Submitted:

11 August 2023

Posted:

14 August 2023

You are already at the latest version

Abstract

Keywords:

MSC: 90B25

1. Introduction

1.1. Background and Rationale

1.2. Literature review

1.3. Aims and objectives

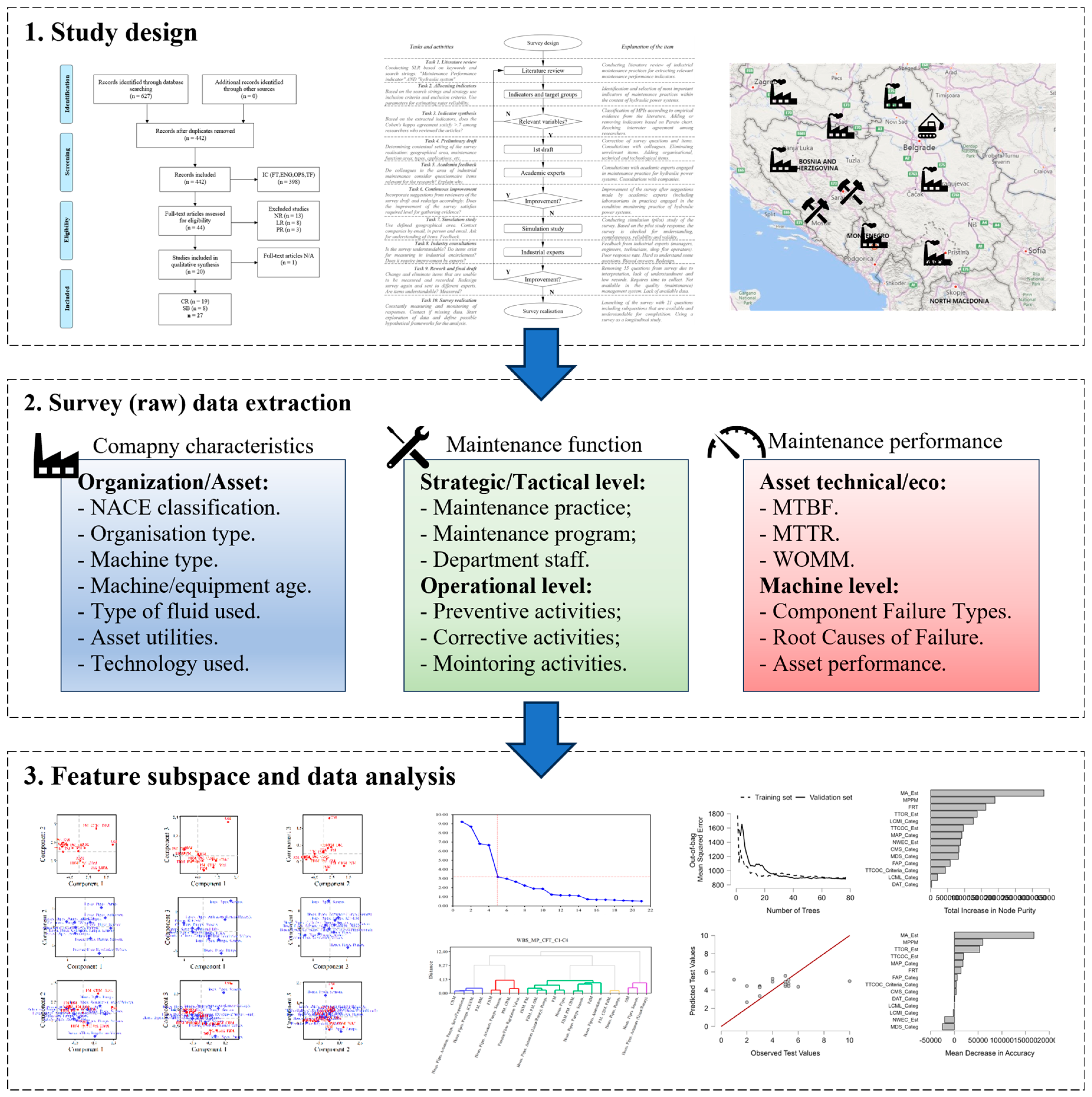

2. Methodology

2.1. Study design

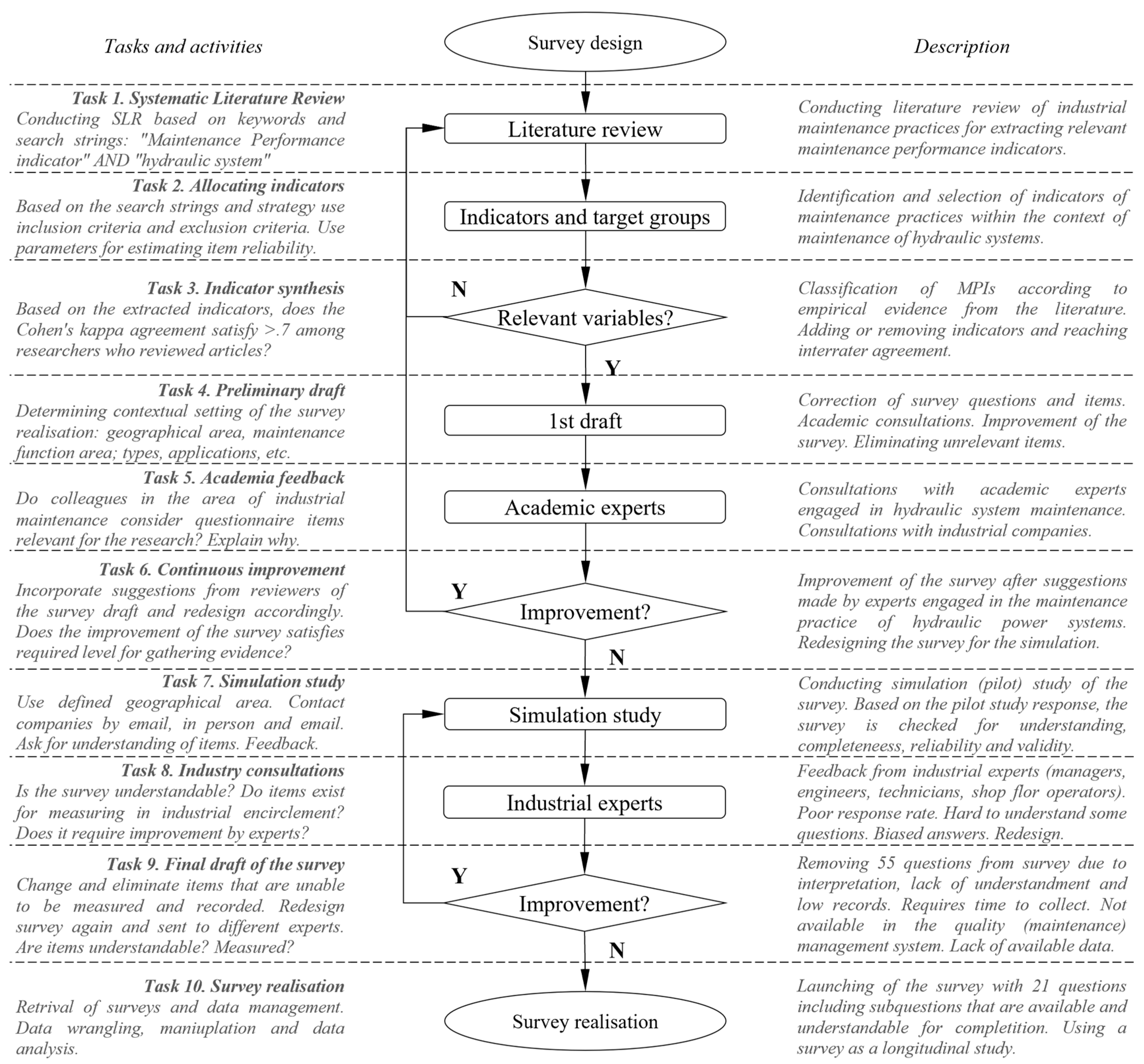

2.2. Survey design and realisation

2.3. Survey items and data extraction

2.4. Correspondence analysis

2.5. Clustering CA-components using AHC

3. Research results

3.1. Survey insights and descriptives

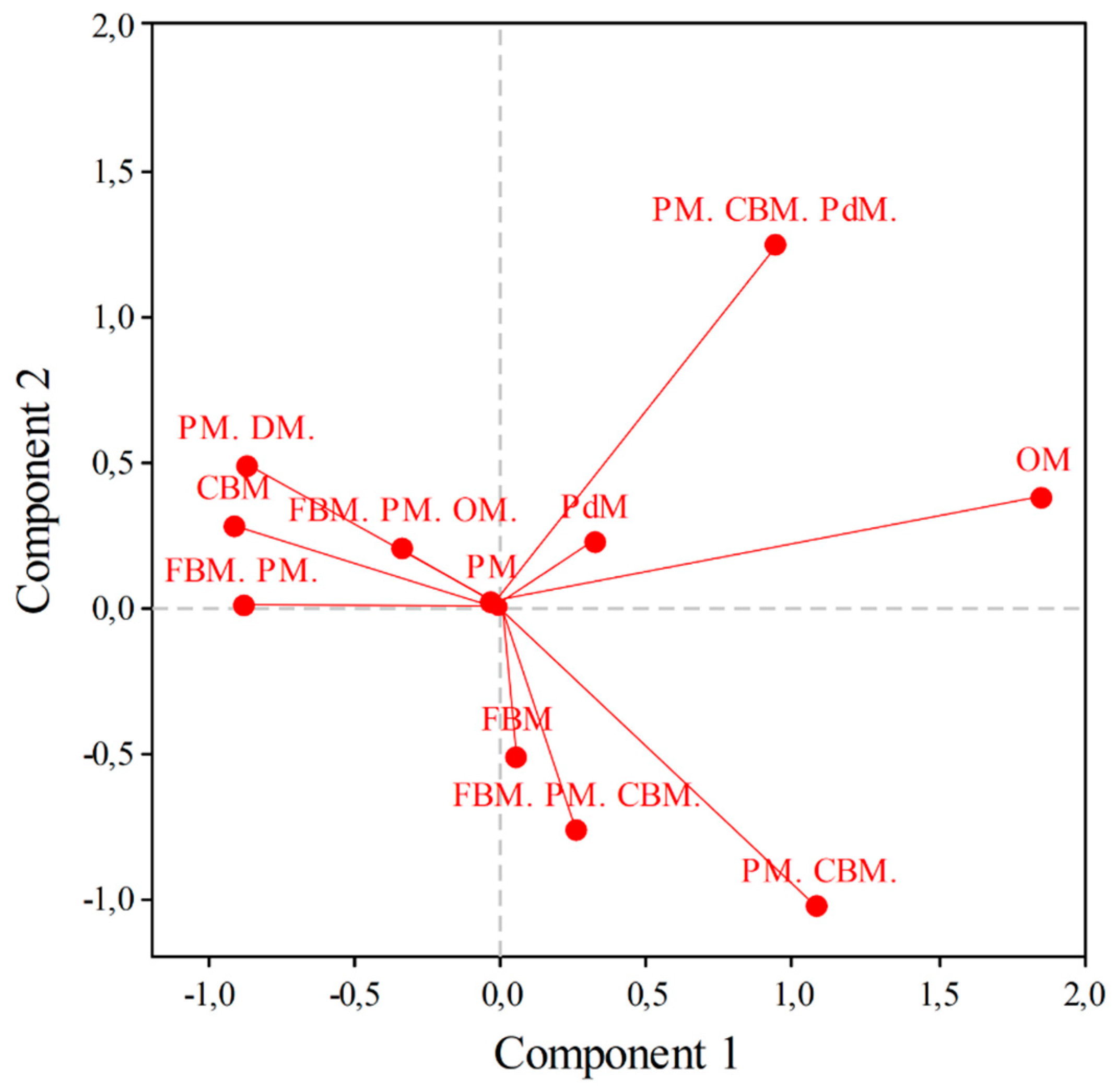

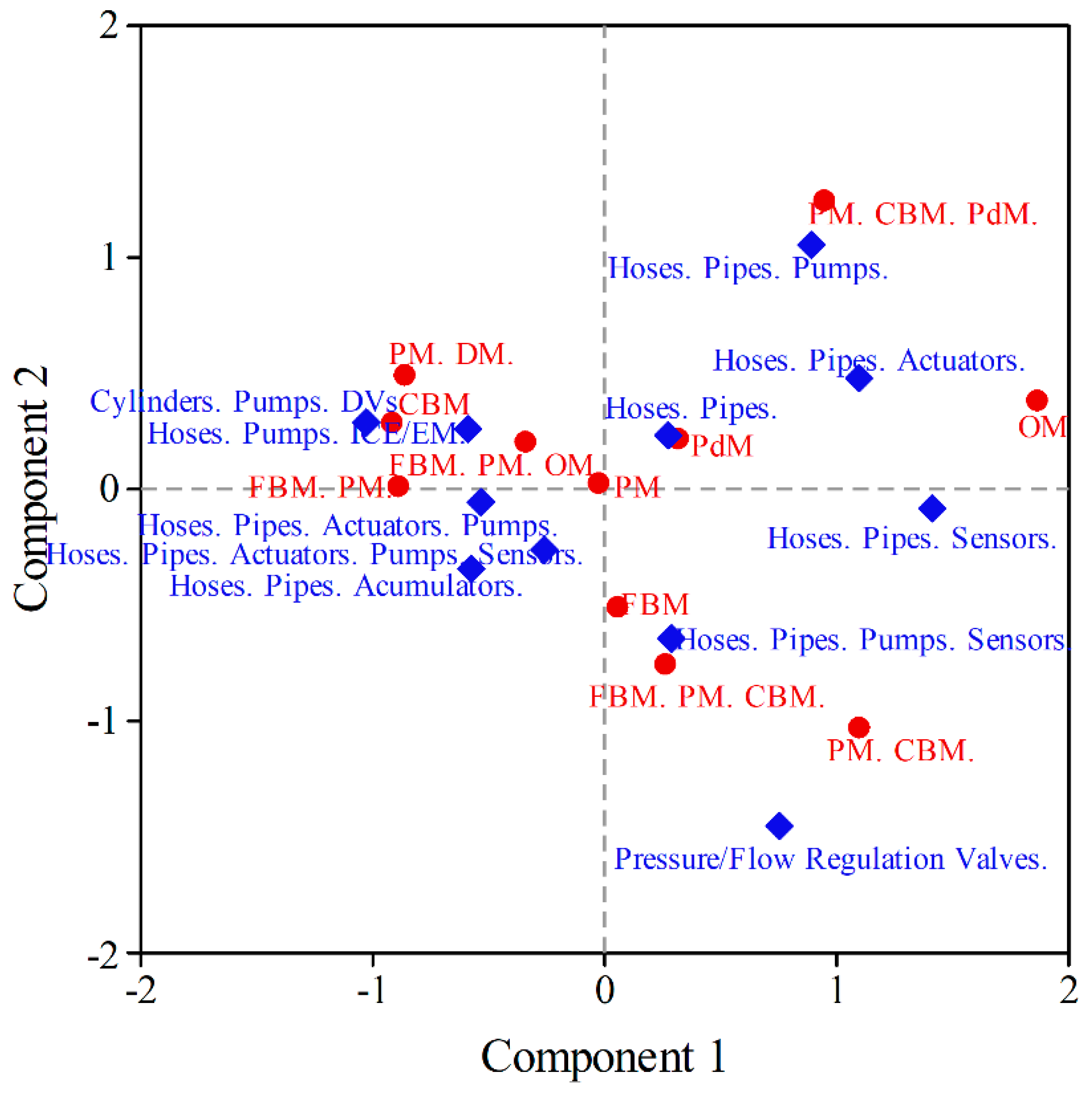

