1. Introduction

Fibre reinforced thermoplastics (FRTP) are primarily used in the transportation sector, such as automobiles and aerospace, relying on lightweight structures combined with high strength and stiffness [

1]. The manufacturing takes place at temperatures near the melting point of the used thermoplastic matrix to reduce its viscosity and enable sufficient impregnation of the fibres. Common melt viscosity values for thermoplastics are

-

, which are much higher compared to those of epoxy polymers during impregnation (

-

) [

2,

3]. As a result, different manufacturing processes need to be considered, and a fundamental understanding of the respective process parameters is crucial. Furthermore, a thermoplastic matrix offers the possibility of short cycle times due to the use of semi-finished materials, such as prepregs (pre-impregnated material), organo sheets, or unidirectional fibre-reinforced tapes (UD-tapes) [

4,

5]. This paper focuses on UD-tapes, which can be oriented in any load direction, allowing for turgeted fulfillment of current load requirements.

The thermoforming process for UD-tapes and hybrid laminates is widely used and has been described in detail in many sourced. Generally, thermoforming involves a stamping process executed under specific pressure, time and a temperature near the melting point of the matrix material [

4,

6,

7,

8]. Consequently, understanding the impact of process parameters on the quality and mechanical properties of the manufactured laminate is of significant interest. Nonetheless, thermally induced residual stress and process-induced defects, such as fibre misalignment, wrinkling and folding, are common challenges when thermoforming thermoplastic prepregs [

6,

9,

10,

11]. These defects can lead to a decrease in mechanical properties, unintended plastic deformation, or premature material failure. Numerous strategies for modeling various effects on the impregnation process have been developed [

12,

13,

14,

15]. However, each simulation is constrained by simplifications, limitations, or a focus on specific aspects due to the complex and interdisciplinary nature of the problem [

16]. Manson et al. [

17] emphasized the significance of uniform pressure distribution for consistent laminate impregnation. Their study found that 8-ply UD-tapes subjected to uniform pressure across the entire laminate exhibited negligible void content, regardless of cooling rates or annealing conditions. Furthermore, annealing increased the crystallinity of the polyether ether ketone (PEEK) matrix [

17], resulting in reduced composite fracture toughness [

18,

19]. Christmann et al. [

13] developed a thermoforming model for FRTP based on the so-called B-Factor model. This model demonstrated identical impregnation quality for different parameter settings. Additionally, model validation indicated that varying pressure settings did not affect impregnation significantly for rapid processing times. Lower pressure settings appeard advantageous for impregnation quality and yielded higher interlaminar shear strength values as well [

20]. Conversely, various observations [

10,

21] suggest that higher pressure leads to improved part quality, particularly concerning the surface roughness.

In the present work, a design of experiments (DOE) is conducted to investigate the effects of pressure and holding time on the tensile strength, elongation at break, and compaction behavior of UD-tapes with basalt fibres (BF) within a polyamide 6 (PA 6) matrix. Furthermore, the macroscopic misalignment of the fibres resulting from the thermoforming process is discussed, and a validation of the developed model is performed.

2. Materials and Methods

2.1. Materials and samples

The material system examined in this study consists of UD-tape comprising basalt fibres and a PA 6 matrix from Cetex Institut gGmbH (Chemnitz, Germany), with a thickness of . The fibre volume fraction (FVF) of is determined following DIN EN ISO 1172. Square laminates measuring are produced using the Collin P 300 P/M hot plate press, in accordance with DIN 65672 standards, resulting in a 6-ply laminate oriented of . Each specimen is cut out using a waterjet and then subjected to accelerated conditioning (DIN EN ISO 1110) for the tensile test as per DIN EN ISO 527-5.

