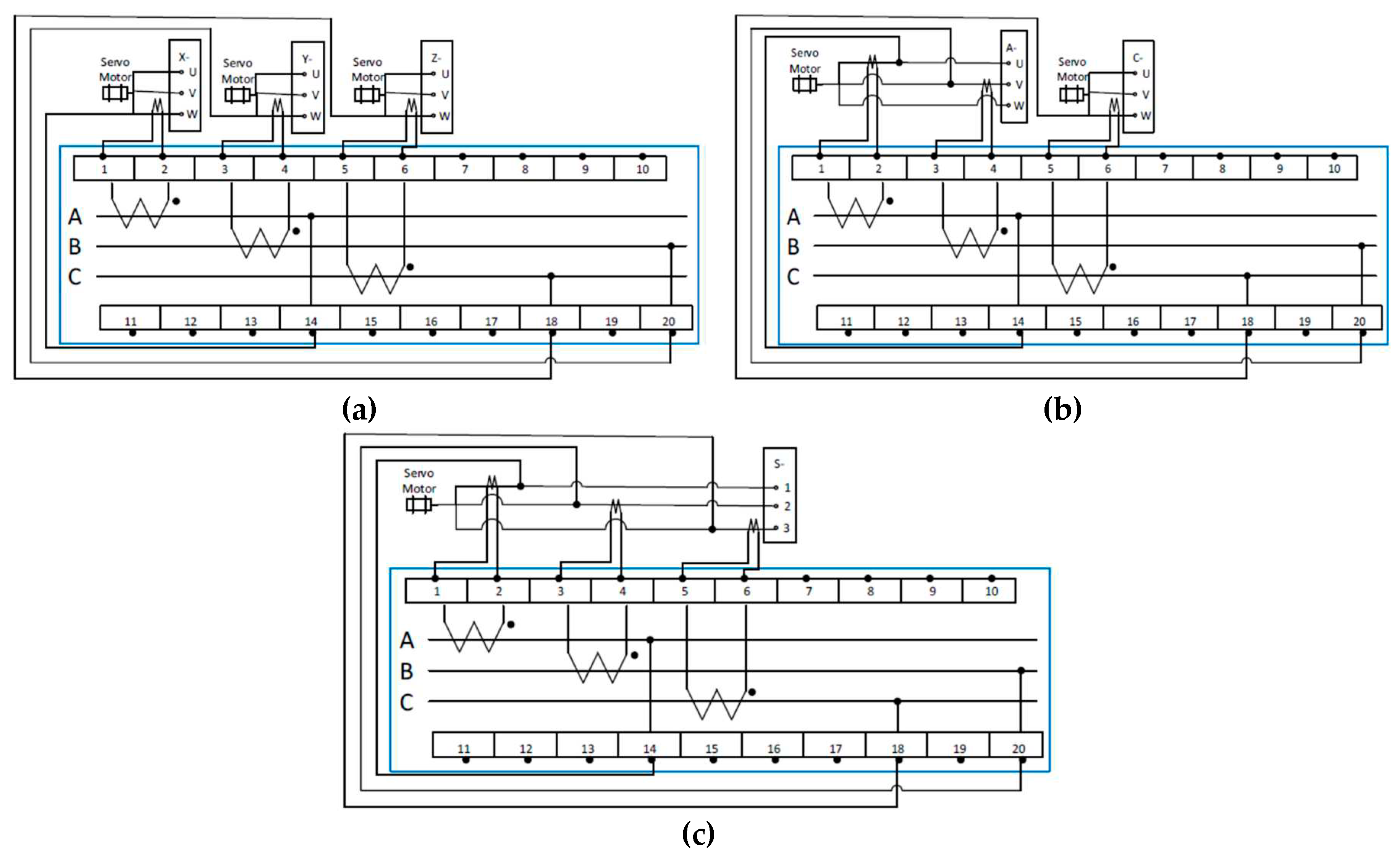

The circuit diagram can be seen in

Figure 3. This research uses three PA-310 3P3W-3CT power meters. Each power meter measures three electrical lines to obtain current and voltage data. Clamp-on current sensors are used in this experiment to read the current on each line. The voltage value on each line is measured directly using a power meter. The first power meter in

Figure 3 (a) measures the current and voltage of the X-axis, Y-axis and Z-axis servo motors via one of the 3 phase lines (cables) on each axis. The second power meter measures the voltage and electric current of the servo motor on one line from the C-axis, namely line W and two lines from the A-axis, namely lines U and V. Each phase provides electrical power, and the phases are typically labeled as U, V, and W, these represent the three phases of alternating current. Connecting the A-axis to lines U and V helps maintain a balanced power distribution. In a three-phase system, distributing the load evenly across all three phases ensures efficient and stable operation. Spindles in CNC machines are responsible for the actual milling or cutting process. They often require higher power output compared to servo motors. Distributing the power across three phases helps in achieving higher torque and speed, contributing to better machining performance, like in the case of the A-axis, connecting the motor to three phases helps balance the load across the power supply. This balance is crucial for stable and reliable operation. Spindle speed and rotation direction are critical parameters in machining. Connecting to three phases allows for precise control over these parameters, enabling the CNC machine to achieve accurate and efficient milling processes. The last power meter measures the voltage and current on three spindle lines, namely S1, S2, and S3. The purpose of measuring each axis of the CNC machine is to determine the energy profile of each axis when carrying out the milling process.

As the example of the circuit for the X-axis shown in

Figure 4(a), it can be seen that the clamp-on sensor is connected to one of the 3 phase X-axis lines, namely line W, then the clamp-on is connected to the input ports 1 and 2 of the power meter. Furthermore, a parallel circuit from the same line is connected to input port 14 to obtain the voltage value on that line. The same connection way is also applied to Y and Z axis. Furthermore, the power meter output port 11 and 12 are connected to the computer via the RS-485 cable to collect the measurement results.

