Submitted:

06 September 2023

Posted:

08 September 2023

You are already at the latest version

Abstract

Keywords:

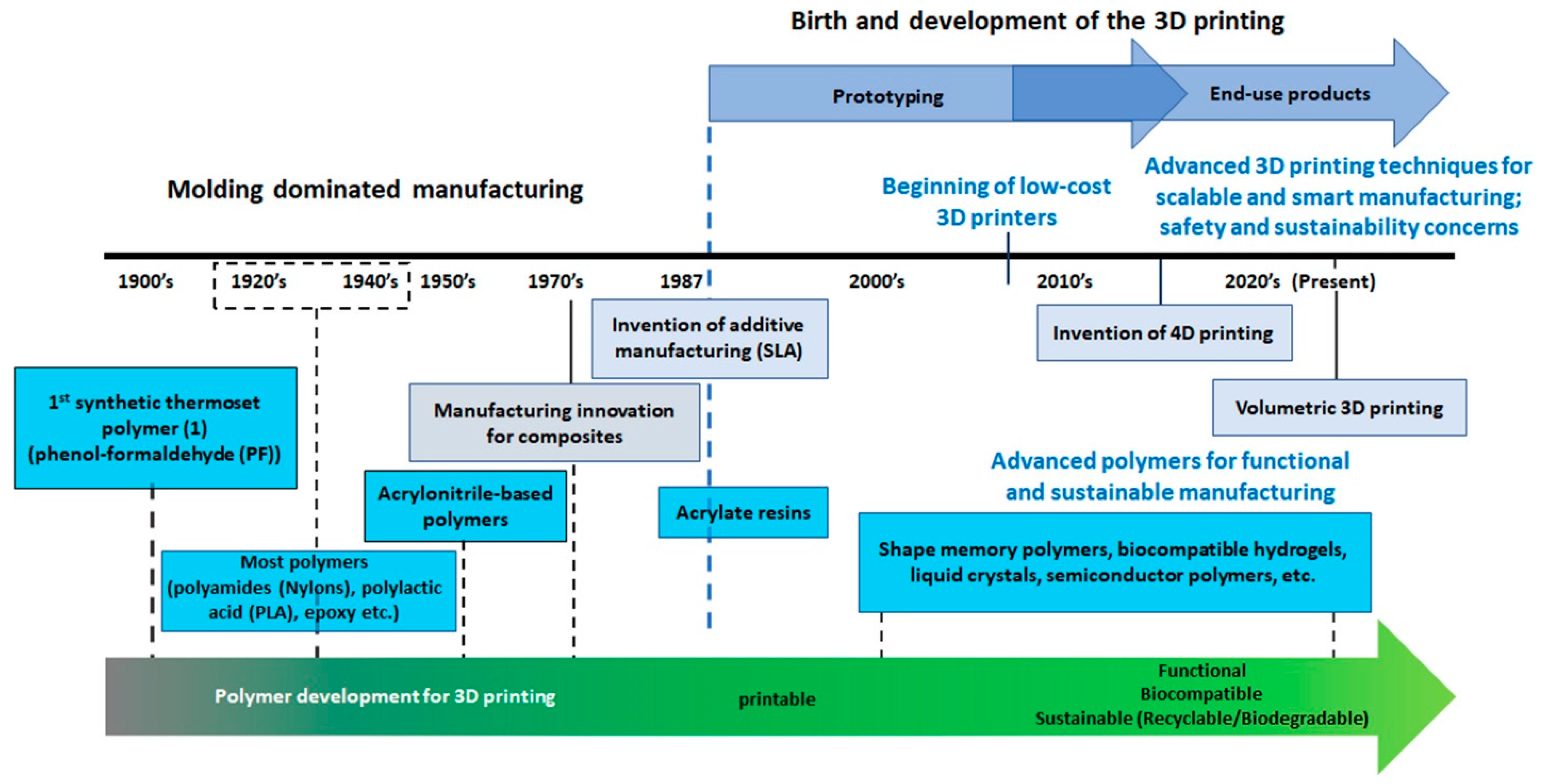

1. Introduction

2. 3D printing materials

2. 3D printing technologies

