1. Introduction

Tunnel construction faces many problems of high ground temperature tunnels [

1,

2,

3,

4], and high ground temperatures can deteriorate the construction operating environment and lead to a significant increase in operating costs [

5,

6,

7]. Curtain grouting technology is one of the important methods to achieve temperature control in high ground temperature tunnels [

8]. In response to the temperature control problems of high geothermal tunnels, some scholars [

9] explored to solve the problems of high geothermal environment from the technical level, but these methods have the problems of insufficient economic benefits and limited conditions. While curtain grouting is one of the most effective methods to achieve temperature control in high geothermal environments [

10], grouting materials with good thermal insulation properties are the key factors to achieve curtain grouting, so it is necessary to study grouting materials with good thermal insulation properties.

Existing high ground temperature grouting materials have insufficient slurry-rock interfacial bonding at temperatures above 50°C, and the strength of the material appears to decrease [

11,

12]. The compressive strength of cementite in the material increases and then decreases with the increase of temperature, and the porosity and permeability keep increasing [

13]. It has been shown that in a high temperature environment, the addition of quick-setting agent can improve the late strength of fly ash-cement slurry [

14], and the addition of slag powder into the cement slurry improves the fluidity and stability of the slurry, and the late compressive strength is significantly improved [

15]. In addition to this, temperature has a significant effect on the relative peak stress of the cement paste [

16], and also increases the elasticity, plasticity and viscosity of the paste, thus increasing its yield stress [

17].

In summary, it can be seen that the grouting in high-temperature tunnels is still dominated by ordinary cement and cement-water glass, which cannot take into account both the working performance and the thermal insulation performance, and it is difficult to form an effective thermal insulation curtain circle layer. The red mud-based grouting material, which is configured by replacing part of the cement with red mud, has excellent working performance [

18]. However, there are fewer engineering applications of red mud as grouting material, and there is still a gap in the research in the field of grouting reinforcement in high geothermal tunnels.

In view of this, this paper carries out the working performance and thermal insulation performance tests of red mud-based grouting material (RMGS), cement slurry, and cement-sodium silicate slurry at different temperatures, analyses the law and degree of the influence of temperature on the basic performance of grouting materials and the microscopic mechanism, and, on this basis, researches the applicability of the three kinds of grouting materials with different environments. This test can provide a basis for the realisation of temperature control of high geothermal tunnels, which is of great significance to the construction, maintenance and repair of high geothermal tunnels and has value for engineering application.

2. Materials and Methods

2.1. Materials

The red mud used in the test was selected from the Bayer red mud produced by Guangxi Pingguo Aluminium Industry, with a particle size of 0.005 μm -0.075 μm and a density of 2.75 g/cm

3. Red mud is a waste product of bauxite extraction of alumina industrial production, which is known as red mud because of its high content of Fe

2O

3 and its appearance is similar to that of the red-coloured mud, and some of the red mud is brown due to the low content of Fe

2O

3, containing a large amount of CaO [

18,

19]. Red mud is a highly alkaline solid waste, usually with pH > 11.0, which is polluting and is pretreated before use. Pretreatment includes (1) water washing to a pH of 8.0-8.5, (2) boiling and washing it using acid, and (3) alkali precipitation after acid dissolution.

The cement used is P.O 42.5 (ordinary silicate cement) produced in southern Hunan province, with a fineness of 800 mesh and a density of 3.05 g/cm

3, which is in line with general Portland cement standards. The quartz powder used is a powdered solid of pure quartz processed after a series of industrial procedures, with a fineness of about 160 mesh. The main component of the modifier is Na

2SiO

3 with a Baume degree of 25 and modulus of 3.5. The chemical composition of the raw materials is shown in

Table 1.

2.2. Sample Preparation

RMGS was used as the test group and its ratio composition is shown in

Table 2. ordinary cement slurry and cement-sodium silicate slurry were used as the control group, the water-cement ratio of ordinary cement slurry was 0.6, and the cement-sodium silicate slurry had a water-cement ratio of 0.6, and waterglass admixture was 20% of the mass of cement [

20].

2.3. Methods

The viscosity test was carried out using a rotational viscometer, the setting time test was carried out using the Vickers meter method, and the compressive strength was determined using the unconfined compressive strength test, with a specimen size of 70.7mm×70.7mm×70.7mm cubic specimen.

Thermal conductivity was prepared using a 40mm×40mm×160mm triple mould, and the specimens were placed in a water bath at the corresponding temperature for 3 days and then taken out for the measurement of thermal conductivity, which was measured using the protective hot plate method [

21]. The specific heat capacity was determined by the mixed calorimetry method [

22]. The equipment for microanalysis was an F200X field emission transmission electron microscope from the Centre for Advanced Studies, Central South University.