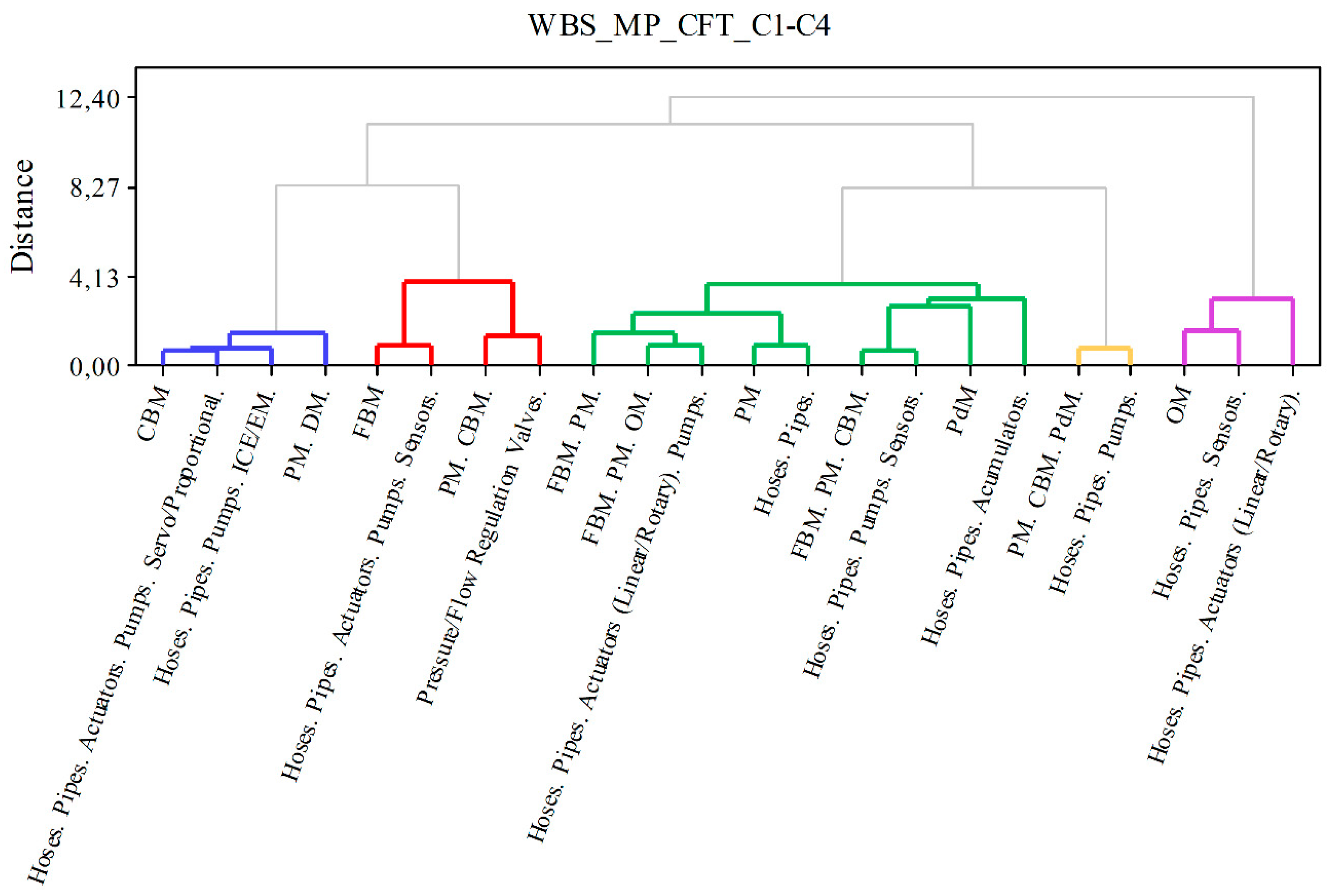

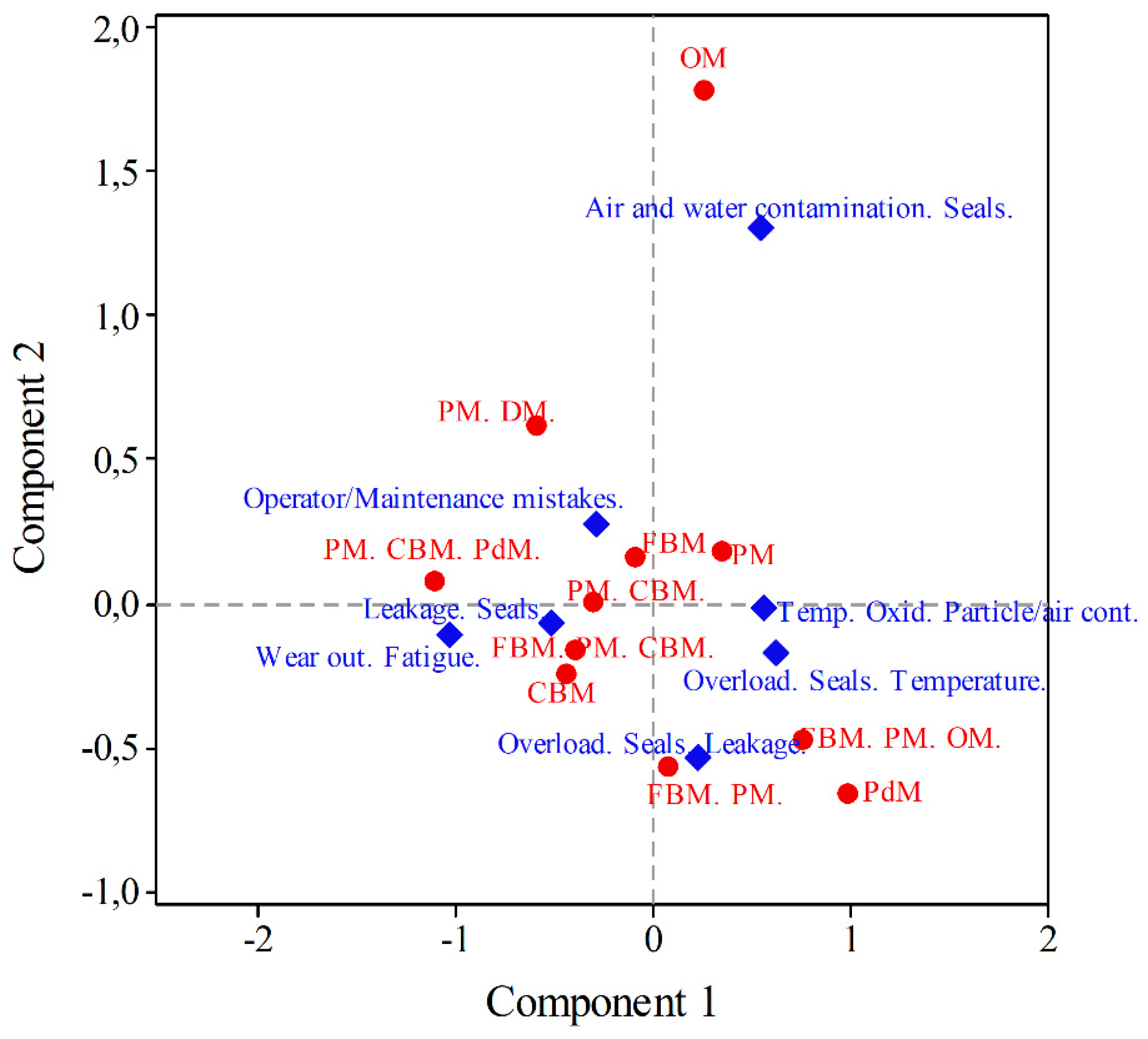

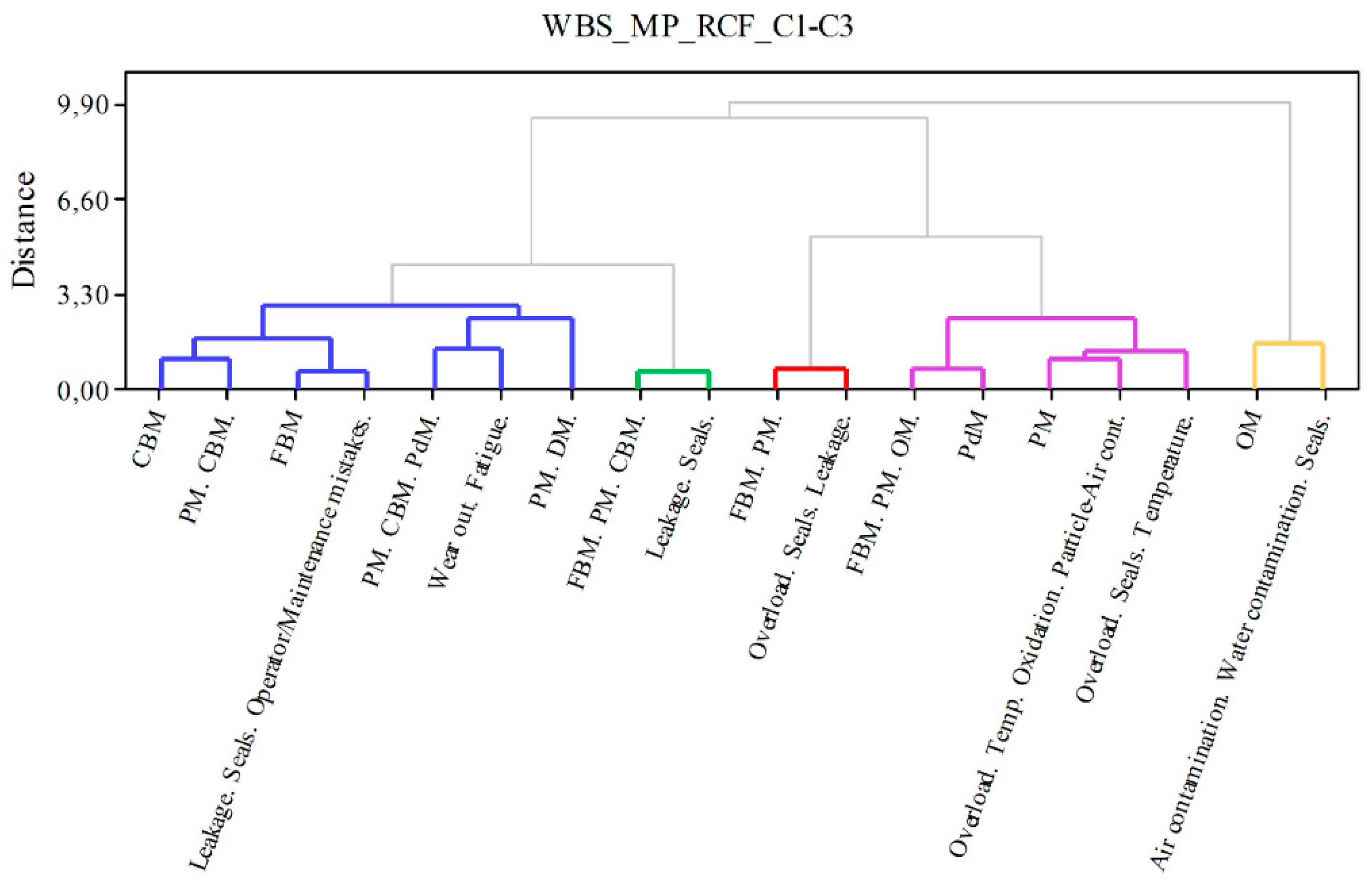

3.2. Relationship between MP and CFT using CA-AHC

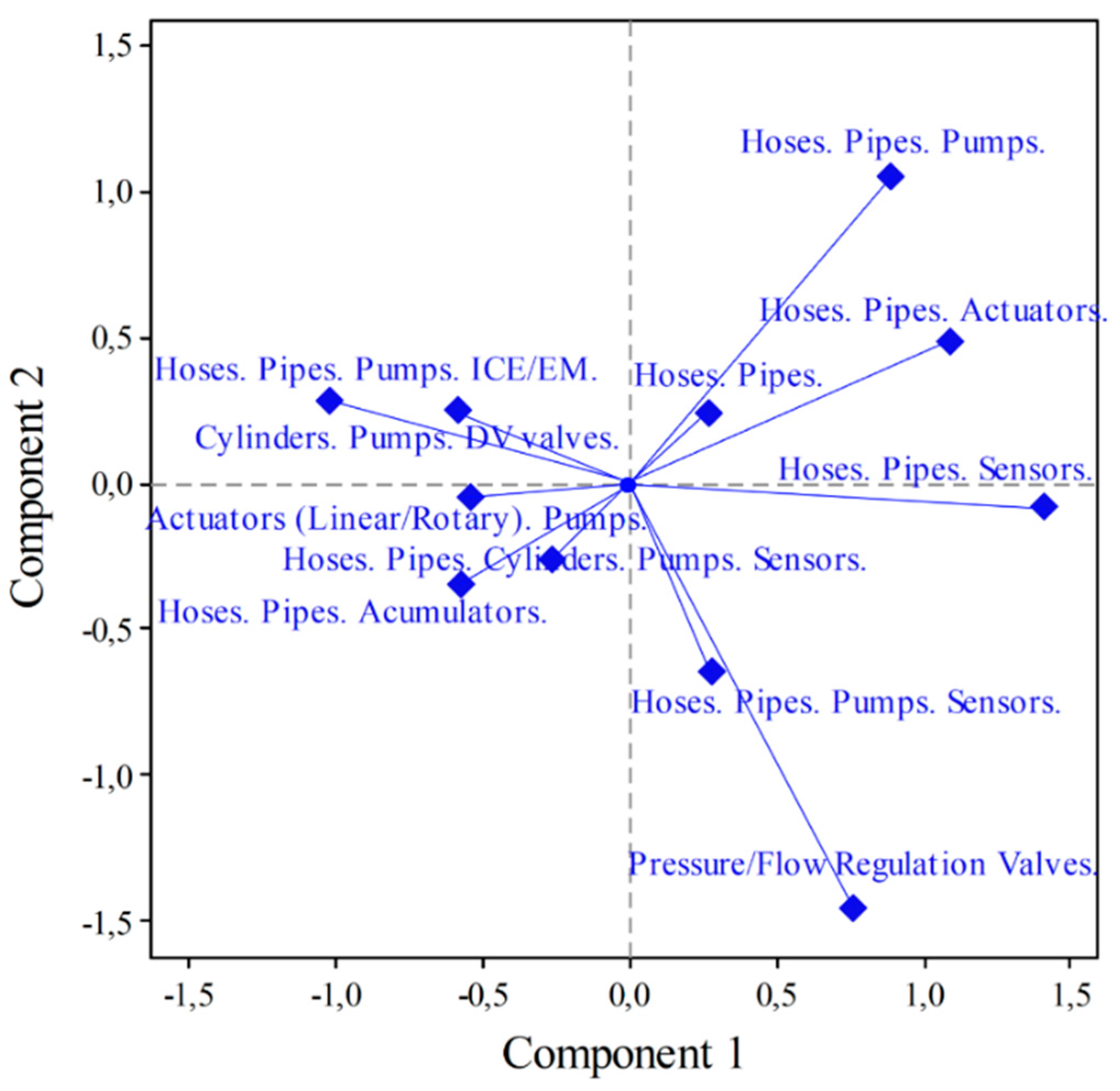

3.3. Relationship between MP and CFT using CA-AHC

3.4. Clusters and performance metrics

| Metric | MTTR | MTBF | WOMM | |||||||||||||||

| Cluster | 0* | 1 | 2 | 3 | 4 | 5 | 0* | 1 | 2 | 3 | 4 | 5 | 0* | 1 | 2 | 3 | 4 | 5 |

| Med | 5 | 3 | 5.1 | 5 | 5 | 4 | 950 | 550 | 1950 | 1500 | 1650 | 945.5 | 26.3 | 40.7 | 22.7 | 23.4 | 9.6 | 30.3 |

