1. Introduction

Recent research in packaging focused on sustainability and how to make packaging materials more eco-friendly [

1,

2]. One of the most widely studied materials for primary and secondary food packaging is paper, a renewable and biodegradable material mainly composed of cellulose from a wide range of sources in nature [

3,

4]. The positive aspects related to the use of paper and recycled paper are also considered by “The UN Agenda 2030 for Sustainable Development” where in section 12.5 it is stated, as one of the main objectives: "by 2030, substantially reduce the production of waste through prevention, reduction, recycling and reuse" [

5]. In addition, CONAI (National Packaging Consortium- Italy) with the guidelines of 2022, has released a new classification, decreasing the rate for the annual contribution that the users of paper and cardboard packaging must pay, encouraging their use as packaging.

However, base paper (or uncoated paper) is not suitable for food with a long shelf-life, because of its inherent shortcomings, such as poor microbial resistance, low mechanical properties and a porous structure which essentially make it difficult to prevent the penetration of moisture, oils and oxygen. Actually, to overcome these drawbacks, various advanced functionalization technologies have been extensively studied and developed. For example, paper is commonly coated with chemicals or laminated with aluminum foil or plastic thin films to improve its barrier effect to water vapor, oxygen, mineral oils, and grease [

6,

7]. The most performing papers’ coating, having excellent barrier properties, is obtained with polyethylene, fluorinated compounds and other petroleum-based polymers. However, the coating with these synthetic polymers strongly reduces the paper’s biodegradability and recyclability, which in turn affects the environmental sustainability of this type of packaging [

8]. In fact, concerns related to the impact of plastic materials and fluorinated compounds (and derivatives) on the ecosystem and on human health have urged the search for alternative solutions for sustainable materials.

Thus, the challenge is finding new eco-friendly and compostable alternatives with the same barrier behavior of polyethylene and fluorinated compounds. To achieve these ecological objectives, the more recent research on sustainable coating is focusing on the use of degradable components of natural origin such as, for example, biopolymers, polysaccharides, and other materials of natural origin. Several studies have demonstrated that different biodegradable polymers such as polylactic acid (PLA), polycaprolactone (PCL) or poly 3-hydroxybutyrate-co-3-hydroxyvalerate (PHBV), starch, chitosan and polysaccharides can be used as barrier coatings for food-packaging paper [

8,

9]. Among those, PCL has been deeply studied, as it is a linear thermoplastic aliphatic polyester, partially crystalline, hydrophobic and biodegradable with good mechanical properties and high extensibility [

10,

11]. Sundar et al. demonstrated that coatings containing PCL (5% - 25%) reduce the water vapor transmission rate (WVTR) of coated paper by 25% compared to uncoated one and increase the oil-grease resistance value, reaching a 12/12 score for the test kit [

12] . Bota et al. have demonstrated that a 10% PCL coating on paper improves the evolution of the water contact angle over time, in fact after 6 s from the deposition of the water drop on the sample, the angle still has a value greater of 15% with respect to uncoated paper [

13].

Another promising candidate to develop biodegradable films and coatings is starch. Starch is characterized by a crystalline structure, presenting itself in the form of granules, and can be obtained from various natural sources, such as corn, wheat, and many others. It is soluble in water, biodegradable and has many industrial applications, playing the role of gelling agent, stabilizer, etc. [

14]. Several studies have been carried out on the possibility to improve the properties of paper and cardboard with the use of starch, particularly enhancing their barrier against edible oils [

15,

16]. These studies have demonstrated that the use of different starch formulations can lead to significant improvements in oil barrier properties, showing, in some cases, a 100% of improvement compared to untreated paper. The studies have also shown that the effectiveness of starch coatings in preventing the passage of fat components can vary depending on the specific composition of the starch. For example, Chi et al. showed that the addition of different potato starch coatings led to varying levels of grease resistance in coated paperboard samples [

14].

These findings suggest that starch coatings have the potential to significantly improve the oil barrier properties of paper and cardboard, with the specific composition of the starch playing an important role in determining their effectiveness [

17]. However, starch has poor mechanical properties compared to conventional synthetic polymers, which limit its use as packaging material. In fact, for example, the higher elongation at break as coating or film with starch for food-packaging reported in literature is around 10- 20 MPa in contrast with 40 - 70 MPa reached by the family of polyethylene polymers [

14,

18,

19]. One of the most promising solutions to overcome starch drawbacks is the mixing with another polymer or add functional reinforcing fillers to create a composite film, for example blending starch with PCL and/or agar [

20,

21]; Agar and starch have been used to develop binary composite films compatible with each other, and their mixtures exhibit improved properties compared to their counterparts [

20]. In fact, Choi et al. have developed a colorimetric pH indicator film using biodegradable materials, such as agar and potato starch; Guo et al. have shown that agar dominates the structure and properties of starch/agar composites, and the best properties can be obtained with a certain starch/agar ratio, in fact, the addition of agar to starch increased both tensile strength and elongation at break, but the improvements were insignificant after the agar content was over 50 wt.% [

15]. Finally, Mahuwala et al. have formulated a cassava starch/Agar nanocomposite containing Ag and ZnO by the solution casting method, with antimicrobial properties [

19]. Therefore, suggesting that starch and agar are promising candidates to comply with the European objectives and standards, also accommodating consumer requests, relating to the sustainability and recyclability of food packaging, as coating for paper for food packaging.

