Submitted:

30 October 2023

Posted:

31 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Previous Experimental research

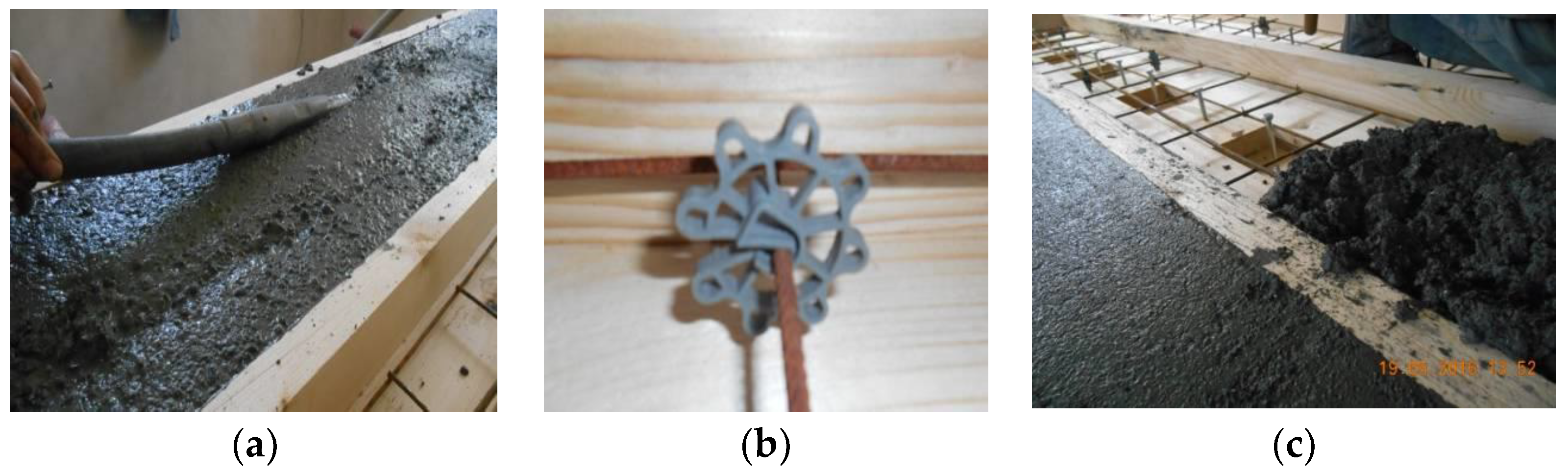

2. Experimental analysis of composite timber-concrete beams

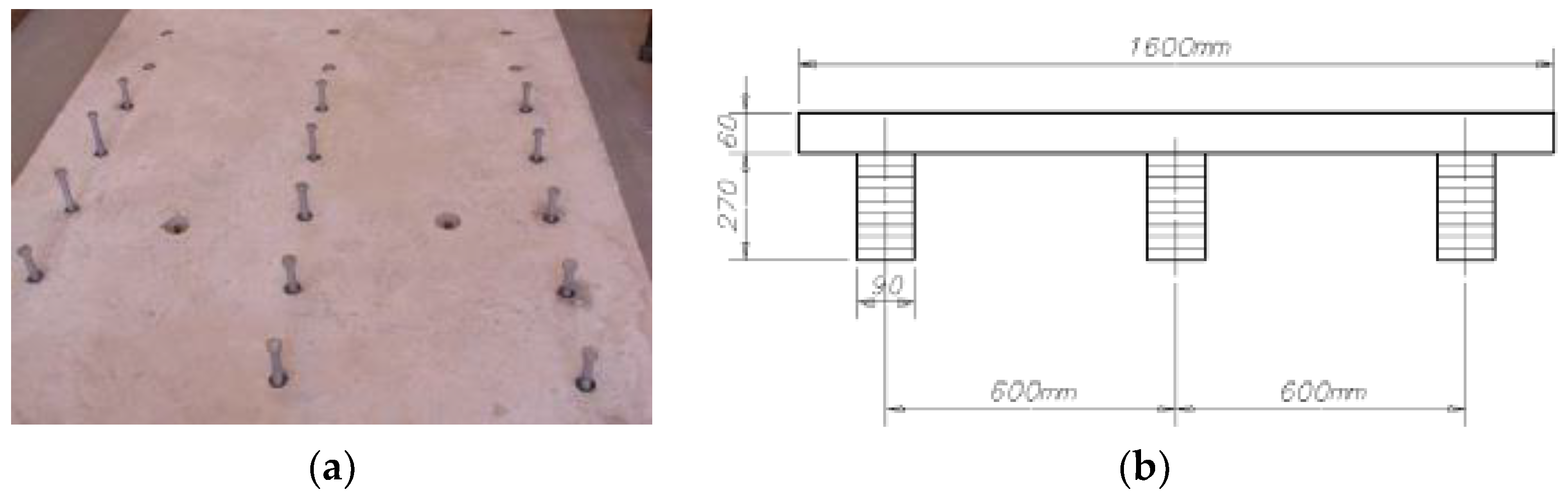

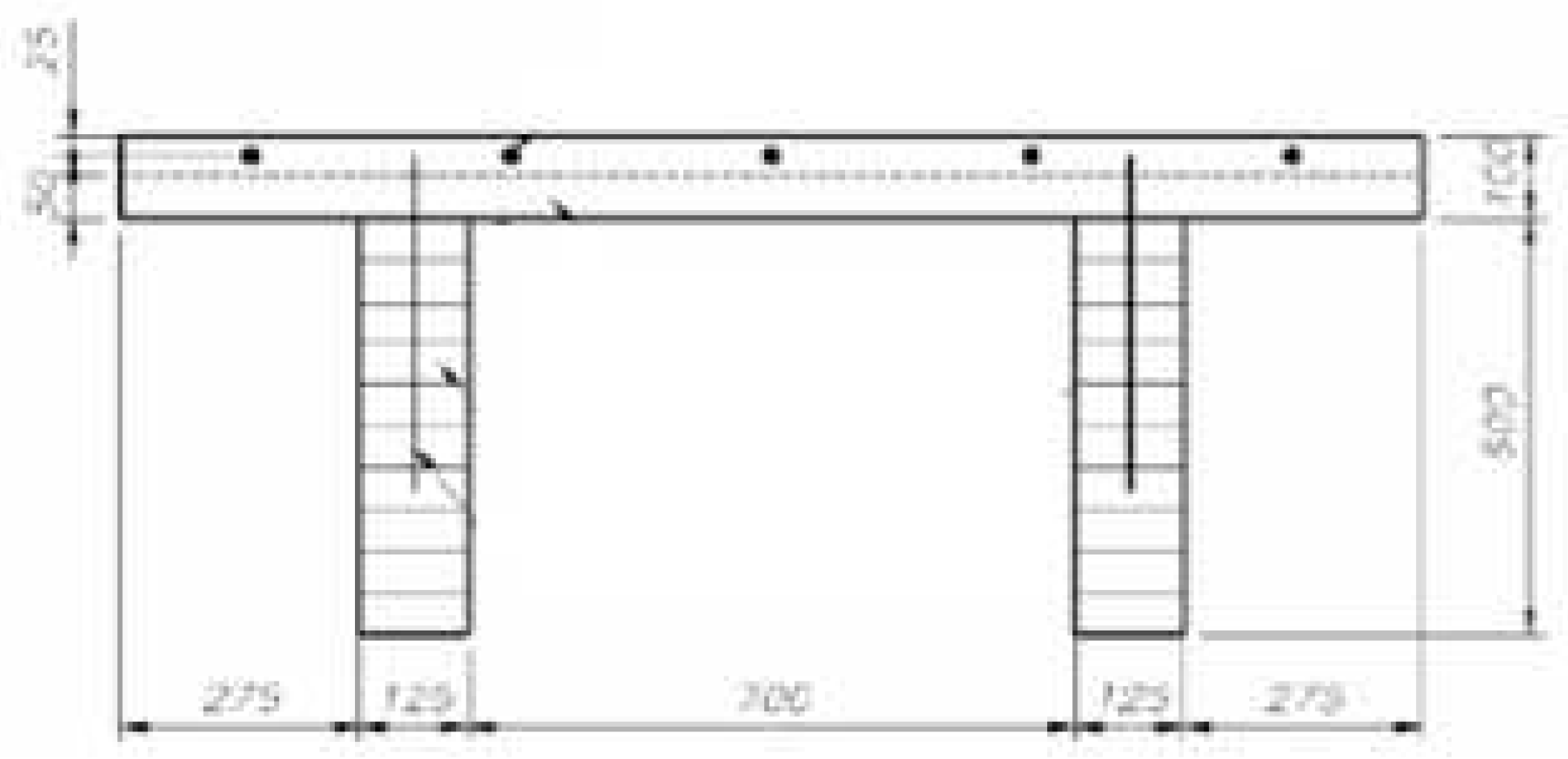

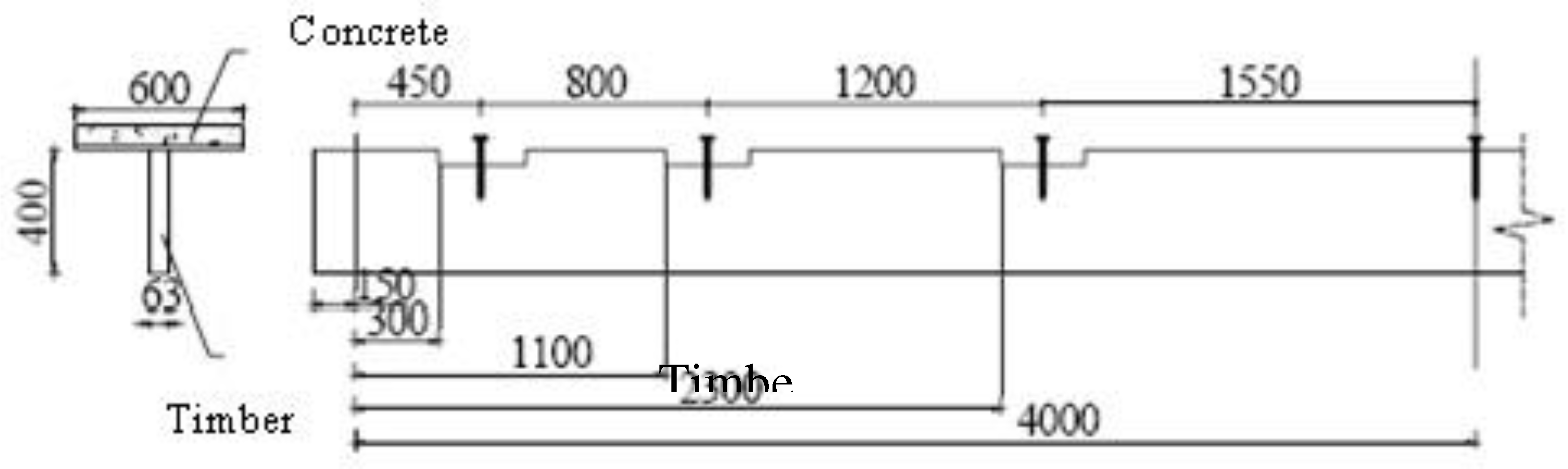

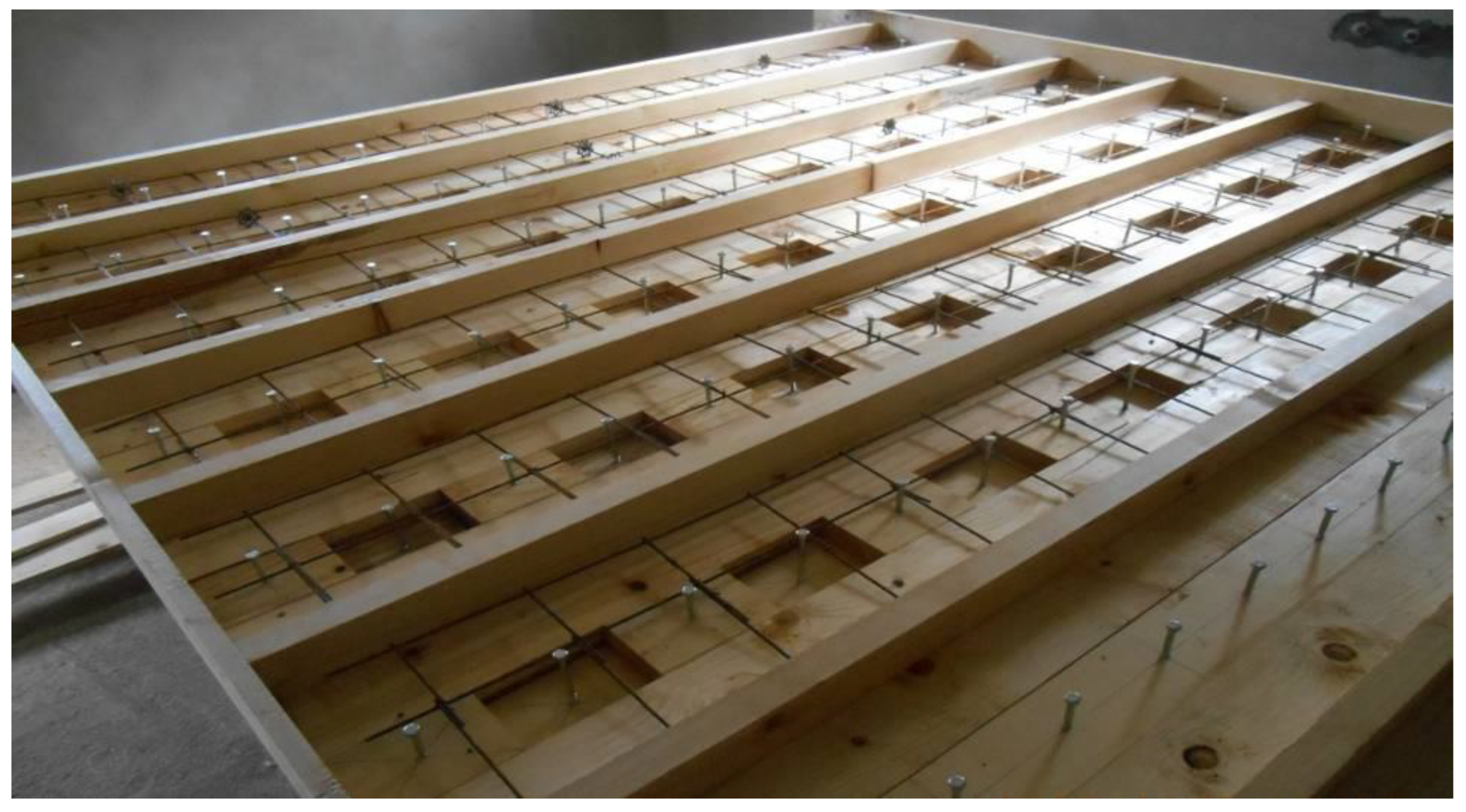

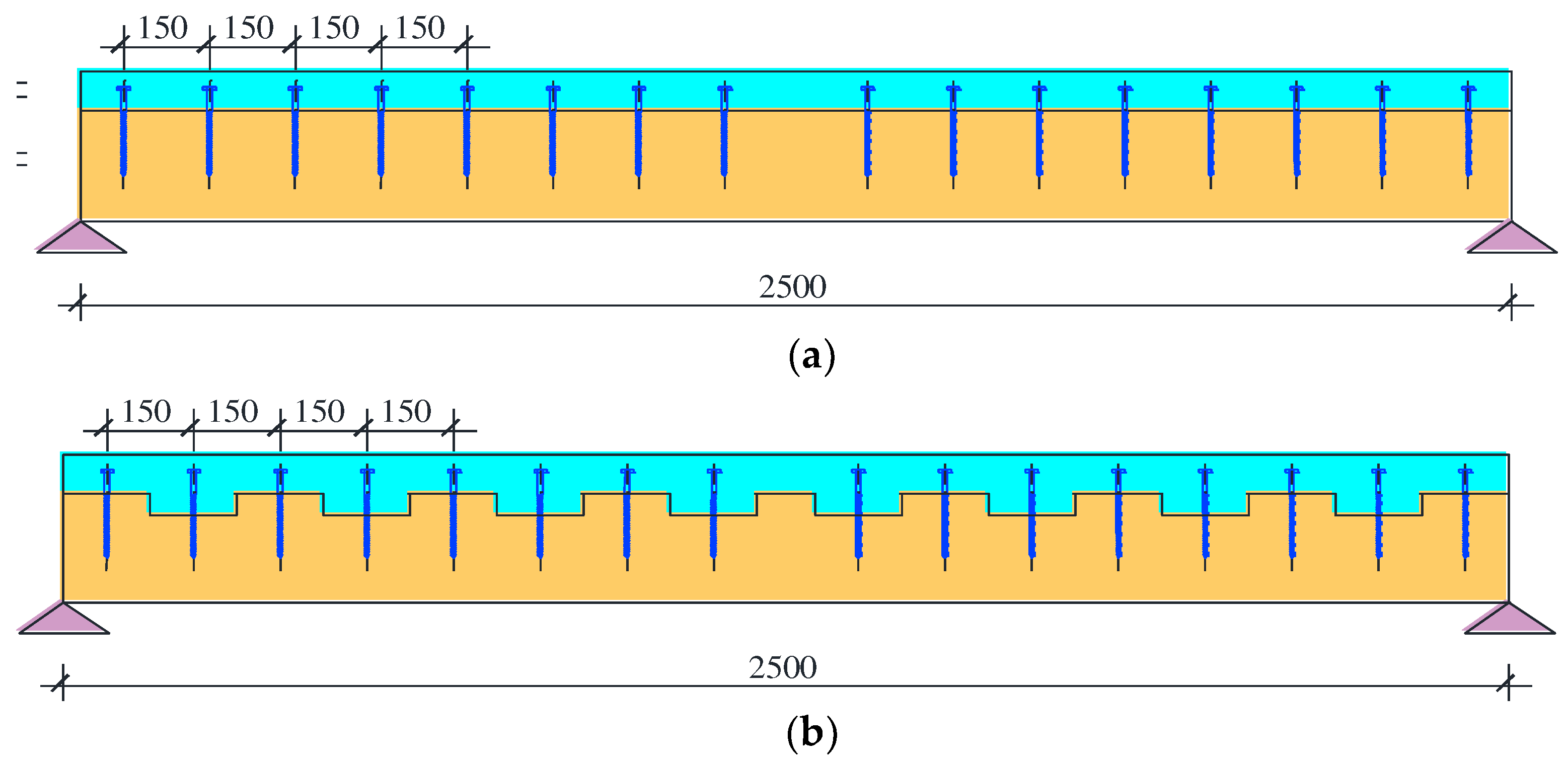

