Submitted:

16 November 2023

Posted:

17 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussions

4. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- White, G.O.; Patton, C.E. Magnetic Properties of Lithium Ferrite Microwave Materials, J. Magn. Magn. Mater. 1978, 9(4), 299-317. [CrossRef]

- Sugimoto, M. The Past, Present, and Future of Ferrites, J. Am. Ceram. Soc. 1999, 82(2), 269-280. [CrossRef]

- Lüders, U.; Barthélémy, A.; Bibes, M.; Bouzehouane, K.; Fusil, S.; Jacquet, E.; Contour, J.-P.; Bobo, J.-F.; J.-F. Fontcuberta, J.-F.; Fert, A. NiFe2O4: A Versatile Spinel Material Brings New Opportunities for Spintronics, Adv. Mater. 2006, 18(13), 1733-1736.

- Suzuki, Y. Epitaxial Spinel Ferrite Thin Films, Annual Review of Materials Research 2001, 31, 265-289.

- Boyraz, C.; Mazumdar, D.; Iliev, M.; Marinova, V.; Ma, J.; Srinivasan, G.; Gupta, A. Structural and magnetic properties of lithium ferrite (LiFe5O8) thin films: Influence of substrate on the octahedral site order, Appl. Phys. Lett. 2011, 98(1), 012507. [CrossRef]

- Wei, J. D.; Knittel, I.; Hartmann, U.; Zhou, Y.; Murphy, S.; Shvets, I. V. et al. Influence of the Antiphase Domain Distribution on the Magnetic Structure of Magnetite Thin Films, Appl. Phys. Lett. 2006, 89(12), 122517. [CrossRef]

- Chen, C. L.; Li, H. P.; Seki, T.; Yin, D. Q.; Sanchez-Santolino, G.; Inoue, K et al. Direct Determination of Atomic Structure and Magnetic Coupling of Magnetite Twin Boundaries, ACS nano, 2008, 12(3), 2662-2668.

- Udhayakumar, S.; Kumar, G. J.; Kumar, E. S.; Navaneethan, M.; Kamala Bharathi, K. Electrical, Electronic and Magnetic Property Correlation Via Oxygen Vacancy Filling and Scaling-law Analysis in LiFe5O8 Thin Films Prepared by Pulsed Laser Deposition, J. Mater. Chem. C 2022, 10(40), 15051-15060.

- Liu, X.; Wu, M.; Qu, K.; Gao, P.; Mi, W. Atomic-Scale Mechanism of Grain Boundary Effects on the Magnetic and Transport Properties of Fe3O4 Bicrystal Films, ACS Appl. Mater. and Inter. 2021, 13(5), 6889-6896.

