Submitted:

30 November 2023

Posted:

01 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. The state of the art

1.2. Brief description of chert gravel

2. Materials and Methods

2.1. Heating and sample types

2.2. Strength assessment

2.3. Crushing test

2.4. Crushing test

3. Results

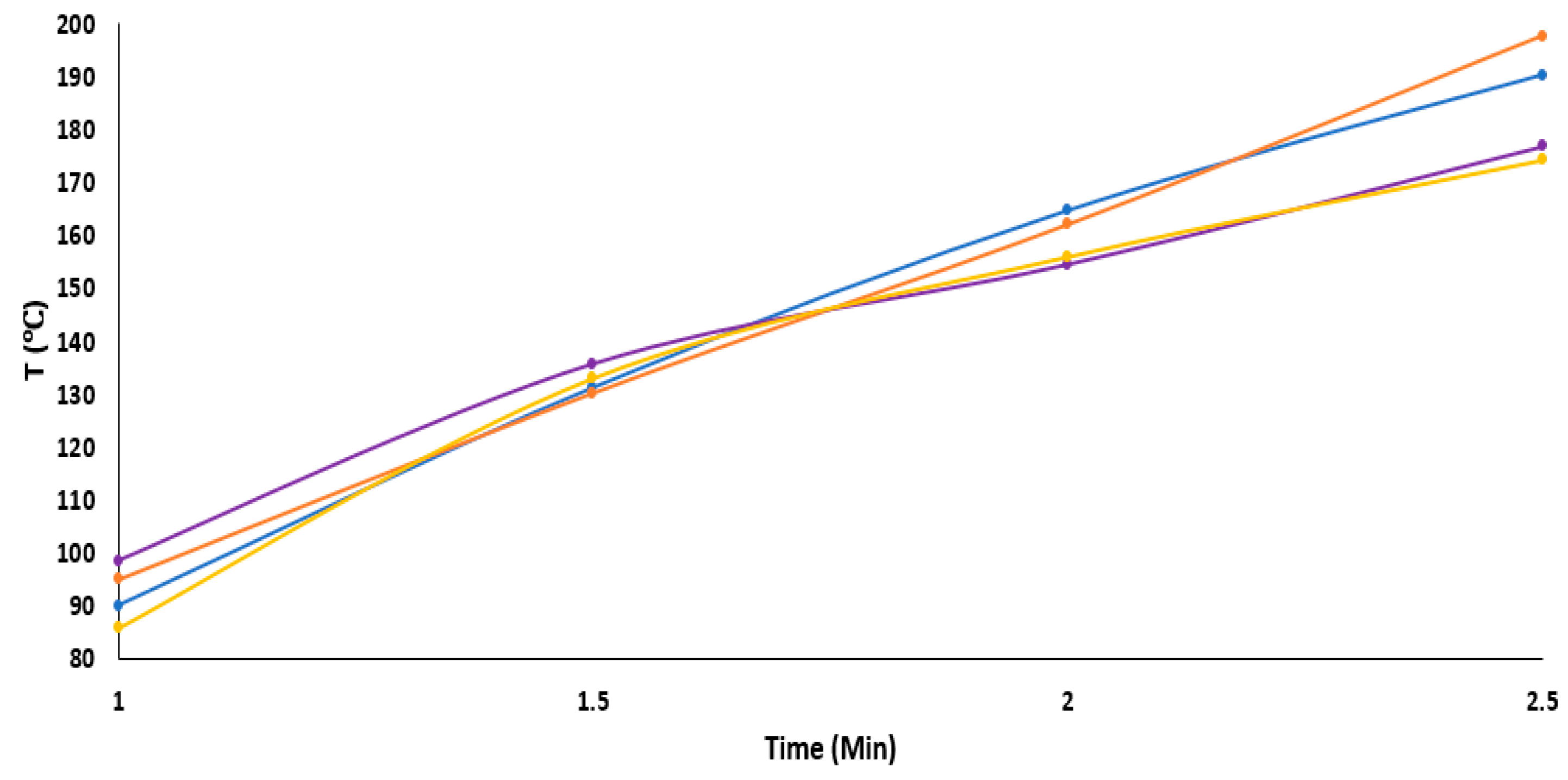

3.1. The results of temperature measurements

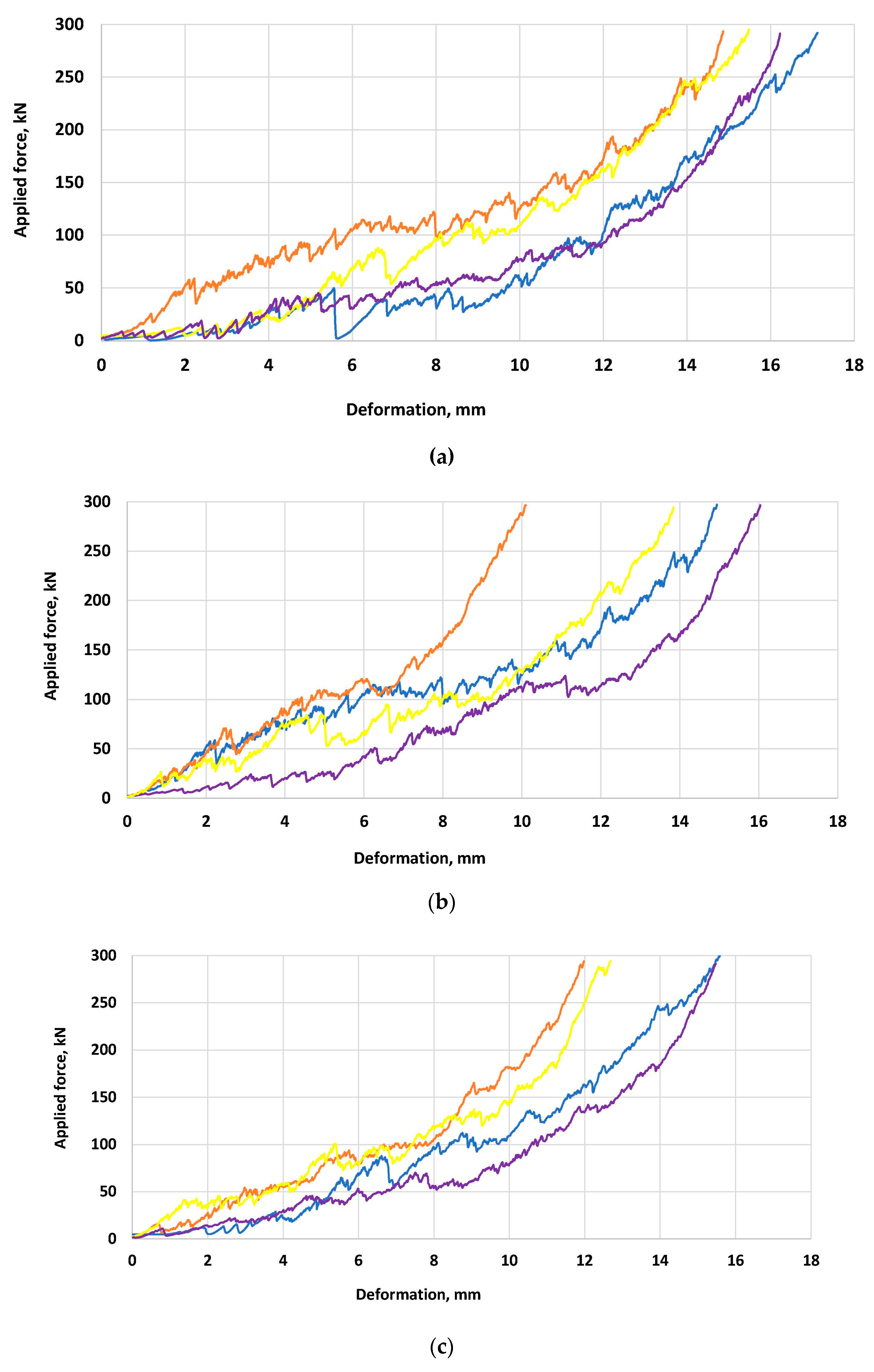

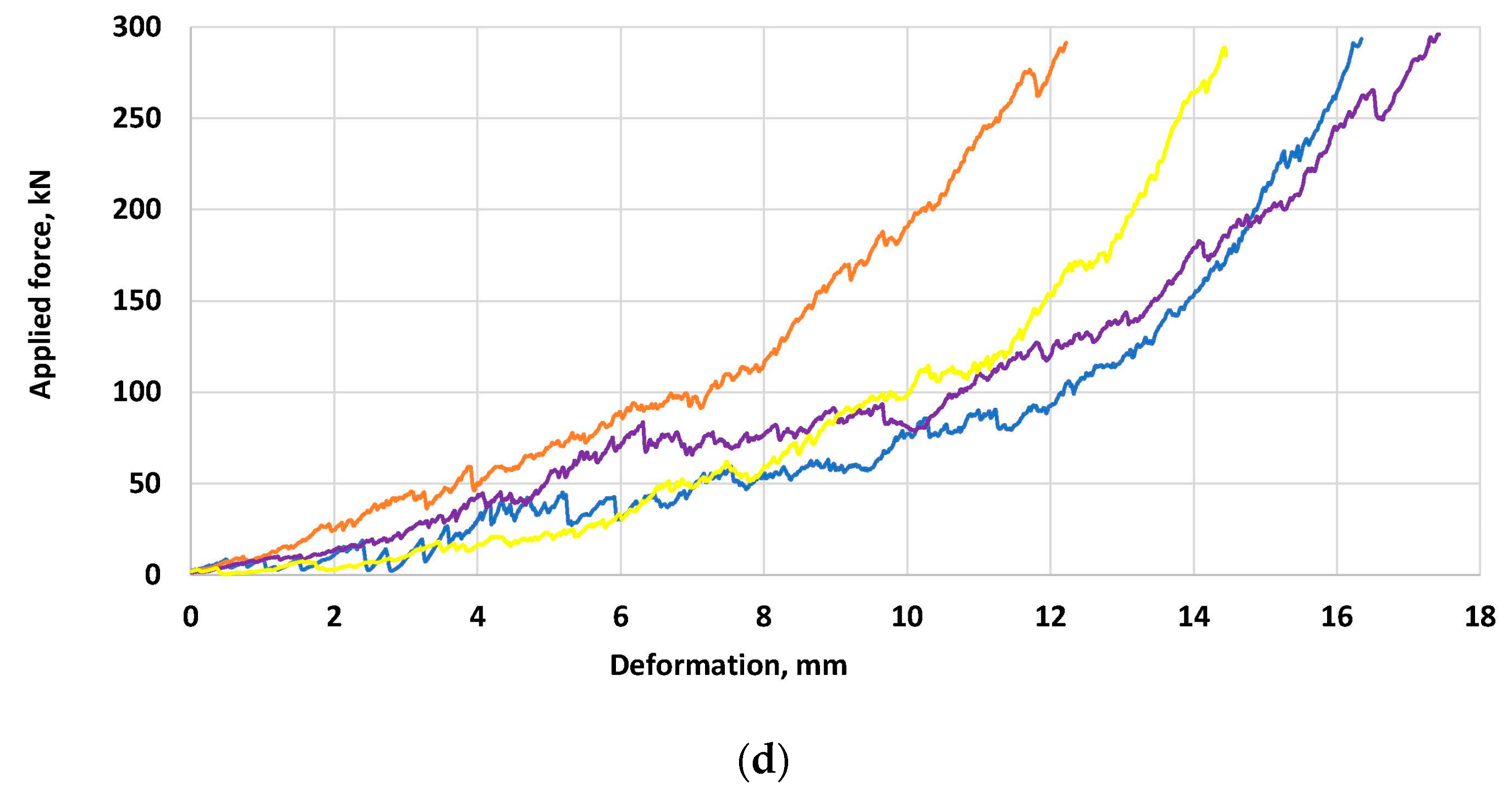

3.2. The results of the crushing test

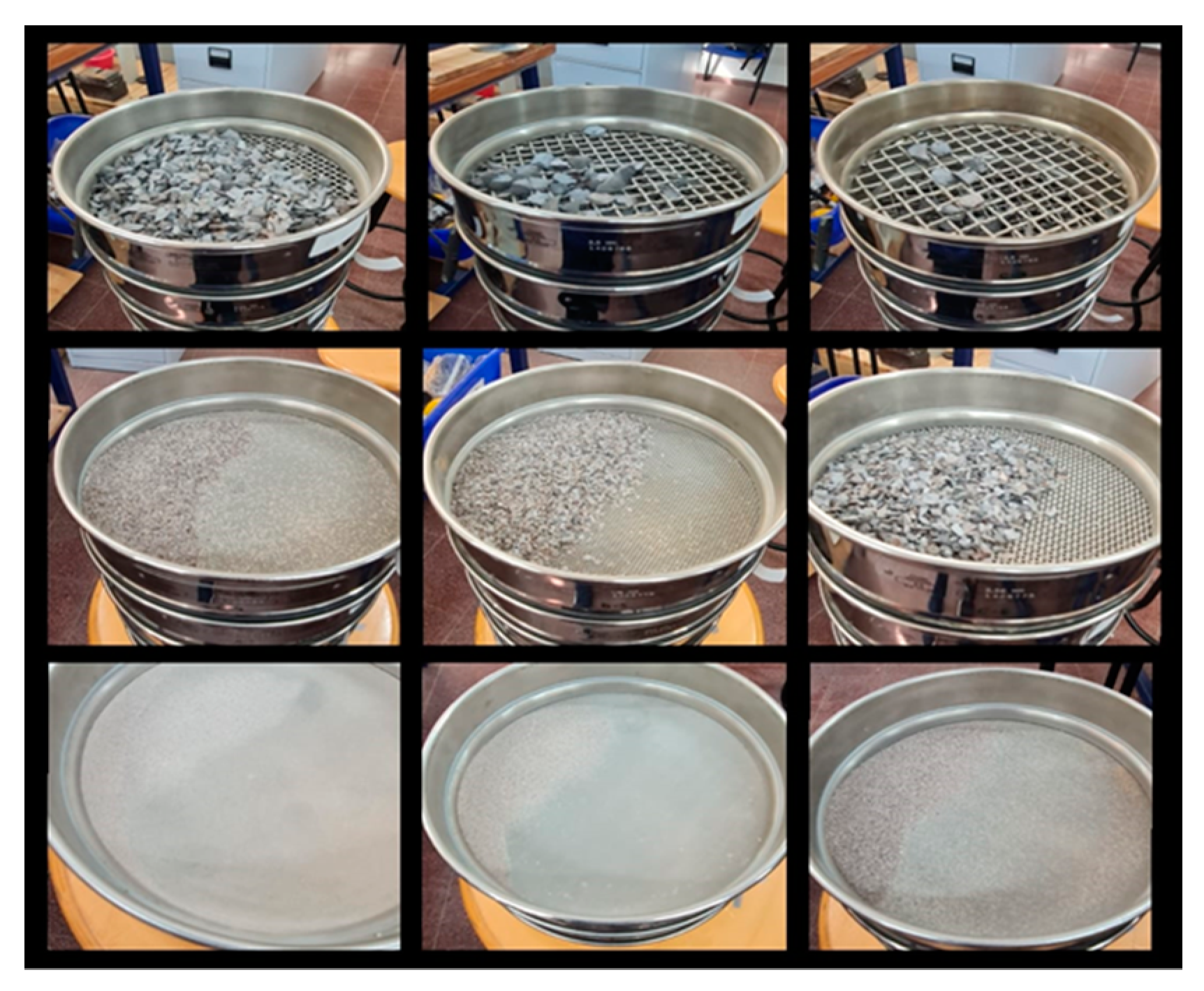

3.3. The results of the sieve analysis

4. Discussion and Conclusion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Adewuyi, S.; Ahmed, H. Methods of Ore Pretreatment for Comminution Energy Reduction. Minerals 2020, 10, 423. [Google Scholar] [CrossRef]

- Jones, D.A.; Kingman, S.W.; Whittles, D.N.; Lowndes, I.S. The influence of microwave energy delivery method on strength reduction in ore samples. Chemical Engineering and Processing 2007, 46, 291–299. [Google Scholar] [CrossRef]