In this context, the aim of this work is a statistical-guided improvement of the physical characteristics of base paper coated with biopolymers and other compostable natural materials, focusing the attention on paper for food wrapping papers (e.g. baking papers, wrapping papers for food delivery), maintaining the adsorption of grease and water from the food to acceptable levels during the transport, storage/shelf-life and consumption of the food. The base paper samples were coated with water-based solutions containing PCL (5% w/v) and variable percentages of native starch (5% - 10% w/w PCL dry weight) and agar (0 - 1.5% w/w PCL dry weight). In addition, and as novelty to previous literature, to prevent the well-known main problem of the starch-agar/PCL blend, that is the phase separation and the weak interfacial adhesion due to the lack of chemical affinity between these polymers, the addition of an interfacial agent or compatibilizer was considered [

22]. In this regard, poly (ethylene glycol) (PEG) (5% w/w PCL dry weight or 15% w/w PCL dry weight) and glycerol (4% w/w PCL dry weight) were introduced to the starch-agar/PCL blend, to improve coating uniformity and diffusion. As further innovation with respect to consolidated research, a Design of Experiments approach was implemented to exactly calculate statistically reliable results in terms of best coating composition, with the lowest possible number of tests, due to the high number of formulation variables taken in consideration [

23]. Mathematical models were implemented for each measured property of the coating, to quantitatively calculate how different percentages of the selected chemicals can affect the coating properties and the overall best coating composition.

2. Materials and Methods

2.1. Materials

In this work a calendered bleached paper (Advantage MG White High Gloss, Mondi Group, Addlestone, UK) was used, gently supplied by Serchio Distribuzione (Roma, Italy). According to technical sheet, the paper is obtained from a long-fiber sulphate pulp, with a grammage of 40 g/m2, a thickness of 54 µm, a tensile strength of 4.3 and 1.8 MPa and a tear resistance of 340 and 520 mN (respectively in machine and cross direction). Poly(hexano-6-lactone) (PCL) was purchased from Sigma Aldrich (Germany) having average Mw 80.000 g/mol, water content < 0.5% and melt flow index (160 °C/5kg) 2.01 - 4.03. Ethyl acetate (Ethyl acetate - ACS reagent, purity >99.5%, Mw: 88.11 g/mol) and Glycerol (1,2,3-Propanetriol, Glycerin, purity >99.5%, Mw: 92.09 g/mol) were purchased from Sigma Aldrich (Germany). Potato starch (CAS-No 9005-84-9, analytical grade) was purchased from PanReac AppliChem ITW Reagents (Cinisello Balsamo, Milano, Italy); Agar agar was purchased from OXOID, Thermo Fisher Scientific (Rodano, Milano, Italy); Polyethylene glycol (PEG) 200 (analytical grade, Density 1.124 - 1.126 g/cm3, Hydroxyl value: 535 - 590, Mw ~190–210 g/mol; Fluka Analytical) was used as a plasticizer.