2.1. Projecting models of composite timber-concrete beams for experimental research

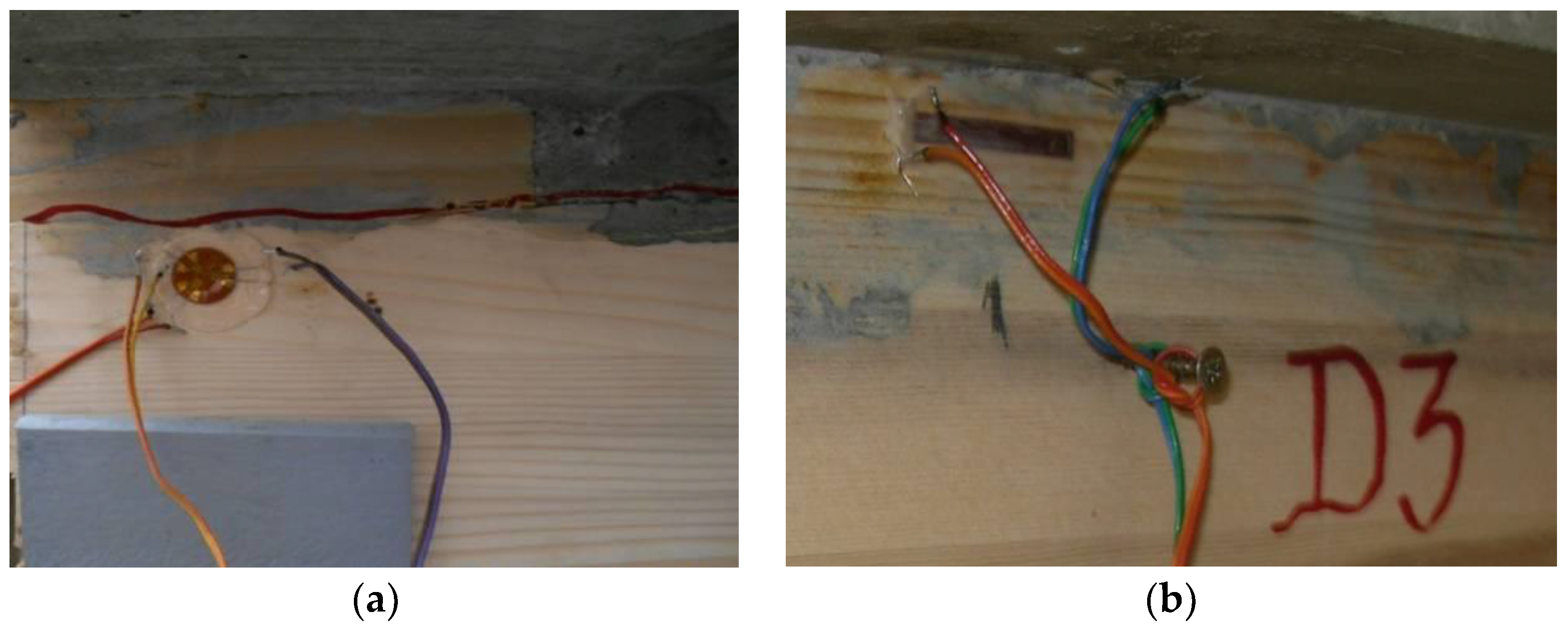

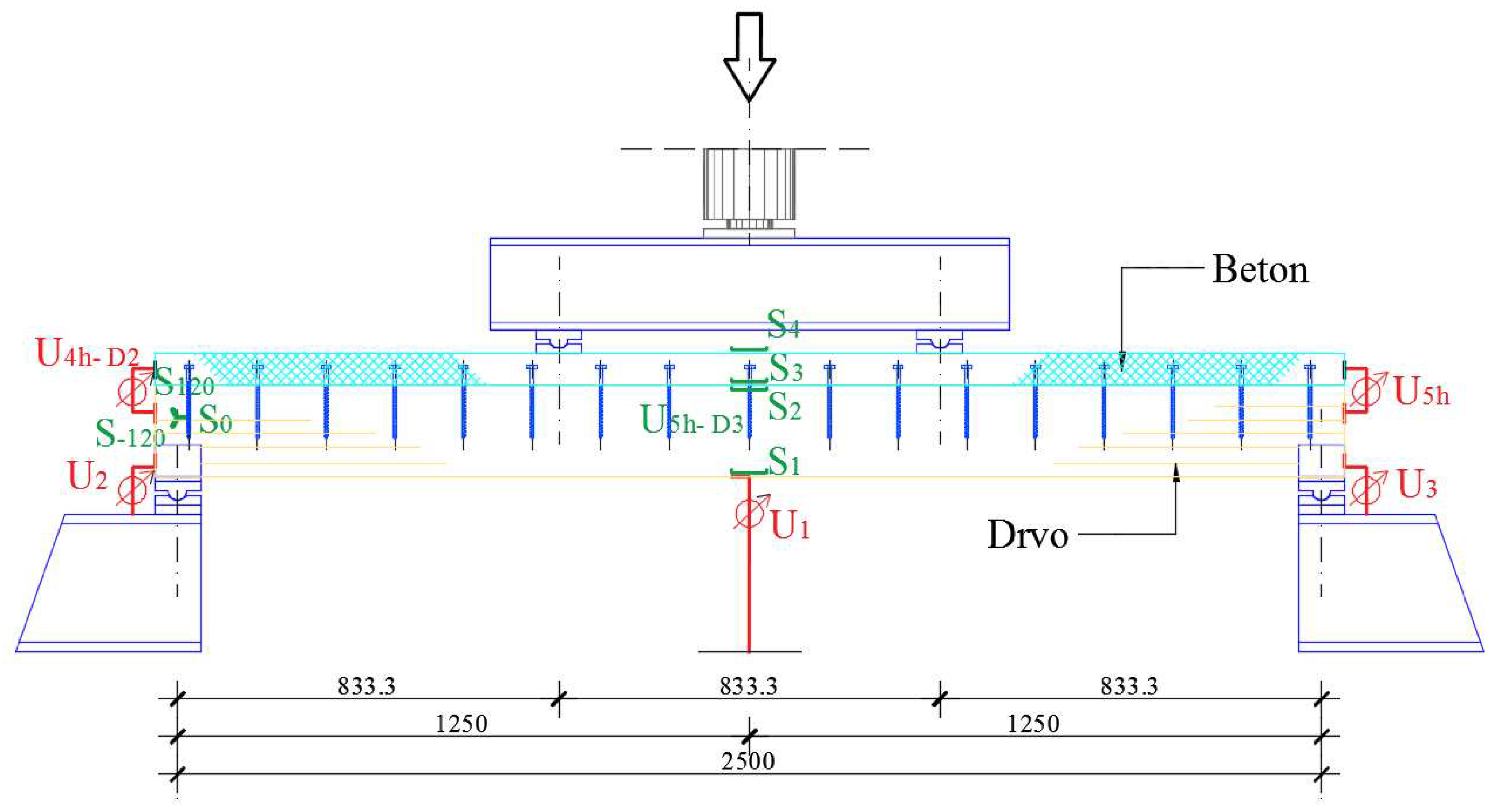

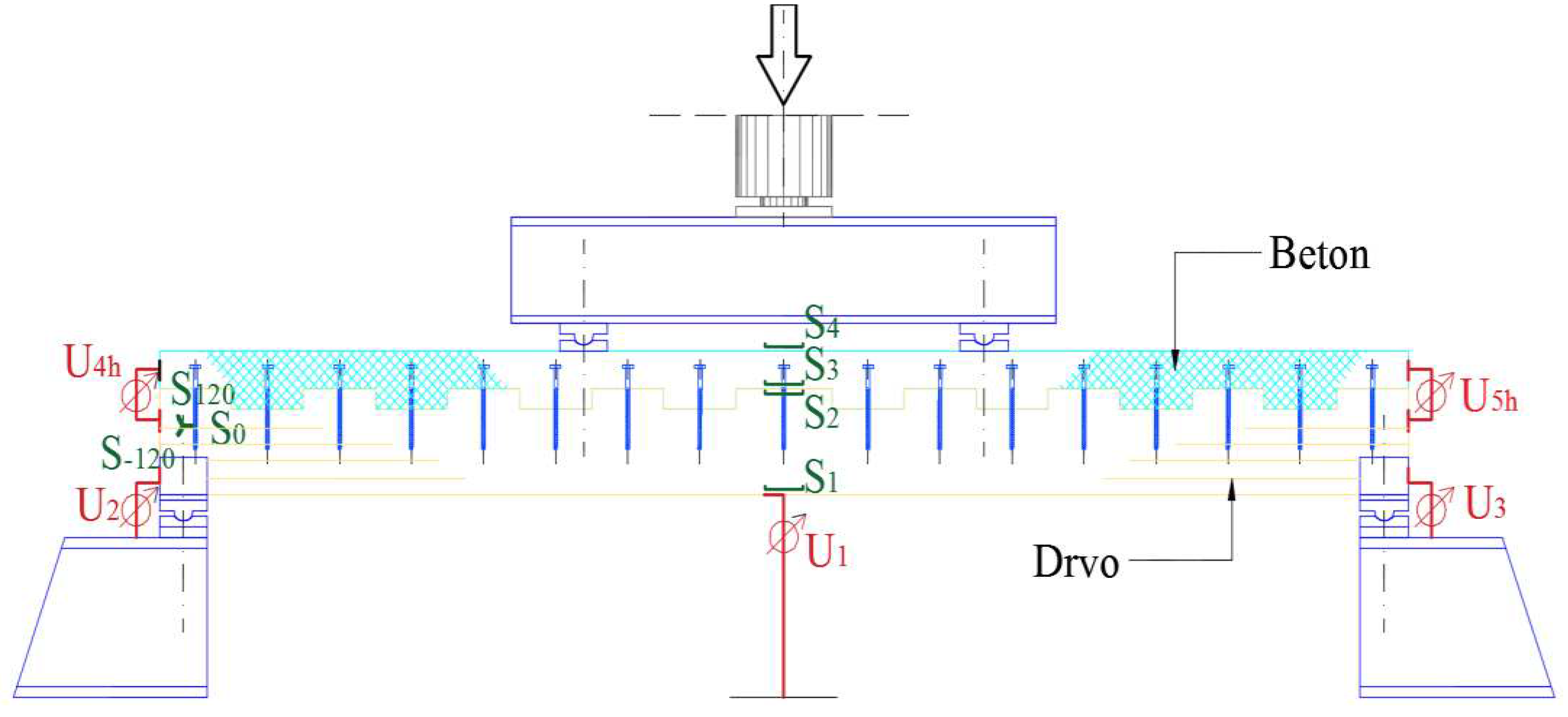

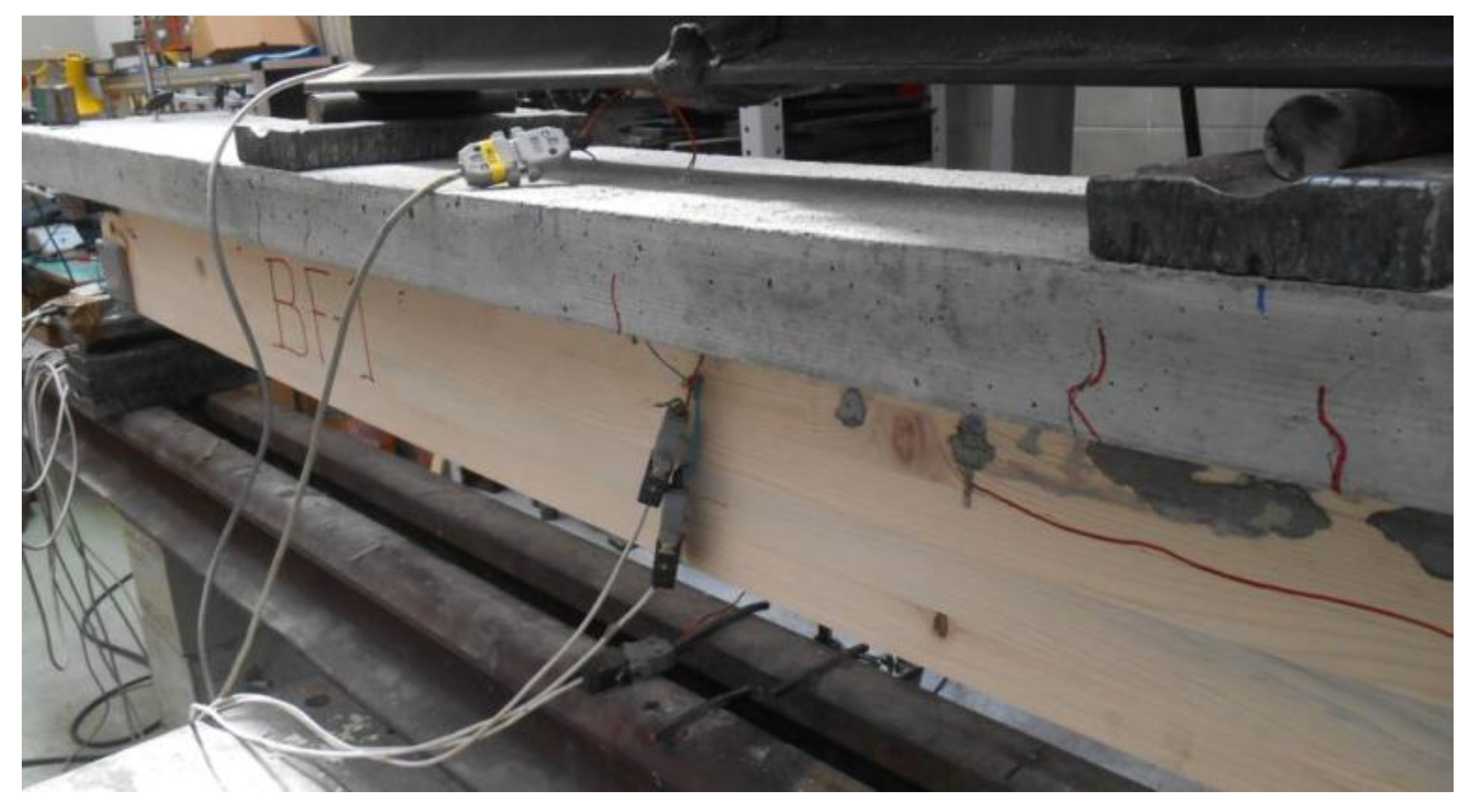

2.2. The experiment setup and the program of testing of the projected types of composite beams

2.2.1. Loading procedure

2.2.2. The testing results of the composite beams of A-series