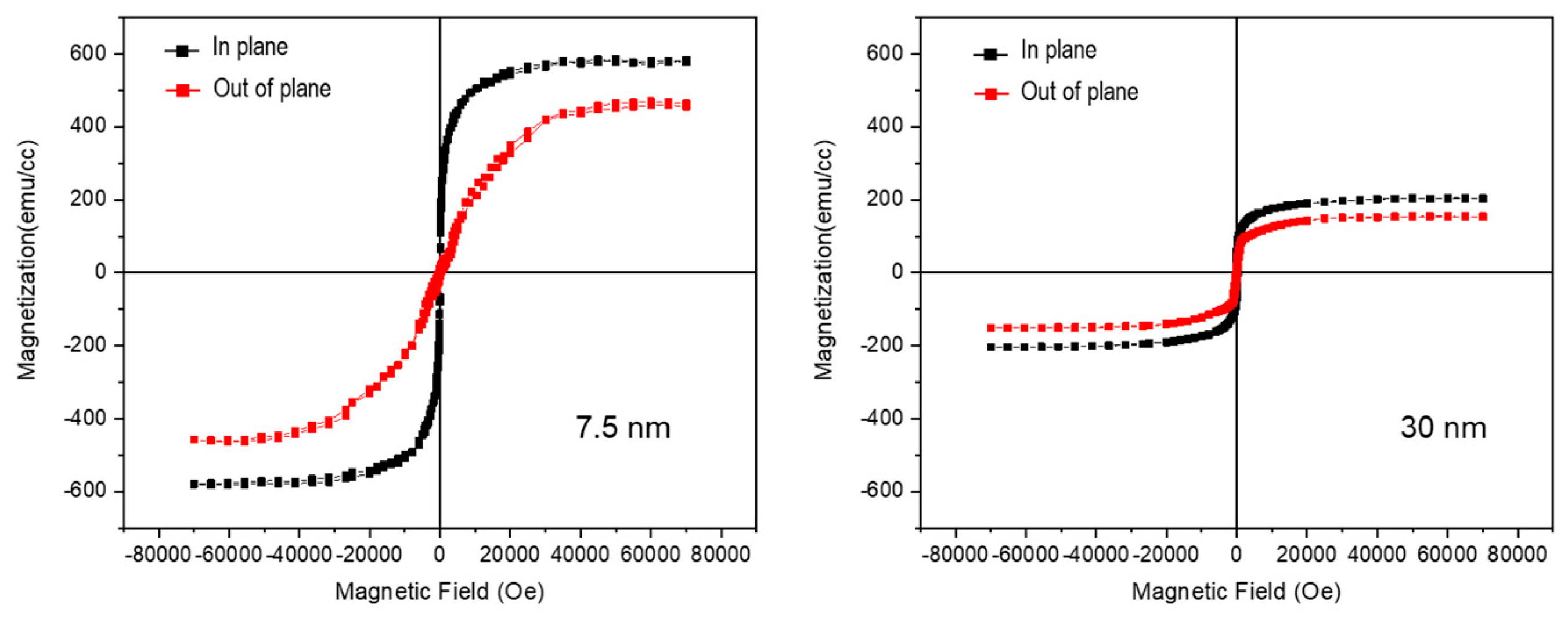

- Zhang, R.; Liu, M.; Lu, L.; Mi, S.B.; Wang, H. Strain-tunable magnetic properties of epitaxial lithium ferrite thin film on MgAl2O4 substrates, J. Mater. Chem. C 2015, 3(21), 5598-5602.

- Hu, G.; Choi, J. H.; Eom, C. B.; Harris, V. G.; Suzuki, Y. Structural Tuning of the Magnetic Behavior in Spinel-Structure Ferrite Thin Films, Phys. Rev. B 2000, 62(2), R779-R782. [CrossRef]

- Uusi-Esko, K.; Rautama, E.-L.; Laitinen, M.; Sajavaara, T.; Karppinen, M. Control of Oxygen Nonstoichiometry and Magnetic Property of MnCo2O4 Thin Films Grown by Atomic Layer Deposition, Chem. Mater. 2010, 22, 6297-6300. [CrossRef]

- Foerster, M.; Rebled, J.M.; Estradé, S.; Sánchez, F.; Peiró, F.; Fontcuberta, J. Distinct Magnetism in Ultrathin Epitaxial NiFe2O4 Films on MgAl2O4 and SrTiO3 Single Crystalline Substrates, Phys. Rev. B 2011, 84(14), 144422. [CrossRef]

- Rigato, F.; Estradé, S.; Arbiol, J.; Peiró, F.; Lüders, U.; Martí, X.; Sánchez, F.; Fontcuberta, J. Strain-induced stabilization of new magnetic spinel structures in epitaxial oxide heterostructures, Materials Science and Engineering: B 2007, 144(1-3), 43-48. [CrossRef]

- Praus, R. B.; Leibold, B.; Gross, G. M.; Habermeier, H.U. Thickness dependent properties of La0.67Ca0.33MnO3 thin films, Appl. Surf. Sci. 1999, 138-139, 40-43. [CrossRef]

