Submitted:

29 November 2023

Posted:

29 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

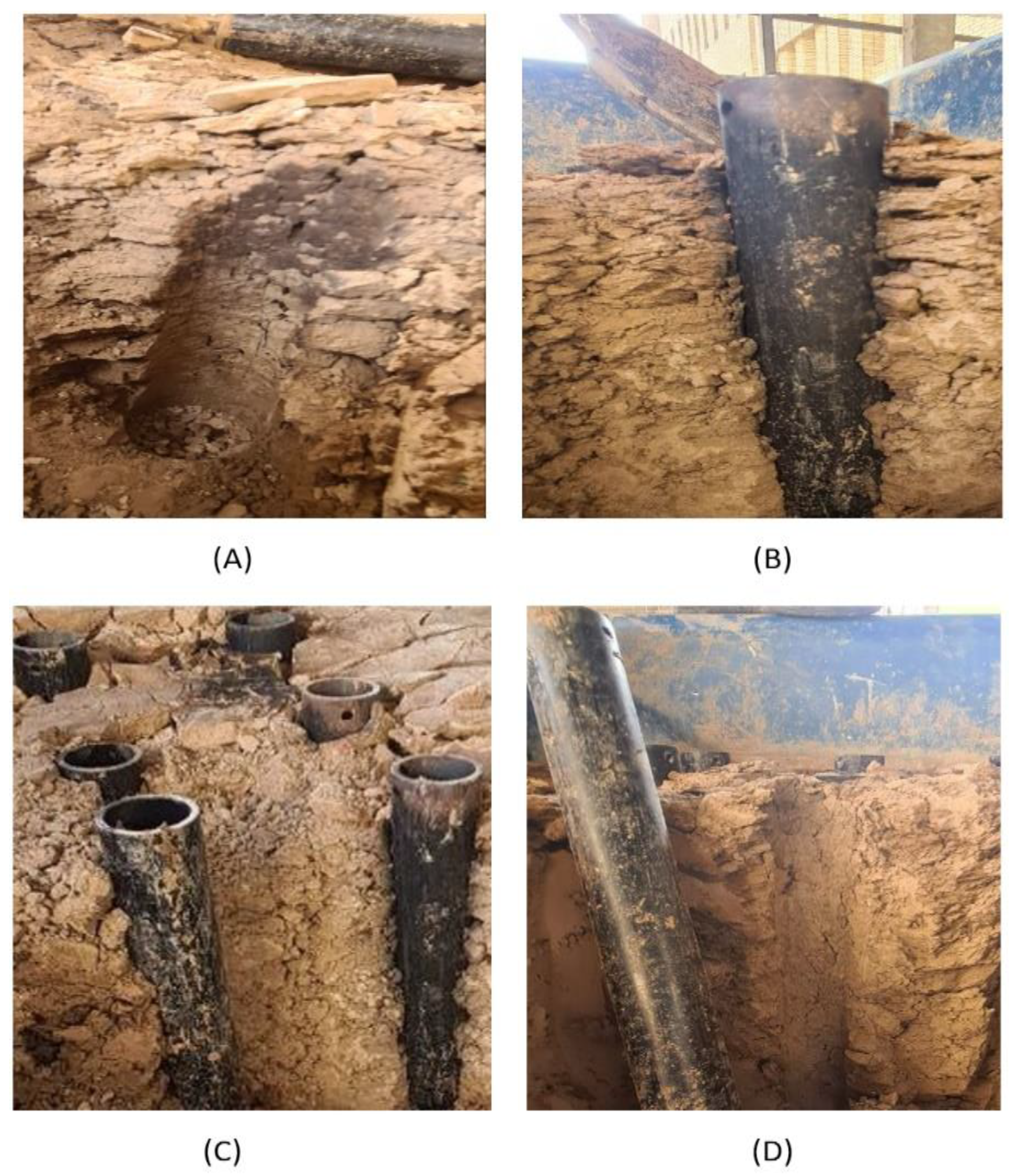

2. Methodology and Experimental Work

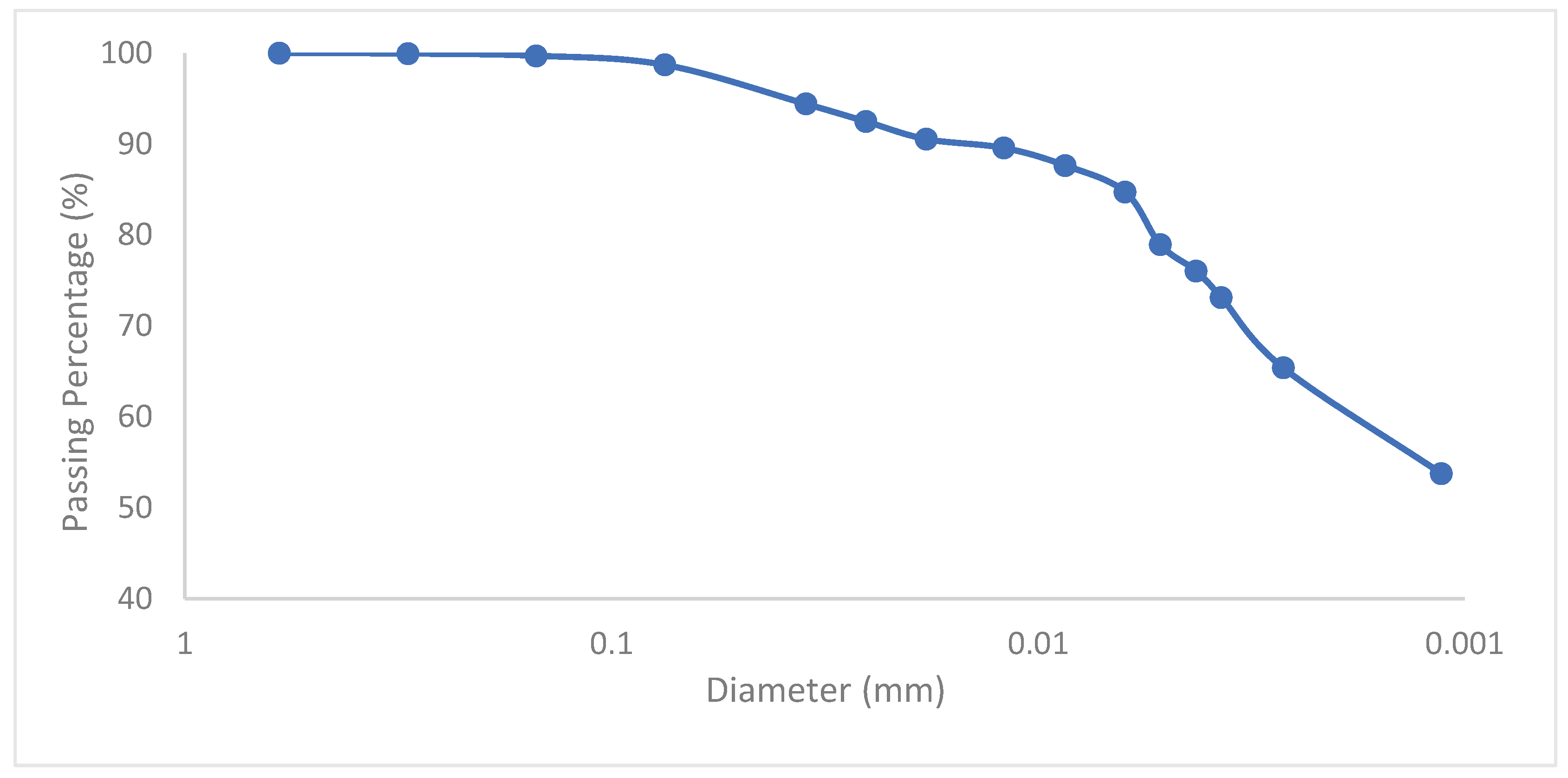

2.1. Materials Used

2.2. Devices and Tests Used in This Study

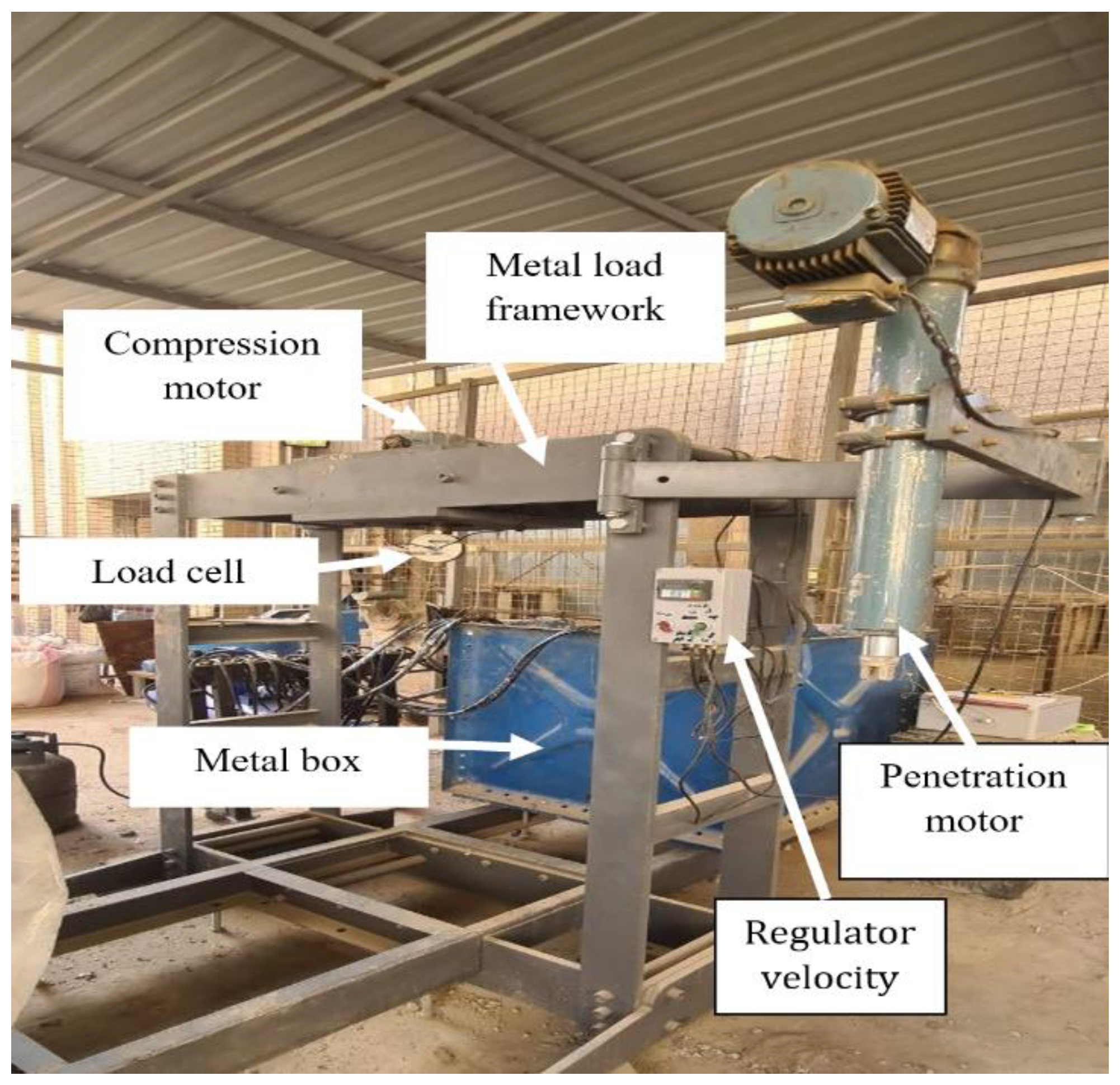

2.2.1. Metal Load Framework

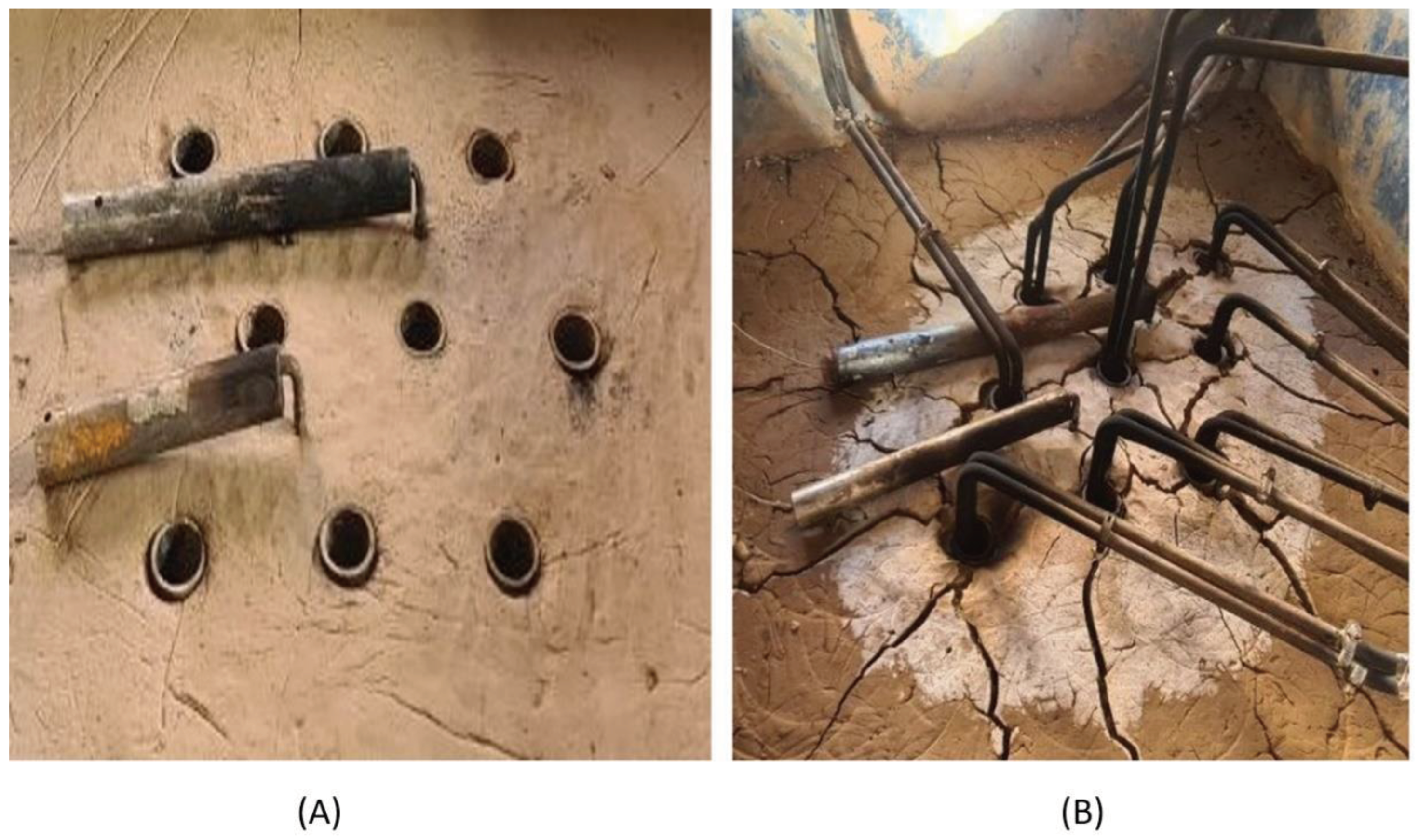

2.2.2. Casing (Barrier Tube)

