Submitted:

12 October 2023

Posted:

12 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Microwave Treatment

2.3. Determination of Particle size Distribution

2.4. Determination of Rheological Properties

2.5. Fluorescence Spectroscopy

2.6. Determination of Total Flavan-3-ols Content

2.7. Statistical Treatment of Data

3. Results

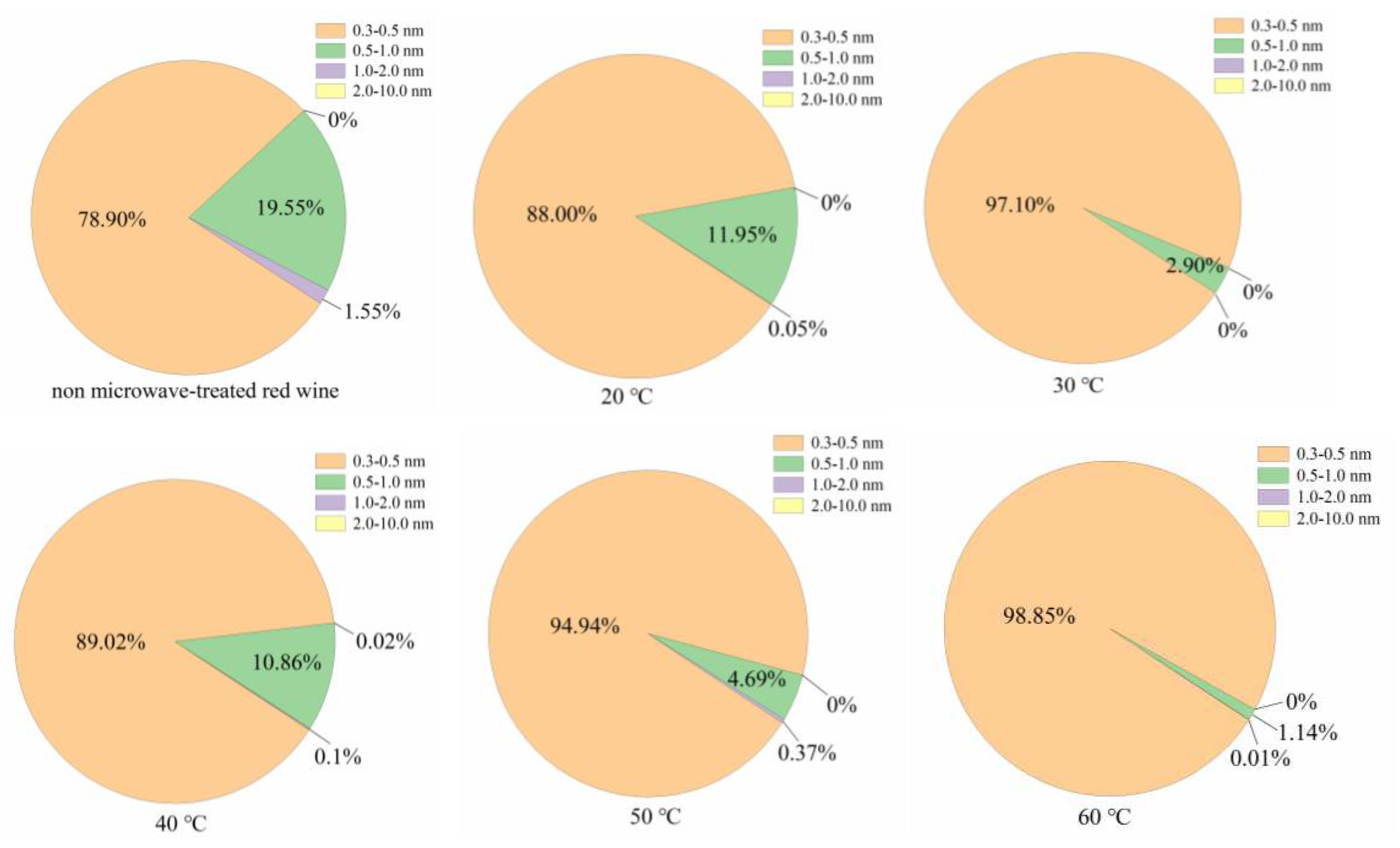

