Submitted:

21 December 2023

Posted:

21 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

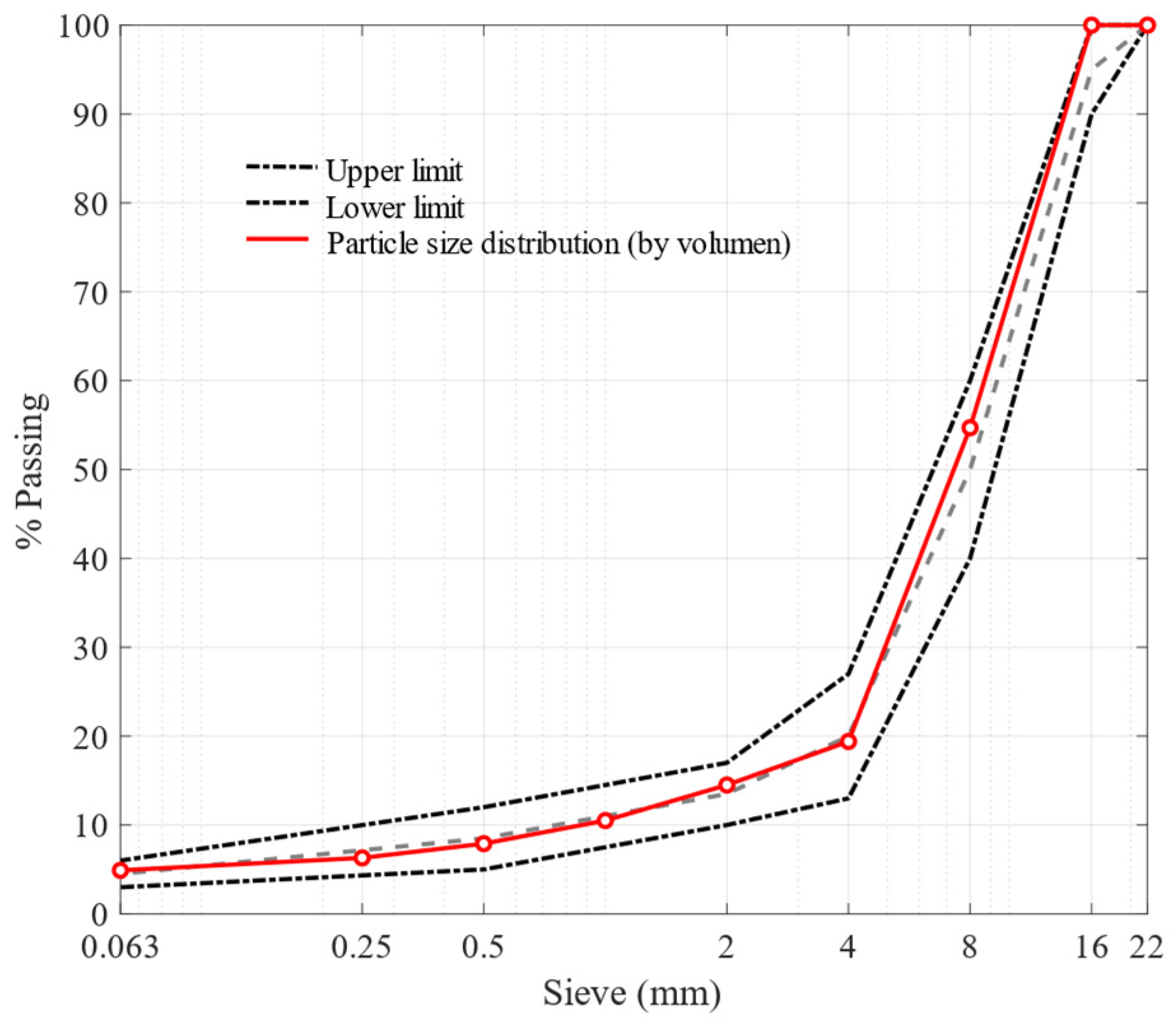

2.1.1. Aggregates

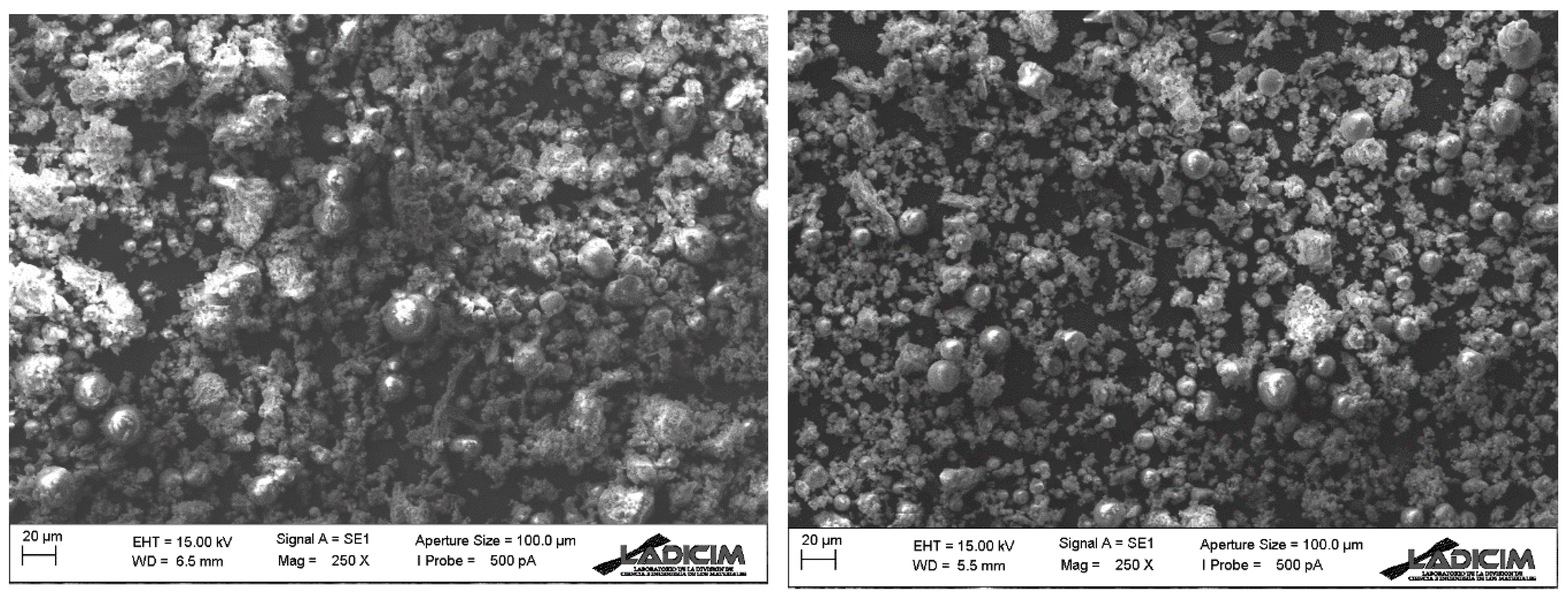

2.1.2. Asphalt binder and modifiers

2.1.3. Asphalt mixes

2.2. Methodology

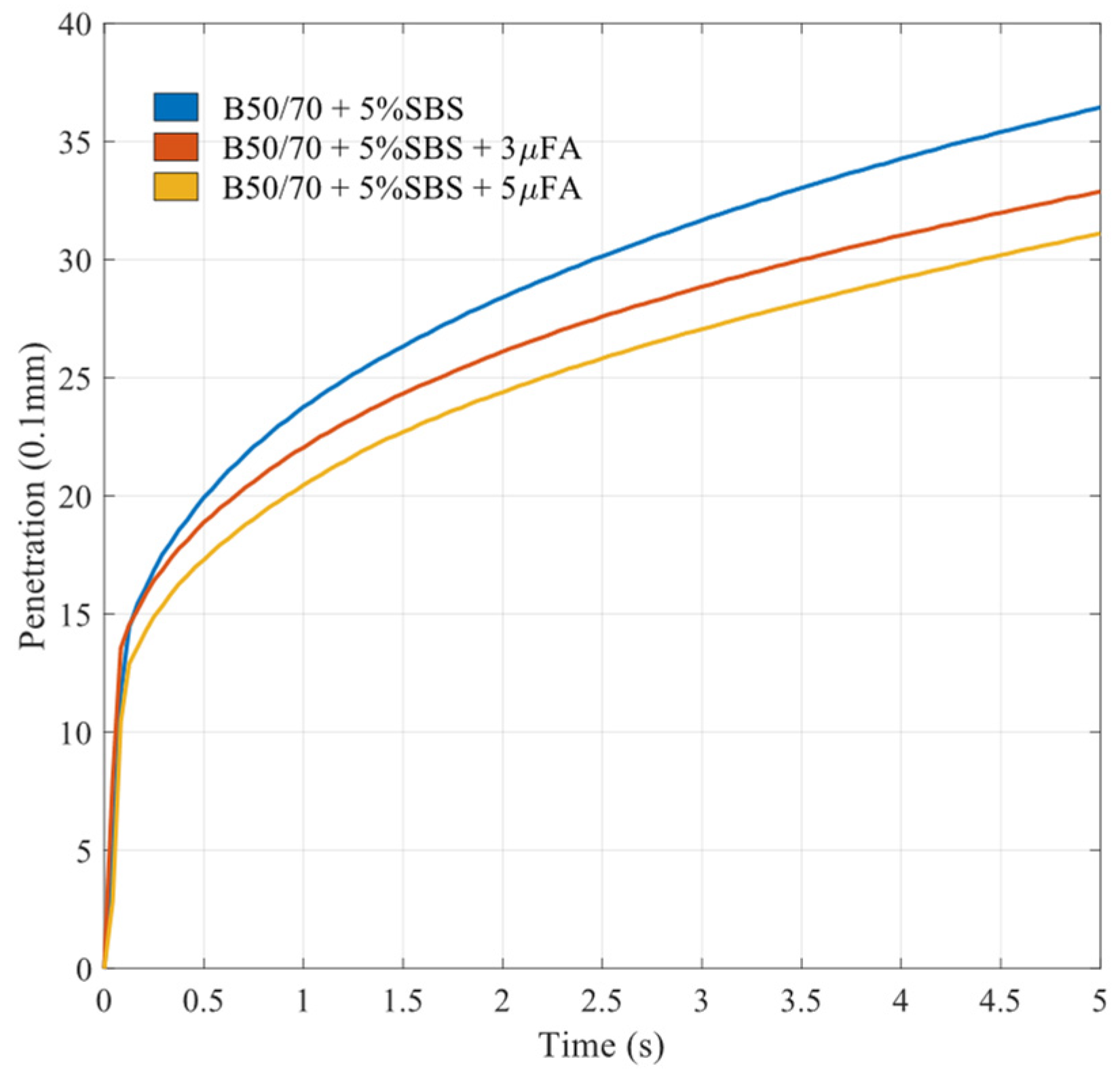

2.2.1. Penetration

2.2.2. Dynamic shear Rheometer (DSR) test

2.2.3. Multiple stress creep and recovery (MSCR)

2.2.4. Linear Amplitude Sweep (LAS)

2.2.5. Binder Yield Energy (BYET) test

2.2.6. Binder Braindown

2.2.7. Volumetric test

2.2.8. Water Sensitivity test

2.2.9. Cantabrian particle loss test

3. Results and discussion

3.1. Penetration