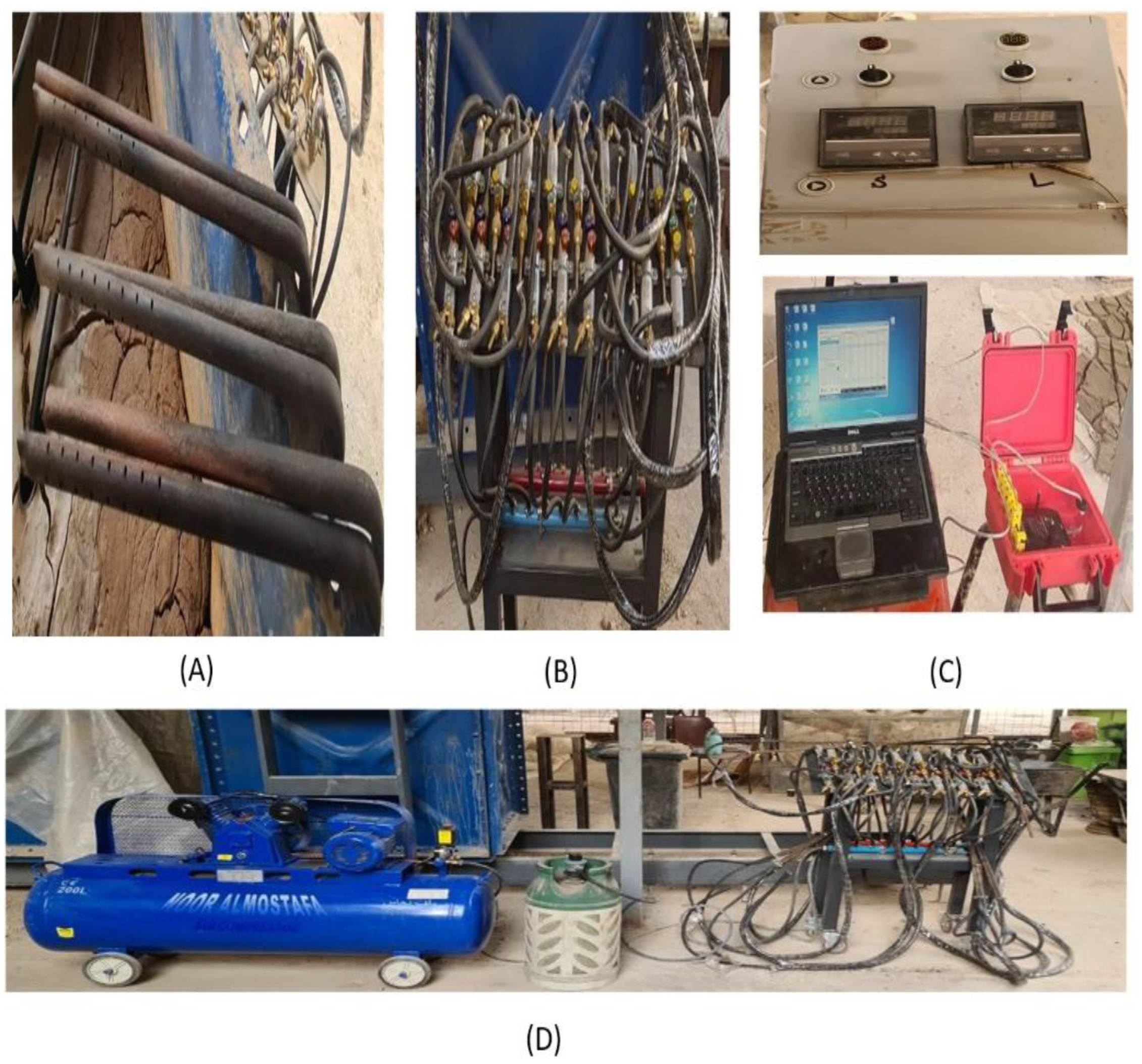

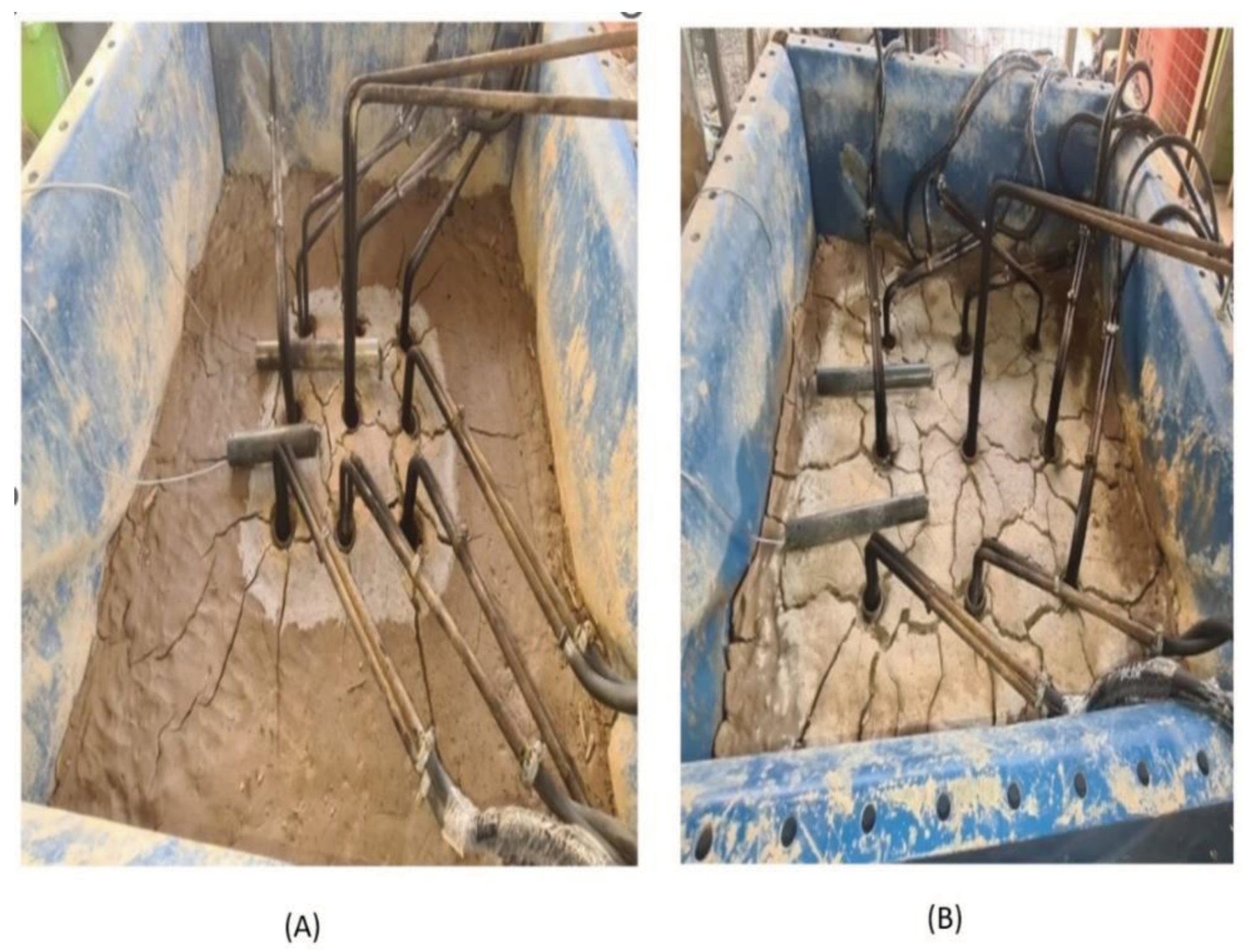

2.2.3. Heating System

2.2.4. CPT Probe Device

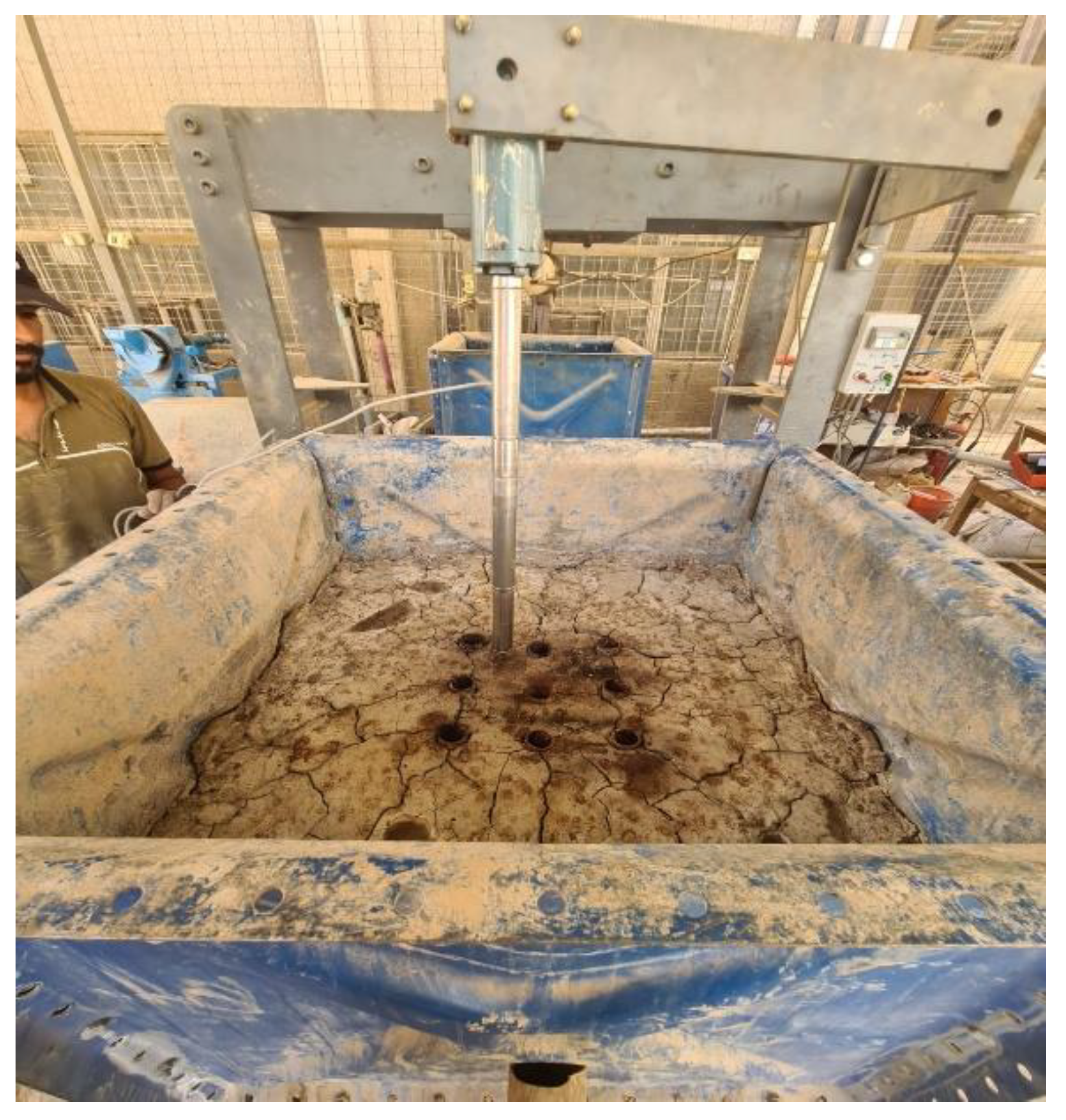

2.3. Establishing the Soil Modeling and Test Procedure

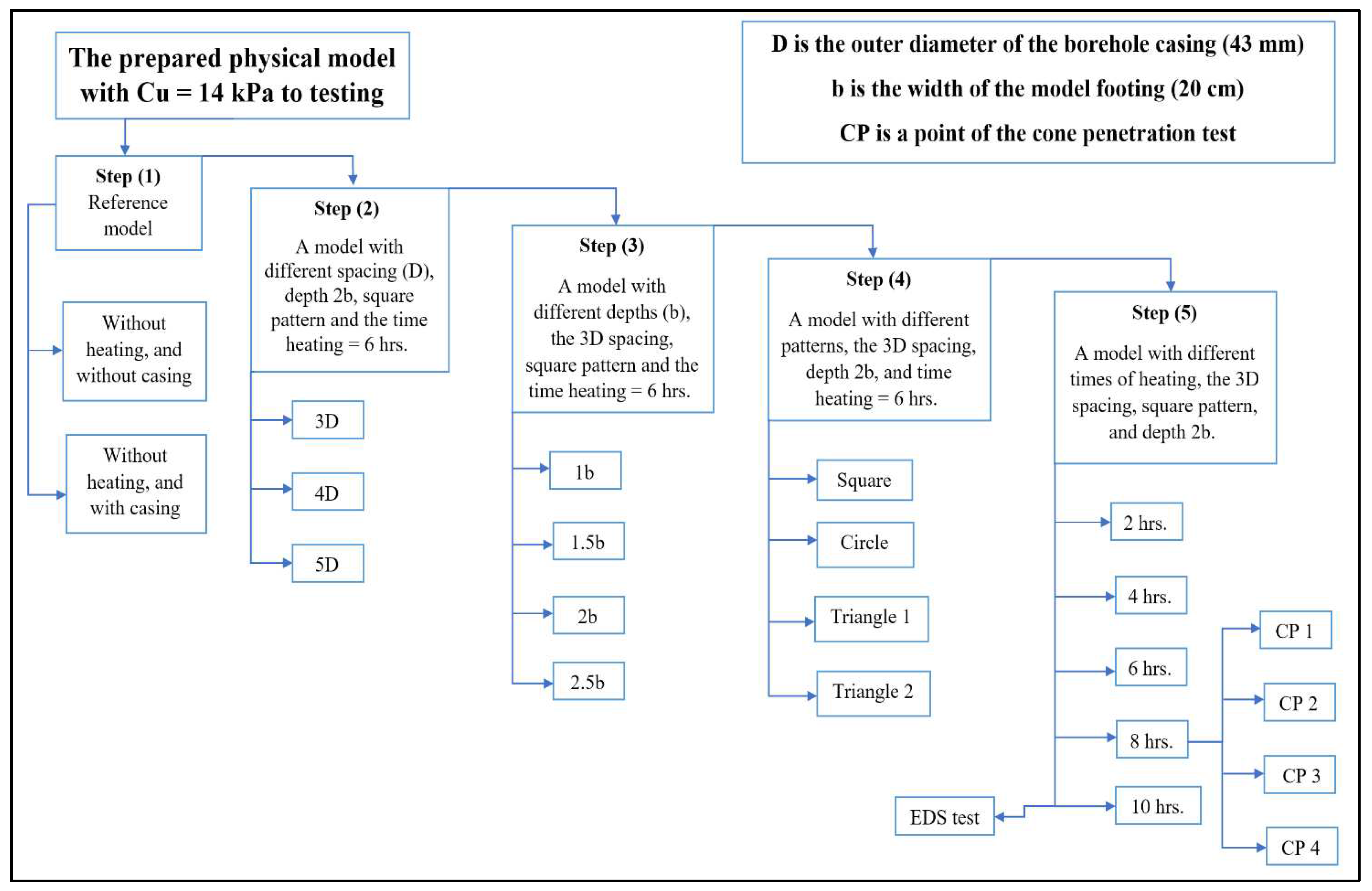

2.4. Testing Program

3. Presentation and Discussion of Test Results

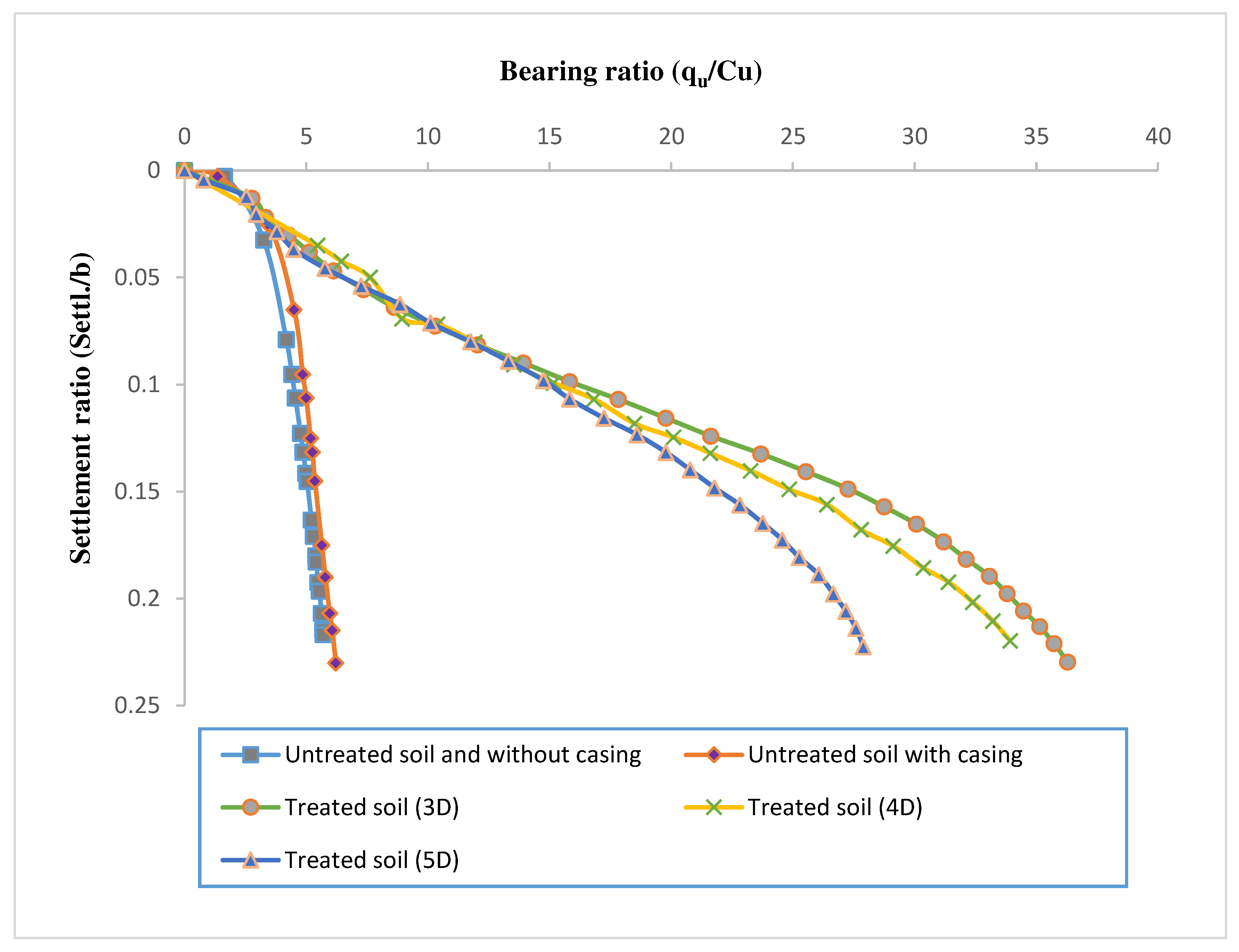

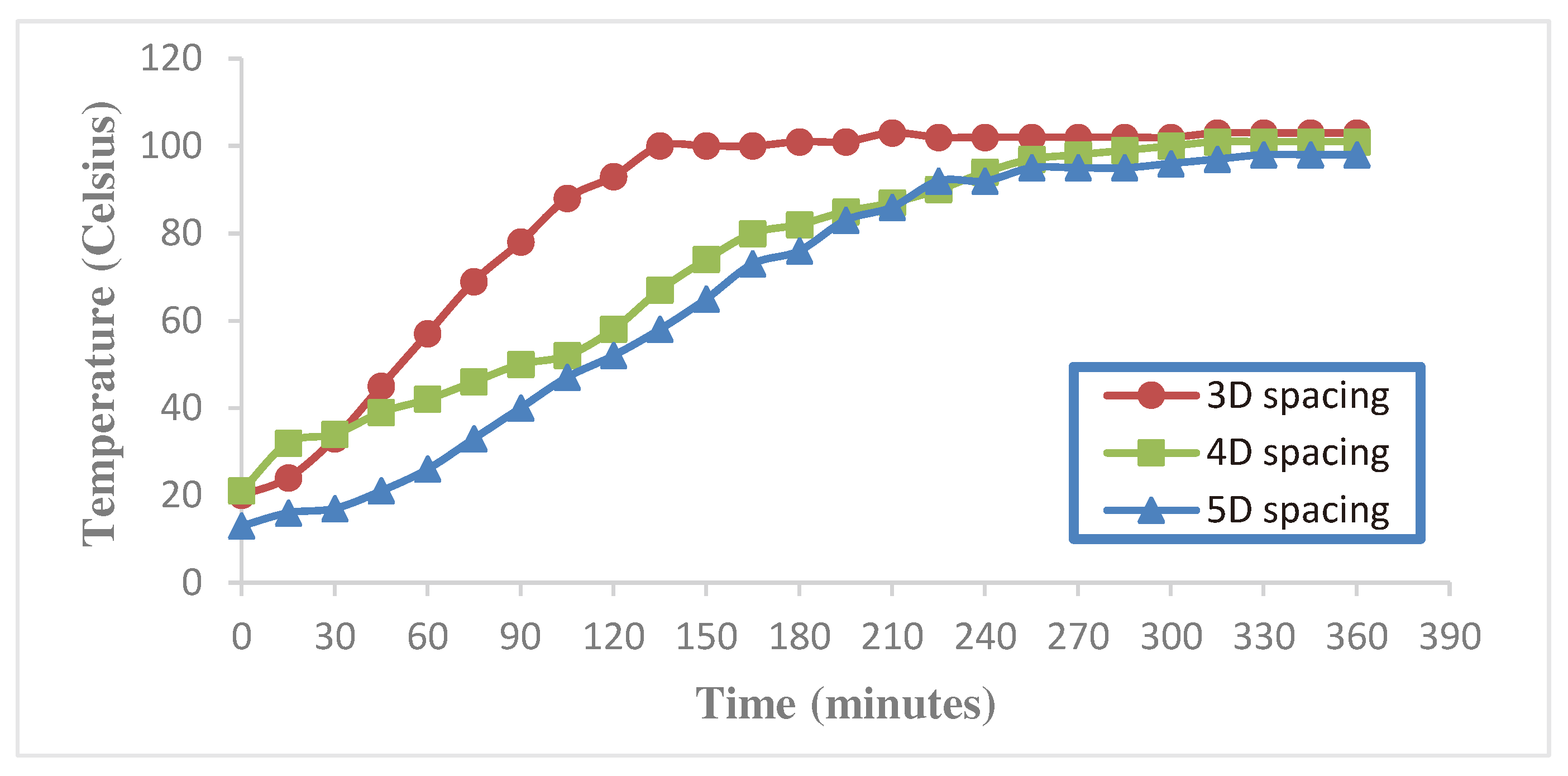