3. Results and analyses

3.1. Viscosity

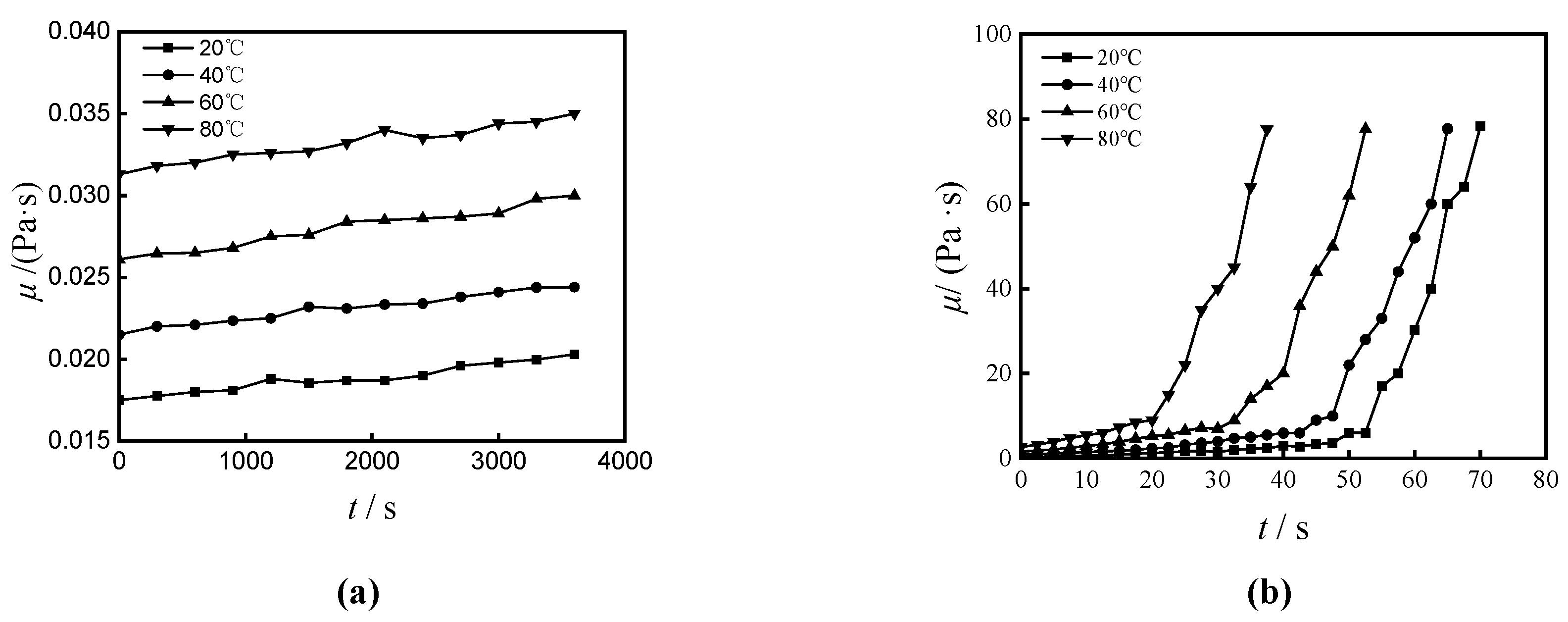

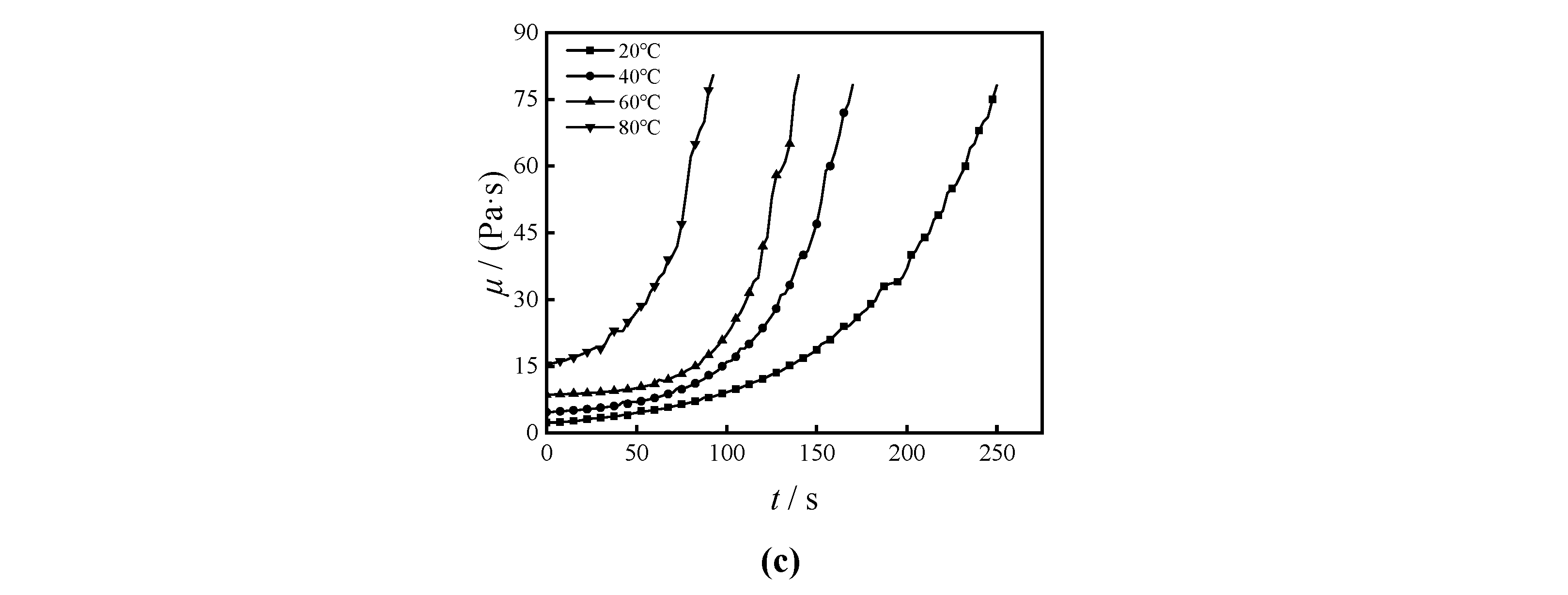

Viscosity reflects the internal resistance of the slurry flow, and reflects the fluidity of the slurry as well as the resistance to scouring The viscosity data of cement slurry, cement-sodium silicate slurry and RMGS at 20, 40, 60 and 80°C were obtained through viscosity measurement tests under different temperature conditions, and the change curves of the three kinds of slurries' viscosity versus time under different temperature conditions are shown in

Figure 1.

As can be seen from

Figure 1, the higher the temperature, the higher the viscosity of the slurry, but the temperature does not change the trend of slurry viscosity change. Based on the effect of temperature on viscosity, the literature [

20] gives the viscosity time-varying curve fitting equations for cement slurry and cement-sodium silicate slurry, and in this paper, the viscosity data of RMGS are fitted, and the fitting equations are shown in

Table 3.

According to the fitting results, the following conclusions can be obtained:

- (1)

The viscosity time-varying equation obtained by function fitting can effectively reflect the time-varying characteristics of the slurry, which can be applied to the calculation and simulation of grouting reinforcement in high ground temperature tunnels.

- (2)

At the same temperature, the viscosity time-varying curves of cement slurry, cement-sodium silicate slurry and RMGS have a large difference, the viscosity time-varying curve of cement slurry conforms to the linear function, the viscosity time-varying curve of cement-sodium silicate slurry conforms to the power function, and the viscosity time-varying curve of RMGS conforms to the exponential function.

- (3)

The effect of temperature on the three slurries is similar, i.e., an increase in temperature accelerates the development of slurry viscosity and increases the viscosity value but does not affect the time-varying characteristics of the slurry.