- Bradshaw, S.; Louw, W.; van der Merwe, C.; Reader, H.; Kingman, S.; Celuch, M.; Kijewska, W. Techno-Economic Considerations in the Commercial Microwave Processing of Mineral Ores. Journal of Microwave Power and Electromagnetic Energy 2005, 40, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Bai, G.; Sun, Q.; Jia, H.; Ge, Z.; Tang, L.; Xue, S. Mechanical responses of igneous rocks to microwave irradiation: a review. Acta Geophysica 2022, 70, 1183–1192. [Google Scholar] [CrossRef]

- Qin, L.; Dai, J. Meso-mechanics simulation analysis of microwave-assisted mineral liberation. Frattura ed Integrità Strutturale 2015, 34, 543–553. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Yin, T. Effect of microwave heating on fracture behavior of granite: An experimental investigation. Engineering Fracture Mechanics 2021, 250, 107758. [Google Scholar] [CrossRef]

- Kafashi, S.; Kuhar, L.; Bóna, A.; Nikoloski, A.N. Review of Fracturing Techniques (Microwaves,High-Voltage Pulses, and Cryogenic Fluids) for Application as Access Creation Method in Low-Permeability Hard Rocks for Potential in situ Metal Recovery, Mineral Processing and Extractive Metallurgy Review. 2023. [Google Scholar] [CrossRef]

- Adewuyi, S.; Ahmed, H. Grinding Behavior of Microwave-Irradiated Mining Waste. Energies 2021, 14, 3991. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Ma, Z.J.; Yang, S.Q.; Zhao, X.B.; He, L.; Li, J.C. A microwave fracturability index (MFI) of hard igneous rocks. International Journal of Rock Mechanics & Mining Sciences 2021, 138, 104566. [Google Scholar]

- Wei, W.; Shao, Z.; Zhang, Y.; Qiao, R.; Gao, J. Fundamentals and applications of microwave energy in rock and concrete processing – A review. Appl. Therm. Engng. 2019, 157, 113751. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Zhao, X.B.; Zhao, Q.H.; Li, J.C.; Zhang, Q.B. Dielectric properties of hard rock minerals and implications for microwave-assisted rock fracturing. Geomech. Geophys. Geo-energ. Geo-resour. 2020, 6, 22. [Google Scholar] [CrossRef]

- Gao, F.; Shao, Y.; Zhou, K. Analysis of Microwave Thermal Stress Fracture Characteristics and Size Effect of Sandstone under Microwave Heating. Energies 2020, 13, 3614. [Google Scholar] [CrossRef]

- Qin, L.; Dai, J. Analysis on the growth of different shapes of mineral microcracks in microwave field. Frattura ed Integrità Strutturale 2016, 37, 342–351. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Ni, J.; Azzam, R.; Fernandez-Steeger, T.M. An experimental study of the mechanical properties of granite after high temperature exposure based on mineral characteristics. Engng. Geol. 2017, 220, 234–42. [Google Scholar] [CrossRef]

- Peng, J.; Rong, G.; Cai, M.; Yao, M.; Zhou, C. Physical and mechanical behaviors of a thermal-damaged coarse marble under uniaxial compression. Engng. Geol. 2016, 200, 88–93. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, X.; Bai, B.; Hu, H. The shear behavior of sandstone joints under different fluid and temperature conditions. Engng. Geol. 2019, 257, 105143. [Google Scholar] [CrossRef]