| Mean | 5.1 | 4.1 | 5.3 | 5.2 | 4.7 | 4 | 1196 | 907.1 | 1558 | 1495 | 1616 | 1010.2 | 39.8 | 39.8 | 41.2 | 27.9 | 30.1 | 30.3 |

| Stdev | 2.3 | 2.7 | 1.5 | 3.1 | 1.8 | 1.1 | 706.6 | 673.6 | 1157.7 | 735.5 | 728.8 | 655.5 | 45.6 | 19.1 | 50.2 | 26.1 | 26.7 | 1.1 |

| Min | 1 | 2 | 3 | 2 | 2 | 3 | 200 | 350 | 150 | 100 | 250 | 450 | 2.22 | 16.1 | 2.5 | 1.25 | 7.2 | 29.4 |

| Max | 12 | 10 | 7.5 | 15 | 8 | 5 | 2650 | 2500 | 2950 | 3500 | 2500 | 1700 | 250 | 71.43 | 136.3 | 142.9 | 62.5 | 31.2 |

| Metric | MTTR | MTBF | WOMM | |||||||||||||||

| Cluster | 0* | 1 | 2 | 3 | 4 | 5 | 0* | 1 | 2 | 3 | 4 | 5 | 0* | 1 | 2 | 3 | 4 | 5 |

| Med | 5 | 5 | 3 | 5.5 | 4 | 3 | 1250 | 950 | 1995.5 | 950 | 1575 | 1570.5 | 26 | 36.5 | 19.4 | 11.9 | 31.3 | 29.4 |

| Mean | 5 | 5.1 | 3.5 | 6.9 | 4.7 | 3 | 1290.8 | 1087.5 | 2023.5 | 1341.7 | 1418.7 | 1570.5 | 36.1 | 41.3 | 19.2 | 29.5 | 27.6 | 29.4 |

| Stdev | 2.8 | 2 | 1.3 | 3.3 | 2.6 | 0 | 710.5 | 805.6 | 1096.3 | 651.5 | 745.4 | 183.1 | 40.3 | 28.9 | 5.9 | 39.3 | 19.5 | 0 |

| Min | 1 | 2 | 2 | 3.5 | 1 | 3 | 150 | 150 | 850 | 950 | 100 | 1441 | 2.2 | 2.5 | 12.2 | 7.1 | 1.3 | 29.4 |

| Max | 15 | 10 | 5.3 | 12 | 12 | 3 | 2950 | 2500 | 3500 | 2500 | 2750 | 1700 | 250 | 129.4 | 26.8 | 108.3 | 71.4 | 29.4 |

