1. Introduction

Titanium dioxide is a widely used white pigment in industries such as coatings, paints, paper, plastic, rubber, ceramics, and textiles. There are two main structures of titanium dioxide particles: rutile and anatase, depending on the production method [

1]. The sulfate process, which involves the decomposition of titanium-containing raw materials using sulfuric acid and the precipitation of titanium sulfate, will be the focus of this paper [

2]. Another method is the chloride process [

3]. The chemical equations for the sulfate process are shown in Eq (1).

To produce a high-quality white pigment, a stable and precise process control of precipitation is required and most

manufacturing companies have attempted to optimize the process. [

4,

5,

6,

7,

8]. The uniformity of particle size during the precipitation process is essential for producing high-quality

pigments. If particles of varying sizes are produced, they may block the pores of the filter cloth in the following washing process [

9]. Inconsistent particle sizes during precipitation can also destabilize the titanyl sulfate solution and affect the washing and preceding processes negatively. To ensure a stable precipitation process with uniform particle size distribution, the agitator in the precipitation tank must meet two specified conditions.

Firstly, the agitator must effectively mix the solution and keep the temperature consistent during the precipitation stages. Secondly, the early injection of seed particles must be rapidly and evenly dispersed.

Many researchers in the chemical field have performed experiments to study this agglomeration [

10,

11,

12,

13,

14]. However, studies analyzing the precipitation process using CFD are extremely limited and there is no design of precipitation through multiphase analysis [

15,

16,

17]. The scarcity of information on the design parameters of agitators in chemical engineering can be attributed to the limited mechanical knowledge regarding mixing efficiency and seed diffusivity based on the shape and location of agitators. In addition, there is a need for more research data on the hydrodynamic characteristics of agitators that incorporate chemical reactions in the field of mechanical engineering.

This study aims to utilize multi-phase CFD for the first time in the precipitation process, to combine knowledge from both chemical and mechanical engineering to understand the impact of various design parameters of agitators on the particle size distribution of pigments. Additionally, this study seeks to analyze the trajectory of seeds injected during the precipitation process and determine the optimal seed injection location for a more evenly distributed outcome. Based on the simulation results, the problem with the current precipitation process will be identified, and a form of the blade and seed inlet location that can increase mixing rates will be proposed.

2. Multi-phase CFD simulation

2.1. Govering Equation.

Computational fluid dynamic (CFD), which we know well, is mainly a single–phase flow that uses the Navier-stokes equation as a governing equation. Equation (2)

However,

Solution meets introducing gas type wet steam in the precipitation tank, and phase changing occurs. Results of multiphase flow, force, and mass exchanges also take place. Therefore, the following governing equation Equations (3) and (4) should be used for multi-phase flow.

The meaning of

is the Volume fraction of

phase, and the momentum equation of

phase can be written as the following Equation (5)

Where is interphase forces exchange, and is interphase mass exchange. Ansys CFX 18.2 is used for governing equations and multiphase solver. The turbulence modeling utilized in this study was the Detached Eddy Simulation (DES).

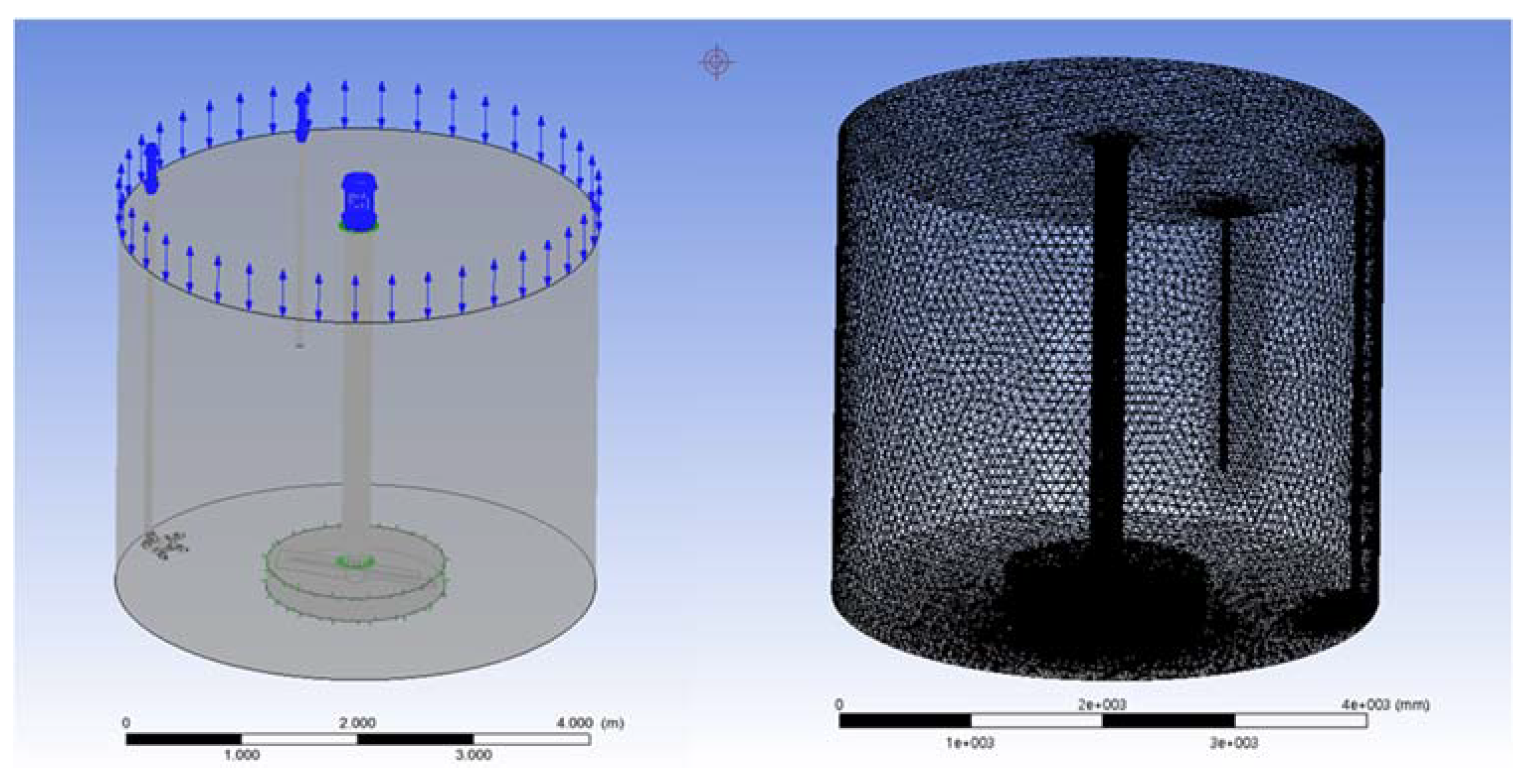

2.2. Geometry and mesh generation

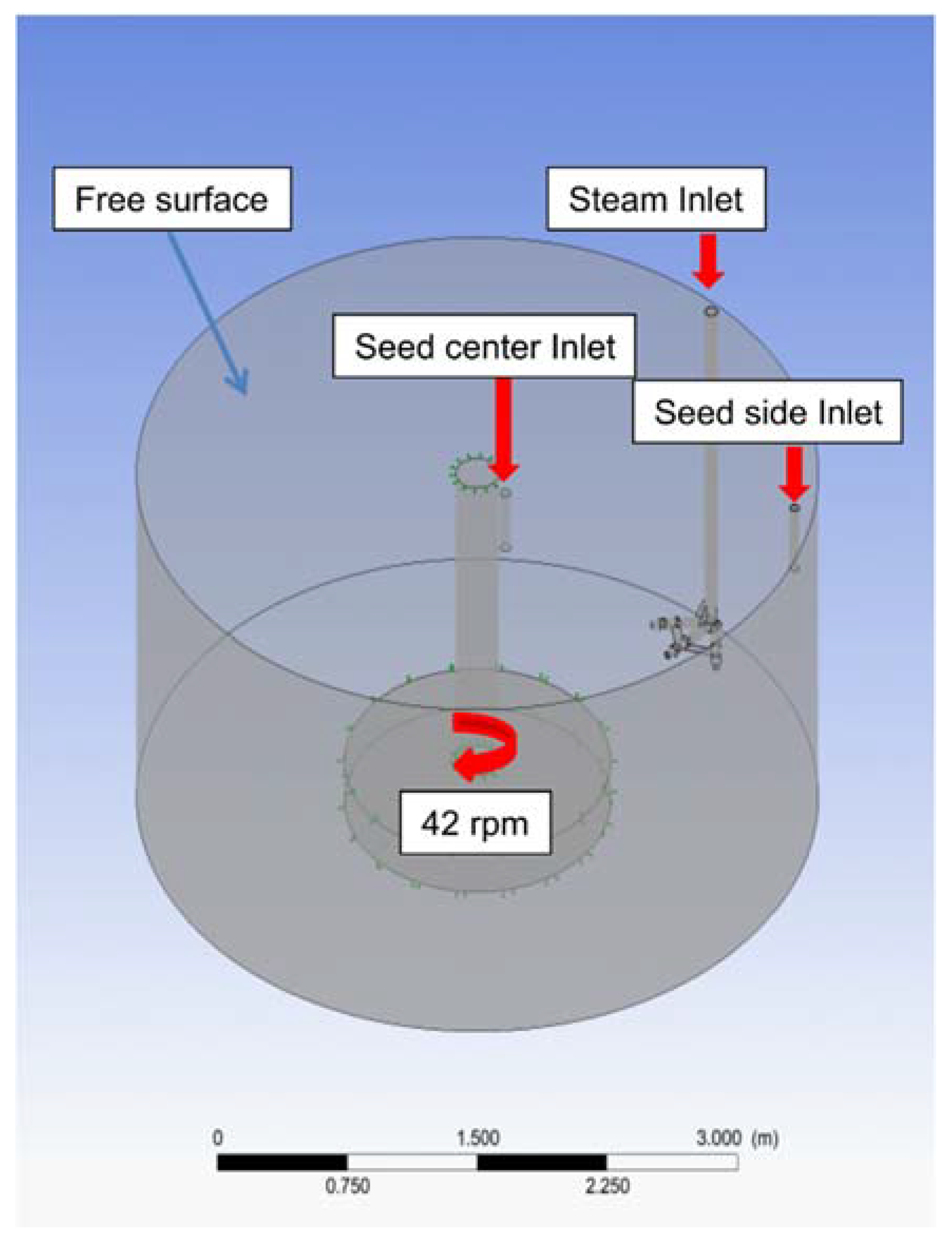

The system design consists of three essential components: the primary tank, an agitator, and a steam nozzle. The primary tank has a diameter of 3.96 meters, while the agitator measures 1.44 meters in length. The steam nozzle is equipped with three injection holes. The arrangement of these components is illustrated in Figure 1

Figure 1.