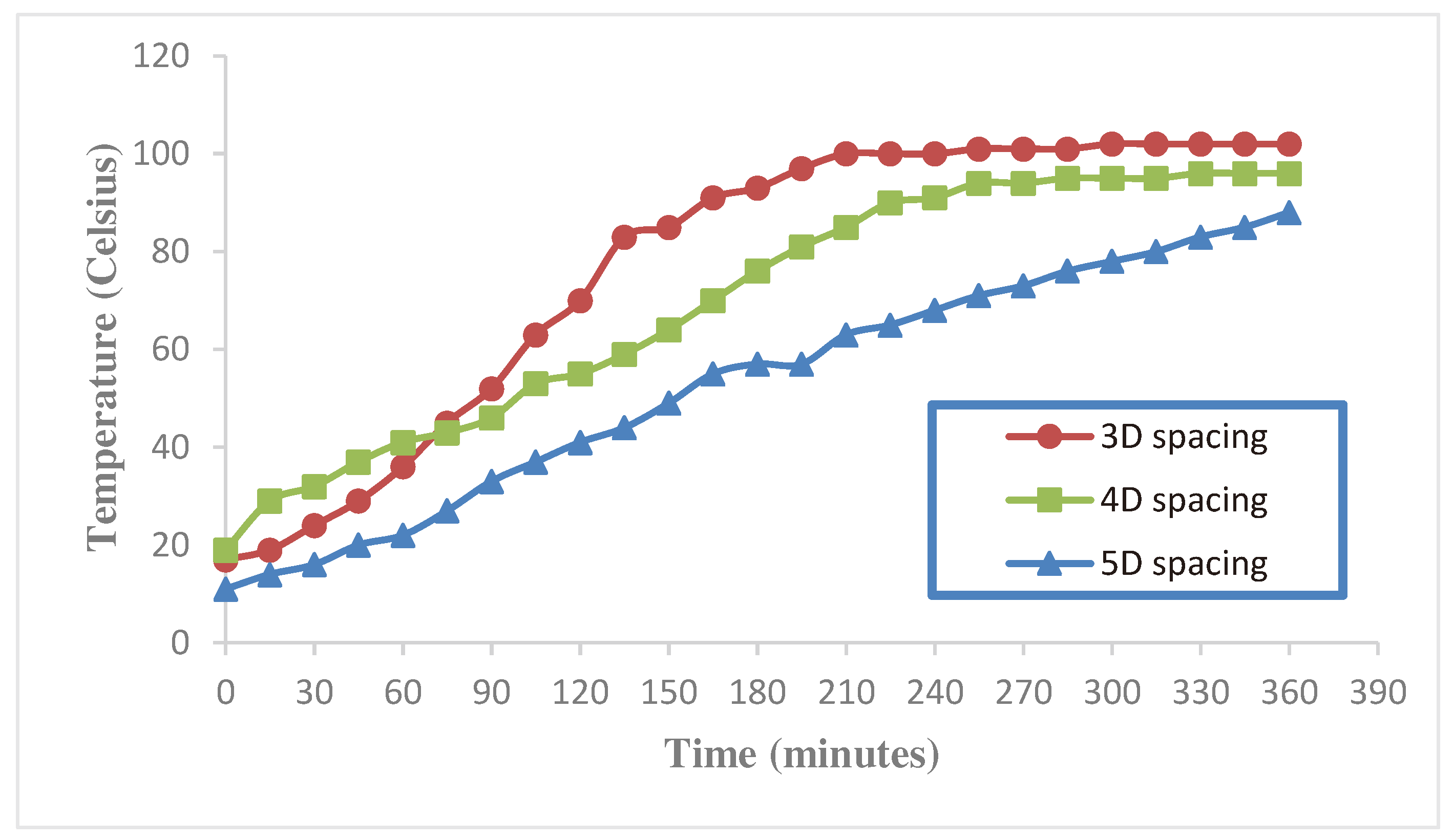

3.1. Impact of Distance between Borehole Casing (Spacing)

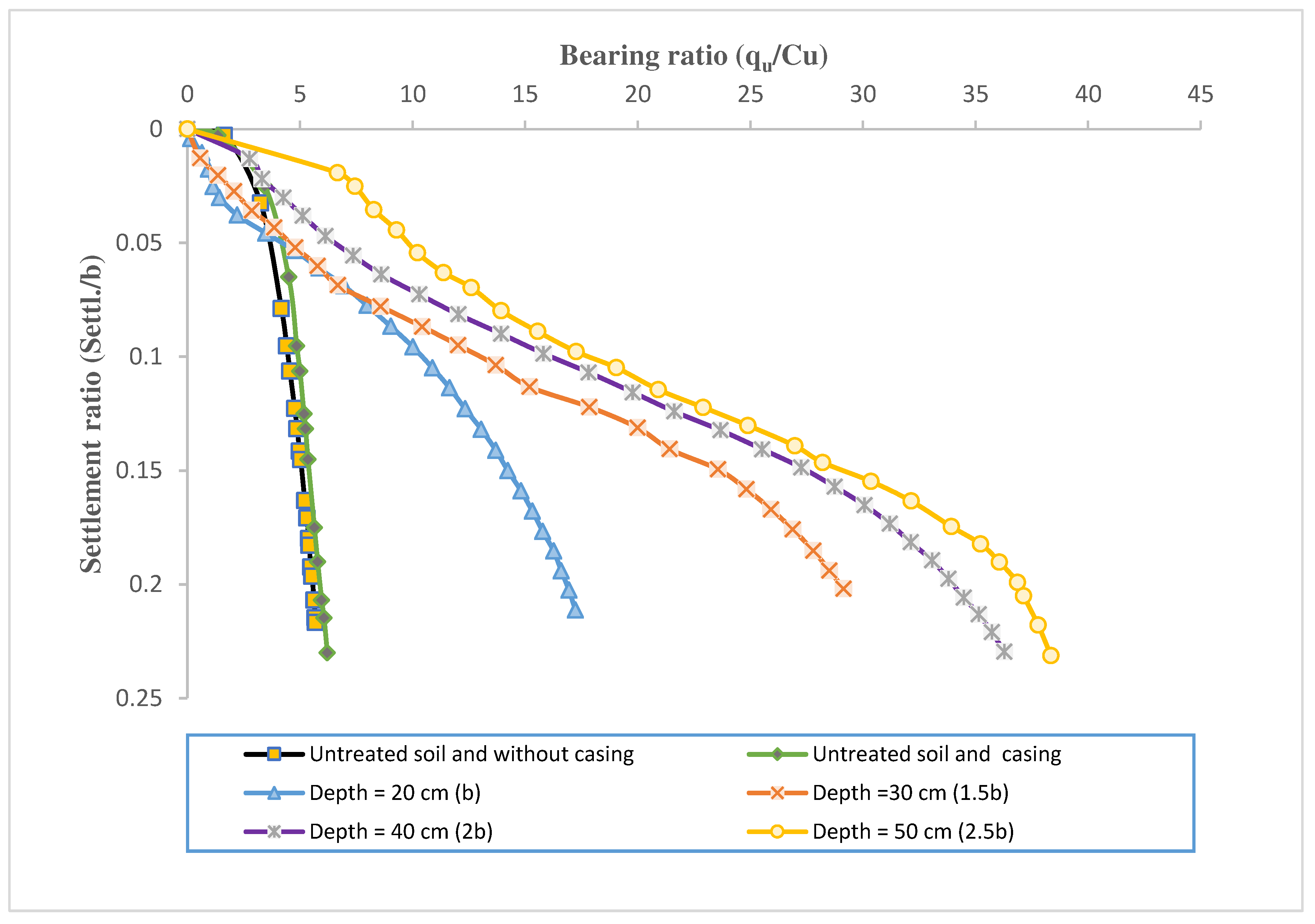

3.2. Impact of Borehole Casing Depth

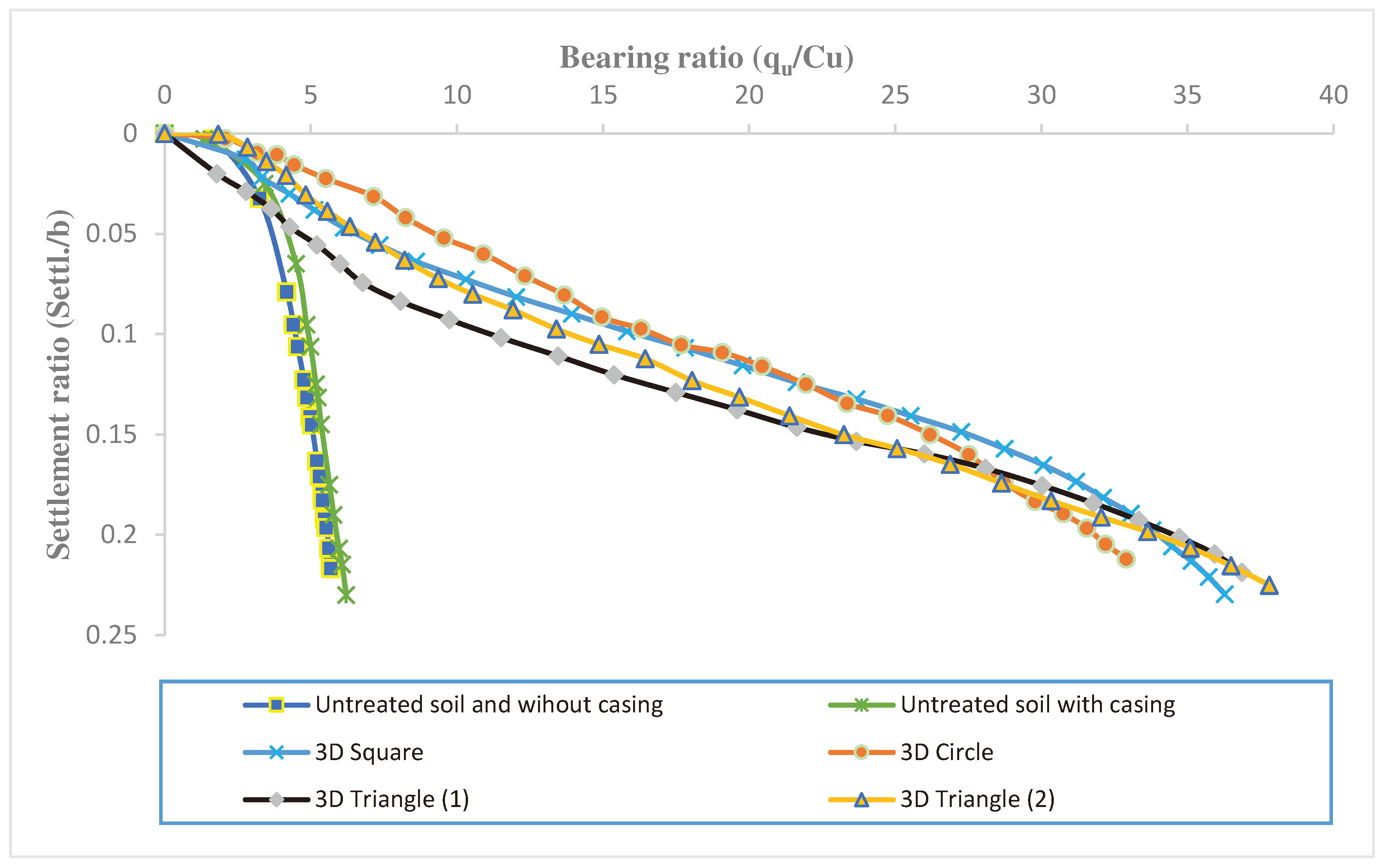

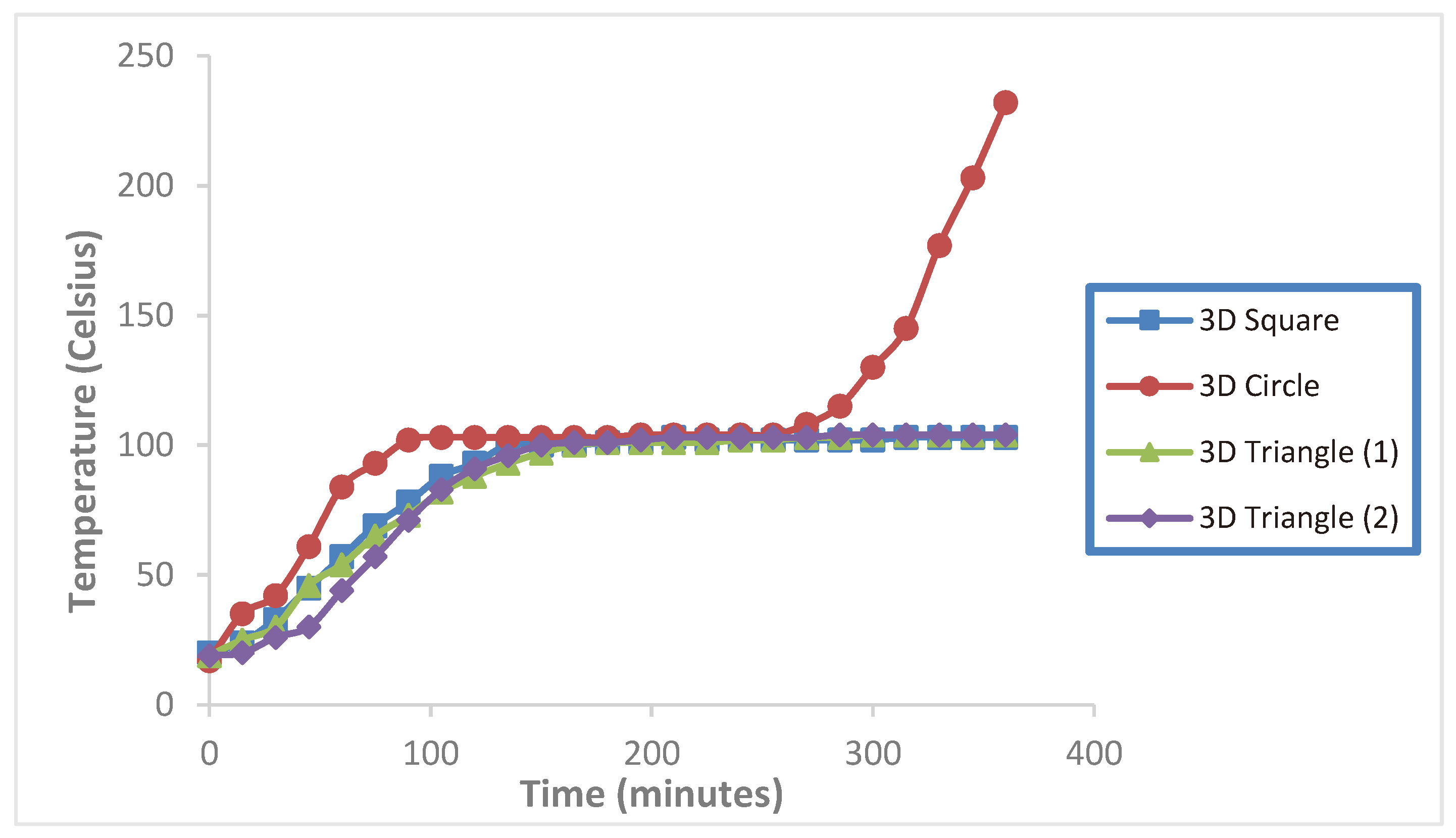

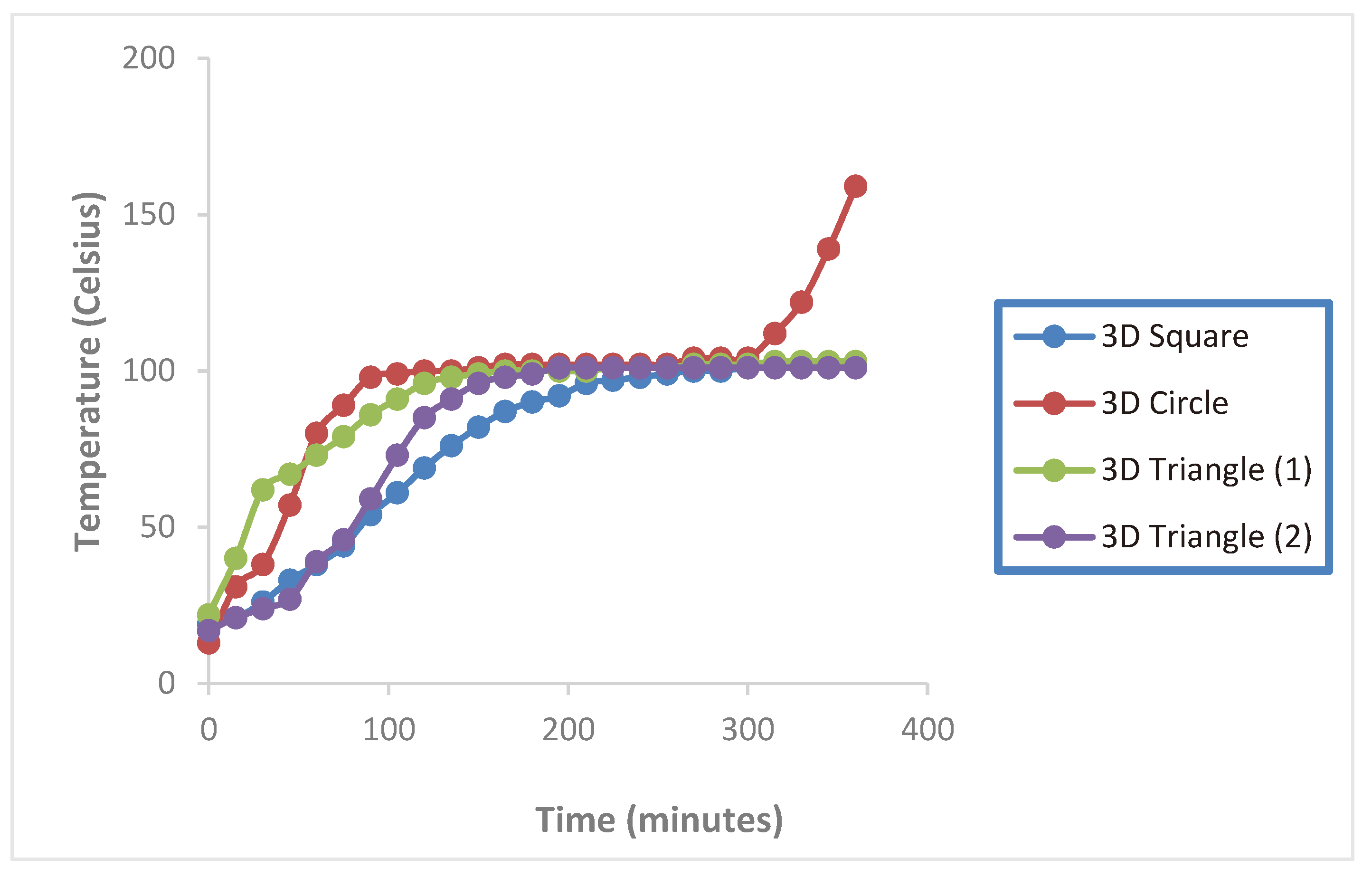

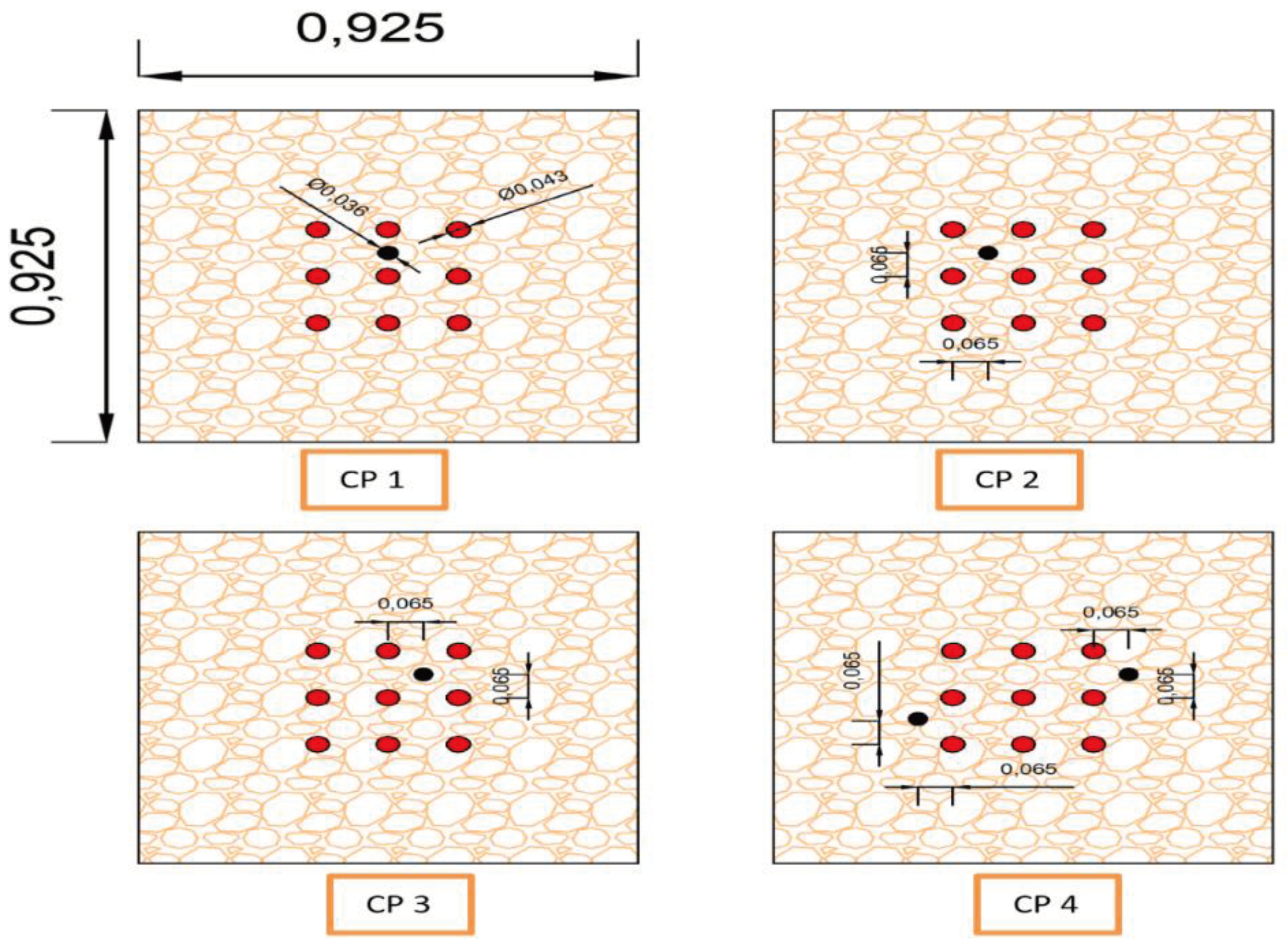

3.3. Impact of Borehole Casing Pattern

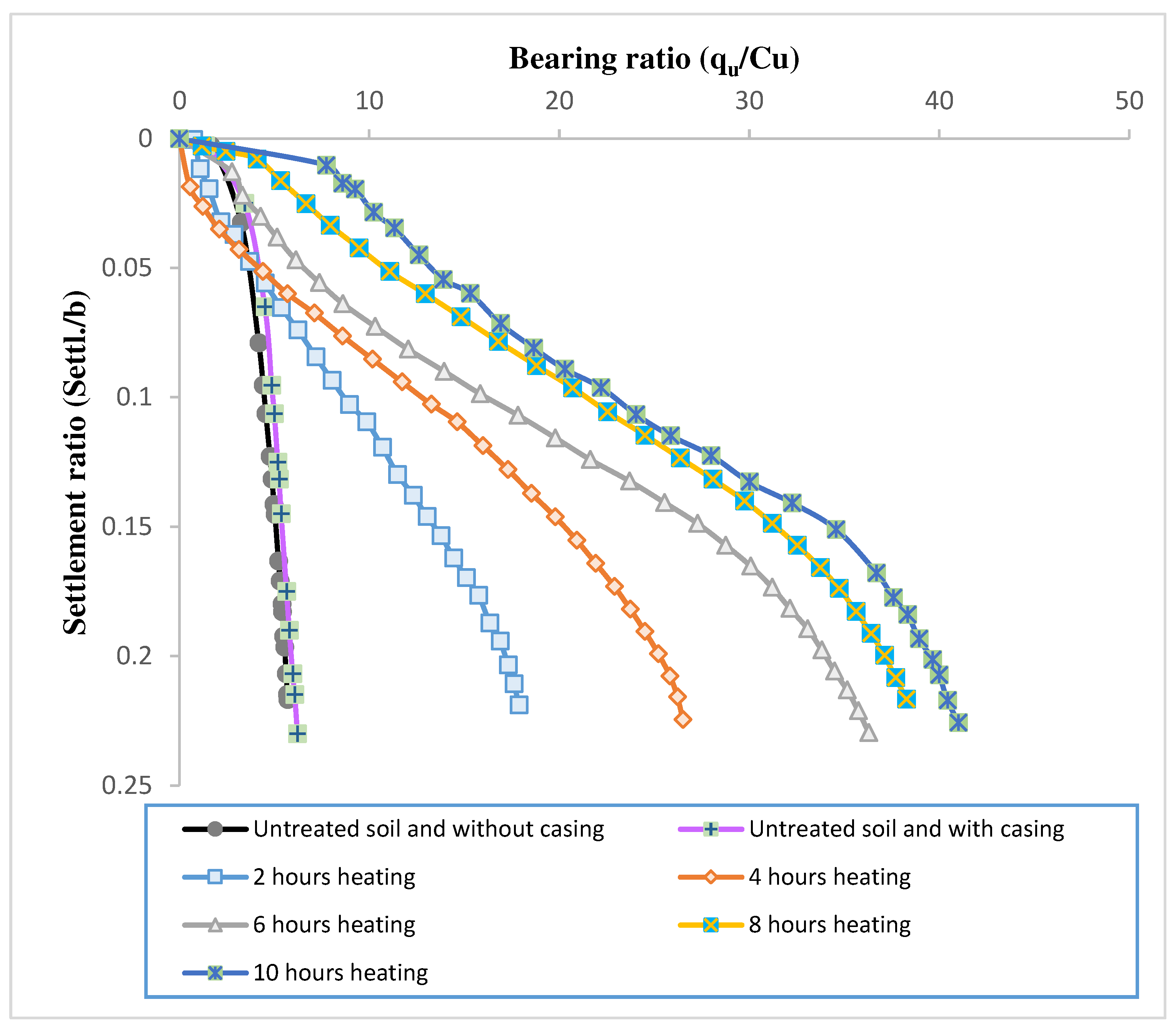

