1. Introduction

It is well known that the global negative impact over the natural environment resulted from people’s daily activities is continuously increasing. The consumption of nonrenewable resources and emissions to air, water and soil place considerable pressure on the Earth’s ecosystem and endanger the development of future generations. Unfortunately, as the awareness level regarding the need of applying the sustainability concept in all economic activities has significantly increased, the volume of environmental burdens has also continuously expanded.

One of the most significant negative impacts that will have an influence over the development of humankind in the future is the amount of natural resources that we are currently consuming. Global consumption rates are currently surpassing the Earth’s capacity of renewing the raw materials stock by 70% [

1,

2]. Another pivotal environmental problem is the degree to which our daily activities influence the global temperature. Nowadays, the global warming phenomena is considered the main and most pressing issue when it comes to the environmental dimension of sustainable development. As mentioned by the Intergovernmental Panel on Climate Change (IPCC) in the Sixth Assessment Report, the global surface temperature registered in 2020 is 1.1 ˚C higher than preindustrial values [

3].

The rise of the global temperature is mainly determined by the amount of greenhouse gases (GHG) emitted into the atmosphere. According to the IPCC report [

3], the average value of GHG emissions registered annually between 2010 and 2019 is higher than any value registered in the previous decades. At the same time, the growth rate registered in the last decade, 1.3% yr

−1, is smaller than the one recorded during 2000-2009—2.1% yr

−1. Regarding the concentration levels of greenhouse gases, the following values were registered in 2019 [

3]: 410 ppm for carbon dioxide (CO

2), 1866 ppb for methane (CH

4) and 332 ppb for nitrous oxide (N

2O). Unfortunately, despite an increase in the level of awareness regarding the negative impact of GHGs over the global warming phenomena in the last few years, there are still some economic sectors lacking in identifying and applying the right solutions in order to improve environmental performances.

At present, in the European Union (EU), energy production and consumption are responsible for approximately 75% of the entire volume of greenhouse gases emissions. Out of all economic activities, the construction sector is responsible for almost 40% of the entire energy consumption registered at the EU level [

4,

5,

6,

7,

8,

9,

10]. Moreover, upon analyzing all activities specific to this sector, the built environment is responsible for 36% of EU GHGs emissions [

8,

9,

11,

12]. By taking the above into account, the construction industry is rightfully considered a key sector in the matter of reducing the total negative effects over the natural environmental at the EU level, with the declared goal that the European continent is to become climate-neutral by 2050 [

4,

5].

In order to achieve the target of the Green Deal [

5], which represents the European Union’s roadmap for significantly reducing the negative global effects of the climate change phenomena, it is necessary to fully comprehend the influence of the existing and future buildings stock. In Europe, it is estimated that the built-up area covers approximately 25 billion square meters, with 10 billion square meters having been completed before 1960 and 20 billion square meters constructed by 1990. Eight in ten buildings in Europe were completed before 1990 [

13]. Considering the performances required by present building codes, 75% of the existing built environment is completely energy inefficient [

12,

13]. Also, seeing that the construction standards that imposed a certain performance for the buildings’ thermal envelope were adopted in European countries after 1970, it can be stated that a considerable part of existing constructions lack in achieving any level of energy efficiency [

13].

85% of the European Union’s existing building stock, i.e., approximately 220 million building units were constructed before 2001, while it is estimated that almost 95% of the present built environment will still be used in 2050 [

10]. In 2021, 6.9% of EU population had major issues in maintaining a proper level of indoor temperature during the cold season due to energy costs [

14]. At present, across the EU member states the renovation rate of the existing building stock is between 0.4 and 1.2% [

5]. At the same time, the rate of deep energy renovations of existing buildings—that can energy consumption by more than 60%, is only 0.2%. There are areas in which there aren’t any renovated buildings [

11]. Moreover, 75% of existing buildings have an extremely inefficient thermal envelope, which places significant pressure over energy consumption and increases greenhouse gases emissions [

11,

13].

Taking into account the above, the present state of the existing European building stock can be deemed to have a tremendous influence over the natural environment as well as over the efforts of achieving a sustainable development in the EU. This is the main reason for considering the construction sector a key element in the existing plans and roadmaps of the European Commission regarding the goal of achieving a climate neutral continent by 2050 [

5,

11,

15]. An important objective that must be achieved is the reduction of greenhouse emissions by 55% until 2030 [

11,

15]. To do so means that by 2023 we must reduce the buildings’ GHGs by 14%, the final energy consumption by 60% and the energy consumption for heating and cooling by 18% [

11]. Taking into account that the residential sector is the most important consumer in what concerns the built environment, and adding that European households use 64.4% of consumed energy for space heating [

16], it is essential for civil engineering specialists to develop and use the correct construction solutions in order to significantly increase the energy performances of the building stock [

17,

18,

19,

20].