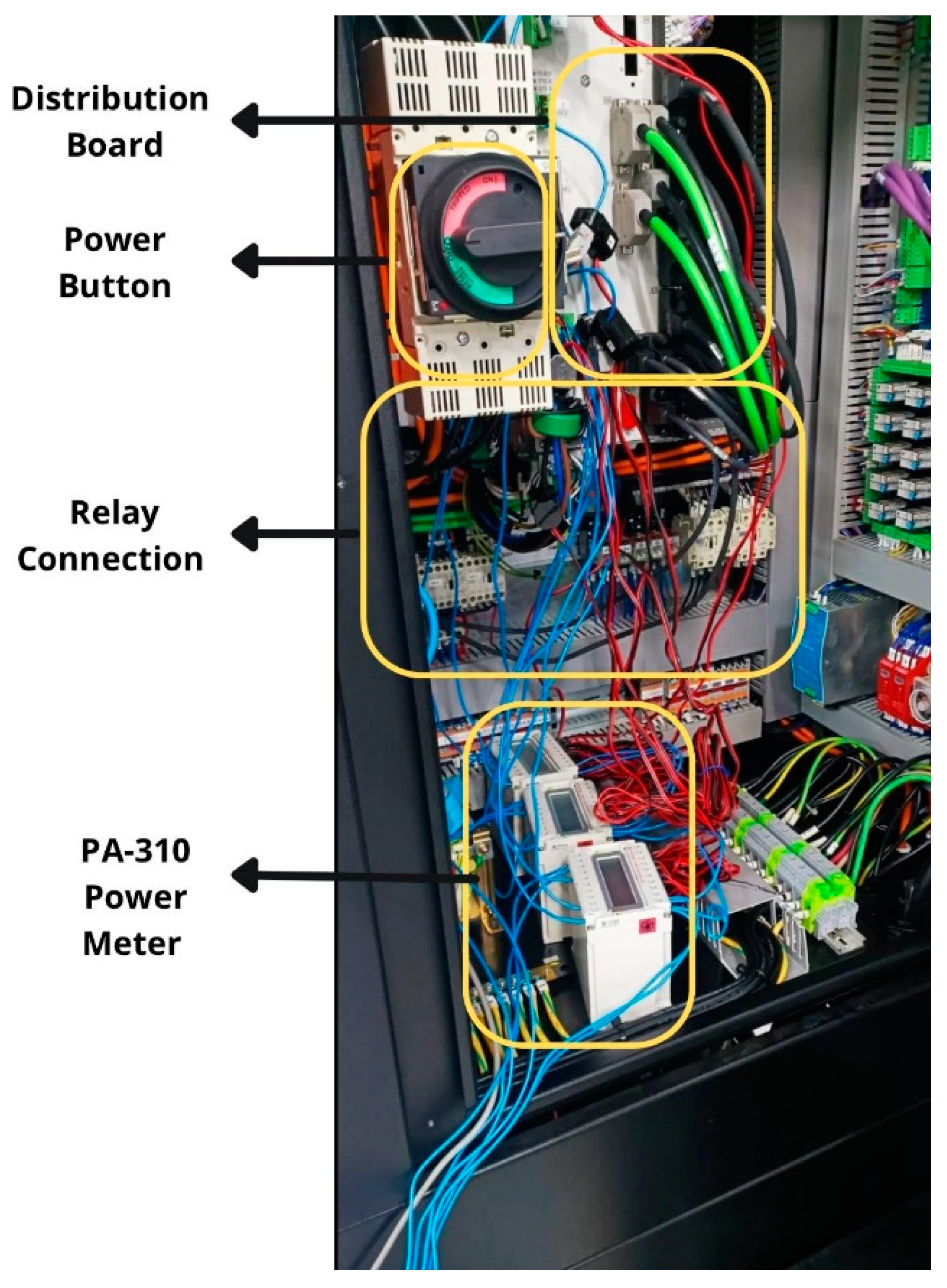

Preceding our research endeavors, the implementation of PA-310 power meters also maintain better accuracy of 1% even under low current condition (< 5A), thus it can still be used in a medium to high voltage system [

44] and was undertaken to systematically monitor the entire electricity consumption [

45]. These meters have been strategically installed on the distribution board, selectively placed at key locations rather than being ubiquitously deployed. Our data acquisition methodology entails the meticulous recording of the complete electricity usage from the distribution boards in a 5-second interval during our experimental trials.

Figure 4 illustrates the installation of the system in the electrical panel, including four distribution boards, these are panels that distribute electrical power to various components in the CNC machine, three PA-310 power meters, they provide information about current, voltage, power factor, and other electrical parameters , and a dedicated server which could be responsible for data storage, processing, and possibly communication with other manufacturing systems.

To streamline our monitoring process, we initiated the installation of current transformers on circuits supplying power to the experimental area. It is noteworthy that each PA-310 power meter integrates three current transformers, enabling the concurrent monitoring of three circuits. This deliberate design not only enhances operational efficiency but also facilitates targeted data collection, ensuring a nuanced understanding of electricity consumption patterns within our experiment.

2.2.2. Cutting path and parameters.

While power consumption monitoring in CNC machining has indeed been explored by various researchers, the distinctive aspect of our study lies in the meticulous attention given to the comprehensive monitoring of power consumption across multiple axes and the spindle motor. Rather than solely emphasizing the overall power consumption, our research delves into the nuanced power dynamics of individual axes and the spindle motor during real cutting processes. This granularity allows us to uncover specific energy consumption patterns, offering a more detailed understanding of how power is utilized in the context of different machining operations. our approach leverages the capabilities of a 3D model from NX simulation, allowing us to measure and analyze power consumption with respect to each parameter. By integrating simulation data, we enhance the precision of our observations, providing valuable insights into the interplay between machining parameters and power consumption. This integration of simulation technology further enriches our study, offering a comprehensive view of energy utilization in CNC machining processes.

Furthermore, we varied the cutting parameters to study their impact on power consumption. We experimented with different widths of cut 1-3 mm, depths of cut 0.5-1.5 mm, and spindle speeds which contain of 4000, 6000, and 8000 rpm, during the cutting process like shown on

Figure 5. Top-right view allow us to observe how the tool engage with workpiece along the patterns is essential for comprehending the power requirement and these variations allowed us to analyze power consumption patterns under different cutting conditions. We designed a circular cutting path to involve the C-axis cutting. The cutting tool follows circular paths in the C-direction until the entire surface is completely cut. Throughout this process, the base of the turning table continuously rotates in the C-axis, allowing us to observe the power consumption in this axis. The obtained experimental results present the power consumption values of X, Y, Z, A, C axes servo motor, and the spindle motor, and illuminate the specific energy requirements of each component during machining.

2.3. Materials and Equipment

Hartford 5A-25R 5-axis Machining Center is a high-performance and versatile industrial machine designed for precision machining tasks [

46]. With advanced features and specifications, this machine is engineered to meet the demands of modern manufacturing processes. The X and Y axes are equipped with 2.18kW drive motors each, ensuring smooth and controlled movements along the longitudinal and cross travel directions. The Z-axis features a powerful 3.5kW drive motor for vertical movements, allowing efficient machining operations at varying depths. the detail specification of the machine as shown in

Table 1.

For the CNC 5 axis machine line with Industry 4.0 principles, the Harford 5A-25R as we can see in

Figure 3 is equipped with connectivity features that facilitate communication with other manufacturing systems. This connectivity enhances automation capabilities, allowing seamless integration into smart manufacturing environments. Extensive scrutiny is applied to the integration of machine learning in optimizing CNC machine tools, with the aim of improving component production stability and minimizing the risk of unexpected failures. The optimization of cutting parameters setting in turning processes is accomplished by employing a response surface approach and machine learning technology. In end milling operations, a machine learning methodology, specifically the Nelder–Mead simplex method, has been developed to optimize the machining variables [

47,

48].

The choice of using aluminum alloy 6000 series in this research can be attributed to several key properties that make this alloy suitable for machining processes, especially in the context of CNC milling. Aluminum alloys like 6111 are commonly employed in the production of automotive exterior or body panels. Inner body panels utilize aluminum alloys such as 5754 and 5083, whereas bonnets are crafted from 6111 [

49]. It is relatively easy to cut, drill, and machine, making it suitable for CNC milling processes. This is essential in achieving precision and intricate shapes in the machining operations. The alloy 6000 significant advantage lies in their high strength-to-weight ratio and the ease of fabrication, making them an excellent choice for replacing steel and cast-iron components [

50,

51]. It provides sufficient strength for structural applications while remaining lightweight. This characteristic is particularly important in industries like aerospace and automotive, where reducing overall weight without compromising strength is crucial, it is also versatile and can be heat-treated to achieve varying levels of strength. This allows for tailoring the material properties to meet specific requirements in different applications The corrosion-resistant properties of aluminum alloys make them ideal for marine applications. They are used in boat construction, shipbuilding, and various marine components due to their durability in saltwater environments [

52].

3. Results & Discussion

In this research, a deliberate selection has been made of four key factors carefully chosen to be the focus of the investigation: (1) Spindle Speed, (2) Feed Rate, (3) Width of Cut, and (4) Depth of Cut as the focal points of investigation, with each of these parameters explored across three distinct levels, as detailed in

Table 2.

In the conventional experimental approach to measuring compressive strength, researchers typically consider four factors, each at three different levels. Using a full factorial design in this context would entail conducting a considerable 243 experiments. Moreover, to enhance the statistical reliability of results, three replications for each parameter combination are commonly included. However, the extensive number of experiments in a full factorial design can be resource-intensive and impractical in many research settings. To address this challenge and streamline the experimental process, researchers often turn to Taguchi’s L9 orthogonal array as an effective alternative. Taguchi methods, developed by Genichi Taguchi, are renowned for their efficiency in experimental design and optimization. In the case of compressive strength experiments, employing Taguchi’s L9 orthogonal array substantially reduces the number of required experiments while still providing valuable insights into the influence of the four factors at their respective level. The L9 orthogonal array systematically samples a subset of combinations from the entire factorial space, allowing researchers to extract maximum information with minimal experimentation. This approach not only optimizes resource utilization but also ensures a comprehensive understanding of the factors affecting compressive strength.

Extending beyond the experimental results, we applied various regression methods to predict power consumption for each axis and the spindle motor based on the cutting parameters. The subsequent step involves a thorough comparison between the predictions generated by each regression method and the actual power consumption observed during real cutting processes. This comparative analysis aims to evaluate the accuracy and reliability of each regression method in predicting power consumption for different machine components. The ensuing discussion will delve into the strengths and limitations of each regression method, providing insights into their effectiveness in capturing the intricate relationships between cutting parameters and power consumption in CNC machining. This comprehensive approach not only contributes valuable empirical data but also enhances our understanding of the predictive capabilities of regression models in the realm of energy consumption monitoring in CNC machining.