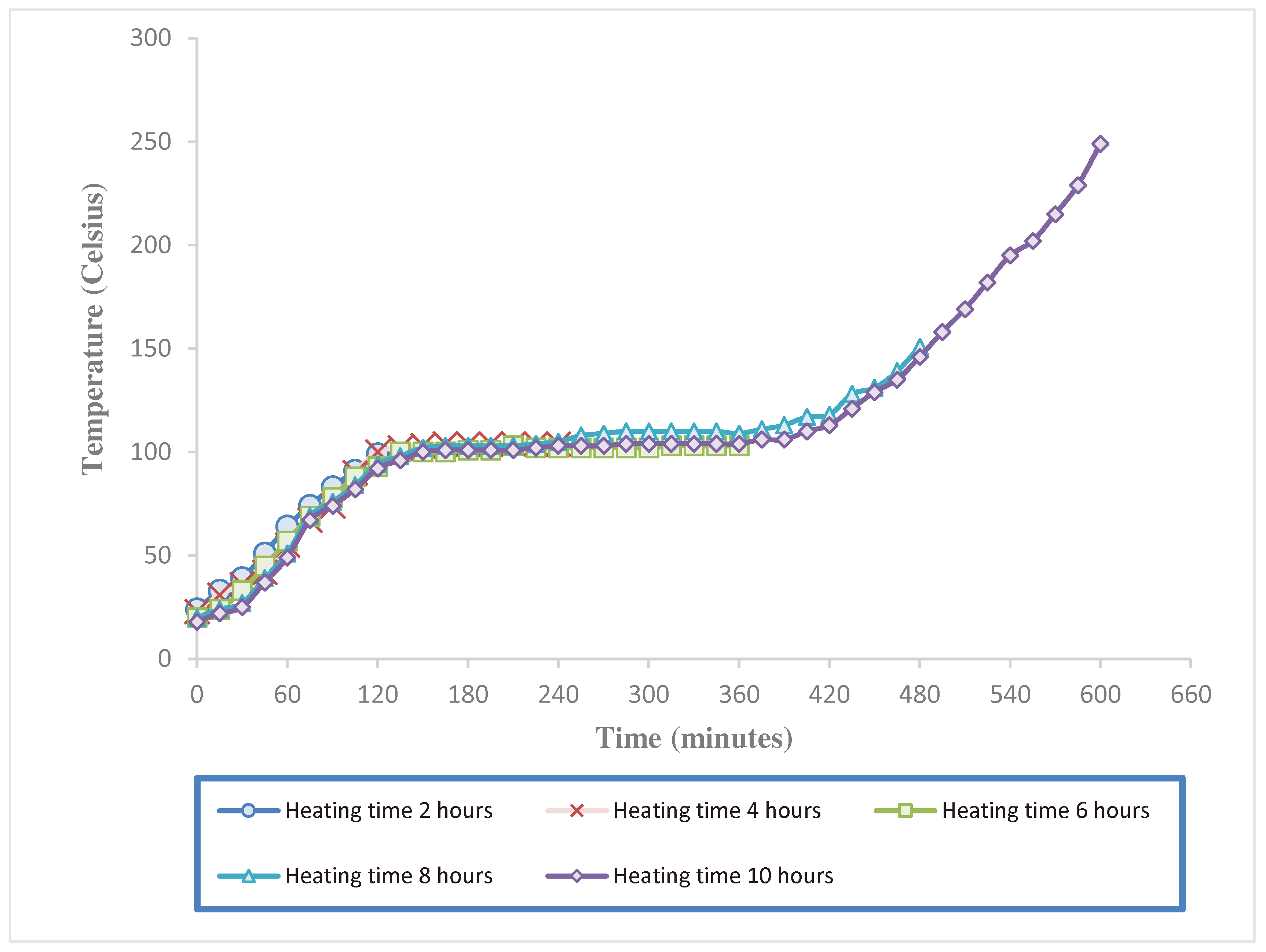

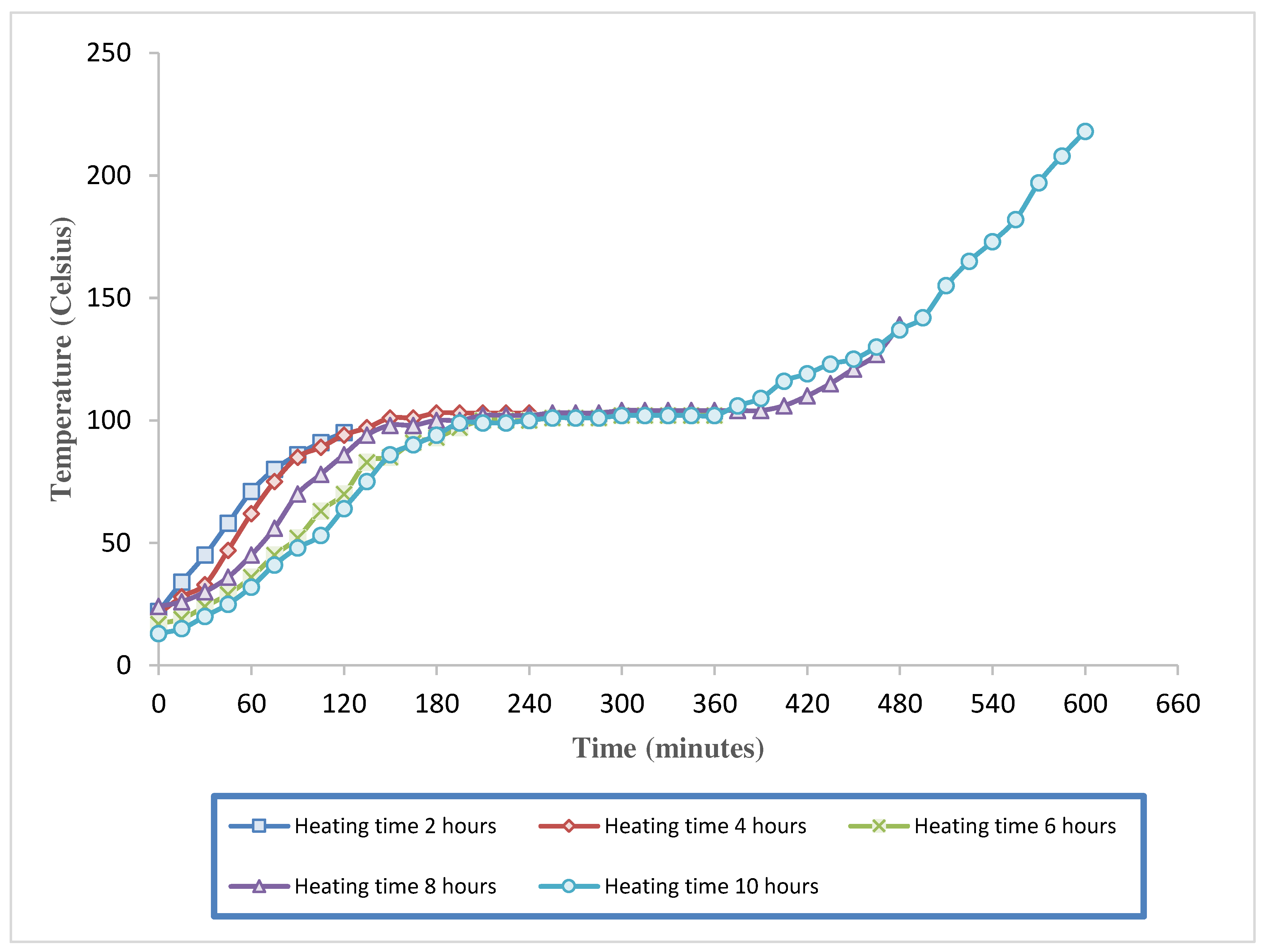

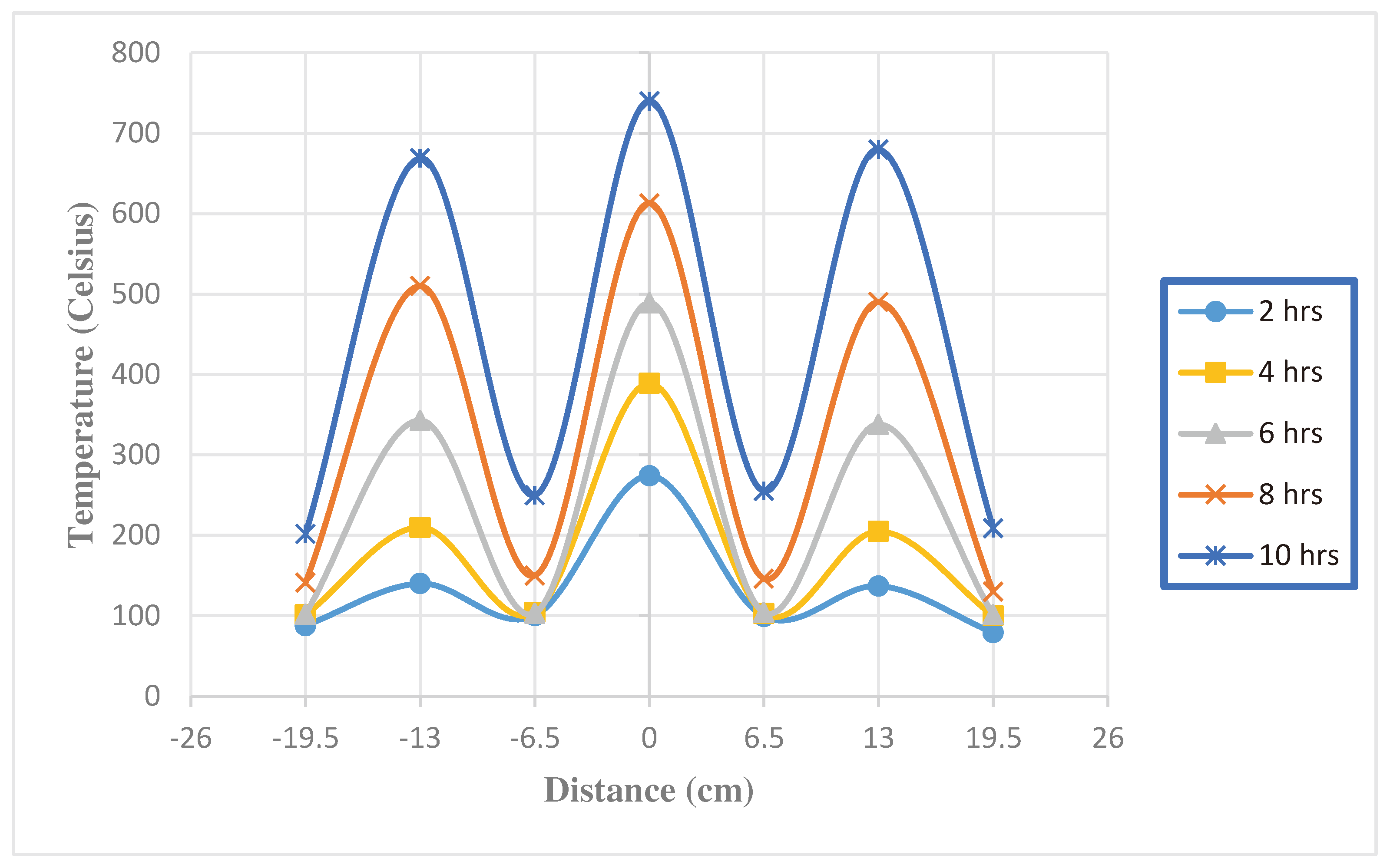

3.4. Impact of Heating Time

4. Conclusions

- The bearing ratio reduces from 27.26 to 21.78 at a 15% settlement ratio if the spacing increases from 3D to 5D. The interlocking between unit cells is significant and reduces the temperature in the center of the treated zone.