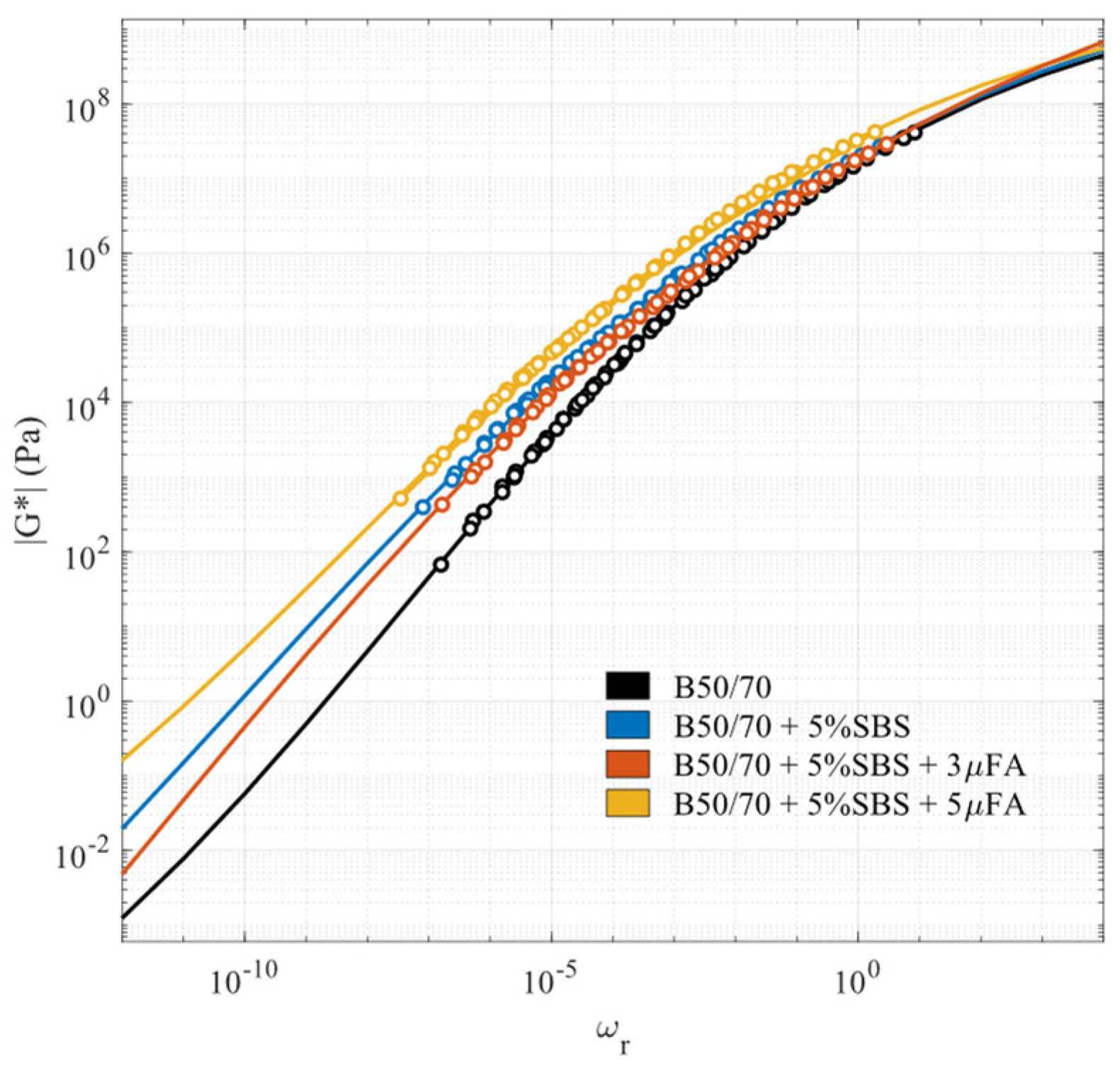

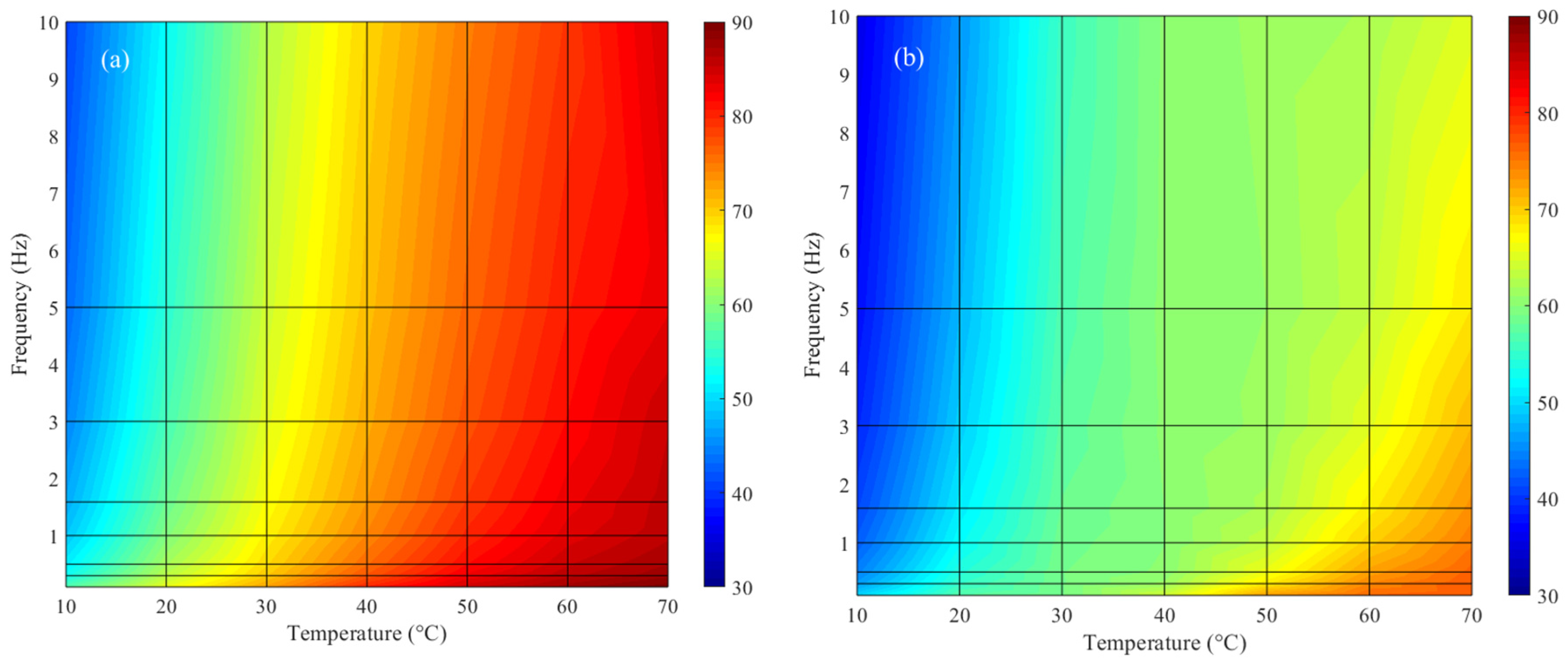

3.2. DSR test

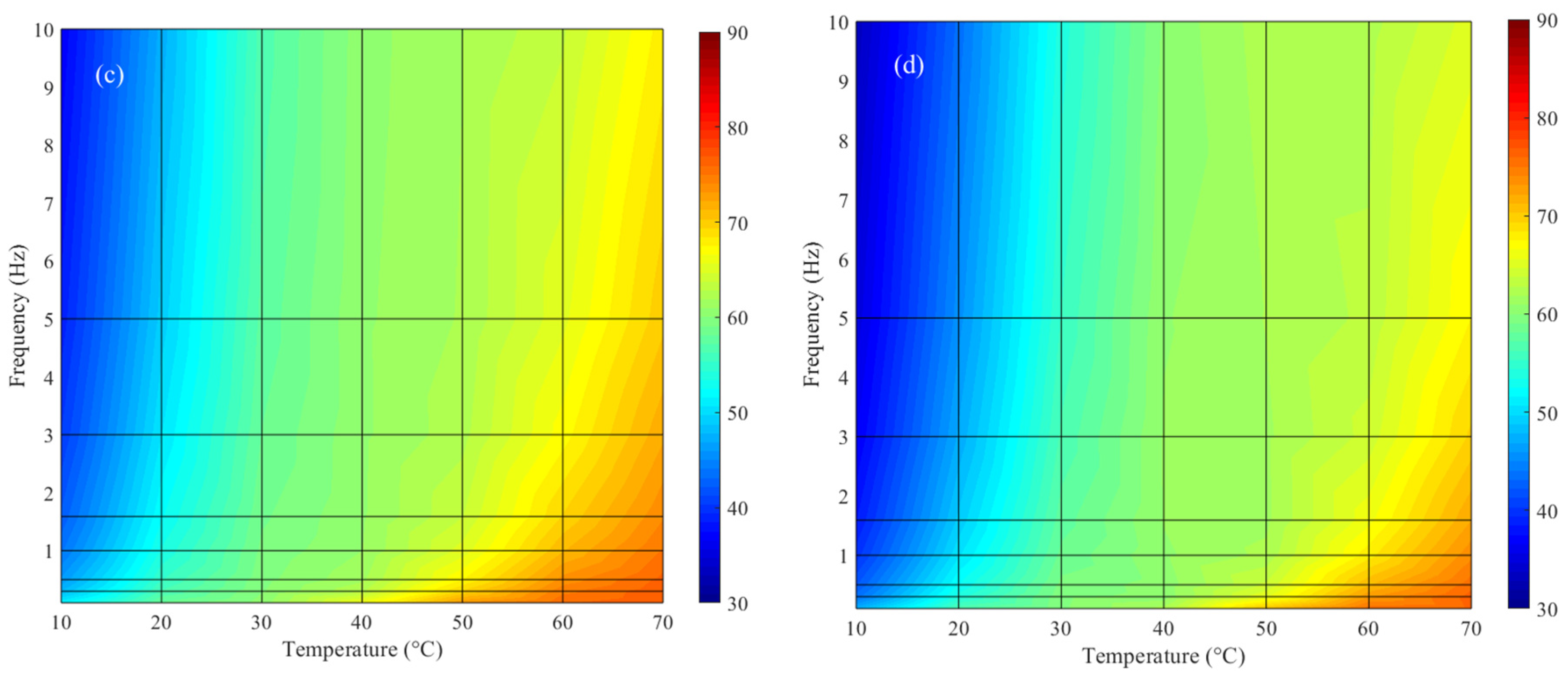

3.3. MSCR test

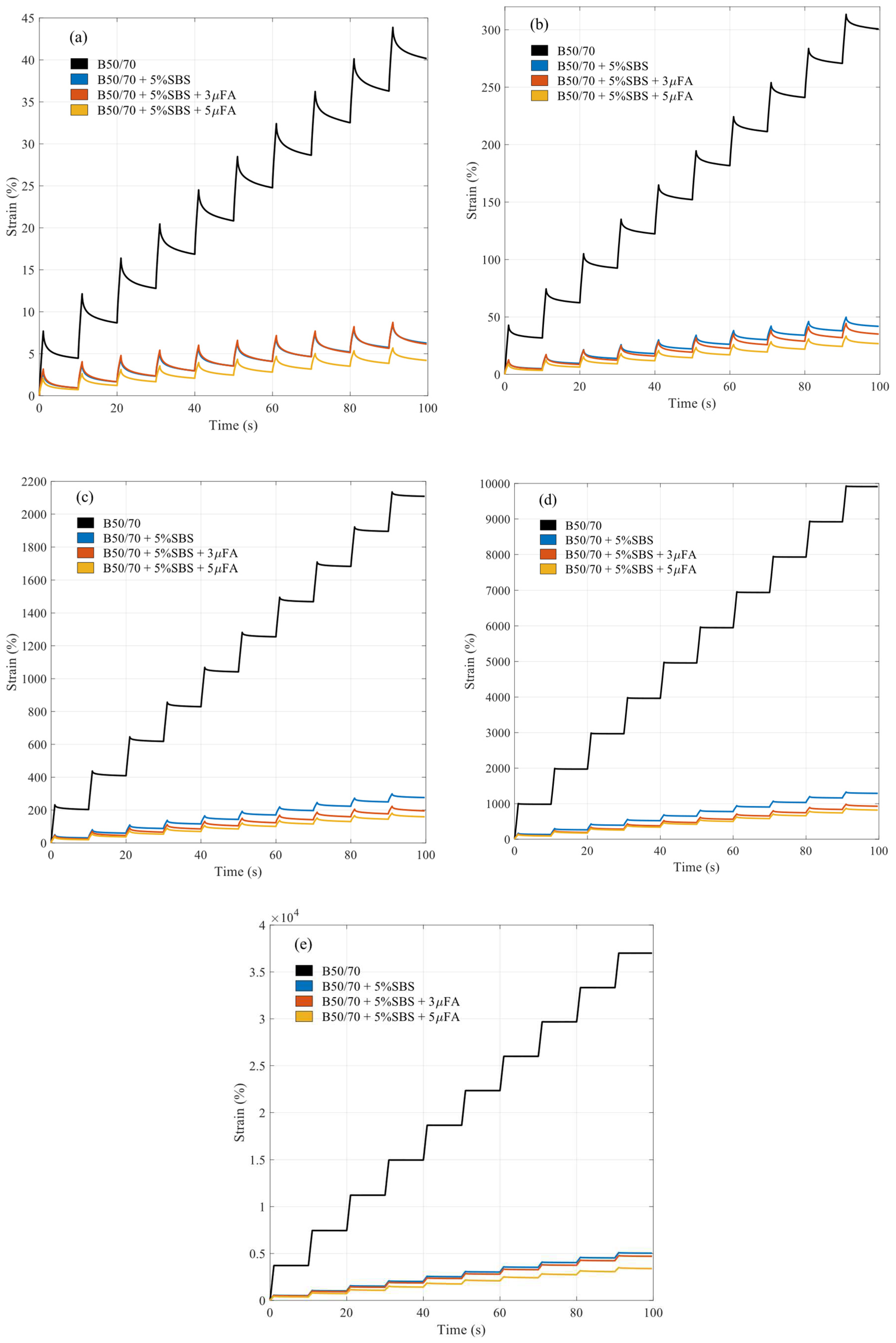

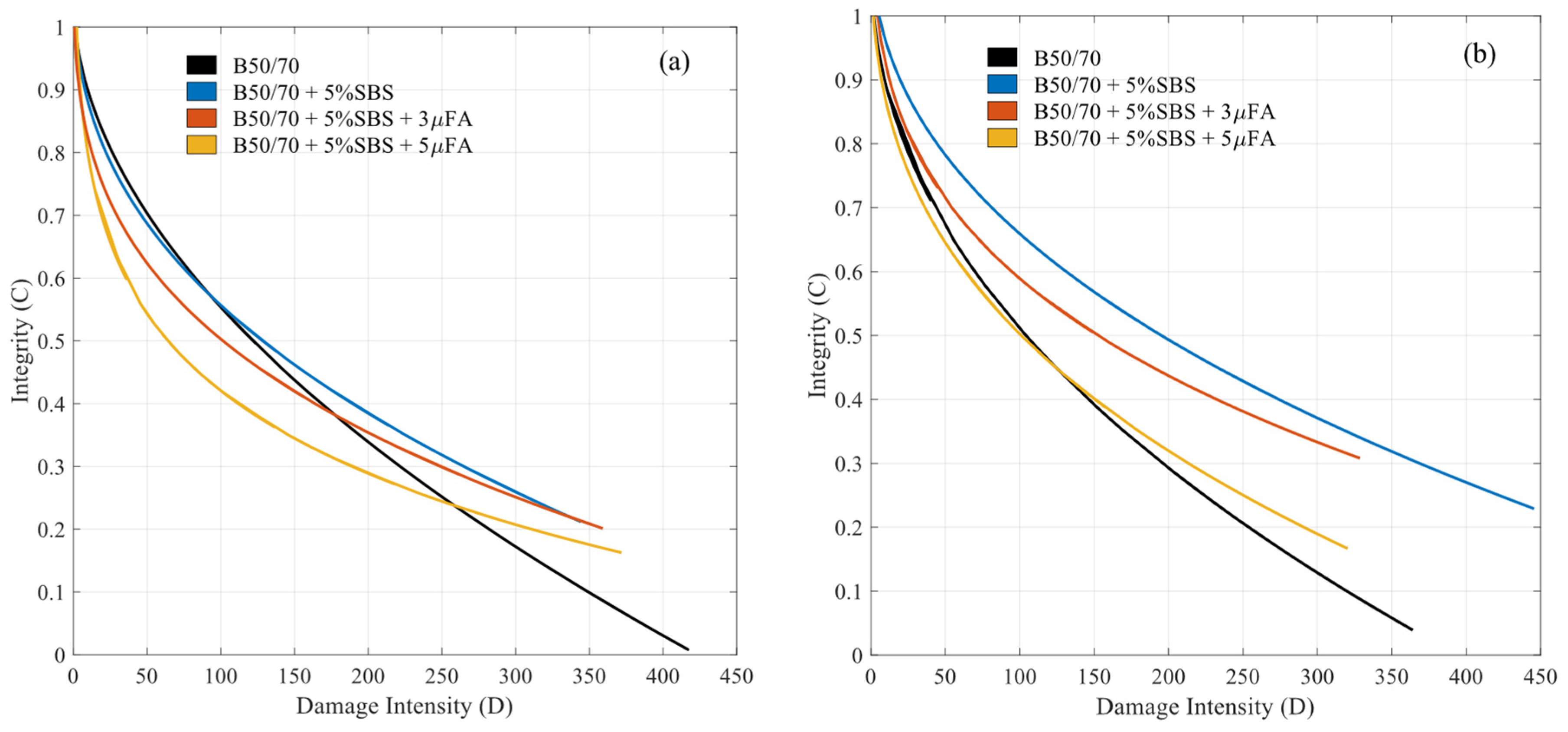

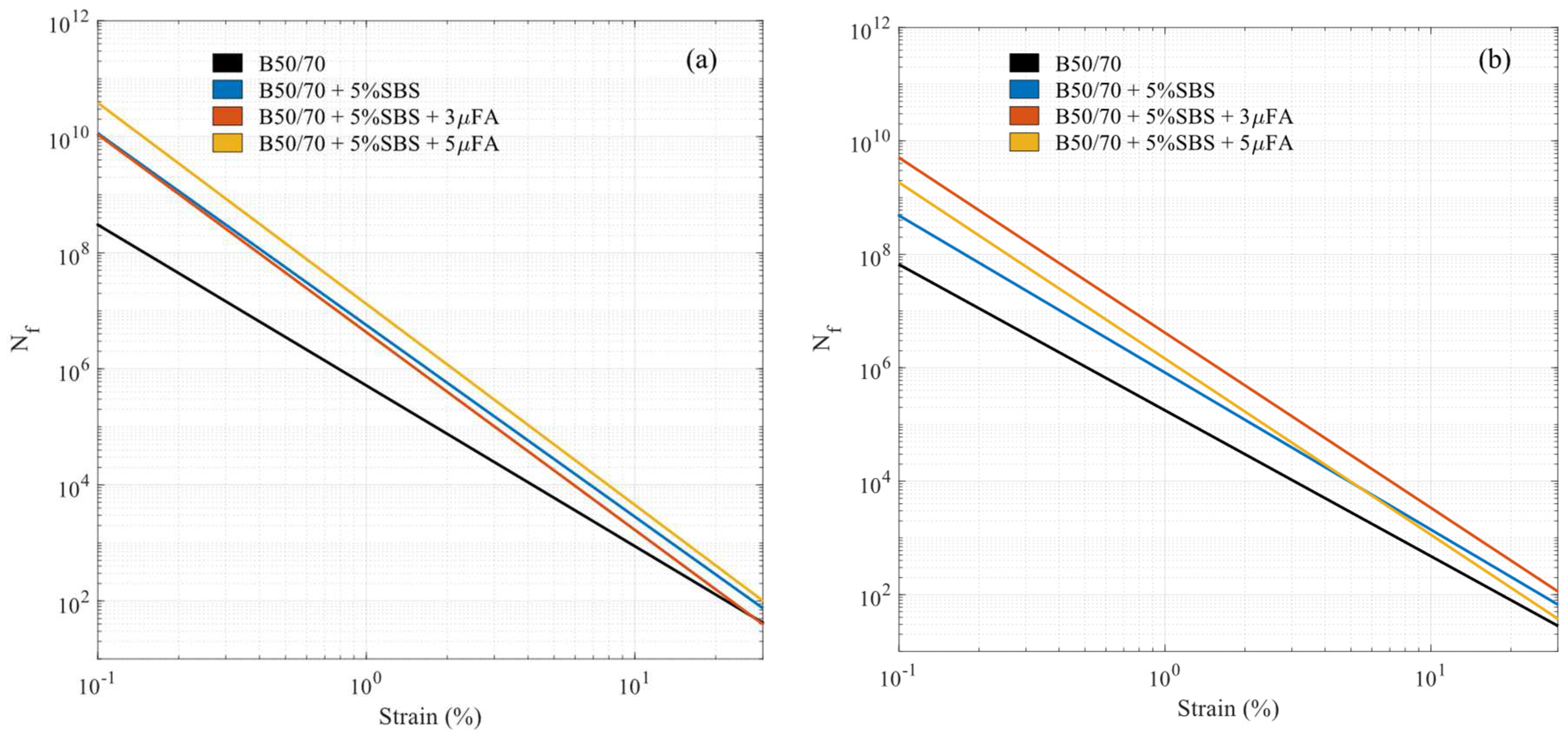

3.4. LAS test

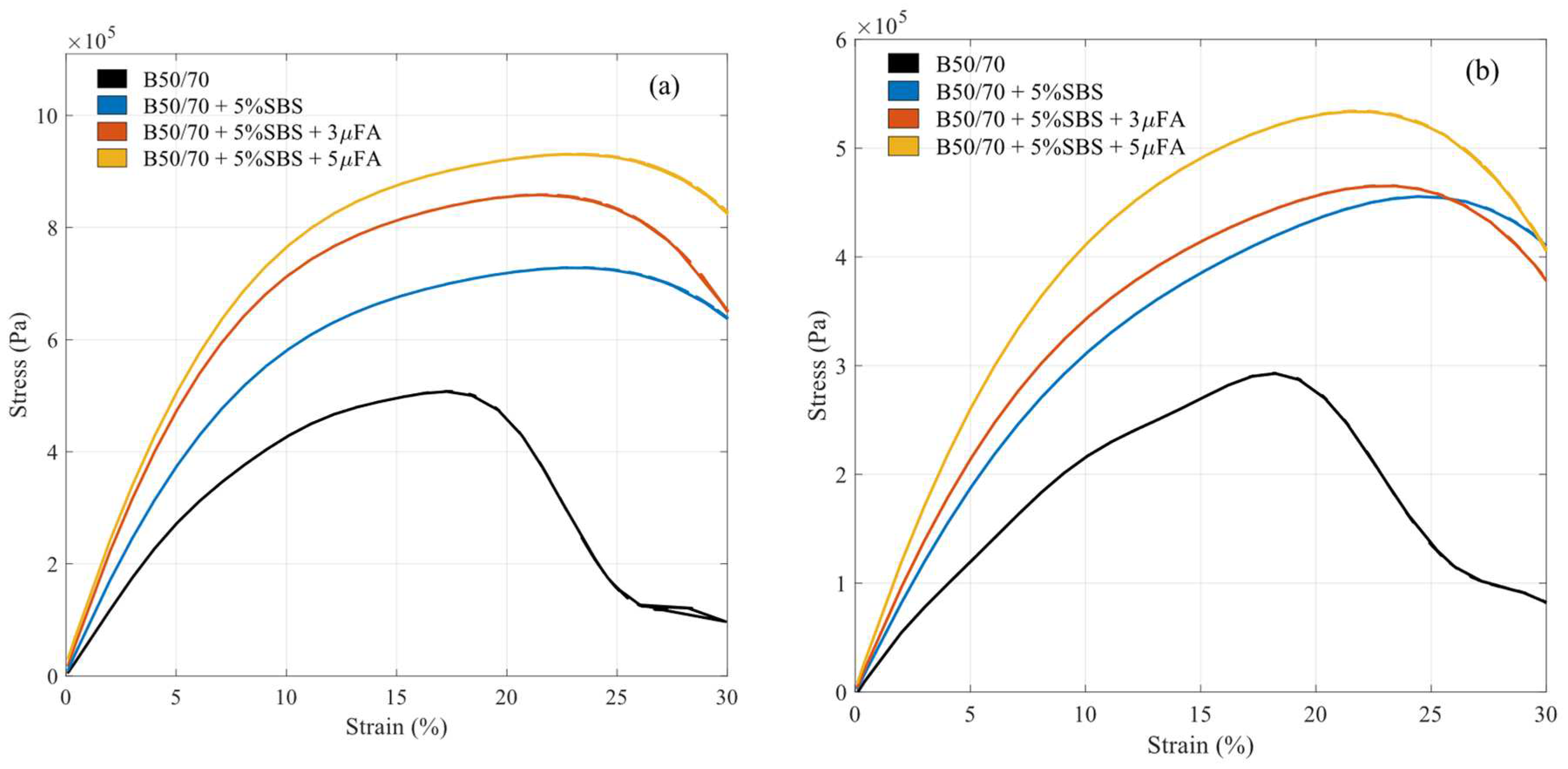

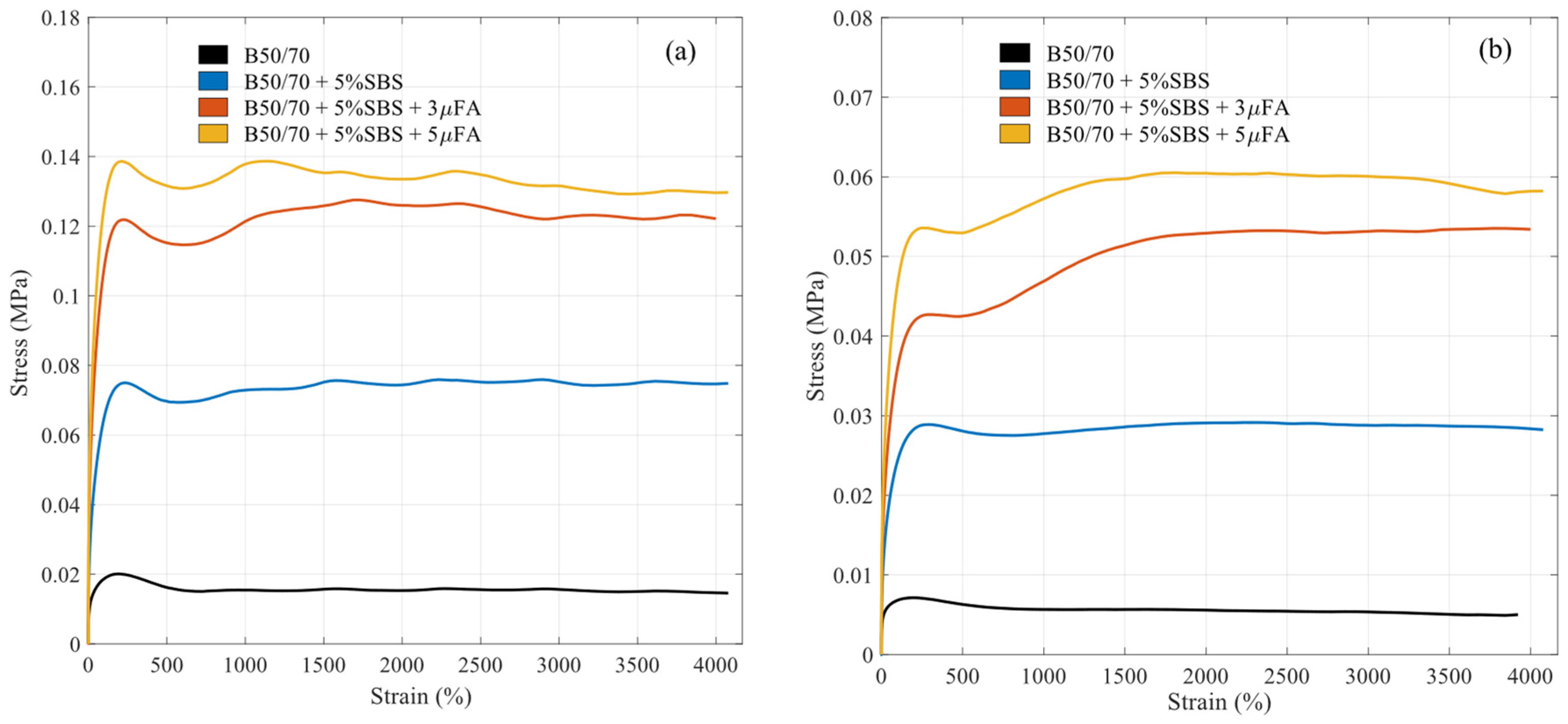

3.5. BYET test

3.6. Binder Draindown

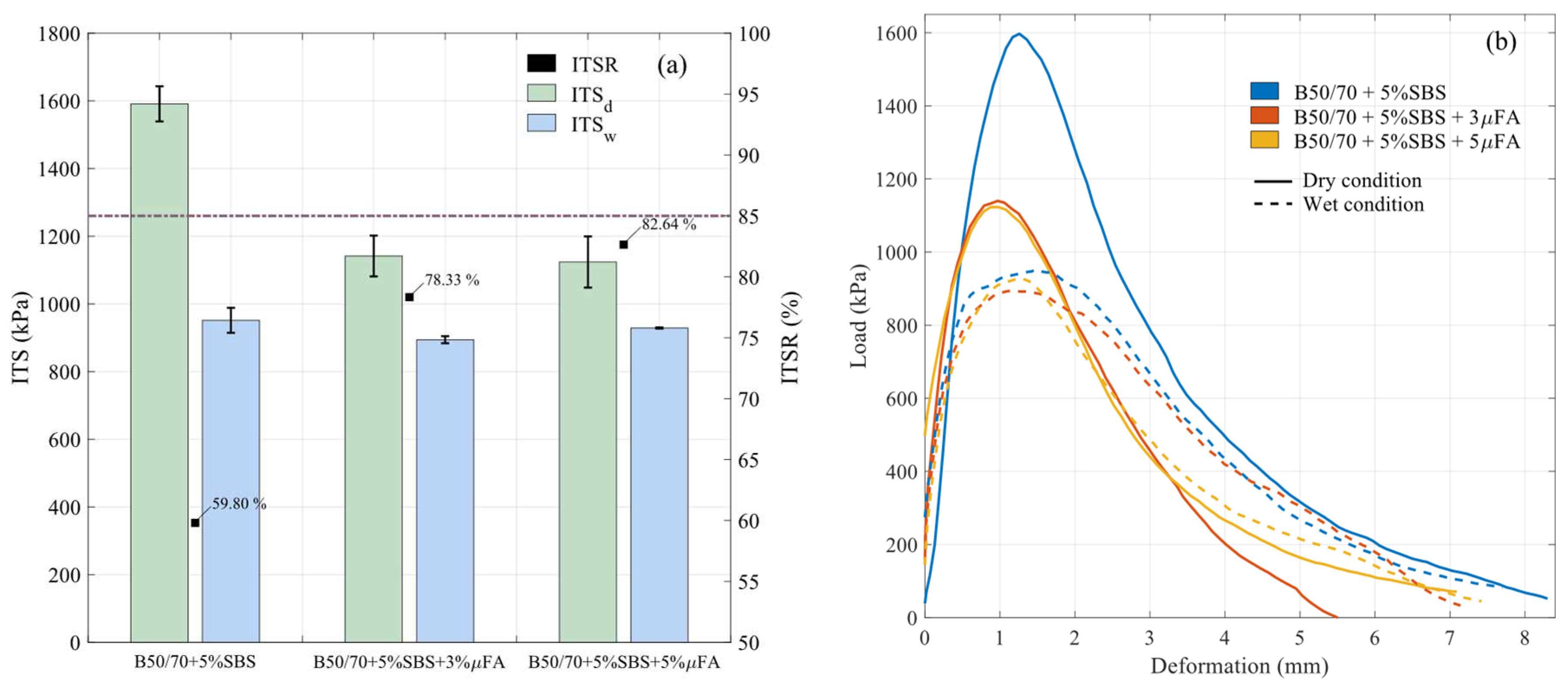

3.7. Water sensitivity test

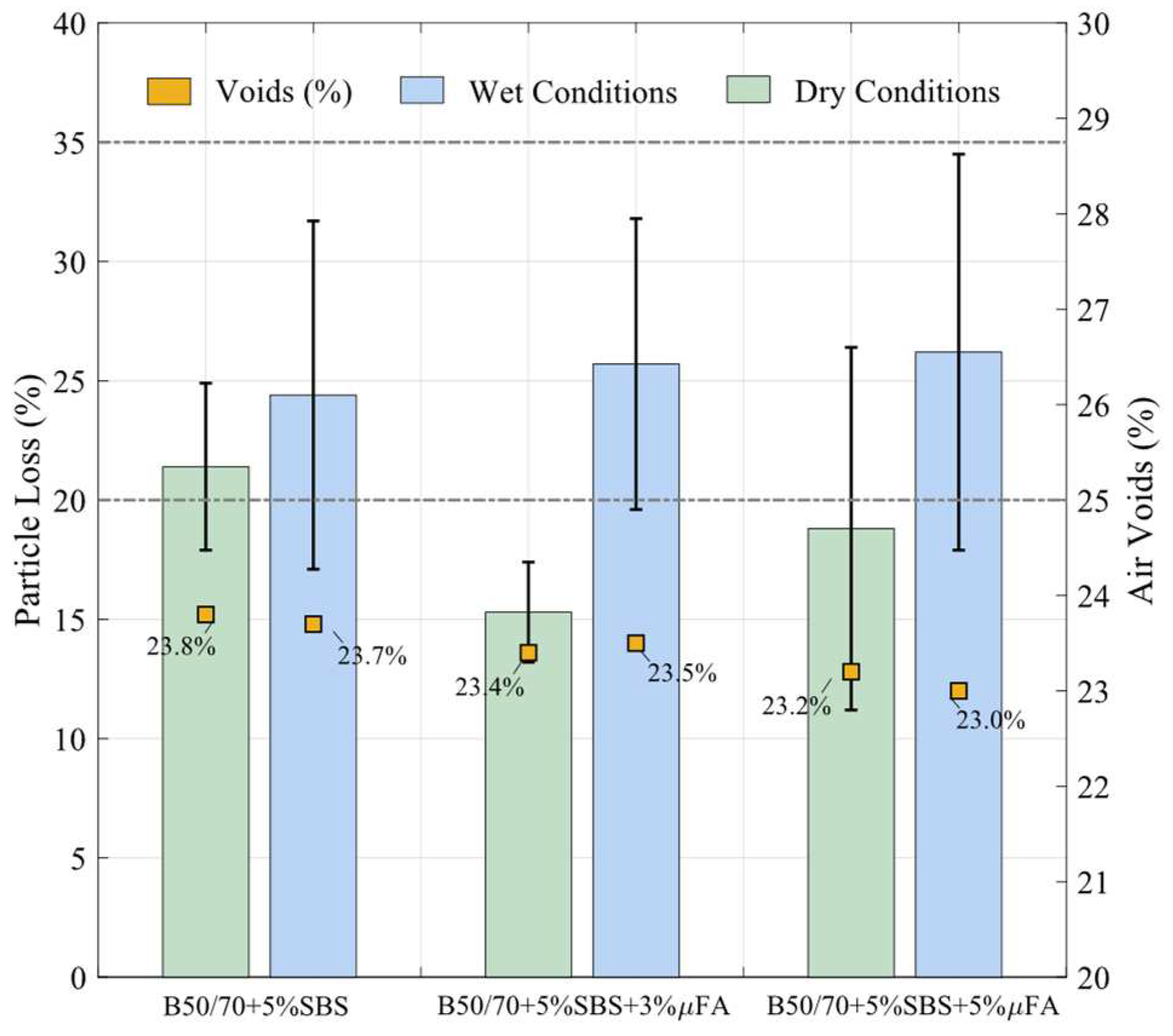

3.8. Cantabrian loss particle test (Dry and wet conditions).

4. Conclusions

- -