3.1. Statistical Analysis

The data presented in

Table 3 encapsulates the R-squared goodness-of-fit derived from a full factorial design based data that we have mention before, involving a comprehensive dataset of 243 data points across various factors. The remarkable fit of 87.21% signifies the model’s proficiency in elucidating the variations in energy consumption (Y), the dependent variable in this context. A higher R-squared value, approaching 1 or 100%, attests to the model’s robustness in capturing the nuanced relationship between the factors considered and energy consumption. Of particular significance is the statistically significant role of spindle speed within our linear regression analysis, evident from a P-value below 1 percent. This underscores the substantial impact of spindle speed on energy consumption, emphasizing its pivotal role in the model. For instance, an increase in spindle speed by every 2000 rpm correlates with a noteworthy reduction in energy consumption by 12Wh, as observed in experiments 1.

Additionally, variations in width of cut and depth of cut by 1mm and 0.5mm, respectively, result in reduced energy consumption by 0.92Wh and 6.6Wh. Furthermore, alterations in feed rate by 300mm/min contribute to an increase in energy consumption by up to 3.9Wh. Notably, the combined impact of spindle speed (increased by every 1000 rpm), feed rate (set at 300mm/min), width of cut (increased by 1mm), and depth of cut (increased by 0.5mm) synergistically leads to a substantial reduction in energy consumption by 15.6Wh . This comprehensive analysis provides valuable insights into the intricate dynamics of the factors influencing energy consumption within the experimental framework.

While the other factors show some influence on energy consumption, their effects are not statistically significant. Examining the graphical representation of the data reveals noticeable distinctions between trial 1 until trial 3. Specifically, when assessing the relationship between residuals (predicted values) and percentages (true values), the proximity of data points to the regression line is indicative of the modeling regression’s quality. A close alignment between the dots and the regression line suggests a robust and accurate representation of the relationship between the factors and energy consumption. The findings underscore the importance of spindle speed in influencing energy consumption, emphasizing its significant role in the model.

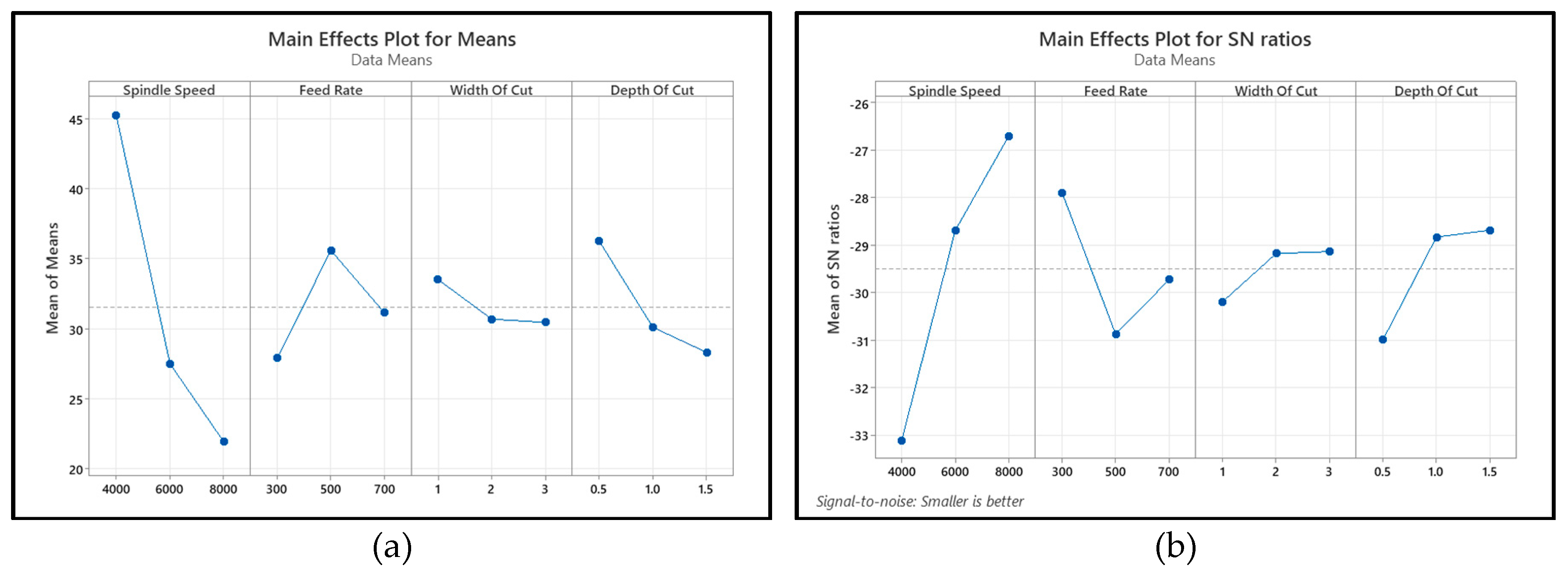

In Taguchi analysis, the consideration of "smaller is better" is informed by extensive literature review findings, which highlight that lower energy consumption correlates with reduced carbon emissions and manufacturing costs. This design philosophy aligns with sustainability goals, making it imperative to minimize the environmental impact and economic expenses associated with energy usage in manufacturing processes. The concept of response noise, depicted on the

Figure 6(a), serves as a measure of robustness. Robustness is crucial in identifying control factor settings that mitigate the influence of external variability or noise on the response. This emphasis on robustness ensures that the designed system or process remains resilient and consistent in its performance, even in the presence of uncontrollable factors. The interpretation of the

Figure 6(b) involves assessing the main effects of control factors on the response. When the line is horizontal, parallel to the x-axis, it indicates the absence of a main effect. In this scenario, each level of the factor has a uniform impact on the response, and the mean response remains consistent across all factor levels. On the other hand, when the line deviates from horizontal, a main effect is present. Different levels of the factor exert varying influences on the response. The slope of the line provides insight into the magnitude of the main effect a steeper slope signifies a more pronounced impact on the response variable.