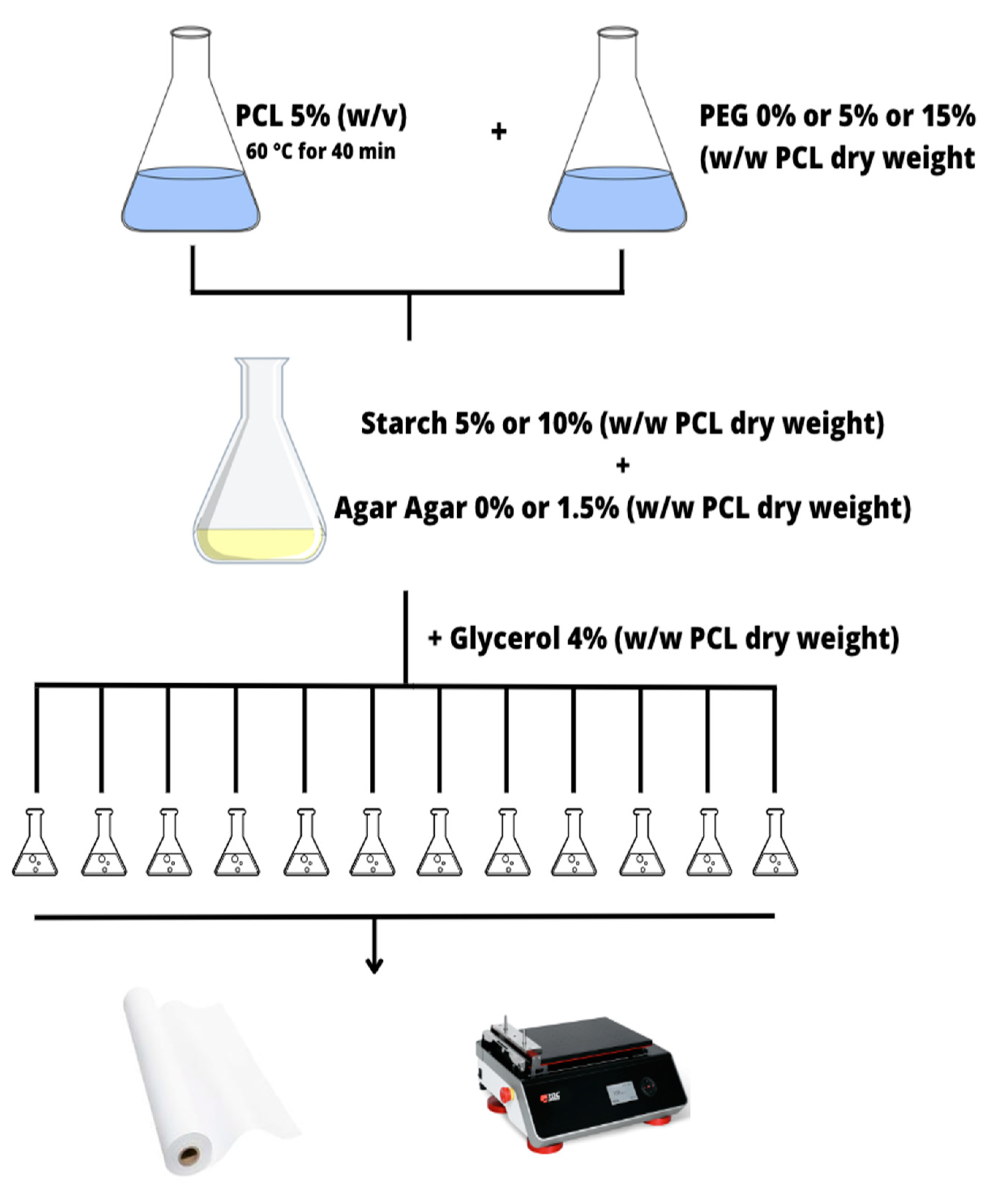

2.2. Coating preparations

In the coating formulation, PCL and glycerol concentration were kept constant, respectively at 5% w/w and 4% w/w PCL dry weight, whereas the amount of agar, starch and PEG was varied among selected ranges, from previous preliminary tests [

10]. Taking to account 3 variables in the coating formulations, a full factorial design was implemented having a total of 12 different coating formulations, each one repeated at least three times for replication. In

Table 1 the different combination of the 12 solutions is reported divided in 3 SETs.

All the solutions were prepared by dissolving 5 g in 100 mL of previously heated ethyl acetate, under continuous stirring in a water bath at 60 °C for 40 min. After the complete cooling of the solution, PEG (5% w/w or 15% w/w PCL dry weight) was added if required following the experimental plan of the formulations (

Table 1). The water-solutions containing starch (5% w/w PCL or 10% w/w PCL dry weight) and agar agar (1.5% w/w PCL dry weight) in its desired concentrations were prepared separately by stirring at room temperature. Finally, after the addition of the starch-agar solution to the one containing PCL and PEG to obtain the desirable solution from the DoE, a 4% (w/w PCL dry weight) of glycerol was added to all the samples. Paper samples (210 x 297 mm) were coated employing the prepared solutions, via bar coating with a Compact AB3650 (TQC Sheen) automatic film applicator, working under a fume hood with the technique of layer by layer (

Figure 1). All samples were made, setting the film applicator with a coating thickness of 100 µm and with an application speed of 50 mm/s. Once coated with the layer, paper samples were dried under a fume hood for about 30 min, to remove the solvent, and then dried in an oven at 80 °C for 1 h. The samples were kept for 24 h at room temperature before testing.

2.3. Characterizations

2.3.1. Grammage and thickness determination

The grammage was calculated by weighing samples of 1 cm x 1 cm (1 cm2) and it was expressed as g/m2. 10 replicates per sample were weighed. A digital micrometer (Syntek, New York) with a sensitivity of 0.001 mm was used to measure the thickness. Three thickness measurements were carried out for each rectangular specimen of 150 x 25 mm (on both sides and in the central part), 10 samples were tested and then a total of 30 measurements, from which the mean and standard deviation values were calculated.