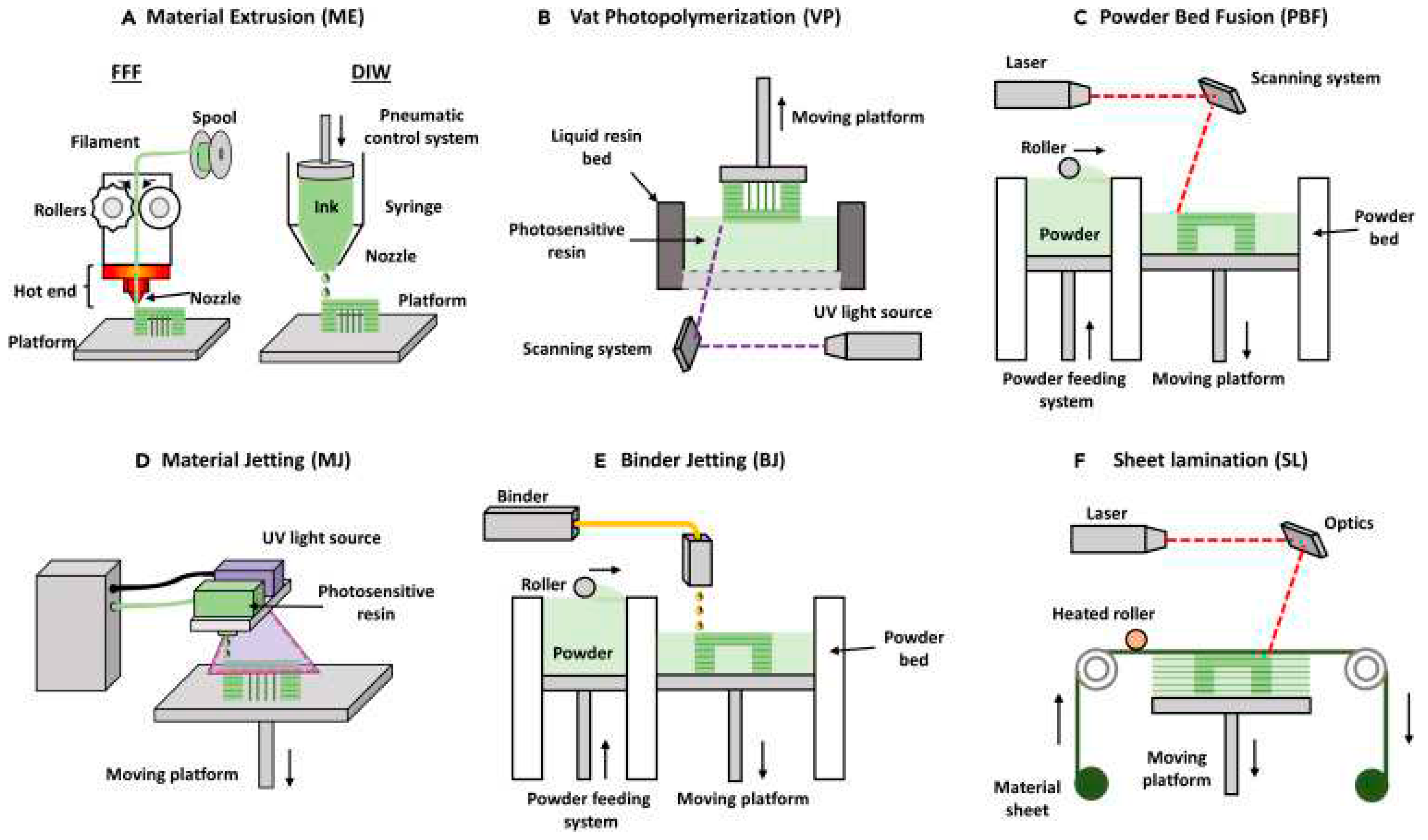

Extrusion material

Vat polymerization

Powder bed fusion

Material stream

Binder blast

Directed energy deposition

Sheet lamination

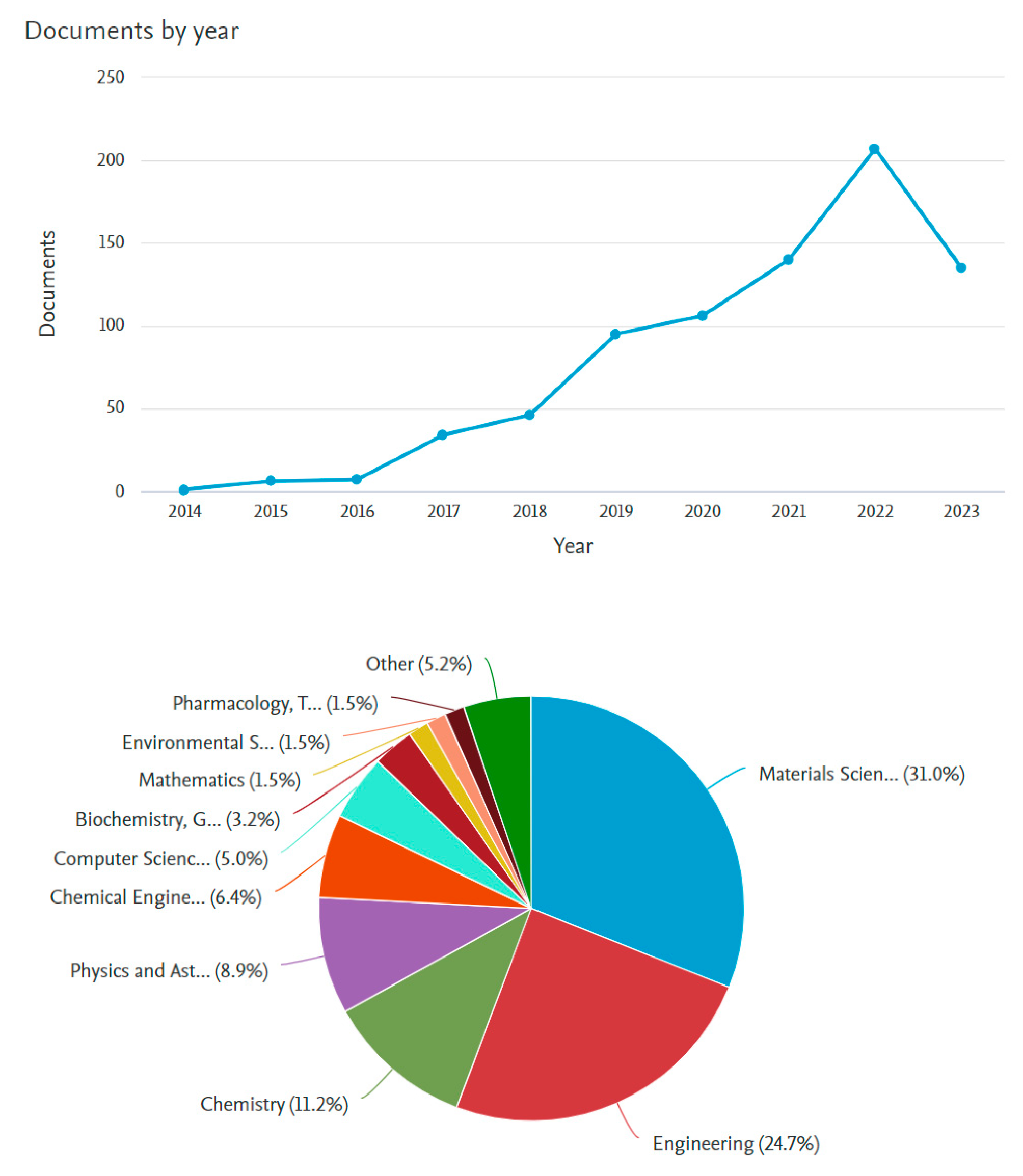

