Submitted:

26 July 2023

Posted:

28 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Sampling Methods for Solid-Liquid Separation (SLS)

2.2. Solid-liquid separation techniques

3. Results and Discussion

3.1. Changes in EC and NaCl content

3.2. Changes of TS and SS contents

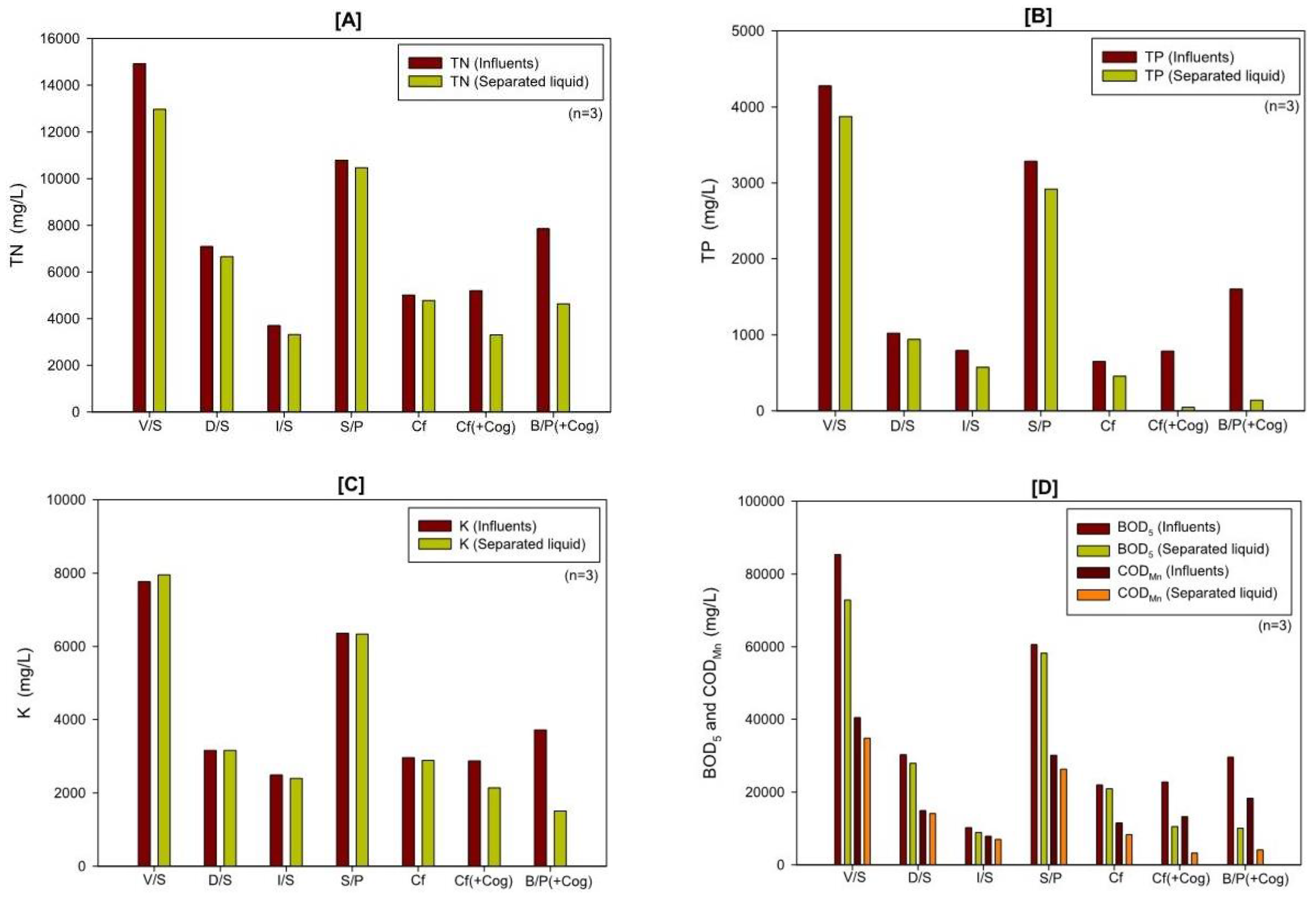

3.3. Changes in nutrient content (TN, TP, and K), BOD5, and CODMn

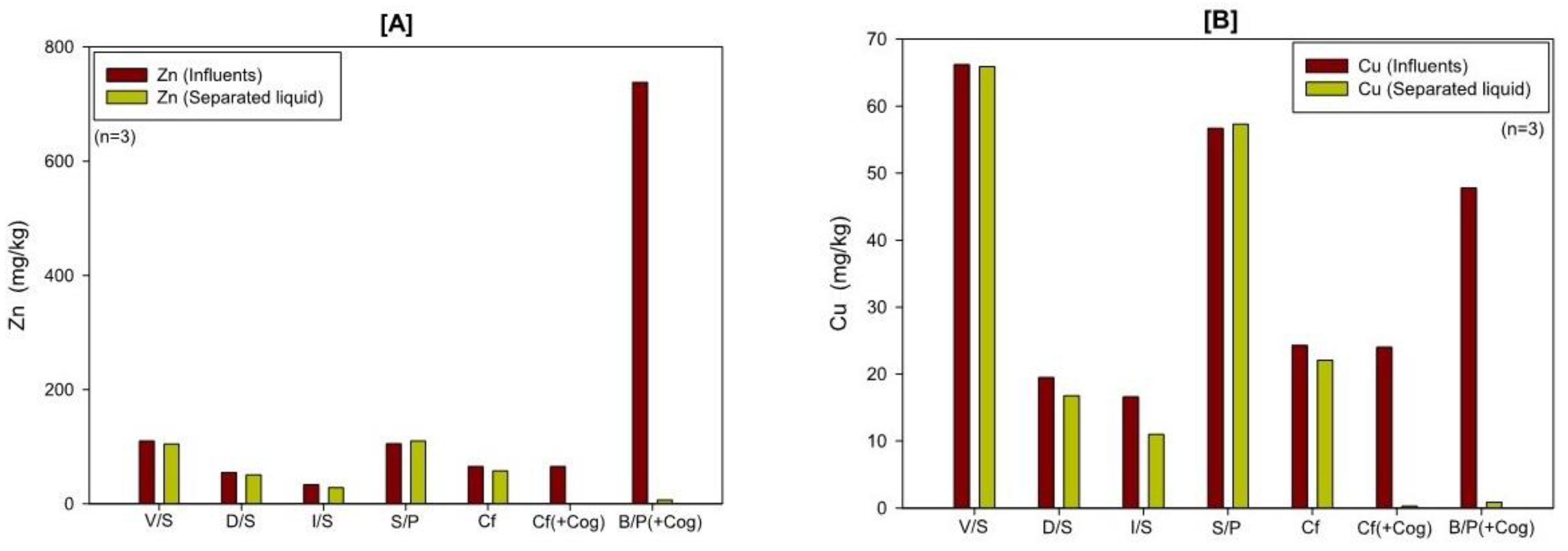

3.4. Changes in Zn and Cu

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bouwman, A. F. and H. Booij 1998 Global use and trade of foodstuffs and consequences for the nitrogen cycle. Nutr. Cycl. Agroecosys., 52: 261–267.

- Le, H. C. 1998 Biodigester effluent versus manure, from pigs or cattle, as fertilizer for duckweed (Lemna spp.), Livest. Res. Rural Dev., 10(3): 56-65.

- Hjorth, M., K. V. Christensen, M. L. Christensen and S. G. Sommer 2010 Solid-liquid separation of animal slurry in theory and practice. A review. Agron. Sustain. Dev., 30: 153–180. 1: 30.

- Burton, C. H. and C. Turner 2003 Manure Management: Treatment Strategies for Sustainable Agriculture, 2nd ed., Silsoe Research Institute, UK.