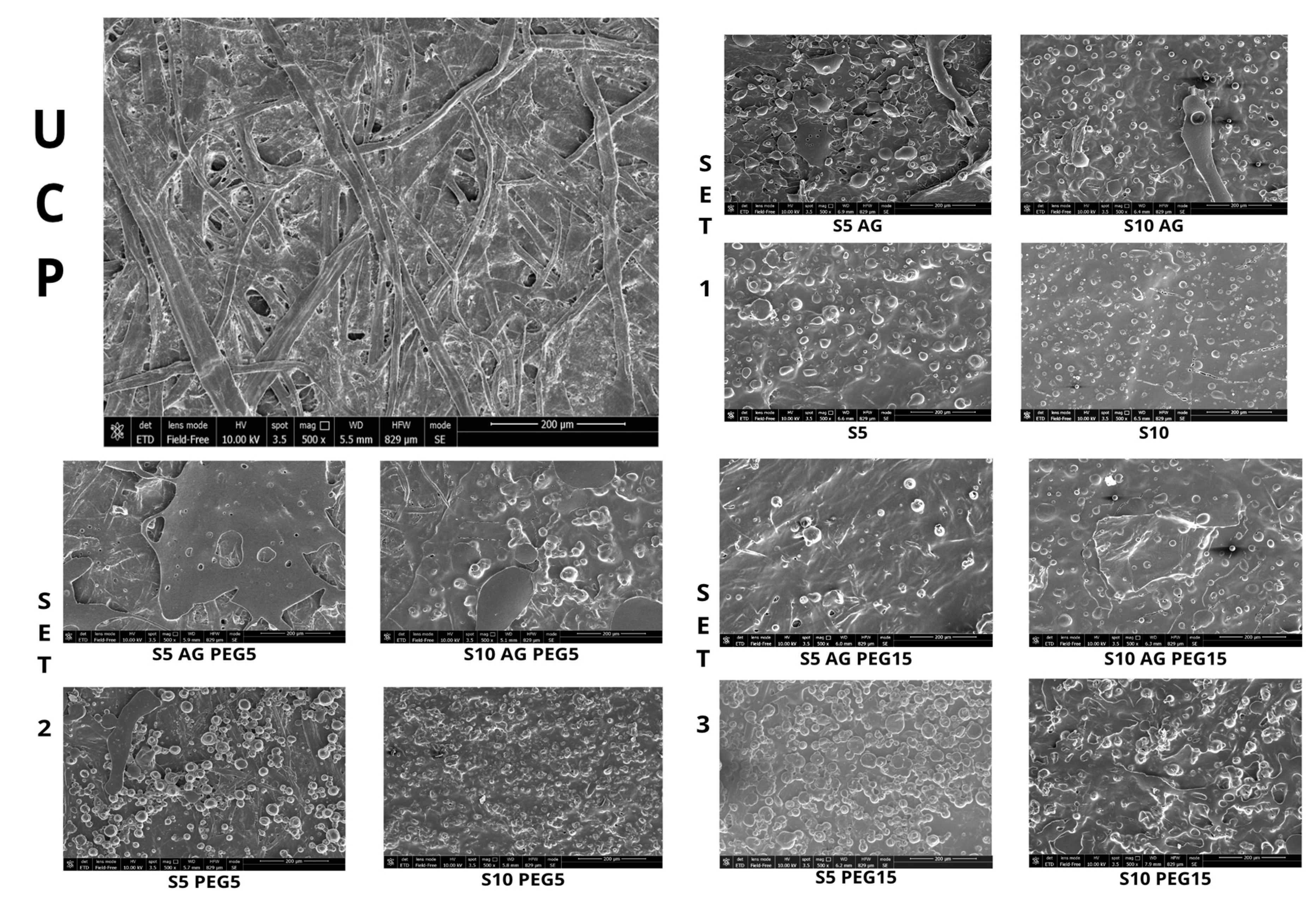

2.3.2. SEM Analysis

The surface of the paper samples was analyzed by scanning electron microscopy using a Nova NanoSEM 450 (FEI, Hillsboro, OR, USA) provided with LVD detector, under low vacuum conditions (80 KPa) and with an acceleration of 10 kV. Images were captured with different magnifications (500×–1000×) and tilts (0◦–40◦), thus allowing the visualization of the section of the surface.

2.3.3. Contact Angle Determination

Contact angle (CA) values were determined by means of an OCA 15EC contact angle meter and using OCA 20 (Dataphysics) software by the sessile drop method. For each type of sample, 1 × 10 cm paper strips were positioned on a film holder. CA measurements were taken depositing 3 µL of water or 7 µL of castor oil on the sample surface. For the CA measurement of each type of paper coating samples, 10 replicates were taken, the average of which was considered. The water CA was measured immediately after the drop deposition (t0), after 15 s (t15) and 30 s (t30) s. Oil CA was measured at different time steps with the same procedure employed for water CA.

2.3.4. Grease Resistance Determination

The grease resistance was tested by using the standard method, namely T 559 pm-96 (or “Kit 12” test) [

24]. According to this test, the 12 solutions envisaged were prepared by mixing castor oil, heptane, and toluene in adequate portions, thus obtaining solutions that emulate different surface tensions. Solutions with higher numbers are more aggressive having lower surface energies (i.e., Solution 1 is the less aggressive, while Solution 12 is the most aggressive). The higher the number of the kit value to which the paper sample resists, the better the resistance to grease is, since the aggressiveness of the test solutions increases with the increase in the heptane content and with the decrease in the oil content of castor. A drop of each solution of the kit test was gently dropped onto the surface of each sample and quickly removed with a clean absorbent cloth after 15 s. The tested area was examined and evaluated, giving a specific value to each sample corresponding to the number of the kit test solution that shows the first signs of degradation. Thereafter, higher is the reported value, higher is the resistance of the sample surface to oils.