In view of the above, the goal of the present paper is to analyze the manner in which the thickness of the thermal insulating layer of the exterior walls that are part of the building’s envelope influences the heating demand of a residential construction specific to the Romanian residential stock. Seeing as at the national level, existing houses are commonly renovated with the goal of increasing energy performances only by increasing the insulation layer of the walls, the paper aims to analyze how this solution influences the consumption of energy for heating. In order to complete the study, for the considered existing dwelling the values of the linear thermal transfer coefficients have been determined in order to analyze the influence of the thermal bridges as well as to fully understand the influence of different standard insulation thicknesses.

2. Materials and Methods

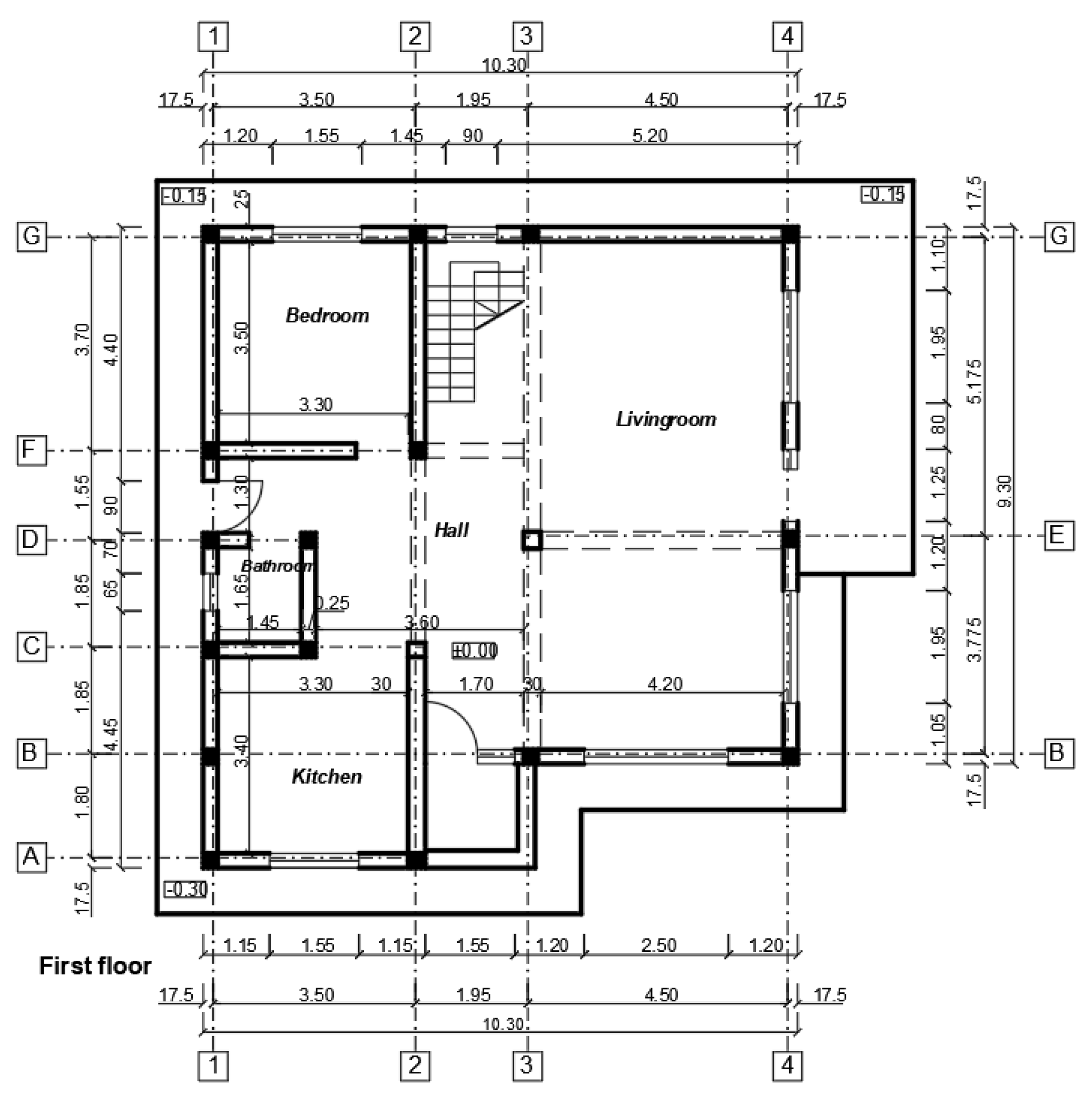

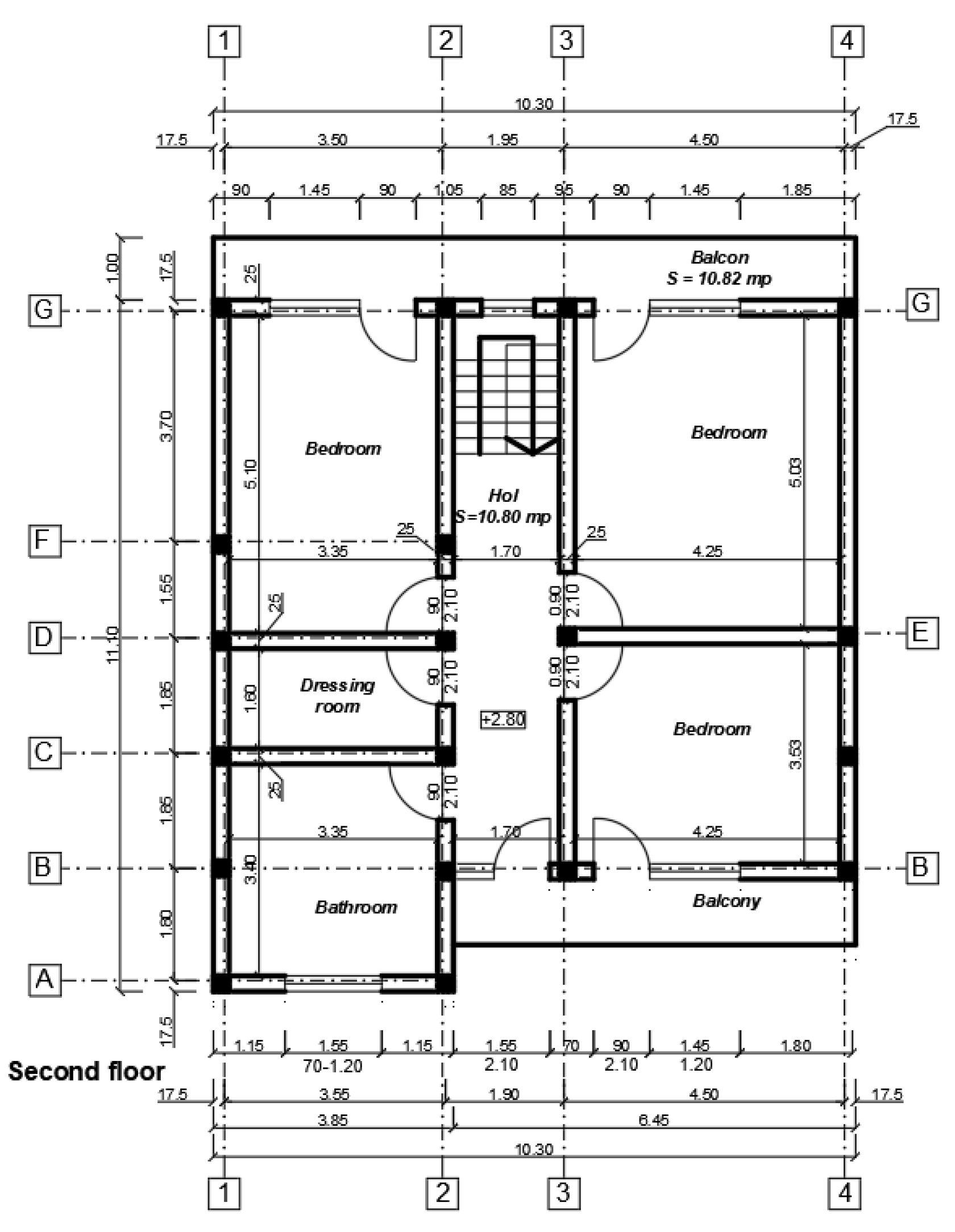

In order to conduct the study, the authors have considered a two-story dwelling built in 2008 in Miroslava village, Iasi County, Romania (

Figure 1). This type of construction has been considered due to it representing a commonly adopted solution for the existing national residential building stock. In order to gain a complete view and understanding of the considered dwelling,