3.1. Effects of Microwave Irradiation on the Particle Size Distribution in Red Wine

3.1.1. Microwave Power on Particle Size Distribution

3.1.2. Microwave Temperature on Particle Size Distribution

3.1.3. Microwave Time on Particle Size Distribution

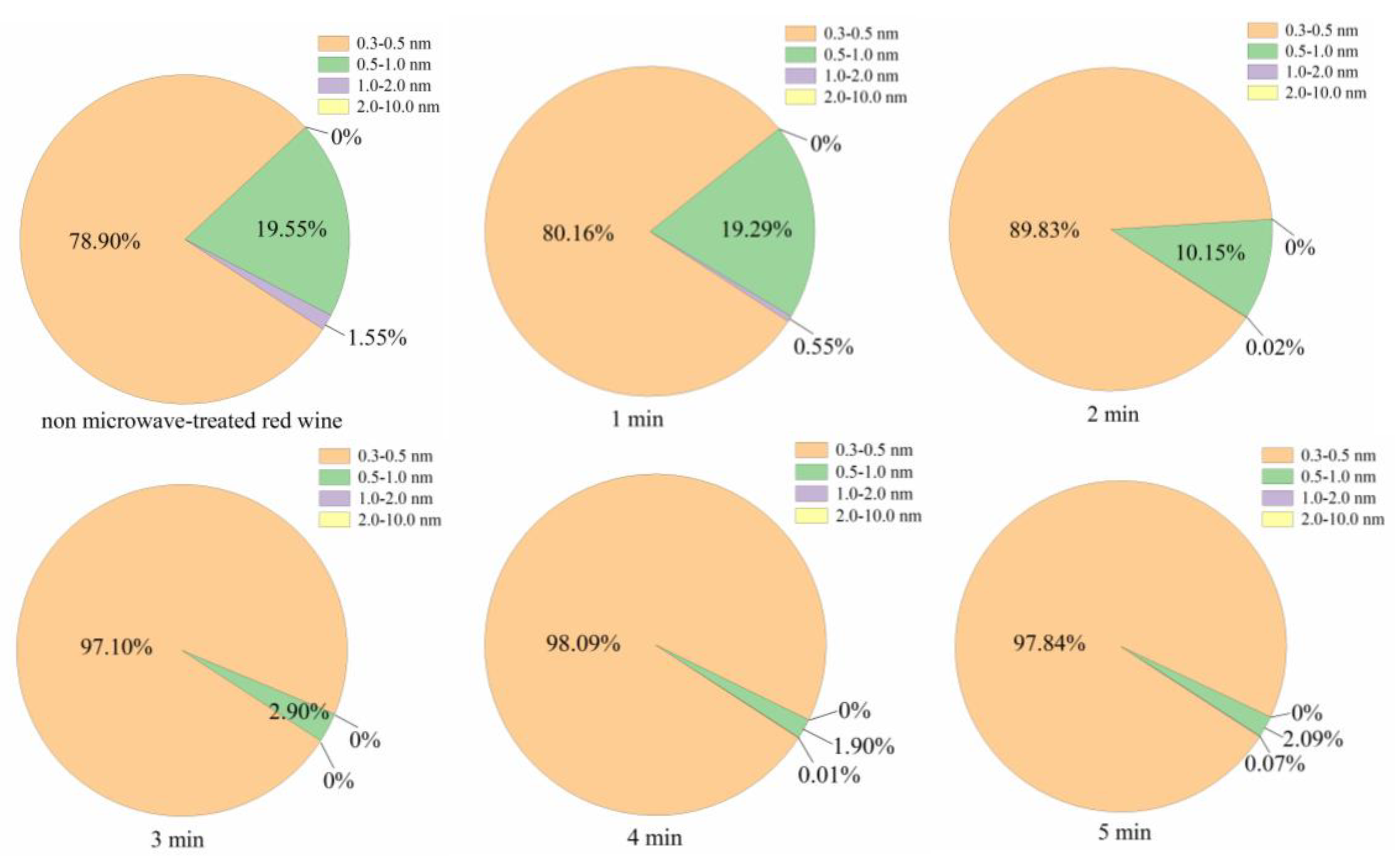

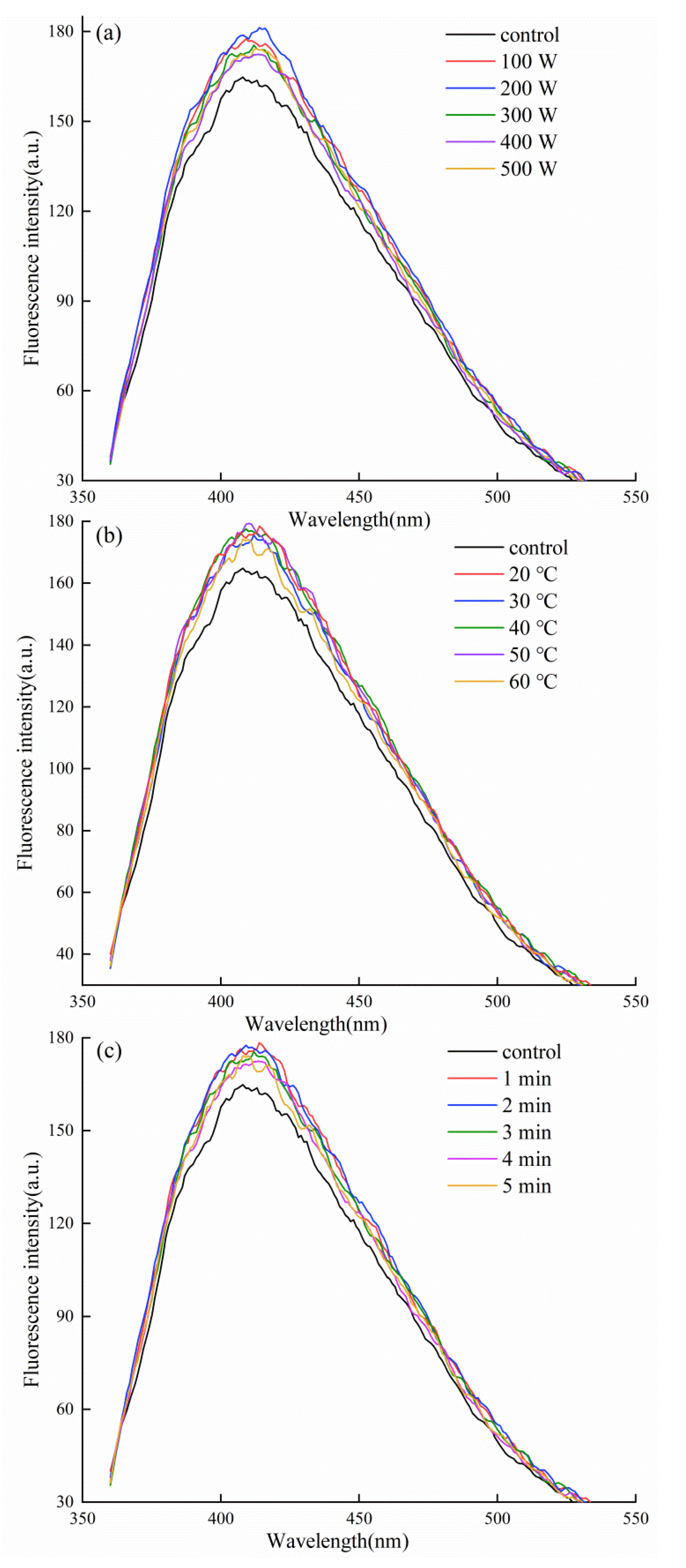

3.2. Rheological Characteristics of Untreated and Microwave-treated Red Wine