- Matvejeff, M.; Lippmaa, M.; Growth of InFeCoO4 thin films on SrTiO3 and MgO substrates, J. Cryst. Growth 2010, 312(16-17), 2386-2392. [CrossRef]

- Wang, Y.; Li, D.F.; Dai, J.Y. Microstructure and magnetic properties of a novel spinel (Zn,Co)Fe2O4 thin film on the SrTiO3 substrate, J. Cryst. Growth 2010, 313(1), 26-29. [CrossRef]

- Moussy, J.B.; Gota, S.; Bataille, A.; Guittet, M.J.; Gautier-Soyer, M.; Delille, F.; Dieny, B.; Ott, F.; Doan, T.; Warin, P.; Bayle-Guillemaud, P.; Gatel, C; Snoeck, E. Thickness dependence of anomalous magnetic behavior in epitaxial Fe3O4(111) thin films: Effect of density of antiphase boundaries, Phys. Rev. B 2004, 70(17). [CrossRef]

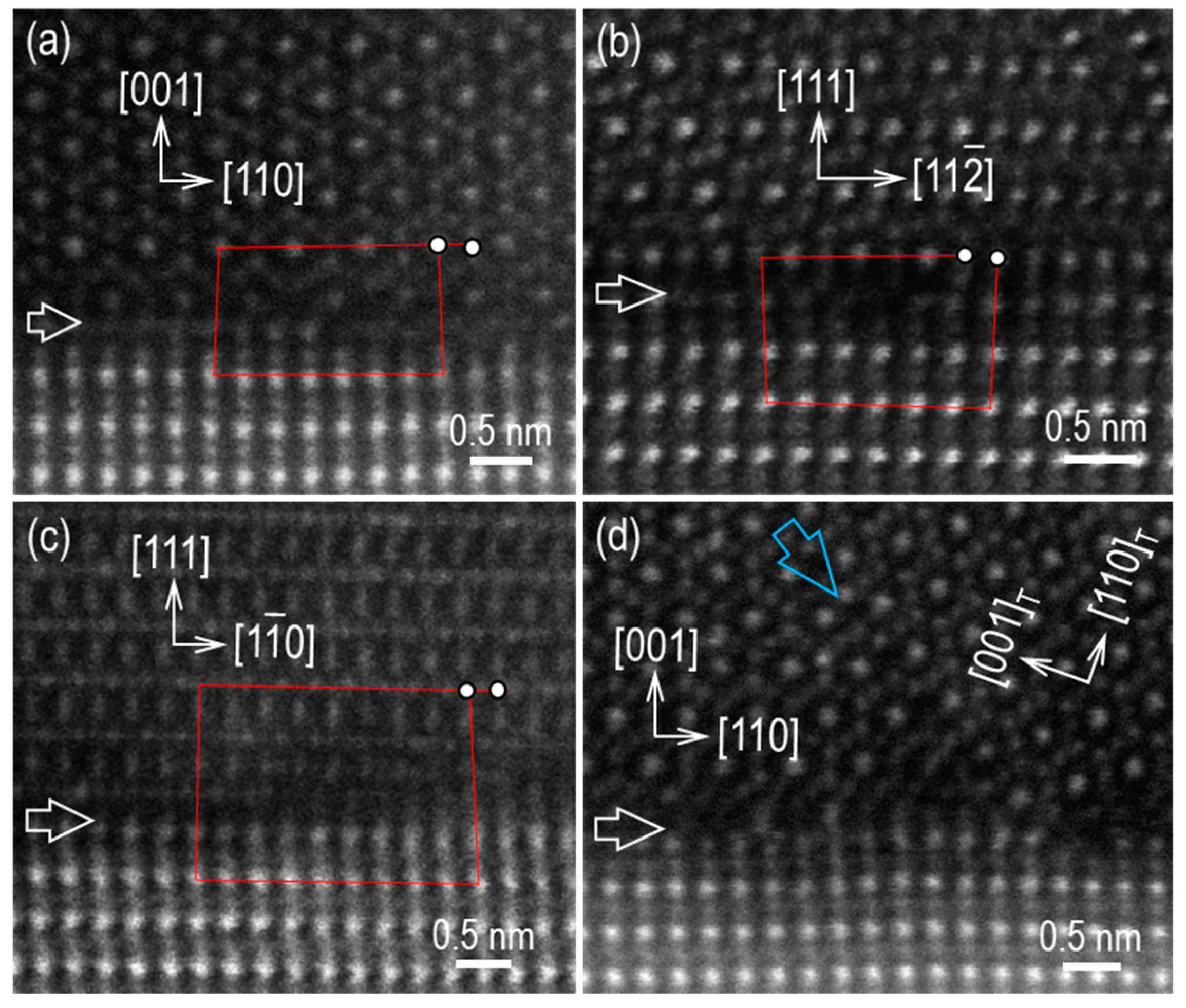

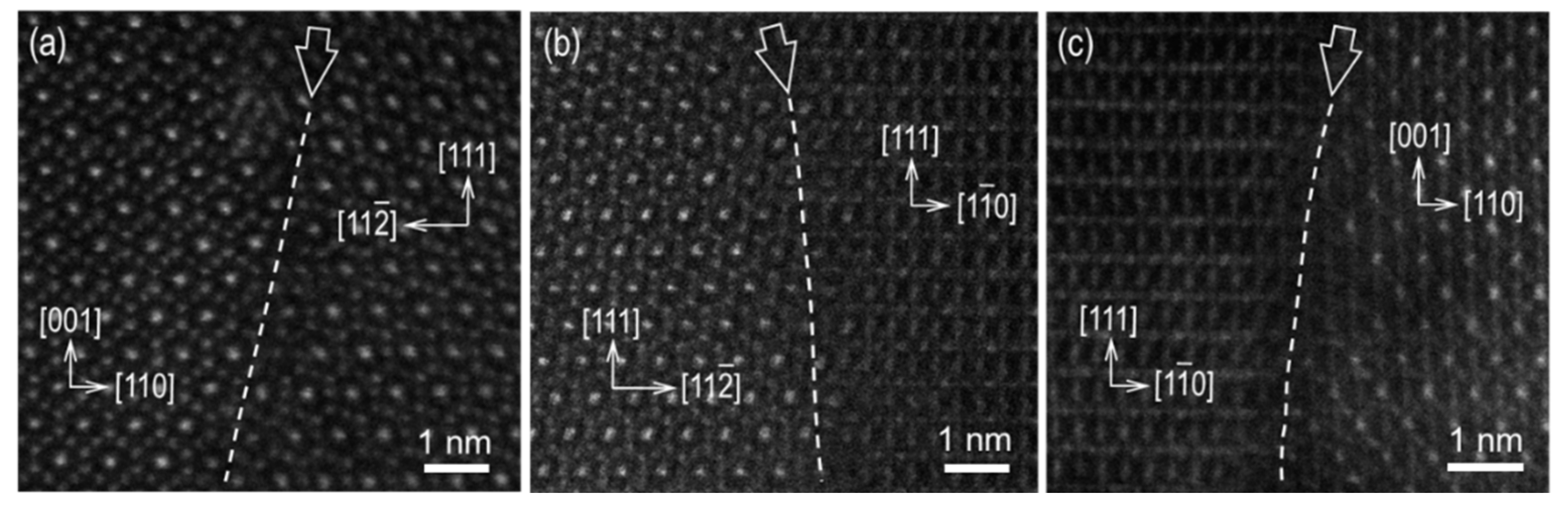

- Mi, S.B.; Zhang, R.Y.; Lu, L.; Liu, M.; Wang, H.; Jia, C.L. Atomic-scale structure and formation of antiphase boundaries in α-Li0.5Fe2.5O4 thin films on MgAl2O4(001) substrates, Acta Mater. 2017, 127, 178-184.