Figure 2 and

Figure 3 show the architectural features of the two stories.

Table 1 presents the geometrical values considered in the analysis.

Taking into account that dwelling was designed and built in 2008, the thickness of the thermal insulating layers is very low compared with present building regulations.

Table 2 shows the dimensions and the type of materials that make up the building’s thermal envelope. The data has been used to determine the thermal transmittance values of the building’s envelope. In order to achieve the goal of the study, the authors have taken under analysis the thermal bridges that have a direct influence on the energy performances of the exterior walls (

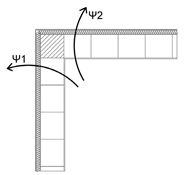

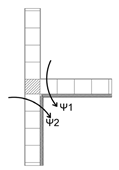

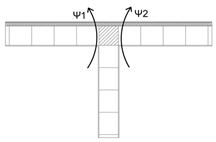

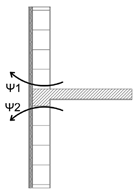

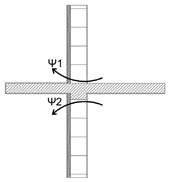

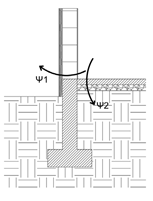

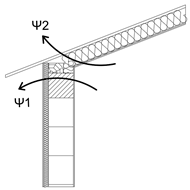

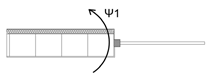

Table 3). An important aspect that influences the heating demand is the area to volume ratio (A/V) of the building—0.87.