2.3.5. Water Vapor Transmission Rate (WVTR)

The WVTR is a measure that indicates the amount of water vapor that can permeate in 24 hours through a square meter of a packaging material under defined conditions of temperature and relative humidity [

25]; This characteristic is of considerable importance, together with the other diffusion properties, in the development of packaging materials, as it has been demonstrated that increasing the hydrophobic properties of the packaging improves the water vapor barrier properties [

26].

The WVTR measurement of the different samples was performed in triplicate according to the ASTM E96 standard method with slight modification [

10]. Ten grams of silica gel were put inside a 25 mL glass vials to achieve a 0% internal RH. The samples were glued on the top of the vials, with the coated part inwards to prevent water vapor tangential diffusion, which were placed in a climate chamber (CH 150 - CLIMATEST Climatic Chamber, ARGO LAB) set at 38 °C (+/- 1 °C) and with 90% RH. The vials were weighted 2 times a day for 5 days of storage. The WVTR value (g 24 h

−1 m

−2) was calculated using the following formula:

where: “∆W/∆t” represents the weight gain as a function of time (g*h

−1), obtained as the slope of the linear regression of the mass gain versus time; “A” corresponds to the exposed surface of the film (7.85 × 10

−5 m

2).

2.3.6. Mechanical properties

The tensile strength measurements of paper samples were determined by a universal testing machine (Zwick/Roell BT1- FR1.0TH.140, Germany) according to ASTM D882 [

27]. For each sample (dimensions of 150 x 25 mm), 10 specimens in machine direction (MD) and 10 specimens in cross direction (XD) were taken. The dynamometer settings were initial strain 0.1 mm/mm, initial grip separation 125 mm and speed of the grip separation 12.5 mm/min. The collected data were processed by the TESTEXPERT®II (V3.31) software. The following mechanical properties have been measured: Young’s modulus (E - MPa), Tensile strength (σ - MPa) and Elongation at break (ɛ - %).

2.4. Statistical Analysis

A Design of Experiments (DoE) approach was employed to set the minimum number of experiments necessary to save time and raw materials, as well as to avoid information loss. As stated in section 2.2, three variables were considered, thereafter a full factorial design was implemented. The other variables that occurred in the process, such as environmental temperature and humidity, were kept constant during all the tests, according to the procedure described in paragraphs 2.2. The Design Expert 13.0 (Stat-Ease, Minneapolis, MN, U.S.A.) code was used both to set up the experimental plan and to analyze the results. A total of 36 experiments were collected in the factorial design, including repetitions for pure error estimation. The central points, considered as the arithmetic mean of the factors’ levels, were included to investigate the presence of curvature in the data analysis. All the experiments (runs) were carried out randomly to avoid the presence of systematic errors, following the experimental method reported in paragraphs 2.2.

The data were analyzed firstly by means of PCA (Principal Component Analysis) which made it possible to evaluate the characteristics of the paper samples in a multivariate manner. In particular, the purpose of the PCA analysis in this context was to evaluate which type of paper had overall better performance considering the characteristics considered: oil repellency, water repellency and mechanical strength. Thereafter, a multivariate regression approach through Analysis of Variance (ANOVA) was set up to mathematically correlate and calculate each formulation effect of the specific evaluated property. The p-value (<0.05), related to the F-test, is the statistical parameter used to evaluate the significance of the model and of each factor. Lack of fit test was also considered, as a significant lack of fit means that the variation of the design points about their predicted values is much larger than the variation of the replicates about their mean values, thereafter, a not significant lack of fit is desired. The quality of fit in terms of regression analysis and the predictive power of the model were assessed using the R

2, Adjusted-R

2 and Pred-R

2. R

2 is the proportion of the variance in the dependent variables that is predictable from the independent variables, Adjusted-R

2 is a corrected R

2 in proportion to the number of tests employed (thereafter attempting to correct any overestimation of the R

2 due to the increasing number of effects included in the model), and Pred-R

2 is analogous to R

2 but associated with predicted values [

23].

Finally, a global desirability function was calculated to provide the most desirable factors combination, considering all the responses analyzed simultaneously. Each response is weighed according to its specific target (

Table 1) in terms of objectives and importance, depending on how much each response must match the tailored purpose, and then combined using a mean. The desirability function range is from 0 to 1, where the lowest value (0) represents a completely undesirable combination of independent factors, and, conversely, the highest value (1) indicates a completely desirable or ideal combination of them [

23].