- Lü, C.; Sun, Q.; Zhang, W.; Geng, J.; Qi, Y.; Lu, L. ; The effect of high temperature on tensile strength of sandstone. Appl. Therm. Engng. 2017, 111, 573–579. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.; Fang, X.; Wen, M.; Zheng, G.; Wang, P. Dynamic splitting tensile behaviors of red-sandstone subjected to repeated thermal shocks: Deterioration and micro-mechanism. Engng. Geol. 2017, 223, 1–10. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.; Liu, S.; Wang, H. Dynamic mechanical properties and deterioration of red-sandstone subjected to repeated thermal shocks. Engng. Geol. 2016, 212, 44–52. [Google Scholar] [CrossRef]

- Yin, T.; Li, Q.; Li, X. Experimental investigation on mode I fracture characteristics of granite after cyclic heating and cooling treatments. Engng. Fract. Mech 2019, 222, 106740. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, W.; Zhu, Y.; Huang, Z. Effect of High Temperatures on the Thermal Properties of Granite. Rock Mech. Rock Engng. 2019, 52, 2691–2699. [Google Scholar] [CrossRef]

- Sun, H.; Sun, Q.; Deng, W.; Zhang, W.; Lü, C. Temperature effect on microstructure and P-wave propagation in Linyi sandstone. Appl. Therm. Engng. 2017, 115, 913–22. [Google Scholar] [CrossRef]

- Mahanta, B.; Singh, T.N.; Ranjith, P.G. Influence of thermal treatment on mode I fracture toughness of certain Indian rocks. Engng. Geol. 2016, 210, 103–14. [Google Scholar] [CrossRef]

- Zuo, J.; Li, Y.; Zhang, X.; Zhao, Z.; Wang, T. The effects of thermal treatments on the subcritical crack growth of Pingdingshan sandstone at elevated high temperatures. Rock Mech. Rock Engng 2018, 51, 3439–3454. [Google Scholar] [CrossRef]

- Yin, T.; Wu, Y.; Li, Q.; Wang, C.; Wu, B. Determination of double-K fracture toughness parameters of thermally treated granite using notched semi-circular bending specimen. Engng. Fract. Mech 2019, 226, 106865. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, Y. Combined effects of salt, cyclic wetting and drying cycles on the physical and mechanical properties of sandstone. Engng. Geol. 2019, 248, 70–79. [Google Scholar] [CrossRef]

- Borinaga-Trevino, R.; Orbe, A.; Norambuena-Contreras, J.; Canales, J. Effect of microwave heating damage on the electrical, thermal and mechanical properties of fibre-reinforced cement mortars. Constr. Build. Mater. 2018, 186, 31–41. [Google Scholar] [CrossRef]

- Yin, T.; Wang, P.; Li, X.; Wu, B.; Tao, M.; Shu, R. Determination of Dynamic Flexural Tensile Strength of Thermally Treated Laurentian Granite Using Semi-Circular Specimens. Rock Mech. Rock Engng 2016, 49, 3887–3898. [Google Scholar] [CrossRef]

- Wang, P.; Yin, T.; Li, X.; Zhang, S.; Bai, L. Dynamic Properties of Thermally Treated Granite Subjected to Cyclic Impact Loading. Rock Mech. Rock Engng 2019, 52, 991–1010. [Google Scholar] [CrossRef]

- Teimoori, K.; Hassani, F.; Sasmito, A.P.; Ghoreishi-Madiseh, S.A. Experimental investigations of microwave effects on rock breakage using SEM analysis. 17th international conference on microwave and high-frequency heating. 2019, Valencia, Spain, September 9-12.

- Grafe, P.H. Experimental Study on Microwave Assisted Hard Rock Cutting of Granite. BHM, 2017, 162(2), 77-81. [CrossRef]

- Jones, D.A.; Kingman, S.W.; Whittles, D.N.; Lowndes, I.S. Understanding microwave assisted breakage. Minerals Engineering 2005, 18, 659–669. [Google Scholar] [CrossRef]

- Lu, G.M.; Feng, X.-T. , Li, Y.-H., Hassani, F.; Zhang, X. Experimental Investigation on the Effects of Microwave Treatment on Basalt Heating, Mechanical Strength, and Fragmentation. Rock Mechanics and Rock Engineering 2019, 52, 2535–2549. [Google Scholar] [CrossRef]

- Tzibulsky, M.; Frid, V. Features of the properties of chert gravels. Minerals 2023, 13, 455. [Google Scholar] [CrossRef]

- Srinivasan, V.; Haseeb Hasainar, T.N. Singh Experimental study on failure and fracturing attributes of granite after thermal treatments with different cooling conditions. Engineering Geology 2022, 310, 106867. [Google Scholar] [CrossRef]

- Shao, S.; Ranjith, P.G.; Wasantha, P.B.; Chen, K. Experimental and numerical studies on the mechanical behavior of Australian Strathbogie granite at high temperatures: an application to geothermal energy. Geothermics 2015, 54, 96–108. [Google Scholar] [CrossRef]