According to the Romanian building norm C107-2005 [

21], in order to analyze the influence of the walls’ insulation thickness over the linear thermal transfer coefficients, the following temperature boundary conditions have been considered: exterior temperature (Te) = -18˚C (specific to Romanian climatic zones, the analyzed construction is in zone III); indoor temperature (Ti) = 20˚C; soil temperature at a depth of 7 m (Tp) = 9˚C. In order to perform the computation of the considered linear thermal bridges, the authors have used the values required by the Romanian normative mentioned above [

21] for the interior thermal resistance (R

Si) and for the exterior thermal resistance (R

Se):

- -

RSi = 0.125 [m2K/w]—for the exterior wall, the intermediary reinforced concrete slab and the roof;

- -

RSi = 0.167 [m2K/w]—for the ground reinforced concrete slab;

- -

RSe = 0.042 [m2K/w]—for all thermal envelope elements, apart from the last layer of soil in the case of the HTB 3 thermal bridge;

- -

RSe = 0 [m2K/w]—for the last layer of soil in the case of the HTB 3 thermal bridge.

3. Results

As stated above, the goal of the present study is to assess how the heating demand of an existing residential construction is influenced by the thickness of the exterior walls’ thermal insulation layer. In order to have a complete understanding over this aspect, the authors have first performed an analysis to determine the magnitude of the linear thermal bridges that directly influence the energy performances of the exterior walls. By using the resulted transfer transmittances and different thicknesses of the walls’ insulation, the energy demand for heating the indoor volume has been determined. To complete the study the following case studies have been considered:

- -

Case study no. 1: 5 cm thickness of the thermal insulation layer for the exterior walls (the present situation);

- -

Case study no. 2: 10 cm thickness of the thermal insulation layer for the exterior walls;

- -

Case study no. 3: 15 cm thickness of the thermal insulation layer for the exterior walls;

- -

Case study no. 4: 20 cm thickness of the thermal insulation layer for the exterior walls.