The increase in temperature makes the ions involved in the hydration reaction more active, so it accelerates the hydration process of the grouting material, so the higher the temperature, the faster the viscosity growth rate and the greater the viscosity. The main reason for the slow growth of viscosity in the early stage of RMGS is that, under the action of modifier, the silica-aluminium component in red mud undergoes depolymerization reaction, the content of free water decreases, [SiO

4]

4- and [AlO

4]

3- undergo polymerization reaction, and free water consumed by depolymerization reaction of the silica-aluminium component is roughly balanced with free water generated by the new polymerization reaction; in the later stage, the viscosity of the slurry of the red mud-based grouting reinforcing materials increases significantly because the hydration products in the slurry are generated in large quantities, and the slurry starts to harden [

23], so the viscosity increases significantly; in addition, Na

2SiO

3 reduces the solubility of the hydration products and reduces the effect of the pores on the viscosity of the slurry, and the [SiO

4]

4- combines with the Ca

2+ in the cement to form 2CaO-SiO

2(C2S), 3CaO-SiO

2(C3S) that accelerates the hardening of the slurry. Therefore, due to the lack of excitation of the modifier in the cement monohydrate slurry, its viscosity grows slowly, and there is a big gap between the RMGS and cement-sodium silicate slurry.

3.2. Setting Time

The setting time reflects the hardening characteristics of the slurry and the time of strength generation, through the setting time test, the data of the initial and final setting time of the cement slurry, cement-sodium silicate slurry and RMGS at 20, 40, 60 and 80 ℃ were obtained, and the change curves of the initial and final setting time of the three kinds of slurries with the temperature are shown in

Table 4.

According to

Table 4, the following conclusions can be obtained:

- (1)

The increase of temperature will shorten the initial and final setting time of the slurry.