2.2.3. The testing results of the composite beams of the B-series

3. Results

3.1. The loading-deflection diagrams, (F-u) of A-series beams

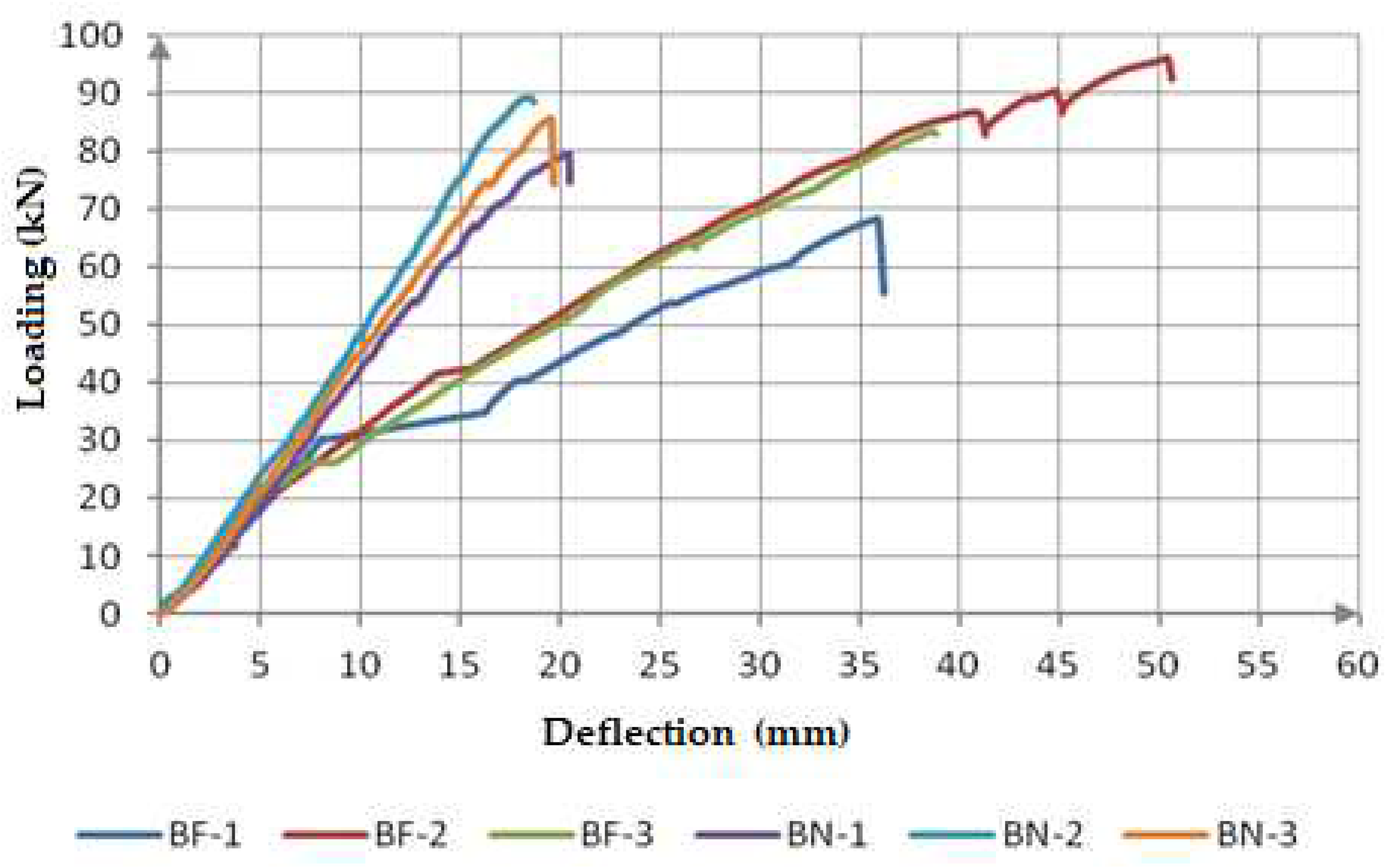

3.2. Loading-deflection diagrams (F-u) of the B series beams

3.3. Stiffness of the A-beams series

3.4. Stiffness of the B- series beams

3.5. Comparative analysis of the results of the experimental research of the A and B-series of composite beams

4. Discussion

4.1. Distribution of strains in edge fibres of beams of the A-series

- In the upper edge grain of the timber part of the coupled cross-section, the pressure dilatation development (the red line), at the moment of fracture, is in the range of 2800-3900 micro-dilatations, or 0,0028–0,0039m/m, or 2,8–3,9‰. The development of this dilatation in all three tested samples is approximately linear and steady;