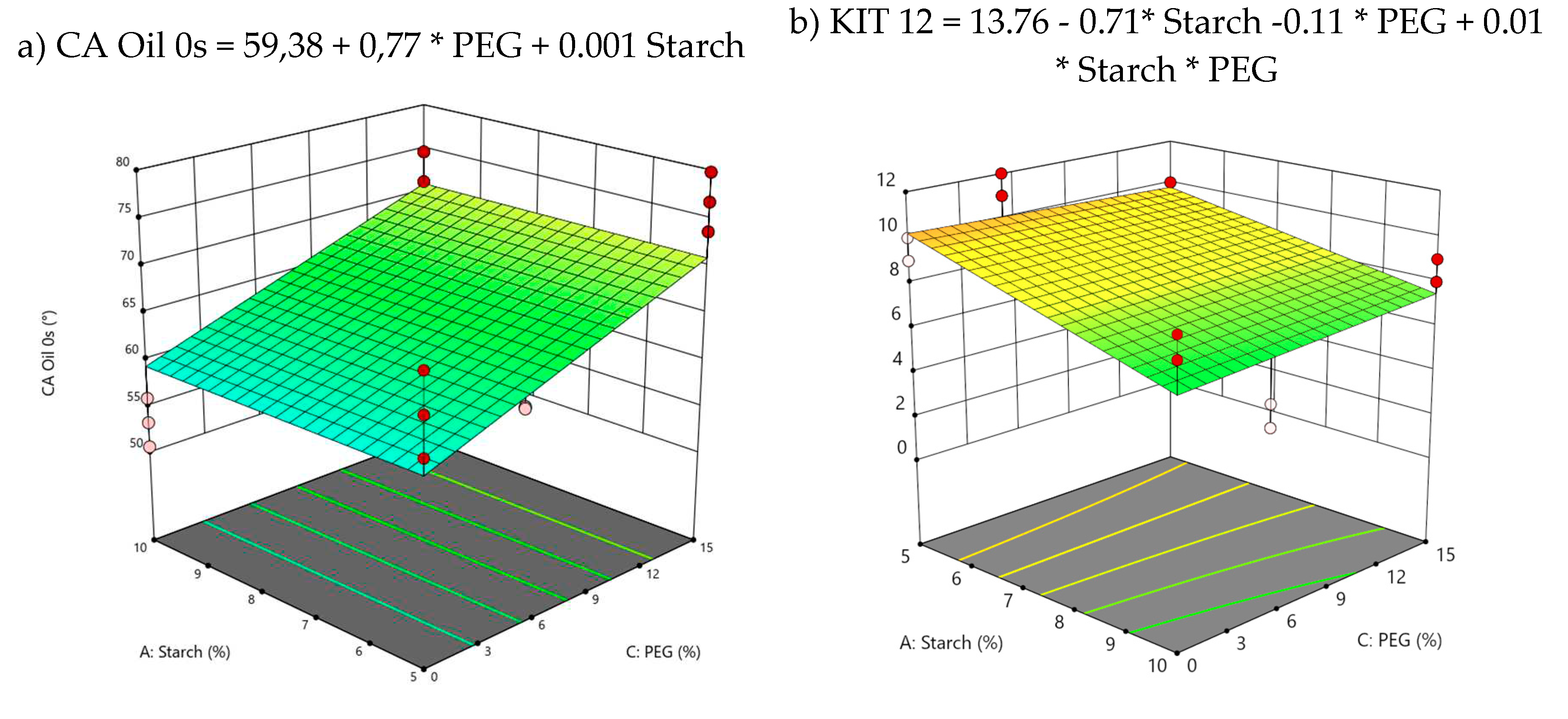

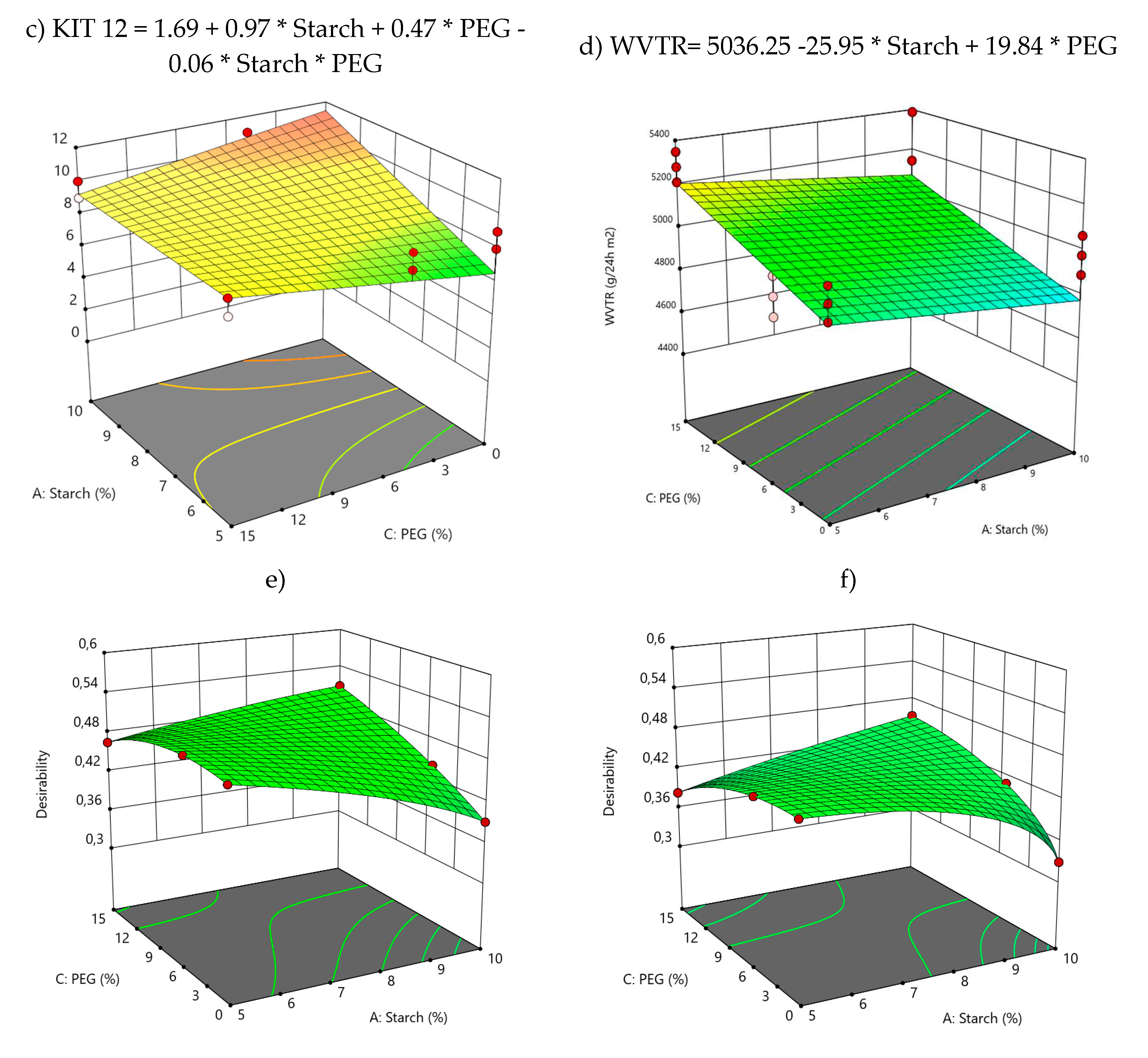

4. Discussion

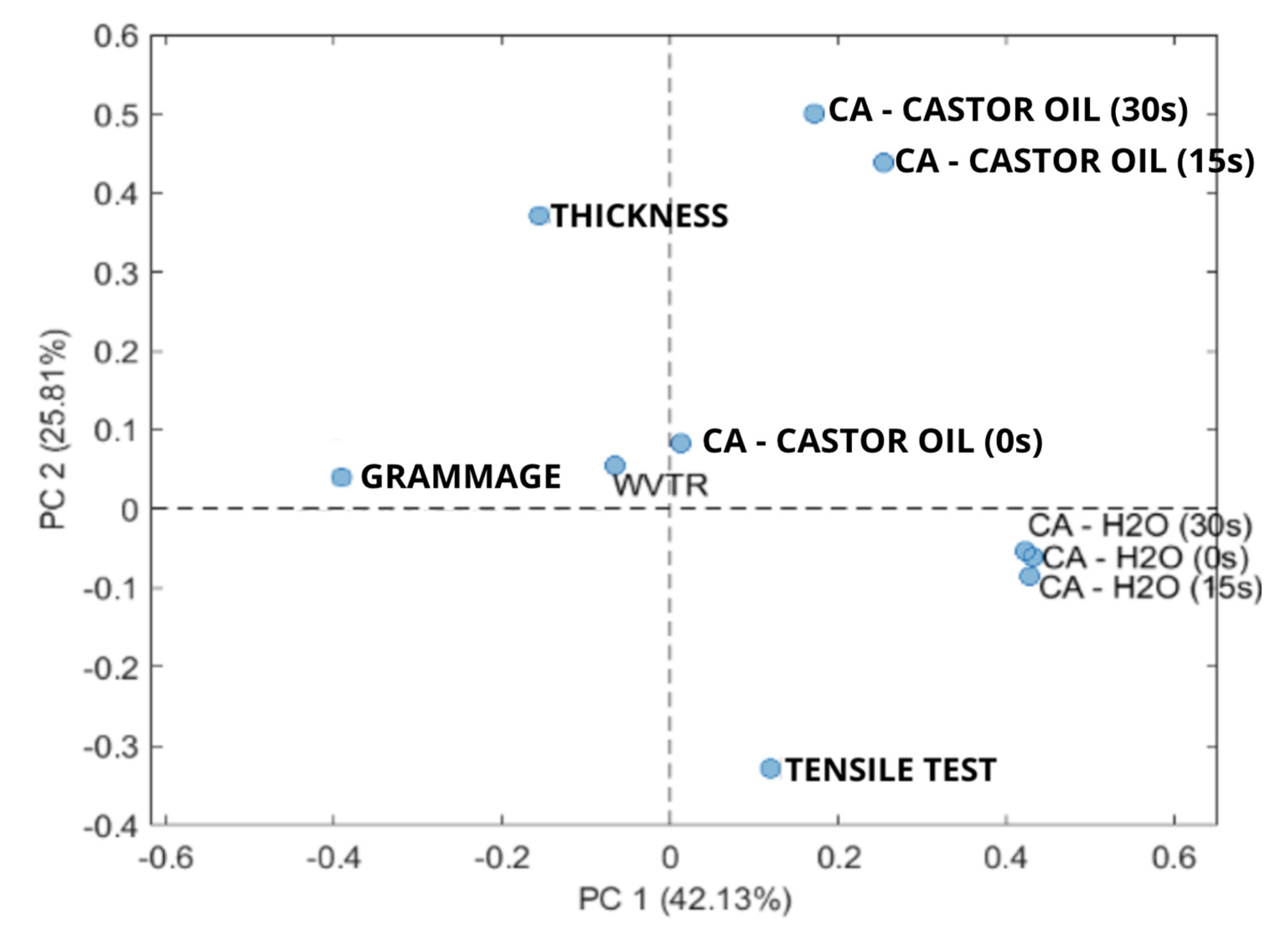

Taking to account all the previous results a complete comparison of the obtained data has been reported, through PCA and multivariate analysis in which a desirability function has been finally calculated. The optimal dimensionality of the PCA model, i.e. the number of PCs to consider, was defined using the screen plot, a graph that displays the percentage of variance explained by each PC. In this specific study, it was decided to consider two principal components, where PC1 describes 42.13% of the explained variance while PC2 describes 25.81% of the explained variance. To fully interpret the results of the PCA model, it is necessary to combine the scores graph (

Figure S3) with the loadings graph (

Figure 4). The scores graph allows you to evaluate the relationships between samples, while the loading graph allows you to evaluate the relationships between output variables. In the score graph (

Figure S3) we can see a clear separation of two groups of samples mainly along PC2, namely, the agar-coated group in red (having PC2 positive values), the group without agar in green (with negative PC2 values) and the control samples, represented in blue, clearly separated from the other samples along PC1. It can therefore state that PC1 mainly allows distinguishing the control samples with the coated paper samples prepared in this study, while PC2 allows to distinguish the samples covered with agar from the samples without agar. Comparing the graph of scores with that of loads (