- At a 15% settlement ratio, the magnitude of the bearing ratio rises from 14.23 to 28.2 for models 1b to 2.5b as the borehole casing depth increases. Also, this substantial increase gradually reduces from 27.26 to 28.2 for models 2b to 2.5b.

- The effect of the pattern is small when the borehole heating casing is used. The bearing ratio is 26.19 for the circle pattern model, while the bearing ratio for the square pattern model is higher at 27.26. The amount of heat gained determines the strength of the treated area. The greater the amount of heat in the footing center, the greater the strength of the heat-treated zone. Also, increasing the strength is the correct distribution of the borehole heating casing, which provides an appropriate treatment area according to the order of the stresses applied mainly to the treatment area consisting of interlocking unit cells.

- The bearing ratio value increases from 13.76 to 34.57 for 2–10 h heating duration models at a 15% settlement ratio. A small increase in the bearing ratio, from 31.19 to 34.57, is observed for 8–10 h heating duration models. Also, the rate of improvement rises rapidly for the first six hours, but diminishes after that.

- The best spacing between boreholes is three times the outer diameter of the borehole, and the best borehole depth is two times the width of the foundation footing with 8 h of heating duration.

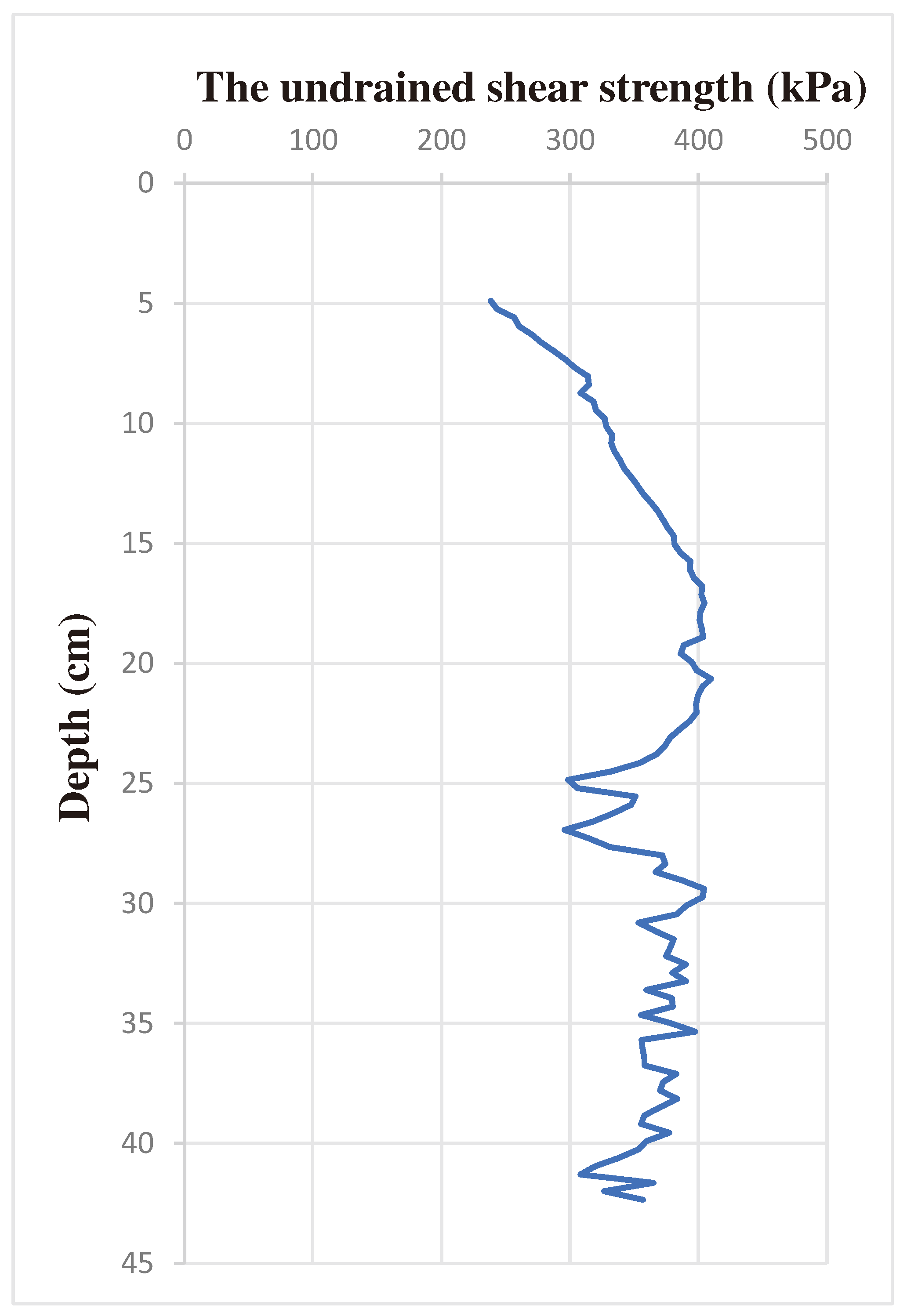

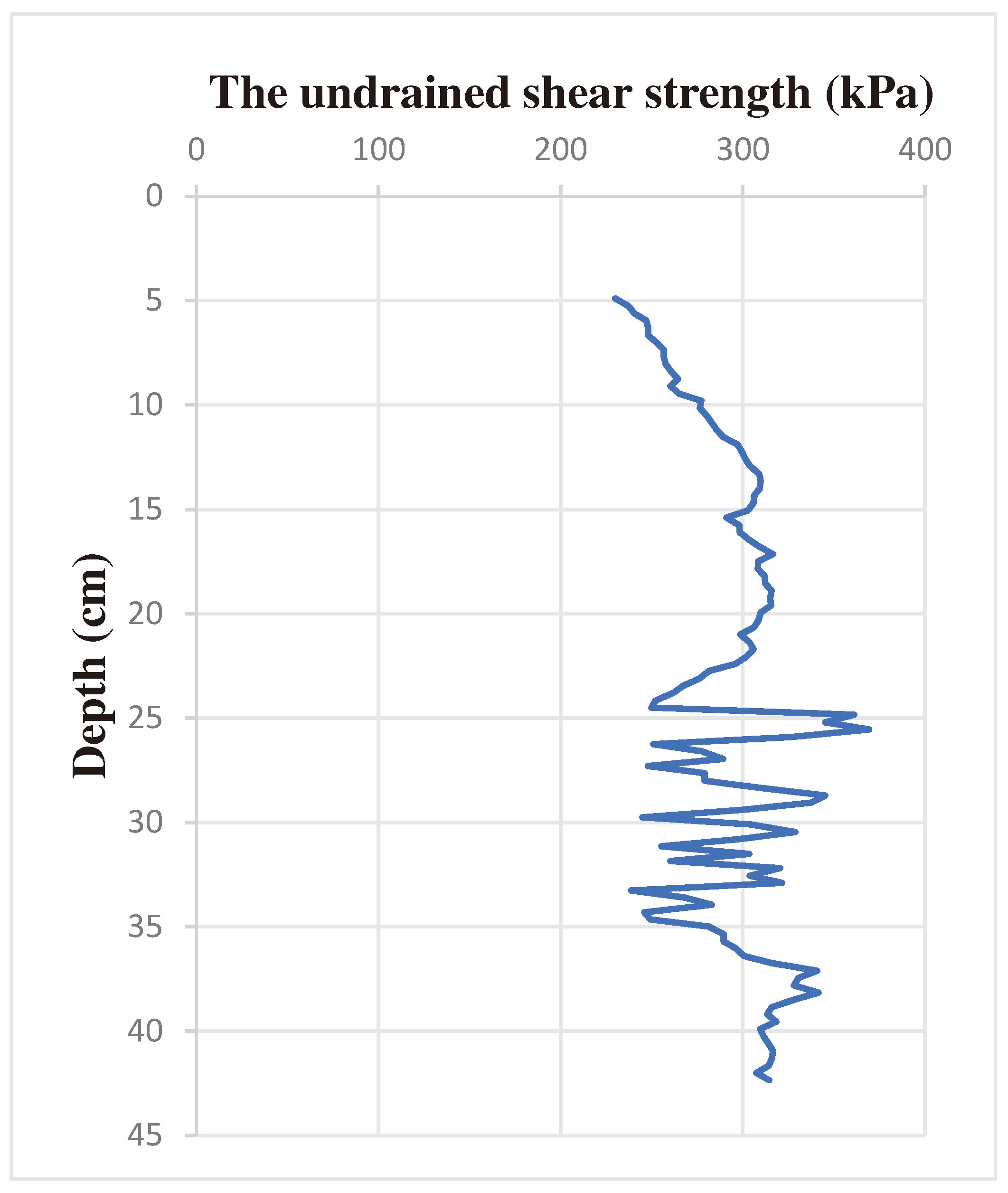

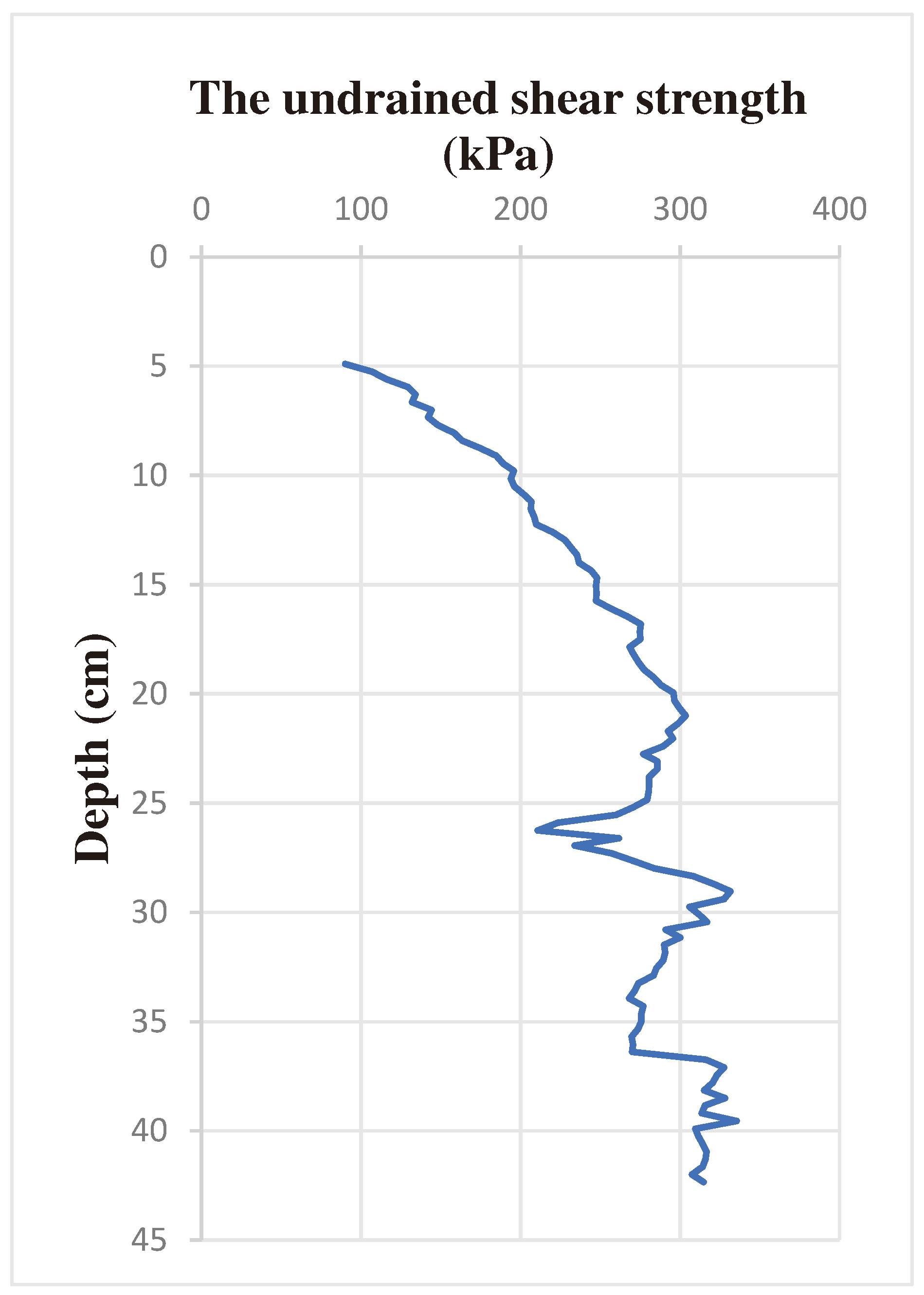

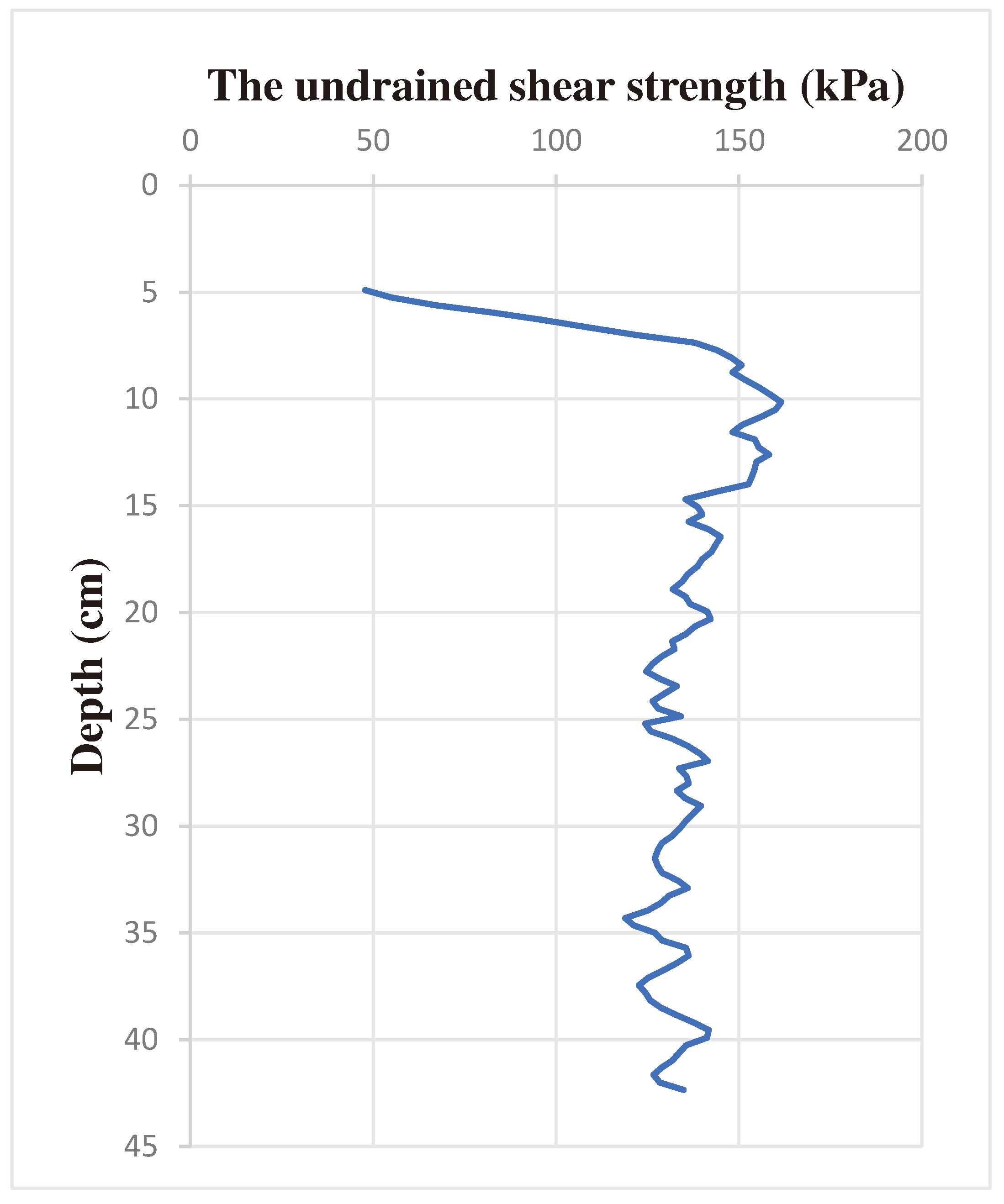

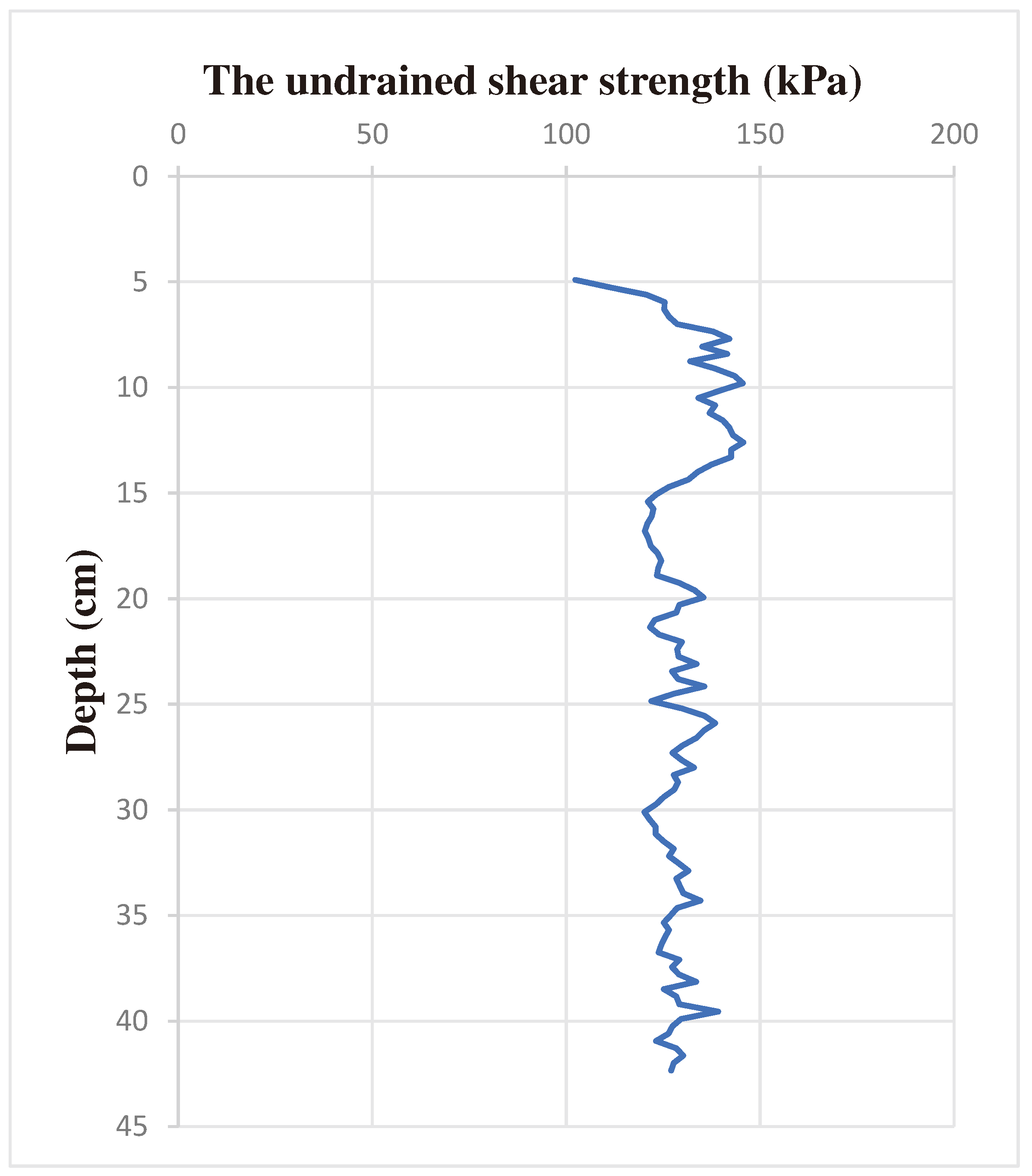

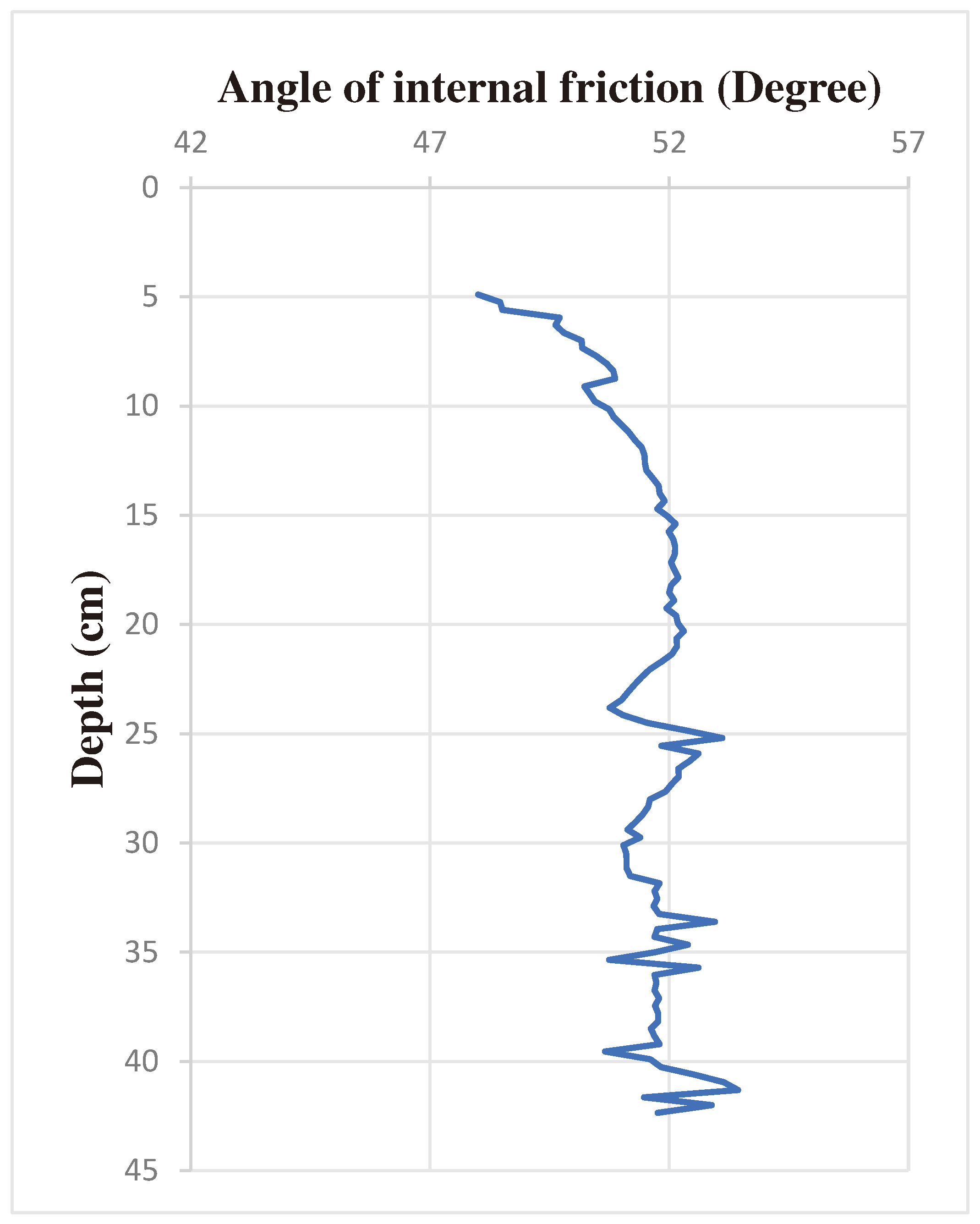

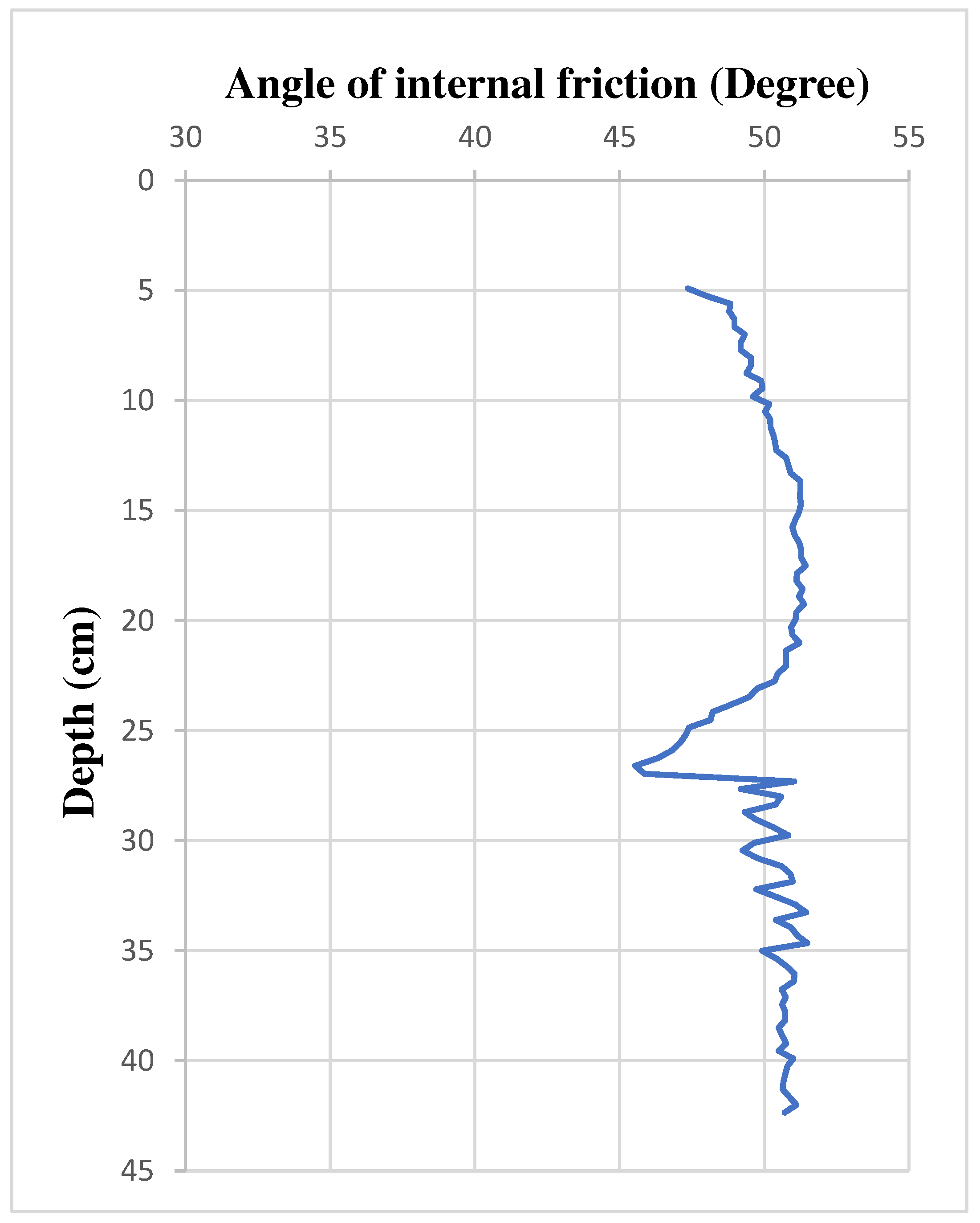

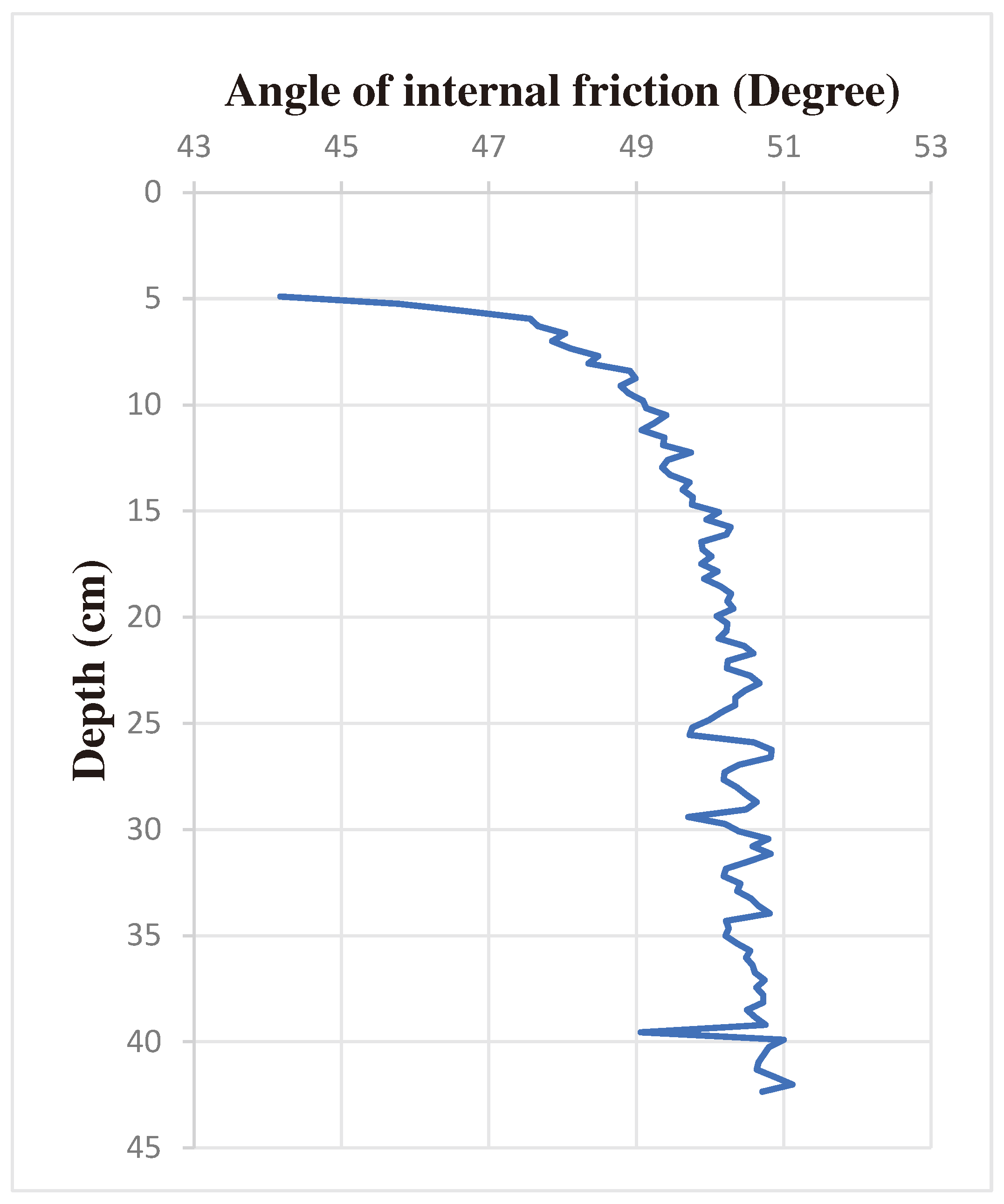

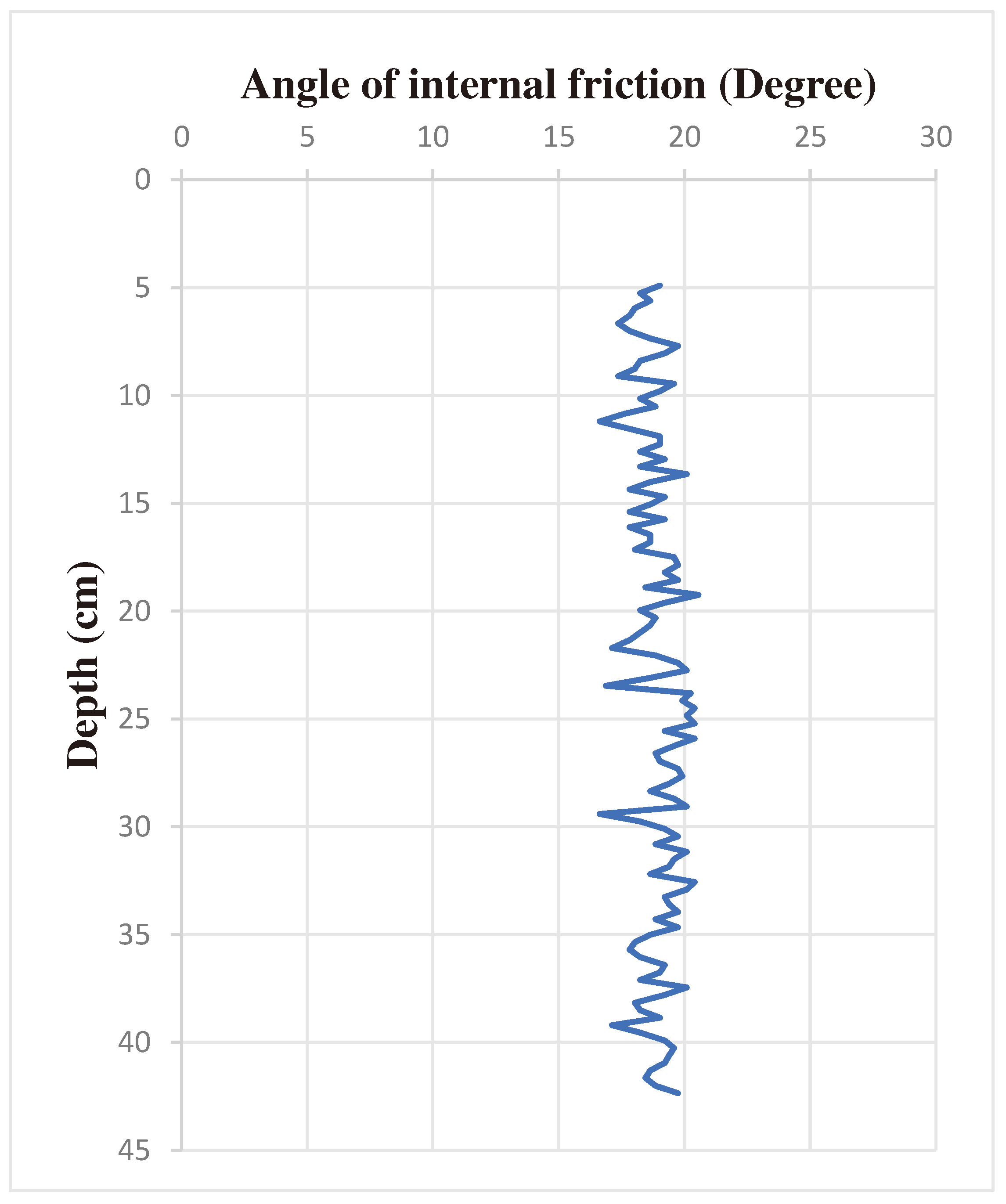

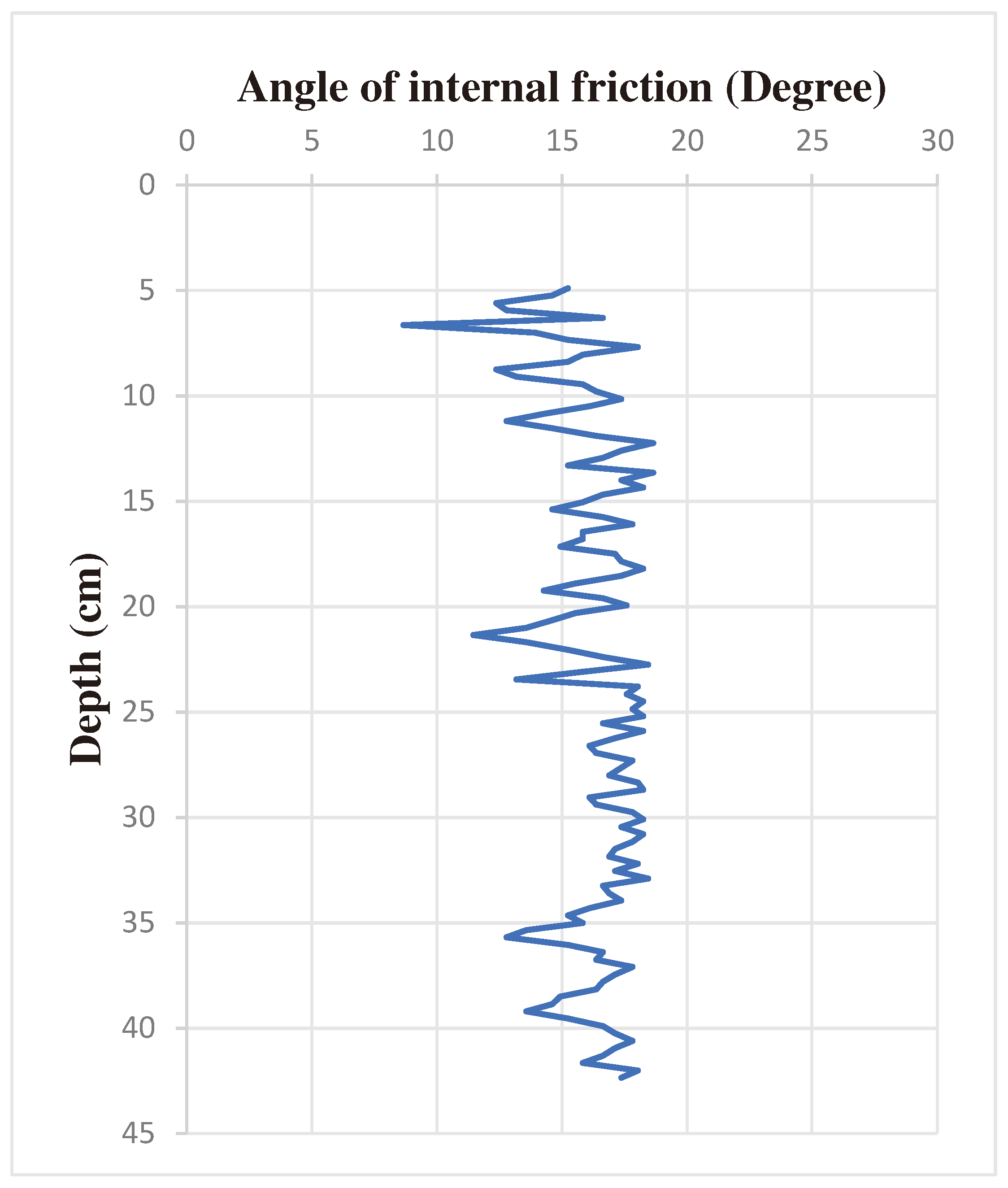

- 6. The values of the undrained shear strength and angle of internal friction at the center of the heating model (CP 1) increase from 14 to 360 kPa and 0 to 52 degrees, respectively.