Tank, Agitator, Steam nozzle geometry.

Figure 1.

Tank, Agitator, Steam nozzle geometry.

The computational domain consists of two distinct zones: a rotating zone that includes the agitator and a fixed zone that does not contain the agitator. These two domains communicate with each other using the General Grid Interface (GGI). However, the rotation of the agitator leads to changes in the cell centers at the interface, which can decrease the accuracy of the calculations. To address this issue, a remeshing method is employed to adjust the cell centers at each time step, thereby improving the accuracy of the calculations.

In total, approximately 4 million unstructured grids are generated in the rotating zone, while 6 million unstructured grids are generated in the fixed zone. This results in a total of 10,348,194 elements and 4,885,988 nodes being constructed. The mesh generation and computational domain are depicted in

Figure 2

In order to apply the Detached eddy simulation (DES) turbulence modeling, 10 layers are generated around the blade with a growth rate of 1.05. The value of Y+ (the nondimensional distance to the wall) is set to 1, ensuring that the turbulence model accurately captures the flow characteristics near the blade.

In this simulation, two different fluids are used. The first fluid is a solution of

, which is contained in the precipitation tank and maintained at a temperature of 55°C. The second fluid is wet steam, introduced from a steam nozzle, and has a temperature of 141°C. The properties of the

solution, wet steam, and initial conditions can be found in

Table 1 below. Additionally, for the purposes of this simulation, a solid-type seed is utilized. The detailed properties of the seed are proprietary information of the company and cannot be disclosed.

Tank wall and steam nozzle surface are set with no-slip wall boundary conditions. The open boundary condition has a zero volume fraction of

, allowing only steam to flow out through the free surface. To make the simulation as realistic as possible, steam with a turbulence intensity of 30% is injected. The seed inlet is located both at the side inlet and the central part, as shown in

Figure 3, which describes the boundary conditions.

2.4. Numerical analysis of single-stage Agitator

A simulation was conducted by changing the position of the seed inlet for a 1440mm single-stage blade currently used in the field and a 1940mm blade, which had the highest mixing rate among single-stage blades [

17]. To validate a developed 3-phase multiphase CFD code, a comparison and analysis was made between the average temperature on each plane and the temperature in the field. The code validation results are explained in

Table 2 blow

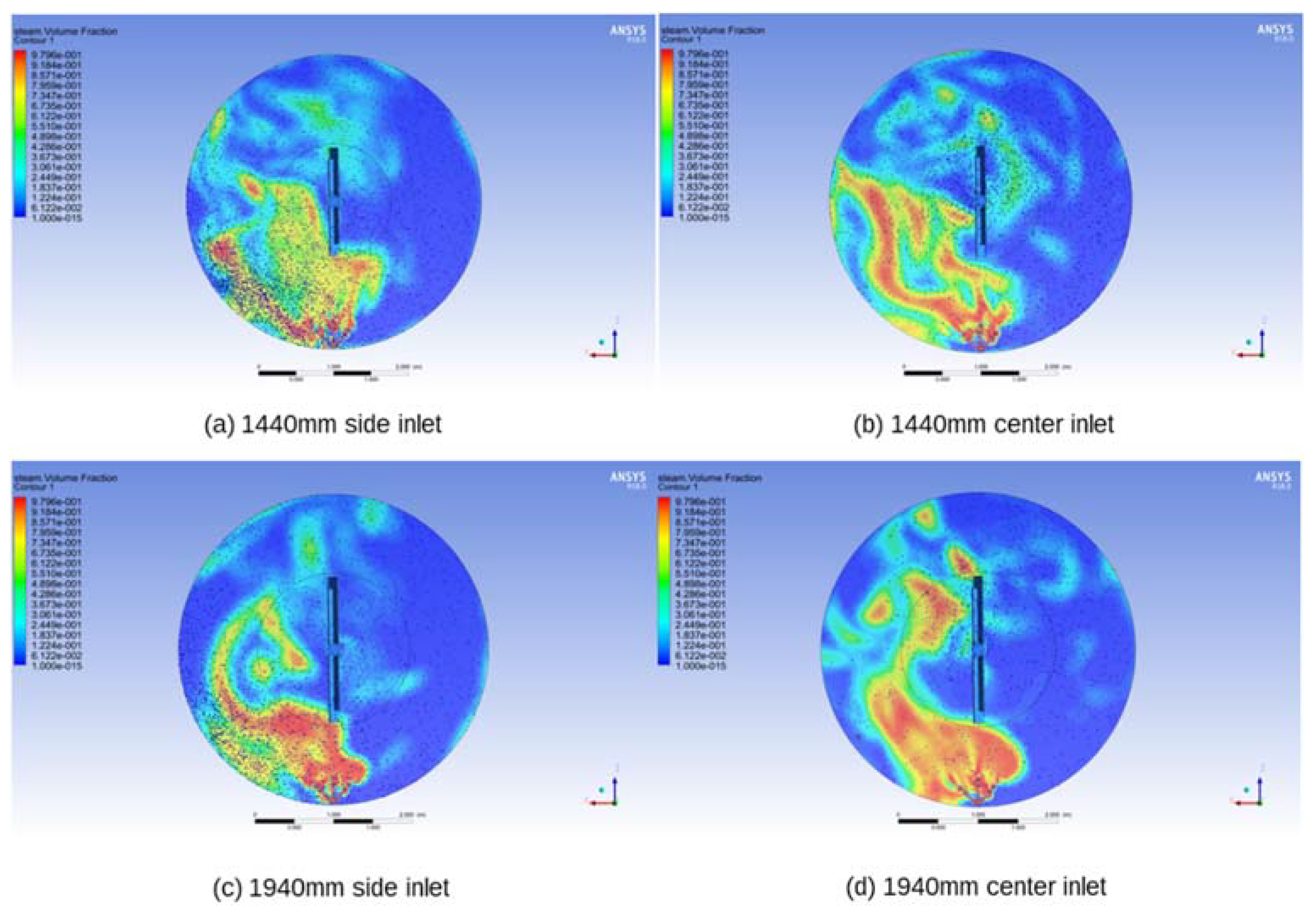

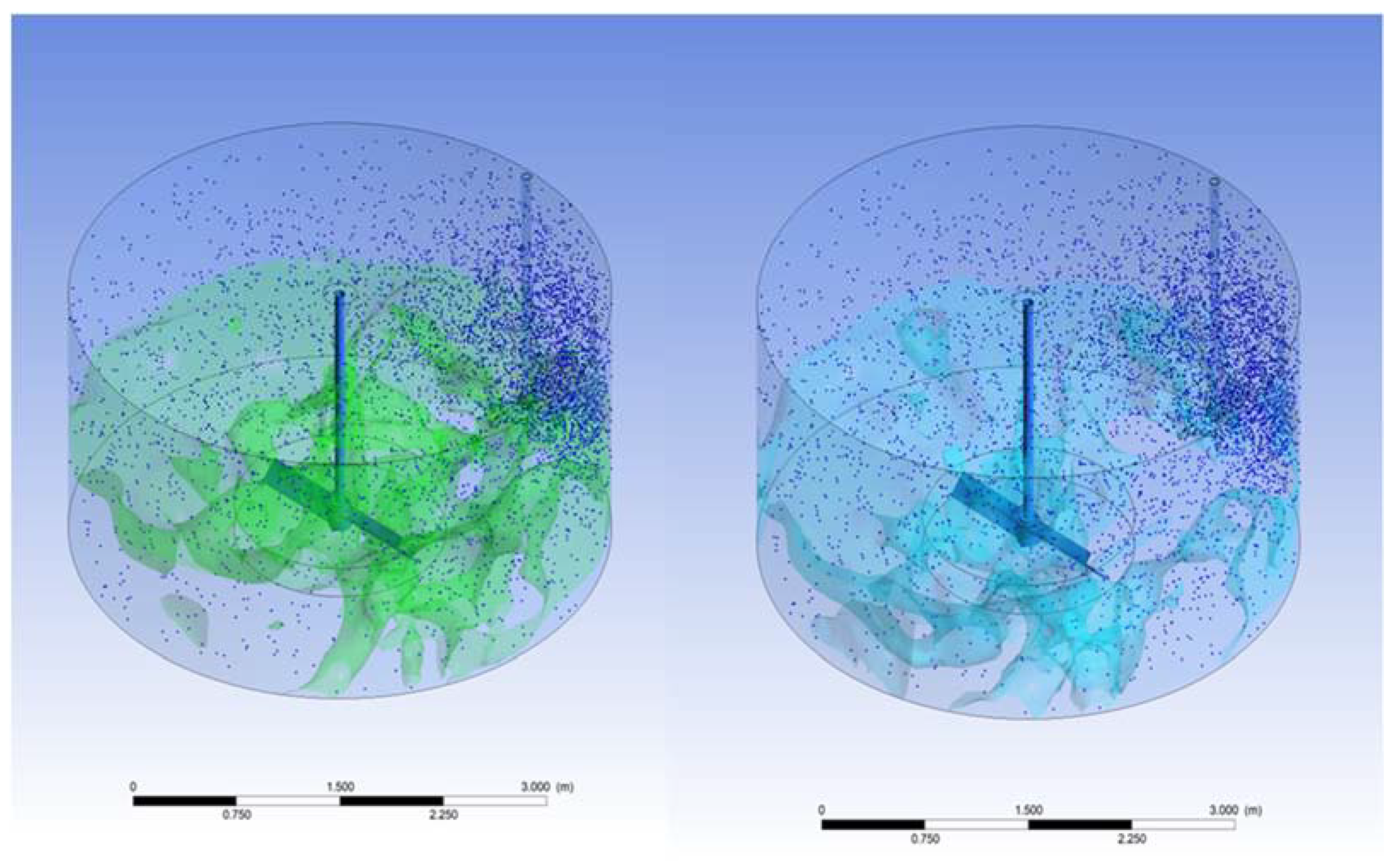

As shown in the left side of

Figure 4 represents the volume fraction of steam discharged from the steam nozzle and right side of

Figure 4 indicates the steam volume fraction from the agitator. Mass and heat transfer between steam and solution has occurred.