- Yin, Q.; Wu, J.; Jiang, Z.; Zhu, C.; Su, H.; Jing, H.; Gu, X. Investigating the effect of water quenching cycles on mechanical behaviors for granites after conventional triaxial compression. Geomech. Geophys. Geo-energ. Geo-resour. 2022, 8, 77. [Google Scholar] [CrossRef]

| Time | A | B | C | D |

|---|---|---|---|---|

| (min) | (℃) | |||

| 1 | 90.02 | 95.0 | 98.42 | 85.82 |

| 1.5 | 131.14 | 130.18 | 135.66 | 133.02 |

| 2 | 164.58 | 161.98 | 154.48 | 155.96 |

| 2.5 | 190.24 | 197.6 | 176.78 | 174.22 |

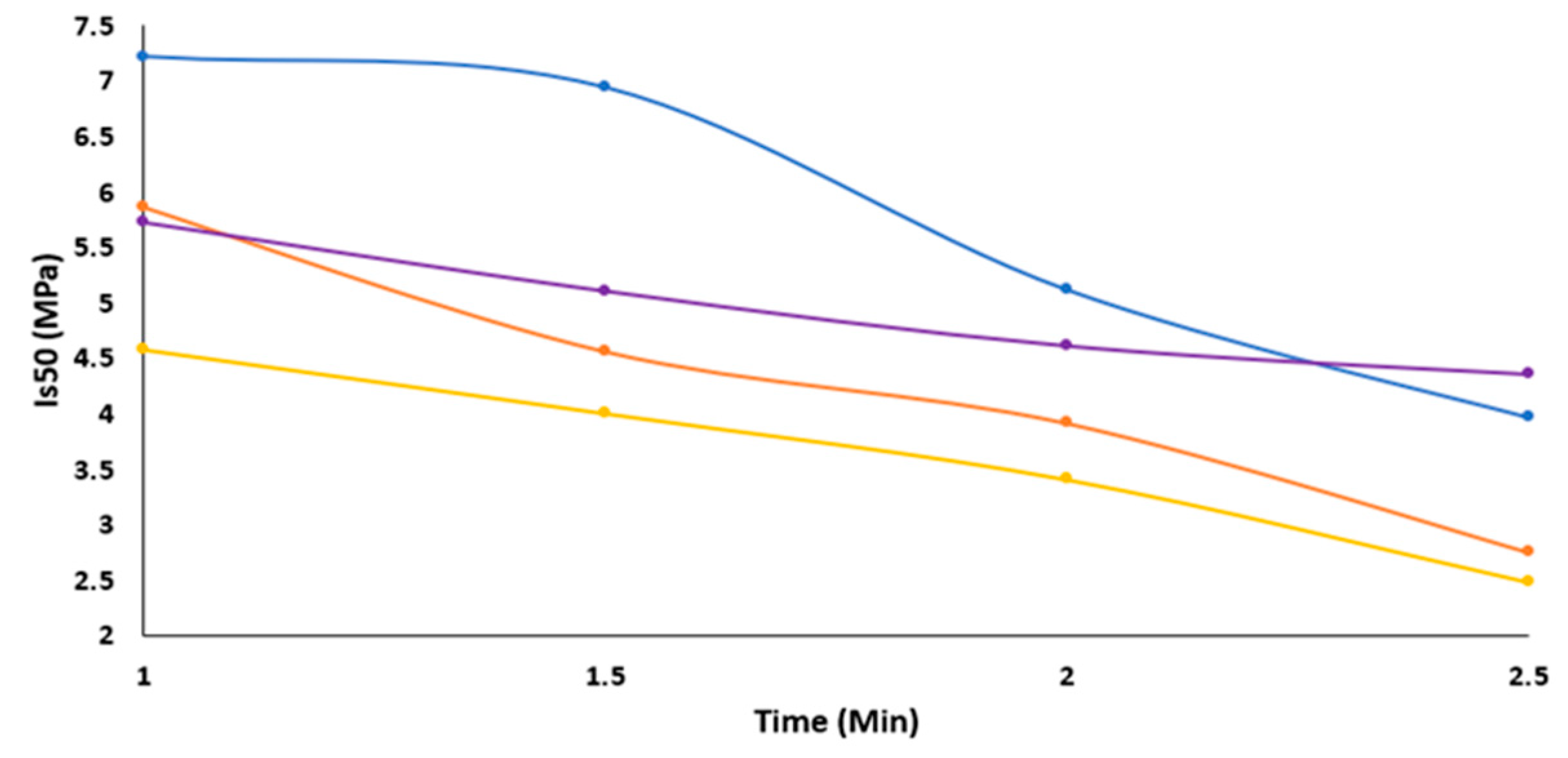

| Time | Is(50)-A | Is(50)-B | Is(50)-C | Is(50)-D |

|---|---|---|---|---|

| (min) | (MPa) | |||

| 1 | 7.219 | 5.860 | 5.728 | 4.576 |

| 1.5 | 6.941 | 4.559 | 5.109 | 4.001 |

| 2 | 5.119 | 3.913 | 4.615 | 3.407 |

| 2.5 | 3.969 | 2.752 | 4.359 | 2.485 |

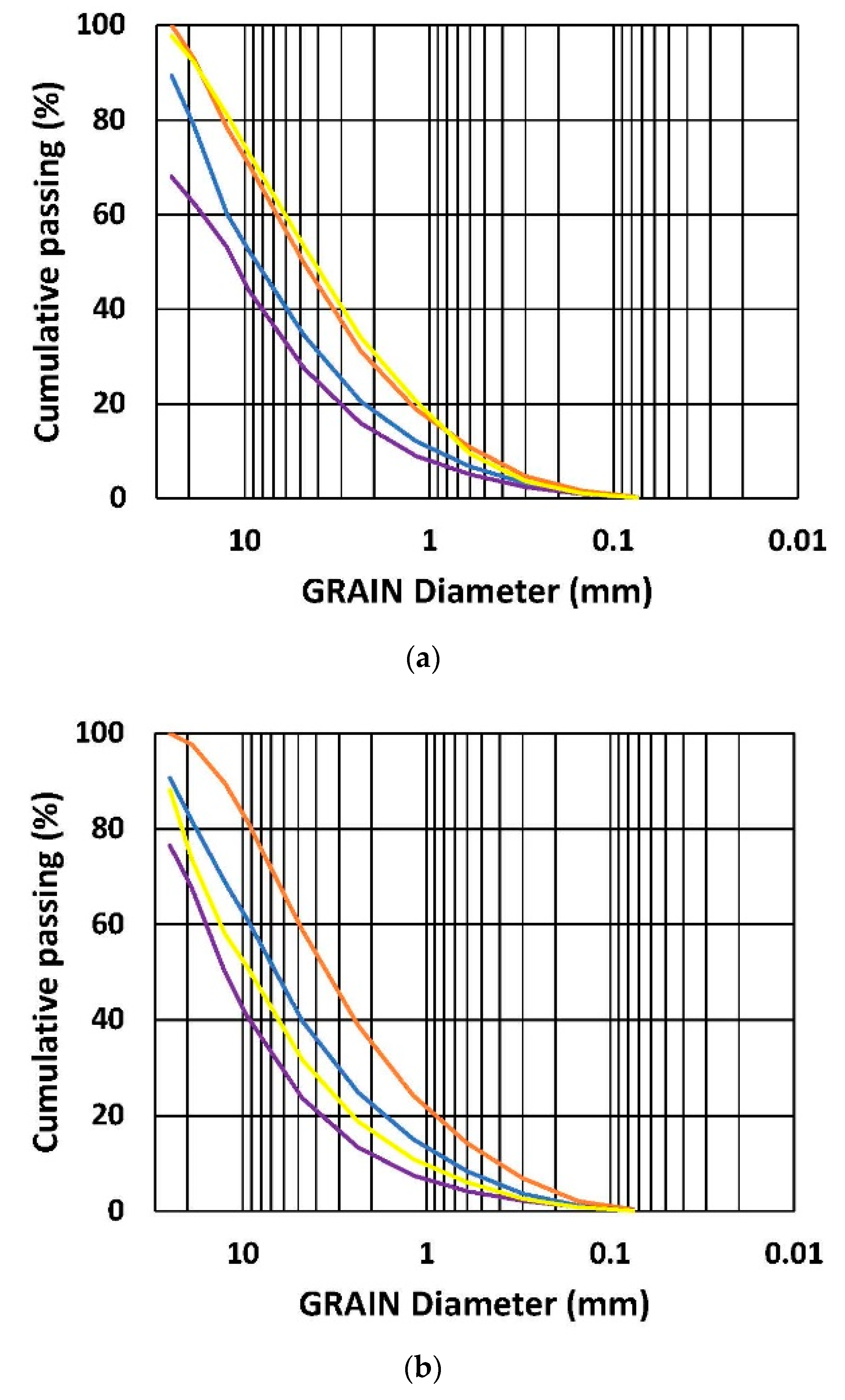

