As mentioned above, after the distribution location and number of orifices are optimized by finite element method, the response surface optimization method is used to obtain certain data through reasonable test design and experiment. The multivariate quadratic regression method is used to fit the functional relationship between the factors and the response value [

20]. The optimal gas chamber diameter, gas chamber height, orifice diameter and orifice height are sought through the analysis of the regression equation.

5.2. Design-expert response surface optimization design

At present, the commonly used response surface test methods mainly include full factor and partial factor test design, Latin hypercube test design, central composite design, Box-Behnken Design (BBD). In this paper, the BBD method is adopted for experimental design, and response surface method is commonly used for three levels test. With the increase of test level, the mismatch probability of response surface fitting increases [

21]. As this test is a four-factor test and the variation range of the factors is small, the test design of four factors and three levels is adopted.

The four factors and three levels experimental scheme designed by Design-expert software according to the combination design principle of Box-Behnken design center is shown in

Table 5. Select the gas chamber diameter, gas chamber height, orifice diameter and orifice height as the investigation factors, and take the loading capacity and stiffness as the response values to conduct the response surface test. The results are shown in

Table 6.

Taking loading capacity and stiffness as response values, the data in

Table 6 are fitted with quadratic response surface, and the multivariate quadratic regression equation of loading capacity

Y1 and stiffness

Y2 is obtained as:

The accuracy test of fitting equation is shown in

Table 7. In engineering application, when the correlation coefficient

R2 of the model is greater than 0.95, the test error is small and the reliability is very high; The closer the correction fitting degree

R2 (Adj) and the prediction fitting degree

R2 (Pred), the Signal-to-Noise Ratio (Adeq Precision) greater than 4 can be considered a good fit [

22]. The coefficient of variation CV is 0.8136% and 4.87% respectively, less than 10%, which indicates that the model has a good stability. Therefore, the fitting function has a good fitting accuracy, so this model can be used to predict the loading capacity and stiffness.