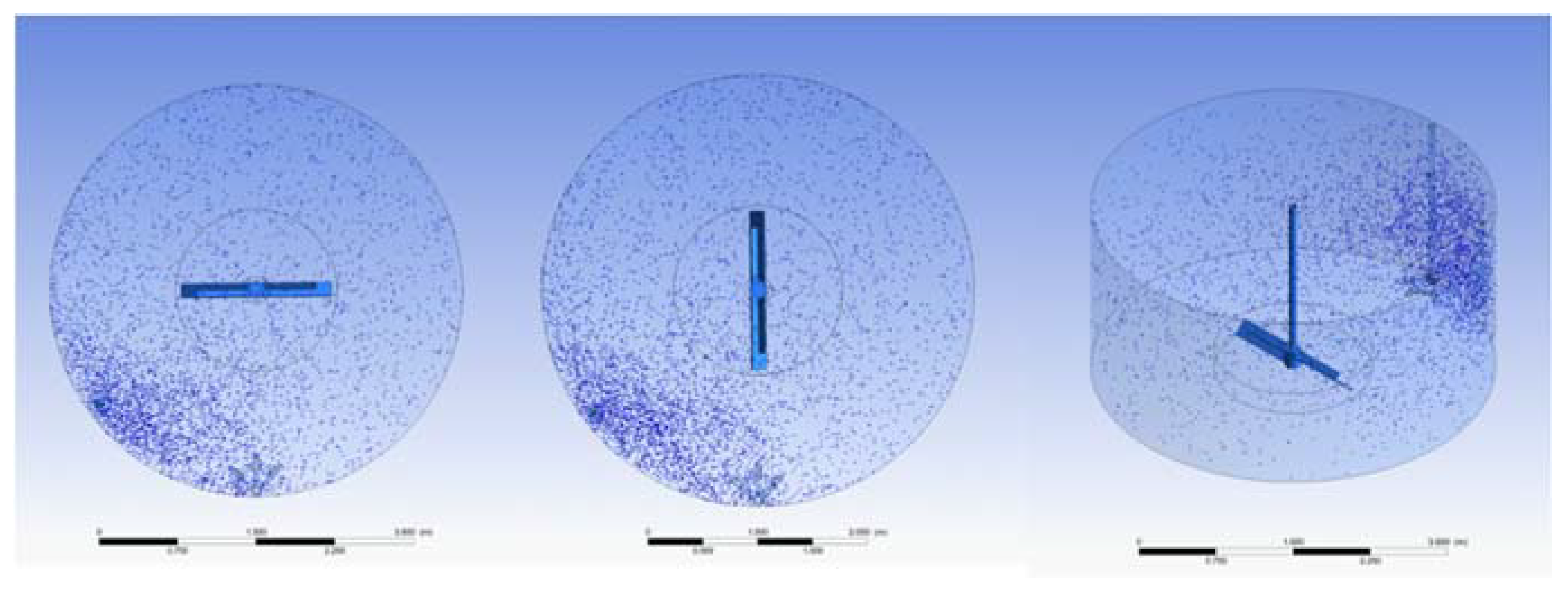

As can be seen in the Fig5. when the seed is input through the side inlet, a large amount of seed accumulates on the left side of the tank and cannot be dispersed.

Figure 5.

Top view of particle distribution.

Figure 5.

Top view of particle distribution.

The process design consists of three essential components: the primary tank, an agitator, and a steam nozzle. The precipitation occurs most actively at the initial stage when the seed is added. Therefore, the early stage of seed addition is more critical than the state where the distribution is uniformly achieved after a sufficient time. Accordingly, this study analyzes the dispersion within 5 minutes after seed addition.

It is difficult to describe the agglomeration phenomenon of nano-sized particles using CFD, and it is almost impossible to represent of primary particles. Therefore, in this paper, it is assumed that uniform-sized agglomerates grow when the injected seed is evenly distributed. When the seeds are not evenly distributed, particulates of less than 100nm are produced by heat and water, which we call pre-hydrolysis. To make a uniform particle size distribution, the optimized blade design is required to avoid pre-hydrolysis,

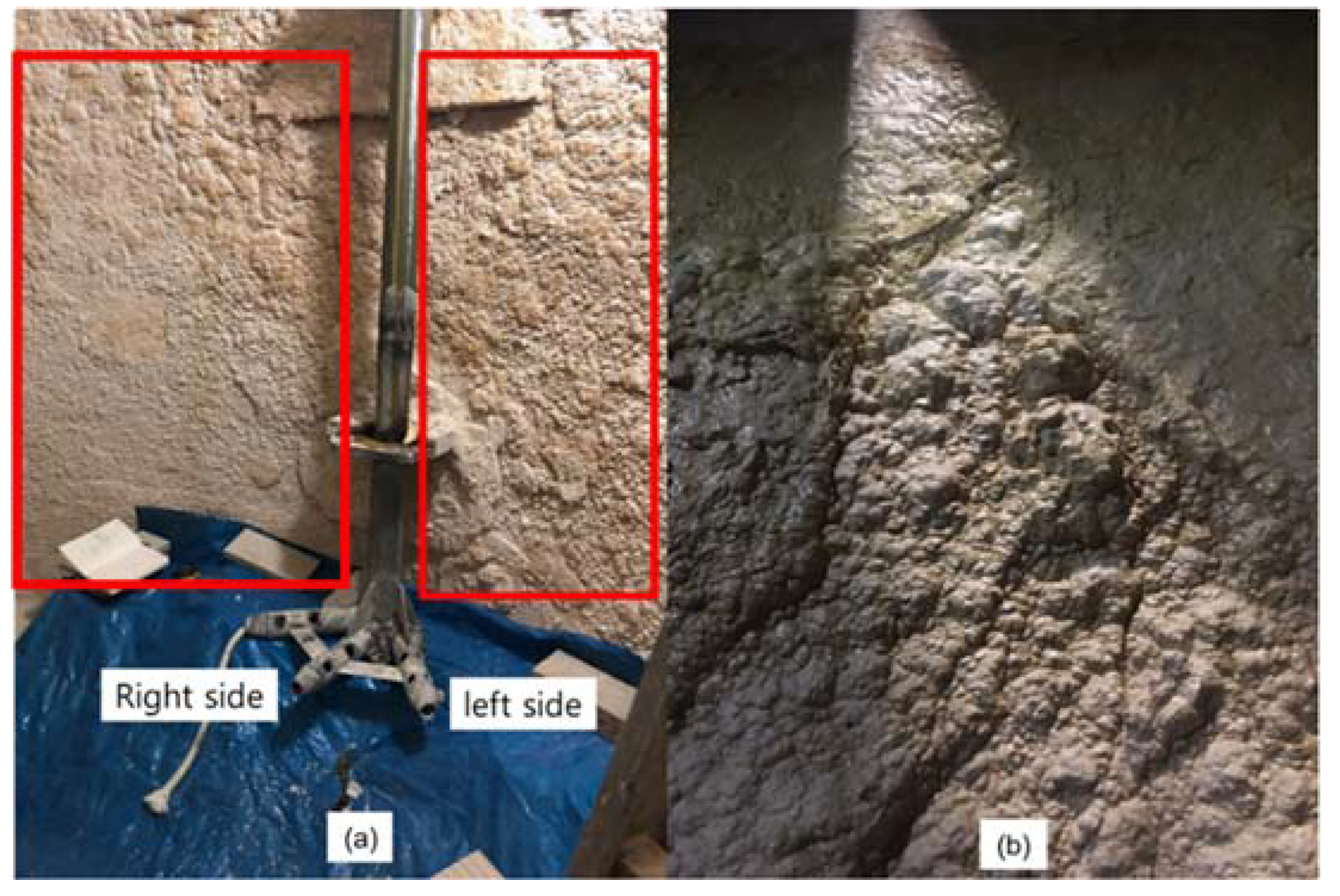

In the case of a side inlet, it was not possible to obtain uniform seed dispersion regardless of the location in a circular tank. Moreover, as shown in

Figure 6, upon observation of the actual site, a significant amount of scale was found to form in the same location where seed had accumulated, on the left side of the nozzle as predicted by the CFD simulation.

Figure 6a illustrates the region around the nozzle in the currently operated precipitation tank, demonstrating that more scale is generated on the left wall of the tank compared to the right wall.

Figure 6b provides an enlarged view of the left wall of the tank, further confirming the substantial scale formation in the area where the seed particles are not dispersed but rather accumulated, consistent with the CFD predictions.