- Based on the results obtained, it is validated that SBS improves the mechanical properties of the conventional binder, increasing the stiffness (G*|) and elasticity. In addition, it was found that by increasing the temperature, the increase in d is reduced, preventing premature softening of the binder. Based on the progressive damage tests, it is determined that SBS reduces the plastic range at high temperatures, increasing the R and decreasing the Jnr. Concerning low temperatures, SBS achieves remarkable behaviour by increasing the damage intensity D, generating a higher C integrity than the conventional binder. Also, SBS increases the fatigue life Nf and creep yield energy Er compared to the conventional binder.

- -

- From rheological tests, adding mFA microfiller significantly improves the stiffness |G*| of SBS binders in the LVE range. However, the incorporation of mFA does not generate a noticeable impact on d, which shows that its incorporation generates mainly a physical and not a chemical contribution. Concerning the MSCR test, mFA reduces all test temperatures for creep and recovery phenomena, performing better against permanent deformation and cupping. Based on the VECD simulation, mFA does not significantly affect the sample`s integrity with increasing damage intensity. In this sense, binders with mFA only achieve better C integrity for high damage intensities (D=176) than the base binder. Concerning the BYET test, the samples with mFA caused an increase in stress after reaching the first maximum stress at 25°C. The authors hypothesise that this behaviour is due to a higher displacement of the binder in the torque caused by the DSR. Thereby, the mFA particles provide extra stiffness, which could be defined as a reserve of the material.

- -

- Based on the results of the PA16 porous mixes, adding mFA to the SBS-modified binder slightly reduces the percentage of voids in the sample (22.45%). This behaviour is because the samples with mFA produce a binder with a thicker film, generating a higher bulk density and less binder run-off. About abrasion resistance, it is concluded that all the samples meet the requirements in dry and wet conditions. However, the samples incorporating mFA in wet conditions achieve a higher particle loss with increasing concentration. In contrast, none of the PA samples meet the water sensitivity requirement. However, the addition of mFA manages to decrease the difference between dry and wet ITS. In the dry state, the samples with micro filler reduce the FE and PE energy due to higher cracking before failure and faster propagation after failure. In the wet state, the mFA samples increase the FE and PE energy due to higher ductility.