- The lower edge grain of the concrete part of the cross-section (the green line) and the upper edge grain of the timber part, the measurement types S2 and S3 up to the level of 20-30% of the applied loading at the moment of the fracture have an almost identical progress, almost equal to zero. After that level of the applied loading, there is a very short tension strain development in the lower edge grain of the concrete, up to the failure of the measurement type, which causes cracks and ultimately indicates the degree of coupling timber and concrete with screws used in the first type of coupling, the degree of slipping of the interlayer and beam stiffness. After that, their diagrams are separated based on the stress, that is the pressure in the upper grain of timber (S2) and tension in the lower grain of concrete (S3). Thus, we can conclude that after approximately 30% of the maximum loading, there is a slip in the interlayer of timber and concrete, and creation of two neutral axes. The composite beams of A-series, beside the above mentioned, are characterized by a high deflection in the middle of the span, which is shown in Table 3. A significant deformity prior to the fracture of the tested beam created a field of micro-cracks and cracks in the middle third of the span, which is a clear proof of the failure of concrete tension strength. In the previously shown pictures, which show BF-i beams, after their fracture, clear positions of the cracks can be noticed, and we should emphasize that they go to the half of the cross-section height of the concrete part;

- The pressure strain in the upper edge grain of concrete (the purple line) up to the failure point has a steady, almost linear course and its value is within the range of 1-2‰. It is lower than the value of the crashing dilatation due to the pressure in concrete of 3.5‰ which means that there is no concrete plastification in that zone.

- All the above mentioned observations indicate a very good matching of the experimental mechanical performance of the tested beams and the achieved values of stress-strain parameters to the general theoretical basis of the elastic coupling theory.

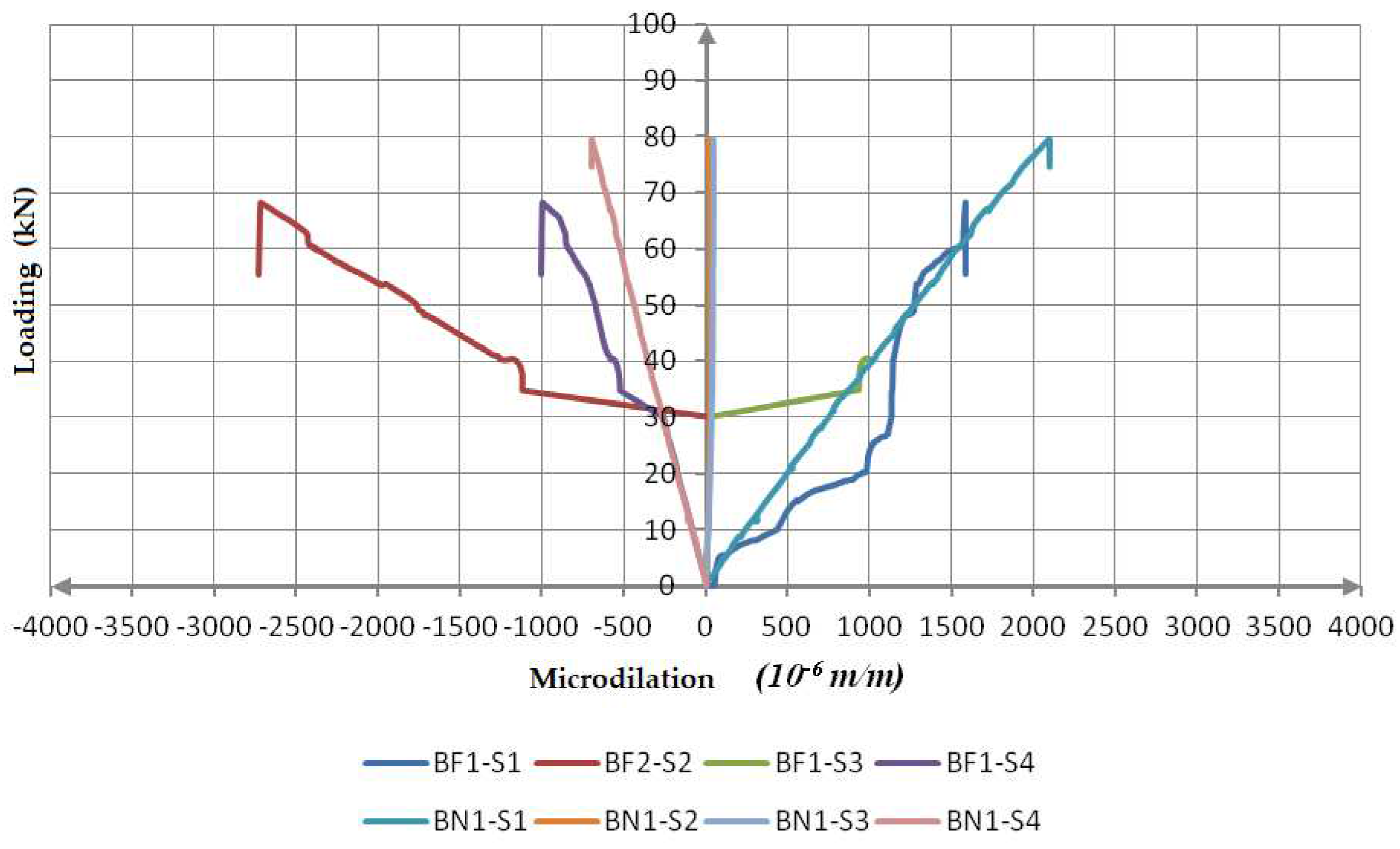

4.2. Distribution of dilatation in the edge grains in the B-series beams

- in the lower edge grain of the timber beam there is a tension dilatation (the blue line) and its value for the B-series ranges from 1400-2100 micro-dilatations (0,0014–0,0021m/m, (1,4-2,1‰));

- in the upper edge grain of the timber part of the coupled cross-section, the development of the pressure dilatation (the red line), at the moment of fracture, ranges from 0-50 micro-dilatations, (0,0–0,00005m/m, (0–0,5‰));

- the dilatations in the lower edge grain of the concrete part of the cross-section (the green line) and the upper edge grain of timber (the red line), which are in the same cross-section and on the same height have an almost identical development during the loading application. Their measured values, which are less than a promil, show that stresses dislocate from the central geometrical plains of the concrete and timber notches towards their edge contacts (in these surfaces there were cracks in concrete and an excessive shear stress parallel to timber grains) and the neutral ax, during the higher levels of loading, is near the timber-concrete interlayer. Almost equal values of dilatations in adjacent grains of different materials, coupled by certain systems indicates a high level of coupling, as the consequence of a high level of stiffness and thus, a low level of slipping in the timber-concrete interlayer;

- the pressure dilatation in the upper edge grain of concrete (the purple line), up to the moment of fracture has a steady, linear development, and its value ranges from 0,6–0,7‰. It is far below the value of the allowed dilatation of the pressure in concrete of 3,5‰, which means that there is no krti concrete fracture, that is, concrete plastification in that zone. This shows that the neutral line is high in the coupled cross-section, so concrete is under low pressure stress and the failure in the compressed zone is not a potential threat.