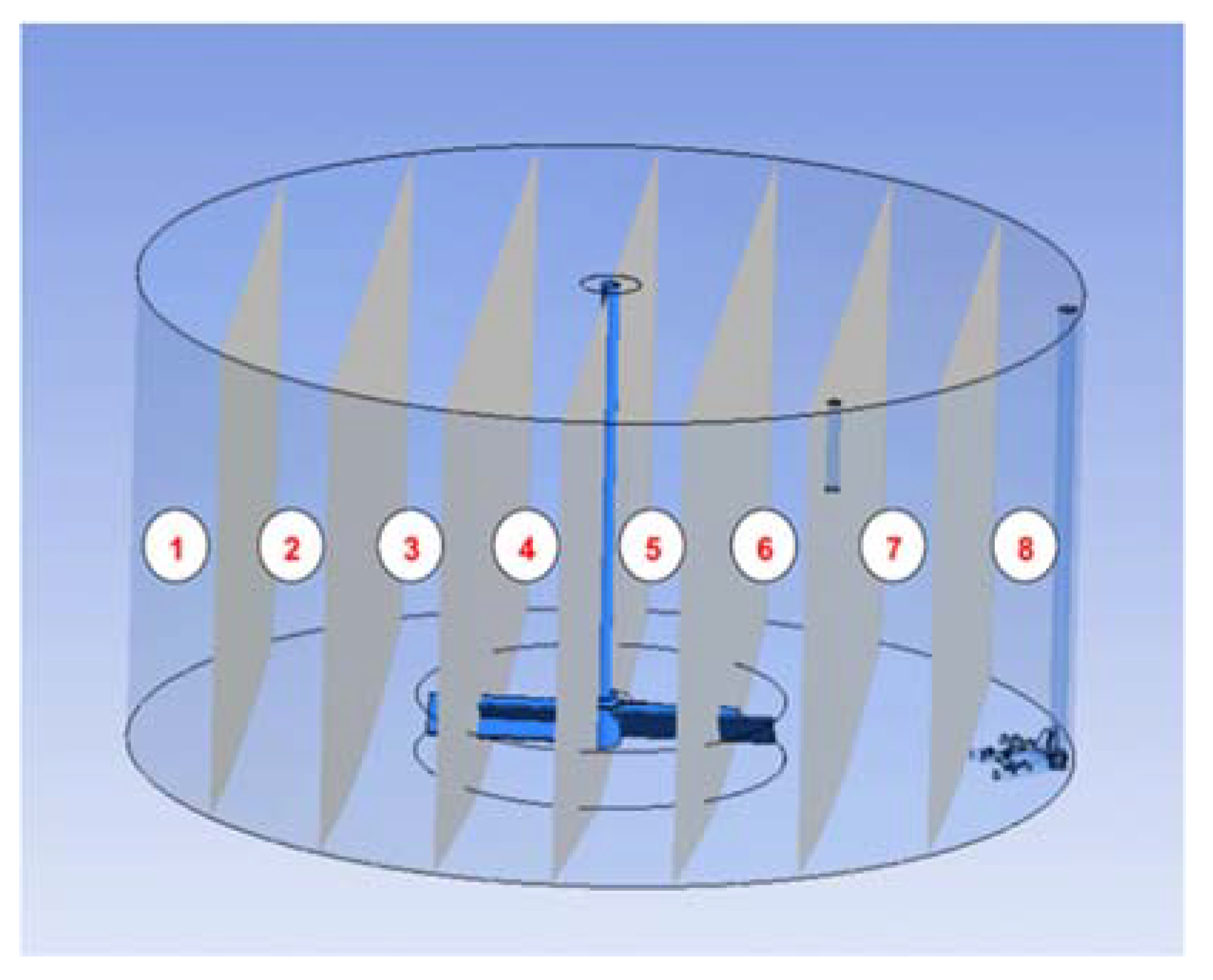

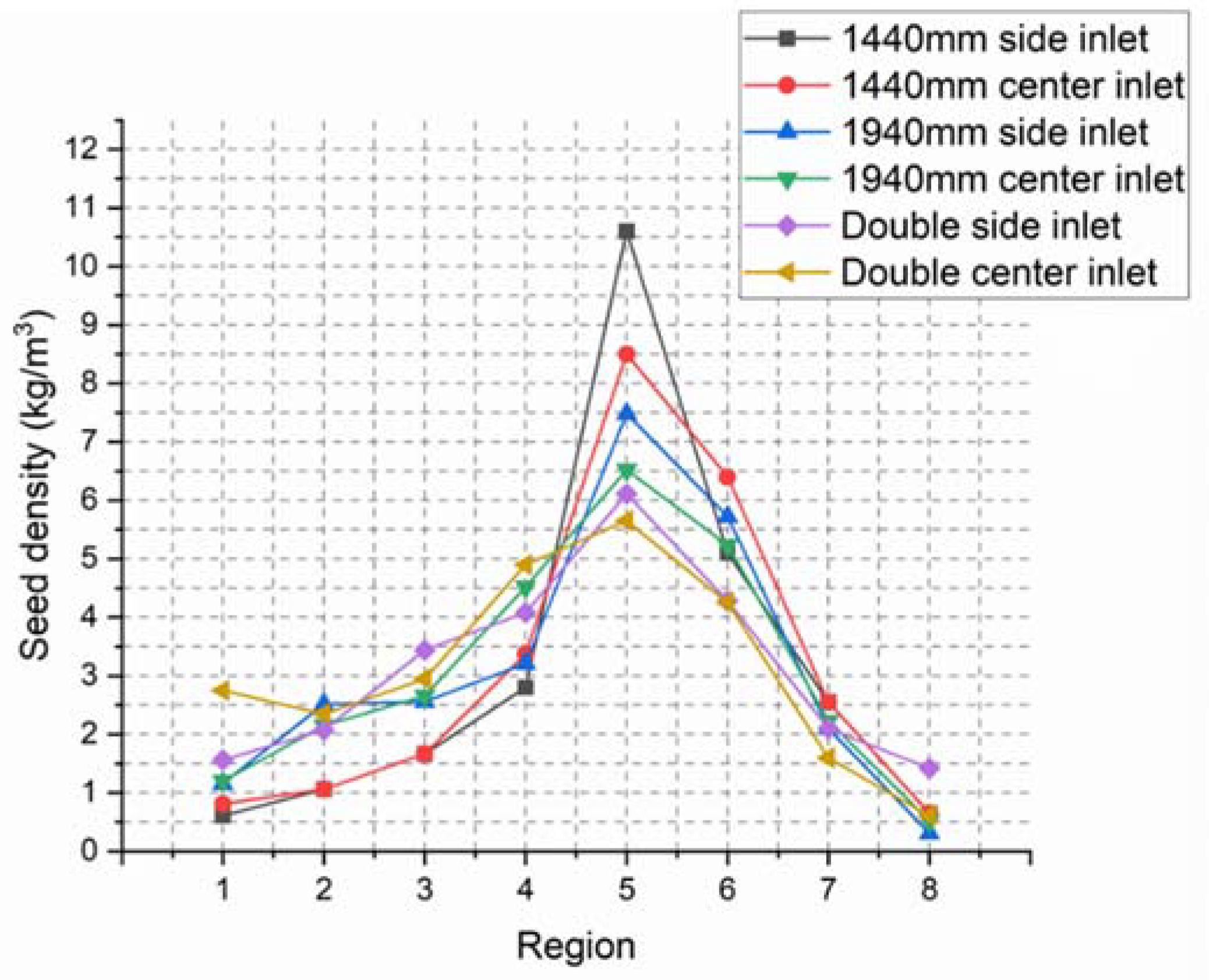

To identify the seed distribution, the tank was divided into eight sections, and the density of particles in each area was measured, as shown in the following

Figure 7 and results are presented in Figure 8

Figure 7.

8 regions of precipitation tank.

Figure 7.

8 regions of precipitation tank.

Figure 8.

Seed distribution of each region (single blade agitator).

Figure 8.

Seed distribution of each region (single blade agitator).

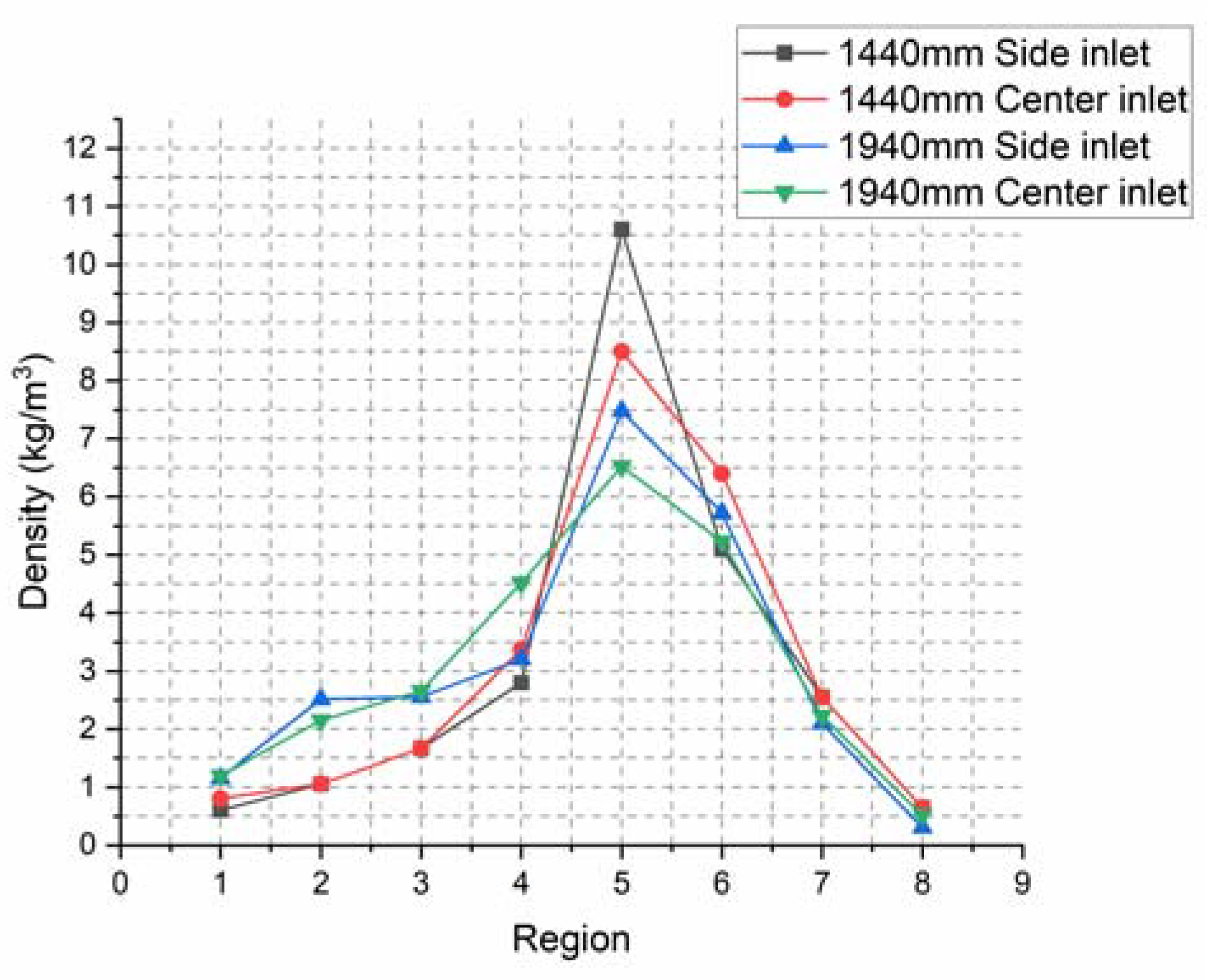

As can be seen from the Figure 8, for the side inlet, both the 1440mm and 1940mm single stage blades have the highest concentration of seeds in region 5, and the lowest distribution of seeds in zone 1. This is because the steam injected faster than the tip speed ratio reaches the wall and then rises along the wall. The risen seeds are rotated by the agitator and dispersed. Even upon inspecting the interior of the tank, it can be observed that a minimal amount of scale is generated on the wall of Region 1.