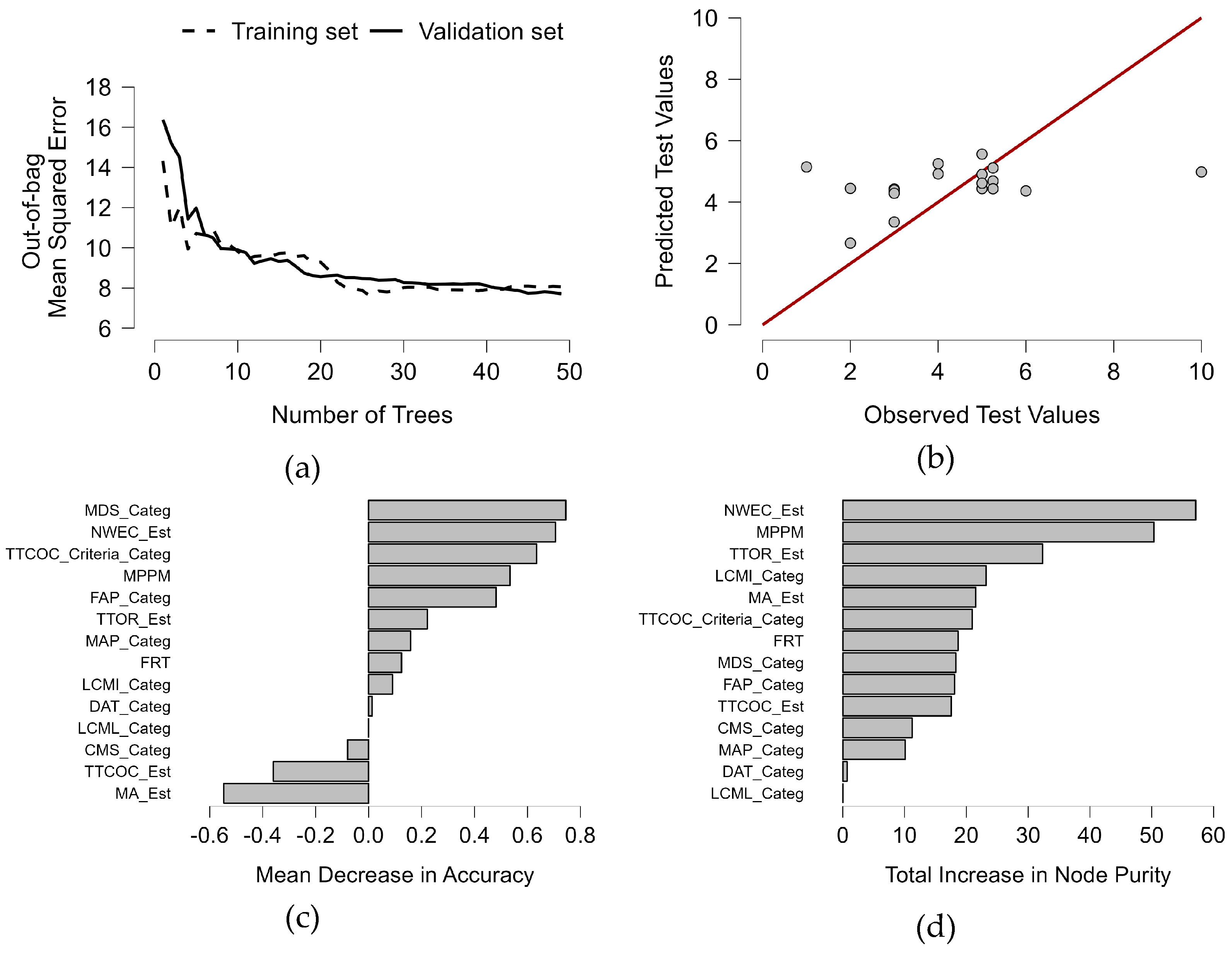

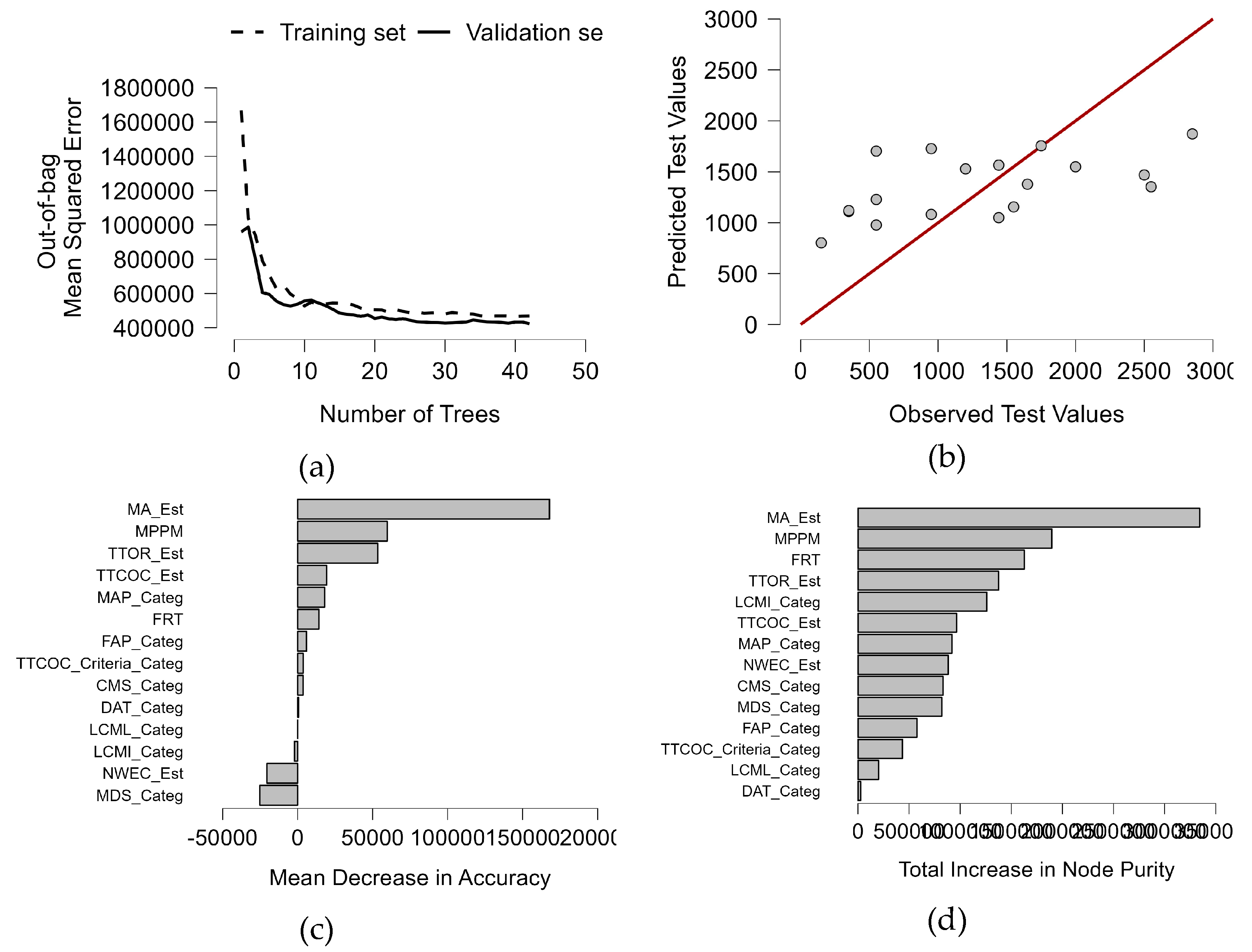

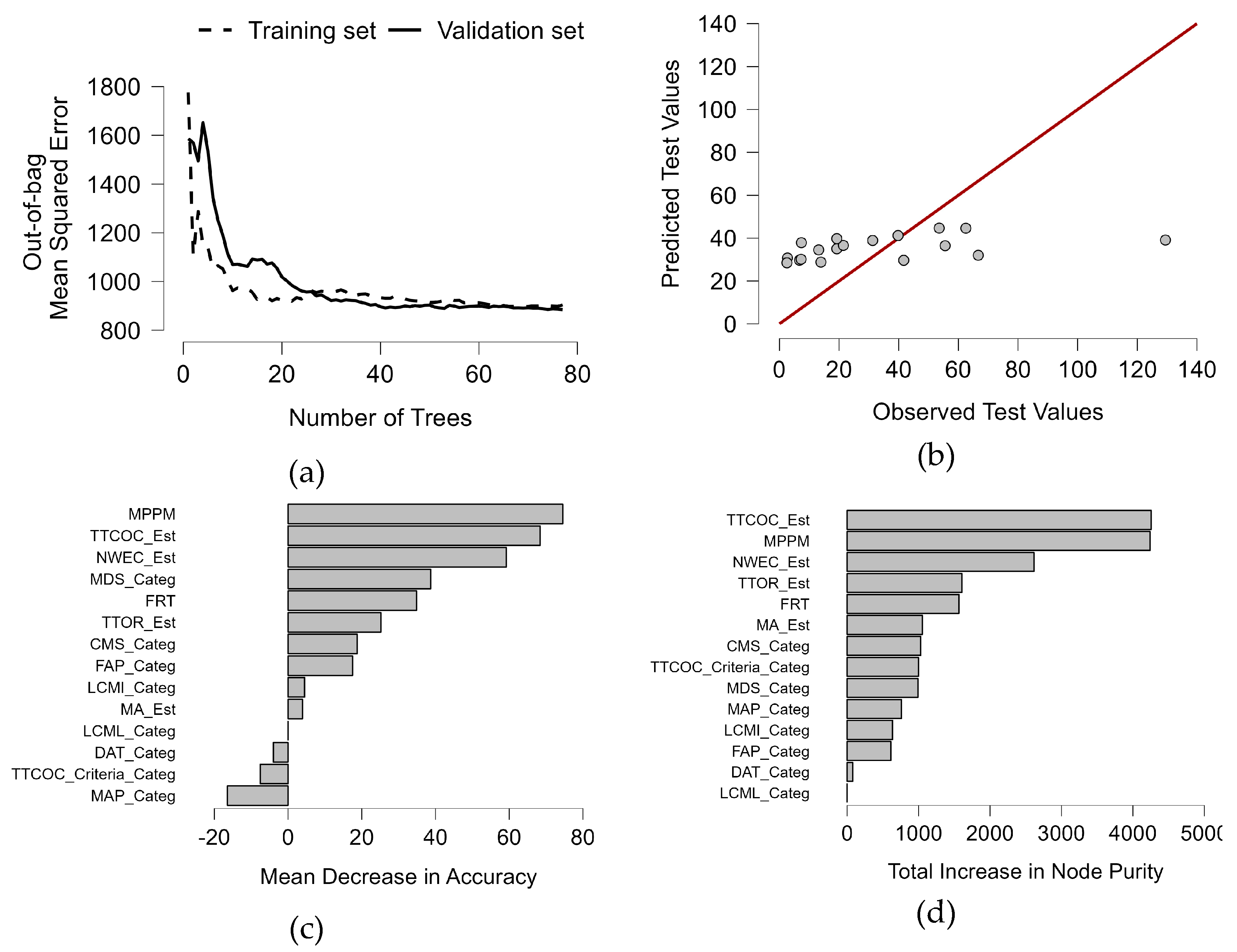

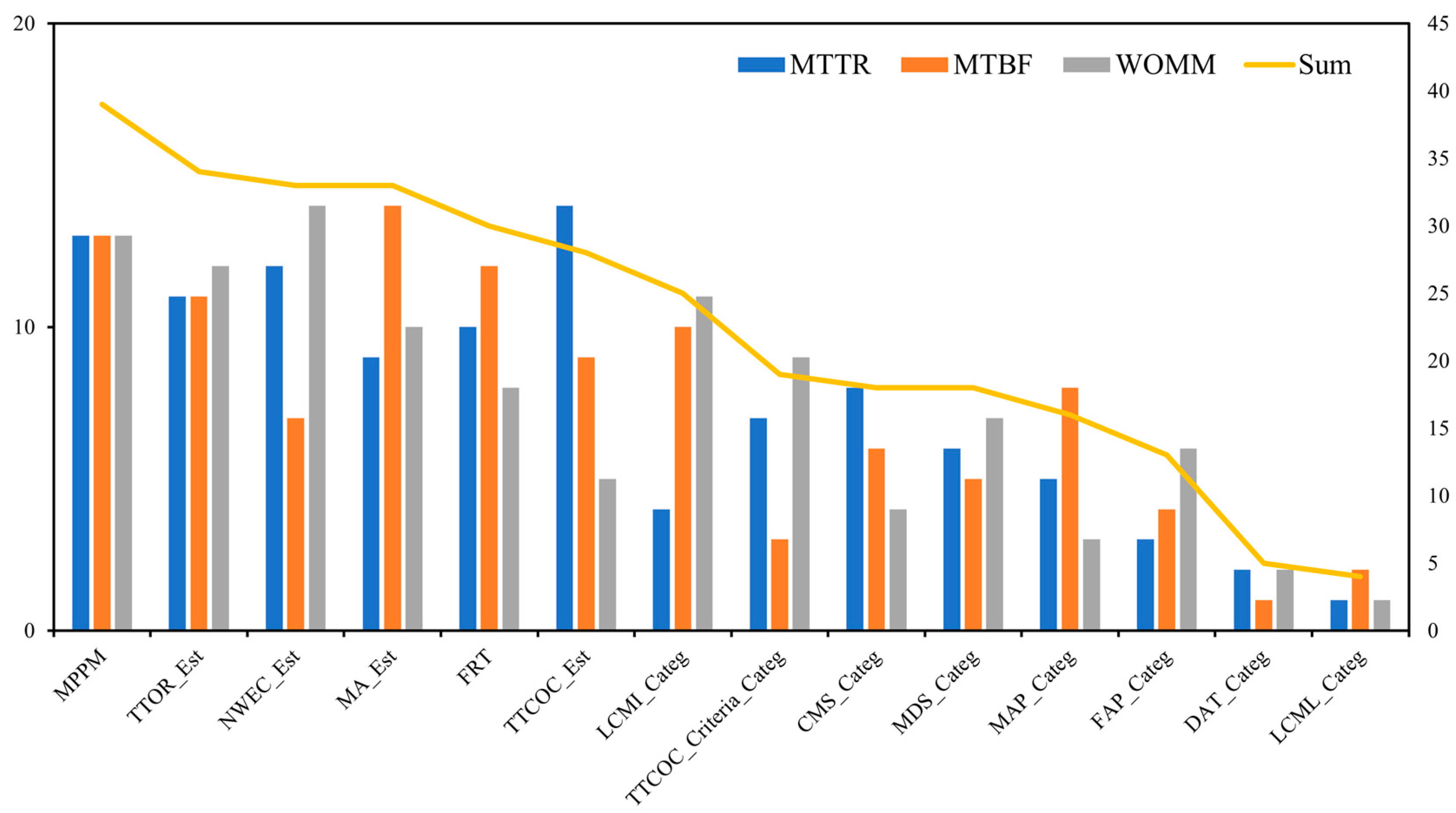

3.5. Machine learning feature importance

| ML | RF | SVM | kNN | DT |

|---|---|---|---|---|

| MSE | 3.412 | 1.009 | 4.846 | 877137.904 |

| RMSE | 1.847 | 1.004 | 2.201 | 936.556 |

| MAE/MAD | 1.314 | 0.627 | 1.694 | 767.94 |

| R2 | 0.125 | 0.002 | 0.033 | 0.009 |

| ML | RF | SVM | kNN | DT |

|---|---|---|---|---|

| MSE | 463982.999 | 833283.033 | 648621.198 | 877137.904 |

| RMSE | 681.163 | 912.843 | 805.37 | 936.556 |

| MAE/MAD | 584.637 | 712.324 | 633.333 | 767.94 |

| R2 | 0.304 | 0.059 | 0.156 | 0.058 |

| ML | RF | SVM | kNN | DT |

|---|---|---|---|---|

| MSE | 853.157 | 991.228 | 1560.16 | 979.015 |

| RMSE | 29.209 | 31.484 | 39.499 | 31.289 |

| MAE/MAD | 22.789 | 23.051 | 27.713 | 20.396 |

| R2 | 0.222 | 0.03 | 0.02 | 0.056 |

4. Discussion

4.1. Research results from the analysis of MP and CFT

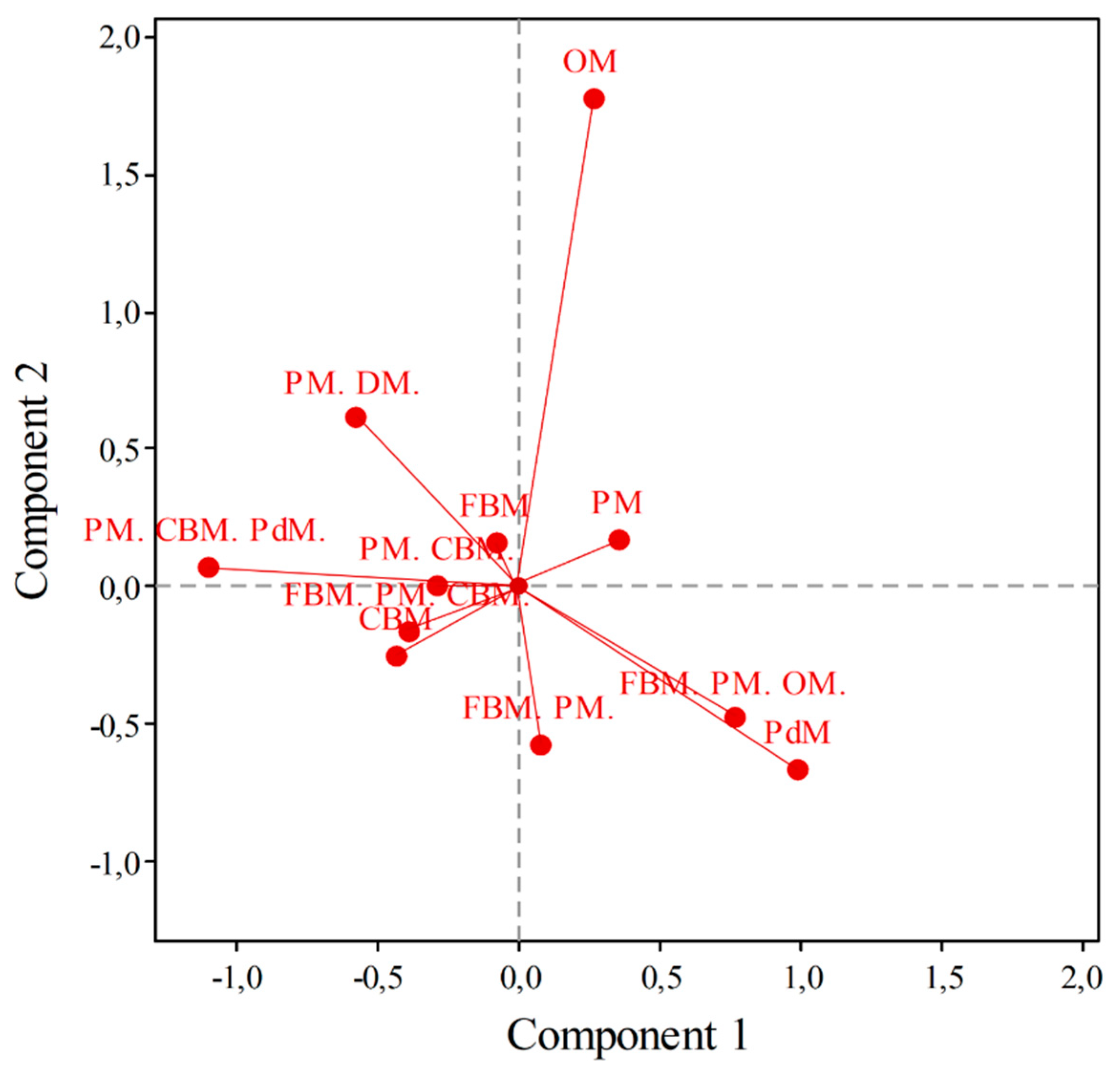

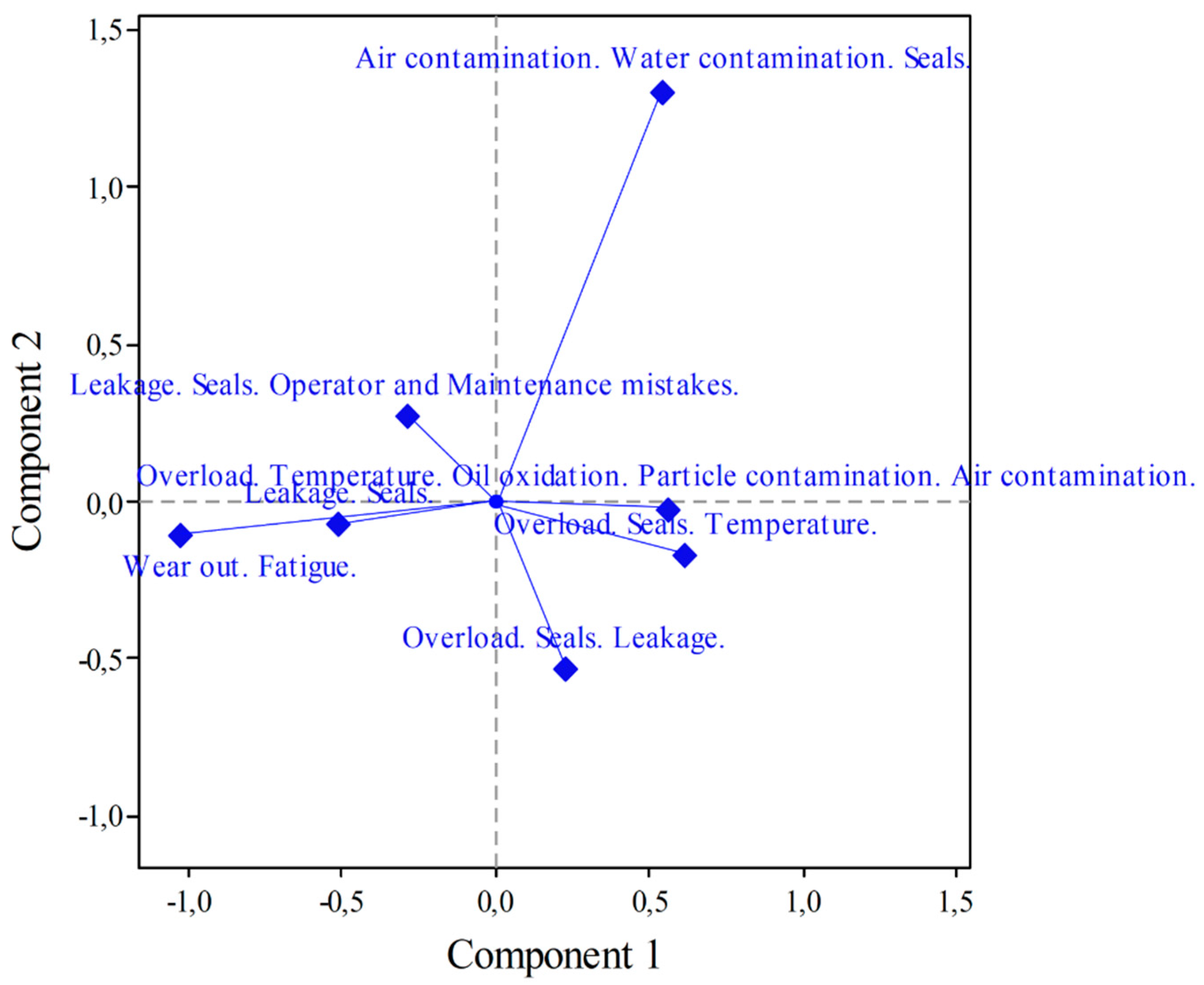

4.2. Results from the analysis of MP and RCF

4.3. Feature importance considering performance metrics

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Orošnjak, M.; Jocanović, M.; Čavić, M.; Karanović, V.; Penčić, M. Industrial Maintenance 4(.0) Horizon Europe: Consequences of the Iron Curtain and Energy-Based Maintenance. J Clean Prod 2021, 314, 128034. [Google Scholar] [CrossRef]

- Simões, J.M.; Gomes, C.F.; Yasin, M.M. A Literature Review of Maintenance Performance Measurement: A Conceptual Framework and Directions for Future Research. J Qual Maint Eng 2011, 17, 116–137. [Google Scholar] [CrossRef]

- Van Horenbeek, A.; Pintelon, L. Development of a Maintenance Performance Measurement Framework-Using the Analytic Network Process (ANP) for Maintenance Performance Indicator Selection. Omega (United Kingdom) 2014, 42, 33–46. [Google Scholar] [CrossRef]

- Orošnjak, M.; Brkljač, N.; Šević, D.; Čavić, M.; Oros, D.; Penčić, M. From Predictive to Energy-Based Maintenance Paradigm: Achieving Cleaner Production through Functional-Productiveness. J Clean Prod 2023, 408, 137177. [Google Scholar] [CrossRef]

- Ding, S.H.; Kamaruddin, S.; Azid, I.A. Maintenance Policy Selection Model - A Case Study in the Palm Oil Industry. Journal of Manufacturing Technology Management 2014, 25, 415–435. [Google Scholar] [CrossRef]