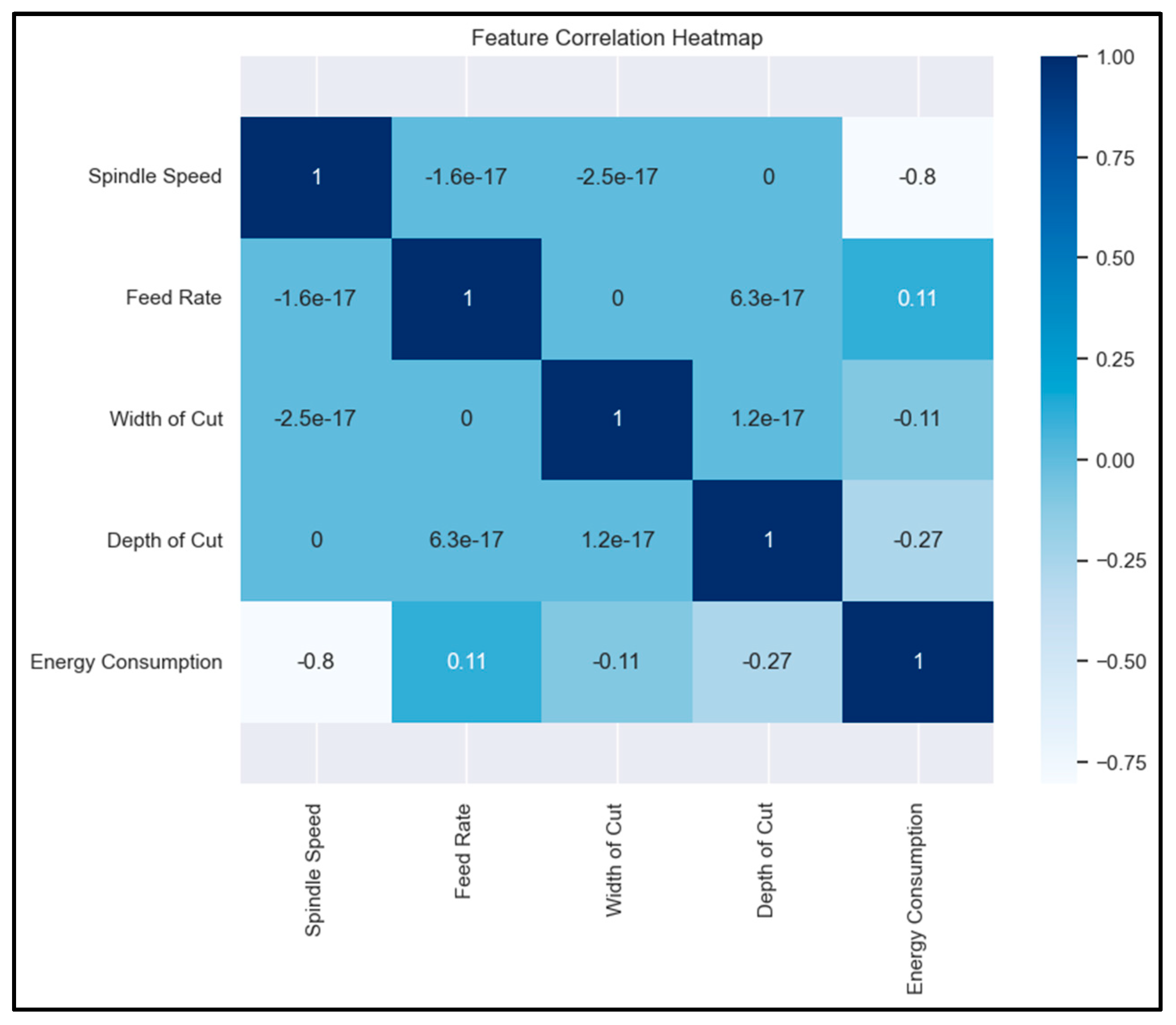

In this research, built upon the current cutting process data using CNC 5-axis machine, The correlation coefficients between the considered 4 factors are depicted in

Figure 6. It’s notable that factors such as Spindle Speed, Feed Rate, Width of Cut, and Depth of Cut, Positive correlations will be represented by darker shades of blue, negative correlations by lighter shades of blue. To conduct a more comprehensive assessment of the performance of the machine learning models. The results of correlation analysis show that, two factors that has strong correlation that is spindle speed and energy consumption.

3.2. Machine Learning Analysis

To conduct a more comprehensive assessment of the performance of the machine learning models. The results of correlation analysis show that, there is has strong correlation between spindle speed and energy consumption. Multiple regression analysis can be conducted due to the robust correlation of other factors with seepage loss. The spindle speed should be given greater attention compared to other factors in the optimization of energy consumption calculations. This observation signifies that elevation potentially wields a substantial influence on the predictive efficacy of ML models.

Figure 7.

This graphical representation aids in understanding the interrelationships and dependencies among the variables, providing valuable insights into the dataset’s structure and potential predictors.

Figure 7.

This graphical representation aids in understanding the interrelationships and dependencies among the variables, providing valuable insights into the dataset’s structure and potential predictors.

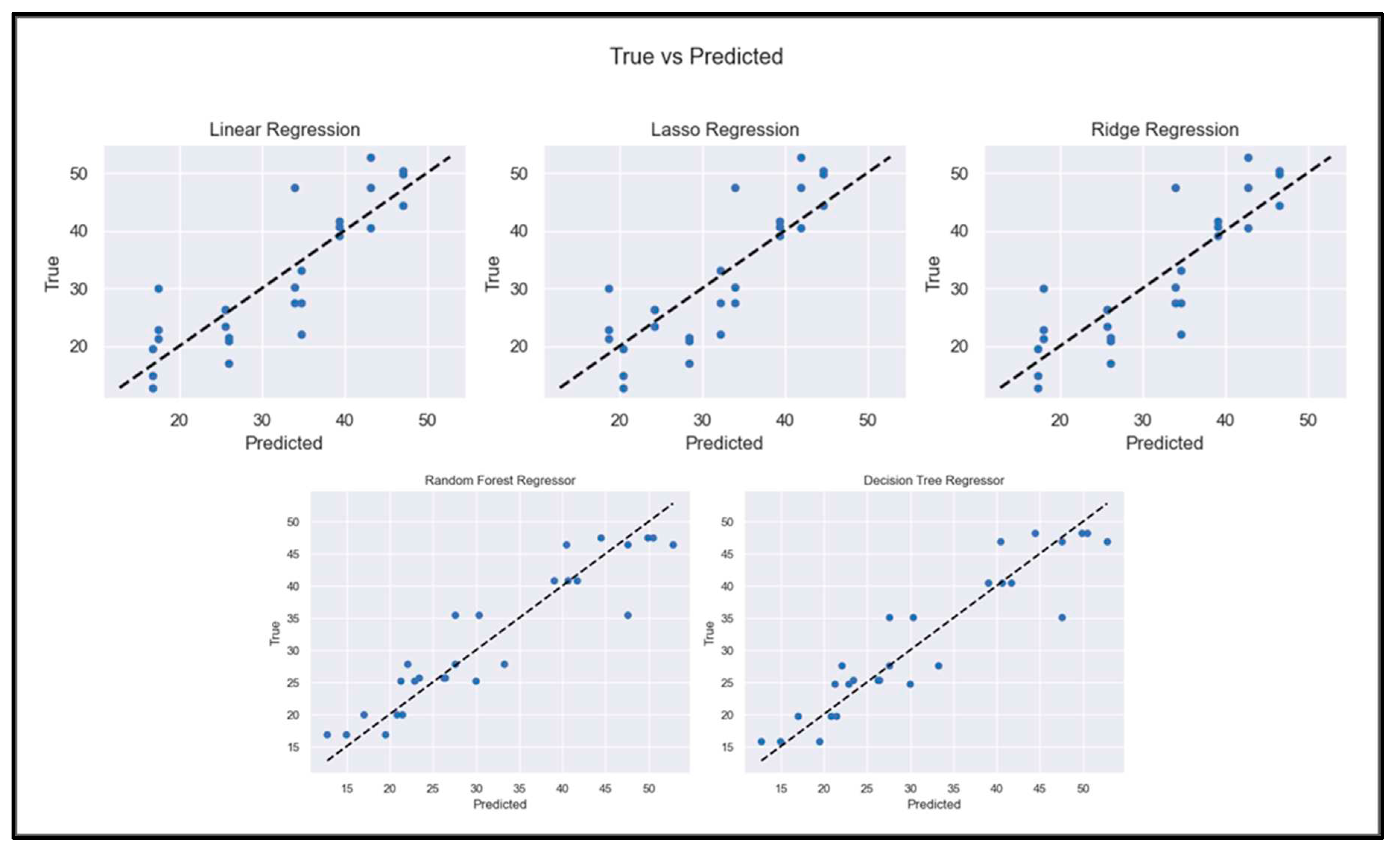

The evaluation of various regression algorithms for predicting power consumption in the 5-axis CNC machining process, as depicted in

Table 4, underscores the dominant efficacy of Decision Tree Regressor and Random Forest Regressor. While linear models exhibit commendable performance, the Decision Tree and Random Forest models emerge as frontrunners, demonstrates superior predictive accuracy and robustness. These tree-based models, with lower Root Mean Squared Error (RMSE), Mean Squared Error (MSE), and Mean Absolute Error (MAE) values, outperform their linear counterparts, highlighting their exceptional ability to minimize prediction errors. Importantly, their elevated coefficient of determination (R-squared, Rsq) values signifies their robustness in elucidating the variability in power consumption. This resilience to non-linear relationships is particularly crucial in the intricate and dynamic landscape of CNC machining, where the Decision Tree and Random Forest models demonstrate a more profound understanding of the system’s complexities. Their practical applicability is further emphasized by their potential for accurate predictions in real-world scenarios, making them compelling choices for optimizing energy efficiency in 5-axis CNC machining processes.