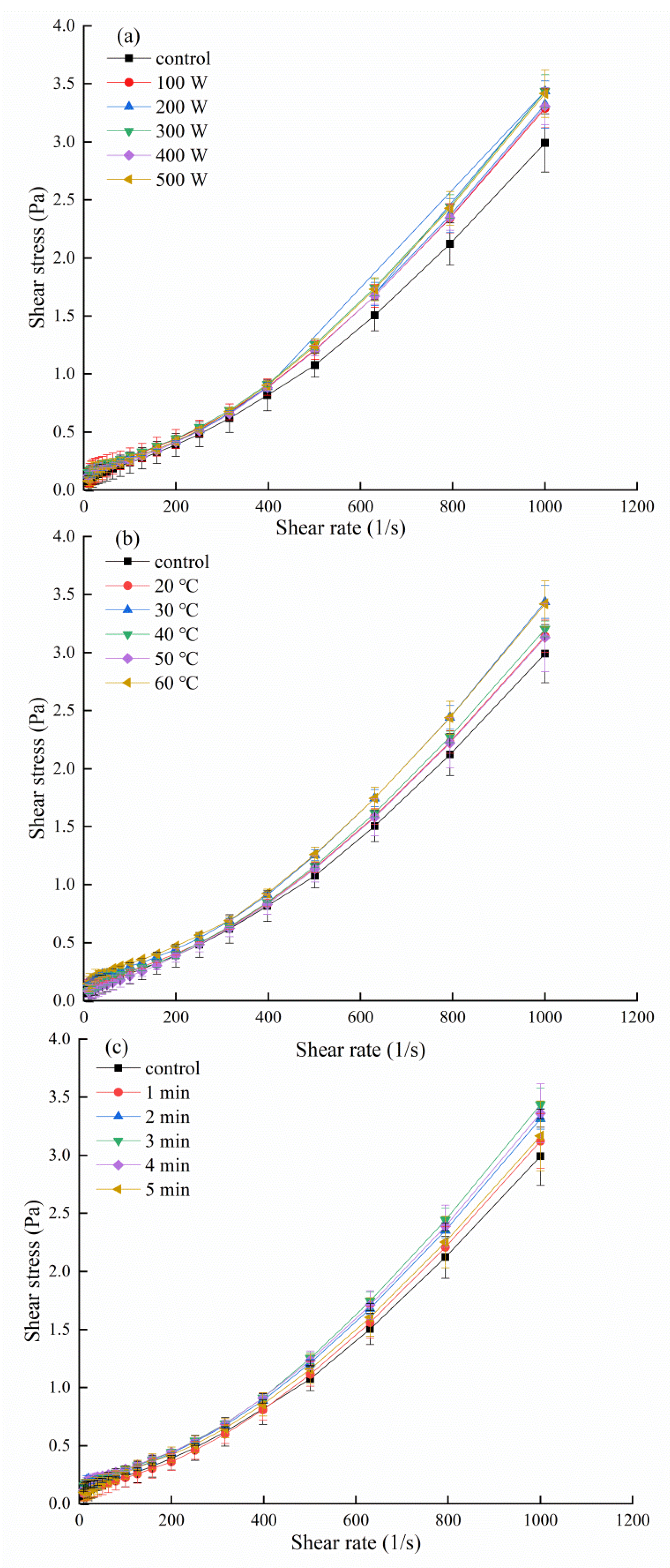

3.3. Influence of Fluorescence Intensity in Red Wine by Microwave Treatment

3.4. Influence of Flavan-3-ols in Red Wine by Microwave Treatment

4. Conclusions

Author Contributions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sánchez-Córdoba, C.; Durán-Guerrero, E.; Castro, R. Olfactometric and sensory evaluation of red wines subjected to ultrasound or microwaves during their maceration or ageing stages. LWT 2021, 144, 111228. [Google Scholar] [CrossRef]

- Carpena, M.; Pereira, A.G.; Prieto, M.A.; Simal-Gandara, J. Wine aging technology: Fundamental role of wood barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef] [PubMed]

- Jackson, R.S. Postfermentation treatments and related topics. Wine Sci. 2008, 2, 418–519. [Google Scholar] [CrossRef]