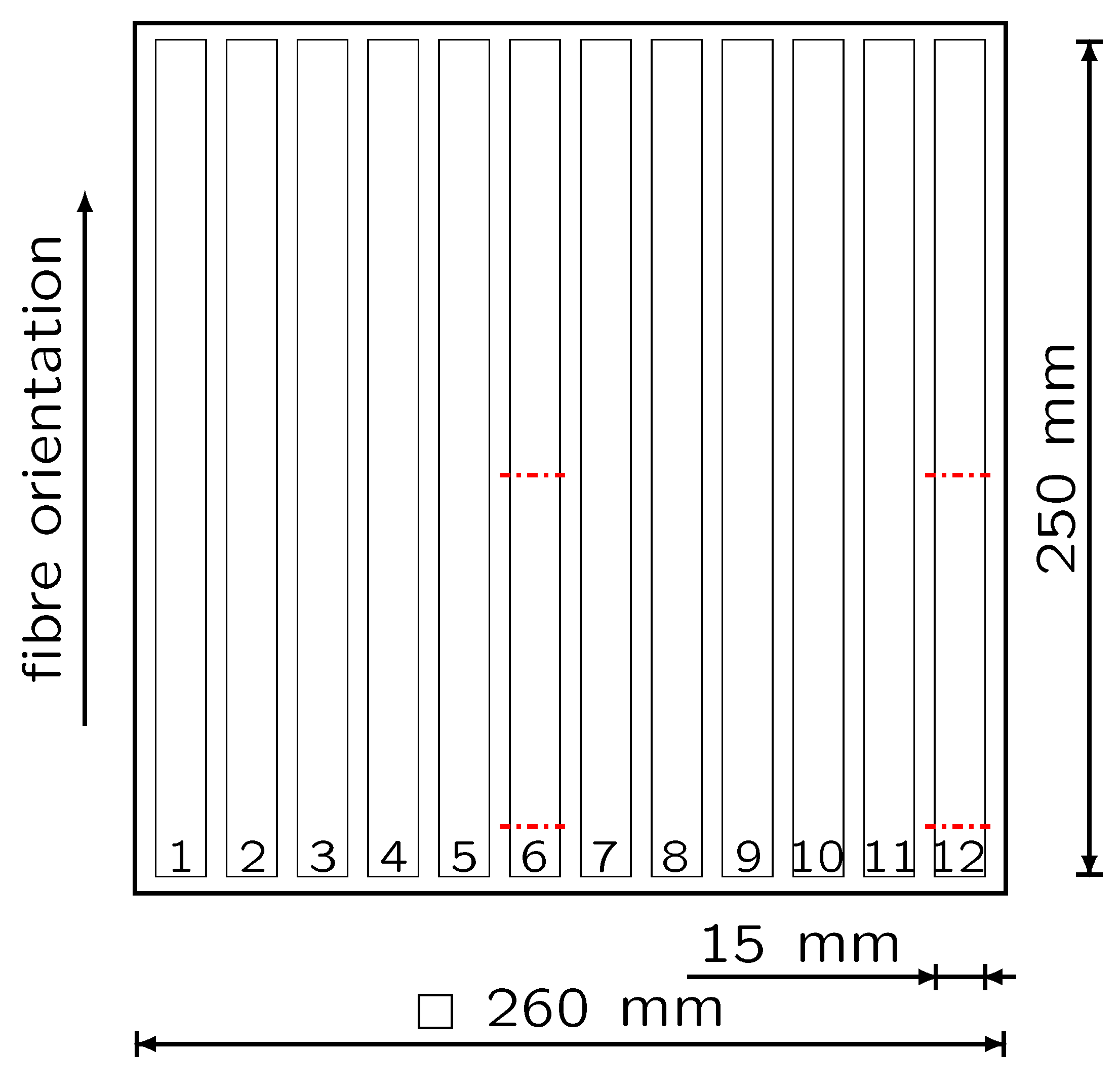

A single laminate allows for the creation of twelve specimens (

Figure 1), out of which eight are designated for the tensile tests, two for FVF measurement, and to two for quality assessment of the laminate. Additionally, two specimens serve as backups in case of damage during waterjet cutting. Multiple light microscopic images are captured from the centre, corner and edges of each laminate, perpendicular to the fibres, to evaluate impregnation and compaction quality.

2.2. Manufacturing process

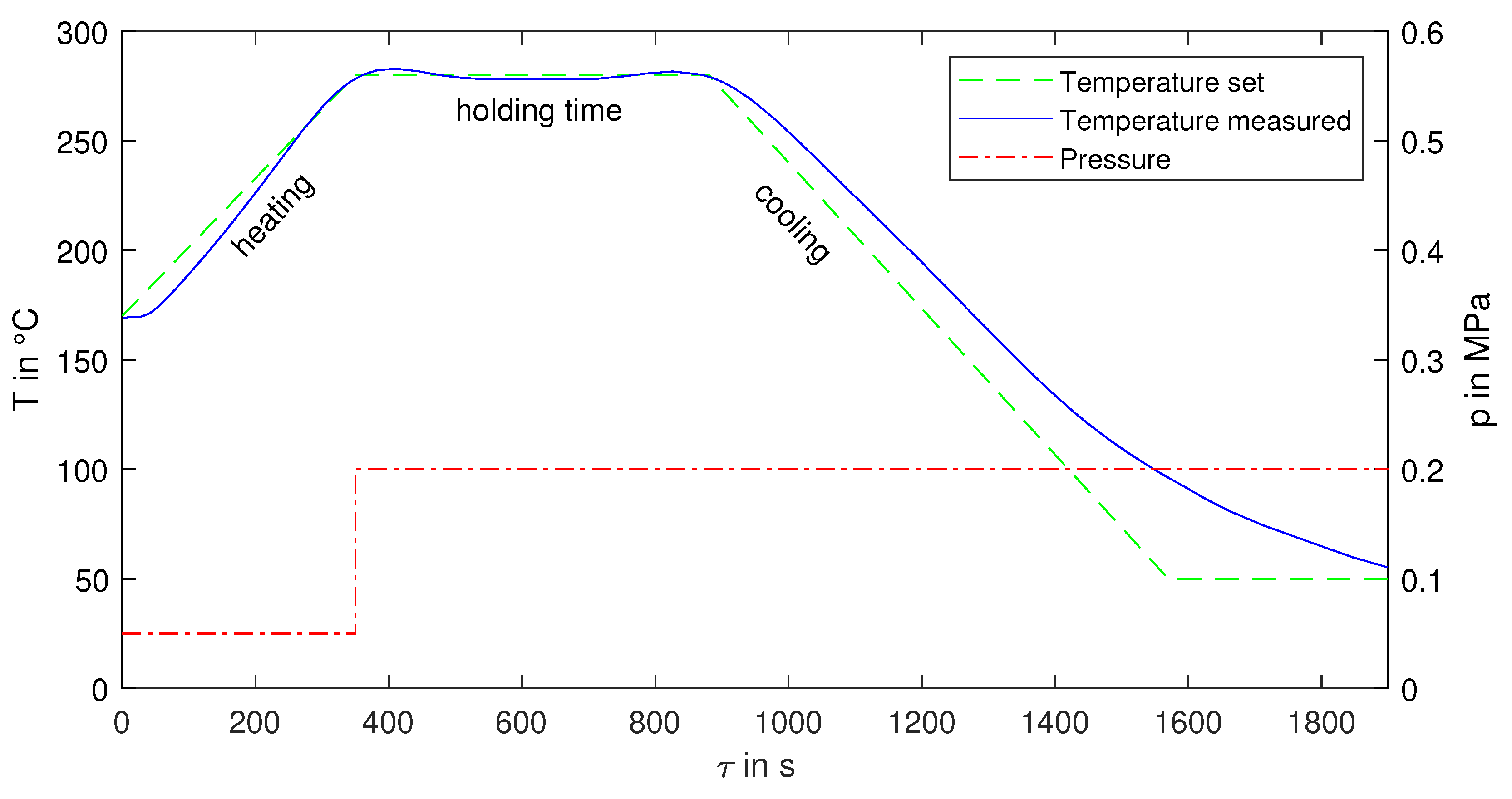

An illustrative instance manufacturing processes is depicted in

Figure 2. The stacked UD-tapes undergo preheating to

and are then up elevated to

at a rate of

. Upon attaining the designated processing temperature, the pressure increases to the predetermined value, maintaining a constant temperature for the specified holding duration. Subsequently, the laminate is gradually cooled at a rate of

until reaching

. The pressure remains constant until the conclusion of the process. The observed temperature closely aligns with the predetermined values. A marginal temperature disparity is observable at the onset of the heating phase. Throughout the cooling process, temperature differences are somewhat more pronounced, although the cooling rate is effectively adhered to.