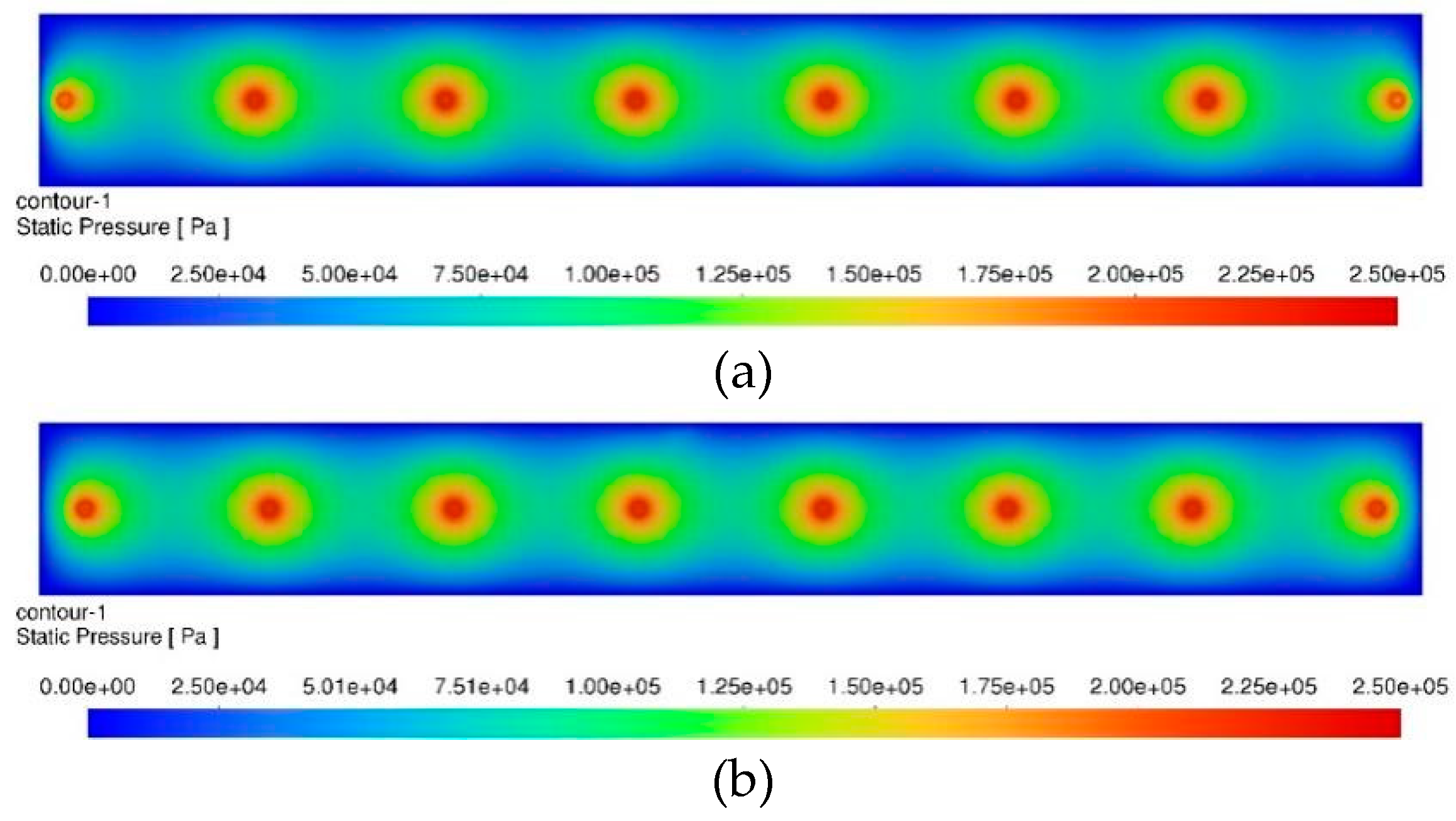

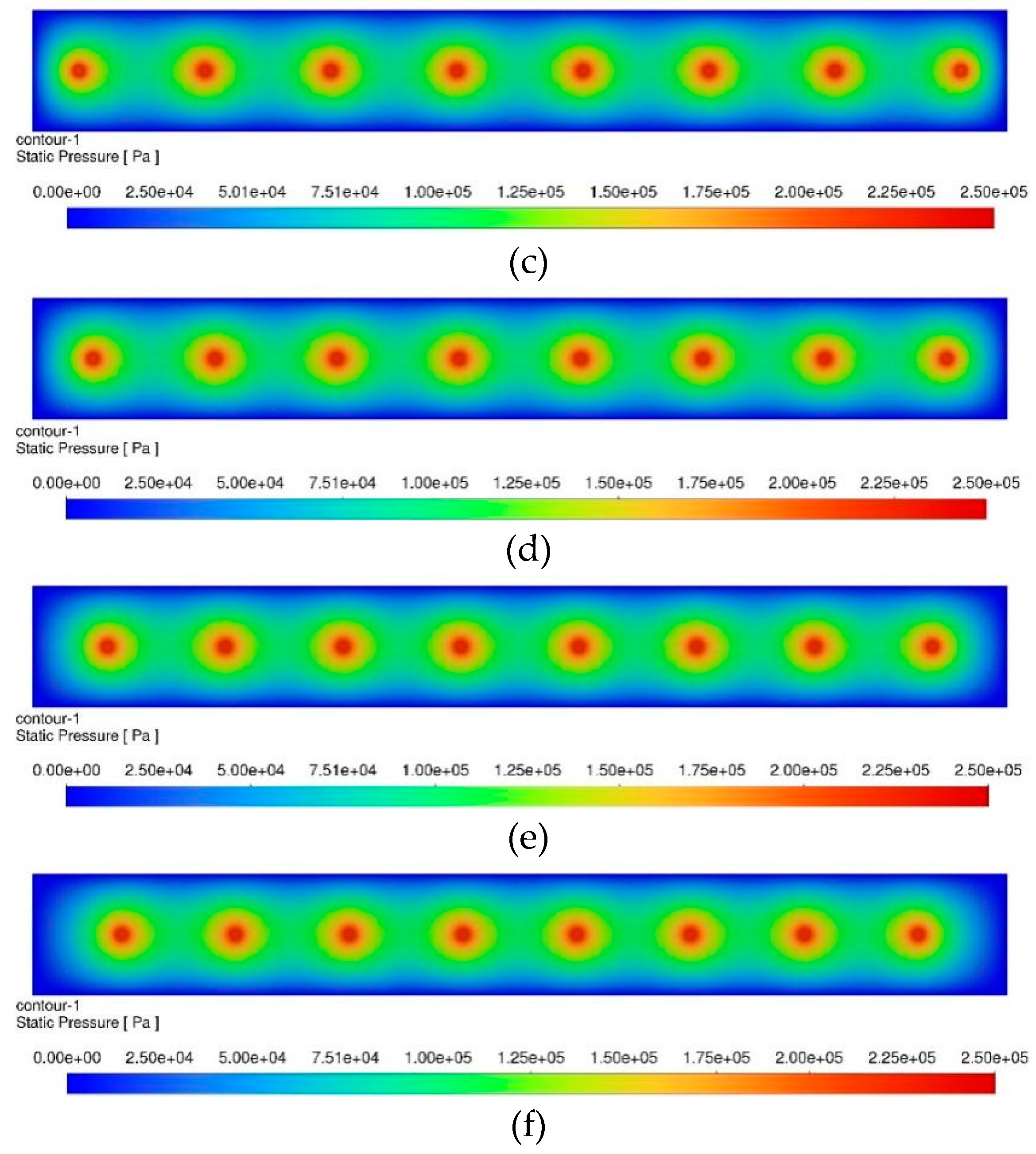

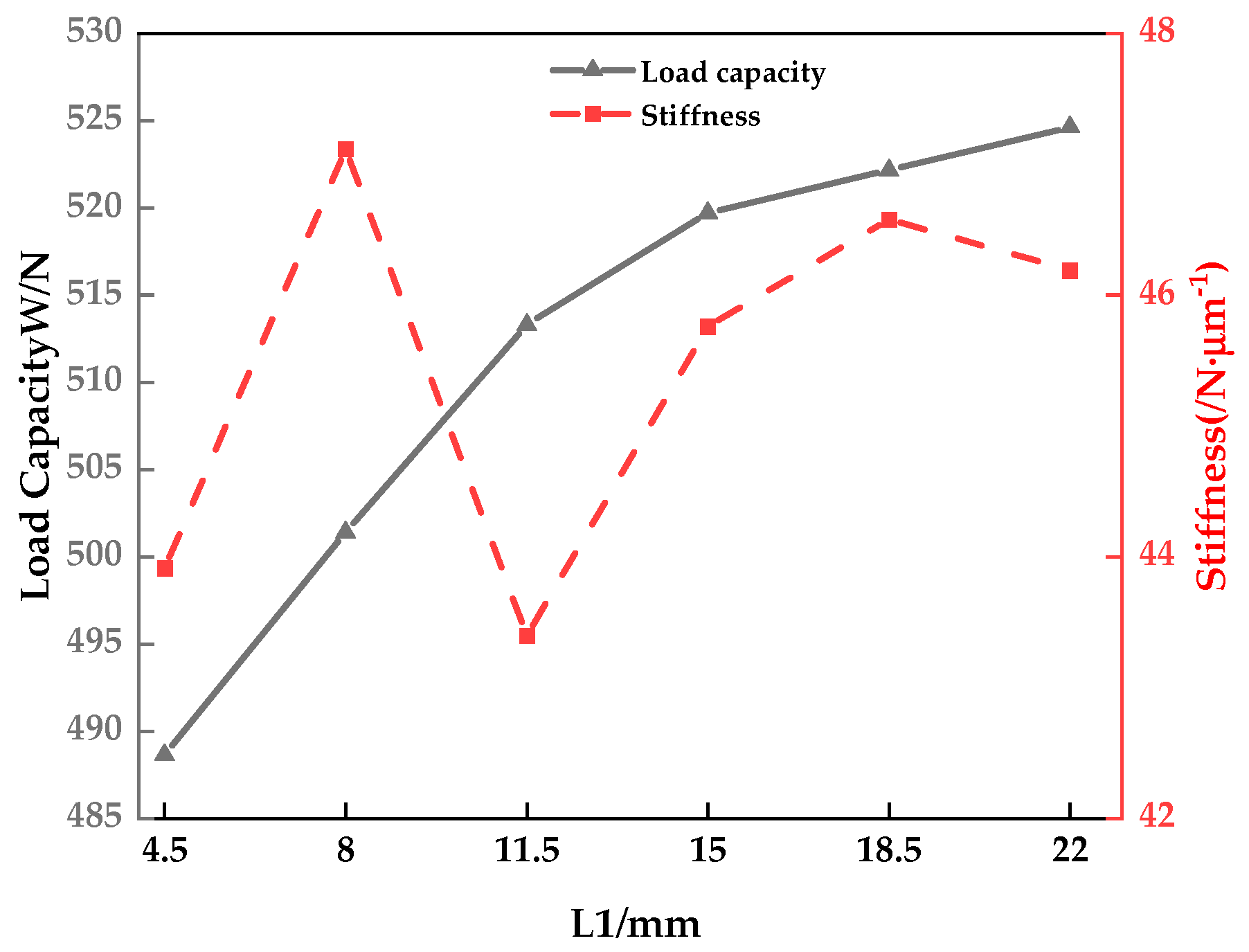

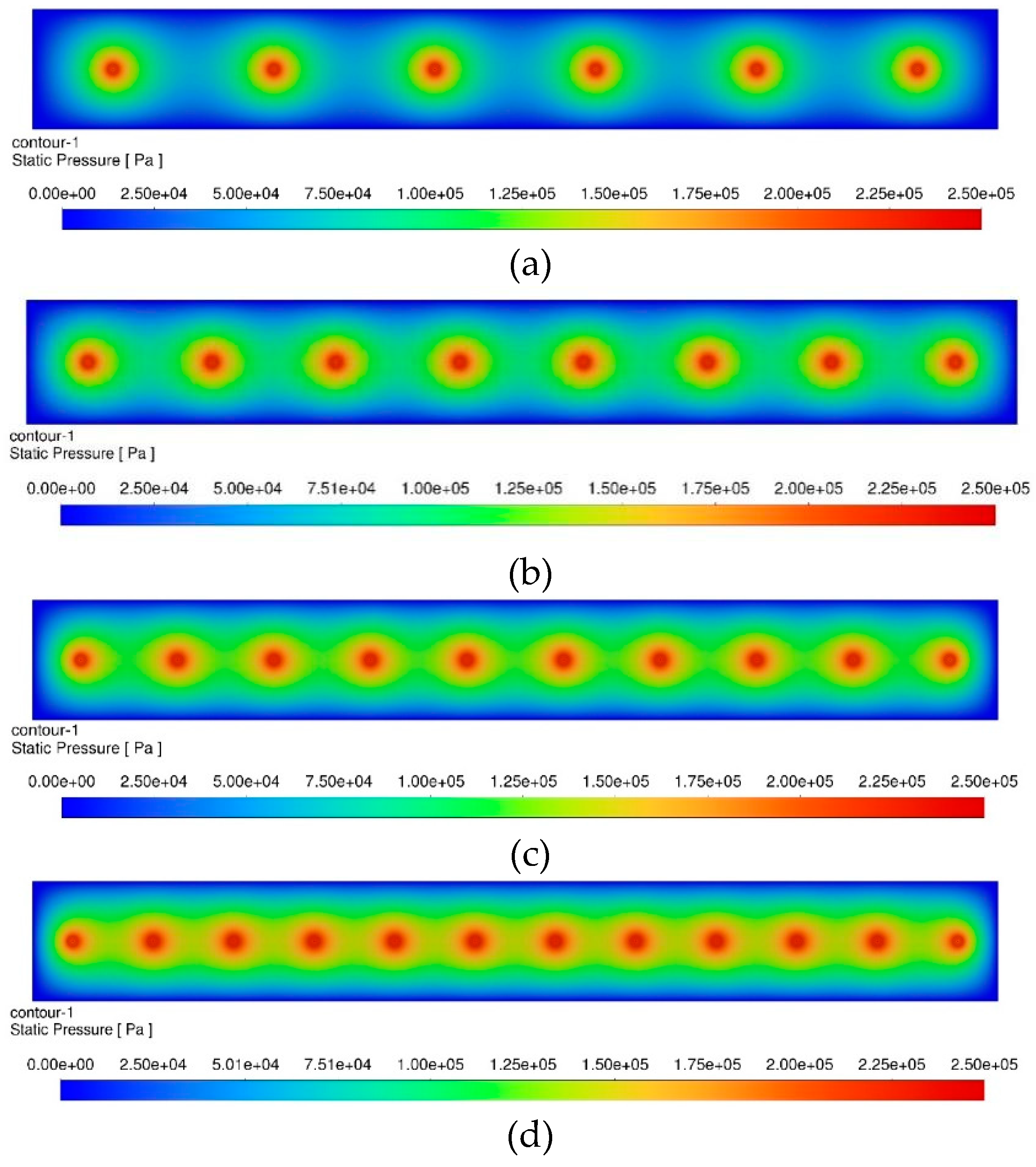

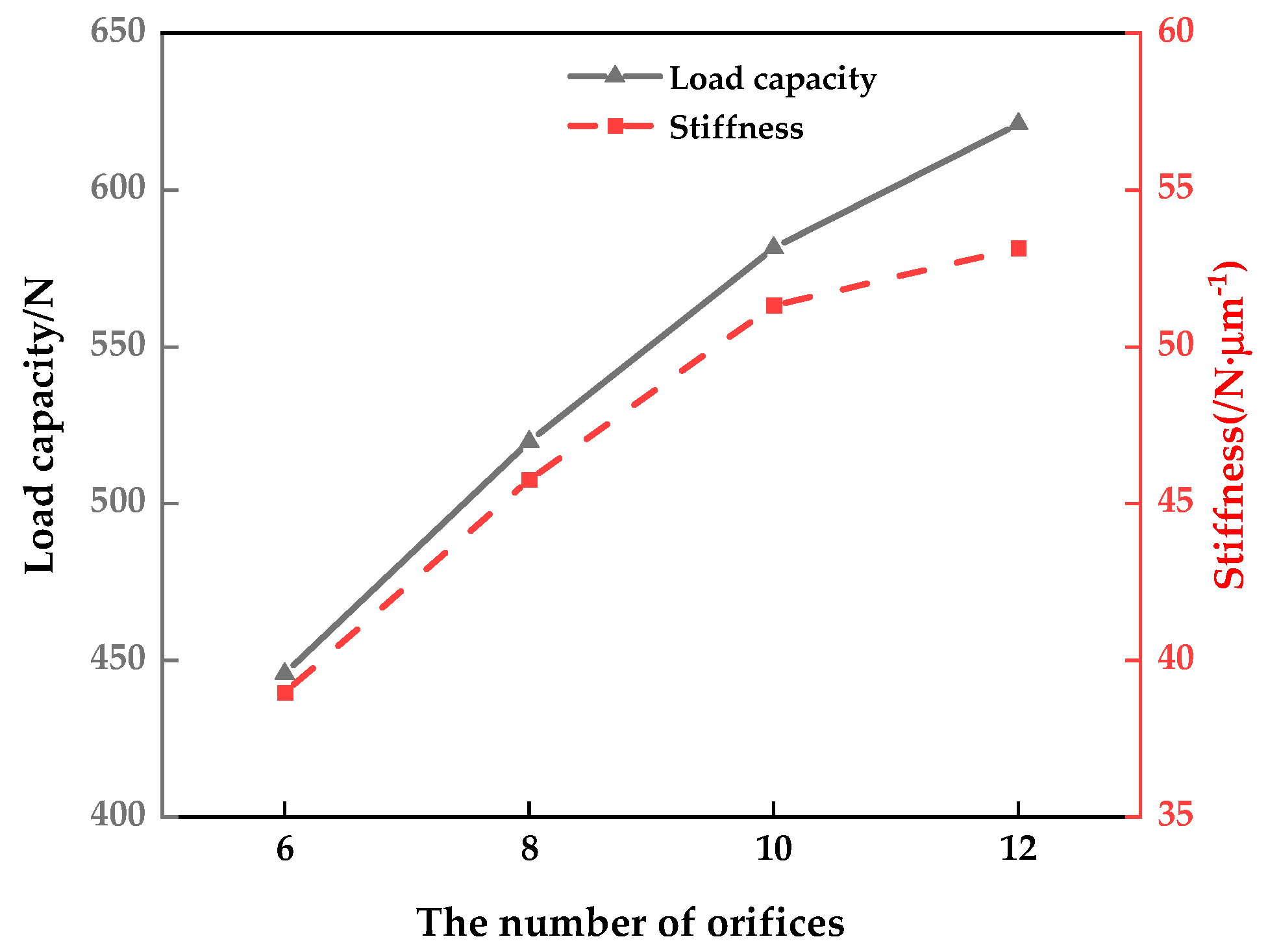

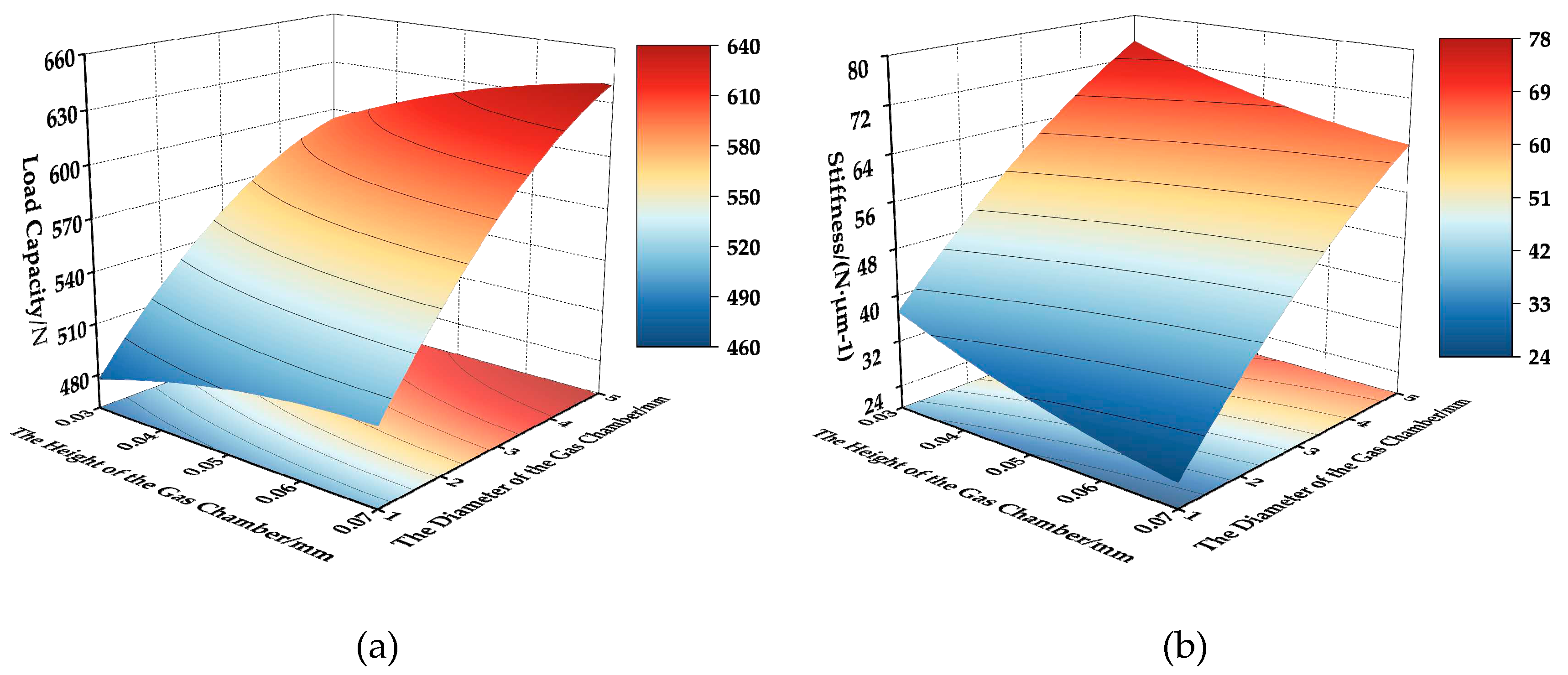

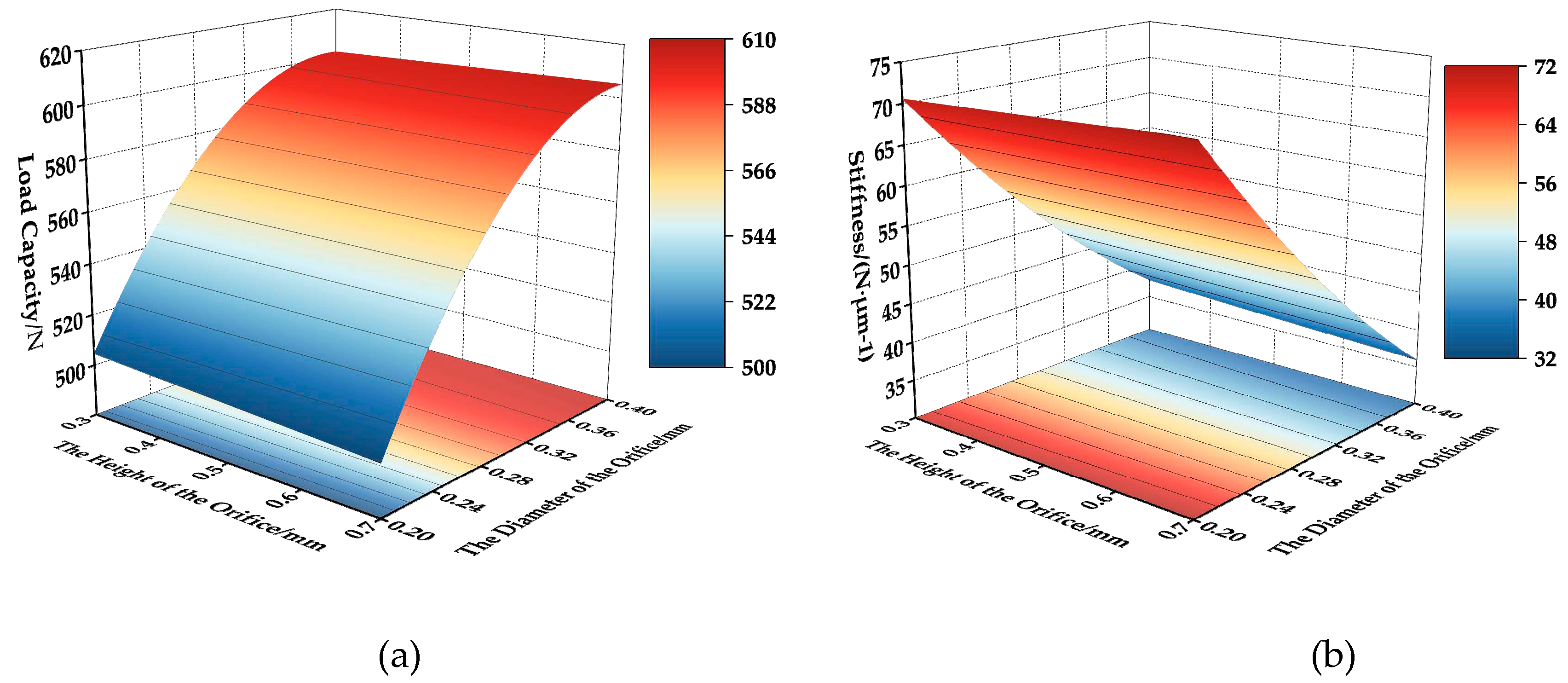

The contour map and response surface map are plotted according to the multivariate quadratic regression equation, and the influence of gas chamber diameter, gas chamber height, orifice diameter and orifice