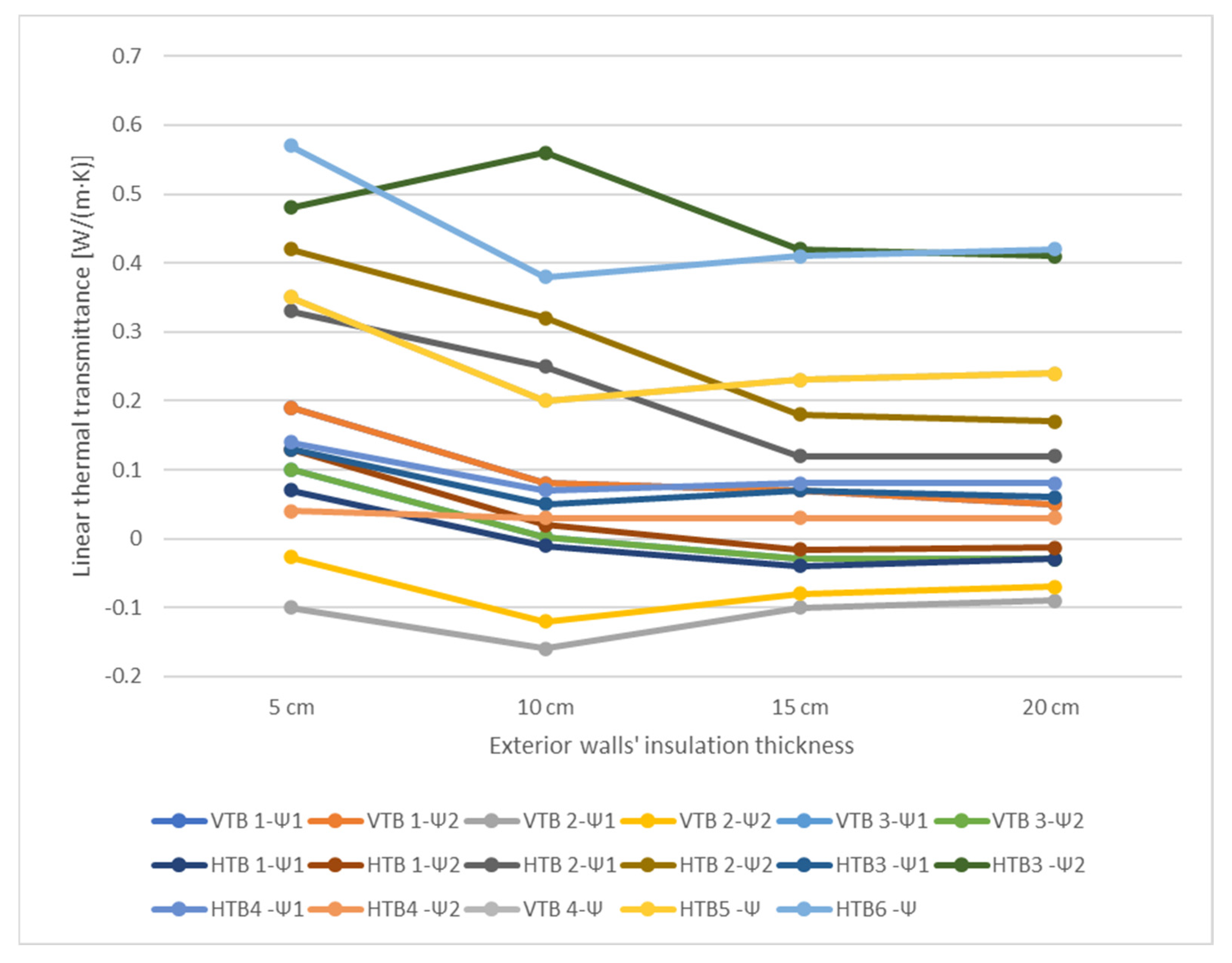

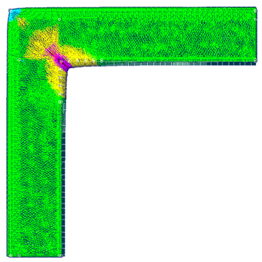

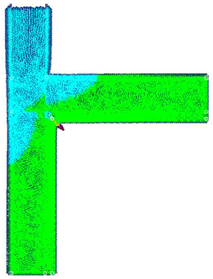

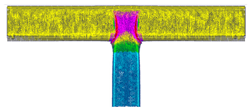

3.1. Assessing the linear thermal transfer coefficients

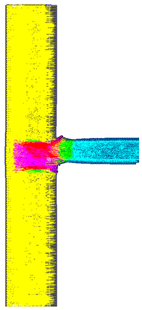

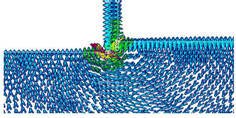

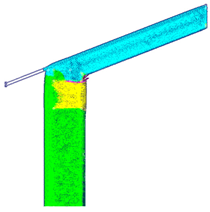

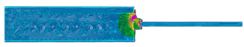

In order to analyze the influence of the linear thermal bridges presented in

Table 3, the authors have conducted a series of finite element method simulations using the specialized software RDM version 7.04 [

22]. The computations have been completed by taking into consideration the requirements in the Romanian building norm C107-2005 [

21] and the European standard EN ISO 10211 [

23]. In the linear thermal bridges simulations, the authors have considered the properties of the materials presented in

Table 4. The study has been completed by using the thermal transmittances presented in

Table 5. Equation 1 has been used for computing the values of the linear thermal transmittance.

where [

23]:

L2D—the thermal coupling coefficient obtained from a 2-D calculation of the component separating the two environments being considered [W/m·K];

Uj—the thermal transmittance of the 1-D component, j, separating the two environments being considered [W/m2·K];

lj—the length over which the value Uj applies [m].

Table 4.

Properties of the materials considered for modelling the linear thermal bridges.

Table 4.

Properties of the materials considered for modelling the linear thermal bridges.

| Material |

ρ [kg/m3] |

λ [W/(m·K)] |

c [J/(kg·K) |

| Interior plaster |

1700 |

0.87 |

840 |

| Ceramic bricks |

1700 |

0.75 |

870 |

| Reinforced concrete |

2500 |

1.74 |

840 |

| Expanded polystyrene |

20 |

0.044 |

1460 |

| Exterior plaster |

1700 |

0.87 |

840 |

| Rockwool |

40 |

0.035 |

1030 |

| Timber |

450 |

0.13 |

1700 |

| Plasterboard |

790 |

0.21 |

1000 |

| Gravel |

1800 |

0.7 |

840 |

| Soil—first layer |

1800 |

2 |

1110 |

| Soil—second layer |

1800 |

4 |

1110 |

| UPVC window frame |

1600 |

0.33 |

1460 |

| Window glazing |

2500 |

0.033* |

840 |

Table 5.

Thermal transmittances of the envelope elements.

Table 5.

Thermal transmittances of the envelope elements.

| Thermal envelope element |

Thermal transmittance [W/m2·K] |

Exterior wall

(different thicknesses for the thermal insulation layer) |

5 cm |

0.54 |

| 10 cm |

0.35 |

| 15 cm |

0.25 |

| 20 cm |

0.19 |

| Slab on grade |

0.34 |

| Roof |

0.21 |

| Windows |

1.11 |

The resulted values for the linear thermal transmittance are presented in

Table 6. It must be mentioned that the only variable the authors have taken into account is the thickness of the thermal insulation of the exterior walls. No other solutions have been considered for the improvement of the energy performances of the existing building (e.g., replacing the windows; improving the insulation around the window frames; increasing the thermal resistance of the slab on the ground).