2.3. Statistical methods

A full factorial design of experiments is executed, encompassing various holding times ranging from

to

. These durations are maintained at a consistent temperature of

, alongside varying pressures from

to

. Each parameter is set at three distinct levels, which results in a total of nine individual laminates. The configuration and assignment of process parameters to each laminate are detailed in

Table 1.

The primary objectives of this DOE encompasses the evluation of tensile strength, elongation at break and FVF. It is persumed that as the holding time and pressure increase, there will be a tendency for the fibre misalignment. Consequently, the fibers may deviate from being parallel to the applied load direction, leading to a reduction in tensile strength. Moreover, a greater degree of fiber misalignment towards the dominant load direction is anticipated to cause a more pronounced decline in elongation at break. This is attributed to potential obstacles in transverse contraction and issues stemming from low adhesion.

After mechanical testing of the samples, an analysis of variance (ANOVA) is conducted to identify significant effects. If detected, main effects and interactions of the manipulated factors are elucidated. Subsequently, a regression model is formulated and its accuracy is validated. Both the ANOVA and the regression model employ statistical tools from MATLAB [

22].

3. Results and discussion

3.1. Macroscopic fibre misalignment and compaction

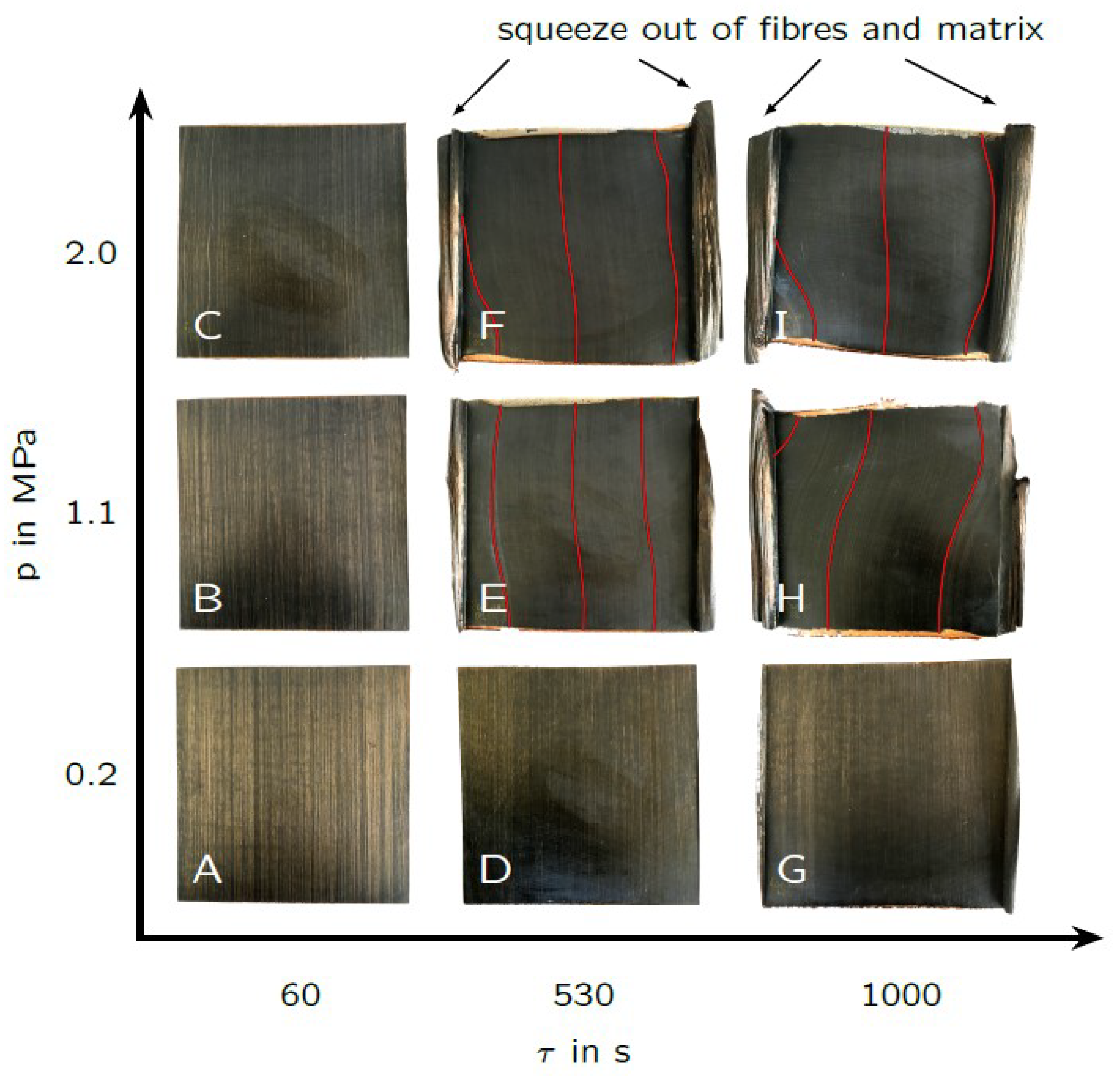

Figure 3 depicts the produced laminates, categorized based on the process parameters outlined in

Table 1. When the holding time or pressure increases, while the other parameter remains at a low level, a minimal amount of fibre and matrix extrusion occurs (laminate G), or no extrusion transpires at all (laminates A-D). In contrast, when both parameters are elevated simultaneously, a substantial extrusion and fibre misalignment are observed across the entirety of laminates E, F, H and I. Consequently, this leads to the formation of a curled structure composed of fibres and matrix along the edges of the laminates, parallel to the direction of the fibres. Furhtermore, areas devoid of fibres emerge at the edges perpendicular to the fibres orientation (

Figure 3). These outcomes underscore the presence of an interaction between the process parameters, namely the holding time and pressure.