- Steinfeld H., P. Gerber, T. Wassenaar, V. Castel, M. Rosales and C. de-Haan 2006 Livestock’s Long Shadow: Environmental Issues and Options, FAO, Rome. ISBN 978-92-5-105571-7. http://www.fao.org/3/a0701e/a0701e.pdf.

- Bernal, M. P., A. Roig, R. Madrid and A. F. Navarro 1992 Salinity risks on calcareous soils following pig slurry applications. Soil UseManage, 8: 125–130.

- Bernal, M. P., A. Roig and D. García 1993 Nutrient balances in calcareous soils after application of different rates of pig slurry. Soil Use Manage, 9: 9–14.

- Møller, H. B., J. D. Hansen and C. A. G. Sørensen 2006 Nutrient recovery by solid-liquid separation and methane productivity of solids. American Society of Agricultural and Biological Engineers, 50(1): 193−200.

- Teira-Esmatges, M. R. and X. Flotats 2003 A method for livestock waste management planning in NE Spain. Waste Management, 23: 917-932.

- Møller, H. B., I. Lund and S. G. Sommer 2000 Solid-liquid separation of livestock slurry: Efficiency and cost. Bioresource Tech. 74(3): 223-229.

- Vanotti, M. B., K. S. Ro, A. A. Szogi, J. H. Loughrin and P. D. Millner 2018 High-Rate Solid-Liquid Separation Coupled With Nitrogen and Phosphorus Treatment of Swine Manure: Effect on Water Quality. Frontiers in Sustainable Food Systems, 2(49): 1-15.

- Steinmetz, R. L. R., A. Kunz, V. L. Dressler, E. M. M. Flores and A. F. Martins 2009 Study of metal distribution in raw and screened swine manure. CLEAN: Soil, Air, Water, 37: 239–244.

- Aguirre-Villegas, H. A., R. A. Larson and M. A. Sharara 2019 Anaerobic digestion, solid-liquid separation, and drying of dairy manure: Measuring constituents and modeling emission. Science of the Total Environment, 696: 134059 11.

- Chastain, J. P., M. B. Vanotti and M. M. Wingfield 2001 Effectiveness of liquid-solid separation for treatment of flushed dairy manure: a case study. Appl. Engr. Agric., 17: 343–354.

- Riaño, B. and M. C. García-González 2014 On-farm treatment of swine manure based on solid-liquid separation and biological nitrification-denitrification of the liquid fraction. Journal of Environmental Management, 132: 87-93 13.

- Cantrell, K. B., T. Ducey, K. S. Ro and P. G. Hunt 2008 Livestock waste-to-bioenergy generation opportunities. Bioresource Technology, 99: 7941–7953.

- Kumaragamage, D., O. O. Akinremi and L. Greiger 2013 Phosphorus fractions in solid and liquid separates of swine slurry separated using different technologies. J. Environ. Qual., 42: 1863–1871.

- Korean Ministry of Environment (KMOE) 2008 Economic analysis of waste-to-energy project. KMOE, Waste-to-Energy Division, Sejong, South Korea.

- Kunz, A., R. L. R. Steinmetz, M. M. Ramme and A. Coldebella 2008 Effect of storage time on swine manure solid separation efficiency by screening. Bioresource Technology, 100: 5485–5489.

- Jørgensen, K. and L. S. Jensen 2009 Chemical and biochemical variation in animal manure solids separated using different commercial separation technologies. Bioresource Technology, 100: 3088–3096.

- Kumaragamage, D., O. O. Akinremi and G. J. Racz 2016 Comparison of Nutrient and Metal Loadings with the Application of Swine Manure Slurries and Their Liquid Separates to Soils. J. Environ. Qual., 45: 1769–1775.

- Gooch, C. A., S. F. Inglis and K. Czymmek 2005 Mechanical solid-liquid manure separation: performance evaluation on four New York state dairy farms - a preliminary report. Annual International Meeting. Paper Number: 05–4104. American Society of Agricultural and Biological Engineers, St. Joseph, Michigan.

- Bernet, N. , and F. Béline 2009 Challenges and innovations on biological treatment of livestock effluents. Bioresour. Technol, 100: 5431e5436.