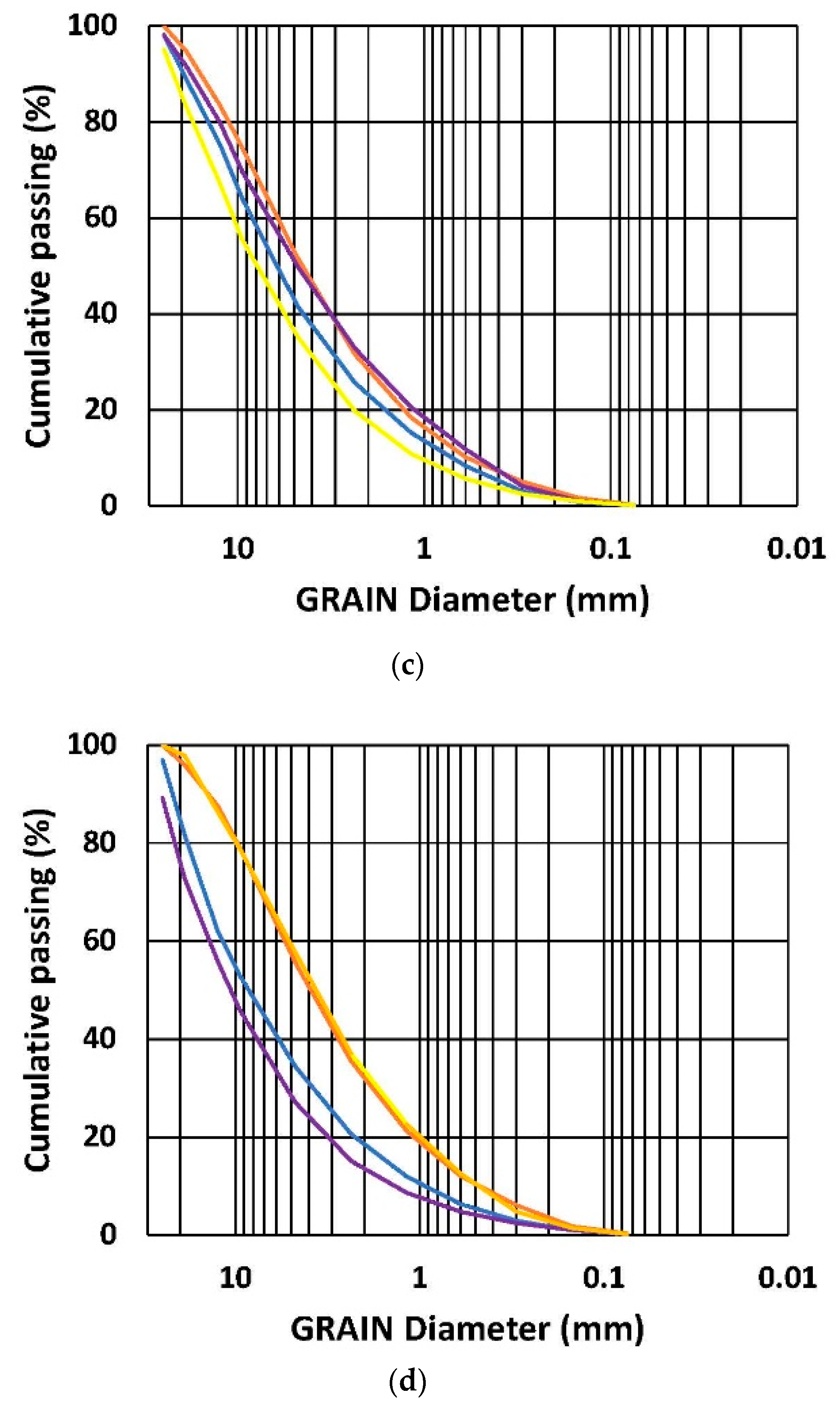

| Time | % pass. after crush. test |

% pass. in the range of Gravel fraction |

USCS index | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gravel | Sand | |||||||||||||

| >4.75 | 4.75-0.075 | 9-25 | 12.5-19 | 4.75-12.5 | ||||||||||

| Min | mm | |||||||||||||

| A: Irradiation of sample with dry surface (quenching not applied) | ||||||||||||||

| 1 | 65.7 | 34.3 | 21.00 | 19.0 | 25.7 | GW | ||||||||

| 1.5 | 60.2 | 39.6 | 18.3 | 12.8 | 29.1 | GW | ||||||||

| 2 | 58.6 | 41.3 | 11 | 13.6 | 34 | GW | ||||||||

| 2.5 | 65.6 | 34.3 | 18.3 | 19.8 | 27.5 | GW | ||||||||

| B: Irradiation of sample with dry surface (quenching applied) | ||||||||||||||

| 1 | 50.5 | 49.5 | 6.9 | 14.8 | 28.8 | GW/SW | ||||||||

| 1.5 | 41.2 | 58.8 | 2.3 | 8.1 | 30.7 | SW | ||||||||

| 2 | 48.5 | 51.5 | 5.2 | 11.2 | 32.1 | GW/SW | ||||||||