The performance comparison across different algorithms, namely linear regression, lasso regression, ridge regression, random forest regression, and decision tree regressor, is visually represented in the provided graph on

Figure 8. Each algorithm’s effectiveness in predicting outcomes is assessed by comparing the experiment data, depicted by the blue dots, against the predicted data, visualized as the black dashed line. As seen in

Figure 8, the random forest and decision tree algorithms exhibit the most favorable results. This is because these two algorithms exhibit the optimum result, indicating the lowest error between the actual and predicted data. As evidence, the blue dots are more clustered around the black dashed line for these methods. The success of the random forest and decision tree methods in achieving optimal results can be attributed to their inherent strengths in capturing complex relationships within the dataset. These tree-based algorithms are adept at handling non-linear patterns and intricate dependencies among variables. As a result, they excel in situations where the relationships between predictors and the dependent variable are dynamic and multifaceted, as often encountered in real-world datasets. It is crucial to acknowledge that the selection of algorithm depends on the nature of the dataset and the specific characteristics of the relationship between variables. Although linear regression, lasso regression, and ridge regression offer commendable performance, particularly in scenarios with linear relationships, the random forest and decision tree methods prove their effectiveness when dealing with complex, non-linear patterns.

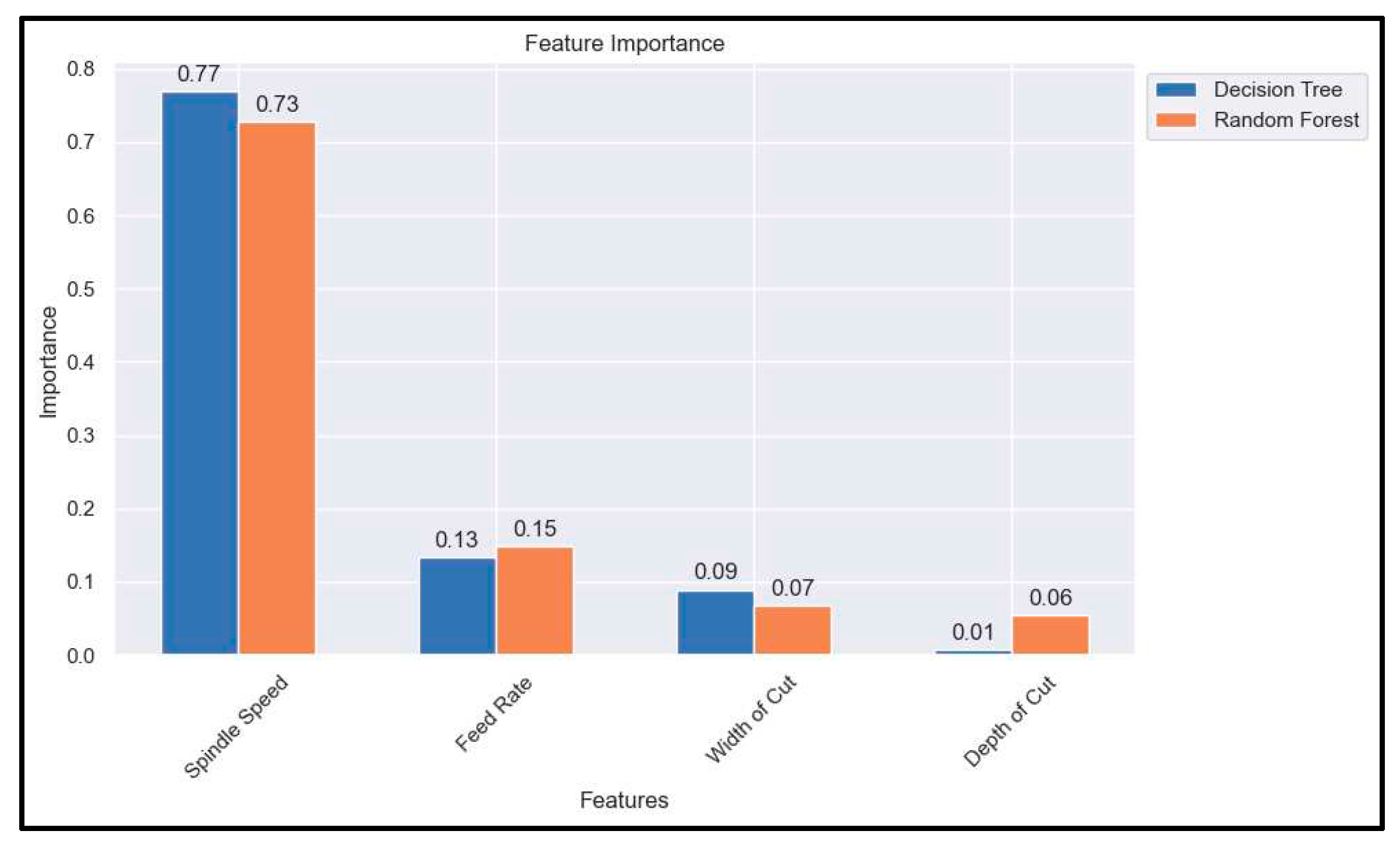

The broader comparison of machine learning regression and classification methods introduces a noteworthy observation – most classification approaches surpass expectations in regression, show lower errors. The subsequent exploration of decision tree and random forest classifiers in constructing predictive models for power consumption and its independent variables reveals their viability. Particularly, the significance of spindle speed is underscored in

Figure 9, demonstrates a substantial deviation in its importance compared to other features. This implies that analyzing results solely with spindle speed can provide valuable insights; however, the experiment emphasizes the imperative of a comprehensive examination of all features. This underscores the nuanced interplay between spindle speed, width of cut, feed rate, and depth of cut, reinforcing the importance of evaluating feature importance comprehensively for a holistic understanding of their collective impact on overall information comprehensiveness. In essence, these analyses deepen our understanding of the intricacies involved in selecting and interpreting machine learning models and features, providing valuable insights for optimizing predictive accuracy in the context of energy consumption prediction in CNC machining processes.