4.3. Failure mechanisams of A-series beams

4.4. Failure mechanisams of B-series beams

5. Conclusions

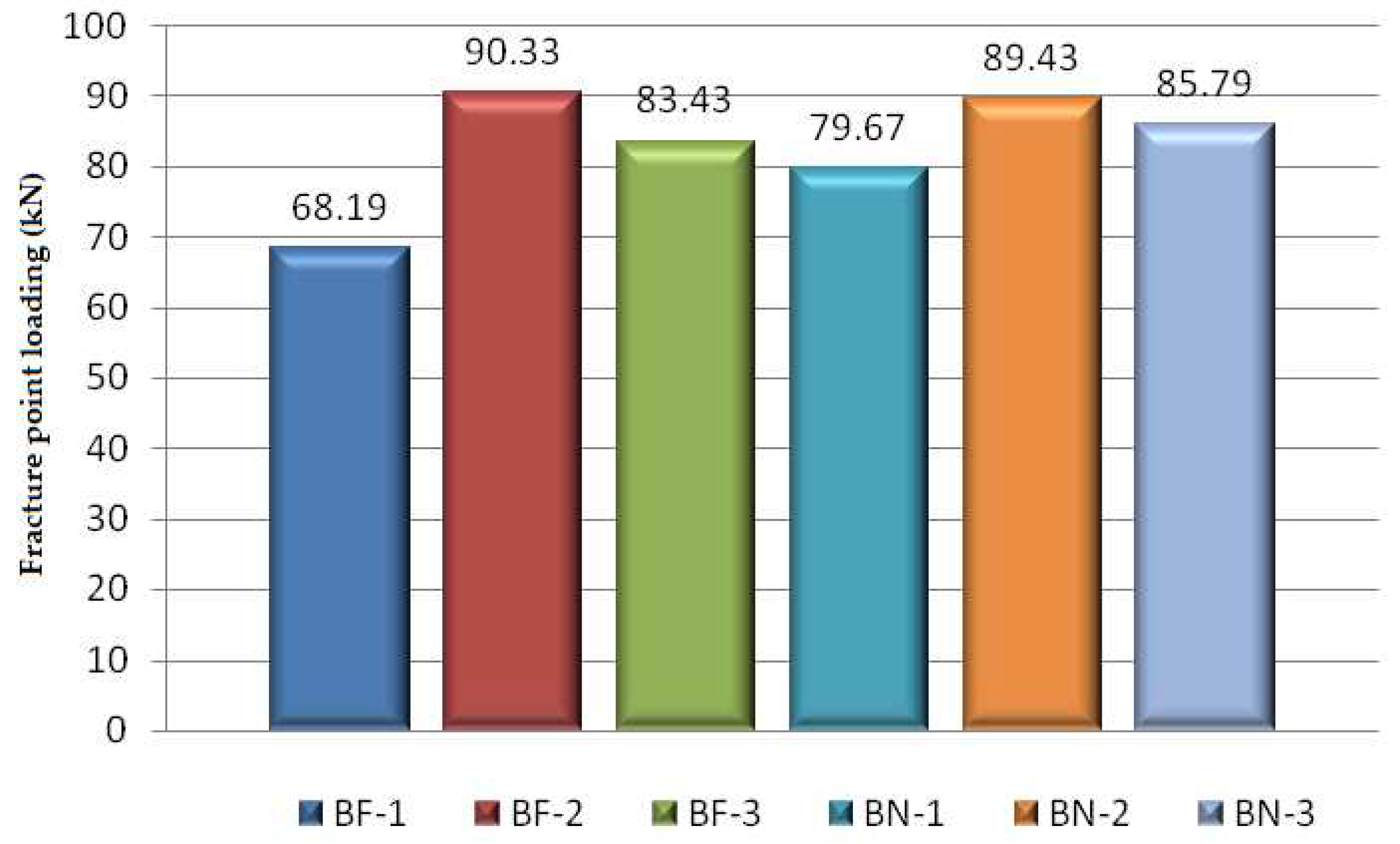

- A-series beams failed under the average loading of 80,65kN, and the B-series beam under the average loading of 84,96kN. We can conclude that the load bearing capacity of the A-series beams is lower when compared to the load bearing capacity of the B-series beams by only 5%. It means that, if we ignore the behaviour of BF-1(previously explained causes of big results dissipation), the beams of both series show almost identical performance regarding the nosivost aspect, before the first signs of their failure (different forms of fracture and major deformities);

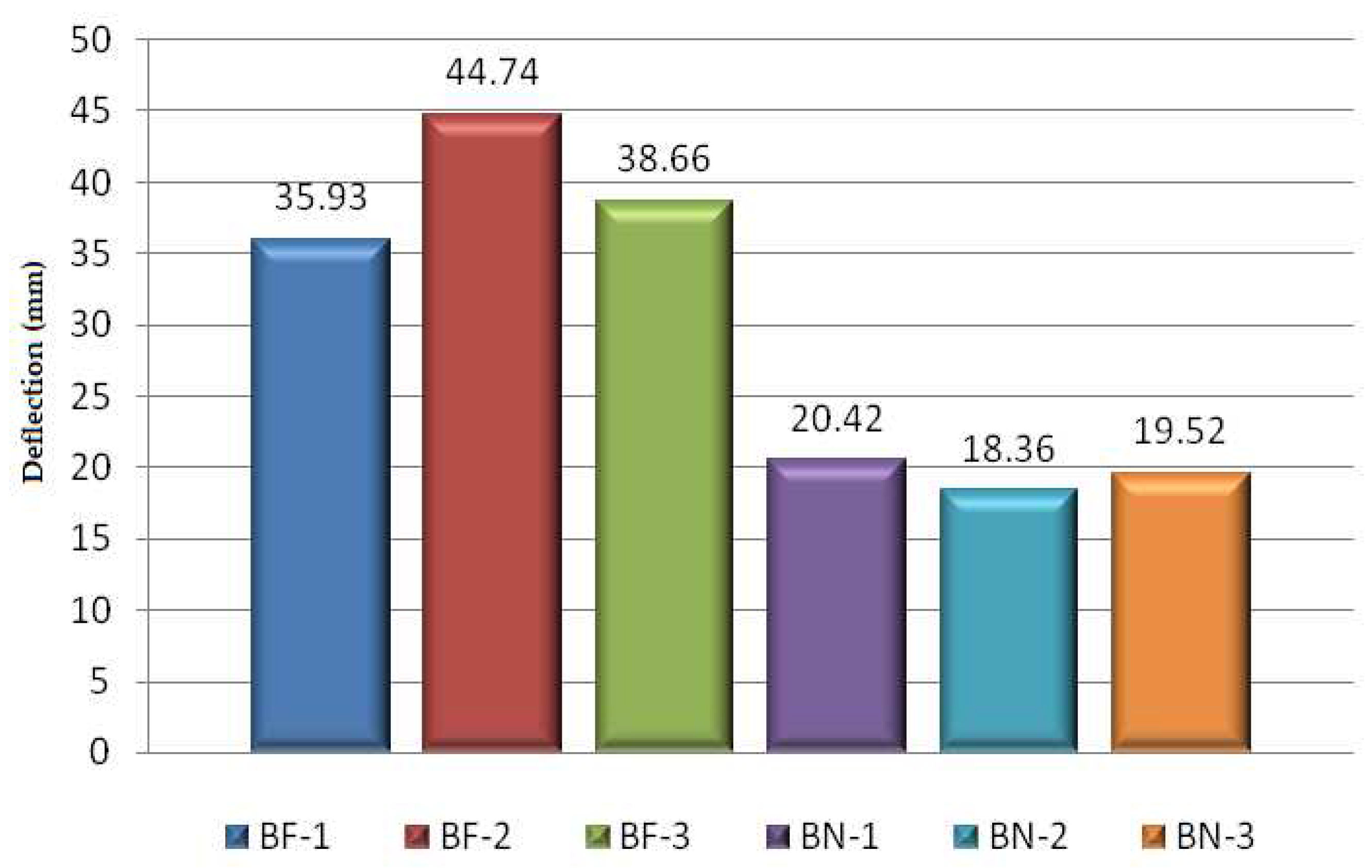

- By comparing the maximum values of deflection in the middle of the span a double deformability of the A-series beams is defined. Their average deflection is twice as big as the deflection of the B series type under the approximately same loading and with the same geometric properties. The explanation lies in the differences of the chosen connecting systems used for the coupling of timber and concrete. The uniformity of deflection values of the B-series beams is on a higher level than in the A-series, which is a consequence of smaller structural and phenomenal changes in the timber part of the B-series beams cross-sections while applying the loading (the bigger deformities, the higher the influence of anisotropy and heterogeneity on the final results);

- The average values of the horizontal displacements, measured in the interlayer between timber and concrete in the support zones (LVDT-U4h) of the B-series samples are about six times lower than the ones in the A-series beams. This is a direct consequence of the type of the fastening system used for coupling the B-series beams, characterized by a minimum slipping, high load bearing capacity of the connecting system itself related to the maximum shear force present in this zone and an emphasized stiffness of the interlayer;