- -

- Using FA micro filler as a secondary modifier in a polymeric binder with SBS improves the mechanical performance at the rheological level and other micro or nanomaterials studied in the literature review, such as clay or silica fume. On the other hand, it is concluded that the operating conditions in the binder modification process can affect the rheological properties and, thus, the future strength of the pavement. Therefore, implementing the fly ash microfiller as a second modifier at different dosages should be further investigated in future research for its correct technical and mechanical implementation and eventual economic improvement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgements

Conflicts of Interest

References

- E.J. Elizondo-Martínez, V.C. Andrés-Valeri, D. Jato-Espino, J. Rodriguez-Hernandez, Review of porous concrete as multifunctional and sustainable pavement, Journal of Building Engineering. 27 (2020). [CrossRef]

- A.M. Youssef, E.A. Fahmy, Evaluation of porous asphalt mixes stabilized by human scalp hair, Case Studies in Construction Materials. 19 (2023). [CrossRef]

- J. Cai, C. Song, X. Gong, J. Zhang, J. Pei, Z. Chen, Gradation of limestone-aggregate-based porous asphalt concrete under dynamic crushing test: composition, fragmentation and stability, Constr Build Mater. 323 (2022). [CrossRef]

- V.C. Andrés-Valeri, J. Rodriguez-Torres, M.A. Calzada-Perez, J. Rodriguez-Hernandez, Exploratory study of porous asphalt mixtures with additions of reclaimed tetra pak material, Constr Build Mater. 160 (2018) 233–239. [CrossRef]

- A.E. Alvarez, A.E. Martin, C. Estakhri, A review of mix design and evaluation research for permeable friction course mixtures, Constr Build Mater. 25 (2011) 1159–1166. [CrossRef]

- M. Lagos-Varas, D. Movilla-Quesada, A.C. Raposeiras, P. Monsalve-Cárcamo, D. Castro-Fresno, Rheological analyses of binders modified with triple combinations of Crumb-Rubber, Sasobit and Styrene-Butadiene-Styrene, Case Studies in Construction Materials. 19 (2023). [CrossRef]

- F. Özel, M.T. Deniz, M.İ. Yüce, Evaluation of olive pomace and SBS modified bitumen to the performance characteristics, Case Studies in Construction Materials. 19 (2023). [CrossRef]

- O.V. Laukkanen, H. Soenen, H.H. Winter, J. Seppälä, Low-temperature rheological and morphological characterization of SBS modified bitumen, Constr Build Mater. 179 (2018) 348–359. [CrossRef]

- B. Shirini, R. Imaninasab, Performance evaluation of rubberized and SBS modified porous asphalt mixtures, Constr Build Mater. 107 (2016) 165–171. [CrossRef]

- J. Liu, H. Li, J. Harvey, G. Airey, S. Lin, S.L.J. Lee, Y. Zhou, B. Yang, Study on leaching characteristics and biotoxicity of porous asphalt with biochar fillers, Transp Res D Transp Environ. 122 (2023). [CrossRef]

- M. Lagos-Varas, D. Movilla-Quesada , A.C. Raposeiras, J.P. Arenas , M.A. Calzada-Pérez, P.L.-G. A. Vega-Zamanillo, Influence of limestone filler on the rheological properties of bituminous mastics through susceptibility master curves, Constr Build Mater. 231 (2020). [CrossRef]

- M. Lagos-Varas, D. Movilla-Quesada, A.C. Raposeiras, D. Castro-Fresno, O. Muñoz-Cáceres, V.C. Andrés-Valeri, M.A. Rodríguez-Esteban, Viscoelasticity modelling of asphalt mastics under permanent deformation through the use of fractional calculus, Constr Build Mater. 329 (2022) 127102. [CrossRef]

- Y. Tian, L. Sun, H. Li, H. Zhang, J. Harvey, B. Yang, Y. Zhu, B. Yu, K. Fu, Laboratory investigation on effects of solid waste filler on mechanical properties of porous asphalt mixture, Constr Build Mater. 279 (2021). [CrossRef]

- B. Yang, H. Li, H. Zhang, L. Sun, J. Harvey, Y. Tian, Y. Zhu, X. Zhang, D. Han, L. Liu, Environmental impact of solid waste filler in porous asphalt mixture, Constr Build Mater. 303 (2021). [CrossRef]

- D. Paul, M. Suresh, M. Pal, Utilization of fly ash and glass powder as fillers in steel slag asphalt mixtures, Case Studies in Construction Materials. 15 (2021). [CrossRef]

- R.S. Blissett, N.A. Rowson, A review of the multi-component utilisation of coal fly ash, Fuel. 97 (2012) 1–23. [CrossRef]

- A.-R.S. SUHEIBANI, THE USE OF FLY ASH AS AN ASPHALT EXTENDER IN ASPHALT CONCRETE MIXES, 1986. https://www.proquest.com/dissertations-theses/use-fly-ash-as-asphalt-extender-concrete-mixes/docview/303423260/se-2?accountid=26778.

- F. Li, Y. Yang, L. Wang, Evaluation of physicochemical interaction between asphalt binder and mineral filler through interfacial adsorbed film thickness, Constr Build Mater. 252 (2020) 119135. [CrossRef]

- R. Mistry, T.K. Roy, Effect of using fly ash as alternative filler in hot mix asphalt, Perspect Sci (Neth). 8 (2016) 307–309. [CrossRef]

- H. Fadil, D. Jelagin, M.N. Partl, A new viscoelastic micromechanical model for bitumen-filler mastic, Constr Build Mater. 253 (2020). [CrossRef]

- M. El-Shafie, I.M. Ibrahim, A.M.M. Abd El Rahman, The addition effects of macro and nano clay on the performance of asphalt binder, Egyptian Journal of Petroleum. 21 (2012) 149–154. [CrossRef]

- C. Roman, M. García-Morales, Comparative assessment of the effect of micro- and nano- fillers on the microstructure and linear viscoelasticity of polyethylene-bitumen mastics, Constr Build Mater. 169 (2018) 83–92. [CrossRef]

- L.G.A.T. Farias, J.L. Leitinho, B. de C. Amoni, J.B.S. Bastos, J.B. Soares, S. de A. Soares, H.B. de Sant’Ana, Effects of nanoclay and nanocomposites on bitumen rheological properties, Constr Build Mater. 125 (2016) 873–883. [CrossRef]

- X. Shi, L. Cai, W. Xu, J. Fan, X. Wang, Effects of nano-silica and rock asphalt on rheological properties of modified bitumen, Constr Build Mater. 161 (2018) 705–714. [CrossRef]

- M. Fathi, A. Yousefipour, E. Hematpoury Farokhy, Mechanical and physical properties of expanded polystyrene structural concretes containing Micro-silica and Nano-silica, Constr Build Mater. 136 (2017) 590–597. [CrossRef]

- M. Lagos-Varas, A.C. Raposeiras, D. Movilla-Quesada, J.P. Arenas, D. Castro-Fresno, O. Muñoz-Cáceres, V.C. Andres-Valeri, Study of the permanent deformation of binders and asphalt mixtures using rheological models of fractional viscoelasticity, Constr Build Mater. 260 (2020). [CrossRef]

- M. Lagos-Varas, D. Movilla-Quesada, A.C. Raposeiras, D. Castro-Fresno, Á. Vega-Zamanillo, M. Cumian-Benavides, Use of Hydrated Ladle Furnace Slag as a filler substitute in asphalt mastics: Rheological analysis of filler/bitumen interaction, Constr Build Mater. 332 (2022) 127370. [CrossRef]

- P. Lastra-González, I. Indacoechea-Vega, M.A. Calzada-Pérez, D. Castro-Fresno, A. Vega-Zamanillo, Mechanical assessment of the induction heating as a method to accelerate the drying process of cold porous asphalt mixtures, Constr Build Mater. 208 (2019) 646–650. [CrossRef]

- C.J. Slebi-Acevedo, P. Lastra-González, I. Indacoechea-Vega, D. Castro-Fresno, Laboratory assessment of porous asphalt mixtures reinforced with synthetic fibers, Constr Build Mater. 234 (2020). [CrossRef]