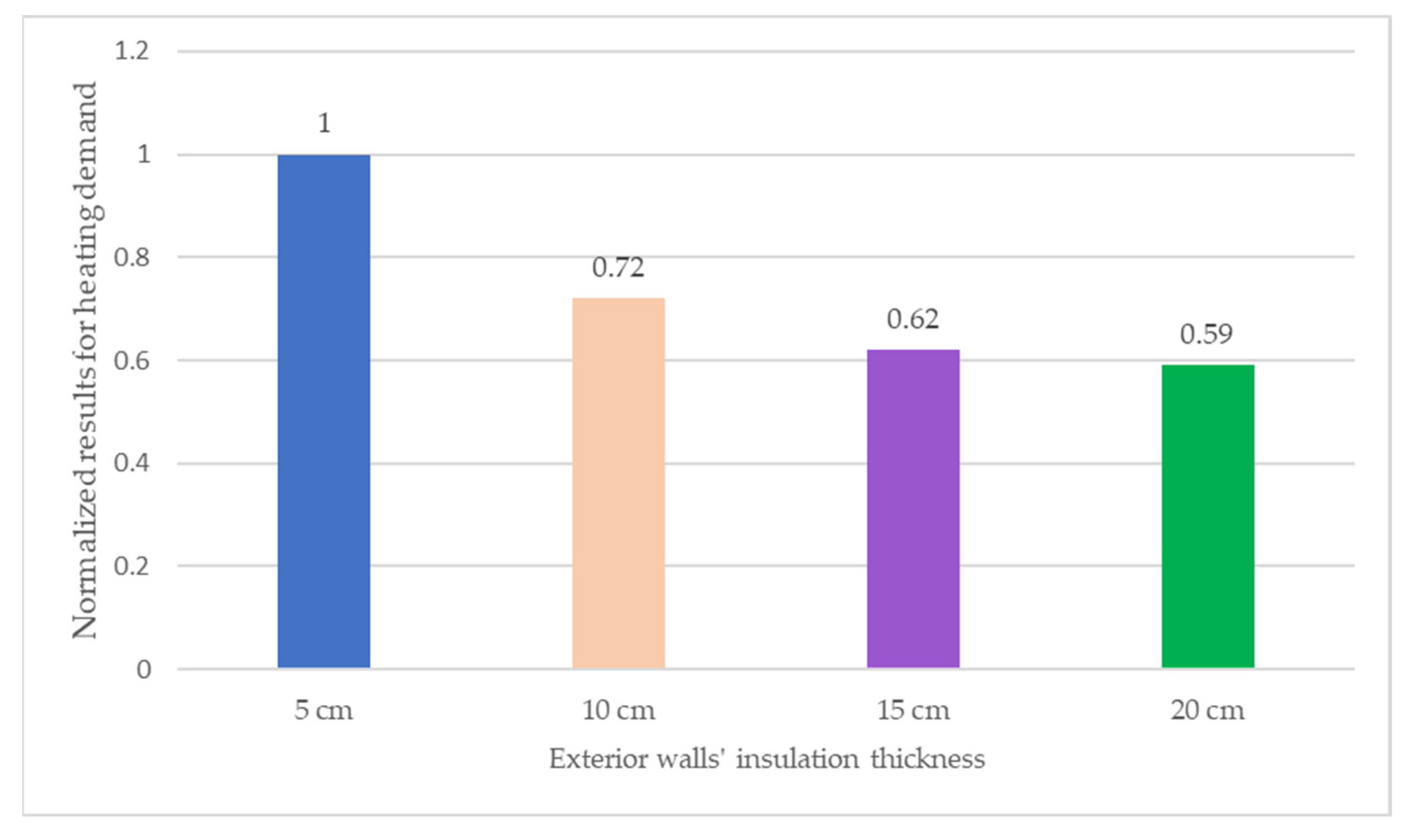

3.2. Determining the heating demand

In order to assess the level of energy efficiency of the building, the authors have used the Passive House Planning Package (PHPP) version 9.6 and the designPH tool. PHPP is an Excel-based tool developed by the Passive House Institute as a planning tool that can be used by civil engineering specialists in order to determine the buildings’ energy efficiency levels. DesignPH, an addition to PHPP, is a 3D data entry tool that can be used for optimizing the thermal performances of buildings [

24]. The values resulted by using the monthly calculation method for the considered case studies are presented in

Table 7.

4. Discussion

The state of the existing built environment places significant pressure over the greenhouse gases emissions in Europe. This negative influence is a direct result of the hydrothermal performances of the buildings’ envelope. The present study clearly shows the existing dwelling has an important energy demand for heating. Taking into account that most of this energy is produced using nonrenewable sources, the building has a significant influence over the concentration of GHGs. This is an important issue in Romania, seeing as most residential buildings completed in the last 20 years use roughly the same thermal insulation solutions as the one analyzed in this paper.