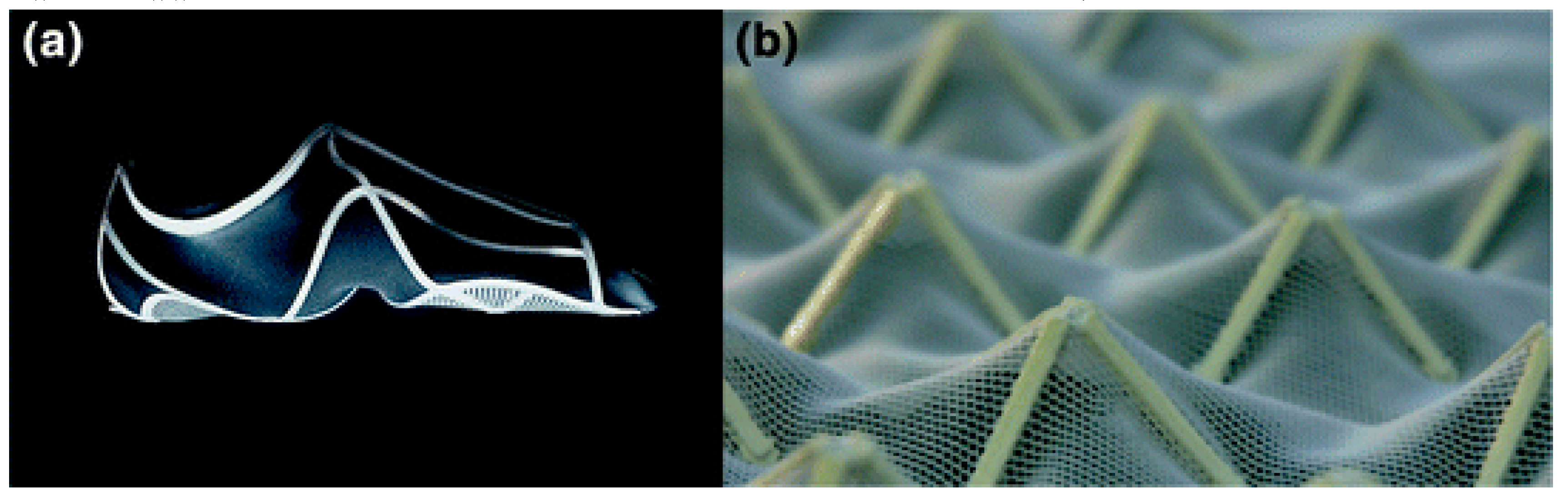

3. Additive manufacturing in textiles

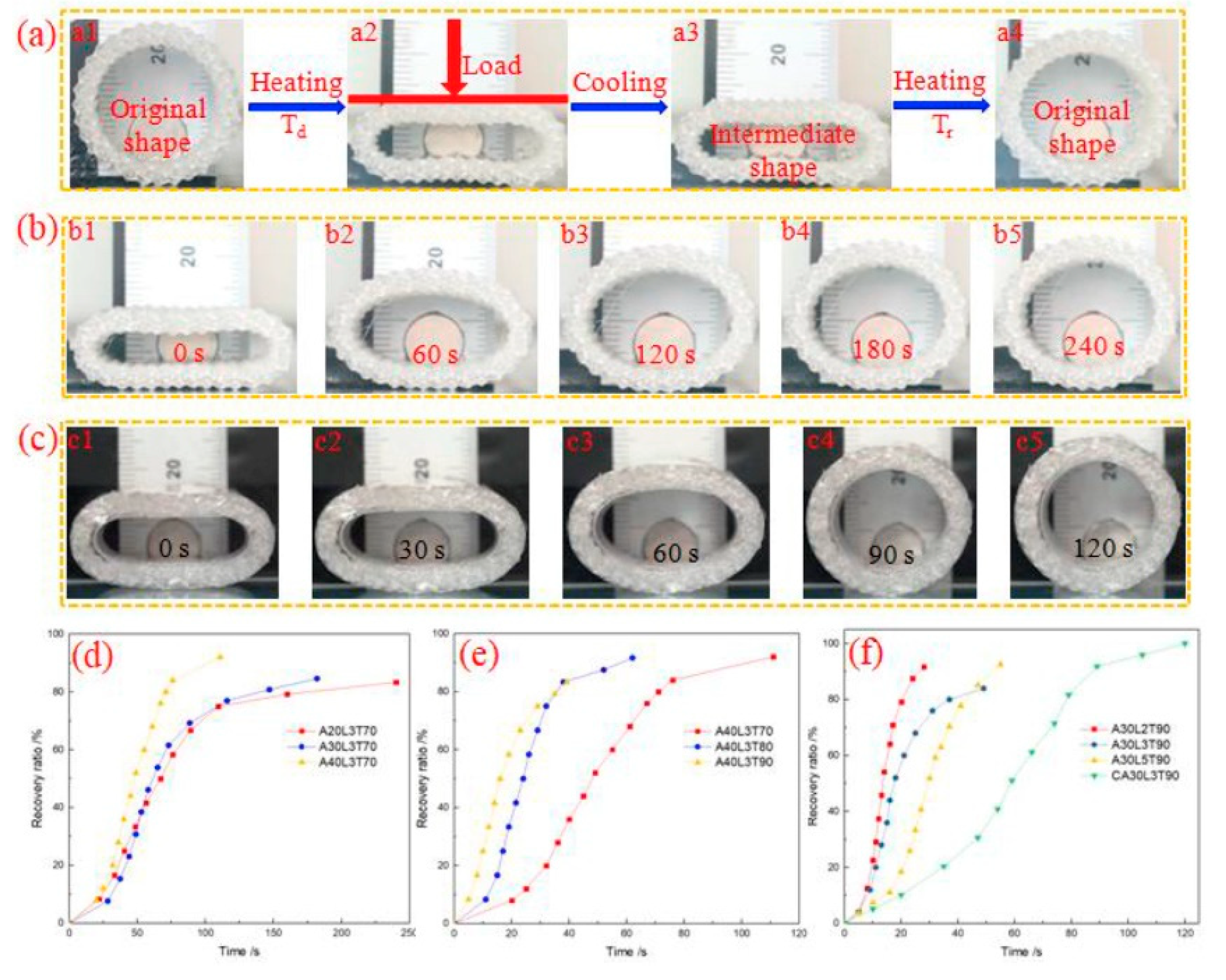

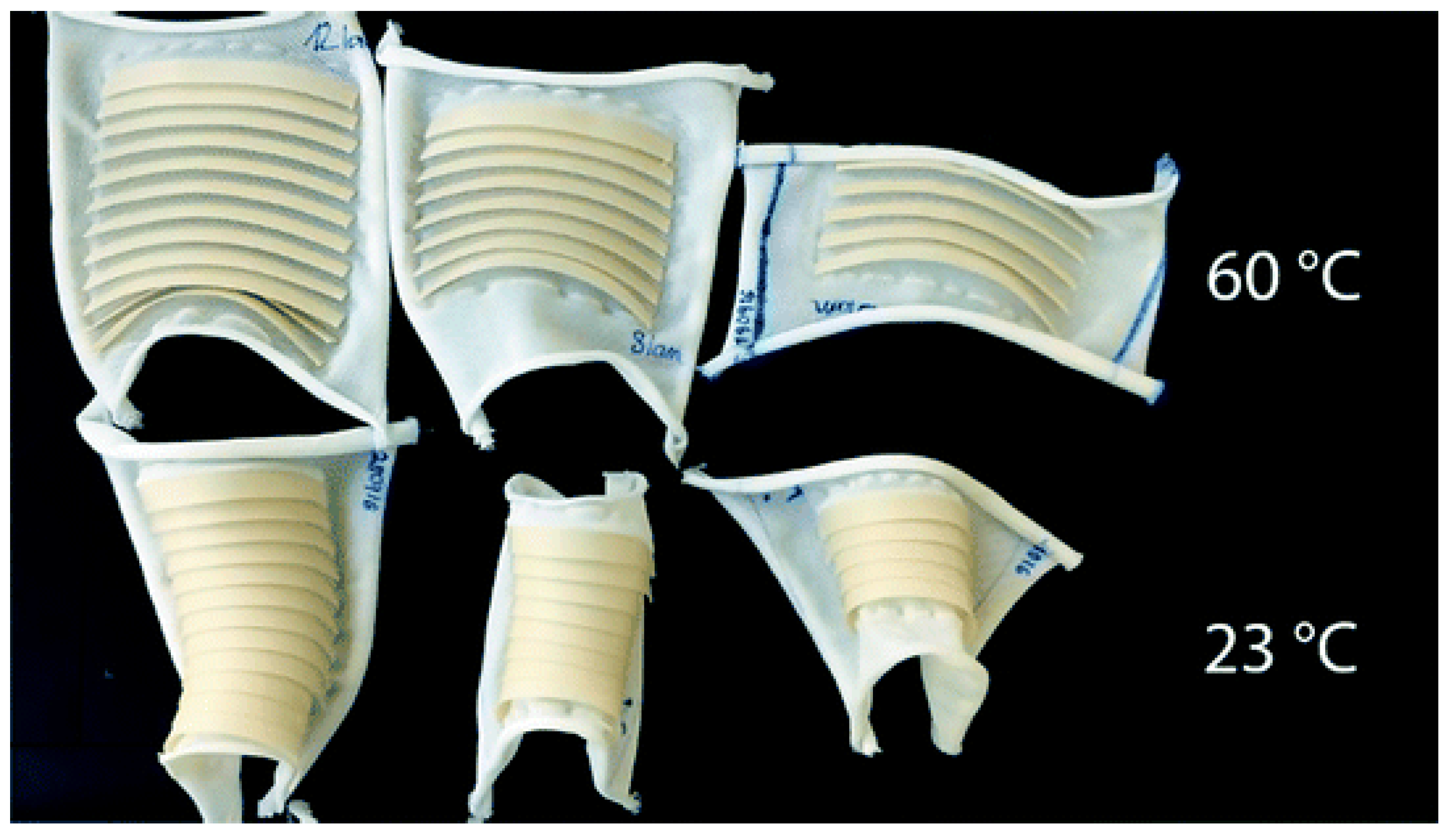

4. From 3D to innovative 4D printing polymer textiles

5. Applications

Breathable fabrics.

