Submitted:

14 August 2023

Posted:

15 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

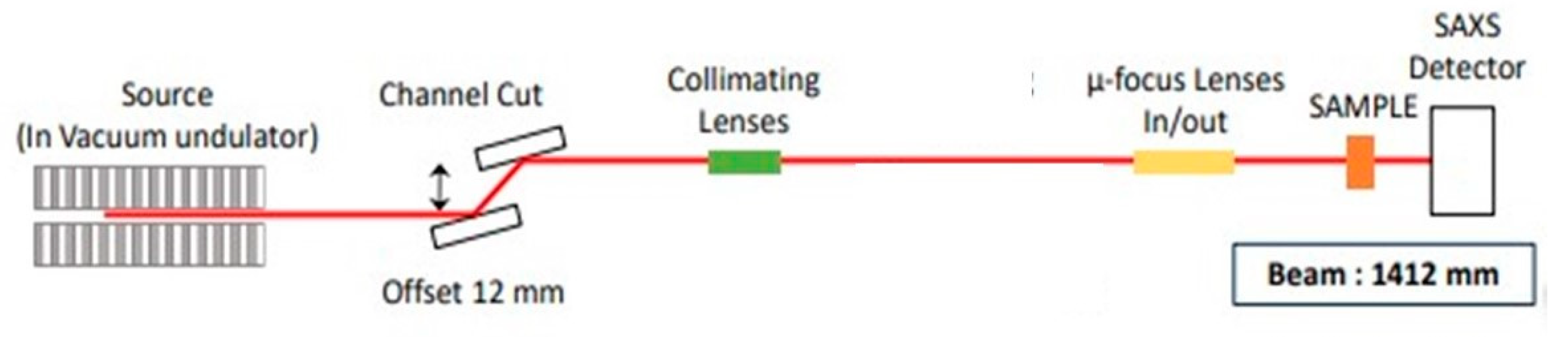

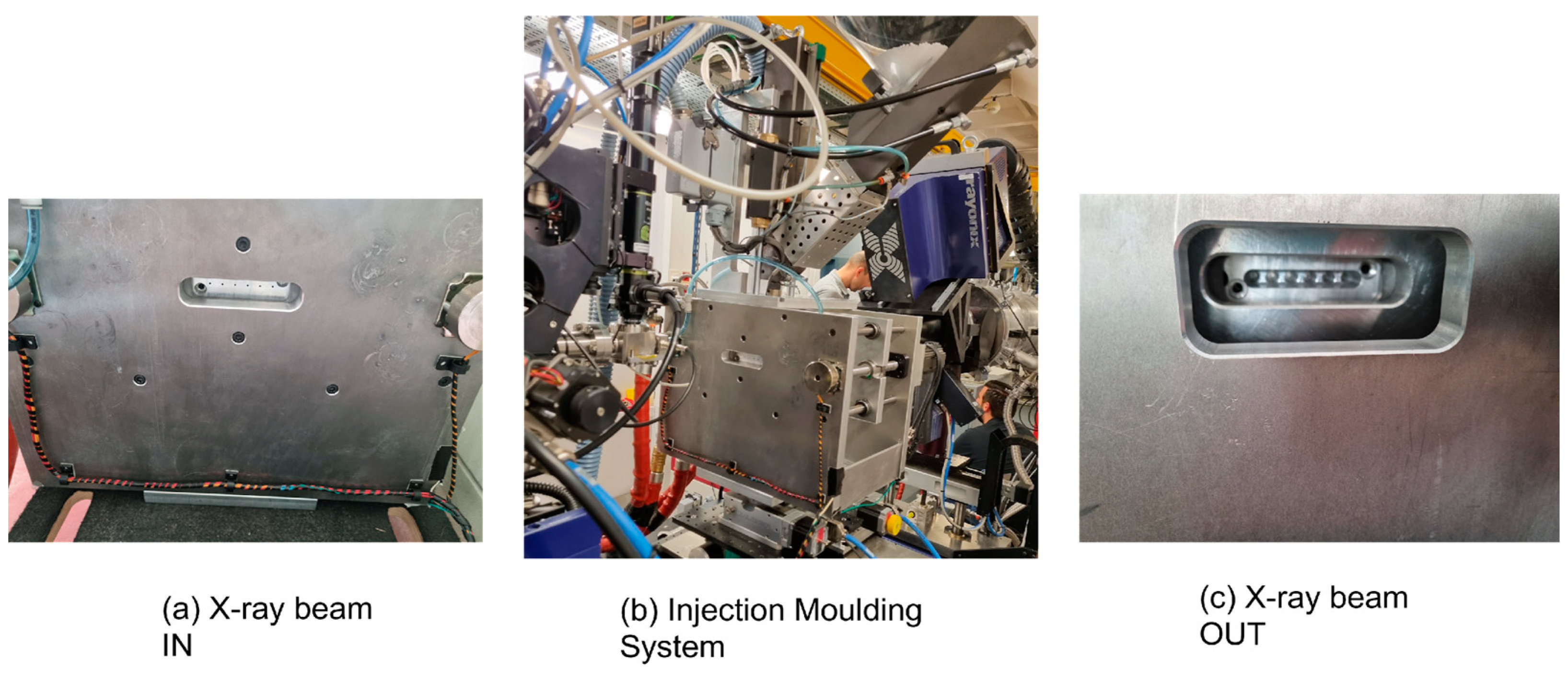

2. Materials and Methods

3. Results

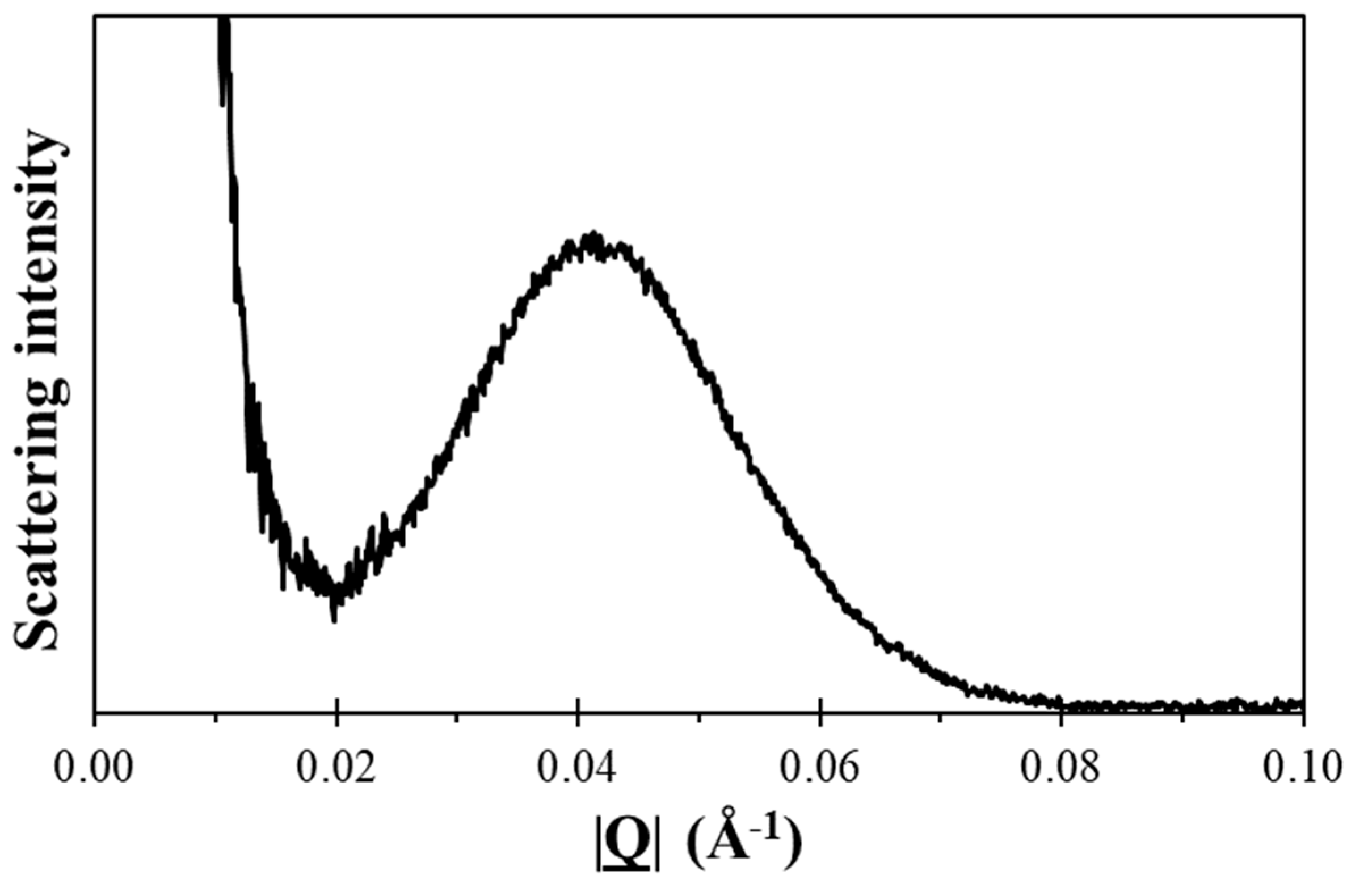

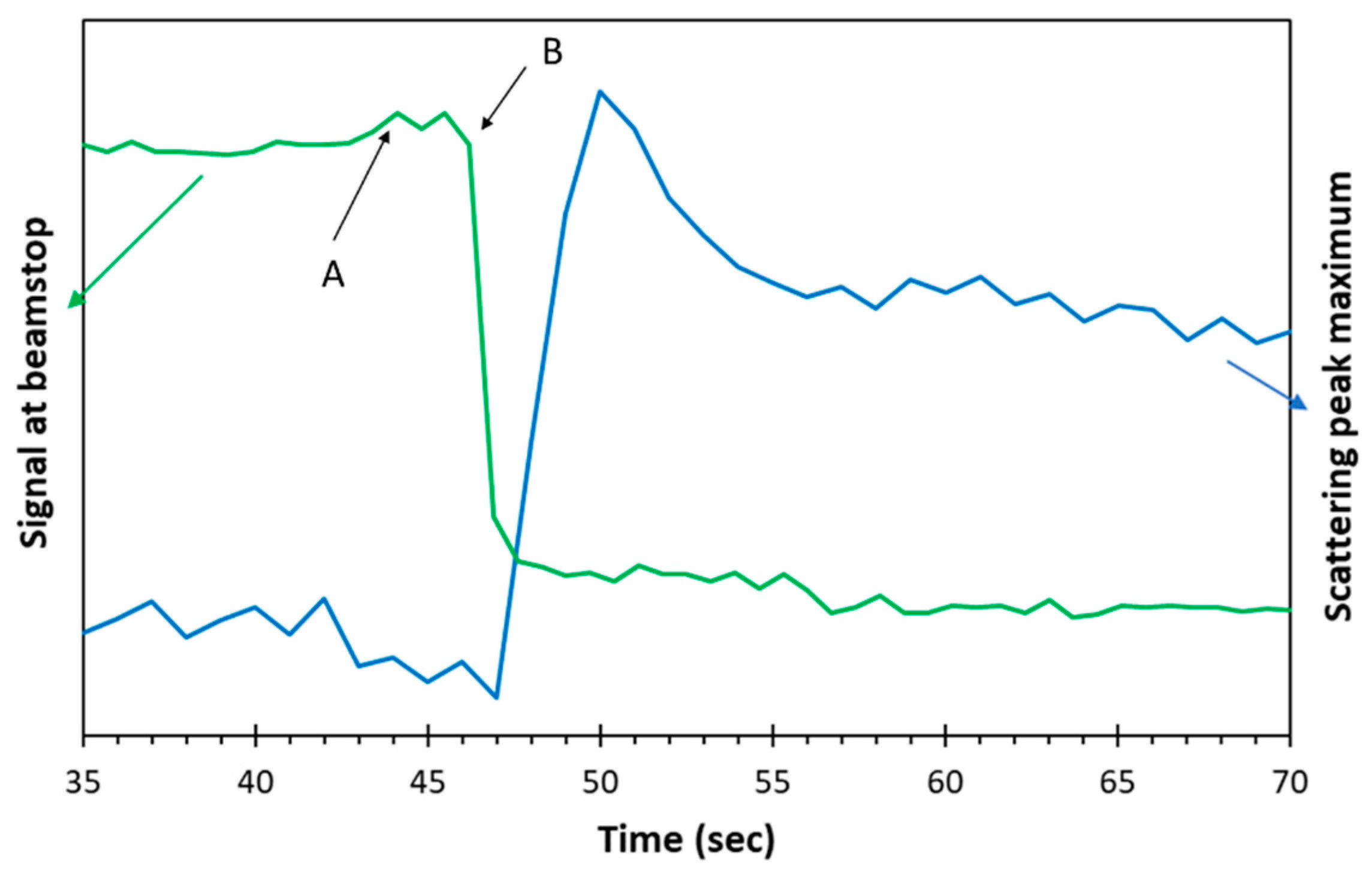

3.1. Basic Observations

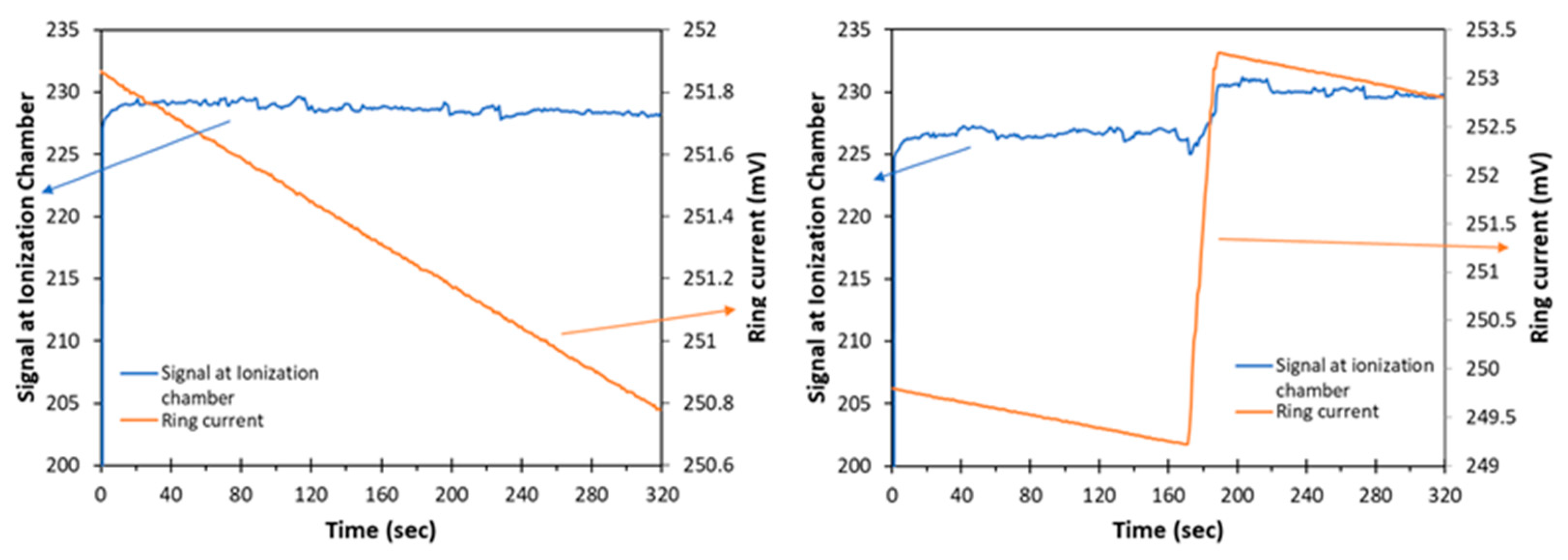

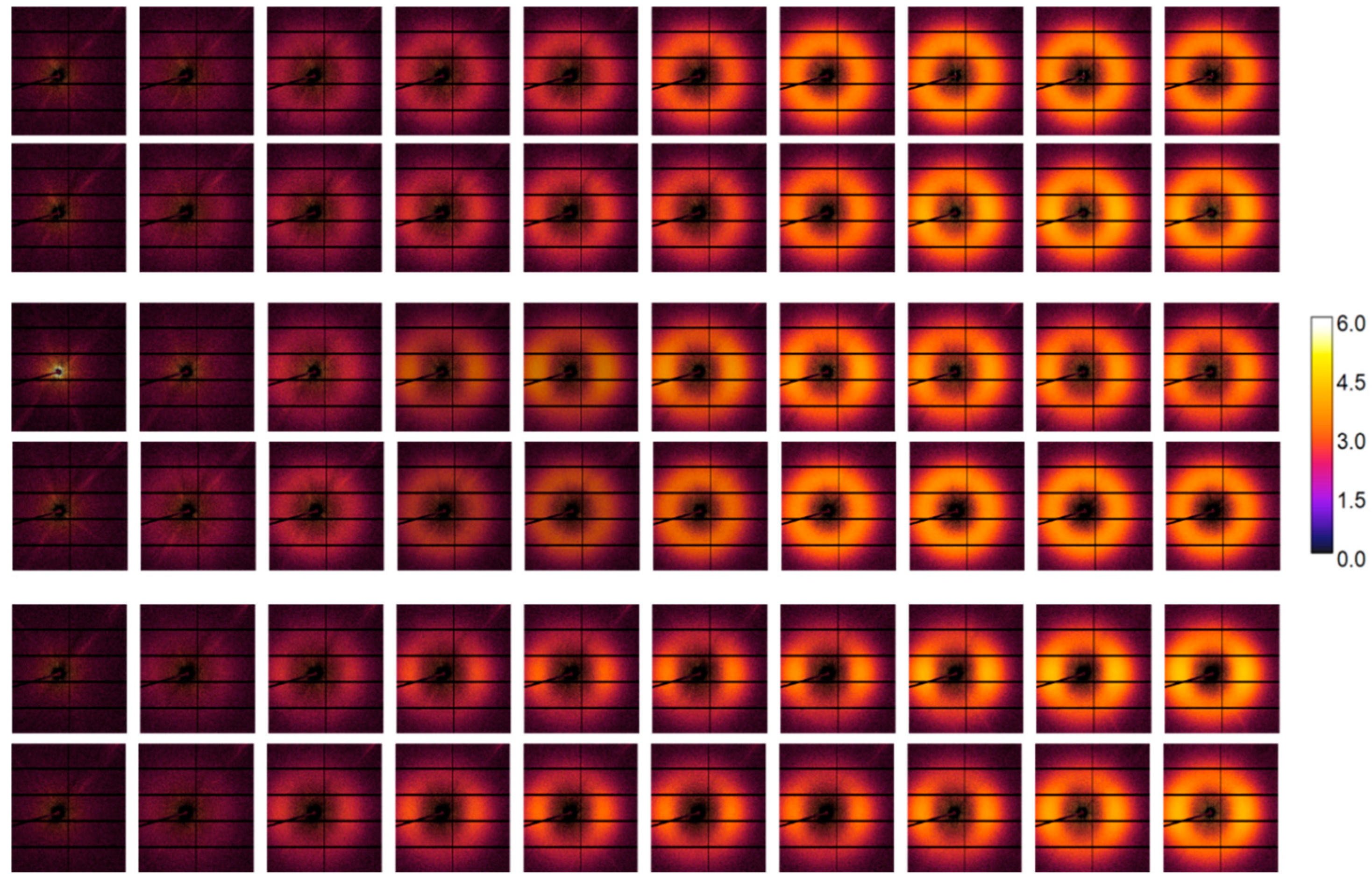

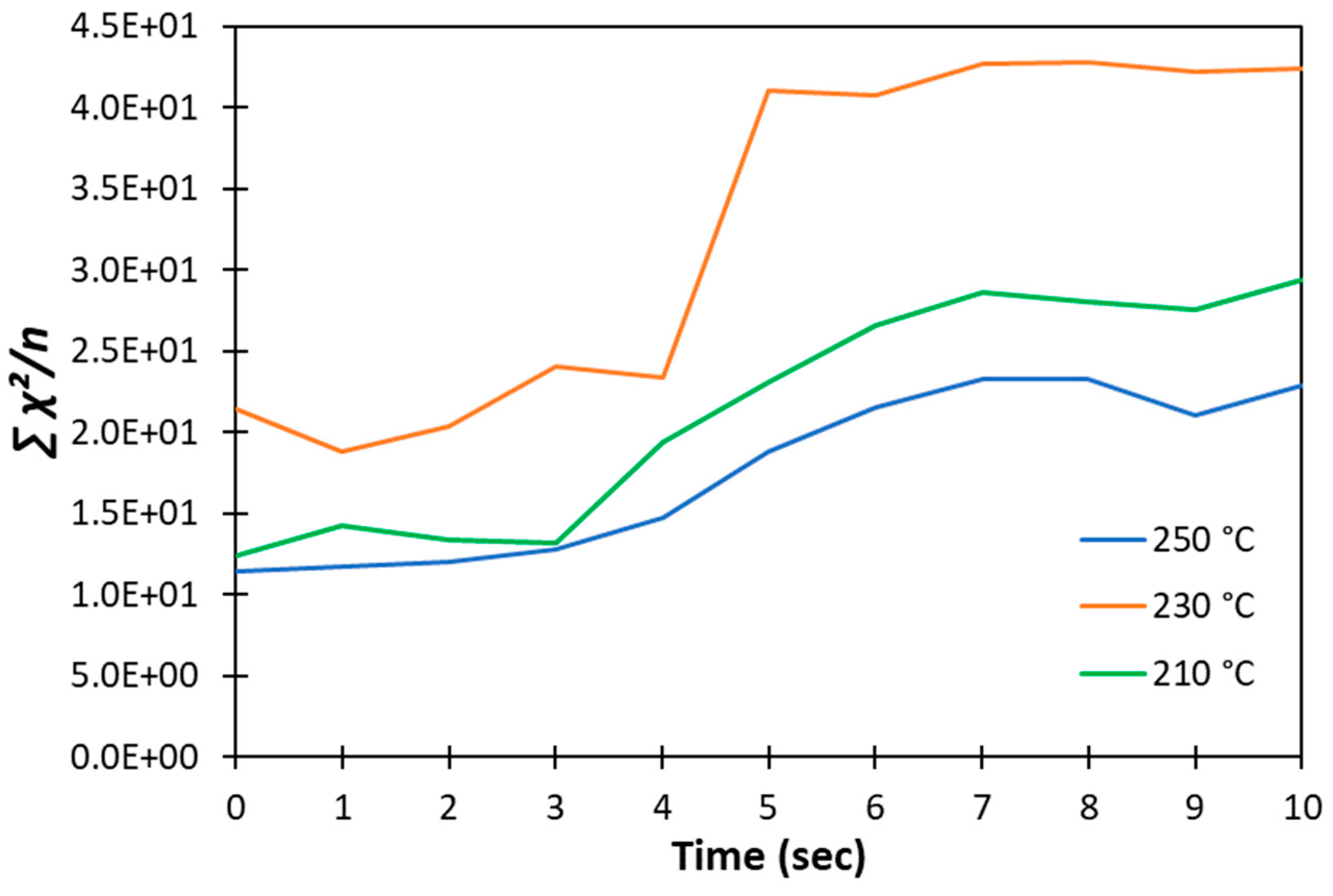

3.2. Reproducibility

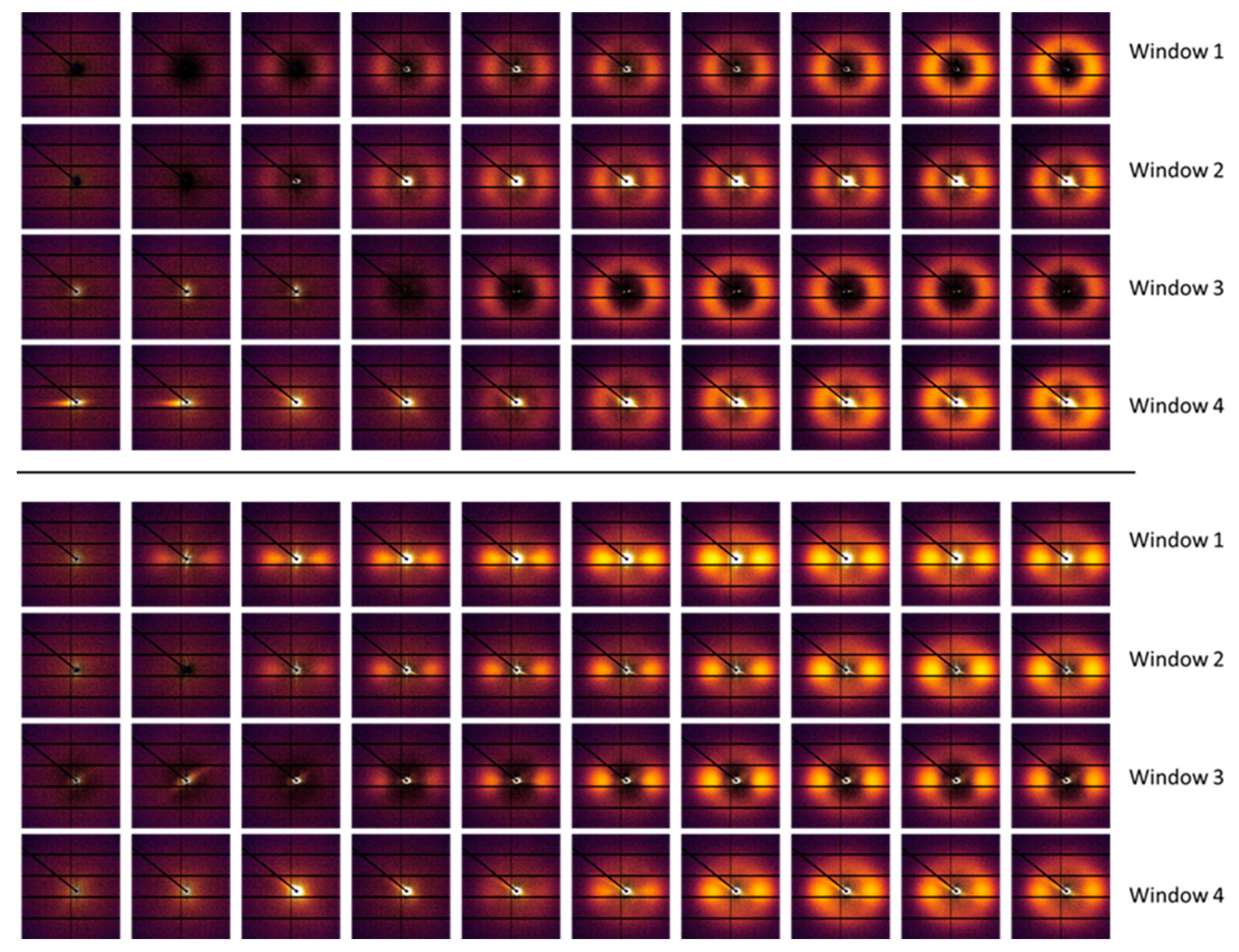

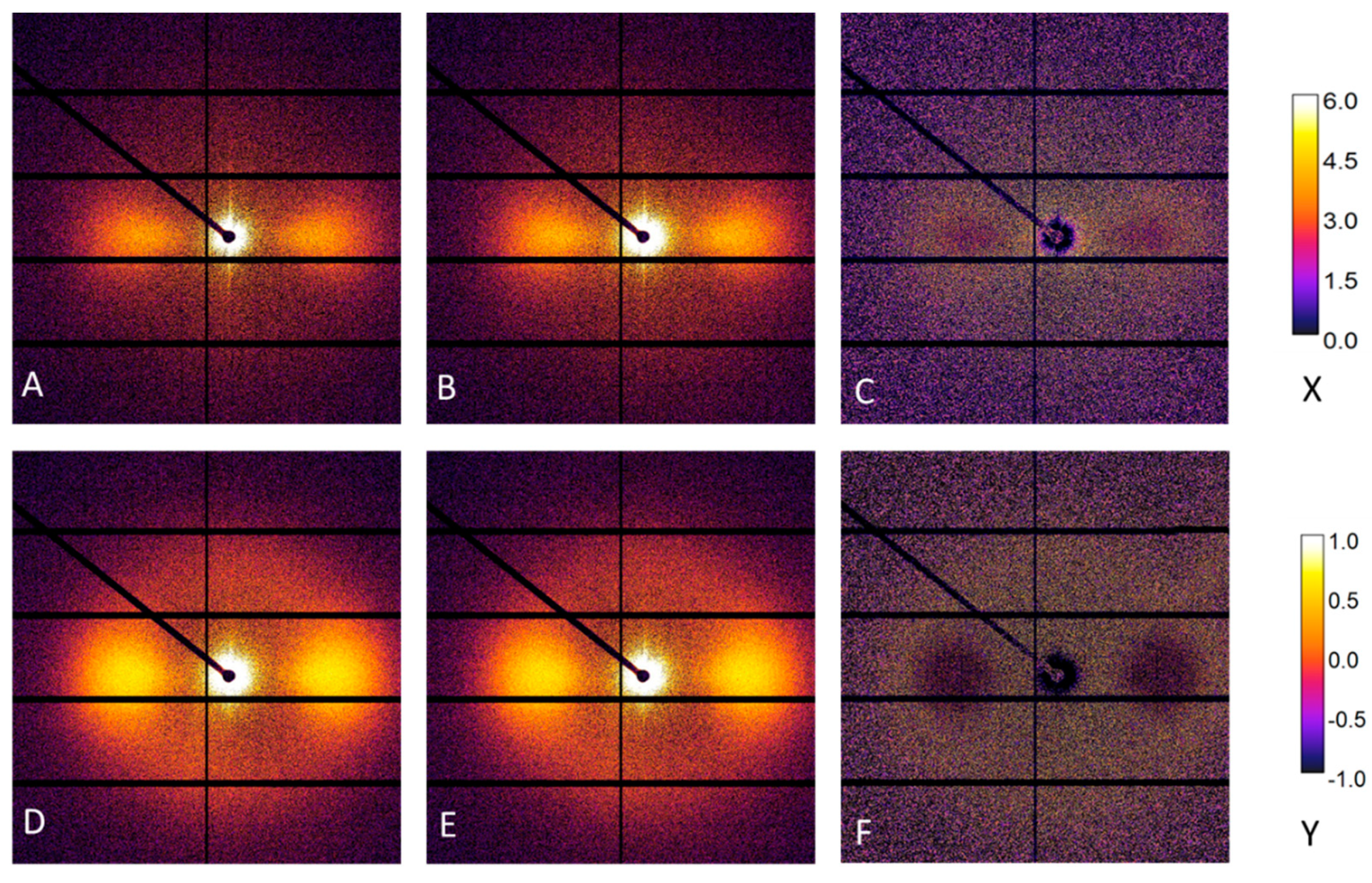

3.3. Spatial variations