- Gao, C.; Jiang, Y.; Yao, T; Tao, A.; Yan, X.; Li, X. et al., Atomic Origin of Magnetic Coupling of Antiphase Boundaries in Magnetite Thin Films, J Mater Sci Technol. 2022, 107, 92-99. [CrossRef]

- 21. Lüders, U; Bibes, M.; Bobo, J.-F.; Cantoni, M; Bertacco R.; Fontcuberta, J. Enhanced Magnetic Moment and Conductive Behavior in NiFe2O4 Spinel Ultrathin Film, Phys. Rev. B 2005, 71(13), 134419.

- Gatel, C.; Warot-Fonrose, B.; Matzen, S.; Moussy, J.B. Magnetism of CoFe2O4 Ultrathin Films on MgAl2O4 Driven by Epitaxial Strain, Appl. Phys. Lett. 2013, 103(9), 092405. [CrossRef]

- Hoppe, M; Döring, S; Gorgoi, M.; Cramm, S.; Müller, M. Enhanced Ferrimagnetism in Auxetic NiFe2O4 in the Crossover to the Ultrathin-Film Limit, Phys. Rev. B 2015, 91(5), 054418.

- Rezlescu, N.; Doroftei, C.; Rezlescu, E.; Popa, P.D. Lithium ferrite for gas sensing applications, Sensors Actuat. B-Chem. 2008, 133(2), 420-425. [CrossRef]

- Yousaf, M.; Naseer, U.; Li, Y. J.; Ali, Z.; Mahmood, N.; Wang, L.; Gao, P.; Guo, S. J. A Mechanistic Study of Electrode Materials for Rechargeable Batteries Beyond Lithium Ions by in Situ Transmission Electron Microscopy, Energy Environ. Sci. 2021,14, 2670-2707.

- Teixeira, S.S.; Graça, M.P.F.; Lucas, J.; Valente, M.A.; Soares, P.I.P.; Lança, M.C.; Vieira, T.; Silva, J.C.; Borges, J.P.; Jinga, L.-I.; et al. Nanostructured LiFe5O8 by a Biogenic Method for Applications from Electronics to Medicine. Nanomaterials 2021, 11, 193.

- Howard, S.A.; Yau, J.K.; Anderson, H.U. Structural Characteristics of Sr1−xLaxTi3+δ as a Function of Oxygen Partial Pressure at 1400 °C, J. Appl. Phys. 1989, 65(4), 1492-1498.

- Jain, S. C.; Harker, A. H.& Cowley, R. A. Misfit Strain and Misfit Dislocations in Lattice Mismatched Epitaxial Layers and Other Systems, Philosophical Magazine A, 1997, 75:6, 1461-1515. [CrossRef]

- Regmi, S.; Li, Z.; Srivastava, A.; Mahat, R.; Shambhu, KC.; Rastogi, A.; Galazka, Z.; Datta, R.; Mewes, T.; Gupta, A. Structural and magnetic properties of NiFe2O4 thin films grown on isostructural lattice-matched substrates. Appl. Phys. Lett. 2021, 118, 152402. [CrossRef]

- Zhang, J.; Liu, W.; Zhang, M.; Zhang, X.; Niu, W.; Gao, M.; Wang, X.; Du, J.; Zhang, R.; Xu, Y. Oxygen pressure-tuned epitaxy and magnetic properties of magnetite thin films. J. Magn. Magn. Mater. 2017, 432, 472-476. [CrossRef]

- Liu, K.; Zhang, R.Y.; Lu, L.; Mi, S.B.; Liu, M.; Wang, H.; Wu, S.Q.; Jia, C.L. Atomic-Scale Investigation of Spinel LiFe5O8 Thin Films on SrTiO3 (001) Substrates, J Mater Sci Technol. 2020, 40(1), 31-38. [CrossRef]

- Fritsch, D.; Ederer, C. Epitaxial Strain Effects in the Spinel Ferrites CoFe2O4 and NiFe2O4 From First Principles, Phys. Rev. B 2010, 82(10), 104117.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).