Shock absorbing fabrics

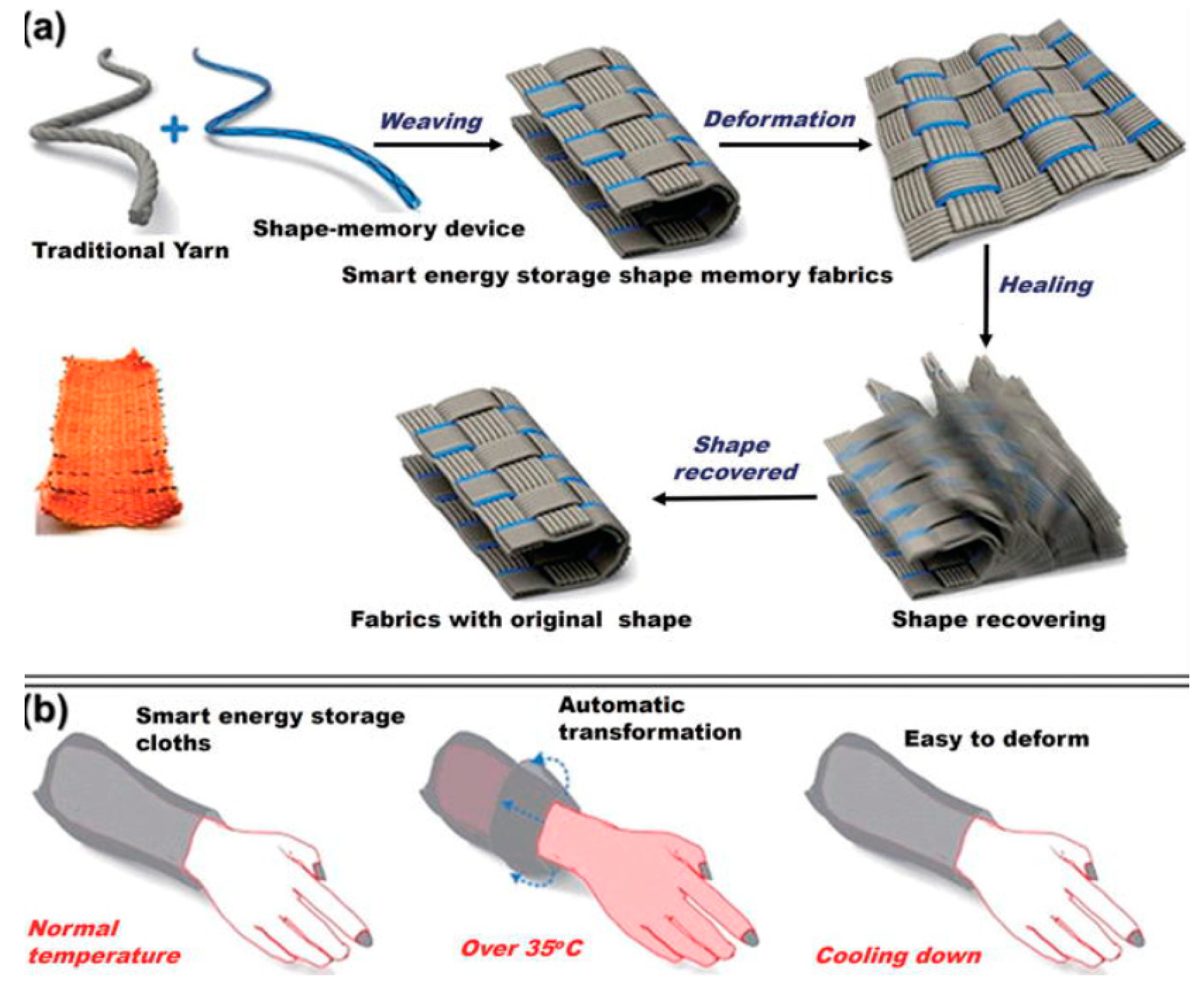

Intelligent textiles for energy storage

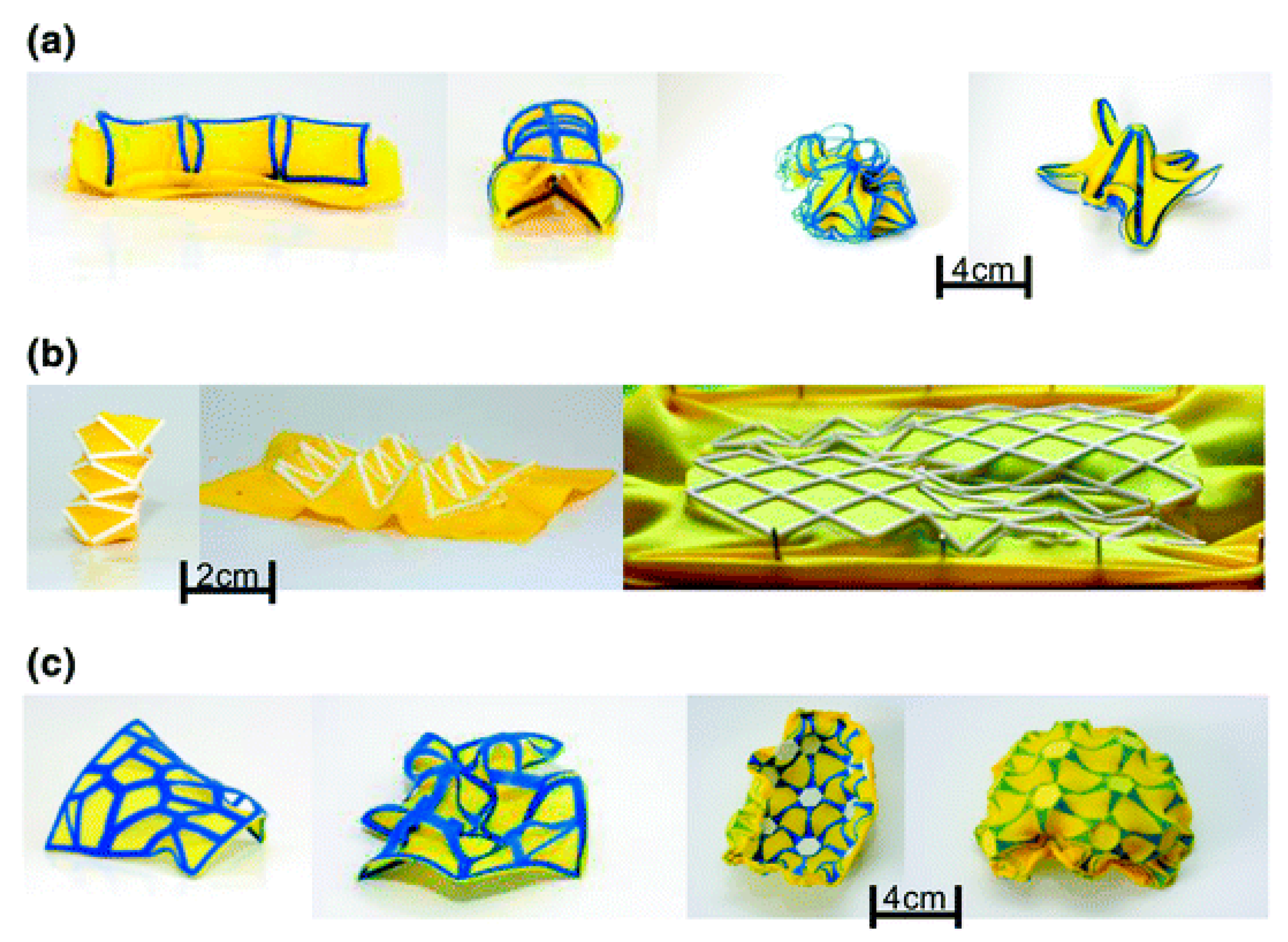

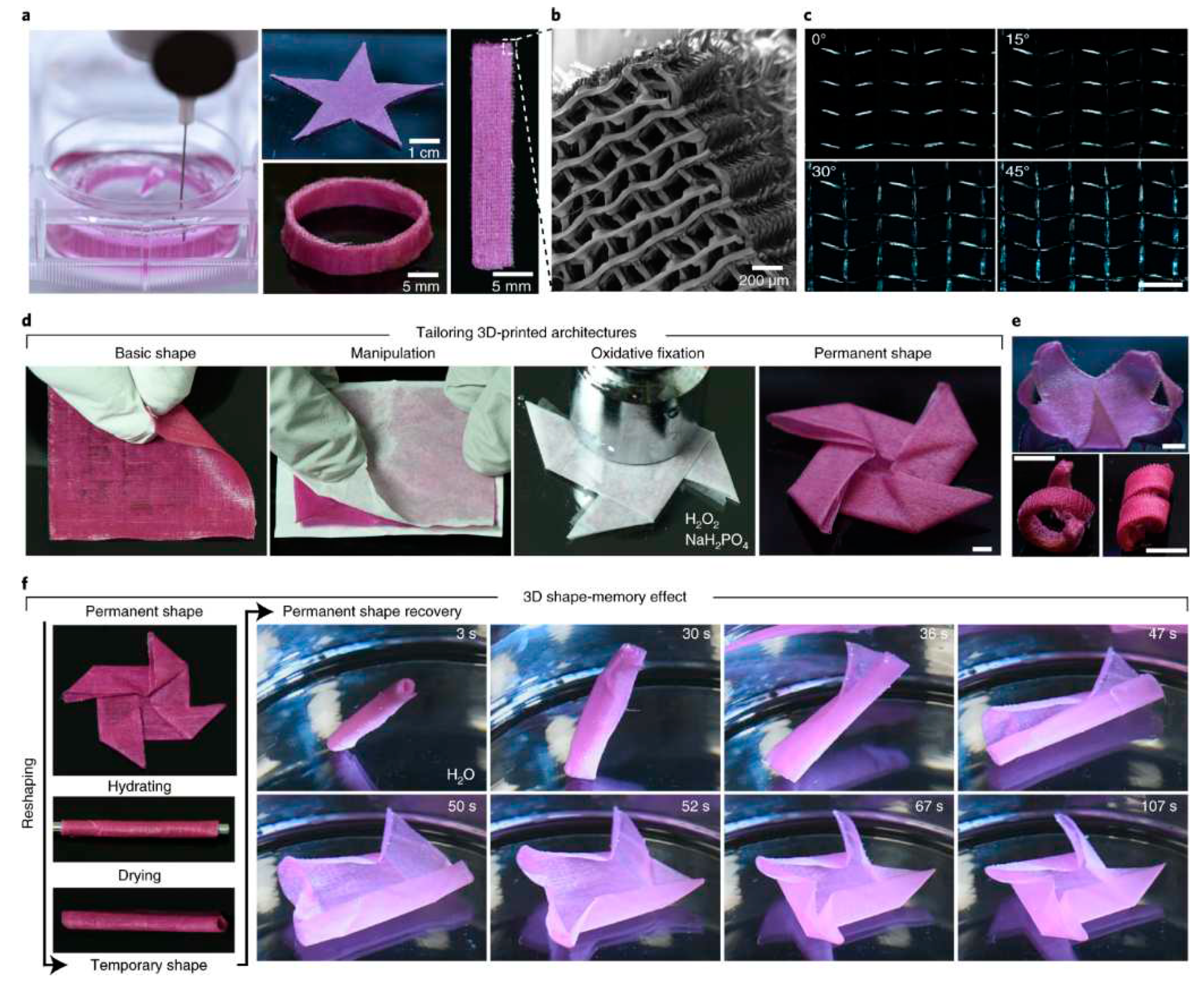

Origami

6. Prospects and conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Qahtani, M.; Wu, F.; Misra, M.; Gregori, S.; Mielewski, D.F.; Mohanty, A.K. Experimental Design of Sustainable 3D-Printed Poly(Lactic Acid)/Biobased Poly(Butylene Succinate) Blends via Fused Deposition Modeling. ACS Sustain. Chem. Eng. 2019, 7, 14460–14470. [Google Scholar] [CrossRef]

- Exconde, M.K.J.E.; Co, J.A.A.; Manapat, J.Z.; Magdaluyo, E.R. Materials Selection of 3D Printing Filament and Utilization of Recycled Polyethylene Terephthalate (PET) in a Redesigned Breadboard. Procedia CIRP 2019, 84, 28–32. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2019, 29, 1–23. [Google Scholar] [CrossRef]