- (2)

The cement slurry has the longest setting time, and the cement-sodium silicate slurry has the shortest setting time.

- (3)

There are large differences in the effects of temperature on the three kinds of slurries. The shortening rate of cement slurry reaches the peak under the condition of 40℃-60℃; the effect of temperature on the setting time of cement-sodium silicate slurry is the smallest; the effect of temperature on the setting time of RMGS decreases gradually with the increase of temperature.

As the red mud contains a large number of water-hardening minerals, such as C2S, C3S and 3CaO-Al2O3 (C3A), and also contains calcium chalcopyrite, hard hydrotalcite and acicular ferrite, etc., the amorphous silica-alumina-like substances in the red mud undergo a hydration reaction to generate hydration gel under normal conditions, whereas the reactive oxides in the red mud and the CO2 in the air generate carbonate-based precipitates or colloidal substances, which in turn form calcite, the RMGS achieves hardening.

In addition, because inert hematite is the main mineral component of red mud, the gelling activity is relatively low, so even under the action of modifier, the initial setting time is still always maintained at more than 30min.

On the one hand, in the high ground temperature tunnel grouting reinforcement project, the initial setting time of the slurry is required to be above 30min to ensure the effective diffusion of the slurry in the fissures of the surrounding rock; on the other hand, in order to improve the efficiency of grouting and shorten the construction period, the initial and final setting time of the slurry should not be too long. Therefore, by comparing the setting time characteristics of the three kinds of slurry under high temperature conditions, it can be inferred that the RMGS is the best material for the grouting and reinforcement project of high geothermal tunnels.

3.3. Compressive strength

The compressive strength determines the structural bearing capacity of the grouted curtain ring layer. The compressive strength data of cement slurry, cement-sodium silicate slurry and RMGS at 20, 40, 60 and 80°C were obtained through uniaxial compressive strength tests, and the change curves of the three slurries' strengths versus temperatures at different curing ages are shown in

Table 5.

According to

Table 5, the following conclusions can be obtained:

- (1)

The effect of temperature on the compressive strength of the three slurries has a large difference.

- (2)

The higher the temperature, the higher the compressive strength of the cement slurry, but at the lower 80 ℃ 14d curing age condition, there is a decrease in strength.

- (3)

The strength of cement-sodium silicate slurry reached its peak at 40°C, and after 40°C, the strength decreased rapidly, and by 80°C, the strength loss was more than half.

- (4)

There are differences in the effect of temperature on the strength of RNGS under different maintenance age conditions. The increase in temperature at the age of 1d has an increasing effect on the compressive strength; the compressive strength of RMGS at the age of 3d, 7d and 14d maintenance age, the strength of the red mud-based grouting materials peaked at 60°C. The strength of the red mud-based grouting materials at 60°C reached its peak.

- (5)

Compared with cement slurry and cement-sodium silicate slurry, the compressive strength of RMGS is less discrete and more stable with the change of temperature.

On the one hand, the faster hydration of cement and the higher hydration activity of red mud at high temperatures play a role like that of evapotranspiration, resulting in higher strength and faster development of cement, cement-sodium silicate slurry, and RMGS. On the other hand, high temperatures may have several adverse effects on the hydration products, leading to a decrease in strength: at the very beginning of hydration, high temperatures may cause the hydration rate to accelerate, the C-S-H gel to lap in disorder, and the skeleton formed to be less dense; at the time of curing, high temperatures may cause the Ca(OH)

2 generated by the hydration to be dissolved, causing Ca

2+ in the C-S-H gel to precipitate out, generating hydroxysilicate calcium stone [

24], which may reduce the strength of the crystal skeleton and increase the number of harmful pores, leading to a decrease in strength at a later stage.

Red mud and quartz powder in RMGS can slow down the hydration and reduce the disordered lap of hydration products, the hydration products of red mud can fill the pores, quartz powder plays the role of aggregate, and the modifier can reduce the dissolution of hydration products, and the joint effect of multiple parties enhances the stability of the strength of RMGS at high temperatures.

3.4. Thermal conductivity

The thermal conductivity reflects the ability of a material to transfer heat and is the amount of heat transferred through the thermal conductive surface of the material at a unit temperature gradient and per unit time. The thermal conductivity of cement slurry, cement-sodium silicate slurry and RMGS was measured at 20, 40, 60 and 80°C using the protective thermal plate method, and the curves of thermal conductivity of the three types of slurry with temperature are shown in

Table 6.

As shown in

Table 6, the thermal conductivity of cement slurry is the highest, and the thermal conductivity of red mud-based grouting material is the lowest. In addition, with the increase of temperature, the thermal conductivity of cement slurry, cement-sodium silicate slurry and RMGS showed linear decay, and with the increase of temperature, the decay rate of the thermal conductivity of the three materials increased, and the thermal conductivity of red mud-based material was the most sensitive to the change of temperature, and the thermal conductivity of the RMGS would be further attenuated when the temperature continued to increase.