- Muchiri, P.N.; Pintelon, L.; Martin, H.; De Meyer, A.-M. Empirical Analysis of Maintenance Performance Measurement in Belgian Industries. Int J Prod Res 2010, 48, 5905–5924. [Google Scholar] [CrossRef]

- Piechnicki, F.; Dos Santos, C.F.; De Freitas Rocha Loures, E.; Dos Santos, E.A.P. Data Fusion Framework for Decision-Making Support in Reliability-Centered Maintenance. Journal of Industrial and Production Engineering 2021, 38, 1–17. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Fu, Y. Joint Optimization of Condition-Based Maintenance and Performance Control for Linear Multi-State Consecutively Connected Systems. Mathematics 2023, 11, 2724. [Google Scholar] [CrossRef]

- Chui, M.; Henke, N.; Miremadi, M. Most of AI’s Business Uses Will Be in Two Areas. Available online: https://hbr.org/2018/07/most-of-ais-business-uses-will-be-in-two-areas (accessed on 8 February 2023).

- Orosnjak, M. Maintenance Practice Performance Assessment of Hydraulic Machinery: West Balkan Meta-Statistics and Energy-Based Maintenance Paradigm. In Proceedings of the 2021 5th International Conference on System Reliability and Safety (ICSRS); IEEE, November 24 2021; pp. 108–114. [Google Scholar]

- Cachada, A.; Moreira, P.M.; Romero, L.; Barbosa, J.; Leitno, P.; Gcraldcs, C.A.S.; Deusdado, L.; Costa, J.; Teixeira, C.; Teixeira, J.; et al. Maintenance 4.0: Intelligent and Predictive Maintenance System Architecture. In In Proceedings of the 2018 IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA); IEEE, September 2018; pp. 139–146. [Google Scholar]

- Nunes, P.; Santos, J.; Rocha, E. Challenges in Predictive Maintenance – A Review. CIRP J Manuf Sci Technol 2023, 40, 53–67. [Google Scholar] [CrossRef]

- Parida, A.; Kumar, U. Maintenance Performance Measurement (MPM): Issues and Challenges. J Qual Maint Eng 2006, 12, 239–251. [Google Scholar] [CrossRef]

- Dui, H.; Zhang, Y.; Zhang, Y.-A. Grouping Maintenance Policy for Improving Reliability of Wind Turbine Systems Considering Variable Cost. Mathematics 2023, 11, 1954. [Google Scholar] [CrossRef]

- Parida, A.; Chattopadhyay, G. Development of a Multi-Criteria Hierarchical Framework for Maintenance Performance Measurement (MPM). J Qual Maint Eng 2007, 13, 241–258. [Google Scholar] [CrossRef]