- Criado-Gonzalez, M.; Dominguez-Alfaro, A.; Lopez-Larrea, N.; Alegret, N.; Mecerreyes, D. Additive Manufacturing of Conducting Polymers: Recent Advances, Challenges, and Opportunities. ACS Appl. Polym. Mater. 2021, 3, 2865–2883. [Google Scholar] [CrossRef]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Wei, J.; Su, P.C. 4D printing of high performance shape memory polymer using stereolithography. Mater. Des. 2017, 126, 219–225. [Google Scholar] [CrossRef]

- Cabral, I.; Souto, A.; Carvalho, H.; Cunha, J. Exploring geometric morphology in shape memory textiles: Design of dynamic light filters. Text. Res. J. 2015, 85, 1919–1933. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 1–25. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef]

- Fang, Z.; Song, H.; Zhang, Y.; Jin, B.; Wu, J.; Zhao, Q.; Xie, T. Modular 4D Printing via Interfacial Welding of Digital Light-Controllable Dynamic Covalent Polymer Networks. Matter 2020, 2, 1187–1197. [Google Scholar] [CrossRef]

- Champeau, M.; Heinze, D.A.; Viana, T.N.; de Souza, E.R.; Chinellato, A.C.; Titotto, S. 4D Printing of Hydrogels: A Review. Adv. Funct. Mater. 2020, 30, 1–22. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K. (Kelvin) 3D printing of polymer composites: Materials, processes, and applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Zhang, M.; Zeng, W.; Lei, Y.; Chen, X.; Zhang, M.; Li, C.; Qin, S. A novel sustainable luminescent ABS composite material for 3D printing. Eur. Polym. J. 2022, 176, 111406. [Google Scholar] [CrossRef]

- Saenz, F.; Otarola, C.; Valladares, K.; Rojas, J. Influence of 3D printing settings on mechanical properties of ABS at room temperature and 77 K. Addit. Manuf. 2021, 39, 101841. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A. Clay-Based Polymer Nanocomposites: Essential Work of Fracture. Polymers (Basel). 2021, 13, 2399. [Google Scholar] [CrossRef]

- Maspoch, M.L.; Franco-Urquiza, E.; Gamez-Perez, J.; Santana, O.O.; Sánchez-Soto, M. Fracture behaviour of poly[ethylene-(vinyl alcohol)]/organo-clay composites. Polym. Int. 2009, 58, 648–655. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.; Perez, J.G.; Sánchez-Soto, M.; Santana, O.O.; Maspoch, M.L. The effect of organo-modifier on the structure and properties of poly[ethylene-(vinyl alcohol)]/organo-modified montmorillonite composites. Polym. Int. 2010, 59. [Google Scholar] [CrossRef]

- Maspoch, M.L.; Santana, O.O.; Cailloux, J.; Franco-Urquiza, E.; Rodriguez, C.; Belzunce, J.; Martínez, A.B. Ductile-brittle transition behaviour of PLA/o-MMT films during the physical aging process. Express Polym. Lett. 2015, 9, 185–195. [Google Scholar] [CrossRef]

- Maspoch, M.L.; Santana, O.O.; Cailloux, J.; Franco-Urquiza, E.; Rodriguez, C.; Belzunce, J.; Martinez, A.B. Ductile-brittle transition behaviour of PLA/o-MMT films during the physical aging process. Express Polym. Lett. 2015, 9, 185–195. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A.; Cailloux, J.; Santana, O.; Maspoch, M.L.; Velazquez Infante, J.C. The Influence of the Clay Particles on the Mechanical Properties and Fracture Behavior of PLA/o-MMT Composite Films. Adv. Polym. Technol. 2015, 34, n. [Google Scholar] [CrossRef]

- Kukkonen, J.; Ervasti, T.; Laitinen, R. Production and characterization of glibenclamide incorporated PLA filaments for 3D printing by fused deposition modeling. J. Drug Deliv. Sci. Technol. 2022, 77, 103843. [Google Scholar] [CrossRef]

- Jain, R.; Gupta, N. Design optimization of PLA lattice in 3D printing. Mater. Today Proc. 2022, 59, 1577–1583. [Google Scholar] [CrossRef]

- Lokesh, N.; Praveena, B.A.; Sudheer Reddy, J.; Vasu, V.K.; Vijaykumar, S. Evaluation on effect of printing process parameter through Taguchi approach on mechanical properties of 3D printed PLA specimens using FDM at constant printing temperature. Mater. Today Proc. 2022, 52, 1288–1293. [Google Scholar] [CrossRef]

- Bainbridge, C.W.A.; Engel, K.E.; Jin, J. 3D printing and growth induced bending based on PET-RAFT polymerization11Electronic supplementary information (ESI) available: Chemicals, characterizations, and experimental procedures. Polym. Chem. 2020, 11, 4084–4093. [Google Scholar] [CrossRef]

- Vamshinath, K.; Niteesh Kumar, N.; Kumar, R.T.; Nagaraju, D.S.; Sateesh, N.; Subbaiah, R. Analysis of the effect of the process parameters on the mechanical strength of 3D printed and adhesively bonded PETG single lap joint. Mater. Today Proc. 2022, 62, 4509–4514. [Google Scholar] [CrossRef]

- Bhagia, S.; Kore, S.; Wasti, S.; Ďurkovič, J.; Kováč, J.; Zhao, X.; Andrews, H.B.; Martin, M.; Gallego, N.C.; Vaidya, U.; et al. 3D printing of a recycled copolyester of terephthalic acid, cyclohexanedimethanol and tetramethylcyclobutanediol. Polym. Test. 2023, 118, 107916. [Google Scholar] [CrossRef]

- Alarifi, I.M. PETG/carbon fiber composites with different structures produced by 3D printing. Polym. Test. 2023, 120, 107949. [Google Scholar] [CrossRef]

- Oussai, A.; Bártfai, Z.; Kátai, L. Development of 3d printing raw materials from plastic waste. A case study on recycled polyethylene terephthalate. Appl. Sci. 2021, 11. [Google Scholar] [CrossRef]

- Vaucher, J.; Demongeot, A.; Michaud, V.; Leterrier, Y. Recycling of Bottle Grade PET: Influence of HDPE Contamination on the Microstructure and Mechanical Performance of 3D Printed Parts. Polymers (Basel). 2022, 14. [Google Scholar] [CrossRef]

- Roudný, P.; Syrový, T. Thermal conductive composites for FDM 3D printing: A review, opportunities and obstacles, future directions. J. Manuf. Process. 2022, 83, 667–677. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, G.; Zheng, X.; Ni, Y.; Liu, F.; Liu, Y.; Xu, L.R. Efficient characterization on the interlayer shear strengths of 3D printing polymers. J. Mater. Res. Technol. 2023, 22, 2768–2780. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.E.; Lee, H.B.; Park, J.; Lee, N.-K.; Son, Y.; Park, S.-H. 3D printing of bio-based polycarbonate and its potential applications in ecofriendly indoor manufacturing. Addit. Manuf. 2020, 31, 100974. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kechagias, J.D. A comprehensive investigation of the 3D printing parameters’ effects on the mechanical response of polycarbonate in fused filament fabrication. Prog. Addit. Manuf. 2022, 7, 713–722. [Google Scholar] [CrossRef]

- Bulanda, K.; Oleksy, M.; Oliwa, R.; Budzik, G.; Przeszłowski, Ł.; Fal, J.; Jesionowski, T. Polymer composites based on polycarbonate (PC) applied to additive manufacturing using melted and extruded manufacturing (MEM) technology. Polymers (Basel). 2021, 13. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Ramakrishnan, R.; Omarbekova, A.; Kumar. R, S. Experimental characterization of mechanical properties and microstructure study of polycarbonate (PC) reinforced acrylonitrile-butadiene-styrene (ABS) composite with varying PC loadings. AIMS Mater. Sci. 2021, 8, 18–28. [Google Scholar] [CrossRef]

- Farcas, M.T.; Stefaniak, A.B.; Knepp, A.K.; Bowers, L.; Mandler, W.K.; Kashon, M.; Jackson, S.R.; Stueckle, T.A.; Sisler, J.D.; Friend, S.A.; et al. Acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) filaments three-dimensional (3-D) printer emissions-induced cell toxicity. Toxicol. Lett. 2019, 317, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Bano, S.; Iqbal, T.; Ramzan, N.; Farooq, U. Study of Surface Mechanical Characteristics of ABS/PC Blends Using Nanoindentation. Processes 2021, 9. [Google Scholar] [CrossRef]

- Yap, Y.L.; Toh, W.; Koneru, R.; Lin, K.; Yeoh, K.M.; Lim, C.M.; Lee, J.S.; Plemping, N.A.; Lin, R.; Ng, T.Y.; et al. A non-destructive experimental-cum-numerical methodology for the characterization of 3D-printed materials—polycarbonate-acrylonitrile butadiene styrene (PC-ABS). Mech. Mater. 2019, 132, 121–133. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Marciniak-Podsadna, L. Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance. Mater. (Basel, Switzerland) 2020, 13. [Google Scholar] [CrossRef]

- Zhang, Y.; Purssell, C.; Mao, K.; Leigh, S. A physical investigation of wear and thermal characteristics of 3D printed nylon spur gears. Tribol. Int. 2020, 141, 105953. [Google Scholar] [CrossRef]

- Carraher, C.E.; Seymour, R.B. SeymourCarraher’s polymer chemistry: an introduction; Dekker, 1996.