The reason why the temperature can accelerate the attenuation of thermal conductivity may be that, with the increase of temperature, the hydration reaction rate of cement as well as red mud becomes faster, the hydration products increase, and the thermal conductivity of the hydration products, such as Ca(OH)

2 and C-S-H, is lower than that of the clinker phases, such as C3S, C2S, C3A, etc. [

25].

RMGS exhibit lower thermal conductivity due to more impurities, significantly more hydration reactants than cement, faster hydration reaction rate and more hydration products during hydration than cement.

In addition, high temperature promotes the development of pores in cementite [

26], and the effect of porosity on the thermal conductivity of the material is given in the literature [

27], and the smaller the volume fraction of aggregate, the smaller the thermal conductivity of the grouting material, as the aggregate forms a good thermal bridge effect inside the grouting material, and the thermal conductivity of air in the pores is lower than that of the constituents in the solid material. Therefore, with the increase of temperature, the thermal conductivity of the material is decreasing gradually.

3.5. Specific heat capacity

Specific heat capacity refers to the internal energy absorbed or released per unit mass of an object when it changes per unit temperature and reflects the ability of a material to store heat. Using the mixed calorimetry method, the specific heat capacities of cement slurry, cement-sodium silicate slurry and RMGS were measured at 20, 40, 60 and 80°C. The curves of the specific heat capacities of the three types of slurries as a function of temperature are shown in

Table 7.

As can be seen from

Table 7, the specific heat capacity of cement slurry, cement-sodium silicate slurry and RMGS all decrease approximately linearly with the increase of temperature. Moreover, the specific heat capacity of the RMGS is the largest, and that of the cement-sodium silicate slurry is the smallest, which is only 70% of that of the RMGS.

The specific heat capacity-temperature relationship equations of the three materials are in line with the linear law of change, with the highest degree of sensitivity of the red mud-based grouting material and the lowest degree of sensitivity of the cement-water-glass bi-liquid slurry.

Analysis of the mechanism of the effect of temperature on the specific heat capacity: in the hydration process, the mass of the original solid material does not decrease, and the main factor affecting the specific heat capacity is the content of free water. As the temperature rises, the faster the hydration rate, the more free water is consumed, and the specific heat capacity of water is 4200J·(kg·K)-1, which is higher than the specific heat capacity of the three materials of the nodular body, and when the content of free water decreases, the specific heat capacity of the material will also decrease. Therefore, the increase in temperature decreases the specific heat capacity of the material.

Analysis of the reason for the high specific heat capacity of RMGS: the hydration reaction of red mud is the most rapid, and the free water is consumed the fastest, so its specific heat capacity decreases at the fastest rate, but due to the hydration reaction of red mud to form the hydration product has a higher specific heat capacity, so the specific heat capacity of RMGS is significantly higher than cement and cement-sodium silicate slurry. The higher specific heat capacity makes the curtain arch ring cast with RMGS absorb the heat transferred by the rock body, and its own temperature grows slowly, which plays a role in controlling the tunnel temperature.