Additionally, the highest concentration of seeds in zone 5 can be attributed to the centrifugal force generated by the rotation of the agitator, which causes the seeds to spread towards both the central and wall areas of the tank. In terms of the relationship between mixing rate and dispersibility, it is evident that the seeds are more evenly dispersed with the more efficient mixing rate of the 1940mm single-stage blade. Figure 8 depicts the top view of different seed inlets for the 1440mm and 1940mm blades, respectively.

Figure 8.

Seed distribution of different seed inlet.

Figure 8.

Seed distribution of different seed inlet.

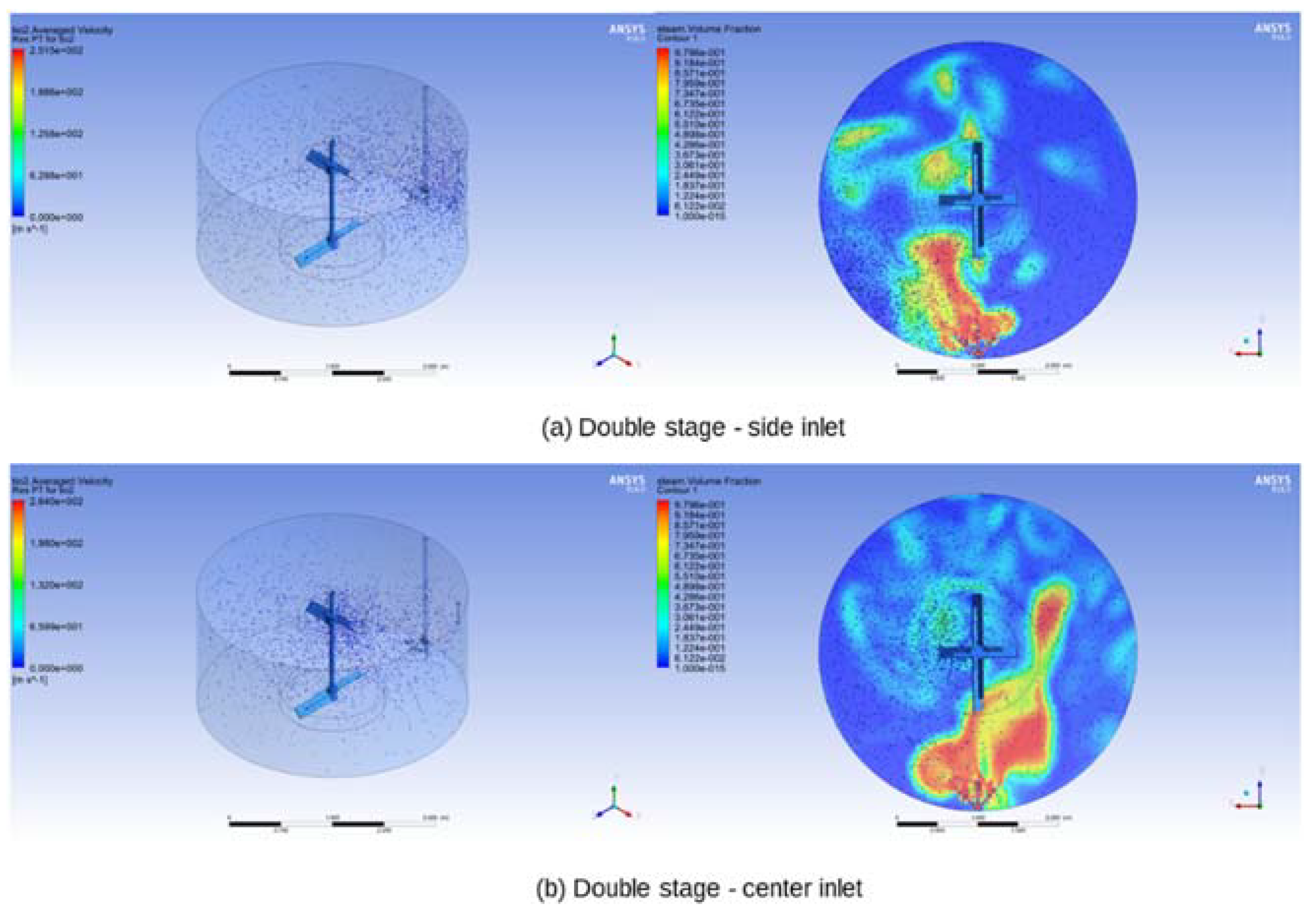

2.5. Numerical analysis of Double-stage Agitator

In Chapter 2.4, the performance of the single stage blade agitator was analyzed by changing the seed injection position. It was found that higher mixing efficiency and a more uniform distribution of the seed were achieved with a 1940mm blade compared to a 1440mm blade. Furthermore, the use of center inlet for seed injection resulted in a more uniform distribution than side inlet. The performance of a double stage blade agitator with a lower blade length of 1440mm and an upper blade length of 960mm, installed by a distance of 1400mm, was also analyzed.This optimized blade shape was explained by anothor paper[

17]. For Comparing the mixing rate of

solutoin, this study using Root Mean Square (RMS) values. The calculation of RMS is explained in Equation (6)

Where

represents the average temperature of the precipitation tank, and T represents the temperature in each cross-sectional area. Comparing the RMS values of a single blade agitator and a double blade agitator, the results are shown in the following

Table 3.

As seen from the mixing rate depending on the blade type, the optimized double stage blade showed the highest mixing rate, and it is therefore considered to have the best seed distribution. This will be also confirmed by analyzing the seed distribution. The following Figure 9 shows the particle trajectory of the seed in the double stage blade, demonstrating that even with the side inlet, it has a more uniform particle distribution than the single stage blade. Moreover, using the center inlet results in an even more uniform particle distribution.

Figure 1.

Particle distribution of seed with double stage blade.

Figure 1.

Particle distribution of seed with double stage blade.

For quantitative analysis, the tank was divided into eight regions as shown in

Figure 7, and the seed density in each region was measured agin.

It is confirmed that there is no change in the total amount of seed, and the distribution of seed for each blade can be seen in the

Table 4 and

Figure 10.

As can be seen in the above

Figure 10, there is a slight difference between the center inlet and side inlet configurations in the optimized double blade with a high mixing rate. By slightly shifting the distribution of seed towards region 1 through the center inlet, a more uniform precipitation process can be achieved.

3. Lab scale experimental results

The double-blade agitator, confirmed through CFD analysis, exhibits a superior solution mixing rate compared to the single-blade agitator currently in use. To validate chemical reactions during the seeding process, it is imperative to carry out laboratory-scale experiments and real-world field tests. To begin with, a scaled-down model experiment was conducted using an actual precipitation tank system at a ratio of 1:32.8, with the dimensions of the reduced model detailed in

Table 5.

Firstly, a reduced model experiment was conducted on an actual precipitation tank system of 1:32.8, and the dimensions of the reduced model are shown in

Table 5.

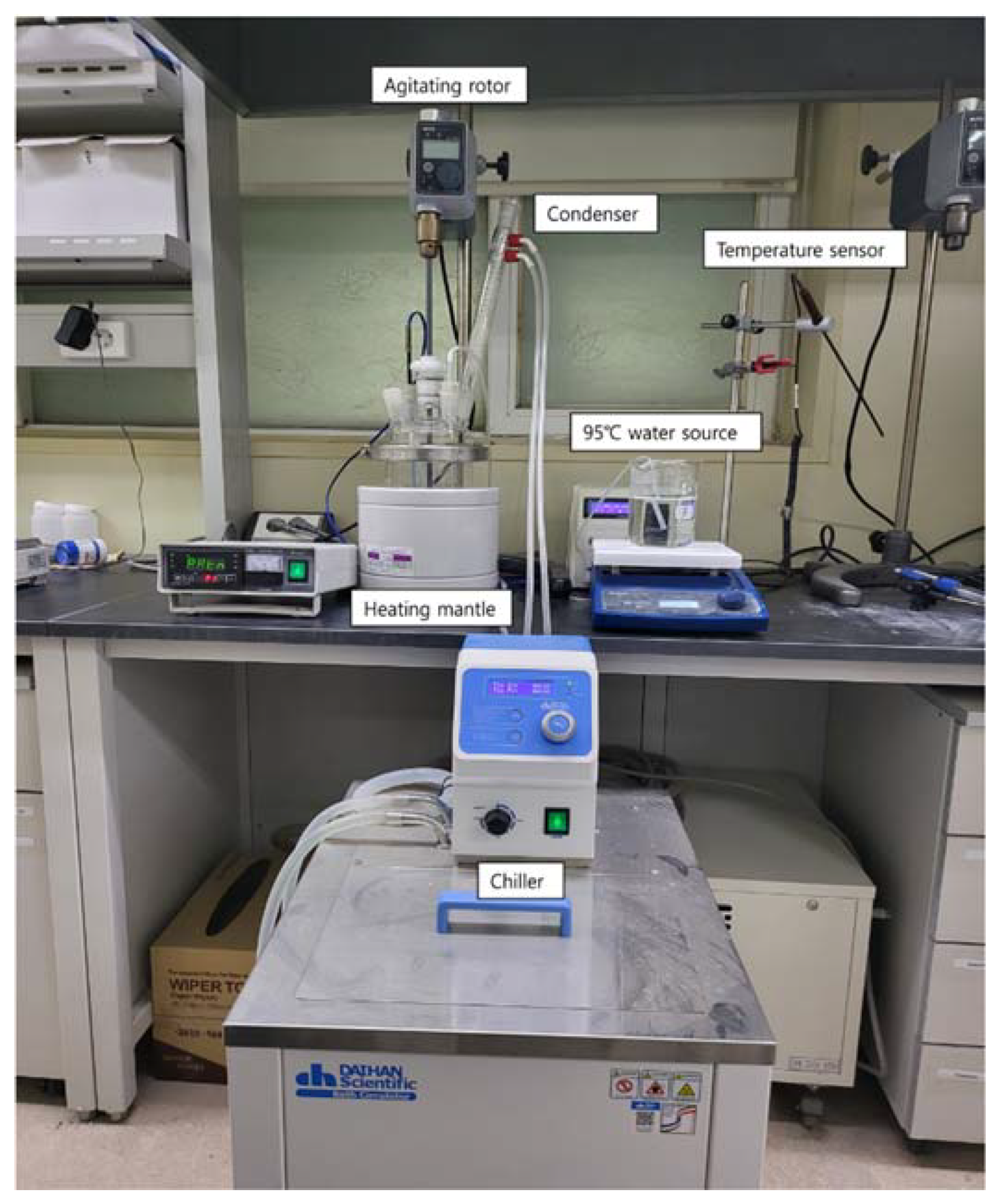

In

Figure 11 below, the explanation includes: a) the 1440mm scale reduction model, b) the 1960mm scale reduction model, and c) the double-stage blade scale reduction model. These three primary blade variations underwent testing to assess the agitator's performance. The precipitation experiment setup is illustrated in