- dos Santos, W.N.; De Sousa, J.A.; Gregorio Jr, R. Thermal conductivity behaviour of polymers around glass transition and crystalline melting temperatures. Polym. Test. 2013, 32, 987–994. [Google Scholar] [CrossRef]

- Tavčar, J.; Grkman, G.; Duhovnik, J. Accelerated lifetime testing of reinforced polymer gears. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, JAMDSM0006–JAMDSM0006. [Google Scholar] [CrossRef]

- Raam Kumar, S.; Sridhar, S.; Venkatraman, R.; Venkatesan, M. Polymer additive manufacturing of ASA structure: Influence of printing parameters on mechanical properties. Mater. Today Proc. 2021, 39, 1316–1319. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure, thermal and mechanical behavior of 3D printed acrylonitrile styrene acrylate. Macromol. Mater. Eng. 2019, 304, 1800793. [Google Scholar] [CrossRef]

- Rossi, S.; Puglisi, A.; Benaglia, M. Additive manufacturing technologies: 3D printing in organic synthesis. ChemCatChem 2018, 10, 1512–1525. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A.; Cailloux, J.; Santana, O.; Maspoch, M.L.; Velazquez Infante, J.C. The influence of the clay particles on the mechanical properties and fracture behavior of PLA/o-MMT composite films. Adv. Polym. Technol. 2015, 34. [Google Scholar] [CrossRef]

- Maspoch, M.L.; Franco-Urquiza, E.; Gamez-Perez, J.; Santana, O.O.; Sánchez-Soto, M. Fracture behaviour of poly[ethylene-(vinyl alcohol)]/organo-clay composites. Polym. Int. 2009, 58. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Aravind Raj, S.; Kandasamy, J.; Shahzad, M.A.; Baghdadi, M.A. 3D Printing Parameter Optimization Using Taguchi Approach to Examine Acrylonitrile Styrene Acrylate (ASA) Mechanical Properties. Polymers (Basel). 2022, 14. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A.; May-Crespo, J.F.; Escalante Velázquez, C.A.; Pérez Mora, R.; González García, P. Thermal Degradation Kinetics of ZnO/polyester Nanocomposites. Polymers (Basel). 2020, 12, 1753. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Taormina, G.; Sciancalepore, C.; Messori, M.; Bondioli, F. 3D printing processes for photocurable polymeric materials: technologies, materials, and future trends. J. Appl. Biomater. Funct. Mater. 2018, 16, 151–160. [Google Scholar] [CrossRef]

- Suntornnond, R.; An, J.; Chua, C.K. Roles of support materials in 3D bioprinting - Present and future. Int. J. bioprinting 2017, 3, 6. [Google Scholar] [CrossRef] [PubMed]

- Garcia-villen, F.; Guembe, A.; Rey, J.M.; Zúñiga, T.; Ruiz-alonso, S.; Saenz-del-burgo, L.; Izco, J.M. Characterization and assessment of new fibrillar collagen inks and bioinks for 3D printing and bioprinting. 2023, x.

- Kouka, M.A.; Abbassi, F.; Habibi, M.; Chabert, F.; Zghal, A.; Garnier, C. 4D Printing of Shape Memory Polymers, Blends, and Composites and Their Advanced Applications: A Comprehensive Literature Review. Adv. Eng. Mater. 2022, 2200650, 1–30. [Google Scholar] [CrossRef]

- Manaia, J.P.; Cerejo, F.; Duarte, J. Revolutionising textile manufacturing : a comprehensive review on 3D and 4D printing technologies. Fash. Text. 2023. [Google Scholar] [CrossRef]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.-H.; Lee, J.-W.; Choi, K.H. 3D printing for soft robotics–a review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef]

- Pugliese, R.; Beltrami, B.; Regondi, S.; Lunetta, C. Polymeric biomaterials for 3D printing in medicine: An overview. Ann. 3D Print. Med. 2021, 2, 100011. [Google Scholar] [CrossRef]

- Costa, P.; Dios, J.R.; Cardoso, J.; Campo, J.J.; Tubio, C.R.; Gonçalves, B.F.; Castro, N.; Lanceros-Méndez, S. Polycarbonate based multifunctional self-sensing 2D and 3D printed structures for aeronautic applications. Smart Mater. Struct. 2021, 30, 85032. [Google Scholar] [CrossRef]

- Li, Q.; Wu, T.; Zhao, W.; Li, Y.; Ji, J.; Wang, G. 3D printing stretchable core-shell laser scribed graphene conductive network for self-powered wearable devices. Compos. Part B Eng. 2022, 240, 110000. [Google Scholar] [CrossRef]

- Schmelzeisen, D.; Koch, H.; Pastore, C.; Gries, T. 4D textiles: Hybrid textile structures that can change structural form with time by 3D printing. Narrow Smart Text. 2017, 189–201. [Google Scholar] [CrossRef]

- Alghamdi, S.S.; John, S.; Choudhury, N.R.; Dutta, N.K. Additive manufacturing of polymer materials: Progress, promise and challenges. Polymers (Basel). 2021, 13, 1–39. [Google Scholar] [CrossRef]

- Korger, M.; Bergschneider, J.; Lutz, M.; Mahltig, B.; Finsterbusch, K.; Rabe, M. Possible applications of 3D printing technology on textile substrates. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing, 2016; Vol. 141; p. 12011. [Google Scholar]

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. In Proceedings of the IOP conference series: materials science and engineering; IOP publishing, 2014; Vol. 62; p. 12018. [Google Scholar]

- Pei, E.; Shen, J.; Watling, J. Direct 3D printing of polymers onto textiles: experimental studies and applications. Rapid Prototyp. J. 2015. [Google Scholar] [CrossRef]

- Richter, C.; Schmülling, S.; Ehrmann, A.; Finsterbusch, K. FDM printing of 3D forms with embedded fibrous materials. In Proceedings of the Design, Manufacturing and Mechatronics: Proceedings of the 2015 International Conference on Design, Manufacturing and Mechatronics (ICDMM2015); pp. 2016961–969.

- Meyer, P.; Döpke, C.; Ehrmann, A. Improving adhesion of three-dimensional printed objects on textile fabrics by polymer coating. J. Eng. Fiber. Fabr. 2019, 14, 1558925019895257. [Google Scholar] [CrossRef]