4. Discussion

4.1. Microscopic mechanism

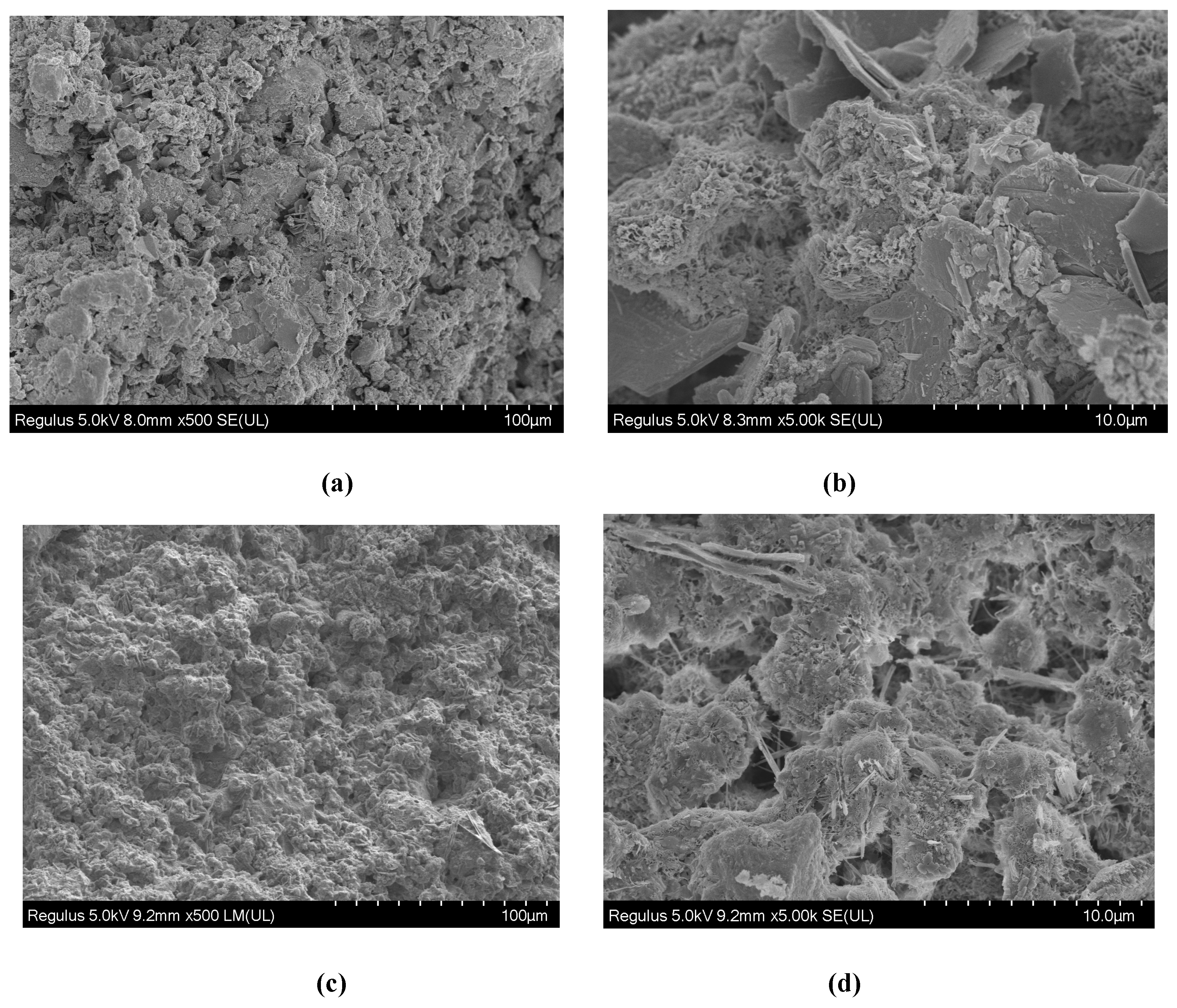

The above tests show that the effect of temperature on the grouting materials is mainly reflected in affecting the rate of hydration reaction, products, and pore development. To further clarify the microscopic characteristics of hydration products and pore characteristics of the slurry under different temperatures and raw material conditions, SEM analyses were carried out on cement slurry and RMGS, as shown in

Figure 2.

As shown in

Figure 2a–d, cement produces hydration products such as C-S-H and Ca(OH)

2 after hydration and the internal pores are filled, while red mud contains more impurities, which produces more hydration products in the hydration reaction. According to

Figure 2e,f, under the action of high temperature, the RNGS showed fissures, and the rapid development of internal pores led to the reduction of aggregate volume fraction, and the thermal conductivity also showed attenuation phenomenon because of the development of pores. The high temperature accelerated the hydration reaction of red mud, which caused the rapid development of viscosity and strength of the grouting material as well as the advancement of the setting time, and also led to the reduction of the specific heat capacity, but it also led to the further decomposition of the hydration products and the production of factors unfavorable to the later strength, which led to the loss of strength of the grouting material in the later stage. In addition, the increase in temperature causes the slurry to undergo thermal expansion, and the combined effect of multiple hydration products results in the RMGS generally outperforming cement slurries and cement-sodium silicate slurry in a high ground temperature environment.

4.2. Applications

The three kinds of slurry under high temperature conditions reflect different properties, therefore, in the actual grouting project, the selection of slurry should be made according to the geological conditions of the site and the characteristics of the grouting materials. Grouting reinforcement of tunnel peripheral rock in different environments has different requirements for grouting materials:

(1) The surrounding rock is less stable and contains hydrostatic water. This working condition requires that the strength of the slurry is high and can effectively reinforce the surrounding rock. Cement slurry reflects the highest compressive strength in the test; therefore, cement slurry is suitable for peripheral rock grouting reinforcement works with hydrostatic water.

(2) The peripheral rock fissures are rich in dynamic water, which needs to be grouted to achieve the purpose of water stopping. This kind of working condition requires the slurry to have low viscosity initially, which can flow in the fissure, and after the end of grouting, the viscosity grows rapidly, which can be bonded with the surrounding rock to resist the impact of dynamic water, and the setting time is fast, to achieve the purpose of stopping water quickly. Cement-sodium silicate slurry double liquid slurry condensation time is short, viscosity growth is divided into obvious slow growth stage and rapid growth stage, therefore, cement-sodium silicate slurry is suitable for fissure dynamic water grouting water stopping project.