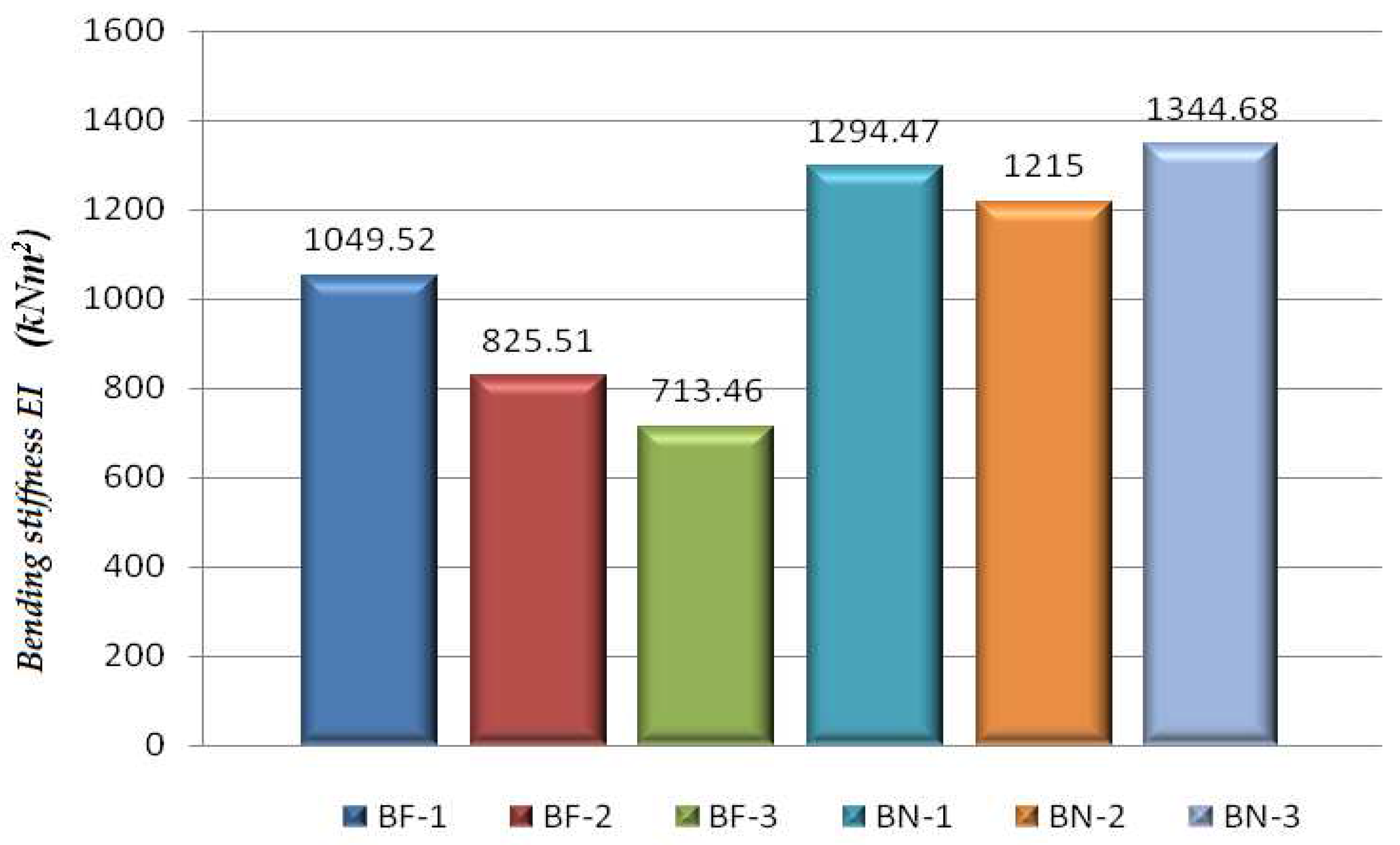

- Comparative presentation of the calculated bending stiffness values at the moment of fracture of all tested beams given in Figure 19 obviously gives advantage to the B-series of composite beams. Expressed in numbers, (figures), bending stiffness of the B-series beams is 32.85% higher than of the A-series beams. With a steady fracture loading level which characterizes the B-series beams, uniform bending stiffness values of those beams were obtained. This is prescribed to the mechanical properties of the applied connecting system which consists of screws combined with concrete notches. Its stiffness has a direct impact on the behavior of this series of the beams, on the overall bending stiffness, the deflection size and the form of the fracture (it was previously mentioned that the form of the fracture of the B-series beams due to an excessive timber shear and tension strengths is localized on the support zones and the middle third of the span, but that is not the case with the A-series beams, characterized by the final fracture due to an excessive timber shear strength parallel to the grain, in a form of a crack that continually goes along the whole length of the samples on the surface close to the neutral surface of the composite cross-section).The testing of the BF-1 beam of the A-series is an interesting one. This beam shows a 30-50% higher stiffness when compared to the stiffness of the other beams of the A-series, where the loading failure value of that beam was 20-30% lower than the loading of the other two beams. If the bending stiffness of the BF-1 beam is compared to the stiffness of the beams of the B series, we can notice that the approaching of the values at the moment of fracture, while the difference in the applied loading is about 20%. A very low increase in the applied loading is needed to reach the failure to reduce the stiffness of the BF-1 so that it is closer to the stiffness values of the BF-2 and BF-3 beams. This shows that the beams of both series up to the point of 50-60% of the loading application have a similar performance, and after that they start acting differently which is the consequence of the different mechanical properties of the used connecting systems;

- Due to numerous data which characterize the dilatation development measured at the cross-section in the middle of the span of the tested beams, as well as the above presented uniformity of dilatations on the level of certain series, Figure 21 shows a mutual presentation of the dilatation development of the BF-1 and BN-1. The dilatation development is the picture of all presented in 1), 2), 3) and 4). A better mechanical behaviour in the sense of the interconnection between the loading and the increase in the dilatations, or stress, in the B-series beams, compared to the A series can be seen in the diagrams in Figure 21. A higher level of stiffness, that is a lower deformability of the B-series beams has an impact on the stress distribution, that is the dilatation on the height of a chosen cross-section and the dilatation diagram show that clearly. For an almost identical fracture loading, the dilatation values are almost equal, but the development of dilatation in the cross-section in the middle of the span of the BN-1 is a lot more regular (linear) than in the BF-1 beam. The dilatation in the interlayer timber-concrete zone of the BN-1 series have values close to zero up to the fracture loading, which indicates a high degree of coupling, that is, a reached so-called rigid coupling. The A-series beams, regarding the measured dilatations, after just about 30% of the fracture loading, show differences in the intensity which shows that it is an elastic coupling because of the deformability of the connecting systems and displacements in the interlayer of timber and concrete;

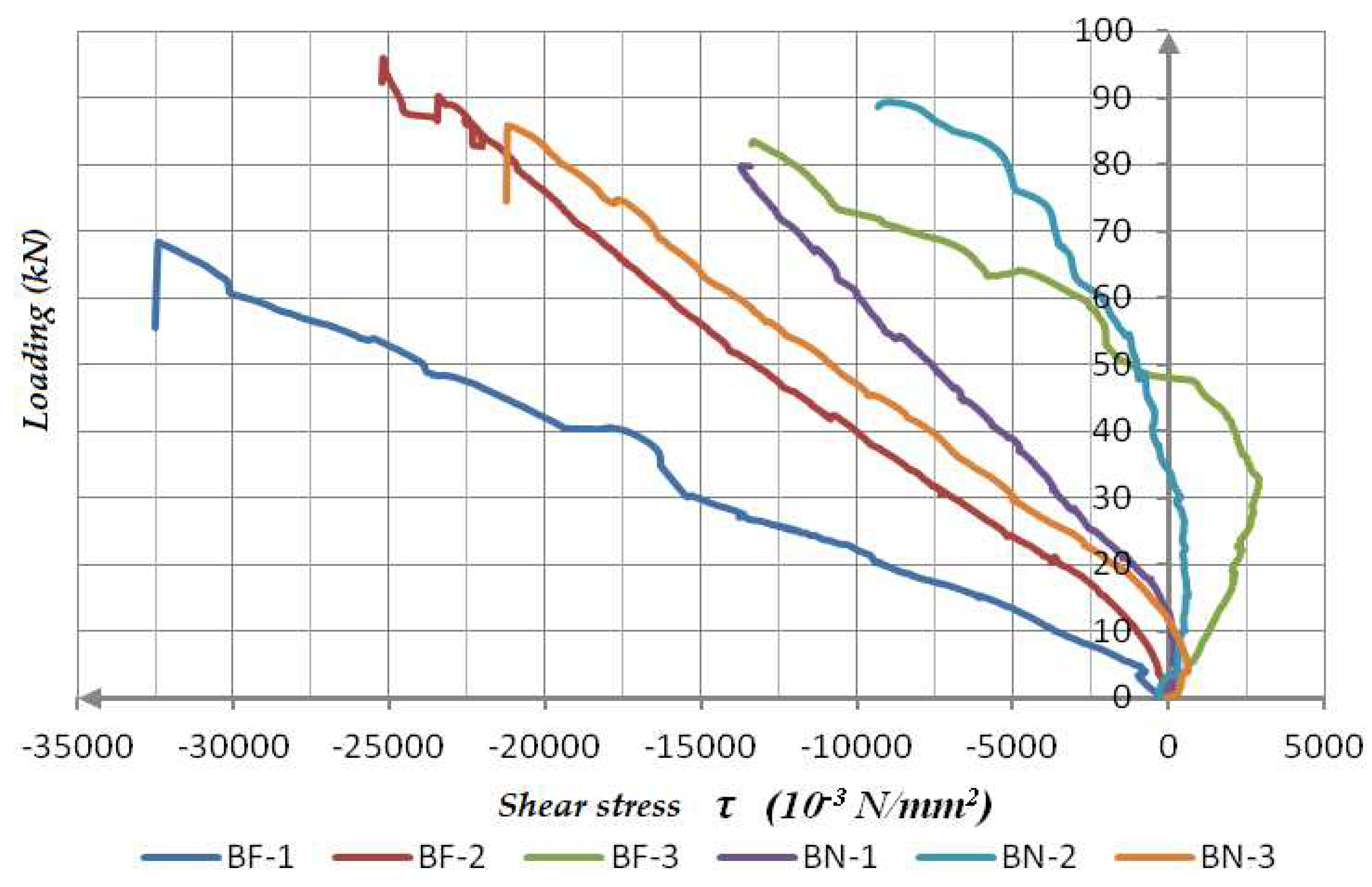

- Related to the shear stress state in the support zones, based on the diagrams from Figure 20 which shows the relationship between loading-shear stress, in the function of the measured and calculated main dilatation ε1 and ε2, we can conclude that the value of the shear stress in the B-series beams ranges from 10-20 N/mm2. And in the A-series beams, the range is from 15-35 N/mm2. The non-linear development of the function of relation F-τ shoes an irregular and non-uniform fracture due to an excessive timber shear strength parallel to the grains, that is in the surfaces with a dominant dilatation development ε1. Thanks to a higher level of bending stiffness of the B-series beams, the dilatation is lower, and thus, a lower level of achieved shear stress state level in the supports.

References

- Cvetković, R. Behaviour of Composite Timber-Concrete Structures with Bending Actions. Master thesis, Ruhr University Bochum, Germany, 2002.

- Stevanović B. Analysis of Composite Timber-Concrete Structures, Ph.D. thesis, University of Belgrade, Serbia, 2003.