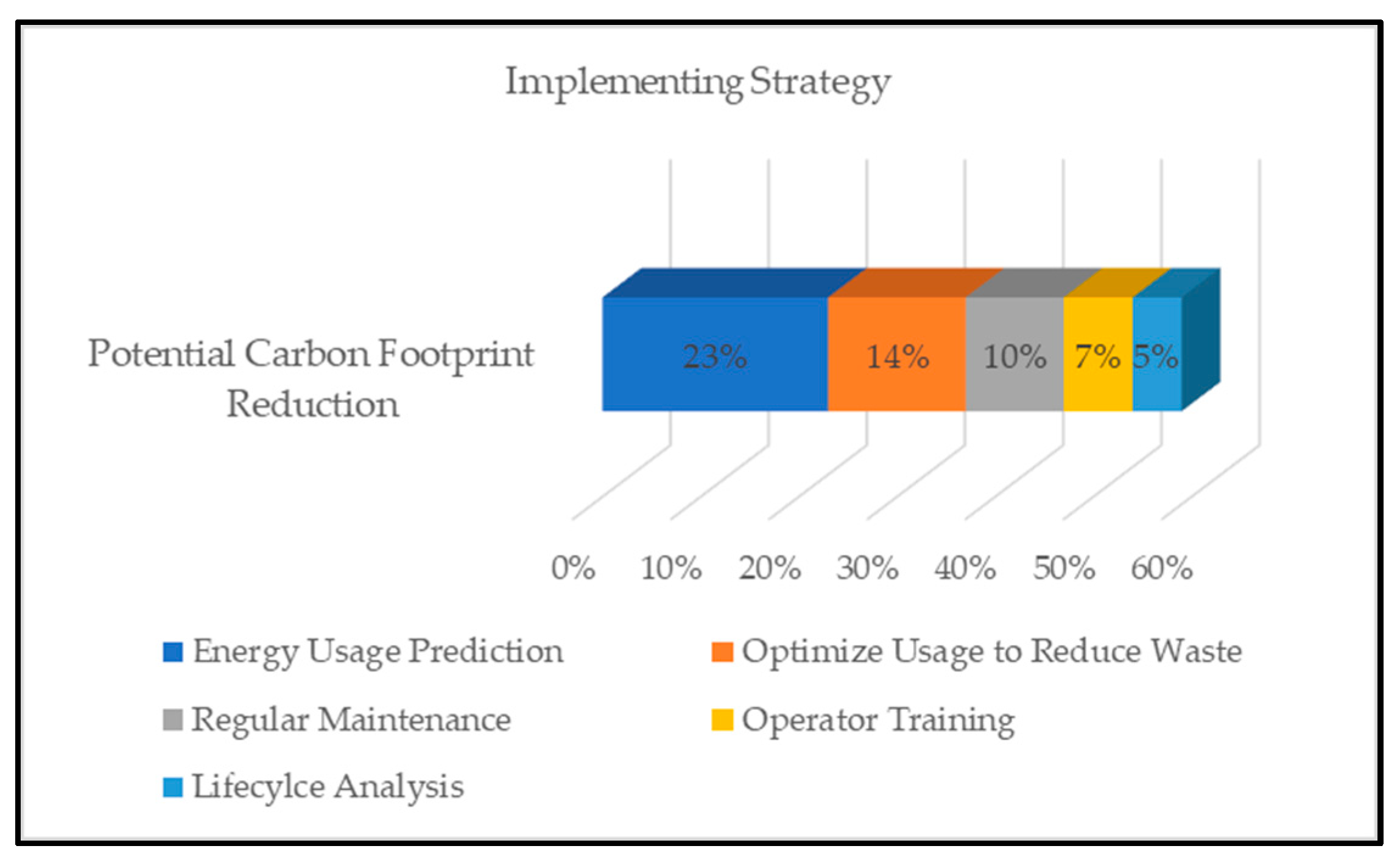

Achieving a substantial reduction in the carbon footprint of a 5-axis CNC machine demands a comprehensive and systematic approach shown on

Figure 10. By strategically addressing various efficiency levels, we can effectively contribute to environmental sustainability. The calculated 23% reduction through precise energy usage predictions exhibits the significance of informed decision-making in machine operations. Additionally, the optimization strategy, accounting for 14% in waste reduction [

53], emphasizes the importance of minimizing resource consumption for a greener manufacturing process. Regular maintenance, contributing 10% to the overall reduction, underlines the role of equipment upkeep in ensuring prolonged and energy-efficient machine life [

54]. The commitment to ongoing operator training, making up 7% of the reduction plan, is pivotal in fostering responsible machine usage and energy conservation [

55]. Conducting a lifecycle analysis, responsible for the remaining 5%, demonstrates a commitment to identifying and rectifying environmental inefficiencies at every stage of the machine’s existence.

4. Conclusion

In essence, the journey toward a reduced carbon footprint for a 5-axis CNC machine requires a multifaceted strategy. Each facet, from energy calculation and optimization to maintenance, operator training, and lifecycle analysis, plays a crucial role in achieving the overall goal of sustainability. This holistic approach not only benefits the environment but also contributes to more efficient and responsible manufacturing practices. In the pursuit of predicting energy consumption in machining processes, leveraging Machine Learning emerges as a robust and effective methodology. The intricate and dynamic nature of machining operations can be better understood and predicted through advanced algorithms, contributing to more accurate estimations of energy usage. By employing Machine Learning, we can discern patterns, optimize parameters, and refine predictions, ultimately establishing a comprehensive and reliable method for energy consumption forecasting in machining. The comprehensive exploration of energy consumption in a 5-axis CNC machining process has yielded profound insights into the intricate dynamics governing power usage. Meticulous measurement setup, involving three power meters strategically positioned across the X, Y, Z, A, and C axes, provided a granular understanding of the energy profile during milling operations. The integration of clamp-on current sensors and direct voltage measurements exhibit a commitment to precision in capturing the nuances of current and voltage on each axis.

The emphasis on designing cutting paths for individual axes, particularly the A-axis with its distinctive 20° curved surface cutting, illuminated the machine’s working space limitations and the consequential impact on power consumption. The deliberate variation of cutting parameters, including width of cut, depth of cut, and spindle speeds, served as a controlled experimentation ground. These variations unveiled discernible patterns in power consumption, establishing a foundational understanding of how these parameters influence energy dynamics. The conventional regression analysis, with a remarkable goodness-of-fit of 87.21%, underscored the significance of spindle speed as a pivotal factor influencing energy consumption. The linear relationship demonstrated a tangible reduction of 6Wh for every 1000 rpm increase in spindle speed, providing a quantitative measure of its impact. Furthermore, the Taguchi analysis reinforced the importance of minimizing energy consumption, aligning with broader sustainability goals by acknowledging the environmental and economic implications of manufacturing processes. The correlation analysis unveiled a strong positive correlation between spindle speed and energy consumption, affirming its central role in the energy dynamics of the CNC machining process. The subsequent application of machine learning models, notably the Decision Tree Regressor and Random Forest Regressor, demonstrate their prowess in predicting power consumption with superior accuracy. This not only validated the findings from the regression analysis but also highlighted the potential of advanced computational approaches in optimizing energy efficiency.

This study transcends a mere investigation of energy consumption in 5-axis CNC machining; it encapsulates a systematic exploration of variables, relationships, and implications. The holistic approach, from electrical structure measurement to cutting path design, from regression analysis to machine learning applications, positions this research at the forefront of understanding and optimizing energy dynamics in advanced manufacturing. The findings not only contribute to the academic discourse but also offer practical insights for industry professionals aiming to enhance sustainability and efficiency in CNC machining processes.

Author Contributions

Conceptualization, H.G. and I.N.; methodology, H.G. and I.N.; validation, H.G. and I.N.; formal analysis, H.G. and I.N.; investigation, H.G. and I.N.; resources, H.C.; data curation, H.C.; writing—original draft preparation, I.N.; writing—review and editing, H.G. and I.N.; visualization, I.N.; supervision, H.G. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Acknowledgments

We extend our heartfelt gratitude to Najmuddin Yahya, for his instrumental contribution to the collection and analysis of electrical data. Thanks to Kevin Chen, another esteemed lab member, who played a crucial role in supporting the 3D model analysis.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

|

Error for the decision tree |

E |

Total energy consumed |

|

Count of incorrectly categorized data entries |

|

baseline or initial power consumption |

|

Penalty complexity of the model |

|

Constant variable Q on the total energy |

|

Total number of training records |

Q |

Variable representing a quantity |

|

Number of nodes in the decision tree |

|

Time duration during which the (E) |

|

Number of training records classified by node t

|

|

Dependent variable |

|

Count data entries for node t

|

|

parameters estimation for linear regression |

|

takes values from 1 to (inclusive) |

|

Independent variables |

|

Fluctuations |

|

Observed value dependent variable |

|

Unobserved random error for the i-th observation |

|

i-th observation of the j-th |

|

Number of predictors |

|

Sample size |

References

- Javaid, M.; Abid, H.; Pratap Singh, R.; Rab, S.; Suman, R. Upgrading the manufacturing sector via applications of Industrial Internet of Things (IIoT). Sens. Int. 2021, 2, 100129. [Google Scholar] [CrossRef]

- Karmakar, A.; Dey, N.; Baral, T.; Chowdhury, M.; Rehan, M. Industrial Internet of Things: A Review; 2019; pp. 1–6. [Google Scholar]

- Kashpruk, N.; Piskor-Ignatowicz, C.; Baranowski, J. Time Series Prediction in Industry 4.0: A Comprehensive Review and Prospects for Future Advancements. Applied Sciences 2023, 13. [Google Scholar] [CrossRef]

- Xu, K.; Luo, M.; Tang, K. Machine based energy-saving tool path generation for five-axis end milling of freeform surfaces. J. Clean. Prod. 2016, 139, 1207–1223. [Google Scholar] [CrossRef]

- Hu, L.; Zha, J.; Kan, F.; Long, H.; Chen, Y. Research on a Five-Axis Machining Center Worktable with Bionic Honeycomb Lightweight Structure. Materials 2021, 14. [Google Scholar] [CrossRef] [PubMed]

- Santos, F.D.; Ferreira, P.L.; Pedersen, J.S.T. The Climate Change Challenge: A Review of the Barriers and Solutions to Deliver a Paris Solution. Climate 2022, 10, 75. [Google Scholar] [CrossRef]

- Stern, N.; Valero, A. Innovation, growth and the transition to net-zero emissions. Res. Policy 2021, 50, 104293. [Google Scholar] [CrossRef]

- Chen, J.; Xu, C.; Gao, M.; Li, D. Carbon peak and its mitigation implications for China in the post-pandemic era. Sci. Rep. 2022, 12, 3473. [Google Scholar] [CrossRef]

- Feng, C.-C.; Chang, K.-F.; Lin, J.-X.; Lee, T.-C.; Lin, S.-M. Toward green transition in the post Paris Agreement era: The case of Taiwan. Energy Policy 2022, 165, 112996. [Google Scholar] [CrossRef]