- Roosefert Mohan, T.; Preetha Roselyn, J.; Annie Uthra, R.; Devaraj, D.; Umachandran, K. Intelligent Machine Learning Based Total Productive Maintenance Approach for Achieving Zero Downtime in Industrial Machinery. Comput Ind Eng 2021, 157, 107267. [Google Scholar] [CrossRef]

- Dalzochio, J.; Kunst, R.; Pignaton, E.; Binotto, A.; Sanyal, S.; Favilla, J.; Barbosa, J. Machine Learning and Reasoning for Predictive Maintenance in Industry 4.0: Current Status and Challenges. Comput Ind 2020, 123. [Google Scholar] [CrossRef]

- He, Y.; Su, H.; Zio, E.; Peng, S.; Fan, L.; Yang, Z.; Yang, Z.; Zhang, J. A Systematic Method of Remaining Useful Life Estimation Based on Physics-Informed Graph Neural Networks with Multisensor Data. Reliab Eng Syst Saf 2023, 237. [Google Scholar] [CrossRef]

- Orošnjak, M.; Delić, M.; Ramos, S. Influence of Maintenance Practice on MTBF of Industrial and Mobile Hydraulic Failures: A West Balkan Study. In Proceedings of the International Conference on Machine and Industrial Design in Mechanical Engineering; Rackov, M., Mitrović, R., Čavić, M., Eds.; SpringerLink, 2022; pp. 617–625. [Google Scholar]

- Wang, S.; Xiang, J. A Minimum Entropy Deconvolution-Enhanced Convolutional Neural Networks for Fault Diagnosis of Axial Piston Pumps. Soft comput 2020, 24, 2983–2997. [Google Scholar] [CrossRef]

- Cheng, X.; Chaw, J.K.; Goh, K.M.; Ting, T.T.; Sahrani, S.; Ahmad, M.N.; Abdul Kadir, R.; Ang, M.C. Systematic Literature Review on Visual Analytics of Predictive Maintenance in the Manufacturing Industry. Sensors 2022, 22, 1–16. [Google Scholar] [CrossRef]

- Zhang, X.; Fujiwara, T.; Chandrasegaran, S.; Brundage, M.P.; Sexton, T.; Dima, A.; Ma, K.-L. A Visual Analytics Approach for the Diagnosis of Heterogeneous and Multidimensional Machine Maintenance Data. In Proceedings of the 2021 IEEE 14th Pacific Visualization Symposium (PacificVis); IEEE, April 2021; Vol. 2021-April; pp. 196–205. [Google Scholar]

- Navinchandran, M.; Sharp, M.E.; Brundage, M.P.; Sexton, T.B. Discovering Critical KPI Factors from Natural Language in Maintenance Work Orders. J Intell Manuf 2022, 33, 1859–1877. [Google Scholar] [CrossRef]

- Lu, Y.; Garcia, R.; Hansen, B.; Gleicher, M.; Maciejewski, R. The State-of-the-Art in Predictive Visual Analytics. Computer Graphics Forum 2017, 36, 539–562. [Google Scholar] [CrossRef]

- Husson, F.; Houee-Bigot, M. Correspondence Analysis Available online:. Available online: https://husson.github.io/MOOC_GB/CA_course_slides.pdf (accessed on 30 December 2022).