- V.S. Arrieta, J.E.C. Maquilón, Resistance to Degradation or Cohesion Loss in Cantabro Test on Specimens of Porous Asphalt Friction Courses, Procedia Soc Behav Sci. 162 (2014) 290–299. [CrossRef]

| Properties | Result | Limits | Standard |

| Limestone | |||

| Los Angeles coefficient | 28 | - | EN 1097-2 |

| Specific weight (g/cm3) | 2.724 | - | EN 1097-6 |

| Sand equivalent | 78 | >55 | EN 933-8 |

| Ophite | |||

| Los Angeles coefficient | 13 | ≤20 | EN 1097-2 |

| Specific weight (g/cm3) | 2.794 | - | EN 1097-26 |

| Polished stone value (PSV) | >56 | ≥50 | EN 1097-8 |

| Flakiness Index (%) | 8 | ≤20 | EN 933-3 |

| Water absorption | 0.60 | - | EN 1097-6 |

| Test | Units | Result | Standard |

| Penetration (25ºC) | dmm | 65 | EN 1426 |

| Softening point | ºC | 48.8 | EN 1427 |

| Density | g/cm3 | 1.045 | EN 15326 |

| Penetration Index | - | -1.0 | EN 12591 |

| Test | Units | Result | Standard |

| Styrene-Butadiene-Styrene | |||

| Size max. | mm | 6.3 | - |

| Specific weight | g/cm3 | 0.93 | - |

| Type | - | Block Copolymer | - |

| Provider | - | Dynasol | - |

| Fly ash filler | |||

| Density | g/cm3 | 2.450 | - |

| Rigden voids | % | 73 | - |

| Size (mm) | 0.063 | 0.056 | 0.050 | 0.040 | 0.032 | 0.025 | 0.015 |

| Passed Through (%) | 84.68 | 69.34 | 57.03 | 39.57 | 19.80 | 9.55 | 6.55 |

| Sample | Variables | 10°C | 20°C | 30°C | 40°C | 50°C | 60°C | 70°C |

| B50/70 | |G*| (kPa) | 10470,60 | 1957,60 | 324,67 | 64,08 | 12,47 | 3,35 | 1,04 |

| |G*|/sin(d) (kPa) | 14306,15 | 2301,72 | 353,28 | 66,96 | 12,71 | 3,38 | 1,05 | |

| |G*|·sin(d) (kPa) | 7663,38 | 1664,93 | 298,38 | 61,33 | 12,23 | 3,33 | 1,04 | |

| B50/70 5%SBS |

|G*| (kPa) | 12353,60 | 2803,60 | 532,72 | 117,50 | 34,05 | 11,00 | 4,26 |

| |G*|/sin(d) (kPa) | 18813,21 | 3608,50 | 626,54 | 135,65 | 38,52 | 11,86 | 4,45 | |

| |G*|·sin(d)(kPa) | 8111,93 | 2178,24 | 452,94 | 101,77 | 30,10 | 10,20 | 4,09 | |

| B50/70 5%SBS 3%mFA |

|G*| (kPa) | 12990,70 | 2784,68 | 574,81 | 141,96 | 41,10 | 12,62 | 4,37 |

| |G*|/sin(d) (kPa) | 19277,19 | 3517,00 | 671,38 | 162,63 | 45,84 | 13,47 | 4,55 | |

| |G*|·sin(d) (kPa) | 8754,30 | 2204,85 | 492,13 | 123,92 | 36,85 | 11,81 | 4,20 | |

| B50/70 5%SBS 5%mFA |

|G*| (kPa) | 20311,90 | 4750,43 | 899,47 | 179,22 | 46,56 | 14,66 | 5,38 |

| |G*|/sin(d) (kPa) | 32723,15 | 6292,15 | 1064,33 | 204,93 | 52,92 | 16,02 | 5,65 | |

| |G*|·sin(d) (kPa) | 12607,99 | 3586,47 | 760,15 | 156,74 | 40,97 | 13,42 | 5,12 |

| Temperature | Variables | B50/70 |

B50/70 5%SBS |

B50/70 5%SBS 3%mFA |

B50/70 5%SBS 5%mFA |

| 30°C | Strain (%) | 40,16 | 6,27 | 6,15 | 4,21 |

| R (%) | 17,80 | 40,36 | 43,54 | 39,57 | |

| Jnr (1/kPa) | 1,25 | 0,20 | 0,20 | 0,13 | |

| 40°C | Strain (%) | 300,64 | 41,83 | 35,07 | 26,75 |

| R (%) | 9,75 | 29,04 | 34,77 | 33,27 | |

| Jnr (1/kPa) | 9,39 | 1,31 | 1,10 | 0,84 | |

| 50°C | Strain (%) | 2108,47 | 276,14 | 195,24 | 159,01 |

| R (%) | 3,73 | 16,16 | 23,36 | 22,81 | |

| Jnr (1/kPa) | 65,89 | 8,63 | 6,10 | 4,97 | |

| 60°C | Strain (%) | 9912,17 | 1290,28 | 927,95 | 819,29 |

| R (%) | 0,56 | 7,31 | 13,58 | 13,09 | |

| Jnr (1/kPa) | 309,76 | 40,32 | 29,00 | 25,60 | |

| 70°C | Strain (%) | 37004,30 | 5036,79 | 4711,44 | 3386,70 |

| R (%) | 0,26 | 3,16 | 4,16 | 6,95 | |

| Jnr (1/kPa) | 1156,38 | 157,40 | 147,23 | 105,83 |

| Temperature | Variables | B50/70 | B50/70 5%SBS |

B50/70 5%SBS 3%mFA |

B50/70 5%SBS 5%mFA |

|---|---|---|---|---|---|

| 20°C | a | 1,38 | 1,65 | 1,7 | 1,73 |

| A | 517000 | 5690000 | 4280000 | 13200000 | |

| B | -2,77 | -2,77 | -3,41 | -3,46 | |

| k | 1,53 | 1,78 | 2,03 | 2,02 | |

| Df | 102 | 181 | 134 | 201 | |

| smáx | 546473 | 818917 | 979366 | 1055270 | |

| Strain | 16,38 | 23,98 | 23,24 | 24,15 | |

| N2,5 | 40842 | 275459 | 188636 | 550618 | |

| N5 | 5988 | 27896 | 17778 | 49874 | |

| N7,5 | 1948 | 7308 | 4466 | 12240 | |

| N10 | 878 | 2825 | 1676 | 4518 | |

| 25°C | a | 1,29 | 1,38 | 1,54 | 1,55 |

| A | 177000 | 823000 | 4150000 | 1450000 | |

| B | -2,57 | -2,77 | -3,09 | -3,11 | |

| k | 1,43 | 1,33 | 1,46 | 1,67 | |

| Df | 72,1 | 147 | 202 | 129 | |

| smáx | 308492 | 491099 | 503937 | 582975 | |

| Strain | 19,35 | 26,6 | 23,54 | 22,72 | |

| N2,5 | 16802 | 65006 | 244761 | 84204 | |

| N5 | 2824 | 9531 | 28779 | 9781 | |

| N5,5 | 995 | 3100 | 8227 | 2776 | |

| N10 | 475 | 1397 | 3384 | 1136 |

| Temperature | Variables | B50/70 | B50/70 5%SBS |

B50/70 5%SBS 3%mFA |

B50/70 5%SBS 5%mFA |

|---|---|---|---|---|---|

| 20°C | smax (MPa) | 0,020 | 0,075 | 0,128 | 0,138 |

| Strain (%) | 190,2 | 234,9 | 225,0 | 215,3 | |

| Er (MPa) | 3.311 | 14,523 | 22,788 | 25,064 | |

| 30ºC | smax (MPa) | 0,007 | 0,0288 | 0,042 | 0,054 |

| Strain (%) | 192,7 | 298,3 | 288,5 | 249,64 | |

| Er (MPa) | 1,244 | 7,329 | 10,417 | 11,215 |

| Air Voids | ±Deviation | Bulk density | ±Deviation | Draindown test | |

|---|---|---|---|---|---|

| (%) | (%) | (gr/cm3) | (gr/cm3) | (%) | |

| B50/70 + 5%SBS | 23,13 | 1,12 | 1,992 | 0,028 | 0,20 |

| B50/70 + 5%SBS + 3%mFA | 22,66 | 1,01 | 2,004 | 0,025 | 0,07 |

| B50/70 + 5%SBS + 5%mFA | 22,45 | 1,28 | 2,009 | 0,032 | 0,04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).