- Le Quéré, C.; Peters, G.P.; Friedlingstein, P.; Andrew, R.M.; Canadell, J.G.; Davis, S.J.; Jackson, R.B.; Jones, M.W. Fossil CO2 emissions in the post-COVID-19 era. Nat. Clim. Change 2021, 11, 197–199. [Google Scholar] [CrossRef]

- Taye, M.M. Understanding of Machine Learning with Deep Learning: Architectures, Workflow, Applications and Future Directions. Computers 2023, 12. [Google Scholar] [CrossRef]

- Elahi, M.; Afolaranmi, S.O.; Martinez Lastra, J.L.; Perez Garcia, J.A. A comprehensive literature review of the applications of AI techniques through the lifecycle of industrial equipment. Discov. Artif. Intell. 2023, 3, 43. [Google Scholar] [CrossRef]

- Sah, S.; Krishnan, M.; Elangovan, R. Optimization of energy consumption for indoor climate control using Taguchi technique and utility concept. Sci. Technol. Built Environ. 2021, 27, 1–19. [Google Scholar] [CrossRef]

- Yang, H.; Ran, M.; Feng, H. Improved Data-Driven Building Daily Energy Consumption Prediction Models Based on Balance Point Temperature. Buildings 2023, 13, 1423. [Google Scholar] [CrossRef]

- Ramos, D.; Faria, P.; Morais, A.; Vale, Z. Using decision tree to select forecasting algorithms in distinct electricity consumption context of an office building. Energy Rep. 2022, 8, 417–422. [Google Scholar] [CrossRef]

- Pan, J.; Li, C.; Tang, Y.; Li, W.; Li, X. Energy Consumption Prediction of a CNC Machining Process With Incomplete Data. IEEE/CAA J. Autom. Sin. 2021, 8, 987. [Google Scholar] [CrossRef]

- Brillinger, M.; Wuwer, M.; Abdul Hadi, M.; Haas, F. Energy prediction for CNC machining with machine learning. CIRP J. Manuf. Sci. Technol. 2021, 35, 715–723. [Google Scholar] [CrossRef]

- Cao, J.; Xia, X.; Wang, L.; Zhang, Z.; Liu, X. A Novel CNC Milling Energy Consumption Prediction Method Based on Program Parsing and Parallel Neural Network. Sustainability 2021, 13. [Google Scholar] [CrossRef]

- Tercan, H.; Meisen, T. Machine learning and deep learning based predictive quality in manufacturing: a systematic review. J. Intell. Manuf. 2022, 33, 1879–1905. [Google Scholar] [CrossRef]

- Sarker, I.H. Machine Learning: Algorithms, Real-World Applications and Research Directions. SN Comput. Sci. 2021, 2, 160. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.; Hu, F.; Liu, Y.; Witherell, P.; Wang, C.C.L.; Rosen, D.W.; Simpson, T.W.; Lu, Y.; Tang, Q. Research and application of machine learning for additive manufacturing. Addit. Manuf. 2022, 52, 102691. [Google Scholar] [CrossRef]

- Lee, J.A.; Sagong, M.J.; Jung, J.; Kim, E.S.; Kim, H.S. Explainable machine learning for understanding and predicting geometry and defect types in Fe-Ni alloys fabricated by laser metal deposition additive manufacturing. J. Mater. Res. Technol. 2023, 22, 413–423. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12. [Google Scholar] [CrossRef]

- Härdle, W.K.; Prastyo, D.D. Chapter 7 - Embedded Predictor Selection for Default Risk Calculation: A Southeast Asian Industry Study. In Handbook of Asian Finance; Gregoriou, G.N., Chuen, D.L.K., Eds.; Academic Press: San Diego, CA, USA, 2014; pp. 131–148. [Google Scholar]

- Zou, H.; Hastie, T. Regularization and Variable Selection via the Elastic Net. J. R. Stat. Society. Ser. B (Stat. Methodol. ) 2005, 67, 301–320. [Google Scholar] [CrossRef]

- Andriopoulos, V.; Kornaros, M. LASSO Regression with Multiple Imputations for the Selection of Key Variables Affecting the Fatty Acid Profile of Nannochloropsis oculata. Mar Drugs 2023, 21. [Google Scholar] [CrossRef]

- Schreiber-Gregory, D. Ridge Regression and Multicollinearity: An In-Depth Review. Model Assist. Stat. Appl. 2018, 13. [Google Scholar] [CrossRef]

- Enwere, K.; Nduka, E.; Ogoke, U. Comparative Analysis of Ridge, Bridge and Lasso Regression Models In the Presence of Multicollinearity. IPS Intelligentsia Multidiscip. J. 2023, 3, 1–8. [Google Scholar] [CrossRef]

- Debeljak, M.; Džeroski, S. Decision Trees in Ecological Modelling; 2011; pp. 197–209. [Google Scholar]

- Camana, M.; Ahmed, S.; García, C.; Koo, I. Extremely Randomized Trees-Based Scheme for Stealthy Cyber-Attack Detection in Smart Grid Networks. IEEE Access 2020, PP, 1–1. [Google Scholar] [CrossRef]

- Lindner, C. Chapter 1 - Automated Image Interpretation Using Statistical Shape Models. In Statistical Shape and Deformation Analysis; Zheng, G., Li, S., Székely, G., Eds.; Academic Press, 2017; pp. 3–32. [Google Scholar]

- Schonlau, M.; Zou, R. The random forest algorithm for statistical learning. Stata J. Promot. Commun. Stat. Stata 2020, 20, 3–29. [Google Scholar] [CrossRef]

- Sun, S.; Cao, Z.; Zhu, H.; Zhao, J. A Survey of Optimization Methods From a Machine Learning Perspective. IEEE Trans. Cybern. 2020, 50, 3668–3681. [Google Scholar] [CrossRef]

- Aminzadeh, M.; Mahmoodi, A.; Sabzehparvar, M. Optimal Motion-Cueing Algorithm Using Motion System Kinematics. Eur. J. Control 2012, 18, 363–375. [Google Scholar] [CrossRef]

- Sharma, N.; Chawla, V.; Chauhan, N. Comparison of machine learning algorithms for the automatic programming of computer numerical control machine. Int. J. Data Netw. Sci. 2020, 4, 1–14. [Google Scholar] [CrossRef]

- Dittrich, M.-A.; Uhlich, F.; Denkena, B. Self-optimizing tool path generation for 5-axis machining processes. CIRP J. Manuf. Sci. Technol. 2019, 24, 49–54. [Google Scholar] [CrossRef]

- Ghosh, T.; Martinsen, K. Generalized approach for multi-response machining process optimization using machine learning and evolutionary algorithms. Eng. Sci. Technol. Int. J. 2020, 23, 650–663. [Google Scholar] [CrossRef]

- Castelino, K.; D’Souza, R.; Wright, P. Tool-path Optimization for Minimizing Airtime during Machining. J. Comput. Inf. Sci. Eng.- JCISE 2004, 22. [Google Scholar]

- Li, L.; Deng, X.; Zhao, J.; Zhao, F.; Sutherland, J.W. Multi-objective optimization of tool path considering efficiency, energy-saving and carbon-emission for free-form surface milling. J. Clean. Prod. 2018, 172, 3311–3322. [Google Scholar] [CrossRef]

- Ahrens, A.; Hansen, C.B.; Schaffer, M.E. lassopack: Model selection and prediction with regularized regression in Stata. Stata J. 2020, 20, 176–235. [Google Scholar] [CrossRef]

- Awad, M.; Khanna, R. Machine Learning. In Efficient Learning Machines: Theories, Concepts, and Applications for Engineers and System Designers, , M.; Awad, M., Khanna, R., Eds.; Apress: Berkeley, CA, 2015. [Google Scholar]

- Mehbodniya, A.; Khan, I.R.; Chakraborty, S.; Karthik, M.; Mehta, K.; Ali, L.; Nuagah, S.J. Data Mining in Employee Healthcare Detection Using Intelligence Techniques for Industry Development. J Heal. Eng 2022, 2022, 6462657. [Google Scholar] [CrossRef] [PubMed]

- Sarker, I.H.; Kayes, A.S.M.; Watters, P. Effectiveness analysis of machine learning classification models for predicting personalized context-aware smartphone usage. J. Big Data 2019, 6, 57. [Google Scholar] [CrossRef]

- Co, A.M. PA310 Clip-on CT Power Meter. Available online: https://www.archmeter.com/en/product-303005/Clip-on-CT-Power-Meter-PA310.