- Cvetković, R.; Stojić, D.; Marković, N.; Trajković, M.; Živković, D. Repair and Strengthening of Timber Floors of Pančevo Diocese by Timber–Concrete CouplingTechnique. Journal Tehnički vjesnik/Technical Gazette (Print: ISSN 1330-3651, Online: ISSN 1848-6339), 2018, Vol. 26/No. 4.

- Maslak, E.; Stojić, D.; Drenić, D.; Mešić, E.; Cvetković, R. Ojačanje spregnutih nosača drvo-beton prednapetom armaturom. Građevinar. 2020, Vol. 72/11, pages 1-10.

- Dias, A. M. P. G.: Mechanical behaviour of timber-concrete joints. Ph.D. thesis, University of Coimbra, Portugal, 2005.

- Clouston, P.; Bathon, L.; Schreyer, A. Shear and bending performance of a novel wood-concrete composite system, Journal of Structural Engineering 2005, 131(9), 1404–1412. [CrossRef]

- Ceccotti, A.; Fragiacomo, M.; Giordano, S. Long-term and collapse tests on a timber-concrete composite beam with glued-in connection, Material and Structures. 2006, 40(1), 15–25. [CrossRef]

- Deam, B. L.; Fragiacomo, M.; Gross, L. S. Experimental behavior of prestressed LVL-concrete composite beams, Journal of Structural Engineering. 2008, 134(5), 801–809. [CrossRef]

- Gutkowski R.; Brown K.; Shigidi A.; Natterer J. Investigation of notched composite wood concrete connections. ASCE Journal of Structural Engineering. 2004, 130(10), 1553-1561. [CrossRef]

- Balogh, J.; Fragiacomo, M.; Gutkowski, R. M.; Fast, R. S. Influence of repeated and sustained loading on the performance of layered wood-concrete composite beams. Journal of Structural Engineering. 2008, 134(3), 430–439. [CrossRef]

- Balogh, Z.; Gutkowski, R. Modelling of shear transfer in wood-concrete notch connections. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2-5 June 2008.

- Fragiacomo, M.; Gutkowski, R.; Balogh, J. and Fast, R. Long-term behaviour of wood-concrete composite floor/deck systems with shear key connection detail. Journal of Structural Engineering. 2007, 133(9), 1307–1315. [CrossRef]

- Gutkowski, R.; Brown, K.; Shigidi, A.; Natterer, J. Laboratory tests of composite wood-concrete beams, Constr. Build. Mater. 2008, 22(6), 1059–1066. [CrossRef]

- Balogh J.; Fragiacomo M.; Miller N.; Gutkowski R.; Atadero R.; To L. Testing of Wood-Concrete Composite Beams with Shear Key Detail, In Proceedings of International Conference on Timber Bridges, Lillehammer, Norway.; September 2010.

- Lukaszewska E. Development of prefabricated timber-concrete composite floors. PhD thesis, Luleå University of Technology, Sweden, 2009.

- Lukaszewska E.; Johnsson H. Connections for prefabricated Timber-Concrete composite systems. In Proceedings of the 9th World Conference on Timber Engineering, Portland, USA, 6-10 August 2006.

- Lukaszewska, E.; Fragiacomo M. Static performance of prefabricated timber-concrete composite systems. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2-5 June 2008.

- Lukaszewska, E., Fragiacomo, M., Johnsson, H.:, Laboratory tests and numerical analyses of prefabricated timber-concrete composite floors. Journal of Structural Engineering. 2010, 136(1), 46–55. [CrossRef]

- Lukaszewska E.; Johnsson H.; Fragiacomo M. Performance of connections for prefabricated timber-concrete composite floors. Material and Structures. 2008, 41(9), 1533–1550. [CrossRef]

- Yeoh, D. Behaviour and design of timber-concrete composite floor system, Ph.D. thesis, University of Canterbury, New Zealand, 2010.

- Yeoh D.; Fragiacomo M.; De Franceschi M.; Buchanan A. Experimental tests of notched and plate connectors for LVL-concrete composite beams. Journal of Structural Engineering. 2001, 137(2), 261–269. [CrossRef]

- Eurocode 2: EN 1992-1-1 Eurocode 2: Design of concrete structures-Part 1-1- General rules and rules for buildings. CEN-European Committee for Standardization, 2004.

- Evrokod 4 -Proračun spregnutih konstrukcija od čelika i betona- Deo 1-1: Opšta pravila i pravila za zgrade, EN 1994-1-1:2004, Beograd, 2006.

- Evrokod 5-Proračun drvenih konstrukcija-Deo 1-1: Opšta pravila i pravila za zgrade, EN 1995-1-1:2004, Beograd, 2009.

- Stevanović, B. Eksperimentalna i teorijska analiza spregnutih nosača drvo-beton izve¬denih mehaničkim spojnim sredstvima, Materijali i konstrukcije, 2004, Vol. 47, No. 1-2, pp. 29-46.

- Cvetković, R. Mehaničko ponašanje spregnutih konstrukcija tipa drvo-beton (Mechanical behaviour of composite structures type timber-concrete). Ph.D. thesis, University of Niš, Serbia, 2017.

| Beams BF-1, BF-2, BF-3 | ||

|---|---|---|

| Measuring point | Description of measuring point | Measurement quantity |

| S1 | Timber lower (the middle of a beam span) | Dilatation |

| S2 | Timber upper (the middle of a beam span) | Dilatation |

| S3 | Concrete lower (the middle of a beam span) | Dilatation |

| S4 | Concrete upper (the middle of a beam span) | Dilatation |

| S0 | Left support | Dilatation |

| S120 | Left support | Dilatation |

| S -120 | Left support | Dilatation |

| U1 | Deflection in the middle of a span | Displacement |

| U2 | Vertical displacement of a left support | Displacement |

| U3 | Vertical displacement of a right support | Displacement |

| U5h | Horizontal displacement in timber-concrete interlayer-right support |

Displacement |

| U5h- D3 | The middle of the cross-sectional height of the timber part (BF 2-base 100mm) | Dilatation |

| DIN | Dinamometer | Force |

| Beams BN-1, BN-2, BN-3 | ||

|---|---|---|

| Measuring point | Description of measuring point | Measurement quantity |

| S1 | Timber lower (the middle of a beam span) | Dilatation |

| S2 | Timber upper (the middle of a beam span) | Dilatation |

| S3 | Concrete lower (the middle of a beam span) | Dilatation |

| S4 | Concrete upper (the middle of a beam span) | Dilatation |

| So | Left support | Dilatation |

| S120 | Left support | Dilatation |

| S-120 | Left support | Dilatation |

| U1 | Deflection in the middle of a span | Displacement |

| U2 | Vertical displacement of a left support | Displacement |

| U3 | Vertical displacement of a right support | Displacement |

| U4h | Horizontal displacement in timber-concrete interlayer-left support |

Displacement |

| U5h | Horizontal displacement in timber-concrete interlayer-right support |

Displacement |

| U4h- D2 | Horizontal displacement in timber-concrete interlayer-left support—(2. notch from the left of zhe BN3) |

Displacement |

| U5h- D3 | Sredina visine preseka drvenog dela(BN 3-baza 25mm) | Dilatation |

| DIN | Dinamometer | Force |

| Sample | Fmax [kN] |

Mmax [kNm] |

Tmax [kN] |

U1max [mm] |

U4h [mm] |

U5h-D3 [mm] |

EI [kNm2] |

|---|---|---|---|---|---|---|---|

| BF-1 | 68,19 | 28,41 | 85,23 | 35,93 | 4,27 | 0,01 | 1049,52 |

| BF-2 | 90,33 | 37,63 | 112,91 | 44,74 | 4,095 | 0,05 | 825,51 |

| BF-3 | 83,43 | 34,76 | 104,28 | 38,66 | 4,095 | 0,002 | 713,46 |

| BN-1 | 79,67 | 33,19 | 99,58 | 20,42 | 0,75 | 0,018 | 1294,47 |

| BN-2 | 89,43 | 37,26 | 111,79 | 18,36 | 0,76 | 0,020 | 1215,94 |

| BN-3 | 85,79 | 35,74 | 107,23 | 19,52 | 0,63 | 0,023 | 1344,68 |

| Mean values, BF-i | 80,65 | 33,60 | 100,81 | 39,78 | 4,15 | 0,0207 | 862,83 |

| Mean values, BN-i | 84,96 | 35,40 | 106,20 | 19,43 | 0,713 | 0,0203 | 1285,03 |

| Statistical analysis of series results BF-i | |||||||

| Stan. deviation | 11,33 | 4,72 | 14,16 | 4,51 | 0,10 | 0,0257 | 141,11 |

| Characterist. values | 42,45 | 17,69 | 53,05 | 24,57 | 3,81 | -0,066 | 285,89 |

| Coeff.var. (%) | 14,0 | 14,0 | 14,0 | 11,3 | 2,4 | 1,244 | 19,8 |

| Statistical analysis of series results BN-i | |||||||

| Stan. deviation | 4,93 | 2,06 | 6,17 | 1,03 | 0,072 | 0,0025 | 64,89 |

| Characterist. values | 68,33 | 28,46 | 85,40 | 15,95 | 0,469 | 0,0118 | 1066,25 |

| Coeff. var. (%) | 5,8 | 5,8 | 5,8 | 5,3 | 10,1 | 12,4 | 5,0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).