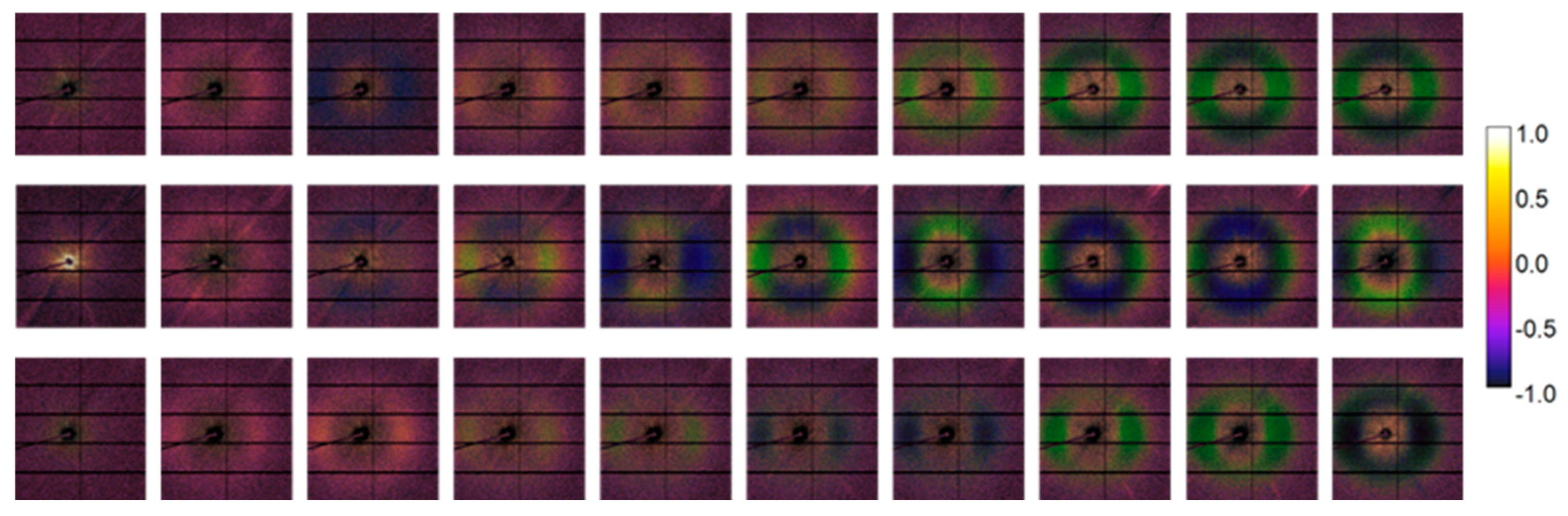

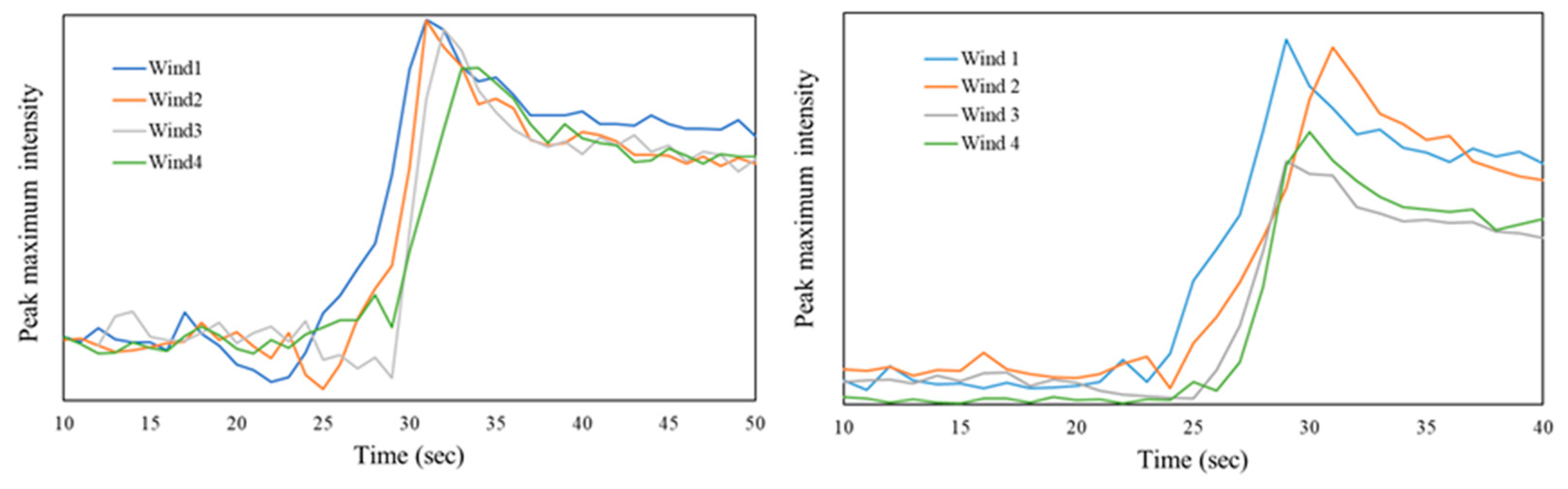

3.4. Time variation

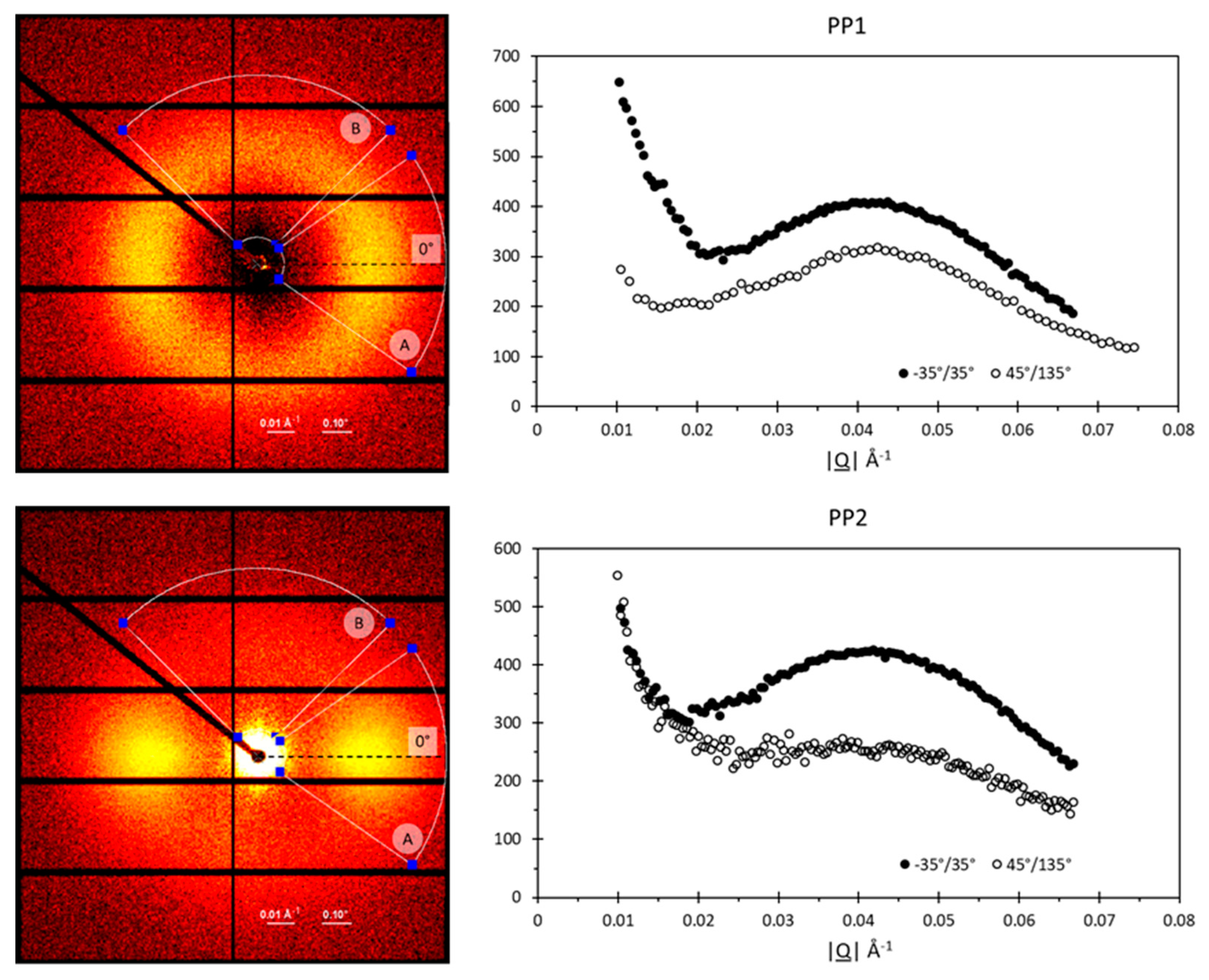

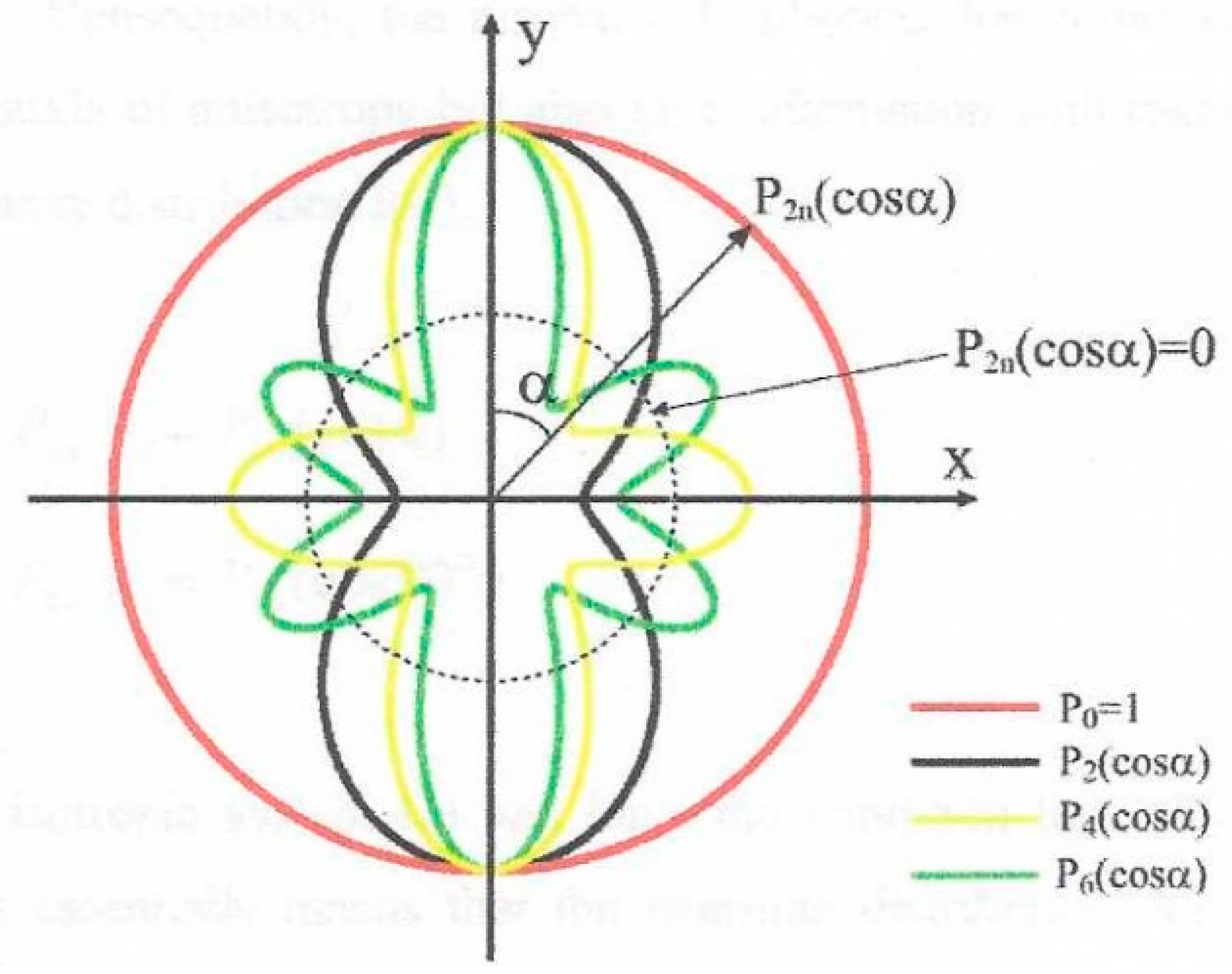

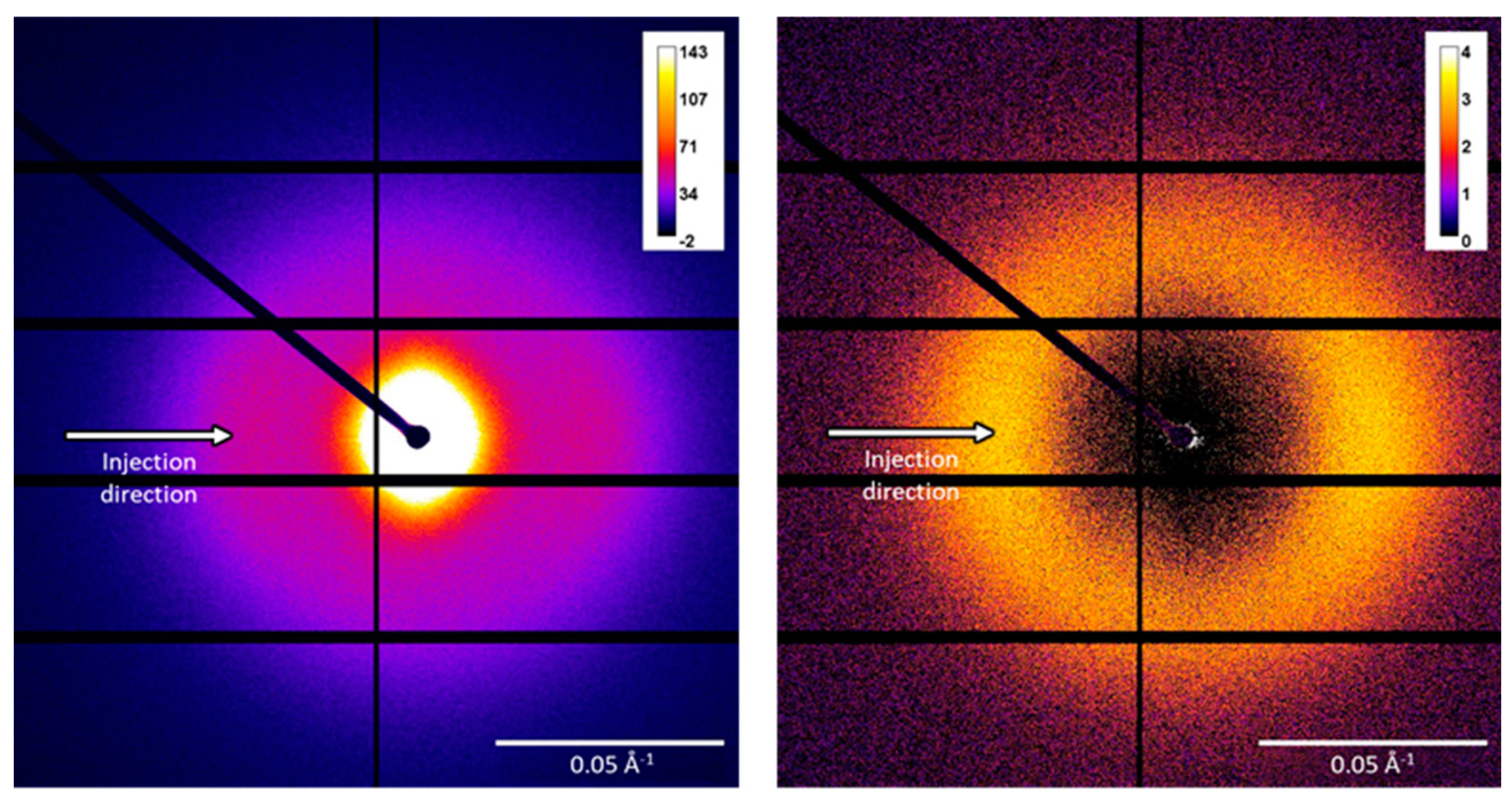

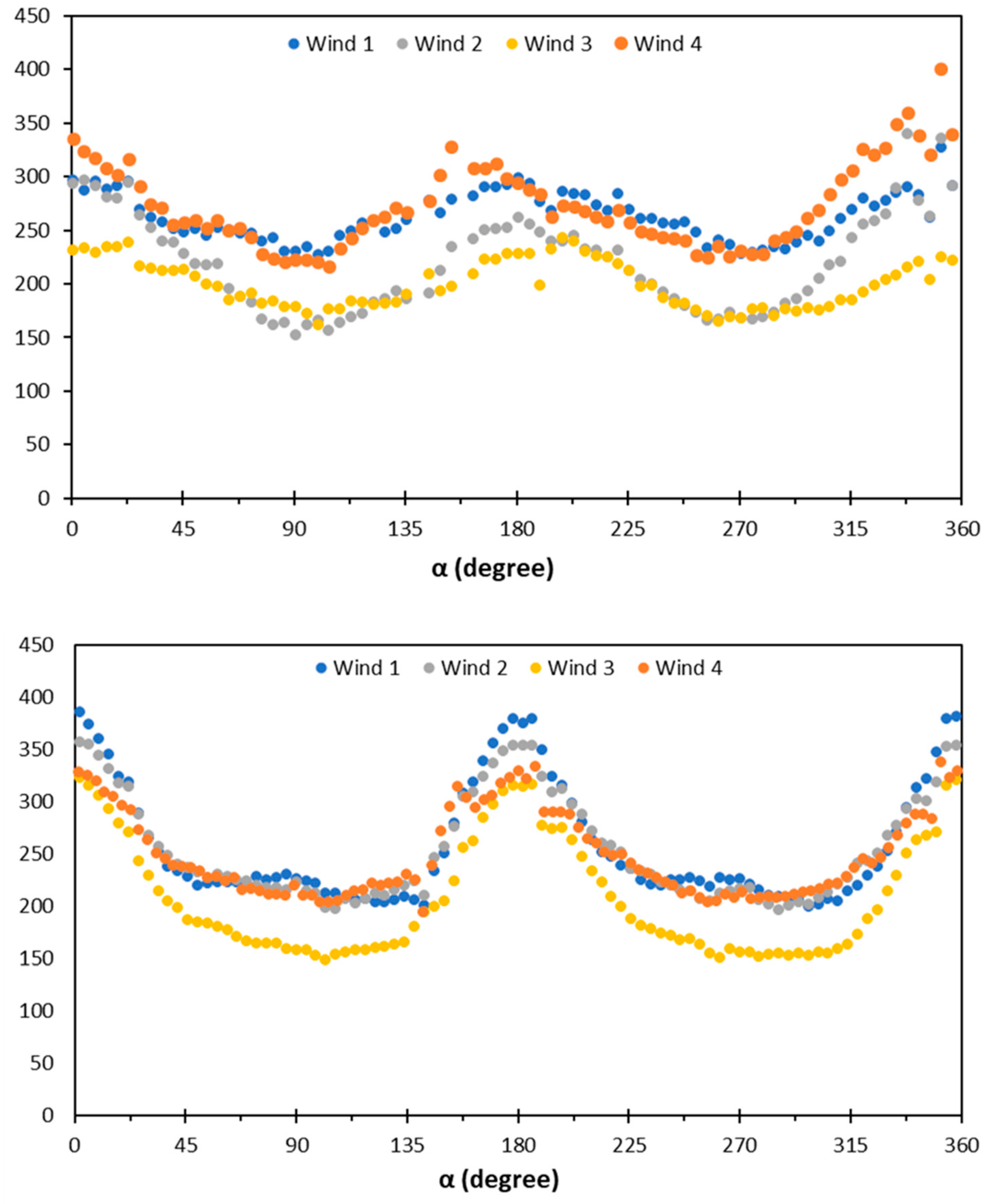

3.5. Preferred Crystal Orientation

4.0. Discussion

5.0. Summary

- We have successful developed and tested operando X-ray scattering measurements during injection moulding. We are able to obtain useful quantitative data on the rate of crystallisation, local temperature variations and the pattern of preferred orientation of the lamellar crystals.