(3) The stability of the surrounding rock is poor, containing dynamic water with fast flow rate and high temperature of the surrounding rock. This working condition requires the grouting material to meet the strength and resistance to dynamic water scouring ability, and at the same time, it also needs to have the role of heat insulation and temperature control. RMGS can still maintain the stability of strength at high temperatures, and the slow growth of viscosity in the early stage so that it can spread rapidly in the surrounding rock, and the viscosity of the later stage is rapidly increased, which can prevent the phenomenon of water penetration, and the faster setting time can shorten the working period, in addition to excellent thermal insulation properties, low thermal conductivity and high specific heat capacity so that it can effectively control the temperature of the tunnel interior and improve the working environment. Therefore, RMGS is suitable for grouting works in high ground temperature environment which requires strength, dynamic water scouring and heat insulation performance.

5. Conclusions

In this paper, the various properties of RMGS under different temperatures are investigated, and cement slurry and cement-sodium silicate slurry are used as control tests to verify the applicability of RMGS in grouting reinforcement of high geothermal tunnels, and to explore the mechanism of the influence of temperature on the performance of the materials. The following conclusions can be obtained:

- (1)

The increase of temperature accelerates the viscosity development of three kinds of grouting materials, but does not change the time-varying characteristic law of viscosity; the increase of temperature accelerates the coagulation of the slurry, but for different slurries, the lifting efficiency has a big difference; the appropriate increase of temperature improves the compressive strength of the slurry, and when the temperature is too high, the loss of strength is serious.

- (2)

The increase of temperature will accelerate the attenuation of thermal conductivity of three kinds of grouting materials, in which the red mud-based grouting materials have the lowest thermal conductivity and the fastest attenuation rate; the increase of temperature will also lead to the reduction of the specific heat capacity of three kinds of grouting materials, and the C-t equation of three kinds of materials conforms to the linear law of change, in which the RMGS have the highest specific heat capacity and the fastest rate of reduction.

- (3)

The increase of temperature will accelerate the hydration reaction speed of the grouting material, red mud due to more impurities, so its hydration reaction is faster than cement, more reaction products, which is an important reason for the big difference between the performance of red mud-based grouting material and cement slurry; in addition, the temperature will also lead to the development of the internal pores of the material, which affects the macroscopic performance of the grouting material.

- (4)

The applicable environments of different grouting materials are quite different. Cement slurry is suitable for grouting and reinforcing of peripheral rock with static water, cement-sodium silicate slurry is suitable for grouting and stopping of water with dynamic water in fissures, and RMGS is suitable for grouting in high-temperature environments, which requires strength, dynamic water scouring, and heat-insulating properties.

The results of the study deepen the understanding of the performance of curtain grouting materials for high-temperature tunnels, which can provide a test basis for the selection of curtain grouting materials for high-temperature mountain tunnels.

Author Contributions

Conceptualization, J.N. and Y.Y.; methodology, Y.Y. and J.N.; software, Y.Y.; validation, Y.S.and L.Q.; formal analysis, Y.Y.; investigation, Y.Y.; resources, J.L.; data curation, Y.Y.; writing—original draft preparation, Y.Y.; writing—review and editing, J.L.; visualization, Y.S.; supervision, J.N.; project administration, J.L.; funding acquisition, J.L. and J.N.. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by National Natural Science Foundation of China ((Grant No. 420510080).

Data Availability Statement

The data used to support the findings of this study are included in the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Cao Zhensheng, Li Jiajun, Ai Zubin. et al. Analysis of the effect of uneven high ground temperature on the mechanical properties of tunnel lining. Railway Construction Technology 2022, 10, 37–42. [Google Scholar]

- He Ping, Zhang Guangze, Qiang Xingang, QIANG Xingang. Study on the causes and route selection of underground hot water in the Sangzhuling tunnel of the sichuan tibet railway. Journal of Railway Engineering 2020, 37, 10–13+23. [Google Scholar]

- Yan Jian, He Chuan, Wang Bo, et al. Study on the characteristics and mechanism of rock burst in high temperature and high stress tunnels. Journal of Railways 2020, 42, 186–194. [Google Scholar]

- Guo Pingye, Bu Mohua, Zhang Peng, et al. Research progress on disaster mechanism and disaster prevention and control of high temperature tunnels [J/OL]. Journal Of Rock Mechanics and Engineering: 1-21 [2023-04-12].

- Lin M, Zhou P, Jiang Y F, et al. Numerical investigation on comprehensive control system of cooling and heat insulation for high geothermal tunnel: A case study on the highway tunnel with the highest temperature in China. International Journal of Thermal Sciences 2022, 173. [Google Scholar]

- Qiao Hongyan. Research on cooling and thermal environment characteristics of long single end construction of high altitude temperature tunnel [J/OL]. Journal of Underground Space and Engineering: 1-8 [2023-04-12].