- García Martín, J.F.; Sun, D.W. Ultrasound and electric fields as novel techniques for assisting the wine ageing process: The state-of-the-art research. Trends Food Sci. Tech. 2013, 33, 40–53. [Google Scholar] [CrossRef]

- Celotti, E.; Stante, S.; Ferraretto, P.; Román, T.; Nicolini, G.; Natolino, A. High power ultrasound treatments of red young wines: Effect on anthocyanins and phenolic stability indices. Foods 2020, 9, 1344. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; García, J.F.; Sun, D.W. Advances in wine aging technologies for enhancing wine quality and accelerating wine aging process. Crit. Rev. Food Sci. 2014, 54, 817–835. [Google Scholar] [CrossRef]

- Guo, Q.S.; Sun, D.W.; Cheng, J.H.; Han, Z. Microwave processing techniques and their recent applications in the food industry. Trends Food Sci. Tech. 2017, 67, 236–247. [Google Scholar] [CrossRef]

- Zheng, X.Z.; Liu, C.H.; Huo, J.W.; Li, C. Effect of the microwave irradiated treatment on the wine sensory properties. Int. J. Food Eng. 2011, 7, 71–78. [Google Scholar] [CrossRef]

- Yuan, J.F.; Wang, T.T.; Chen, Z.Y.; Wang, D.H.; Gong, M.G.; Li, P.Y. Microwave irradiation: Impacts on physicochemical properties of red wine. CyTA-J. Food 2020, 18, 281–290. [Google Scholar] [CrossRef]

- Yuan, J.F.; Lai, Y.T.; Chen, Z.Y.; Song, H.X.; Zhang, J.; Wang, D.H.; Gong, M.G.; Sun, J.R. Microwave irradiation: Effects on the change of colour characteristics and main phenolic compounds of Cabernet Gernischt dry red wine during storage. Foods 2022, 11, 1778. [Google Scholar] [CrossRef]

- Yuan, J.F.; Wang, T.T.; Wang, D.H.; Zhou, G.H.; Zou, G.X.; Wang, Y.; Gong, M.G.; Zhang, B. Effect of microwave on changes of gallic acid and resveratrol in a model extraction solution. Food Bioprocess. Tech. 2020, 13, 1246–1254. [Google Scholar] [CrossRef]

- Yuan, J.F.; Chen, Z.Y.; Wang, D.H.; Gong, M.G.; Qiu, Z.J. Microwave-induced free radicals production in red wine and model wine by electron paramagnetic resonance spin trapping. J. Food Process. Pres. 2021, 45, e15407. [Google Scholar] [CrossRef]

- Yuan, J.F.; Hou, Z.C.; Wang, D.H.; Qiu, Z.J.; Gong, M.G.; Sun, J.R. Microwave irradiation: Effect on activities and properties of polyphenol oxidase in grape maceration stage. Food Biosci. 2021, 44, 101378. [Google Scholar] [CrossRef]

- Yuan, J.F.; Chen, Z.Y.; Lai, Y.T.; Qiu, Z.J.; Wang, D.H.; Zhao, J.F.; Sun, J.R.; Li, X. . Microwave irradiation: The influence on the production of xanthylium cation pigments in model wine. Food Bioprocess. Tech. 2022, 15, 2210–2225. [Google Scholar] [CrossRef]

- Lai, Y.T.; Yuan, J.F.; Chen, Z.Y.; Wang, D.H.; Sun, J.R.; Ma, J. L. Microwave irradiation: Reduction of higher alcohols in wine and the effect mechanism by employing model wine. LWT 2023, 181, 114765. [Google Scholar] [CrossRef]

- Zheng, X.H.; Zhang, M.; Fang, Z.X.; Liu, Y.P. Effects of low frequency ultrasonic treatment on the maturation of steeped greengage wine. Food Chem. 2014, 162, 264–269. [Google Scholar] [CrossRef] [PubMed]

- Sádecká, J.; Jakubíková, M. Varietal classification of white wines by fluorescence spectroscopy. J. food sci. tech. MYS. 2020, 57, 2545–2553. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.G.; Wang, Z.B. Fluorescence Analysis Methods, 3rd Ed.; Beijing Science Press: 2006.