Figure 12, with a detailed test procedure outlined in

Table 6 further below. The tests were conducted within a glass reactor. In the real-world application, steam is employed to raise the temperature. However, due to constraints in laboratory-scale experiments, which involve challenges in steam generation and maintaining a steady supply, the temperature was elevated using a heating mantle and water at 100°C. Additionally, a condenser linked to a coolant system was installed to prevent concentration effects arising from evaporation.

The temperature control system was set up for automatic operation with a predefined interval. This automated temperature control system connects a temperature sensor and a Temperature Controller to the heating mantle. The concentration of titanium (Ti) and the quenching process in the solution, used for single decomposition, typically ranges from 180g/L to 220g/L and is considered proprietary technology. Therefore, a specific quantity of water at 95°C is added to a beaker for stable test. This water is heated using a heating mantle, and any evaporated water is condensed and returned through a condenser and chiller. The precipitation process comprises several stages, including initial heating, seed injection, aging, secondary heating, and temperature stabilization. Seed injection occurs when the solution temperature reaches 96°C. The crucial aspect of seed injection is ensuring the uniform dispersion of the seed into the tank. To maintain similarity with the process, the rotational speed of the agitator is a critical factor in these laboratory experiments.

Once the precipitation process is completed, the mother liquor is subjected to filtration using a 5-micron filter until the residual iron content reaches a level of 100 mg/L. After the initial washing, water is poured onto the resulting cake, and re-pulping is carried out. The resulting solution is then mixed with sulfuric acid and aluminum powder and heated to 70°C for bleaching. This bleaching process effectively removes chromium, arsenic, and iron. Subsequently, a second washing is performed using the same method as the first washing until the residual iron content reaches 3 mg/L. The resulting solid is subjected to calcination in an electric furnace. The temperature is gradually increased from 350°C to 950°C over two hours and maintained at 950°C for one hour. Following calcination, the solid is pulverized using a pulverizer equipped with a 0.2 mm mesh. Analytical equipment such as ICP-OES, ICP-MS, XRF, and Microtrac is employed to assess heavy metal content, particle size, and distribution.

Figure 12.

Experimental apparatus

Figure 12.

Experimental apparatus

To ensure experimental similarity, selecting the Reynolds number would lead to a high RPM that exceeds testing capabilities. Consequently, we opted for the lab experiment to utilize the Froude number Equation (7), which accounts for inertia and gravity.

Where Fr is the Froude number, V is the velocity of the agitator blade (m/s), g is the acceleration due to gravity (m/s

2), and L is the diameter of the impeller (m). The rpm, which is related to the Froude number, was adjusted through checalc.com which is web application that calculates various physical properties used in chemical experiments. This web application can perform scale-up and scale-down based on criteria such as equal tip speed, power per unit volume, equal Reynolds number, Froude number, etc., using real field data. Results are described in

Table 7.

Throughout the heating process, bubbles naturally formed in both the actual field and laboratory experiments. In the actual field, these bubbles typically had a negligible size. However, in the lab tests, these bubbles had a significant impact on the mixing rate. To mitigate this effect, the initial heating was carried out with minimal heat for an extended period before seed injection. However, during the second heating stage, which required a temperature of 110°C, it was challenging to avoid bubble formation in the lab-scale experiment. Additionally, due to the influence of these bubbles, it was difficult to discern the differences between the side inlet and center inlet methods of seed injection in the experiments.