Figure 4) we can also see that the samples with agar, positioned at positive values of PC2, show high values of thickness and high levels of CA OIL (0s, 15s and 30s), as they are variables with positive loading values along PC2, indicating that agar has a more positive influence on these responses. In addition, agar content should be carefully considered in combination with PEG or starch, as positive values of PC2 are distributed along different values of PC1. Furthermore, the tensile strength and thickness variables are inversely related to each other as they are opposite the origin in the load graph PC1 and PC2, thereafter at greater coating thickness also lower values of tensile strength are observed. Finally, grammage is inversely related to the CA value with water (CA-H2O 0s, 15s, 30s), thereafter, indicating that some restrictions on the coating formulation must be applied to balance these two responses. For this reason, it is necessary to calculate the best coating formulation to satisfy all the output variables through a desirability function as explained in paragraph 2.4. In fact, with the desirability function we can take in consideration the synergic effect among variables and calculate the optimum conditions of work, in this case the best coating formulation. The results of the calculation of this function are graphically shown in

Figure 3 where the graphs are reported for the two conditions: with and without agar, respectively

Figure 3e and

Figure 3f. As it is possible to see the condition with the higher desirability regards the formulations with agar (

Figure 3e) showing desirability over 0.5. More in depth the calculated best coating formulation is : 10% w/ w PCL dry weight Starch, 1.5% w/w PCL dry weight agar and 15% w/w PCL dry weight PEG, showing that all the compounds investigated in this study are relevant to produce the more promising coating for packaging paper.

5. Conclusion