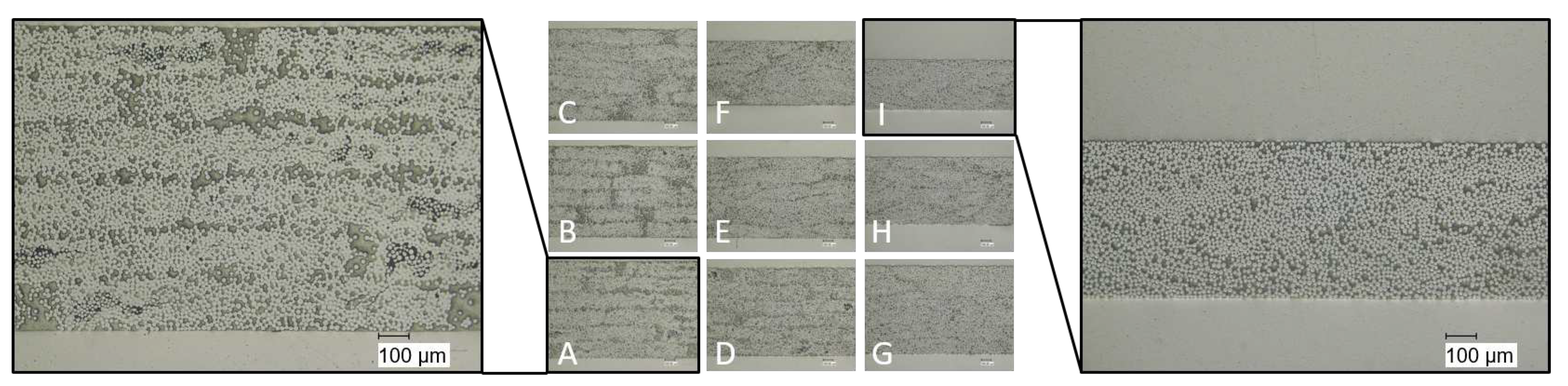

The optical micrograph captured from the centre of all laminates (

Figure 4) reveals minor discrepancies across the samples A-C, D and G. In the case of laminates A-C and D, distinct layers from the original UD-tapes, or even the primary fibre rovings within each layer, are clearly discernible. Occasional microscopic voids (depicted as black regions in

Figure 4) are only observable within the initial fibre rovings of laminates A and D. Consequently, the impregnation quality for all laminates is excellent. The compaction process for laminates E, F, H and I has progressed to the extent that fibres from individual layers have merged into adjacent ones, and thus no separation of individual layers is recognisable. The laminates A-D and G exhibit comparable thicknesses, ranging from

to

. In contrast, laminates E, F, H, and I display noticeable thickness variations, with laminate I measuring only

of the thickness of laminate A. This divergence is a direct consequence of the pronounced material extrusion detailed earlier and evident in

Figure 3. Once more, significant differences are recognisable when both process parameters are concurrently altered, as opposed to modifying only a single parameter. This serves to reinforce the assumption of an interaction between the process parameters.

3.2. Mechanical properties

The tensile tests are conducted following DIN EN ISO 527-5. It’s noteworthy to mention that the thickness of laminates F, H and I falls below the prescribed range stipulated by the standard, as evident from

Figure 4. These mentioned laminates do not align with the standardized method’s specifications; however, it’s worth noting that despite this variance, the standard deviation of the tensile strength remains consistent with the values observed in samples adhering to the standard.

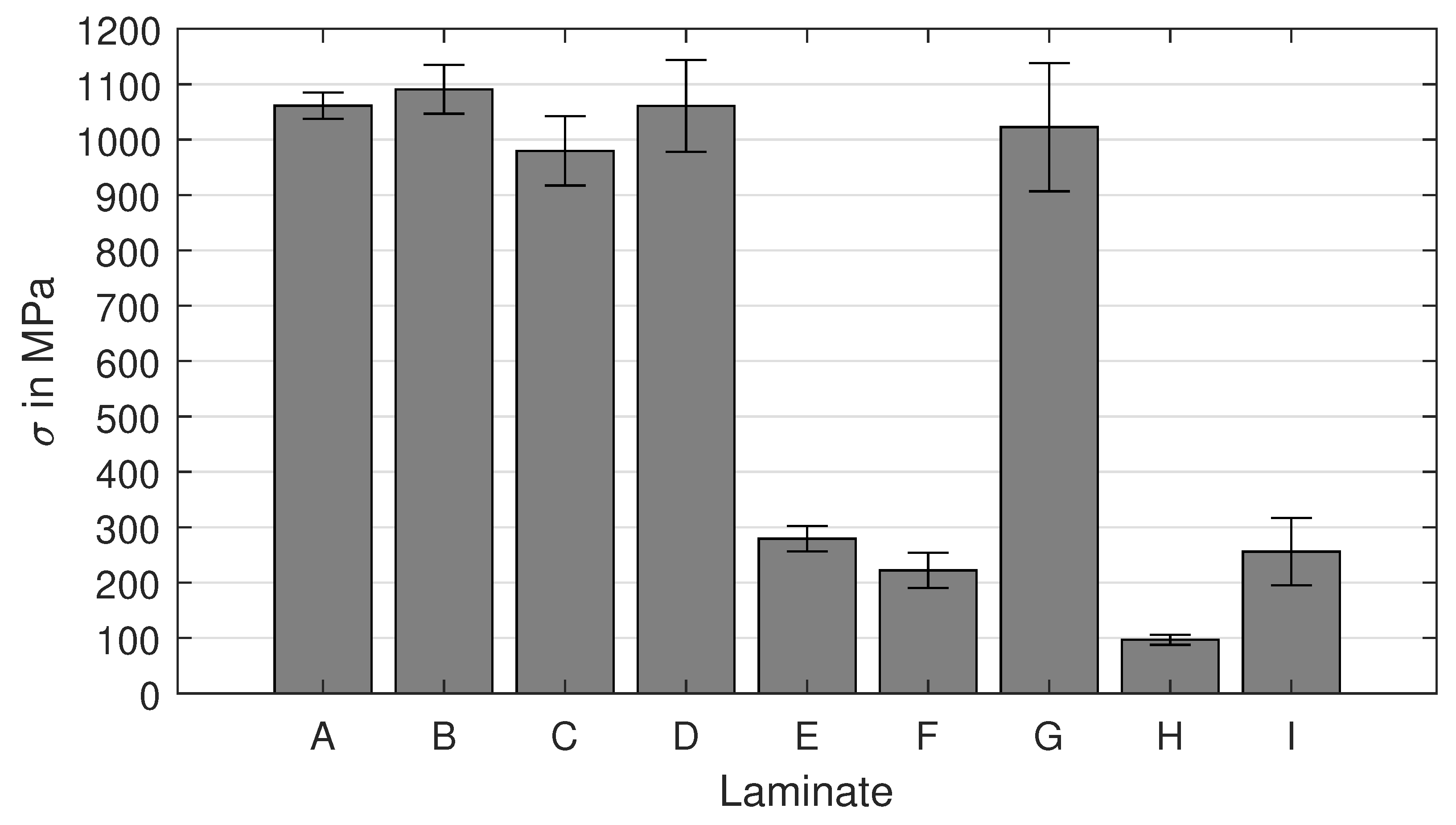

The results for tensile strength are shown in

Figure 5. The highest values are attained by laminates A, B and D with approximately