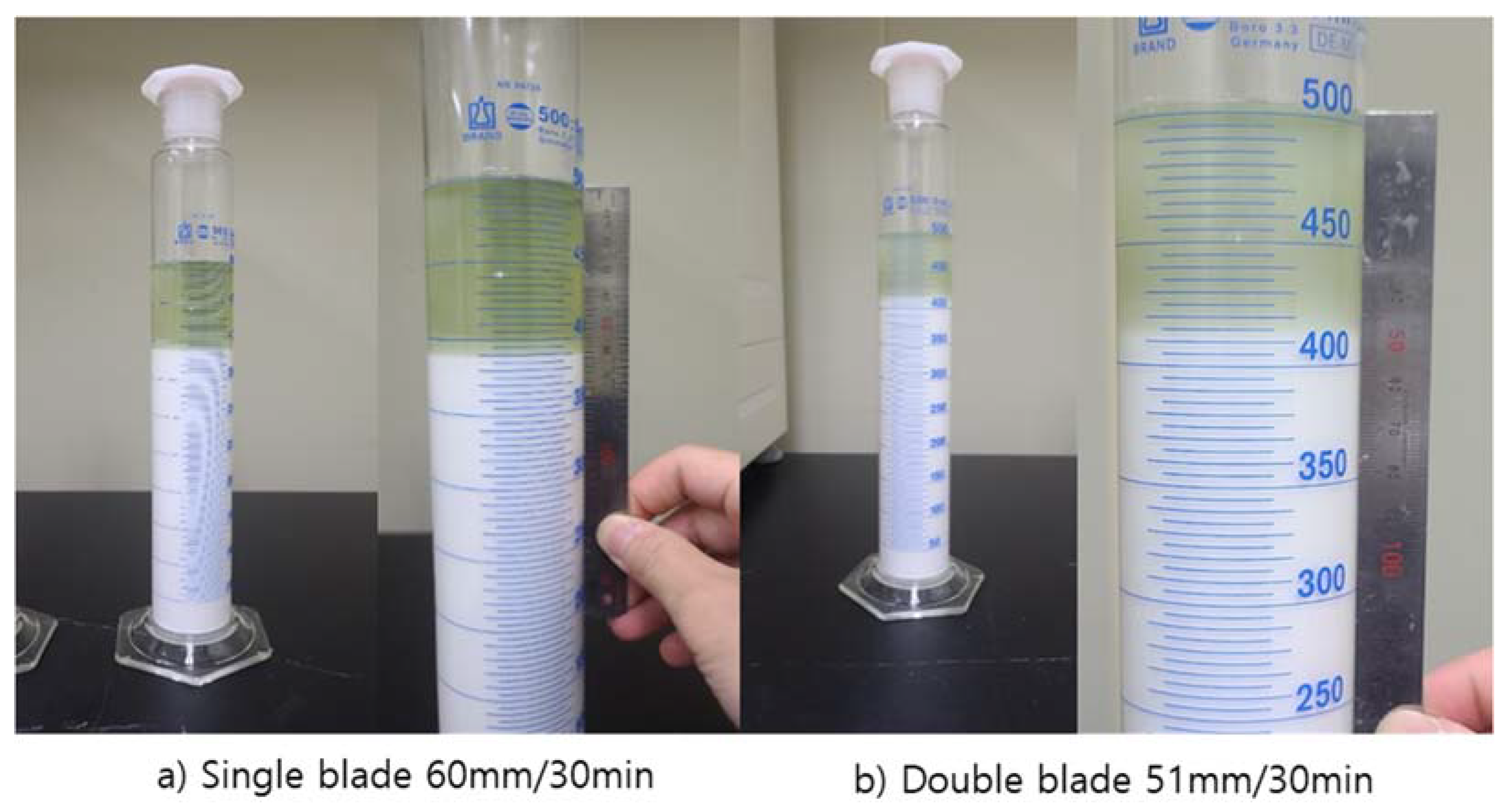

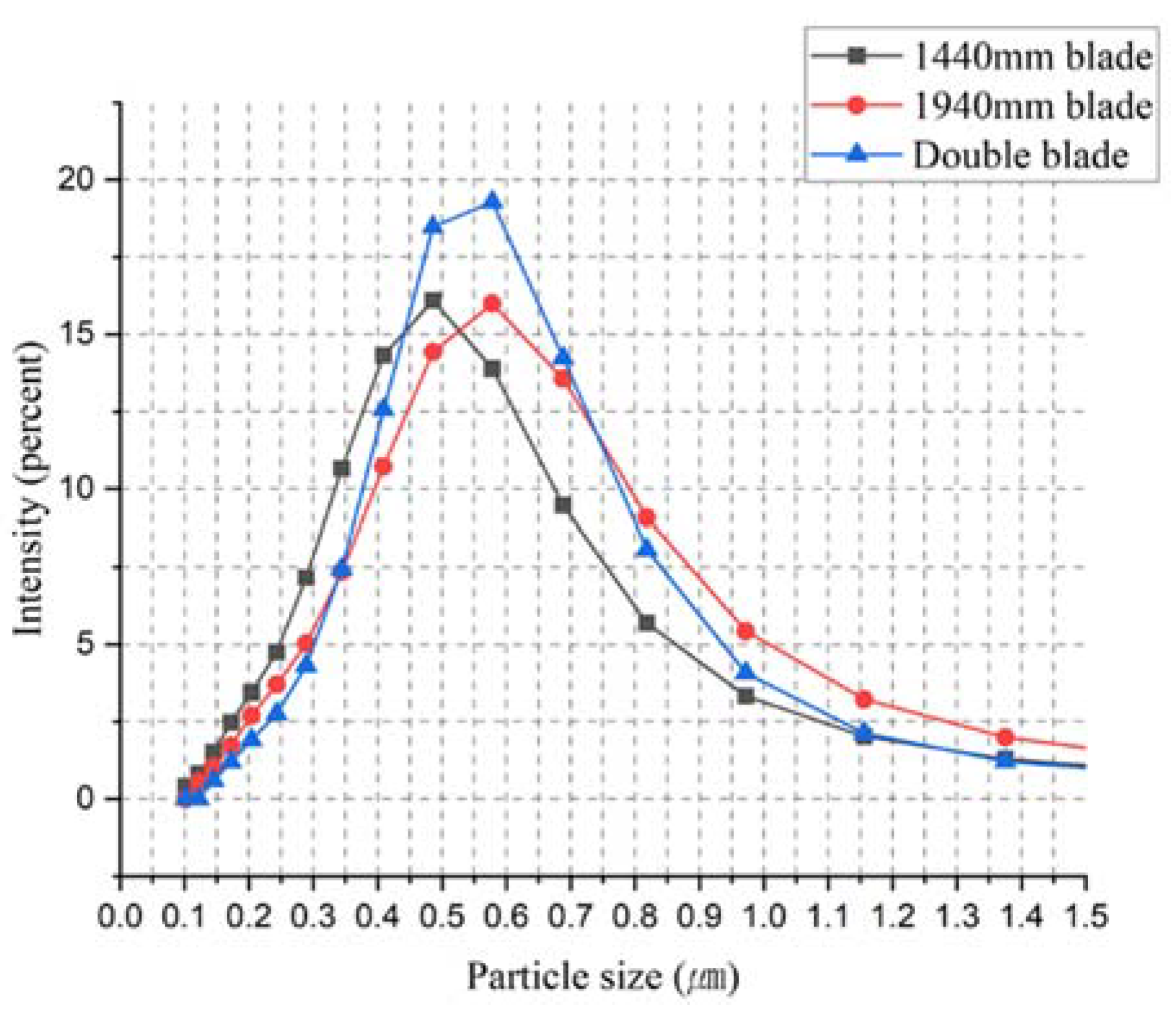

Nonetheless, as illustrated in

Figure 13 below, the particle distribution in experiments utilizing a double-stage blade configuration was superior to that of a single-stage blade. Each test was conducted three times, and the average data from these test results were compared.

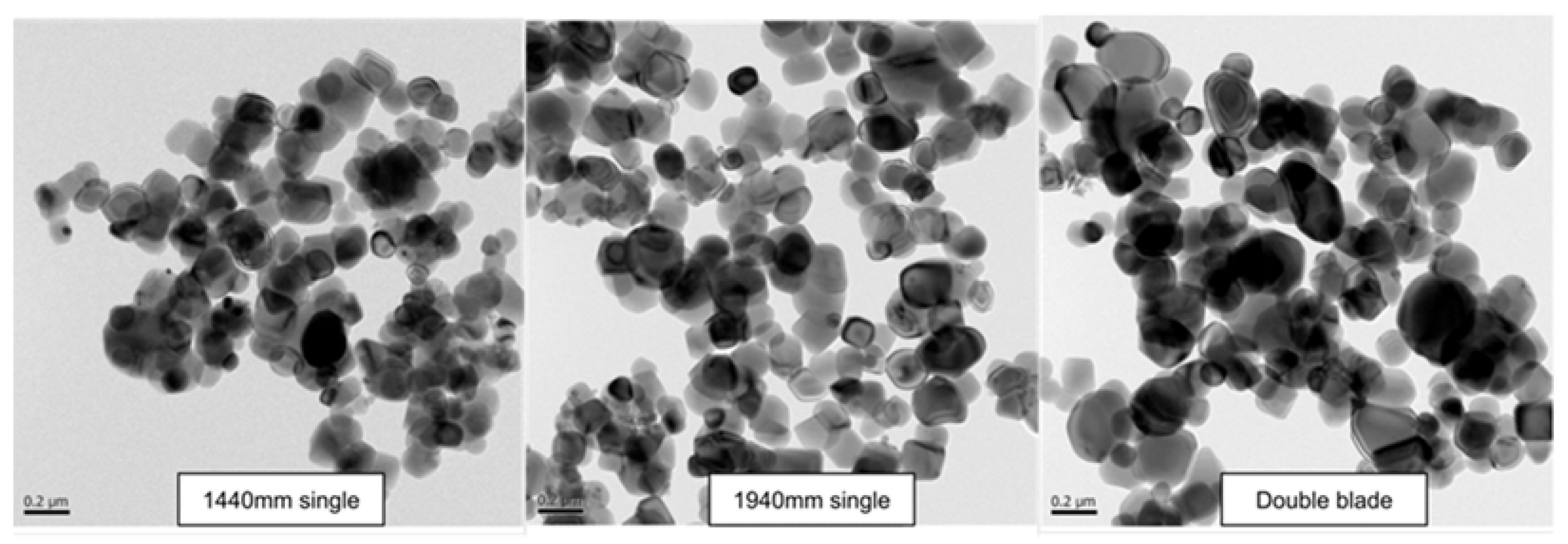

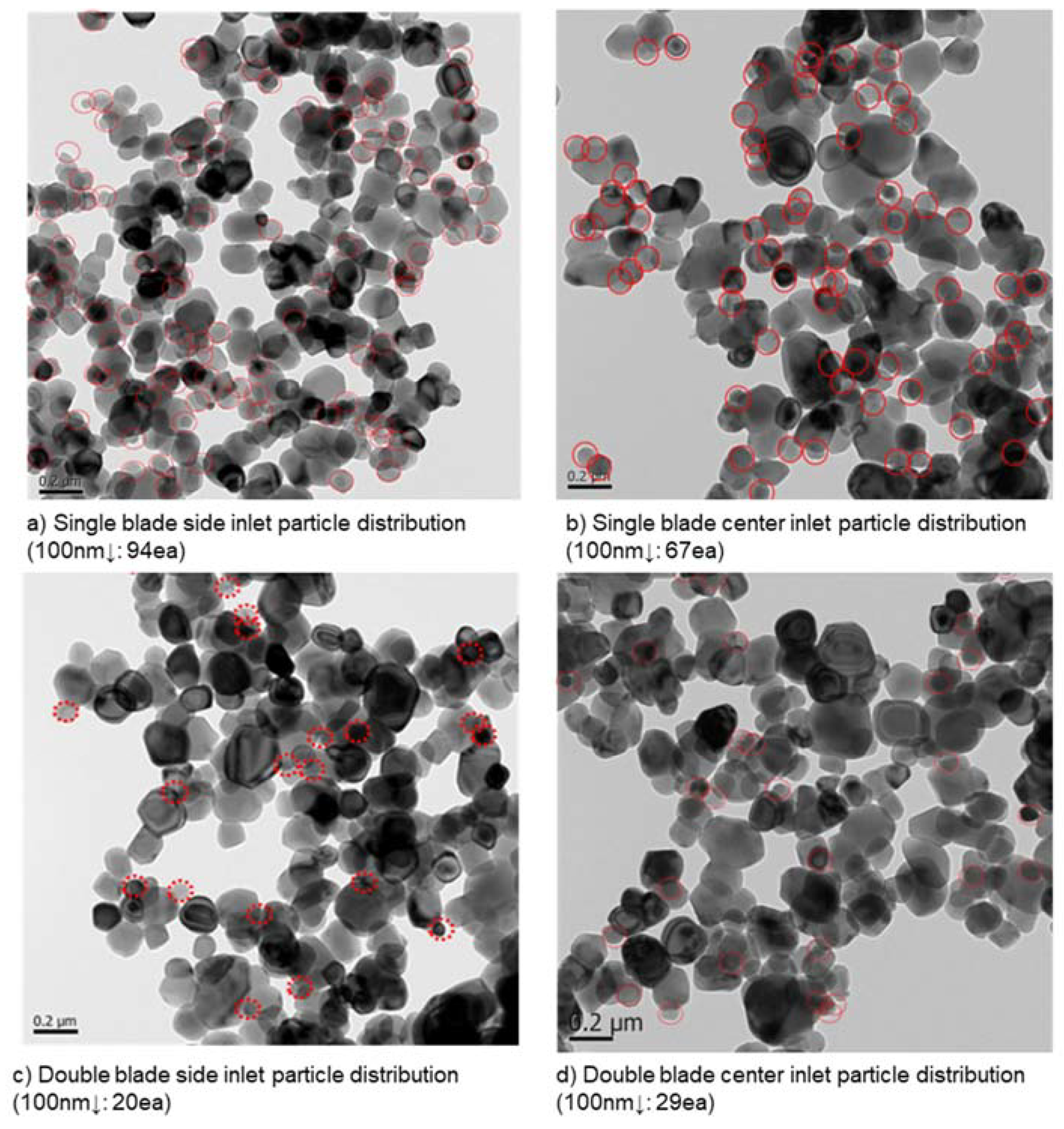

Figure 14 provides an explanation of the Transmission Electron Microscopy(TEM) analysis.