- Rausser, G.; Strielkowski, W.; Streimikiene, D. Smart meters and household electricity consumption: A case study in Ireland. Energy Environ. 2017, 29, 0958305X1774138. [Google Scholar] [CrossRef]

- Harford 5 Axis AI Vertical Machining Center. Available online: https://www.hartford.com.tw/en/product/5A-40R (accessed on 25 December 2023).

- Bagga, P.; Makhesana, M.; Pala, A.; Chauhan, K.; Patel, K. A Novel Computer Vision Based Machine Learning Approach For Online Tool Wear Monitoring. Machining 2021. [Google Scholar]

- Pham, N.; Wilamowski, B.M. Improved Nelder Mead’s simplex method and applications. J. Comput. 2011, 3, 55–63. [Google Scholar]

- Poznak, A.; Freiberg, D.; Sanders, P. Automotive Wrought Aluminium Alloys; 2018; pp. 333–386. [Google Scholar]

- Shin, J.; Kim, T.; Kim, D.; Kim, D.; Kim, K. Castability and mechanical properties of new 7xxx aluminum alloys for automotive chassis/body applications. J. Alloys Compd. 2017, 698, 577–590. [Google Scholar] [CrossRef]

- Joseph, O.O.; Babaremu, K.O. Agricultural Waste as a Reinforcement Particulate for Aluminum Metal Matrix Composite (AMMCs): A Review. Fibers 2019, 7, 33. [Google Scholar] [CrossRef]

- Atif Wahid, M.; Siddiquee, A.; Khan, Z. Aluminum alloys in marine construction: characteristics, application, and problems from a fabrication viewpoint. Mar. Syst. Ocean Technol. 2019, 15, 1–11. [Google Scholar]

- Li, C.; Tang, Y.; Cui, L.; Li, P. A quantitative approach to analyze carbon emissions of CNC-based machining systems. J. Intell. Manuf. 2013, 26. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, P. Sustainability Evaluation of Process Planning for Single CNC Machine Tool under the Consideration of Energy-Efficient Control Strategies Using Random Forests. Sustainability 2019, 11. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, H.; Li, W.; Yu, Y.; Guan, Y.; Ding, X. Exergy Loss Assessment Method for CNC Milling System Considering the Energy Consumption of the Operator. Processes 2023, 11, 2702. [Google Scholar] [CrossRef]

Figure 1.

Timeline Carbon footprint Issued [

6,

7,

8,

9,

10].

Figure 1.

Timeline Carbon footprint Issued [

6,

7,

8,

9,

10].

Figure 2.

Machine Learning based on Data Mining from CNC 5-axis Machine.

Figure 2.

Machine Learning based on Data Mining from CNC 5-axis Machine.

Figure 3.

Wiring diagram for (a) X-, Y-, Z-axis motor, (b) A- and C-axis motor, (c) Spindle motor.

Figure 3.

Wiring diagram for (a) X-, Y-, Z-axis motor, (b) A- and C-axis motor, (c) Spindle motor.

Figure 4.

PA-310 power meter is installed to measure the current and voltage on the CNC 5 axis machine panel, each smart meter is dedicated to measuring the output of each axis motor, which is X, Y, Z, C, A, and the spindle speed motor.

Figure 4.

PA-310 power meter is installed to measure the current and voltage on the CNC 5 axis machine panel, each smart meter is dedicated to measuring the output of each axis motor, which is X, Y, Z, C, A, and the spindle speed motor.

Figure 5.

NX 3D Siemens simulation cutting process from X-, Y-, Z-, C-axis and A-axis with angle of 10 degree. This level of granularity enables us to uncover specific energy consumption patterns, providing a detailed understanding of how power is utilized in the context of different machining operations.

Figure 5.

NX 3D Siemens simulation cutting process from X-, Y-, Z-, C-axis and A-axis with angle of 10 degree. This level of granularity enables us to uncover specific energy consumption patterns, providing a detailed understanding of how power is utilized in the context of different machining operations.

Figure 6.

(a) signal to noise with rule smaller is better, (b) plot for means with Taguchi analysis.

Figure 6.

(a) signal to noise with rule smaller is better, (b) plot for means with Taguchi analysis.

Figure 8.

Performance comparison between true vs predicted among different algorithm.

Figure 8.

Performance comparison between true vs predicted among different algorithm.

Figure 9.

Comparative analysis of parameter significance for Decision Tree and Random Forest Algorithms.

Figure 9.

Comparative analysis of parameter significance for Decision Tree and Random Forest Algorithms.

Figure 10.

Comprehensive approach to substantially reduce the Carbon Footprint of a CNC 5-axis machine.

Figure 10.

Comprehensive approach to substantially reduce the Carbon Footprint of a CNC 5-axis machine.

Table 1.

Harford A-25R 5-axis Machining Center.

Table 1.

Harford A-25R 5-axis Machining Center.

| Subject |

Detail specification |

| Electric Power Consumption |

20kva |

| Machine Weight |

3300kg |

Motor Rated Output

(X/Y/Z/A/C) |

Spindle Drive Motor 7.5kw

X,Y,Z,A,C Axis Drive Motor 2.18kw/2.18kw/3.5kw/1.2kw/1.7kw |

| Stroke |

X-axis (Longitudinal Travel) : 350mm

Y-axis (Cross Travel) : 300mm

Z-axis (Vertical Travel) :250mm

A-axis (inclined) : -120° ~+30°

C-axis (Rotation) :360° |

Feed (rapid traverse)

(X/Y/Z/A/C) |

36000 (OP:40000) mm/minute |

| Spindle Speed |

12000rpm |

Table 2.

L9 orthogonal array for Energy Calculation.

Table 2.

L9 orthogonal array for Energy Calculation.

| Spindle Speed |

Feed Rate |

Width Of Cut |

Depth Of Cuth |

Energy Cons. |

4000rpm

4000rpm

4000rpm

6000rpm

6000rpm

6000rpm

8000rpm

8000rpm

8000rpm |

300mm/min

500mm/min

700mm/min

300mm/min

500mm/min

700mm/min

300mm/min

500mm/min

700mm/min |

1mm

2mm

3mm

2mm

3mm

1mm

3mm

1mm

2mm |

0.5mm

1.0mm

1.5mm

1.5mm

0.5mm

1.0mm

1.0mm

1.5mm

0.5mm |

50.4592Wh

47.5774Wh

40.6281Wh

21.3878Wh

47.5774Wh

33.2004Wh

12.7415Wh

22.8102Wh

26.3904Wh |

Table 3.

Regression analysis from each factor with three repetition.

Table 3.

Regression analysis from each factor with three repetition.

| Term |

Experiment 1 |

Experiment 2 |

Experiment 3 |

| Coef. |

T-Value |

Coef. |

T-Value |

Coef. |

T-Value |

Constant

Spindle Speed

Feed Rate

Width Of Cut

Depth Of Cut

R-Square

R-Square (Adj) |

80.5

-0.006

0.013

-0.920

-13.20 |

5.87*

-4.56*

0.93-0.33

-2.35** |

63.2

-0.004

0.003

-0.280

-6.020 |

4.60*

-3.55*

0.22

-0.10

-1.07 |

76.5

-0.006

0.008

-3.400

-4.600 |

4.38*

-3.41*

0.46

-0.95

-0.64 |

87.21%

74.43% |

77.52%

55.03% |

76.72%

53.44% |

Table 4.

Performance metric with different algorithm.

Table 4.

Performance metric with different algorithm.

| Model |

RMSE |

MSE |

MAE |

Rsq |

| Linear Regression |

5.98 |

35.78 |

4.71 |

0.74 |

| Lasso Regression |

6.31 |

39.78 |

5.03 |

0.72 |

| Ridge Regression |

5.99 |

35.91 |

4.72 |

0.74 |

| Decision Tree Regressor |

4.24 |

17.97 |

3.23 |

0.87 |

| Random Forest Regressor |

4.28 |

18.28 |

3.33 |

0.87 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).