- We are able to operate on a 1s data cycle time and the possibilities of reducing this to 0.5s are promising.

- The design of the injection moulding unit enables modifications to be made easily and control the processing parameter.

- On this basis of these validation experiments, we are posied to perform defined injection moulding cycles to test specific aspects of the process of transforming molten plastic in to a shaped moulded solid product.

- These validation experiments have confirmed that the microscopic characteristics of the process of transforming molten plastic to solid plastic are reproducible with successive moulding cycles, and this opens up the possibility of exploring spatial variations within the mould cavity using the predetermined window locations.

- We have been able to obtain quantitative time-resolving data which can be compared with the predicts of computer simulations.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ebnesajjad, S. (2003) “Injection Moulding” Chapter 7 in “Melt Processible Fluoroplastics”, Editor Sina Ebnesajjad pages 151-193 William Andrew Publishing, Norwich. ISBN 13: 9781884207969.

- Smith Hyatt and John W. Hyatt “Improvement in processes and apparatus for manufacturing pyroxyline” US Patent 133, 229. November 19, 1872.

- Mitchell, P., Editor “Tool and Manufacturing Engineers Handbook: Plastic Part Manufacturing”, Society of Manufacturing Engineers, 1996 online https://books.google.pt/books?id=Q4X1ovFVBvoC&printsec=frontcover&hl=pt-PT&source=gbs_ge_summary_r&cad=0#v=onepage&q&f=false accessed 30 July 2023.

- Sailors, H.R. & Hogan, J.P. (1981) History of Polyolefins, Journal of Macromolecular Science: Part A Chemistry, 15:7, 1377-1402. [CrossRef]