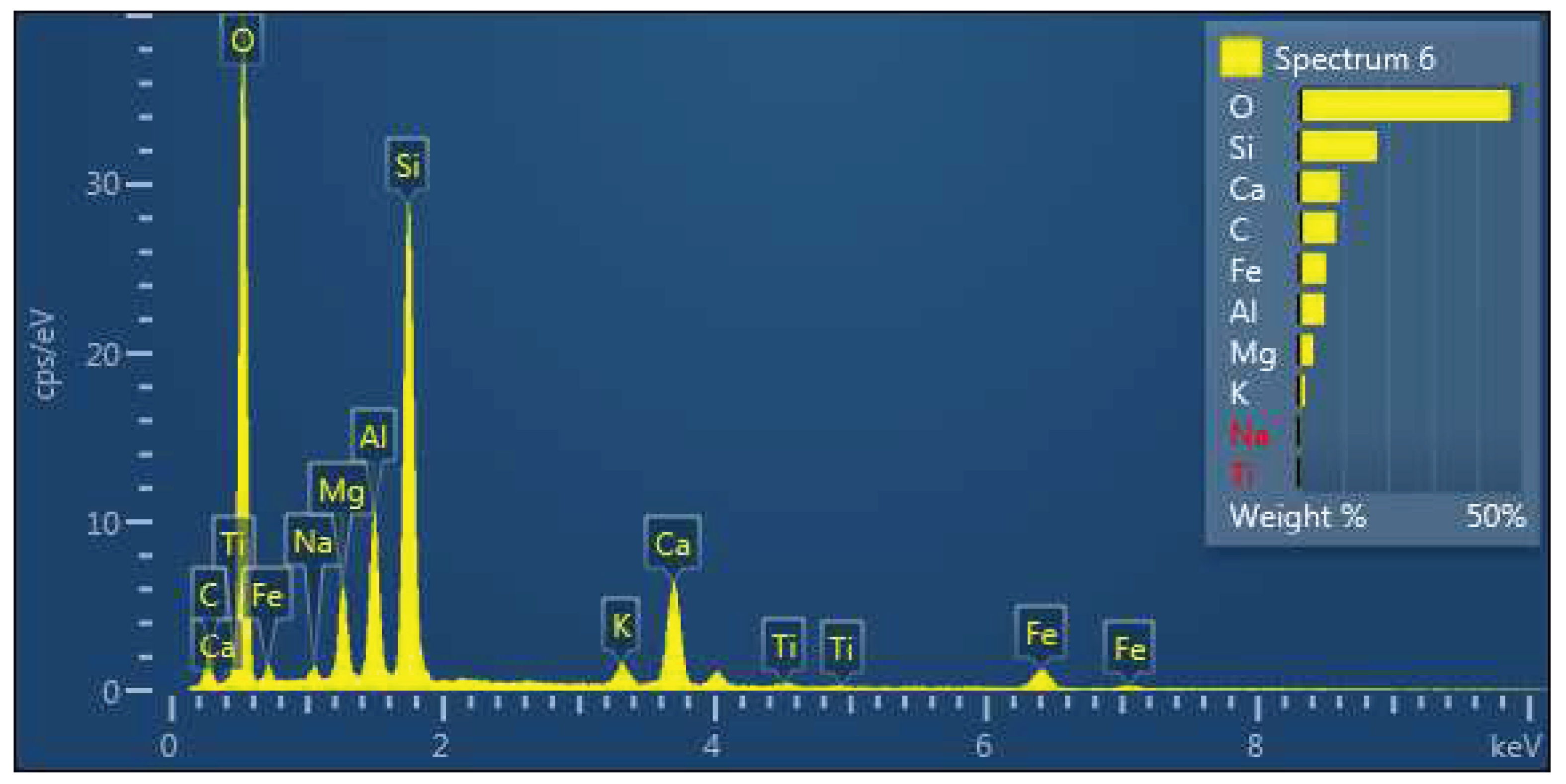

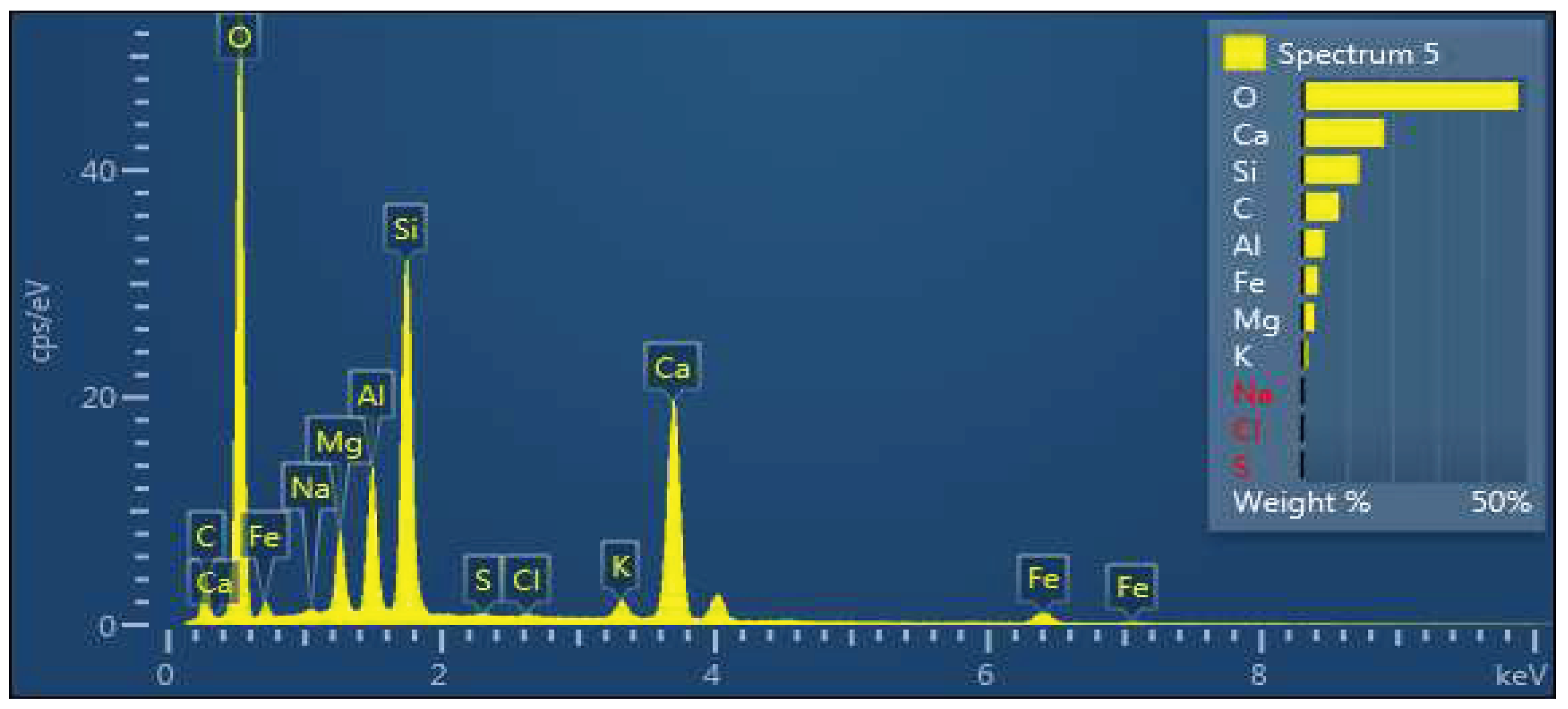

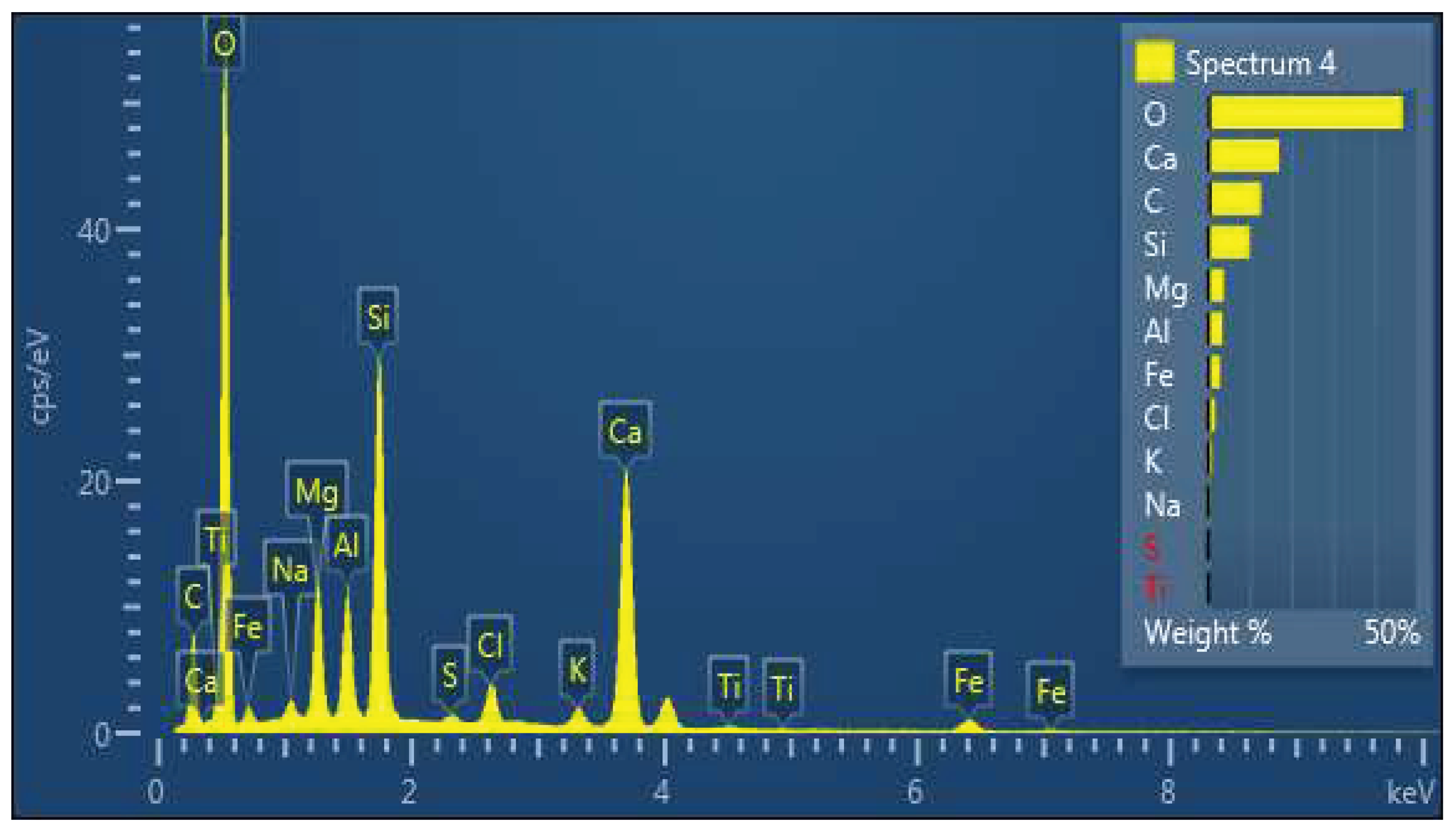

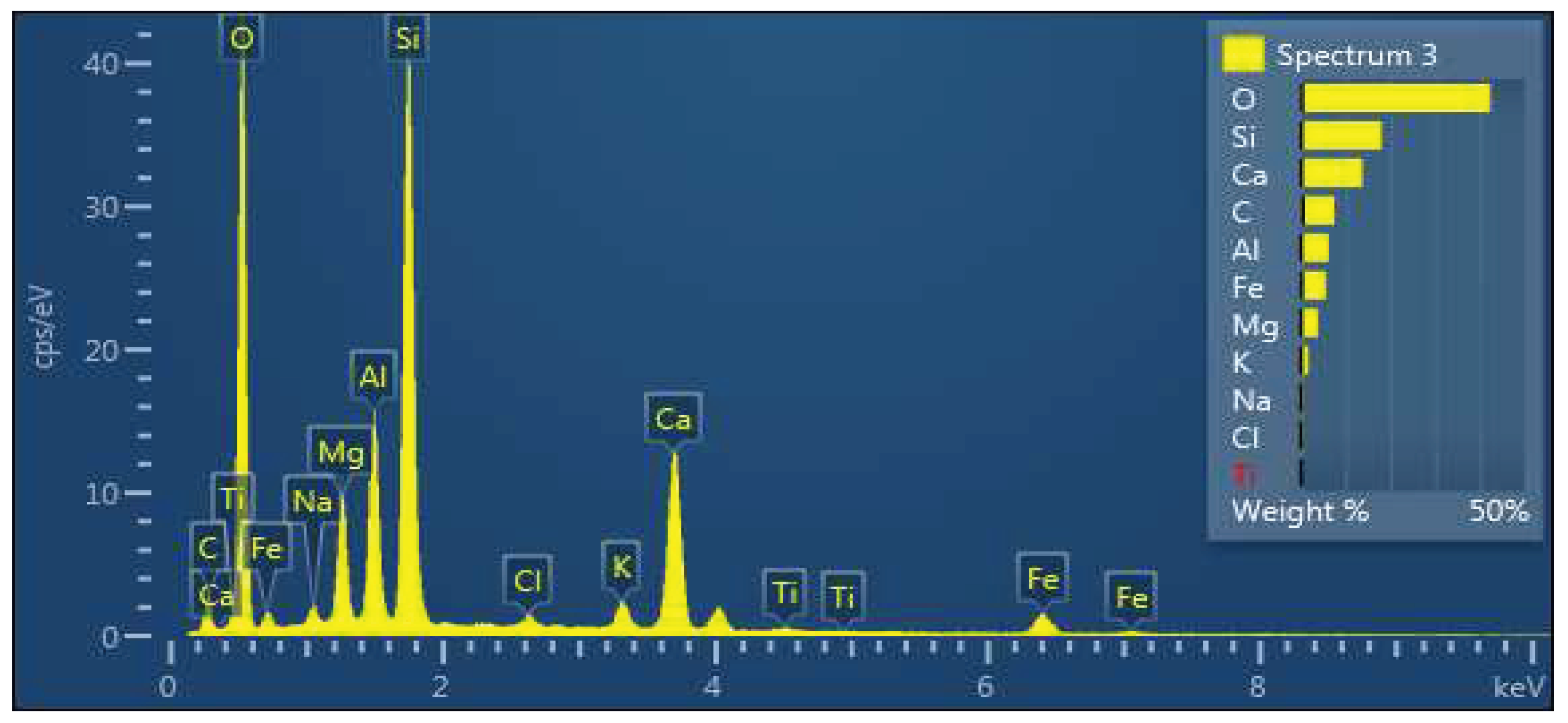

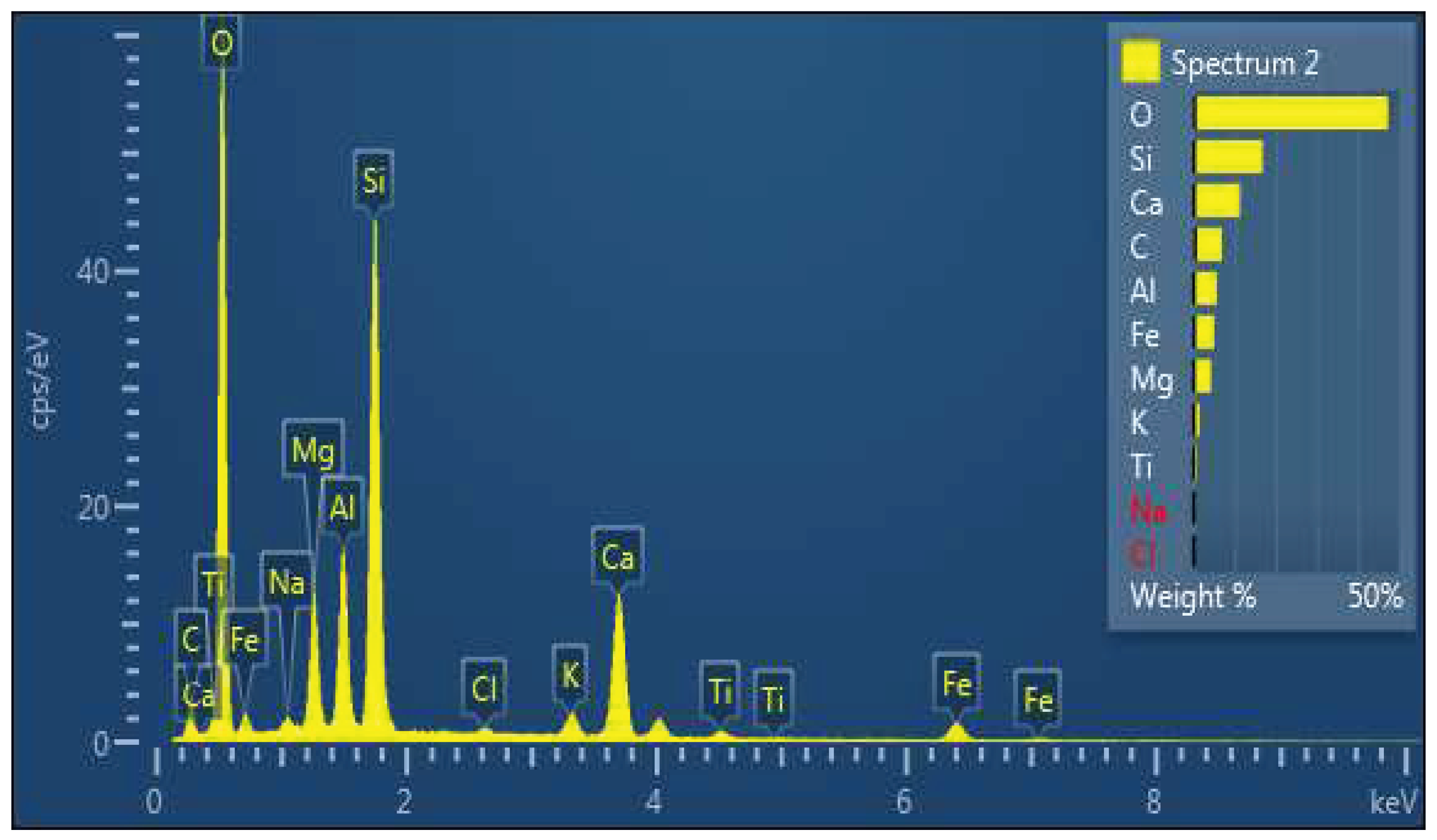

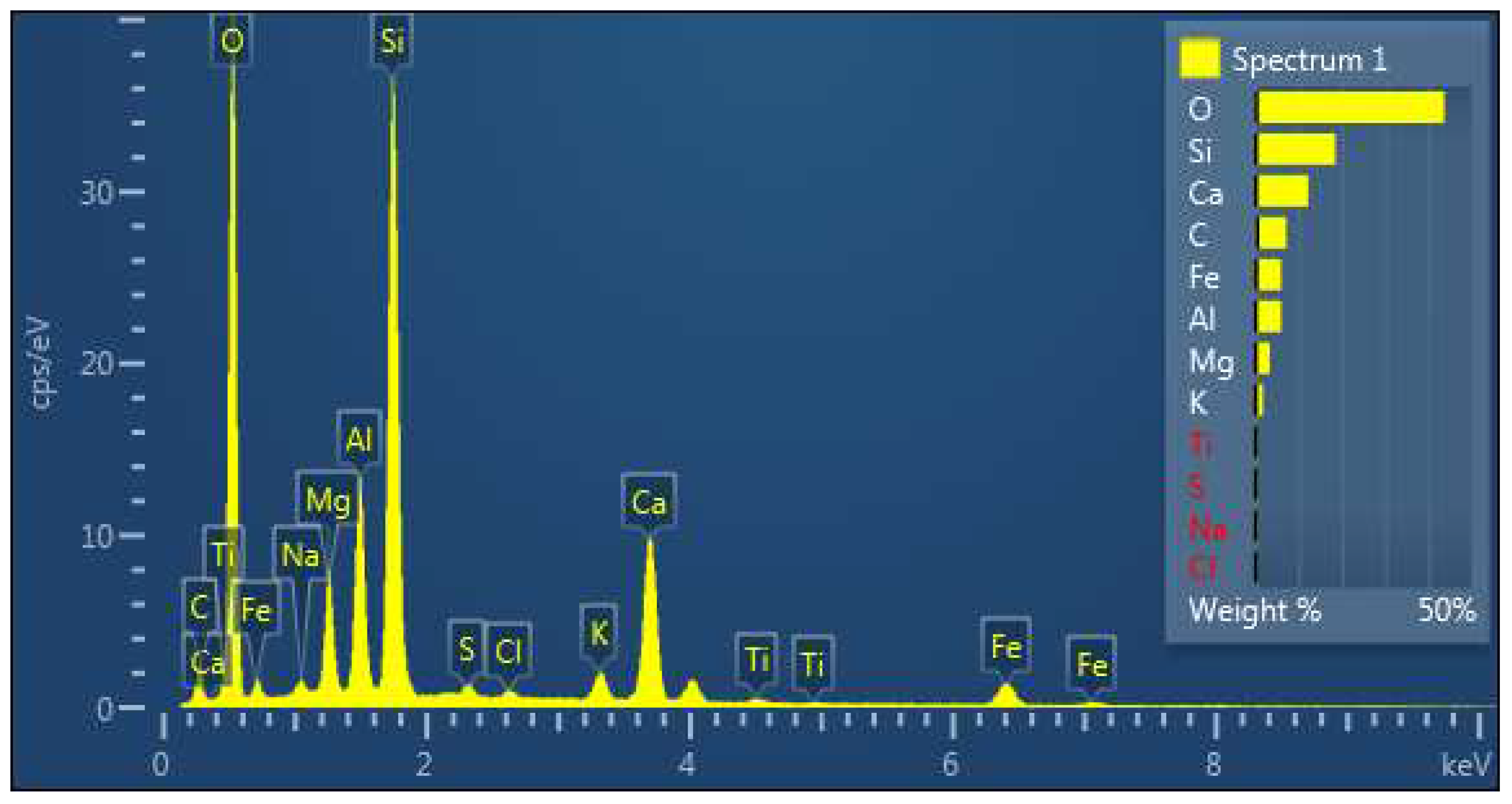

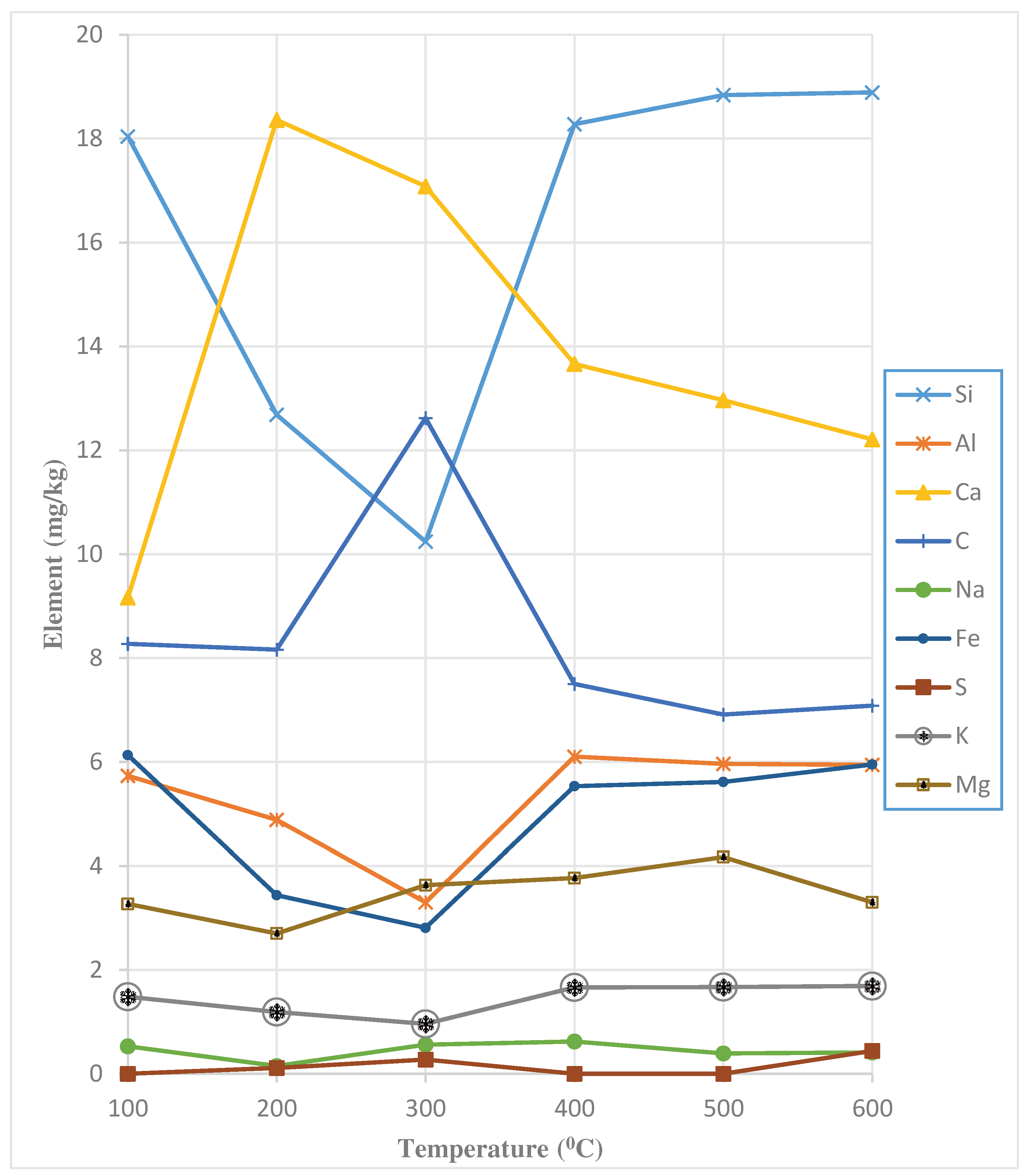

- The EDS pattern for the treated soils demonstrates that the percentage of elements such as silicon, aluminum, and iron decreases at 300 °C and increases at 400 °C. Moreover, the percentage of calcium increases as the temperature reaches 200 °C and sharply decreases when it reaches 400 °C. The amount of carbon increases as the temperature rises to 300 °C and decreases at 400 °C.

- The amounts of the measured elements exhibit either low or negligible fluctuations when the temperature falls within the range of 400 °C to 600 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Neami, M.A.M. Reducing settlement of soft soils using local materials. Eng. Technol. J. 2010, 28, 6649–6661. [Google Scholar] [CrossRef]

- Sasanian, S. The Behaviour of Cement Stabilised Clay at High Water Contents; The University of Western Ontario: London, ON, Canada, 2011. [Google Scholar]

- Ahmed, A. Compressive strength and microstructure of soft clay soil stabilised with recycled bassanite. Appl. Clay Sci. 2015, 104, 27–35. [Google Scholar] [CrossRef]

- Sukpunya, A.; Jotisankasa, A. Large simple shear testing of soft Bangkok clay stabilised with soil–cement-columns and its application. Soils Found. 2016, 56, 640–651. [Google Scholar] [CrossRef]

- Tan, Ö.; Yılmaz, L.; Zaimoğlu, A.S. Variation of some engineering properties of clays with heat treatment. Mater. Lett. 2004, 58, 1176–1179. [Google Scholar] [CrossRef]

- Abu-Zreig, M.M.; Al-Akhras, N.M.; Attom, M.F. Influence of heat treatment on the behavior of clayey soils. Appl. Clay Sci. 2001, 20, 129–135. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, W.; Qian, H. Effects of high temperature thermal treatment on the physical properties of clay. Environ. Earth Sci. 2016, 75, 610. [Google Scholar] [CrossRef]

- Geng, J.; Sun, Q. Effects of high temperature treatment on physical-thermal properties of clay. Thermochim. Acta 2018, 666, 148–155. [Google Scholar] [CrossRef]

- Hu, Q.; Gu, Y.; Zeng, J.; He, L.; Tang, H.; Wei, G.; Lu, X. Microwave irradiation reinforcement of weak muddy intercalation in slope. Appl. Clay Sci. 2019, 183, 105324. [Google Scholar] [CrossRef]

- Zhang, S.; Ding, Y.; Lu, X.; Mao, X.; Song, M. Rapid and efficient disposal of radioactive contaminated soil using microwave sintering method. Mater. Lett. 2016, 175, 165–168. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, H.; Yan, Z.; Zhao, L.; Shen, Y.; Misra, A. Experimental study on physical properties of soft soil after high temperature exposure. Eng. Geol. 2016, 204, 14–22. [Google Scholar] [CrossRef]