Apart from achieving a high thermal transmittance of the building’s envelope component, a poor level of insulation bears a significant influence on the impact of the linear thermal bridges, which further increases energy consumption. The resulted values, presented in

Table 6, show that for the first analyzed case study, in which the authors have considered the actual state of the building, almost all linear thermal bridges have a massive adverse effect. The only negative values obtained for the linear thermal coefficients in the case of the 5 cm insulation thickness is for the VTB 2 thermal bridge (inverted exterior walls corner). By analyzing

Figure 4, it can be observed that for the majority of the assessed linear thermal bridges, the achieved results are significantly reduced with every increase in thermal insulation thickness. For example, for VTB 1 the coefficients resulted in the last case study are approximately 74% lower than initial values. It can also be observed that the reduction rate of linear thermal coefficients decreases as the thermal insulation thickness increases.

The resulted values for heating demands (

Table 7) show that a thicker insulation of the exterior walls significantly reduces the energy demand.

Figure 5 highlights that by only increasing the thickness of the walls’ insulation by 15 cm, the heating demand is reduced by 41%. The study has considered an increasing step of 5 cm for the thermal insulation and by analyzing the resulted values, it can be observed that from the first expansion step of the insulation the energy need for heating is significantly reduced. In

Table 7, it can be seen that in case study number 2, the result is lower by 38.80 [kWh/m

2·year], this being the highest decreasing value registered for a 5 cm increasing step.

Analyzing the results obtained in case studies 3 and 4, with 15 and 20 cm insulation layers respectively, it can be seen that the influence of the increase in the thickness of the layer by 5 cm represents a decrease in the heating demand of approximately 3%, as depicted in

Table 7 and

Figure 5. These results show that when polystyrene is used as an insulating material, a 15 cm thickness can be considered the most suitable solution for heating demand reduction.

5. Conclusions

The construction sector is one of the most polluting economic activities, exerting a significant influence over the European efforts of achieving a sustainable development. The tremendous amounts of consumed materials and nonrenewable energy as well as the emissions specific to this industry have transformed the built environment into one of the most significant aggressors of the natural environment. Due to the current state of a large part of the existing building stock, in the European Union, the energy efficiency of constructions has become a key target in the regulations and legislations regarding the reduction of the negative environmental impact. The massive negative environmental impact of buildings is a direct result of the energy consumption needed to create adequate indoor conditions. Therefore, civil engineering specialists must properly address building energy renovation solutions in order to significantly reduce the negative ecological impact during the use phase from the life cycle of a construction.

Taking into account that residential constructions have an important influence over the environmental performances of the built environment both at European and national levels, the present study has taken under observation an energy renovation solution that is commonly adopted in Romania. The authors have analyzed how increasing the thermal insulation of the exterior walls of an existing dwelling influences the values of linear thermal coefficients and the heating demand. In order to achieve this goal, four case studies have been considered, differentiated only by the thickness of the walls’ insulations: 5 cm (the actual thickness) to 20 cm, with an increasing step of 5 cm. The authors have not considered any other energy renovation solutions during the study.

Linear thermal bridges simulations have been performed by using the RDM 7.04 and the heating demand has been computed with the help of the PHPP tool. The resulted values show that for the majority of the considered linear thermal bridges, their influence is significantly reduced by having a thicker insulation layer. Another important conclusion is that the decrease rate of the linear thermal transmittances is lower as the insulation thickness increases. Regarding the energy needed for heating, it is clear that the values are lower when there is a better thermal resistance. However, it is critical to note that a deep renovation of the building cannot be achieved by only increasing the thickness of the thermal insulation of the exterior walls despite obtaining a significant reduction in heating demand.

Author Contributions

Conceptualization, S.G.M, D.N.I. and L.M.M; methodology, S.G.M. and L.M.M.; software, S.G.M., I.R.B. and A.C.; validation, D.N.I. and L.M.M.; formal analysis, S.G.M. and I.R.B.; investigation, S.G.M., I.R.B. and A.C.; resources, S.G.M., D.N.I. and L.M.M; data curation, S.G.M.; writing—original draft preparation, S.G.M, D.N.I., I.R.B.; writing—review and editing, S.G.M, D.N.I., I.R.B.; visualization, S.G.M.; supervision, S.G.M, D.N.I. and L.M.M; project administration, D.N.I.; funding acquisition, D.N.I. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant of the Ministry of Research, Innovation and Digitization, CCCDI-UEFISCDI, project number PN-III-P2-2.1-PED-2021-4137, within PNCDI III-CT 714PED/2022.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Global Footprint Network. Available online: https://overshoot.footprintnetwork.org/ (accessed on 2 November 2023).