- Mandelkern, L. The Relation between Structure and Properties of Crystalline Polymers. Polym J 17, 337–350 1985. [CrossRef]

- Hu, A.O., Hua, W-Q., Zhong, G.J., Wang, Y-D., Gao, Y-T., Hong, C-X., Li, Z-M., Bian, F-G., Xiao, T-Q., Macromolecules 2020, 53, 15, 6498–6509. [CrossRef]

- Björn, L., Mazza, R.M., Andreasson, E., Linell, F., Lutz-Bueno, V., Guizar-Sicairos, M., Jutemar, E.P., and Liebi, M. ACS Appl. Polym. Mater. 2023, XXXX, XXX, XXX-XXX.

- Michael J. Elwell, Mortimer, S., and Ryan, A.J., “A Synchrotron SAXS Study of Structure Development Kinetics during the Reactive Processing of Flexible Polyurethane Foam ”Macromolecules 1994, 27, 19, 5428–5439. [CrossRef]

- J.L. Stanford, J.R. Powell, A.N. Wilkinson, “Structural composites formed by reaction injection moulding”, in Editor(s): A G Gibson, FRC 2000–Composites for the Millennium, Woodhead Publishing, 2000,191-199, ISBN 9781855735507. [CrossRef]

- Mateus, A,, Bartolo, P., and Mitchell, G.R.,“In-situ time-resolving small-angle X-ray scattering studies of reaction kinetics and morphology in reaction injection moulding” unpublished work.