| 2.5 | 44.5 | 55.6 | 4.0 | 8.5 | 31.9 | SW | ||||||||

| C: Irradiation of sample with wet surface (quenching not applied) | ||||||||||||||

| 1 | 72.6 | 27.4 | 37.5 | 9.4 | 25.7 | GW | ||||||||

| 1.5 | 76.4 | 23.6 | 32.4 | 17.7 | 26.3 | GW | ||||||||

| 2 | 50.3 | 49.5 | 8.3 | 8.3 | 11.8 | 30.2 | 30.2 | GW | ||||||

| 2.5 | 72.9 | 27.1 | 27.1 | 17.1 | 28.7 | GW | ||||||||

| D: Irradiation of sample with wet surface (quenching applied) | ||||||||||||||

| 1 | 46.9 | 53 | 7.7 | 11.3 | 27.9 | SW | ||||||||

| 1.5 | 68.4 | 31.6 | 26.3 | 15.8 | 26.3 | GW | ||||||||

| 2 | 64.8 | 35.2 | 16.4 | 16.1 | 32.1 | GW | ||||||||

| 2.5 | 42.3 | 57.7 | 2.0 | 11.6 | 28.5 | SW | ||||||||

| The typical grain size content of the chert sample to which irradiation was not applied | ||||||||||||||

| 0 | 76.6 | 23.4 | 33.8 | 15.4 | 27.4 | GW | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).