In the present research, a quantitative calculation of the most performing paper coating for food wrapping application has been investigated. Agar, PEG and starch, in combination with PCL and glycerol dissolved in water, showed highly functional potential as a polymer matrix for film-coating formation. The application of a Design of Experiments approach allowed investigating the influence of environmental-friendly plasticizer and cross-linking agents onto physical properties of paper coating in a systematic way, by clearly identifying composition regions where the formation of a well-balanced coating is promoted and where a synergetic effect can be observed between agar, PEG and starch. The addition of starch, even at its lowest level (5% w/w PCL dry weight) is fundamental for oil resistance as it has a relevant influence on the CA measured with oil. Furthermore, a positive interaction in this sense has been observed when PEG (15% w/w PCL dry weight) is employed in the coating formulation, as it leads to positive changes in coating structure. In addition, agar presence has shown in combination with PEG a beneficial key role for oil resistance and for water vapor transmission rate, nevertheless, causing a significant detriment of the mechanical properties. The best coating composition has been calculated, and it is: 10% w/w PCL dry weight of starch, 1.5% w/w PCL dry weight of agar and 15% w/w PCL dry weight of PEG. However, improvements should be made (in terms of new further mixture components) to overcome mechanical properties depletion and to achieve a trend comparable to uncoated paper. In addition, further study regarding degradation mechanisms related to this type of coating should be addressed to evaluate their performance during time and at the end of their life. This study confirms that a well-balanced combination of biopolymers, also from natural origins, could be used to obtain bioplastic coating suitable for the functionalization of paper for food packaging in a circular economy perspective.