- R. Kolb, S. Seifert, N. Stribeck, H.G. Zachmann, “Investigation of the high-speed spinning process of poly(ethylene terephthalate) by means of synchrotron X-ray diffraction” Polymer, 41, 2000, 2931-2935. [CrossRef]

- van Drongelen, M., Cavallo, D., Balzano, L., Portale, G., Vittorias, I., Bras, W., Alfonso, G.C. and Peters, G.W.M. (2014), Structure Development of Low-Density Polyethylenes During Film Blowing: A Real-Time Wide-Angle X-ray Diffraction Study. Macromol. Mater. Eng., 299: 1494-1512. [CrossRef]

- E.M. Troisi, M. van Drongelen, H.J.M. Caelers, G. Portale, G.W.M. Peters, Structure evolution during film blowing: An experimental study using in-situ small angle X-ray scattering, European Polymer Journal 74, 2016, 190-208. [CrossRef]

- Qianlei Zhang, Wei Chen, Haoyuan Zhao, Youxin Ji, Lingpu Meng, Daoliang Wang, Liangbin Li, “In-situ tracking polymer crystallization during film blowing by synchrotron radiation X-ray scattering: The critical role of network”, Polymer, 198 2020, 122492. [CrossRef]

- Li, YW., Liu, GF., Wu, HJ. et al. BL19U2: Small-angle X-ray scattering beamline for biological macromolecules in solution at SSRF. NUCL SCI TECH 31, 117 (2020). [CrossRef]

- Tao Liao, Xintong Zhao, Xiao Yang, Phil Coates, Ben Whiteside, David Barker, Glen Thompson, Yuqing Lai, Zhiyong Jiang, Yongfeng Men,”In situ synchrotron small angle X-ray scattering investigation of structural formation of polyethylene upon micro-injection molding”, Polymer, 215, 2021, 123390. [CrossRef]

- Costa, A.A.; Gameiro, F.; Potêncio, A.; Silva, D.P.d.; Carreira, P.; Martinez, J.C.; Pascoal-Faria, P.; Mateus, A.; Mitchell, G.R. Evaluating the Injection Moulding of Plastic Parts Using In Situ Time-Resolved Small-Angle X-ray Scattering Techniques. Polymers 2022, 14, 4745. [CrossRef]

- J.B. González*, N. González, C. Colldelram, L. Ribó, A. Fontserè, G. Jover -Manas, J. Villanueva, M. Llonch, G. Peña, A. Gevorgyan, Y. Nikitin, J.C. Martínez, C. Kamma-Lorger, E. Solano, I. Sics, S. Ferrer, M. Malfois 2018 Mechanical Eng. Design of Synchrotron Radiation Equipment and Instrumentation MEDSI2018, Paris, France JACoW Publishing ISBN: 978-3-95450-207-3. [CrossRef]

- Ishige, R. Precise structural analysis of polymer materials using synchrotron X-ray scattering and spectroscopic methods. Polym J 52, 1013–1026 (2020). [CrossRef]

- Saeed Mohan, Robert H Olley, Alun S Vaughan and Geoffrey R Mitchell ‘Evaluating Scales of Structure in Polymers’ in “Controlling Controlling the Morphology of Polymers: Multiple Scales of Structure and Processing." Springer 2016 ed G.R.Mitchell and A.Tojeira ISBN 978-3-319-39320-9.

- Shin, S. New era of synchrotron radiation: fourth-generation storage ring. AAPPS Bull. 31, 21 (2021). [CrossRef]

- D.H. Bilderback, B.W. Batterman, M. J. Bedzyk.K. Finkelstein, C. Henderson, A. Merlini.W. Schildkamp, Q. Shen, J. White, Blum, E.B., P.J. Viccaro, D. M. Mills, S. Kim, G. K. Shenoy, K. E. Robinson, F. E. James, and J.M. Slater (1989) “Performance of a hard X-ray undulator at CHESS” Rev. Sci. Instrum. 60 (7), 1419-1425.

- 6082 Aluminum Alloy 6082-T6 T651 AlMgSi1 (AlSi1MgMn - 3.2315) Properties (theworldmaterial.com) online accessed 30 July 2023.

- UAI - Babyplast online accessed 30 July 2023.

- Costa, A.A., Gameiro, F., Olivereria, L., da Silva, D.P., Carreira, P., Martínez, J.C., Martinho, P.G., Mateus, A., Mitchell, G.R., “Industrially relevant Injection Moulding Apparatus for Operando Time- Resolving Small-Angle X-ray Scattering Measurements” J. Manufacturing Processes submitted.

- Keller, A., & Kolnaar, HWH. (1997). Flow-induced orientation and structure formation. In Materials Science and Technology (pp. 187 - 268).

- Pinheiro J., Abdulghani, S., Pascoal-Faria, P., Sousa, D., Pedro Carreira, Tânia Viana, Christina S. Kamma-Lorger, Geoffrey Mitchell; Tools to define and evaluate morphology mapping, a route to complex structures using direct digital manufacturing. AIP Conference Proceedings 24 July 2019; 2116 (1): 230003. [CrossRef]

- Lovell, R. & Mitchell, G. R. (1981). Molecular orientation distribution derived from an arbitrary reflection. Acta Cryst. A37, 135–137.

- Mitchell, G.R., Saengsuwan, S., Bualek-Limcharoen, S. (2005). Evaluation of preferred orientation in multi-component polymer systems using X-ray scattering procedures. In: Stribeck, N., Smarsly, B. (eds) Scattering Methods and the Properties of Polymer Materials. Progress in Colloid and Polymer Science, vol 130. Springer, Berlin, Heidelberg.

- L. Hay, M. Jaffe & K. F. Wissbrun (1976) A phenomenological model for row nucleation in polymers, Journal of Macromolecular Science, Part B, 12:3, 423-428. [CrossRef]

- James J Holt, Supatra Pratumshat, Paula Pascoal-Faria, Artur Mateus, and Geoffrey Robert Mitchell “Crystallisation from Anisotropic Polymer Melts” Chapter 10 in “Polymer crystallization: Methods, Characterization, and Applications”, editors Jyotishkumar Parameswaranpillai, Jenny Jacob, Senthilkumar Krishnasamy, Aswathy Jayakumar, and Nishar Hameed Wiley-VCH 2023 pages 225-284 ISBN 9783527350810.

- Muszyński, Paweł, Przemysław Poszwa, Krzysztof Mrozek, Michał Zielinski, Piotr Dalewski, and Michał Kowal. 2021. "Design and Simulation Study of the Induction Heated Injection Mold with Sliders" Materials 14, no. 23: 7476. [CrossRef]

- R. Sánchez, A. Martinez, D. Mercado, A. Carbonel, J. Aisa, (2021) “Rapid heating injection moulding: An experimental surface temperature study”,Polymer Testing, 93, 106928. [CrossRef]

- ALBA II — en (albasynchrotron.es) ONLINE accessed 30th July 2023.

- Reichert, H., Honkimäki, V. (2015). High-Energy X-ray Scattering and Imaging. In: Jaeschke, E., Khan, S., Schneider, J., Hastings, J. (eds) Synchrotron Light Sources and Free-Electron Lasers. Springer, Cham. [CrossRef]

| Acronym | Manufacturer | Grade | MFI g/10 mins at 230C | Notes |

|---|---|---|---|---|

| PP1 | Lyndon Basel | MOPLEN HP 500N | 12 | General purpose suitable for food contact applications. |

| PP2 | Repsol | ISPLEN PR595C2M | 45 | Phthalate free random copolymer which is clarified and contains antistatic additives. |

| PP3 | SABIC | 595A | 47 | Designed for Automotive applications. |

| D2n | PP1 | PP2 |

|---|---|---|

| D2 | 0.50 | |

| D4 | -0.28 | |

| D6 | -0.26 |

| Lp ( Å) | PP1 | PP2 |

| -35°/35° | 113 | 106 |

| 45°/135° | 121 | 116 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).