- Saeys, W., A. M. Mouazen and H. Ramon 2005 Potential for onsite and online analysis of pig manure using visible and near infrared reflectance spectroscopy. Biosystems Eng., 91: 393–402.

- Møller, H. B., S. G. Sommer, and B. K. Ahring 2002 Separation efficiency and particle size distribution in relation to manure type and storage conditions. Bioresource Tech. 85(2): 189-196.

- Vanotti, M. B., D. M. C. Rashash and P. G. Hunt 2002 Liquid–solids separation of flushed swine manure with PAM: effect of wastewater strength. Trans. ASAE, 45: 1959– 1969.

- Zhu, J., P. M. Ndegwa and A. Luo 2001 Effect of solid–liquid separation on BOD and VFAs in swine manure. Environ. Technol, 22: 1237–1243.

- Chastain, J. P. and M. B. Vanotti 2003 Correlation Equations to Predict the Solids and Plant Nutrient Removal Efficiencies for Gravity Settling of Swine Manure. In: R.T. Burnes (ed), Animal, Agricultural and Food Processing Wastes IX : Proceedings of the Nineth International Symposium, Research Triangle Park, NC, Oct. 12-15, ASAE, St. Joseph, MI, pp 487-495.

- Bolan, N., D. Adriano and S. Mahimairaja 2004 Distribution and bioavailability of trace elements in livestock and poultry manure by products. Crit. Rev. Environ. Sci. Technol., 34: 291-338.

- Zhang, F., Y. Li, M. Yang and W. Li 2012 Content of heavy metals in animal feeds and manures from farms of different scales in northeast China. Int. J. Environ. Res. Public Health, 9: 2658-2668.

| Sampling site | Pig (head) | Solid-liquid separation (SLS) | Abbreviations |

|---|---|---|---|

| Pig farm A (Nonsan) | 2,000 | Drum screen (+Screw Press) | D/S |

| Pig farm B (Yeoju) | 2,200 | ||

| Pig farm C (Gongju) | 1,000 | Inclined screen (+Screw Press) | I/S |

| Pig farm D (Jincheon) | 6,000 | ||

| Pig farm E (Yeongcheon) | 10,000 | ||

| Pig farm F (Icheon) | 1,600 | Vibration screen (+Screw Press) | V/S |

| Pig farm G (Gumi) | 3,000 | Screw Press | S/P |

| Pig farm H (Boeun) | 1,000 | ||

| Pig farm I (Hapcheon) | 2,000 | Centrifuge | Cf |

| Pig farm J (Yeongju) | 3,800 | ||

| Pig farm I (Hapcheon) | 2,000 | Centrifuge (+coagulation agent) | Cf (+Cog) |

| Pig farm J (Yeongju) | 3,800 | ||

| Pig farm K (Changwon) | 4,200 | Belt Press (+coagulation agent) | B/P (+Cog) |

| Items | Units | stages | V/S | D/S | I/S | S/P | Cf | Cf (+Cog) |

B/P (+Cog) |

|---|---|---|---|---|---|---|---|---|---|

| pH | Influents | 6.90 | 7.08 | 7.20 | 7.00 | 7.28 | 7.40 | 7.15 | |

| Separated liquid | 6.65 | 7.23 | 7.23 | 6.88 | 7.25 | 7.53 | 7.20 | ||

| EC | (mS/cm) | Influents | 50.10 | 34.88 | 22.77 | 44.63 | 28.08 | 29.85 | 32.65 |

| Separated liquid | 42.60 | 33.70 | 21.13 | 41.05 | 27.65 | 17.75 | 31.90 | ||

| (Reduction, %) | (15.0) | (3.4) | (7.2) | (8.0) | (1.5) | (40.5) | (2.3) | ||

| NaCl | (%) | Influents | 1.38 | 0.68 | 0.63 | 2.43 | 0.72 | 0.75 | 0.80 |

| Separated liquid | 1.42 | 0.67 | 0.43 | 2.32 | 0.69 | 0.19 | 0.22 | ||

| (Reduction, %) | (-2.3) | (0.5) | (32.0) | (4.7) | (4.9) | (74.6) | (72.9) | ||