. A slight decrease in mean tensile strength is observed for laminates C and G, with about

. For these samples, only one parameter is varied while keeping the other at its lowest setting. However, when both process parameters are concurrently adjusted, the tensile strength decreases suddenly below

for laminates E, F, H and I. This trend aligns with the laminates where fibre misaglinments are clearly visible (

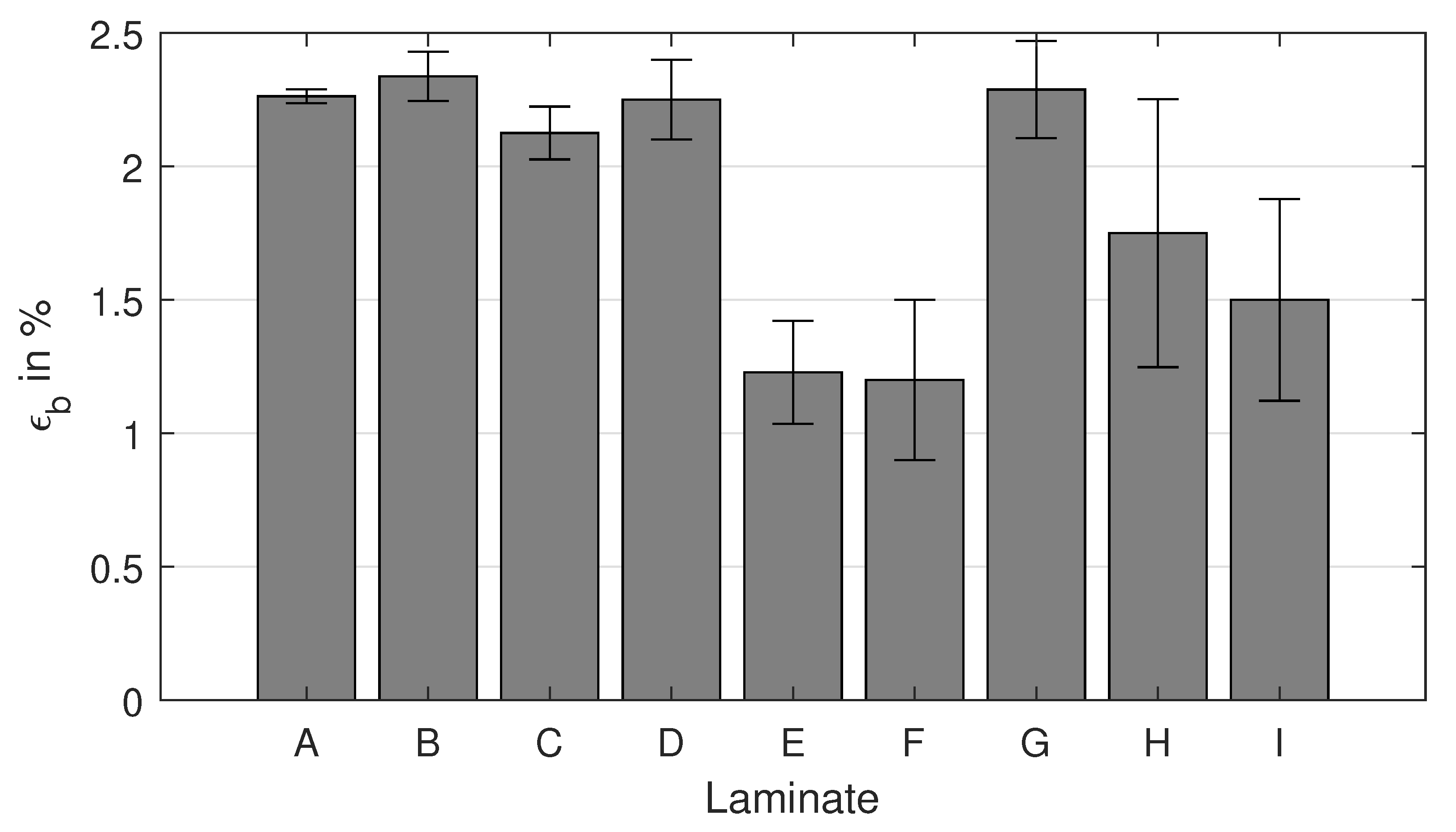

Figure 4). A similar trend is noticeable in the elongation at break results (

Figure 6), but in a lesser degree in comparison on tensile strength. Furthermore, the variance of the elongation at break seems to rise when the settings are incrementally increased. This variance ranges from

for laminate A up to a 16 times higher standard deviation for laminate H with

.

The results from the tensile tests substantiate the assumption of diminishing tensile strenght and elongation at break, attributed to fibre misalignment in laminates E, F, H and I. It strongly suggests the existence of a notable interaction among the process parameters. The subsequent ANOVA aim to ascertain the potential demonstrability of these effects.

3.3. ANOVA and interactions

An ANOVA is performed to conducted to assess the significance of various effects on the respective objectives of tensile strength (

Table 2), elongation at break (

Table 3), and FVF (

Table 4).