- Maxineasa, S.G. , Isopescu, D.N.; Baciu, I.-R., Ed.; Lupu, M.L. Environmental Performances of a Cubic Modular Steel Structure: A Solution for a Sustainable Development in the Construction Sector. Sustainability 2021, 13, 12062. [Google Scholar] [CrossRef]

- IPCC; 2023: Climate Change 2023: Synthesis Report Contribution of Working Groups, I.; II; III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change [Core Writing Team, H. Lee and J. Romero (eds.)]. IPCC, Geneva, Switzerland, 184 pp. [CrossRef]

- uropean Commission, Directorate-General for Communication. What is the European Green Deal?. Publications Office, 2019. /: 2019. https, 2019. Available online: https://data.europa.eu/doi/10.2775/275924.

- European Commission, Communication from the Commission to the European Parliament, The European Council, The Council, The European Economic and Social Committee and the Committee of the Regions. The European Green Deal, 2019.

- Schito, E.; Lucchi, E. Advances in the Optimization of Energy Use in Buildings. Sustainability 2023, 15, 13541. [Google Scholar] [CrossRef]

- Kukharets, V.; Hutsol, T.; Kukharets, S.; Glowacki, S.; Nurek, T.; Sorokin, D. European Green Deal: The Impact of the Level of Renewable Energy Source and Gross Domestic Product per Capita on Energy Import Dependency. Sustainability 2023, 15, 11817. [Google Scholar] [CrossRef]

- Skaar, C.; Labonnote, N.; Gradeci, K. From Zero Emission Buildings (ZEB) to Zero Emission Neighbourhoods (ZEN): A Mapping Review of Algorithm-Based LCA. Sustainability 2018, 10, 2405. [Google Scholar] [CrossRef]

- Economidou, M.; Todeschi, V.; Bertoldi, P.; D’Agostino, D.; Zangheri, P.; Castellazzi, L. Review of 50 years of EU energy efficiency policies for buildings. Energ Buildings 2020, 225, 110322. [Google Scholar] [CrossRef]

- D’Agostino, D.; Tzeiranaki, S.T.; Zangheri, P.; Bertoldi, P. Assessing Nearly Zero Energy Buildings (NZEBs) development in Europe. Energy Strateg Rev 2021, 36, 100680. [Google Scholar] [CrossRef]

- European Commission, Communication from the Commission to the European Parliament, The European Council, The Council, The European Economic and Social Committee and the Committee of the Regions. A Renovation Wave for Europe - greening our buildings, creating jobs, improving lives, 2020.

- Filippidou, F.; Jimenez Navarro, J.P. Achieving the cost-effective energy transformation of Europe’s buildings, EUR 29906 EN, Publications Office of the European Union, Luxembourg, 2019, ISBN 978-92-76-12394-1. JRC117739. [CrossRef]

- Gkatzogias, K.; Pohoryles, D.; Romano, E.; Bournas, D.; Negro, P.; Tsionis, G.; Dimova, S. Integrated seismic and energy renovation of buildings, EUR 31465 EN, Publications Office of the European Union, Luxembourg, 2023, ISBN 978-92-68-01355-7. JRC132940. [CrossRef]

- Eurostat. Available online: https://ec.europa.eu/eurostat/cache/visualisations/sdgs/index.html?country=EU27_2020&goal=SDG7&ind=4&chart=line (accessed on 7 November 2023).

- Council of the European Union, Fit for 55. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/#what (accessed on 10 November 2023).

- Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_consumption_in_households (accessed on 10 November 2023).

- Cojocaru, A.; Isopescu, D.N.; Maxineasa, S.G.; Petre, S. Assessment of Thermal and Mechanical Properties of Cement-Based Materials. Part 1: Crumb Rubber Concrete, Buildings, Special Issue: Development and Characterization of Advanced and Sustainable Cement-Based Materials. 2023; 13. [Google Scholar] [CrossRef]

- Petre, S.G.; Isopescu, D.N.; Pruteanu, M.; Cojocaru, A.L. Effect of Exposure to Environmental Cycling on the Thermal Conductivity of Expanded Polystyrene. Materials, 2022; 15. [Google Scholar] [CrossRef]

- Maxineasa, S.G.; Isopescu, D.N.; Baciu, I.-R.; Lupu, M.L. Environmental Performances of a Cubic Modular Steel Structure: A Solution for a Sustainable Development in the Construction Sector. Sustainability 2021, 13, nr–21. [Google Scholar] [CrossRef]

- Baciu, I.-R.; Isopescu, D.N.; Țăranu, N.; Lupu, L.M.; Maxineasa, S.G. Comparative Analysis of the Effect of Different Types of Green Roofs over the Linear Thermal Bridges, The 8th International Conference on Modern Technologies in Industrial Engineering, ModTech 2020, IOP Conference Series: Materials Science and Engineering, 2020, vol. 916. [CrossRef]

- C107/1-2010, Normative regarding thermotechnical calculation of construction elements of buildings (in Romanian).

- RDM Version 7.04. Available online: https://iut.univ-lemans.fr/ydlogi/rdm_version_7.html.

- EN ISO 10211, Thermal bridges in building construction—heat flows and surface temperatures—Detailed calculations.

- Passive House Planning Package (PHPP). Available online: https://passivehouse.com/04_phpp/04_phpp.htm.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).