- Pu Song, Wang Huiwu, Li Mengke, et al. Research on response measures for high temperature TBM railway tunnel construction. Railway Standard Design 2023, 67, 116–121+129. [Google Scholar] [CrossRef]

- Kang F C, Li Y C, Tang C A, et al. Numerical study on thermal damage behavior and heat insulation protection in a high-temperature tunnel. Applied Sciences-Basel 2021, 11. [Google Scholar]

- Li Zhun. Cooling technology and economic research on high temperature tunnel of Yumo railway. Journal of Railway Engineering 2022, 39, 95–99. [Google Scholar]

- Yao W J, Lyimo H, Pang J Y. Evolution regularity of temperature field of active heat insulation roadway considering thermal insulation spraying and grouting: A case study of Zhujidong coal mine, China. High Temperature Material and Processes 2021, 40, 151–170. [Google Scholar] [CrossRef]

- Fan Lidan, Sun Liang, Yu Yongqiang, et al. The effect of HGM mass fraction and environmental temperature on the performance of cement-based thermal insulation grouting materials [J/OL]. Journal of Henan University of Technology (Natural Science Edition): 1-8 [2023-04-25].

- Fan Lidan, Sun Liang,et al. Metakaolin improves the adaptability of cement-based grouting materials in high temperature tunnel engineering. Materials Herald 2022, 36, 105–112. [Google Scholar]

- Ding Jianxin, Xi Yan, Jiang Jiwei, et al. Changes in cement stone's mechanical and porous permeability characteristics under high and ultra high temperature. Drilling and Completion Fluids 2022, 39, 754–760. [Google Scholar]

- Lv Pengcheng, Xie Youjun, Long Guangcheng, et al. The effect of accelerator on the performance of cement paste under high temperature drying. Journal Of Railway Science and Engineering 2022, 19, 2295–2304. [Google Scholar] [CrossRef]

- CHEN P, ZHANG S M, YANG H M, et al. Effects of Curing Temperature on Rheological Behaviour and Compressive Strength of Cement Containing GGBFS. JOURNAL OF WUHAN UNIVERSITY OF TECHNOLOGY-MATERIALS SCIENCE EDITION 2019, 34, 1155–1162. [Google Scholar] [CrossRef]

- Wang M M, Hu Y P, Jiang C, et al. Mechanical characteristics of cement-based grouting material in high-geothermal tunnel. Materials 2020, 13. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.Q.; Wang, Y .; Wu, A.X.; Qi, Y .; Chen, Z.Q. Effect of temperature on the structure of paste slurry at low constant shear rate. Energy Sources Part A Recovery Util. Environ. Eff. 2019, in press.

- Zhang Jian, Wang Chuan, Li Shaofeng, et al. Experimental study on engineering characteristics of red mud-based green high-performance grouting material. Journal of Rock Mechanics and Engineering 2022, 41, 3339–3352. [Google Scholar]

- Liu Qing, Wang Qiang, Wu Peng, et al. Research progress on application of red mud in cementitious materials. Journal of Shandong University of Science and Technology (Natural Science Edition) 2022, 41, 66–74. [Google Scholar]

- Niu J D, Wang B, Feng C, et al. Experimental Research on Viscosity Characteristics of Grouting Slurry in a High Ground Temperature Environment. MATERIALS 2020, 13. [Google Scholar] [CrossRef] [PubMed]

- Gong Hongxiu. The influencing factors and error analysis of the thermal conductivity of insulation materials detected by the protective hot plate method. Bulk Cement 2021, 120–122+125. [Google Scholar]

- Li Shunqun, Wang Xingxing, Xia Jinhong, et al. Test method for specific heat capacity of frozen soil based on the principle of mixed calorimetry. Journal of Geotechnical Engineering 2018, 40, 1684–1689. [Google Scholar]

- Zhang Ning, Wang Mengya, Wang Chuan et al. Preparation and performance study of red mud based grouting reinforcement materia. Modern Tunnel Technology 2023, 60, 270–280. [Google Scholar] [CrossRef]

- Wu Z Q, Xie R J, Yang J, et al. High-temperature mechanical properties and microstructure of high belite cement. Frontiers in Materials 2022, 9. [Google Scholar]

- Du Yuanbo, Ge Yong. A computational model for the thermal conductivity of cement paste. Journal Of Silicates 2022, 50, 466–472. [Google Scholar]

- Ho L., S. , Nakaral K., Eguchi K., et al. Difference in strength development between cement-treated sand and mortar with various cement types and curing temperatures. Materials 2020, 13. [Google Scholar]

- Zhu De, Han Yang, Duan Junfeng et al. Calculation method for effective thermal conductivity of steel fiber reinforced concrete after high temperature. Silicate Bulletin 2021, 40, 1510–1519. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).