- Ivanova, V.; Stefova, M.; Vojnoski, B.; Dörnyei, A.; Márk, L.; Dimovska, V.; Stafilov, T.; Kilár, F. Identification of polyphenolic compounds in red and white grape varieties grown in R. Macedonia and changes of their content during ripening. Food Res. Int. 2011, 44, 2851–2860. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave food processing-A review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Thostenson, E.T.; & Chou, T.W.; & Chou, T. W. Microwave processing: Fundamentals and applications. Compos. Part A-Appl. S. 1999, 30, 1055–1071. [Google Scholar] [CrossRef]

- Xu, B.W.; Shen, Y.; Zhang, Q.A.; Zhao, W.Q.; Yi, X. Effect of ultrasound irradiation on the particle size distribution and rheological properties of red wine. CyTA-J. Food 2019, 17, 180–188. [Google Scholar] [CrossRef]

- Košmerl, T.; Abramovič, H.; Klofutar, C. The rheological properties of Slovenian wines. J. Food Eng. 2000, 46, 165–171. [Google Scholar] [CrossRef]

- Staroszczyk, H.; Fiedorowicz, M.; Opalińska-Piskorz, J.; Tylingo, R. Rheology of potato starch chemically modified with microwave-assisted reactions. LWT 2013, 53, 249–254. [Google Scholar] [CrossRef]

- Holdsworth, S.D. Applicability of rheological models to the interpretation of flow and processing behavior of fluid food products. J. Texture Stud. 1971, 2, 393–418. [Google Scholar] [CrossRef] [PubMed]

- Araujo, L.D.; Parr, W.V.; Grose, C.; Hedderley, D.; Masters, O.; Kilmartin, P.A.; Valentin, D. In-mouth attributes driving perceived quality of Pinot noir wines: Sensory and chemical characterisation. Food Res. Int. 2021, 149, 110665. [Google Scholar] [CrossRef] [PubMed]

- Li, R.J.; Huang, L.L.; Zhang, M.; Mujumdar, A.S.; Wang, Y.C. Freeze drying of apple slices with and without application of microwaves. Dry. Technol. 2014, 32, 1769–1776. [Google Scholar] [CrossRef]

- Liu, Z.Z.; Qiao, L.; Yang, F.J.; Gu, H.Y.; Lei, Y. Bronsted acidic ionic liquid based ultrasound-microwave synergistic extraction of pectin from pomelo peels. Int. J. Biol. Macromol. 2017, 94, 309–318. [Google Scholar] [CrossRef]

- Airado-Rodríguez, D.; Durán-Merás, I.; Galeano-Díaz, T.; Wold, J.P. Front-face fluorescence spectroscopy: A new tool for control in the wine industry. J. Food Compos. Anal. 2011, 24, 257–264. [Google Scholar] [CrossRef]

- Dufour, É.; Letort, A.; Laguet, A.; Lebecque, A.; Serra, J.N. Investigation of variety, typicality and vintage of French and German wines using front-face fluorescence spectroscopy. Anal. Chim. Acta 2006, 563, 292–299. [Google Scholar] [CrossRef]

- Hoenicke, K.; Simat, T.J.; Steinhart, H.; Kohler, H.J.; Schwab, A. Determination of free and conjugated indole-3-acetic acid, tryptophan, and tryptophan metabolites in grape must and wine. J. Agric. Food Chem. 2001, 49, 5494–5501. [Google Scholar] [CrossRef]

- Lei, X.Q.; Zhu, Y.Y.; Wang, X.Y.; Zhao, P.T.; Liu, P.; Zhang, Q. T.; Chen, T.G.; Yuan, H.H.; Guo, Y.R. Wine polysaccharides modulating astringency through the interference on interaction of flavan-3-ols and BSA in model wine. Int. J. Biol. Macromol. 2019, 139, 896–903. [Google Scholar] [CrossRef] [PubMed]