4. Actual field test results

For the Actual field test, one of the precipitation tanks in operation was set double-stage blade verified with CFD and a lab-scale test. The single and double-stage blades are explained in

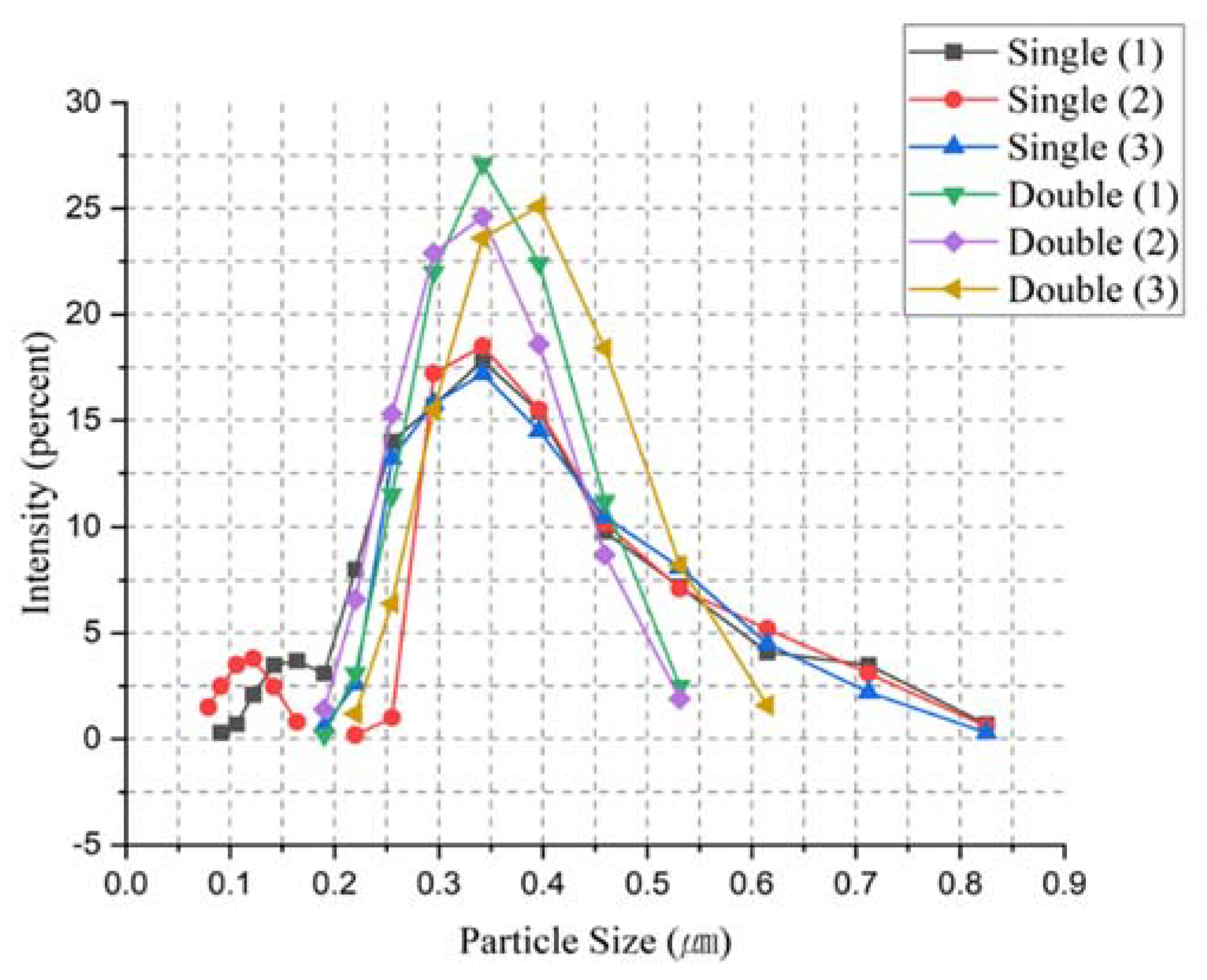

Figure 15. Take the liquid samples from two different types of precipitation tanks and analyze particle distribution. The particle distribution is explained in

Figure 16. Malvern planetary was used to analyze particle size distribution

Figure 17 is a TEM photograph of the particle distribution. Several fine particles less than 100nm were counted in single-blade cases, and the uniformity of particle size distribution was increased compared to a single-blade.

In this study, a settling value test, widely employed for assessing particle size uniformity, was conducted. Subsequently, we aim to perform a comparative analysis of particle distribution between the single blade and double blade configurations. The settling value test involves diluting 114ml (190g/L ) of the hydrolyzed solution with 300ml of water. After cooling to 25 degrees, additional water is added to make up a 500ml solution. After 30 minutes, the suspension length is measured. A high settling value indicates a broader accumulation of smaller particles in the gaps between larger particles, resulting in a longer suspension length. On the contrary, a low settling value demonstrates that larger than 400nm particles are uniformly generated and there are significant presence of voids between particles.

This study determined that the optimal washing efficiency of the Moore Filter (MF) used in the Cosmo chemical process was 50 mm/30 min. It was found that the 1440 mm single-blade and side inlet, which had the lowest mixing rate in this study, had a settling value of over 67. The increase in settling value indicates that the development of flocs between particles is high and that there is a significant difference in particle size. The following Figure18 and

Table 8 represent the results of the settling value test for single blade and double blades with center seed inlet.

Figure 18.

Settling value test for single and double blades

Figure 18.

Settling value test for single and double blades

5. Results

This study primarily focuses on optimizing the operational parameters of the precipitation process through Multiphase CFD simulation, lab scale experimental and actual field tests, with the main goal of achieving a uniform particle size distribution. A Fluid-Gas-Solid coupled multiphase solver, explicitly tailored for handling precipitation involving solid-type seeds, was developed. This 3-phase CFD solver enables the identification of the distribution and trajectory of seeds that cannot be visually observed, establishing a strong correlation between the mixing rate and seed distribution.

As the mixing rate of the solution and steam increased, a more uniform distribution of seeds was achieved, effectively minimizing pre-hydrolysis in areas devoid of seeds. Consequently, the utilization of a double-stage agitator with a high mixing rate resulted in a notable decrease in the number of particles below 100 nm, accompanied by a pronounced centralization of the particle distribution. Moreover, it was observed that using a center inlet for seed injection in a single-stage blade yielded a more uniform seed distribution compared to a side inlet.

In the context of a double blade, which boasts a high mixing rate, both side inlet and center inlet configurations produced uniform seed distributions. However, using a center inlet demonstrated superior performance by ensuring an even particle distribution through the uniform supply of seeds to the opposite side of the nozzle. This uniform particle distribution not only facilitated consistent precipitation but also hindered the formation of particles smaller than 100 nm.

In conclusion, the optimized blade, as validated by CFD, demonstrated exceptional mixing capabilities during field experiments within the precipitation process. It not only ensured a uniform temperature distribution of solution but also created a consistent seed distribution. Additionally, by operating the precipitation process uniformly and stably, particles with a uniform size could be produced. This enhanced uniformity in distribution played a pivotal role in improving settling value and filtration seconds. The optimization of the precipitation process, as the key outcome of this research, had a significantly positive impact on the subsequent washing process. This resulted in a substantial improvement in productivity efficiency and played a pivotal role in the high-quality production process of .

Acknowledgement

This research was supported by COSMO Chemical Co., Ltd.

References

- Kristen, G.; lvana, F.; Emanuele, C.; Julia, K. Distinctive Toxicity of Rutile/Anatase mixed phase nanoparticles, Chem. RES.Toxicol. 2012, 25, 646–655. [Google Scholar]

- Braun,J. H.; Baidins,A.; Marganski, R.E. A Review of the production cycle of Titanium dioxide pigment, A review. Prog. in org. coating, 1992, 20, 105–138. [Google Scholar]

- Kang J.S; Toru, H.O. Production of Titanium Dioxide Directly from Titanium Ore through selective Chlorination using Titanium Tetrachlorie. Mater.Trans, 2014, 55, 591–598. [Google Scholar] [CrossRef]

- Laware, S.L.; Shipha, R. ; Effect of Titanium Dioxide Nanoparticles on Hydrolytic and Antioxidant Enzymes druring Seed Germination in Onion, Int. J. Curr. microbio. 2014, 3, 749–760. [Google Scholar]

- Egor, A.; Moskalenko, A.A.; Sadovnikov, A.E. Synthesis of Nanocrystalline Titania via Microwave-Assisted Homogeneous Hydrolysis under Hydrothermal Conditions, Curr. Microw. Chem., 2014, 1, 81–86. [Google Scholar]

- Albena, B.N.; Stancho, Y.; Reni, I.; Irina, S. The Solvent Role on the Hydrolysis-Condensation Process and Obtaining of TiO2Nanopowders, J. Chem. Technol. Metall., 2018, 54, 292–302. [Google Scholar]

- Min, Z.; Naofumi, U.; Takashi, K.; Kazuyuki, K. Characterization of TiO2 Photocatalyst Nanoparticles Prepared by Low Temperature Hydrolysis Reaction of Alkoxides, Proc. Int. Eco. Sci., 2007, 1, 788–790. [Google Scholar]

- Andreas, L.; Thomas, S.; Permorsing, L. Urea decomposition and HNCO hydrolysis studied over titanium dioxide, Appl. Catal., B, 2011, 106, 273–279. [Google Scholar]

- Windler, L.; Lorenz., C; Nvon, G.; Hungerbuhler, K. Release of Titanium Dioxide from Textiles during washing. Environ. Sci. Technol. 2012, 46, 8181–8188. [Google Scholar] [CrossRef] [PubMed]

- Zouhir, E.; Allouni, H.; Mihaela, R.; Cimpan, P.; Hol, J. Agglomeration and sedimentation of TiO2 nanoparticles in cell culture medium. Colloids Surf., B. 2009, 68, 83–87. [Google Scholar]

- Allisonk, M.H.; Andrea, C.N. ; Randall, E; Mielke, H, Dispersion of TiO2 Nanoparticle Agglomerates by pseudomonas aeruginosa, Appl. Environ. Microbiol. 2010, 76, 7292–7298. [Google Scholar]

- Plazl, I.; Leskovsek., S.; Koloini, A. Hydrolysis of sucrose by conventional and microwave heating in stirred tank reactor. Chem.Eng.J. 1995, 59, 253–257. [Google Scholar] [CrossRef]

- Barbara, G.; Daniel, G.; Bogumil, K. Effects of Processing Parameters on Hydrolysis of TiOSO4, J. Chem. Technol., 2009, 11, 15–21. [Google Scholar]

- Kim, K.D.; Lee, T.J.; Kim, H.T. Optimal Conditions for Synthesis of TiO2 Nano Particles in SemiBatch Reactor, Colloids Surf. A Physicochem. Eng. Asp., 2003, 224, 1–9. [Google Scholar] [CrossRef]

- Thong, L.B; Gyula, G.; Vincent, O.O. A CFD Study on Heat Transfer Performance of SiO2-TiO2 Nanofluids under Turbulent Flow, J. Nanomater, 2022, 12, 299–302. [Google Scholar]

- Kaya, H.; Ekiciler, E.; Arslan, B. CFD Analysis of laminar forced convective heat transfer for TiO2/water nanofluid in semi-circular cross-section micro- channel. J. Ther. Eng. 2019, 5, 123–137. [Google Scholar]

- Han, J.H.; Hyojong, K.; Dohyoung, L. Parametric study of agitator in TiO2 precipitation tank using multiphase CFD simulation and experiments, J. Enhanced heat transfer, 2023, 30, 1–20. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).