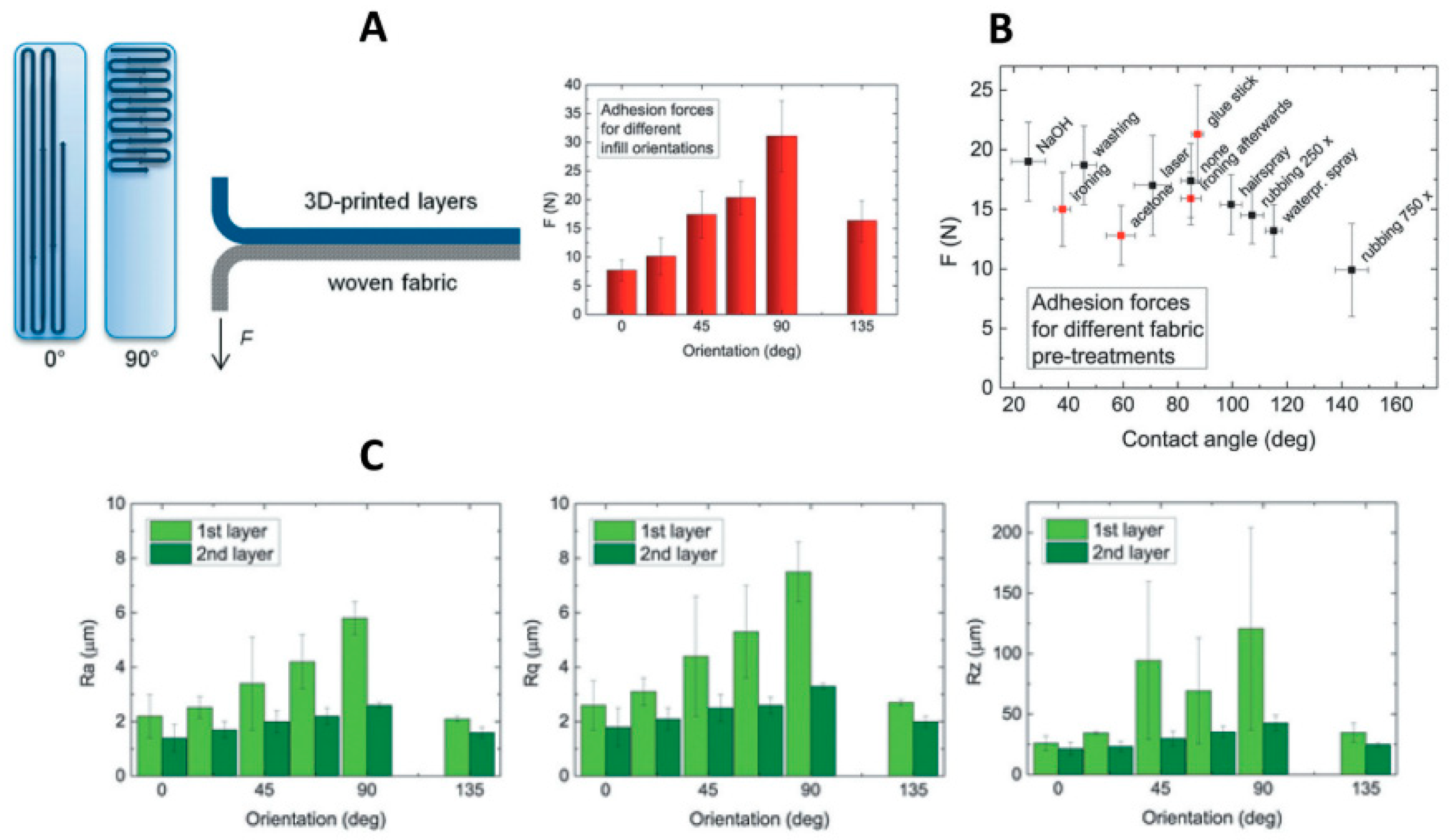

- Kozior, T.; Döpke, C.; Grimmelsmann, N.; Juhász Junger, I.; Ehrmann, A. Influence of fabric pretreatment on adhesion of three-dimensional printed material on textile substrates. Adv. Mech. Eng. 2018, 10, 1687814018792316. [Google Scholar] [CrossRef]

- Grimmelsmann, N.; Kreuziger, M.; Korger, M.; Meissner, H.; Ehrmann, A. Adhesion of 3D printed material on textile substrates. Rapid Prototyp. J. 2018, 24, 166–170. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A.; Escamilla, Y.R.; Llanas, P.I.A. Characterization of 3d printing on jute fabrics. Polymers (Basel). 2021, 13. [Google Scholar] [CrossRef] [PubMed]

- Loh, G.H.; Sotayo, A.; Pei, E. Development and testing of material extrusion additive manufactured polymer–textile composites. Fash. Text. 2021, 8. [Google Scholar] [CrossRef]

- Rivera, M.L.; Moukperian, M.; Ashbrook, D.; Mankoff, J.; Hudson, S.E. Stretching the bounds of 3D printing with embedded textiles. In Proceedings of the Proceedings of the 2017 CHI conference on human factors in computing systems; pp. 2017497–508.

- Keefe, E.M.; Thomas, J.A.; Buller, G.A.; Banks, C.E. Textile additive manufacturing: An overview. Cogent Eng. 2022, 9. [Google Scholar] [CrossRef]

- Ge, Q.; Dunn, C.K.; Qi, H.J.; Dunn, M.L. Active origami by 4D printing. Smart Mater. Struct. 2014, 23, 94007. [Google Scholar] [CrossRef]

- Joharji, L.; Mishra, R.B.; Alam, F.; Tytov, S.; Al-Modaf, F.; El-Atab, N. 4D printing: A detailed review of materials, techniques, and applications. Microelectron. Eng. 2022, 265, 111874. [Google Scholar] [CrossRef]

- André, J.-C. From additive manufacturing to 3D/4D printing 3: breakthrough innovations: programmable material, 4D printing and bio-printing; John Wiley & Sons, 2017; ISBN 1119482771.

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D Printing of Liquid Crystal Elastomeric Actuators with Spatially Programed Nematic Order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef]

- Rodriguez, J.N.; Zhu, C.; Duoss, E.B.; Wilson, T.S.; Spadaccini, C.M.; Lewicki, J.P. Shape-morphing composites with designed micro-architectures. Sci. Rep. 2016, 6, 27933. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef]

- Sydney Gladman, A.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D printing. Nat. Mater. 2016, 15, 413–418. [Google Scholar] [CrossRef] [PubMed]

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, L.A. Three-Dimensional Printing of pH-Responsive and Functional Polymers on an Affordable Desktop Printer. ACS Appl. Mater. Interfaces 2016, 8, 28946–28954. [Google Scholar] [CrossRef] [PubMed]

- Tibbits, S. Self-assembly lab: experiments in programming matter; Taylor & Francis, 2016; ISBN 1317437020.

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D printing: Fundamentals, materials, applications and challenges. Polymer (Guildf). 2021, 228, 123926. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, H.; Hwang, T.; Lee, J.-G.; Cho, M. Sequential Folding using Light-activated Polystyrene Sheet. Sci. Rep. 2015, 5, 16544. [Google Scholar] [CrossRef]

- Yang, W.G.; Lu, H.; Huang, W.M.; Qi, H.J.; Wu, X.L.; Sun, K.Y. Advanced Shape Memory Technology to Reshape Product Design, Manufacturing and Recycling. Polymers (Basel). 2014, 6, 2287–2308. [Google Scholar] [CrossRef]

- Liu, Y.; Genzer, J.; Dickey, M.D. “2D or not 2D”: Shape-programming polymer sheets. Prog. Polym. Sci. 2016, 52, 79–106. [Google Scholar] [CrossRef]

- Breger, J.C.; Yoon, C.; Xiao, R.; Kwag, H.R.; Wang, M.O.; Fisher, J.P.; Nguyen, T.D.; Gracias, D.H. Self-Folding Thermo-Magnetically Responsive Soft Microgrippers. ACS Appl. Mater. Interfaces 2015, 7, 3398–3405. [Google Scholar] [CrossRef] [PubMed]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Self-expanding/shrinking structures by 4D printing. Smart Mater. Struct. 2016, 25, 105034. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Agkathidis, A.; Varinlioglu, G. 4D Printing on Textiles: developing a file to fabrication framework for self-forming, composite wearables. In Advances in Product Design Engineering; Springer, 2022; pp. 61–81.

- Zhang, W.; Zhang, F.; Lan, X.; Leng, J.; Wu, A.S.; Bryson, T.M.; Cotton, C.; Gu, B.; Sun, B.; Chou, T.-W. Shape memory behavior and recovery force of 4D printed textile functional composites. Compos. Sci. Technol. 2018, 160, 224–230. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Leist, S.K.; Gao, D.; Chiou, R.; Zhou, J. Investigating the shape memory properties of 4D printed polylactic acid (PLA) and the concept of 4D printing onto nylon fabrics for the creation of smart textiles. Virtual Phys. Prototyp. 2017, 12, 290–300. [Google Scholar] [CrossRef]

- Maiti, S.; Das, D.; Sen, K. Flexible non-metallic electro-conductive textiles. Text. Prog. 2017, 49, 1–52. [Google Scholar] [CrossRef]

- An, T.; Koch, H.C.; Schmelzeisen, D.; Gries, T.; Koch, H.C.; Schmelzeisen, D.; Gries, T. 4D Textiles Made by Additive Manufacturing on Pre-Stresse 4D Textiles Made by Additive Manufacturing on Pre-Stressed Textiles — An Overview. 2021.