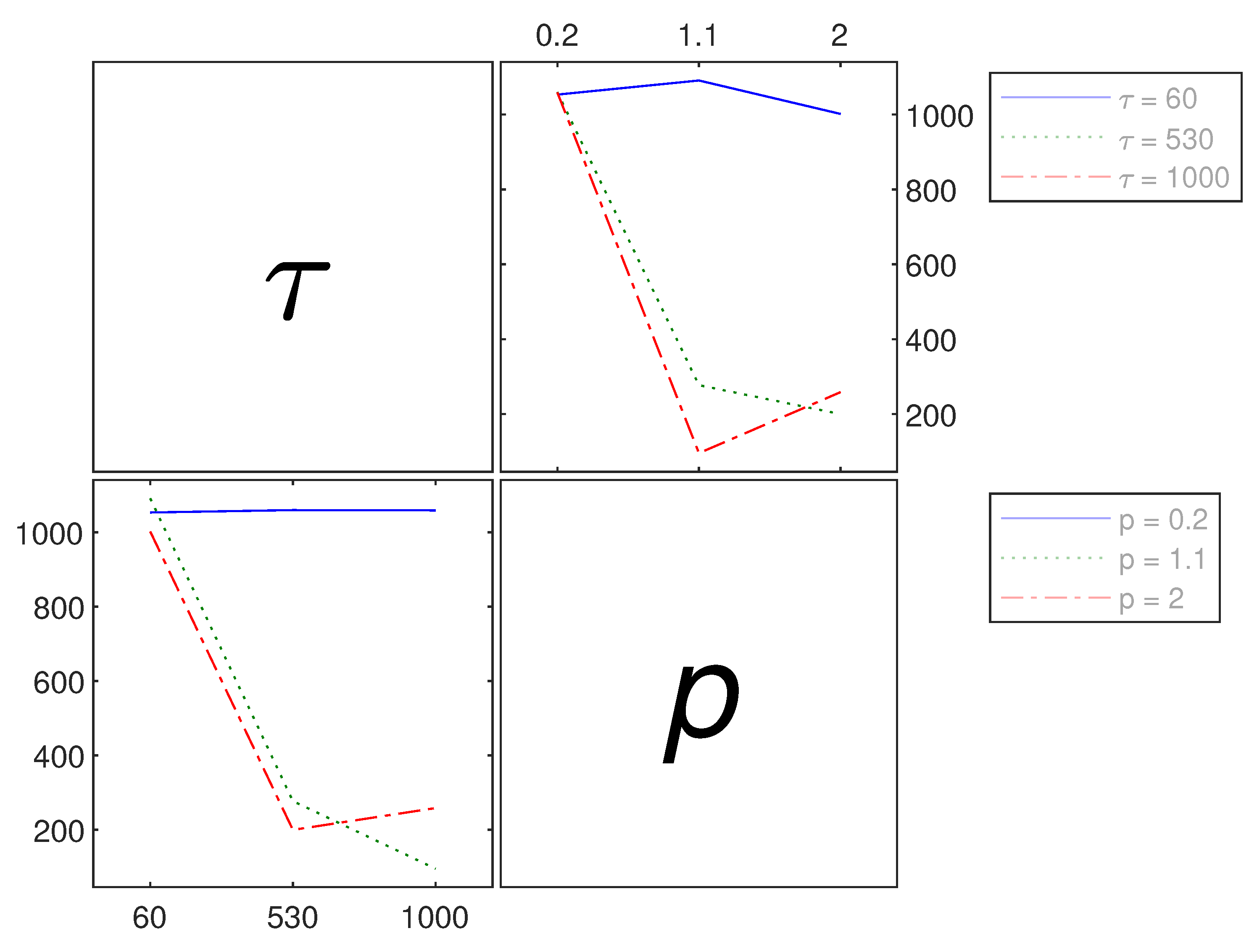

The interaction between holding time

and pressure

p with regard to tensile strenght shows a very small p-value of

, which indicates a high level of significance. This is supported by much higher F-values for both the main effects and the interaction, compared to the critical F-value of

and

, respectively. However, the significant main effects in

Table 2 are questionable, particularly when considering the raw results depicted in

Figure 5. In those results, alterations in tensile strength are not substantially apparent when only one parameter changes, contrary to the presence of a significant interaction. Conversely, when the main effects are not factored in, the F-value for the interaction decreases to

, accompanied by a p-value to

. Additionally, the accuracy of the regression model diminishes. Consequently, the main effects are retained within the ensuing regession model. The affected results concerning the interaction between holding time

and pressure

p are shown in

Figure 7. Concurrent variations in both parameters causes a decrease in tensile strength (illustrated by the dotted and dash-dotted lines in

Figure 7). Conversely, modifying just one parameter while maintaining the other at its lowest setting yields hardly any discrenible effect on the target value (solid line in

Figure 7).