- Yin, T.; Liu, G.; Guo, Z. Theoretical and experimental study on thermal consolidation characteristics of typical soft clay in Ningbo region. Build. Struct. 2014, 44, 66–69. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, Z.; Cui, Y.; Ye, W.; Liu, Q. Effect of cement solutions on the swelling pressure of compacted GMZ bentonite at different temperatures. Constr. Build. Mater. 2019, 229, 116872. [Google Scholar] [CrossRef]

- Reinosa, J.J.; García-Baños, B.; Catalá-Civera, J.M.; Fernández, J.F. A step ahead on efficient microwave heating for kaolinite. Appl. Clay Sci. 2019, 168, 237–243. [Google Scholar] [CrossRef]

- Yao, H.; Lu, J.; Bian, H.; Zhang, Z. Influence of microwave heating on the swelling properties of expansive soil in Hefei. Case Stud. Therm. Eng. 2022, 39, 102466. [Google Scholar] [CrossRef]

- Demirbas, A. Fuel properties of hydrogen, liquefied petroleum gas (LPG), and compressed natural gas (CNG) for transportation. Energy Sources 2002, 24, 601–610. [Google Scholar] [CrossRef]

- Rahil, F.; Baqir, H.; Alkabee, H. Bearing capacity of soft clay improved by heating through different spacing cased boreholes. Kufa J. Eng. 2019, 10, 68–77. [Google Scholar] [CrossRef]

- Bai, B.; Long, F.; Rao, D.; Xu, T. The effect of temperature on the seepage transport of suspended particles in a porous medium. Hydrol. Process. 2017, 31, 382–393. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, Z.; Wang, Y.; Yan, Z. Experimental investigation on heat transfer characteristics of soft clay at high temperatures. Jpn. Geotech. Soc. Spec. Publ. 2015, 1, 40–44. [Google Scholar] [CrossRef]

| Index Property | Index Value |

|---|---|

| Liquid Limit (%) | 45 |

| Plastic Limit (%) | 23 |

| Plasticity Index (%) | 22 |

| Specific Gravity | 2.69 |

| Gravel % | 0 |

| Sand % | 2 |

| Silt % | 20 |

| Clay % | 78 |

| Classification (USCS) | CL |

| Organic Matter (%) | <0.01 |

| Total Dissolved Salt (%) | 2.21 |

| pH Value | 7.2 |

| Property | Value |

|---|---|

| Density at 20 °C (kg/dm3) | 785 |

| Thermal conductivity at 20 °C (W/m K) | 50 |

| Specific thermal capacity at 20 °C (J/kg K) | 460 |

| Element | Untreated Soil | Treated Soil at 200 °C | Treated Soil at 300 °C | Treated Soil at 400 °C | Treated Soil at 500 °C | Treated Soil at 600 °C |

|---|---|---|---|---|---|---|

| Weight (mg/kg) | Weight (mg/kg) | Weight (mg/kg) | Weight (mg/kg) | Weight (mg/kg) | Weight (mg/kg) | |

| Si | 18.04 | 12.68 | 10.24 | 18.28 | 18.84 | 18.89 |

| O | 47.39 | 47.26 | 46.37 | 42.29 | 42.91 | 43.69 |

| Al | 5.73 | 4.88 | 3.3 | 6.1 | 5.96 | 5.94 |

| C | 8.27 | 8.16 | 12.62 | 7.5 | 6.91 | 7.08 |

| Ca | 9.16 | 18.36 | 17.08 | 13.66 | 12.96 | 12.21 |

| Na | 0.53 | 0.15 | 0.56 | 0.62 | 0.39 | 0.41 |

| K | 1.48 | 1.19 | 0.96 | 1.66 | 1.67 | 1.69 |

| Fe | 6.13 | 3.44 | 2.81 | 5.53 | 5.61 | 5.95 |

| Mg | 3.27 | 2.7 | 3.63 | 3.77 | 4.17 | 3.3 |

| S | 0 | 0.11 | 0.27 | 0 | 0 | 0.44 |

| Cl | 0 | 0.12 | 1.67 | 0.52 | 0.28 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).