- Vinas, P.; Lopez-Erroz, C.; Marin-Hernandez, J.J.; Hernandez-Cordoba, M. Determination of phenols in wines by liquid chromatography with photodiode array and fluorescence detection. J. Chromatogr. A 2000, 871, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Airado-Rodríguez, D.; Galeano-Díaz, T.; Durán-Merás, I.; Wold, J.P. Usefulness of fluorescence excitation-emission matrices in combination with PARAFAC, as fingerprints of red wines. J. Agric. Food Chem. 2009, 57, 1711–1720. [Google Scholar] [CrossRef]

- Zhang, H.J.; Tao, F.R.; Cui, Y.Z.; Xu, Z. The aggregation induced fluorescence effect enhanced by a reasonable length of carbon chain. J. Mol. Liq. 2020, 302, 112550. [Google Scholar] [CrossRef]

- González-Manzano, S.; Dueñas, M.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T.; Santos-Buelga, C. Studies on the copigmentation between anthocyanins and flavan-3-ols and their influence in the colour expression of red wine. Food Chem. 2008, 114, 649–656. [Google Scholar] [CrossRef]

| Parameters | Rheological constant n |

Regression coefficient R12 |

Yield Stress τ0 (Pa) |

Viscosity coefficient K (Pa sn)×10-3 |

Regression Coefficient R22 |

Flavan-3-ols concentration (mg/mL) |

|

|---|---|---|---|---|---|---|---|

| Untreated | 1.3029±0.1529 | 0.9859 | 0.6556±0.1803 | 2.8200±0.1411 | 0.9979 | 0.4240 | |

| Microwave power | 100 W | 1.2711±0.1055 | 0.9777 | 0.7427±0.1625 | 2.8933±0.1041 | 0.9983 | 0.3264 |

| 200 W | 1.2941±0.0356 | 0.9802 | 0.7383±0.0266 | 2.9167±0.1405 | 0.9992 | 0.2951 | |

| 300 W | 1.2804±0.0167 | 0.9758 | 0.7769±0.0130 | 2.9367±0.0850 | 0.9993 | 0.2553 | |

| 400 W | 1.3053±0.0546 | 0.9795 | 0.7308±0.0475 | 2.9167±0.1415 | 0.9991 | 0.2364 | |

| 500 W | 1.3177±0.0271 | 0.9832 | 0.7141±0.0885 | 2.9967±0.0289 | 0.9980 | 0.2714 | |

| Microwave temperature | 20℃ | 1.2884±0.0288 | 0.9789 | 0.7283±0.0159 | 2.8200±0.0889 | 0.9995 | 0.2857 |

| 30℃ | 1.2804±0.0167 | 0.9758 | 0.7769±0.0130 | 2.9367±0.0850 | 0.9993 | 0.2553 | |

| 40℃ | 1.3193±0.0606 | 0.9868 | 0.6775±0.0637 | 2.9200±0.1153 | 0.9989 | 0.3264 | |

| 50℃ | 1.3435±0.0564 | 0.9908 | 0.6609±0.1085 | 2.9333±0.1193 | 0.9980 | 0.2468 | |

| 60℃ | 1.2406±0.0359 | 0.9724 | 0.8073±0.0262 | 2.8933±0.0723 | 0.9981 | 0.2344 | |

| Microwave time | 1min | 1.3598±0.1281 | 0.9846 | 0.6617±0.1713 | 2.9067±0.1380 | 0.9989 | 0.3027 |

| 2min | 1.2755±0.0169 | 0.9758 | 0.7657±0.0156 | 2.8767±0.0493 | 0.9990 | 0.2819 | |

| 3min | 1.2804±0.0167 | 0.9758 | 0.7769±0.0130 | 2.9367±0.0850 | 0.9993 | 0.2553 | |

| 4min | 1.2588±0.0206 | 0.9749 | 0.7817±0.0345 | 2.8833±0.0971 | 0.9984 | 0.2497 | |

| 5min | 1.2849±0.0672 | 0.9843 | 0.7028±0.1200 | 2.8733±0.1069 | 0.9984 | 0.2809 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).