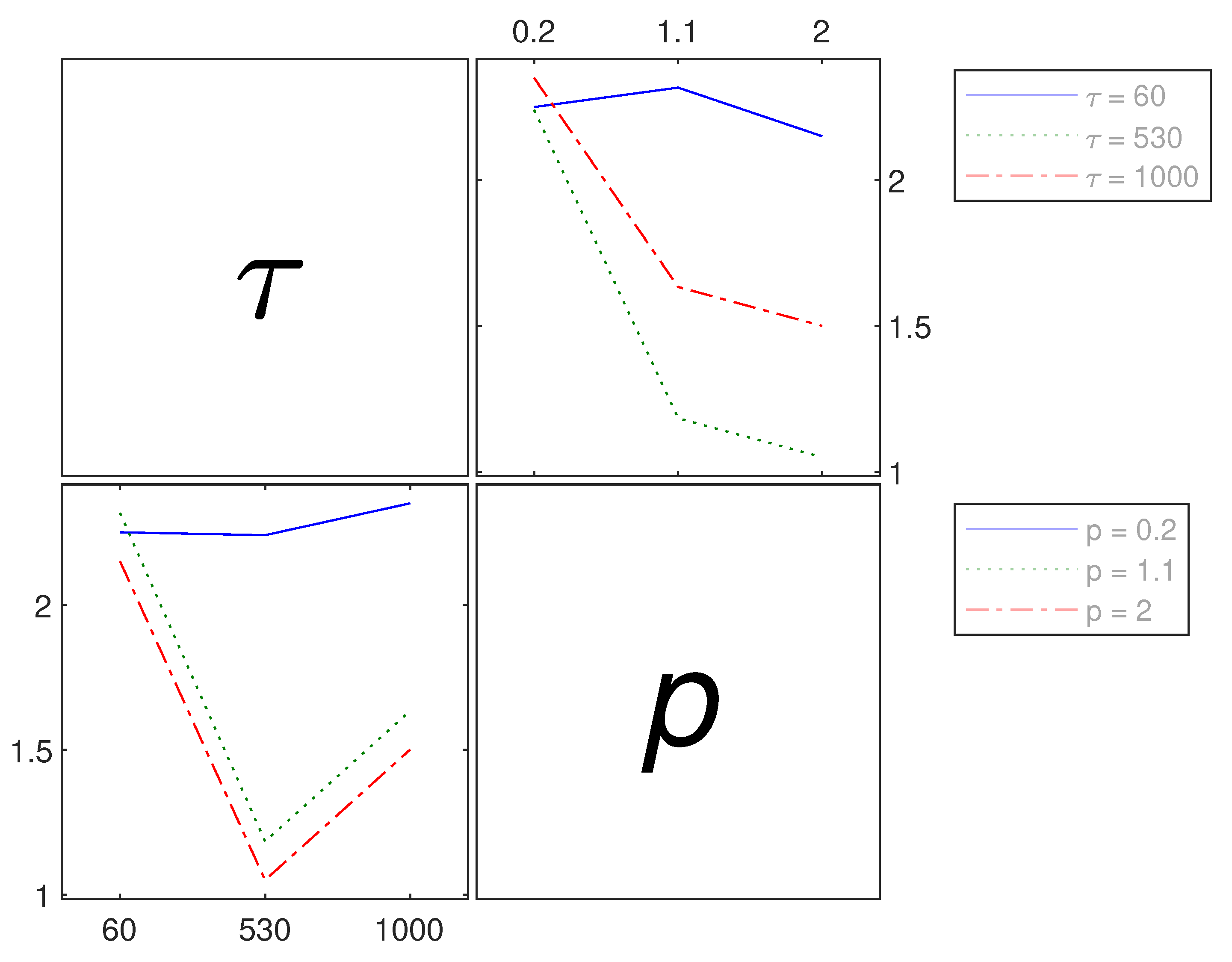

The calculated p-value of

, signifying the interaction among the observed process parameters for elongation at break (

Table 3), also highlights its significant influence. As well as for the tensile strength, the presence of interaction between holding time and pressure, along with the similiar trends in elongation at break when only one parameter is altered (

Figure 6), suggests that debating the main effects might be unnecessary. Moreover, if the interaction is exclusively deemed relevant, the F-value decreases to

and the p-value decreases to

. This adjustment would also lead to a regression model of lesser accuracy. As a result, the main effects continue to be considered for the subsequent regression model.

Figure 8 shows the interaction between the process parameters affecting the elongation at break. When one parameter is maintanined at its lowest setting, there is hardly any noticable effect on the target value. However, wehen the pressure is above

and holding time increases from

to

, a moderate increase in elongation at break is observed. Furthermore, an extended holding time of

seems to result in a relatively smaller reduction in the target value compared to the moderate setting of (

).

Nonetheless, for achieving high values of both tensile strength and elongation at break, opting for lower seetings of both parameters is deemed preferable. This finding is consisting with Christmann et al. [

13] and Kropka et al. [

20], but it contrasts with other observations [

10,

21].

Regarding the FVF, no main effects or interaction of the process parameters are detected (

Table 4). As detailed earlier, the impregnation quality and compaction of all laminates are excellent (

Figure 4). This outcome is likely a consequence of the effective pre-impregnation of the UD-tapes, which in turn contributes to the minimal presence of microscopic voids prior to thermoforming. Additionally, the absence of substantial pressure requirement to eliminate macroscopic voids further attests to the quality of the prepreg material. Consequently, the quality of the prepreg may effect the objectives significantly as proposed by Kropka et al. [

20].

3.4. Regression model and validation

Regression models are formulated based on the experimental and statistical evaluation of the process parameters. Equation (

1) offers a solution for the tensile strenght

in

, depending on the holding time

in

s and the pressure

p in

:

Equation (

2) describes the predicted target value for the elongation at break

in % affected by the process parameters:

The subsequent process parameters are set to validate the model for predicting high values of tensile strength and elongation at break:

holding time

pressure

A laminate is fabricated with the aforementioned parameters, followed by the execution of tensile tests.

Table 5 presents a comparison between the measurements aquired from the validation samples and the corresponding predicted results. The calculated values exhibit a strong correspondance with the measured results. Both the tensile strenght and elongation of the validation samples fall within the confidence intervals (CI) establised by the model, while the means are slightly above the predictions. The percentage error between the predicted and measured mean values remains notably low, at

for the tensile strenght and

for the elongation at break.

4. Conclusions

This paper demonstrates the efficacy of employing statistical methods as a suitable approache for developing a predictive tool in the context of UD-tape thermoforming. Based on the regression model, it becomes apparent that a shorter holding time and lower pressure yield higher tensile strength and elongation at break. When only one parameter undergoes variation while the other remains low, the target values exhibit minimal alteration. A strong interaction is observed between the process parameters of holding time and pressure, resulting in a sudden decrease in tensile strength and elongation at break due to fibre misalingments when both parameters are concurrently elevated. However, the fibre volume fraction remains unaffected by the process parameters, possibly due to the effective pre-impregnation of the UD-tapes. Further research endeavors should incorporate additional input variables, such as prepreg quality, process temperature, varying matrix materials, as well as multi-level variations of holding time and pressure. This approach would foster a more comprehensive understanding of the effects of relevant parameters on the thermoforming process.

Author Contributions

Conceptualization, J.W., D.N. and L.K.; methodology, J.W.; validation, J.W.; formal analysis, J.W.; investigation, J.W.; resources, L.K.; data curation, J.W.; writing—original draft preparation, J.W.; writing—review and editing, J.W., D.N. and L.K.; visualization, J.W.; supervision, D.N. and L.K.; project administration, J.W. and D.N.; funding acquisition, D.N. and L.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research financed with tax funds on the basis of the budget adopted by the Saxon State Parliament via the Sächsische Aufbaubank (SAB) and carried out under the project "SmartHouB" in the frame of M-era.Net program. The publication of the article was funded by the Deutsche Forschungsgesellschaft (DFG, German Research Foundation) project number 491193532 and the Chemnitz University of Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the Cetex Institut gGmbH (Chemnitz, Germany) for the provision of the UD-tapes free of charge.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| ANOVA |

Analysis of variance |

| BF |

Basalt fibre |

| CI |

Confidence interval |

| DOE |

Design of experiments |

| FRTP |

Fibre reinforced thermoplastic |

| FVF |

Fibre volume fraction |

| PA 6 |

Polyamide 6 |

| PEEK |

Polyether ether ketone |

| Prepreg |

Preimpregnated material |

| SD |

Standard deviation |

| UD-tape |

Unidirectional fibre-reinforced tape |

References

- Witten, E.; Mathes, V. Der europäische Markt für Faserverstärkte Kunststoffe / Composites 2022: Marktentwicklungen, Trends, Herausforderungen undAusblicke.