height on the loading capacity and stiffness are analyzed. The results are shown in

Figure 9 and

Figure 10. The contour map and response surface map can intuitively reflect the impact of interaction on the response value. The steeper the surface is, the denser the contour is, and the more significant the impact is [

23]. The analysis of

Figure 9 shows that the gas chamber diameter has a great influence on the loading capacity. With the increase of the gas chamber diameter, the loading capacity increases significantly, while the gas chamber height has a small influence on the loading capacity. With the increase of the gas chamber height, the loading capacity increases slowly; Similarly, the gas chamber diameter has a great influence on the stiffness. With the increase of gas chamber diameter, the stiffness increases significantly, and with the increase of gas chamber height, the stiffness decreases slowly. The analysis of

Figure 10 shows that the diameter of orifice has a significant impact on the loading capacity and stiffness. With the increase of the diameter of orifice the loading capacity increases significantly, but the stiffness decreases significantly. In comparison, the height of orifice has a small impact on the loading capacity and stiffness. With the increase of the height of orifice, the loading capacity decreases slowly, while the stiffness almost remains the same.

Regression prediction of the experimental results based on Design-expert’s response function shows that when the gas chamber diameter, gas chamber height, orifice diameter and orifice height are 5 mm, 0.05 mm, 0.4 mm and 0.5 mm respectively, the maximum loading capacity is 667.595N and the stiffness is only 50.977 . When the gas chamber diameter, gas chamber height, orifice diameter and orifice height are 5 mm, 0.05 mm, 0.2 mm and 0.5 mm respectively, the maximum stiffness is 89.881 , loading capacity only 528.095 N. Based on the response surface analysis, the loading capacity and stiffness are optimized at the same time. At this time, the gas chamber diameter, gas chamber height, orifice diameter and orifice height are 5 mm, 0.07 mm, 0.265 mm and 0.696mm respectively, the loading capacity is 614.455 N and the stiffness is 73.634 . In order to consider the processing problem, the diameter of orifice is rounded to 0.3mm, the height of orifice is rounded to 0.7 mm, and the loading capacity and stiffness at this time are respectively 644.58 N and 63.405 by the finite element calculation.