| TS | Influents | 15.82 | 5.53 | 3.47 | 12.55 | 4.19 | 4.68 | 8.24 | |

| Separated liquid | 12.17 | 4.82 | 2.78 | 10.74 | 3.39 | 1.50 | 1.75 | ||

| (Reduction, %) | (23.0) | (12.8) | (19.9) | (14.5) | (19.0) | (67.9) | 78.8) | ||

| SS | Influents | 10.42 | 3.99 | 2.30 | 9.42 | 2.74 | 3.21 | 6.43 | |

| Separated liquid | 7.92 | 3.44 | 1.98 | 8.66 | 1.86 | 1.11 | 0.20 | ||

| (Reduction, %) | (24.1) | (13.6) | (14.0) | (8.1) | (32.2) | (65.5) | (96.9) | ||

| TN | (mg/L) | Influents | 14,933 | 7,088 | 3,704 | 10,787 | 5,015 | 5,197 | 7,852 |

| Separated liquid | 12,973 | 6,648 | 3,319 | 10,471 | 4,781 | 3,304 | 4,631 | ||

| (Reduction, %) | (13.1) | (6.2) | (10.4) | (2.9) | (4.7) | (36.4) | (41.0) | ||

| TP | Influents | 4,277 | 1,022 | 793 | 3,285 | 650 | 785 | 1,603 | |

| Separated liquid | 3,874 | 940 | 573 | 2,919 | 457 | 46 | 137 | ||

| (Reduction, %) | (9.4) | (8.0) | (27.7) | (11.2) | (29.8) | (94.2) | (91.5) | ||

| K | Influents | 7,768 | 3,159 | 2,487 | 6,360 | 2,961 | 2,873 | 3,722 | |

| Separated liquid | 7,953 | 3,162 | 2,400 | 6,335 | 2,885 | 2,139 | 1511 | ||

| (Reduction, %) | (-2.4) | (-0.1) | (3.5) | (0.4) | (2.6) | (25.6) | (59.4) | ||

| BOD5 | Influents | 85,350 | 30,290 | 10,229 | 60,585 | 21,948 | 22,825 | 29,580 | |

| Separated liquid | 72,850 | 27,940 | 8,894 | 58,250 | 20,915 | 10,525 | 10,050 | ||

| (Reduction, %) | (14.6) | (7.8) | (13.0) | (3.9) | (4.7) | (53.9) | (66.0) | ||

| CODMn | Influents | 40,527 | 14,923 | 7,822 | 3,0171 | 11,491 | 13,287 | 18,263 | |

| Separated liquid | 34,884 | 14,139 | 6,977 | 2,6291 | 8,295 | 3,245 | 4,104 | ||

| (Reduction, %) | (13.9) | (5.3) | (10.8) | (12.9) | (27.8) | (75.6) | (77.5) | ||

| Zn | Influents | 110.4 | 55.0 | 33.4 | 105.0 | 65.6 | 65.6 | 738.0 | |

| Separated liquid | 104.6 | 50.7 | 28.0 | 109.8 | 57.5 | ND* | 6.8 | ||

| (Reduction, %) | (5.2) | (7.8) | (16.0) | (-4.6) | (12.4) | (100.0) | (99.1) | ||

| Cu | Influents | 66.2 | 19.5 | 16.6 | 56.7 | 24.3 | 24.0 | 47.8 | |

| Separated liquid | 65.9 | 16.8 | 11.0 | 57.3 | 22.1 | 0.3 | 0.9 | ||

| (Reduction, %) | (0.4) | (13.8) | (33.7) | (-1.1) | (9.1) | (98.6) | (98.1) | ||

| +MC | (%) | Influents | - | - | - | - | - | - | - |

| Separated solid | 73.2 | 68.6 | 74.7 | 65.7 | 47.4 | 74.0 | 76.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).