- Baur, E.; Brinkmann, S.; Osswald, T.A.; Rudolph, N.; Schmachtenberg, E.; Saechtling, H. Saechtling Kunststoff Taschenbuch, 31. ausgabe ed.; Hanser: München, 2013. [Google Scholar]

- Dagdag, O.; Hsissou, R.; Safi, Z.; Hamed, O.; Jodeh, S.; Haldhar, R.; Verma, C.; Ebenso, E.E.; El Bachiri, A.; El Gouri, M. Viscosity of epoxy resins based on aromatic diamines, glucose, bisphenolic and bio-based derivatives: a comprehensive review. Journal of Polymer Research 2022, 29, 1–29. [Google Scholar] [CrossRef]

- Neitzel, M.; Mitschang, P.; Breuer, U. Handbuch Verbundwerkstoffe: Werkstoffe, Verarbeitung, Anwendung, 2., aktualisierte und erweiterte auflage ed.; Hanser eLibrary, Hanser: München, 2014. [Google Scholar] [CrossRef]

- Cherif, C. Textile Werkstoffe für den Leichtbau; Springer Berlin Heidelberg: Berlin, Heidelberg, 2011. [Google Scholar] [CrossRef]

- Bersee, H.; Robroek, L. The role of the thermoplastic matrix in forming processes of composite materials. Composites Manufacturing 1991, 2, 217–222. [Google Scholar] [CrossRef]

- Akkerman, R.; Haanappel, S.P. Thermoplastic composites manufacturing by thermoforming. In Advances in composites manufacturing and process design; Boisse, P., Ed.; Woodhead publishing series in composites science and engineering; Woodhead Publishing: Cambridge, UK, 2015; pp. 111–129. [Google Scholar] [CrossRef]

- Nestler, D.; Trautmann, M.; Zopp, C.; Tröltzsch, J.; Osiecki, T.; Nendel, S.; Wagner, G.; Kroll, L. Continuous Film Stacking and Thermoforming Process for Hybrid CFRP/aluminum Laminates. Procedia CIRP 2017, 66, 107–112. [Google Scholar] [CrossRef]

- Wolthuizen, D.J.; Schuurman, J.; Akkerman, R. Forming Limits of Thermoplastic Composites. Key Engineering Materials 2014, 611–612, 407–414. [Google Scholar] [CrossRef]

- Schug, A.; Winkelbauer, J.; Hinterhölzl, R.; Drechsler, K. Thermoforming of glass fibre reinforced polypropylene: A study on the influence of different process parameters. Proceedings of the 20th International ESAFORM Conference on Material Forming. AIP Publishing, 2017, AIP Conference Proceedings, pp. 030010–1 – 030010–6. [CrossRef]

- Stamopoulos, A.G.; Di Ilio, A. On the Predictive Tools for Assessing the Effect of Manufacturing Defects on the Mechanical Properties of Composite Materials. Procedia CIRP 2019, 79, 563–567. [Google Scholar] [CrossRef]

- Mayer, C. Prozeßanalyse und Modellbildung zur Herstellung gewebeverstärkter, thermoplastischer Halbzeuge: Zugl.: Kaiserslautern, Univ., Diss., 1999, als ms. gedr ed.; Vol. 5, Schriftenreihe / Institut für Verbundwerkstoffe GmbH, IVW, Inst. für Verbundwerkstoffe GmbH: Kaiserslautern, 2000.

- Christmann, M.; Mitschang, P.; Medina, L. Impregnation Performance of Non-Isobaric Processes. 20th Internaional Conference on Composite Materials, 2015.

- Nishi, M.; Hirashima, T.; Kurashiki, T.; Kurose, M.; Kaburagi, T.; Uenishi, K. Thermoforming Simulation of Thermoplastic Pre-Impregnated Textile Reinforcement. 20th Internaional Conference on Composite Materials, 2015.

- Xiong, H.; Hamila, N.; Boisse, P. Consolidation Modeling during Thermoforming of Thermoplastic Composite Prepregs. Materials (Basel, Switzerland) 2019, 12. [Google Scholar] [CrossRef]

- Chen, H.; Li, S.; Wang, J.; Ding, A. A focused review on the thermo-stamping process and simulation progresses of continuous fibre reinforced thermoplastic composites. Composites Part B: Engineering 2021, 224, 109196. [Google Scholar] [CrossRef]

- Manson, J.A.E.; Schneider, T.L.; Seferis, J.C. Press-forming of continuous-fiber-reinforced thermoplastic composites. Polymer Composites 1990, 11, 114–120. [Google Scholar] [CrossRef]

- Talbott, M.F.; Springer, G.S.; Berglund, L.A. The Effects of Crystallinity on the Mechanical Properties of PEEK Polymer and Graphite Fiber Reinforced PEEK. Journal of Composite Materials 1987, 21, 1056–1081. [Google Scholar] [CrossRef]

- Ma, X.l.; Wen, L.h.; Wang, S.y.; Xiao, J.y.; Li, W.h.; Hou, X. Inherent relationship between process parameters, crystallization and mechanical properties of continuous carbon fiber reinforced PEEK composites. Defence Technology 2023, 24, 269–284. [Google Scholar] [CrossRef]

- Kropka, M.; Reichstein, J.; Neumeyer, T.; Altstaedt, V. Effect of the pre-consolidation process on quality and mechanical properties of mono- and multi-material laminates based on thermoplastic UD-tapes. 21st International Conference on Composite Materials, 2017.

- Hou, M. Stamp forming of continuous glass fibre reinforced polypropylene. Composites Part A: Applied Science and Manufacturing 1997, 28, 695–702. [Google Scholar] [CrossRef]

- The MathWorks Inc.. MATLAB, 2022.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).