- Husson, F.; Lê, S.; Pagès, J. Computer Science and Data Analysis Series: Exploratory Multivariate Analysis by Example Using R; CRC Press. Taylor & Francis Group, 2017; ISBN 9781138196346. [Google Scholar]

- Le, S.; Josse, J.; Husson, F. FactoMineR: An R Package for Multivariate Analysis. Journal of Statistical Software2 2008, 25, 1–18. [Google Scholar]

- Nielsen, F. Hierarchical Clustering. In Introduction to HPC with MPI for Data Science; Undergraduate Topics in Computer Science; Springer International Publishing: Cham, 2016; pp. 223–239. ISBN 978-3-319-21902-8. [Google Scholar]

- Murtagh, F.; Contreras, P. Algorithms for Hierarchical Clustering: An Overview. Wiley Interdiscip Rev Data Min Knowl Discov 2012, 2, 86–97. [Google Scholar] [CrossRef]

- Murtagh, F.; Contreras, P. Methods of Hierarchical Clustering. 2011; 1–21. [Google Scholar]

- Mourtzis, D.; Zogopoulos, V.; Vlachou, E. Augmented Reality Application to Support Remote Maintenance as a Service in the Robotics Industry. Procedia CIRP 2017, 63, 46–51. [Google Scholar] [CrossRef]

| Feature | AFF1 | CON1 | MAN1 | M&Q1 |

|---|---|---|---|---|

| HMA | 10.5 | 10.25 | 11.80 | 10.54 |

| NoM | 62.4 | 41.86 | 52.94 | 85.2 |

| MPPM | 0.55 | 0.37 | 1.09 | 0.62 |

| 1AFF=Agriculture, forestry, and fishing; CON=Construction; MAN=Manufacturing; M&Q=Mining and quarrying; | ||||

| Dimension | SV* | Inertia | Chi2 | Sig. | Proportion of Inertia | Confidence SV | |||

| Accounted | Cumulative | St. dev | Corr. C2 | Corr. C3 | |||||

| C1 | .673 | .452 | .315 | .315 | .051 | .159 | .417 | ||

| C2 | .526 | .277 | .193 | .508 | .083 | .160 | |||

| C3 | .515 | .265 | .185 | .693 | .099 | ||||

| C4 | .406 | .165 | .115 | .808 | |||||

| C5 | .355 | .126 | .088 | .896 | |||||

| C6 | .267 | .071 | .050 | .946 | |||||

| C7 | .187 | .035 | .024 | .970 | |||||

| C8 | .156 | .024 | .017 | .987 | |||||

| C9 | .130 | .017 | .012 | .999 | |||||

| C10 | .040 | .002 | .001 | 1.00 | |||||

| Total | 1.435 | 165.021 | .000 | 1.00 | 1.00 | ||||

| MP | Mass | Coordinates | λ | Correlation | Contribution | |||||||

| C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | Qual | |||

| CBM | .113 | -.915 | .288 | .338 | .160 | .209 | .034 | .049 | .591 | .058 | .081 | .731 |

| FBM | .096 | .055 | -.508 | -.021 | .105 | .001 | .089 | .000 | .003 | .234 | .000 | .238 |

| FBM. PM. | .104 | -.885 | .012 | .143 | .160 | .181 | .000 | .008 | .510 | .000 | .013 | .523 |

| FBM. PM. CBM. | .096 | .259 | -.760 | -.319 | .114 | .014 | .200 | .037 | .056 | .483 | .085 | .624 |

| FBM. PM. OM. | .061 | -.339 | .208 | -.324 | .044 | .015 | .009 | .024 | .158 | .059 | .145 | .362 |

| OM | .035 | 1.861 | .382 | 2.115 | .290 | .266 | .018 | .586 | .415 | .018 | .536 | .969 |

| PdM | .026 | .321 | .224 | -.964 | .050 | .006 | .005 | .091 | .054 | .026 | .488 | .568 |

| PM | .330 | -.031 | .022 | .075 | .061 | .001 | .001 | .007 | .005 | .003 | .031 | .038 |

| PM. CBM. | .052 | 1.092 | -1.023 | -.343 | .175 | .138 | .197 | .023 | .356 | .313 | .035 | .704 |

| PM. CBM. PdM. | .078 | .945 | 1.246 | -.760 | .244 | .155 | .439 | .170 | .286 | .497 | .185 | .968 |

| PM. DM. | .009 | -.869 | .489 | .360 | .031 | .015 | .008 | .004 | .210 | .066 | .036 | .312 |

| Total | 1.00 | 1.435 | 1.00 | 1.00 | 1.00 | |||||||

| CFT | Mass | C1 | C2 | C3 | λ | Correlation | Contribution | |||||

| C1 | C2 | C3 | C1 | C2 | C3 | Qual | ||||||

| Hoses. Pipes. | .096 | .269 | .239 | -.236 | .079 | .015 | .020 | .020 | .088 | .069 | .068 | .225 |

| Hoses. Pipes. Actuators. | .070 | 1.090 | .483 | .611 | .147 | .183 | .059 | .098 | .563 | .111 | .177 | .851 |

| Hoses. Pipes. Actuators. Pumps. | .200 | -.537 | -.052 | -.024 | .104 | .127 | .002 | .000 | .556 | .005 | .001 | .562 |

| Hoses. Pipes. Accumulators. | .035 | -.573 | -.340 | .021 | .078 | .025 | .015 | .000 | .147 | .052 | .000 | .199 |

| Hoses. Pipes. Act. Pumps. S-PV. | .217 | -.585 | .257 | .185 | .130 | .164 | .052 | .028 | .569 | .110 | .057 | .737 |

| Hoses. Pipes. Act. Pumps. Sensors. | .043 | -.258 | -.260 | .174 | .066 | .006 | .011 | .005 | .044 | .045 | .020 | .109 |

| Hoses. Pipes. Pumps. | .070 | .897 | 1.05 | -1.12 | .236 | .124 | .277 | .326 | .237 | .324 | .366 | .927 |

| Hoses. Pipes. Pumps. ICE/EM. | .035 | -1.02 | .289 | .435 | .070 | .080 | .011 | .025 | .521 | .042 | .094 | .657 |

| Hoses. Pipes. Pumps. Sensors. | .148 | .289 | -.645 | -.350 | .134 | .027 | .222 | .068 | .092 | .458 | .135 | .684 |

| Hoses. Pipes. Sensors. | .043 | 1.414 | -.081 | 1.57 | .211 | .192 | .001 | .402 | .412 | .001 | .506 | .920 |

| Pressure/Flow Control-Reg. | .043 | .759 | -1.45 | -.406 | .181 | .055 | .332 | .027 | .139 | .508 | .040 | .686 |

| Total | 1.00 | 1.435 | 1.00 | 1.00 | 1.00 | |||||||

| Component | Inertia | Chi2 | Sig. | Proportion of Inertia | Confidence Singular Value | |||

| Accounted | Cumulative | C1 | C2 | C3 | ||||

| 1 | .245 | .329 | .329 | .064 | .044 | -.450 | ||

| 2 | .196 | .262 | .591 | .090 | .144 | |||

| 3 | .124 | .166 | .757 | .081 | ||||

| 4 | .113 | .151 | .909 | |||||

| 5 | .052 | .070 | .979 | |||||

| 6 | .016 | .021 | 1.00 | |||||

| Total | .746 | 85.769 | 0.016 | 1.00 | 1.00 | |||

| MP | Mass | C1 | C2 | C3 | λ | Correlation | Contribution | |||||

| C1 | C2 | C3 | C1 | C2 | C3 | Qual | ||||||

| CBM | .113 | -.436 | .245 | .135 | .065 | .088 | .035 | .016 | .329 | .104 | .031 | .465 |

| FBM | .096 | -.085 | -.166 | .309 | .024 | .003 | .013 | .074 | .029 | .111 | .386 | .525 |

| FBM. PM. | .104 | .072 | .570 | .707 | .095 | .002 | .173 | .420 | .006 | .357 | .549 | .911 |

| FBM. PM. CBM. | .096 | -.400 | .157 | -.60 | .063 | .062 | .012 | .275 | .242 | .037 | .541 | .820 |

| FBM. PM. OM. | .061 | .760 | .476 | -.10 | .067 | .143 | .071 | .005 | .526 | .206 | .010 | .742 |

| OM | .035 | .259 | -1.78 | .532 | .127 | .010 | .566 | .079 | .018 | .870 | .077 | .966 |

| PdM | .026 | .985 | .658 | -.22 | .045 | .103 | .058 | .010 | .558 | .249 | .027 | .834 |

| PM | .330 | .347 | -.177 | -.18 | .075 | .163 | .053 | .083 | .532 | .139 | .137 | .809 |

| PM. CBM. | .052 | -.296 | -.008 | -.15 | .040 | .019 | .000 | .010 | .114 | .000 | .030 | .145 |

| PM. CBM. PdM. | .078 | -1.11 | -.077 | -.08 | .116 | .395 | .002 | .005 | .835 | .004 | .005 | .844 |

| PM. DM. | .009 | -.588 | -.615 | .569 | .028 | .012 | .017 | .023 | .106 | .116 | .099 | .321 |

| Total | 1.00 | .746 | 1.00 | 1.00 | 1.00 | |||||||

| MP | Mass | C1 | C2 | C3 | Inertia | Correlation for column | Contribution | |||||

| C1 | C2 | C3 | C1 | C2 | C3 | Qual | ||||||

| AWCS | .070 | .548 | -1.306 | .175 | .149 | .085 | .607 | .017 | .140 | .796 | .014 | .950 |

| LS | .226 | -.509 | .073 | -.415 | .120 | .239 | .006 | .313 | .489 | .010 | .324 | .823 |

| LSOMM | .235 | -.291 | -.272 | .200 | .067 | .081 | .089 | .076 | .299 | .261 | .141 | .701 |

| OSL | .183 | .227 | .533 | .472 | .115 | .038 | .265 | .328 | .082 | .451 | .354 | .887 |

| OST | .209 | .618 | .170 | -.351 | .136 | .325 | .031 | .207 | .584 | .044 | .188 | .817 |

| OTOPAW | .035 | .562 | .021 | .126 | .045 | .045 | .000 | .004 | .243 | .000 | .012 | .256 |

| WFF | .043 | -1.024 | .110 | .395 | .114 | .186 | .003 | .055 | .401 | .005 | .060 | .466 |

| Total | 1.00 | .746 | 1.00 | 1.00 | 1.00 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).