- Persson, N.-K.; Martinez, J.G.; Zhong, Y.; Maziz, A.; Jager, E.W.H. Actuating Textiles: Next Generation of Smart Textiles. Adv. Mater. Technol. 2018, 3, 1700397. [Google Scholar] [CrossRef]

- Sitotaw, D.B.; Ahrendt, D.; Kyosev, Y.; Kabish, A.K. Additive manufacturing and textiles—state-of-the-art. Appl. Sci. 2020, 10, 5033. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Ehrmann, G.; Ehrmann, A. Shape memory textiles–technological background and possible applications. Commun. Dev. Assem. Text. Prod. 2021, 2, 162–172. [Google Scholar] [CrossRef]

- Khan, M.K.R.; Hassan, M.N. Understanding the concept of 4D textiles. South Asian Res. J. Eng. Technol. 2021, 3, 93–95. [Google Scholar]

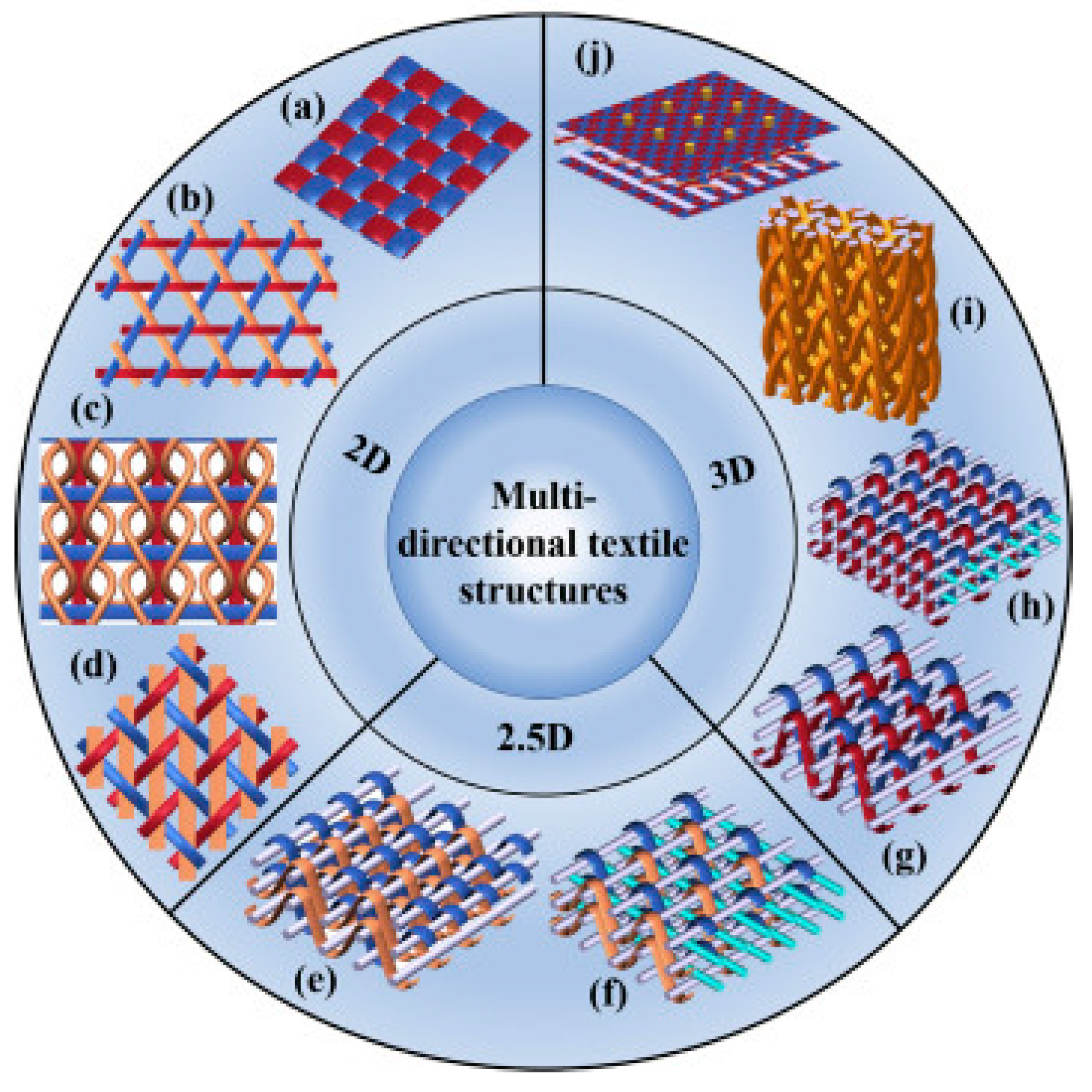

- Liu, Y.; Chou, T.-W. Additive manufacturing of multidirectional preforms and composites: from three-dimensional to four-dimensional. Mater. Today Adv. 2020, 5, 100045. [Google Scholar] [CrossRef]

- Chou, T.-W. Textile structural composites. Compos. Mater. Seris 3 1989. [Google Scholar]

- Bilisik, K. Multiaxis three-dimensional weaving for composites: a review. Text. Res. J. 2012, 82, 725–743. [Google Scholar] [CrossRef]

- Kostar, T.D.; Chou, T.-W. A methodology for Cartesian braiding of three-dimensional shapes and special structures. J. Mater. Sci. 2002, 37, 2811–2824. [Google Scholar] [CrossRef]

- Gude, M.; Hufenbach, W.; Koch, I. Damage evolution of novel 3D textile-reinforced composites under fatigue loading conditions. Compos. Sci. Technol. 2010, 70, 186–192. [Google Scholar] [CrossRef]

- Quan, Z.; Wu, A.; Keefe, M.; Qin, X.; Yu, J.; Suhr, J.; Byun, J.-H.; Kim, B.-S.; Chou, T.-W. Additive manufacturing of multi-directional preforms for composites: opportunities and challenges. Mater. Today 2015, 18, 503–512. [Google Scholar] [CrossRef]

- Quan, Z.; Larimore, Z.; Wu, A.; Yu, J.; Qin, X.; Mirotznik, M.; Suhr, J.; Byun, J.-H.; Oh, Y.; Chou, T.-W. Microstructural design and additive manufacturing and characterization of 3D orthogonal short carbon fiber/acrylonitrile-butadiene-styrene preform and composite. Compos. Sci. Technol. 2016, 126, 139–148. [Google Scholar] [CrossRef]

- Liem, H.; Yeung, L.Y.; Hu, J.L. A prerequisite for the effective transfer of the shape-memory effect to cotton fibers. Smart Mater. Struct. 2007, 16, 748. [Google Scholar] [CrossRef]

- Korkmaz Memiş, N.; Kaplan, S. Smart polyester fabric with comfort regulation by temperature and moisture responsive shape memory nanocomposite treatment. J. Ind. Text. 2022, 51, 7920S–7941S. [Google Scholar] [CrossRef]

- Liu, X.; Hu, J.; Murugesh Babu, K.; Wang, S. Elasticity and shape memory effect of shape memory fabrics. Text. Res. J. 2008, 78, 1048–1056. [Google Scholar]

- Jahid, M.A.; Hu, J.; Wong, K.; Wu, Y.; Zhu, Y.; Sheng Luo, H.H.; Zhongmin, D. Fabric coated with shape memory polyurethane and its properties. Polymers (Basel). 2018, 10, 681. [Google Scholar] [CrossRef]

- Mondal, S.; Hu, J.L. Water vapor permeability of cotton fabrics coated with shape memory polyurethane. Carbohydr. Polym. 2007, 67, 282–287. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Kim, J. 4D-Printing — Fused Deposition Modeling Printing and PolyJet Printing with Shape Memory Polymers Composite. Fibers Polym. 2020, 21, 2364–2372. [Google Scholar] [CrossRef]

- Zhuo, H.; Hu, J.; Chen, S. Study of water vapor permeability of shape memory polyurethane nanofibrous nonwovens. Text. Res. J. 2011, 81, 883–891. [Google Scholar] [CrossRef]

- Thakur, S. Shape memory polymers for smart textile applications. Text. Adv. Appl. 2017, 323–336. [Google Scholar]

- DeGaspari, J. ’Smarter’seat belt fiber.(Materials and Assembly). Mech. Eng. 2002, 124, 22–24. [Google Scholar]

- Huang, Y.; Zhu, M.; Pei, Z.; Xue, Q.; Huang, Y.; Zhi, C. A shape memory supercapacitor and its application in smart energy storage textiles. J. Mater. Chem. A 2016, 4, 1290–1297. [Google Scholar] [CrossRef]

- Cera, L.; Gonzalez, G.M.; Liu, Q.; Choi, S.; Chantre, C.O.; Lee, J.; Gabardi, R.; Choi, M.C.; Shin, K.; Parker, K.K. A bioinspired and hierarchically structured shape-memory material. Nat. Mater. 2021, 20, 242–249. [Google Scholar] [CrossRef]

- Kolesky, D.B.; Truby, R.L.; Gladman, A.S.; Busbee, T.A.; Homan, K.A.; Lewis, J.A. 3D bioprinting of vascularized, heterogeneous cell-laden tissue constructs. Adv. Mater. 2014, 26, 3124–3130. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).